球墨铸铁是20世纪发展起来的低成本、综合性能优异的材料[1],在机械、汽车、能源等国民经济支柱行业应用十分广泛。但是诸如电梯曳引轮、曲轴、轧辊等球墨铸铁零部件,在承受剧烈的磨损、冲击等环境下,其表面性能就难以满足使用要求,长期工作时会出现磨损严重、不均匀等严重问题,使球墨铸铁零件无法正常工作或失效,带来重大的经济损失。

目前,国内外研究人员已在碳钢、不锈钢、模具钢、钛合金、高温合金等表面开展了很多激光熔覆研究工作,除了激光熔覆铁基、镍基、钴基自熔性合金粉末的研究外,为了有效提升表面激光熔覆层的性能,近年来,在合金粉末中添加硬质相强化熔覆层的研究成为了该领域的研究热点之一。Lee等[7]在STS410钢上激光熔覆WC/NiCr复合的钴基合金,发现WC颗粒度过大会导致熔覆层凝固后裂纹的生成与传播。Ma等[8]在Q550钢上用宽带光纤激光器熔覆含WC的镍基合金,熔覆层中形成M23C6碳化物,其耐磨性比传统圆形光斑激光高3倍。Leunda等[9]在Cr3C2-NiCr涂层中添加WC提高了耐磨性,但发现小颗粒WC在熔覆层重叠区域孔隙率较高,不利于耐磨,球形WC熔覆层开裂倾向低于不规则粉末。Xu等[10]在316L钢上激光熔覆TiC/镍基合金,通过激光工艺参数调整细化了熔覆层组织,得到细小均匀分布的TiC,硬度和抗拉强度较纯镍基合金熔覆层均提升了近1倍。Diao和Zhang[11]在TC2钛合金上激光熔覆TiC/TiB2,显微硬度提高到基体的3~4倍。

然而在球墨铸铁基体上激光熔覆研究进展却相对缓慢。由于球墨铸铁中石墨对激光的吸收比基体高得多,而且球墨铸铁的特殊组织结构会对其中的热传导产生重要影响[12],产生非均匀温度场,加之球墨铸铁的膨胀系数较小,因此,在修复或者表面强化的过程中具有很大的形成裂纹和气孔的倾向,难于找到一种组织结构和机械性能俱佳的熔覆材料[13]。国内外的研究者,如Li等[13]尝试采用Ni-Cu合金、新型FeNiCr合金等粉末材料,杨鹏聪等[14]采用铁基合金粉末,Xu等[15]采用高速钢粉末,Arias-González等[12]采用镍基合金粉末,在球墨铸铁上进行了激光熔覆实验研究,但是均未涉及添加硬质相的熔覆层的研究。

1 实验方法

表1 球墨铸铁基体和钴基合金粉末的化学成分 (mass fraction / %)

Table 1

| Material | C | Cr | Si | W | Fe | Mo | Ni | Mn | B | Co |

|---|---|---|---|---|---|---|---|---|---|---|

| Nodular cast iron | 3.60 | - | 2.71 | - | Bal. | - | - | 0.42 | - | - |

| Co-based alloy powder | 0.2 | 21.0 | 1.6 | 4.5 | 3.0 | 0.4 | 4.0 | 0.3 | 2.4 | Bal. |

图1

图1

TiC颗粒及TiC-Co基合金混合粉末的SEM像

Fig.1

SEM images of TiC particles (a) and TiC-Co-based alloy powders (b)

实验前,将球墨铸铁基体表面打磨去掉氧化皮,并用电炉将其预热到250 ℃,采用预置粉末法将混合合金粉末平铺在球墨铸铁基体上,并采用DLA6000型CO2激光器,通过调整激光参数开展熔覆实验。激光熔覆时,稀释率对熔覆层质量影响非常大,而稀释率主要受比能量(E)的影响(

表2 激光熔覆工艺参数

Table 2

| Scheme | P / kW | V / (mm·min-1) |

|---|---|---|

| 1 | 3.2 | 390 |

| 2 | 3.3 | 390 |

| 3 | 3.4 | 390 |

| 4 | 3.4 | 410 |

| 5 | 3.5 | 390 |

| 6 | 3.6 | 390 |

| 7 | 3.6 | 410 |

| 8 | 3.2 | 350 |

| 9 | 3.2 | 370 |

| 10 | 3.2 | 410 |

激光熔覆后得到的试样使用线切割机垂直于熔覆表面切割,获得15 mm×10 mm×8 mm的金相试样,打磨抛光,使用HF、HNO3和H2O的混合试剂腐蚀,腐蚀时间为28 s。采用GX71 型光学显微镜(OM)观察试样熔覆层组织;使用配备能谱仪(EDS)的Sigma型扫描电镜(SEM)观察试样熔覆层组织形貌并进行成分分析;采用Smart Lab型X射线衍射仪(XRD)进行激光熔覆层组织的物相分析;采用MHV2000型数显显微硬度计测试熔覆层硬度,测试条件为施加载荷200 g,时间15 s。

2 实验结果

2.1 TiC-Co基合金激光熔覆层的组织

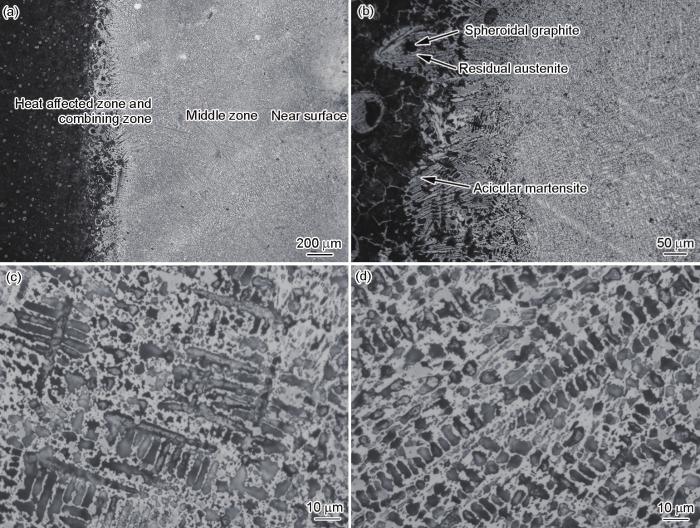

在激光功率为3.2 kW、扫描速率为410 mm/min时,将TiC-Co基合金激光熔覆于球墨铸铁表面,所形成的熔覆层横截面组织形貌,如图2所示。从图2a可看出,熔覆层在结构上分为熔化区(包括熔覆层中部及表层)、结合区和热影响区。图2b为熔覆层热影响区及结合区组织形貌。球墨铸铁基体表面下近表层被高能激光快速加热和冷却,形成热影响区,主要由片状马氏体、少量残余奥氏体和石墨球组成[24],而基体表面在高能激光的作用下部分熔化,与熔化了的熔覆粉末相混合构成结合区,凝固时此处受较快的冷却速率和较大的温度梯度影响,会以稀释后的基体表面为形核基底形核,并以枝晶状生长。从图2b可看到,熔覆层与基体结合紧密,形成良好的冶金结合。图2c为熔覆层中间层组织,中间层温度梯度相对变小,树枝晶生长的方向性弱化,向等轴枝晶转变;图2d为熔覆层表层区域,此区域由于同时存在着向熔体表层和向基体方向的双向散热,冷却速率较中层快,从而有利于细树枝晶的生长。

图2

图2

球墨铸铁表面熔覆TiC-Co基合金熔覆层显微组织(P=3.2 kW、V=410 mm/min)

(a) the whole laser cladding layer;(b) heat affected zone and combining zone;(c) middle zone;(d) near surface

Fig.2

Microstructures of the TiC-Co-based alloy laser cladding layer on the surface of ductile cast iron (P=3.2 kW, V=410 mm/min)

2.2 激光熔覆工艺参数对TiC-Co基合金熔覆层组织的影响

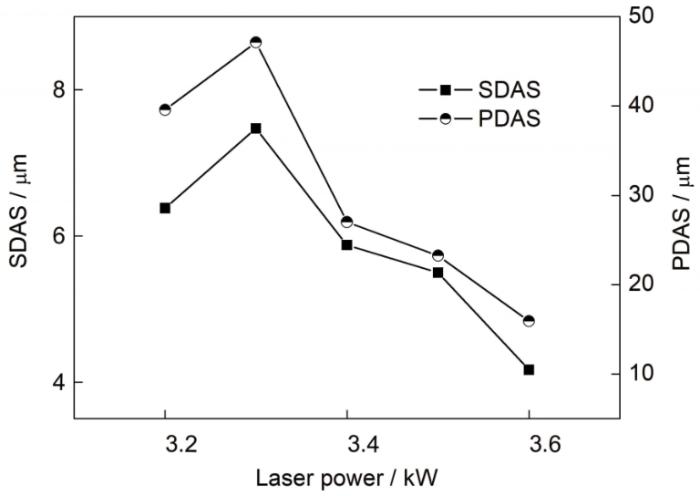

图3

图3

激光扫描速率390 mm/min、不同激光功率下熔覆层组织

(a) P=3.2 kW;(b) P=3.3 kW;(c) P=3.4 kW;(d) P=3.5 kW;(e) P=3.6 kW

Fig.3

Microstructures of cladding layer of different laser powers at V=390 mm/min

图4

图4

激光功率对熔覆层组织枝晶间距的影响

Fig.4

Effect of laser power on the dendrite arm spacing of laser cladding layer (V=390 mm/min, SDAS—secondary dendrite arm space, PDAS—primary dendrite arm space)

图5

图5

激光功率P=3.2 kW、不同激光扫描速率下熔覆层显微组织

Fig.5

Microstructures of cladding layer of different scanning rates at P=3.2 kW(a) V=350 mm/min (b) V=370 mm/min (c) V=410 mm/min

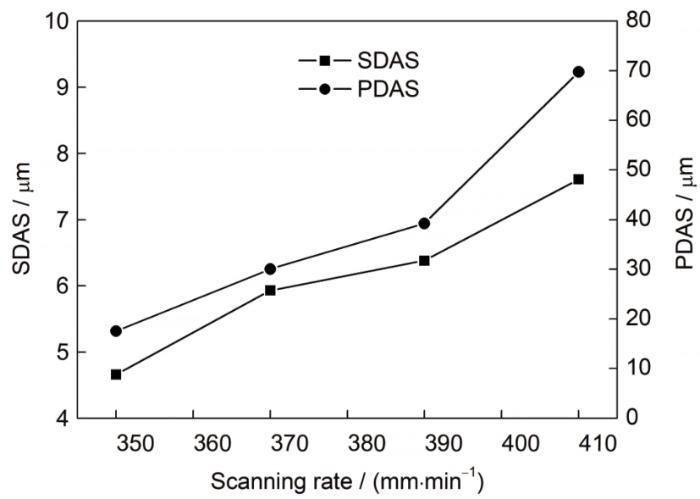

图6

图6

激光扫描速率对熔覆层组织枝晶间距的影响

Fig.6

Effect of the scanning rate of laser on the dendrite arm spacing of laser cladding layer (P=3.2 kW)

3 分析讨论

3.1 TiC-Co基合金熔覆层组织物相组成

为了确定TiC-Co基合金熔覆层组织中的物相组成,对所制备的熔覆层进行了XRD分析,结果如图7所示。可看到,熔覆层主要由γ-Co、Cr-Ni-Fe-C相、TiC/(Ti, W)C1-x和Cr7C3组成。常温下Co以hcp结构的ε-Co形式存在,温度超过417 ℃时则转变为bcc结构的γ-Co。由于激光熔覆快速冷却的特点,熔覆熔池凝固时先结晶析出高温下稳定存在的γ-Co,但是在接下来的快速冷却时γ-Co来不及通过相变而转变为ε-Co,从而保留到最终的熔覆层组织中,成为亚稳相。Ti元素的化学活性非常强,在熔覆层凝固的过程中,会与C元素结合析出TiC,从文献[25]可知,TiC和(Ti, W)C的衍射峰基本是重合的,而本工作激光熔覆采用的钴基合金粉末中含有一定量的W元素,在析出TiC时,也会结合W元素形成(Ti, W)C1-x。而钴基合金粉末中Cr元素含量相对较多,且与C元素亲和力也较强,在凝固时C元素会与部分Cr元素结合形成少量Cr的碳化物,余下大部分的Cr元素会与Fe及少量Ni元素形成Cr-Ni-Fe-C相。

图7

图7

TiC-Co基合金熔覆层的XRD谱

Fig.7

XRD spectrum of the laser cladding layer of TiC-Co-based alloy

3.2 熔覆层中TiC形貌及变化

图8

图8

激光扫描速率为410 mm/min、不同激光功率条件下制备得到的熔覆层横截面SEM像及EDS结果

(a, b) P=3.6 kW;(c, d) P=3.4 kW;(e, f) P=3.2 kW

Fig.8

SEM images (a, c, e) and corresponding EDS results (b, d, f) of the cross-sections of cladding layers (V=410 mm/min)

熔覆层熔体凝固时,这些未溶解TiC (颜色略深)将成为溶解TiC再析出(颜色较浅)的非均质形核核心,因此,TiC将先于γ-Co初生相而析出,而后随着γ-Co初生相形核和生长过程中的溶质再分配不断进行,溶解在熔体中的Ti和C元素在γ-Co初生相生长界面前沿不断富集,为TiC晶体的生长提供了成分条件,使得TiC晶体也不断长大,从而形成了中间颜色较深而周围颜色较浅的TiC晶体。从图8还可看到,共晶组织层片和TiC晶体是连接在一起的,说明在凝固后期,层片状共晶组织可依托于TiC晶体而生长。

另外,从图8的EDS结果可看到,W元素原子分数较高,这说明熔覆层组织中存在着(Ti, W)C1-x相。W是强碳化物形成元素,但在熔覆熔池凝固时,因WC无异质形核核心可依附,相比TiC而言,难于在凝固界面前沿形成晶核,而TiC是fcc结构,而WC是简单六方结构,易于溶解于TiC中,随着凝固进行,W、Cr等元素在凝固前沿富集,从而可以TiC为基析出WC,形成TiC为基的合金碳化物。Kwon等[25]认为,与WC相比,TiC更稳定,因此,在有W存在的条件下,更倾向于生成(Ti, W)C。而如前所述,未溶解的固体TiC颗粒在后续凝固过程中,将保持原有状态不变,因此,在熔覆层组织中将会出现TiC和(Ti, W)C1-x共同存在的组织状态。

在激光功率较高时,由于激光热输入量高,TiC颗粒大部分溶解,小颗粒完全溶解,而大颗粒溶解成小颗粒(即未完全溶解的TiC),形貌由熔覆前带有尖锐棱角的多边形(图1a),溶解变为不规则、边界不明显的形状,而在熔池中熔体凝固时,这些未溶解的小颗粒TiC会成为TiC异质晶核,最终生长成为近圆形的TiC晶体,而溶解在熔体中的Ti和C元素,原位生长TiC新晶核的机会很少,除了固溶于γ-Co相外,更多的是通过溶质再分配富集在γ-Co相的凝固前沿,供已经形成的TiC晶核生长。因此,最终熔覆层组织中TiC晶体尺寸较大,数量较少,而且分布不均匀。而随着激光功率降低,熔覆层熔池中热输入量减小,TiC的溶解量随之减少,完全溶解的小颗粒减少,而大颗粒的溶解量也减少,从而使TiC未溶解部分的尺寸比激光功率高时变大,形貌仍然保持不规则多边形状,在随后的熔覆层熔体凝固时,TiC晶体长大受限,最终组织中TiC晶体尺寸又比激光功率高时减小,数量也更多,分布也更均匀。因此,通过激光工艺参数的调整可实现对熔覆层中TiC的形貌、尺寸与分布进行调控。

3.3 TiC对熔覆层组织的影响

从熔覆层凝固组织中可看到,TiC呈弥散状存在于二次枝晶臂根部、顶端或者一次枝晶臂上,TiC的存在对枝晶臂的生长不仅具有一定的机械阻碍和阻断作用,而且在凝固过程中,TiC晶体的析出会影响熔体局部过冷度,从而影响初生相的生长。如前所述,γ-Co枝晶生长时,TiC晶核也在γ-Co晶体周围的熔体中析出和生长,如图9所示。Ti元素为强碳化物形成元素,合金熔体中的Ti与C形成TiC时,有:

式中,

图9

图9

TiC-Co基合金熔覆层凝固枝晶生长示意图

Fig.9

Schematic of solidified dendrite growth of laser cladding layer of TiC-Co-based alloy

以二次枝晶间距的变化为例,随着激光功率的增加,熔覆层熔体的过热度越大,熔体凝固时的冷却速率越小,二次枝晶间距越大。但是当激光功率增加到某一定值时,熔覆层熔体中溶解的TiC量显著增加,在凝固时,TiC重新析出将显著降低初生γ-Co枝晶前沿的过冷度,降低了枝晶干上某些突起的优先快速生长[29],使枝晶干上更多突起趋于同时生长,二次枝晶间距不再继续增大。随着激光功率增加,溶解的TiC的量逐渐增加,二次枝晶间距逐渐减小(图4),在激光功率为3.3 kW时,二次枝晶间距出现了极大值。同理,随着激光扫描速率的减小,相当于增加了熔覆层的热输入量,使TiC的溶解量增加,熔覆层组织的二次枝晶间距随之减小(图6),但是由于本实验的参数范围所限,二次枝晶间距与激光扫描速率的关系未出现极值。

3.4 TiC-Co基合金熔覆层硬度变化

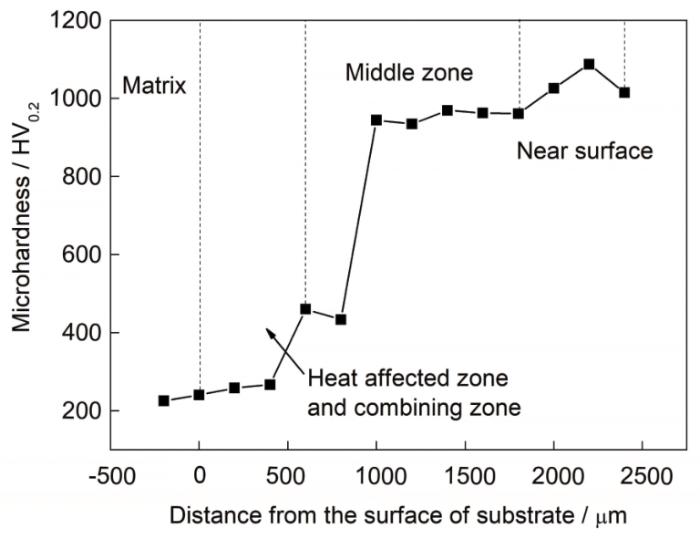

图10

图10

熔覆层断面硬度随与球墨铸铁基体表面的距离的变化

Fig.10

Change of microhardness on the cross-section of laser cladding layer with the distance from the matrix surface of ductile cast iron when P=3.4 kW and V=390 mm/min

图11

图11

激光工艺参数对熔覆层硬度的影响

(a) the effect of laser power at V= 390 mm/min;(b) the effect of laser scanning rate at P=3.2 kW

Fig.11

Effects of laser parameters on the microhardness of laser cladding layer

如前文所述,尽管随着激光功率的提高,二次枝晶间距会增加,但与此同时,TiC的溶解量也越来越大,会使二次枝晶间距逐渐减小,2个因素中,后者会逐渐占主导,熔覆层表层的二次枝晶间距表现为如图4所示的变化规律。单从组织上看,随着激光功率提高,熔覆层硬度应提高,但是,在熔覆层凝固时再析出的TiC的尺寸会增大,数量会减少,分布也会变得不均匀,从而导致熔覆层的硬度随着激光功率的提高而降低。从图11a的实测结果可以看出,随着激光功率的提高,TiC的不均匀分布对熔覆层硬度的影响更显著。而激光扫描速率的降低,相当于提高激光功率,增加热输入量,对于熔覆层组织和硬度的影响不再赘述。因此,在本实验范围内,降低激光功率或增加扫描速率时,可减少TiC颗粒的熔化和分解,从而控制熔覆层中TiC颗粒尺寸和分布,显著提高熔覆层的硬度。

4 结论

(1) 熔覆层主要由γ-Co、TiC/(Ti, W)C1-x、Cr-Ni-Fe-C和少量的Cr7C3相组成。

(2) 从基体表面到熔覆层表层的组织形态转变为细树枝晶→等轴枝晶→细树枝晶,TiC呈弥散状存在于靠近二次枝晶臂根部、顶端或者一次枝晶臂上;在熔覆层的凝固过程中TiC的析出会抑制一次枝晶或二次枝晶的生长。

(3) 随着激光功率降低,熔覆层枝晶含量增加,一次枝晶间距和二次枝晶间距先增大后减小,TiC形貌从边缘平滑的近圆形向不规则多边形转变,尺寸逐渐变小,含量明显增多,分布更为均匀;随着激光扫描速率增加,熔覆层中枝晶数量增加,一次枝晶间距和二次枝晶间距均增大。

(4) 随着与基体表面距离增加,硬度在结合区显著增大后,在熔覆层区域呈现一定的波动,直到熔覆层表层区域,硬度又明显增加后小幅下降;随着激光功率降低或扫描速率增加,熔覆层表层硬度逐渐增加,当P=3.2 kW、V=410 mm/min时,最高硬度为1246.6 HV0.2,相对基体(200~250 HV0.2)提升5倍。

参考文献

The birth, application, tendency of technologh development—The one of the most important technology progresses of the material science of the 20th century

[J].

现代球墨铸铁的诞生、应用及技术发展趋势—20世纪材料科学最重大的技术进展之一

[J].

Microstructure and wear resistance of in-situ TiC-Al2O3 particles reinforced Fe-based coatings produced by gas tungsten arc cladding

[J].

Fabrication and properties of Al2O3-TiB2-TiC/Al metal matrix composite coatings by atmospheric plasma spraying of SHS powders

[J].

Microstructure and properties of hard and wear resistant MMC coatings deposited by laser cladding

[J].

Cavitation erosion mechanisms in stainless steels and in composite metal-ceramic HVOF coatings

[J].

New development of laser rapid forming and its application in high performance materials processing

[J].

激光快速成形技术新进展及其在高性能材料加工中的应用

[J].

Residual stress and crack initiation in laser clad composite layer with Co-based alloy and WC + NiCr

[J].

Investigation on core-eutectic structure in Ni60/WC composite coatings fabricated by wide-band laser cladding

[J].

Laser cladding strategies for producing WC reinforced NiCr coatings inside twin barrels

[J].

Morphologies, microstructures and properties of TiC particle reinforced Inconel 625 coatings obtained by laser cladding with wire

[J].

Microstructure and corrosion resistance of TC2 Ti alloy by laser cladding with Ti/TiC/TiB2 powders

[J].

Fiber laser cladding of nickel-based alloy on cast iron

[J].

Microstructure characteristics and mechanical properties of new-type FeNiCr laser cladding alloy coating on nodular cast iron

[J].

Effect of scanning speed on microstructure of laser cladding layer on nodular cast iron

[J].

扫描速度对球墨铸铁激光熔覆层组织的影响

[J].

Process optimization and properties of laser cladding high vanadium high speed steel coatings on nodular cast iron

[J].

Laser coatings to improve wear resistance of mould steel

[J].

Reaction sintering of titanium carbide and titanium silicide prepared by high-energy milling

[J].

Selective laser melting of TiC/Ti bulk nanocomposites: Influence of nanoscale reinforcement

[J].

Fabrication and characterisation of titanium matrix composites obtained using a combination of self propagating high temperature synthesis and spark plasma sintering

[J].

Effect of laser cladding process parameters on clad quality and in-situ formed microstructure of Fe-TiC composite coatings

[J].

Microstructure and properties of TiC/Co-based alloy by laser cladding on the surface of nodular graphite cast iron

[J].etc.. However, in the harsh environment, it often leads to failure due to the serious surface wear. At present, the repair methods for the damaged parts are mainly thermal spraying, deposit welding and other methods, but the properties and application effect of the repaired parts need to be improved. In order to significantly improve the surface properties of ductile cast iron, the 30%TiC/Co-based alloy cladding layer prepared by laser cladding is put forward on the surface of ductile cast iron in this work. The microstructure, composition, phase, hardness of the laser cladding layer are investigated and analyzed by OM, SEM, EDS, XRD, TEM and MHV2000 digital microhardness tester. The results show that the cladding layer can be integrated metallurgically with the nodular graphite cast iron matrix. The cladding layer consists of a surface layer of dendritic crystals and an internal cellular crystal. The primary phase of TiC from the melt is precipitated in situ during the solidification after laser heating. The amount of the primary TiC is gradually increased from the inner layer to the surface layer. Meanwhile, the undissolved TiC is dispersively distributed among the dendrites. The laser cladding layer is mainly composed of γ-Co, TiC, CoCx and a small amount of Cr7C3. The hardness maximum of the cladding layer is 1278.8 HV0.2, up to 5 times more than the hardness of the nodular graphite cast iron matrix.]]>

球墨铸铁表面激光熔覆TiC/钴基合金组织和性能研究

[J].γ-Co、TiC、CoCx和少量的Cr7C3相组成,熔覆层的最高硬度是1278.8 HV0.2,提高到球墨铸铁基体的5倍以上。]]>

Latest developments of laser cladding technology

[J].

激光熔覆技术研究进展

[J].

Effect of laser irradiation on failure mechanism of TiCp reinforced titanium composite coating produced by laser cladding

[J].

Phase evolution of ductile iron during laser cladding processing

[J].

Preparation of a highly toughened (Ti, W)C-20Ni cermet through in situ formation of solid solution and WC whiskers

[J].

Thermodynamics and kinetic of forming TiC in Al-Ti-C system

[J].

Al-Ti-C系中TiC形成的热力学与动力学研究

[J].研究了在用熔体反应法制备Al-Ti-C中间合金过程中TiC形成的热力学与动力学, 实验结果表明:在850℃的Al熔体中, 石墨颗粒周围的K2TiF6与Al发生剧烈的化学反应放出大量的热, 在熔体中形成大量的局部高温微区. 在这些高温微区内, 熔体中的Ti或TiAl3达到了与C形成TiC的热力学条件, 从而在石墨颗粒周围生成大量TiC粒子, 根据熔体化学反应的热力学条件.

Study on the thermodynamics of high temperature chemical reaction of TiC/Fe composite synthesized by reaction-casting

[J].

反应铸造TiC/Fe复合材料过程中高温化学反应的热力学研究

[J].提出了一种不同于现有的反应铸造工艺的一种新工艺,一方面通过试验制备得到TiC/Fe复合材料;另一方面结合制备过程温度场的测试结果,通过对合金液中原位合成TiC高温化学反应的热力学计算与分析,从理论上验证了本工艺方法的可行性.同时,也为控制过程提供理论指导.