B4Cp/Al复合材料具有重量轻、稳定性好、中子吸收能力强及力学性能优异等优点,是用于乏燃料贮运、中子源吸收等方面的理想材料。随着金属基复合材料应用领域的不断拓展,高性能B4Cp/Al复合材料在军事、航空航天和电子等领域得到了广泛应用[1,2]。然而由于增强颗粒的加入,B4Cp/Al复合材料二次加工过程中材料变形抗力增大,其微观组织变化更为复杂,可加工性显著下降[3]。若热加工工艺选择不当,复合材料二次加工中很容易产生缺陷,如锻件内部和表面裂纹、轧制板材和挤压棒材的开裂、增强体颗粒带偏聚等[4,5,6]。因此,如何选择合理的热加工工艺,提高B4Cp/Al复合材料的加工性能,合理调控复合材料基体微观组织尤为重要。

近年来,关于金属基复合材料热加工行为的研究大多集中在SiC和Al2O3增强铝基复合材料。1981年,Raj[7]首先提出了加工图概念,并研究了不同体积分数SiC和Al2O3颗粒增强铝基复合材料的损伤机制,得出在应变速率和温度的某个区域,材料的变形能力最优。随后,许多学者研究了SiCp/Al复合材料应变速率范围在0.001~10 s-1,温度范围为300~500 ℃的热变形行为,并基于动态材料模型(dynamic material model,DMM)建立了加工图[8,9,10,11]。通过加工图不仅可以优化热加工工艺参数,还可以通过功耗效率的分析和微观结构观察来预测微观结构的演变,从而很好地避开失稳区。与SiCp/Al复合材料相比,对B4Cp/Al复合材料热加工及热变形行为的研究较少。Gangolu等[12]研究了A356合金及A356+5%B4C (体积分数)复合材料在温度和应变速率分别为470~570 ℃和10-3~1 s-1条件下的热变形行为,结果表明A356合金失稳区域为温度510~570 ℃,应变速率(1~4)×10-2 s-1,而对于A356+5%B4C复合材料,在相同的应变速率下,其失稳区域温度变为470~570 ℃。这是由于增强相的存在导致变形阻力增加,与基体相比,复合材料的最大功率耗散效率降低,而失稳区域范围有所扩大。Li等[13]以热压缩实验数据为基础,研究了B4Cp/6061Al复合材料的热变形行为,其中增强相颗粒尺寸和体积分数分别为18.5 μm和30%。结果表明,B4Cp/6061Al复合材料的最佳加工区域为温度487~530 ℃、应变速率0.01~0.05 s-1,典型的材料不稳定性被认为是由孔洞形成、绝热剪切带(ASB)、颗粒脱黏和基体开裂引起的。关于金属基复合材料热变形行为的研究大多集中在低应变速率(<1 s-1)下,而实际的二次加工 (如轧制) 过程中复合材料将会经历很大的塑性变形,且应变速率远大于1 s-1。

本工作对粉末冶金法制备的31%B4Cp/6061Al (体积分数)复合材料进行了较宽温度和应变速率范围的热压缩实验,研究了其热变形行为及热变形条件对流变应力的影响规律,并基于改进的动态材料模型(modified dynamic material model,MDMM)建立了不同应变下复合材料的功率耗散效率及加工图,确定了最佳加工区域。此外,还分析了热压缩过程中的微观组织演变。

1 实验方法

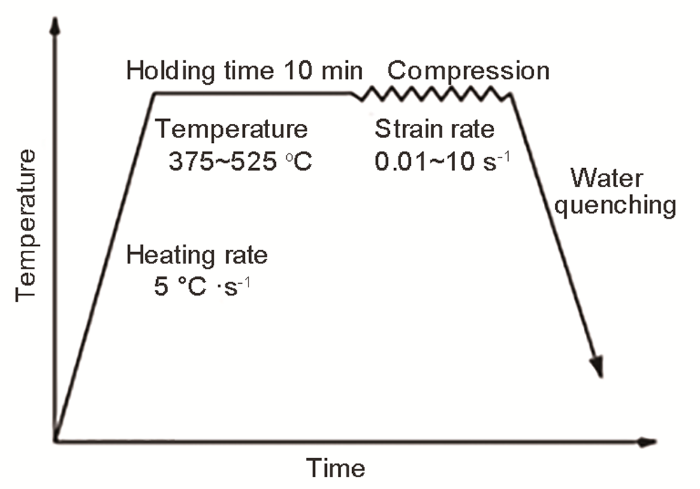

实验所用材料为粉末冶金法制备的31%B4Cp/6061Al复合材料,其中B4C颗粒平均尺寸约为7 μm,6061Al合金的主要化学成分(质量分数,%)为:Fe 0.70,Si 0.80,Mn 0.15,Cr 0.35,Mg 1.20,Zn 0.25,Al 余量。在经过均匀化处理的31%B4Cp/6061Al热轧板上沿着板厚方向取样,加工成直径8 mm×12 mm的圆柱体试样。为减小试样与砧子之间的摩擦,压缩前在试样两端涂抹润滑剂(75%石墨+20%机油+5%硝酸三甲苯脂,体积分数)。采用Gleeble-3800热模拟试验机进行高温压缩实验,实验温度为375、400、425、450、475、500和525 ℃,应变速率(

图1

利用线切割设备将试样沿着压缩方向的中心截面抛开,对该截面进行研磨、抛光处理后,利用SUPRA40超高分辨率冷场发射扫描电子显微镜(SEM)观察试样内部颗粒分布情况及内部缺陷。然后用Weck试剂对试样进行腐蚀,并用DMI500M型金相显微镜(OM)观察不同变形条件下试样的微观组织变化。

2 结果与分析

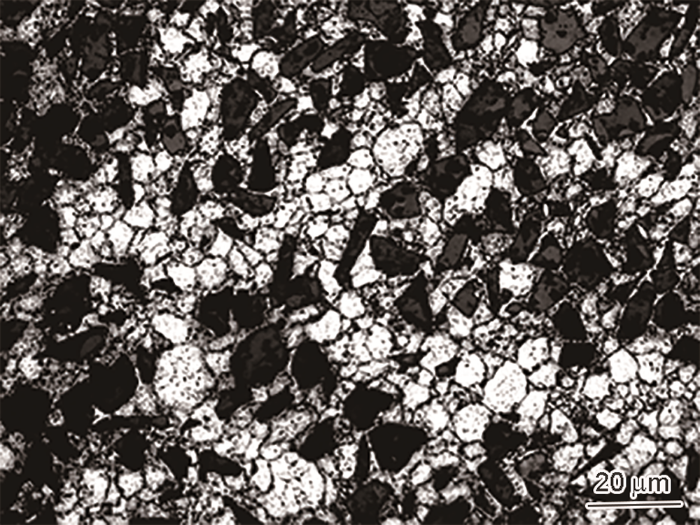

2.1 31%B4Cp/6061Al复合材料的原始组织

图2为31%B4Cp/6061Al复合材料的显微组织的OM像。可以看出,基体为典型的等轴晶晶粒,晶粒平均尺寸约为13 μm,B4C颗粒分布在晶界周围。

图2

2.2 热变形流变曲线

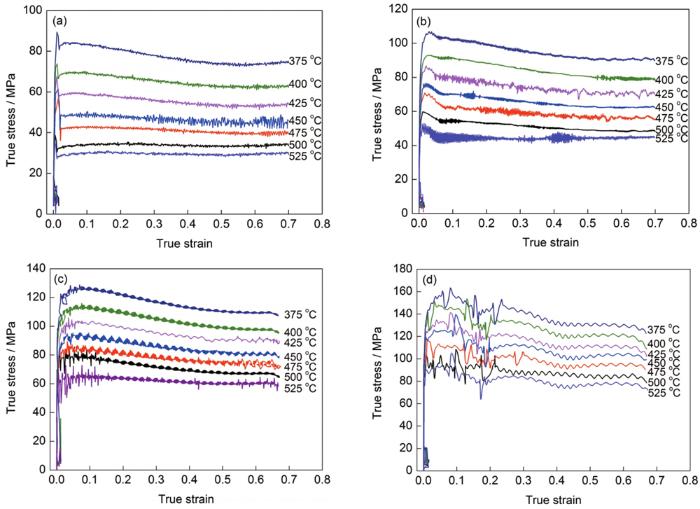

31%B4Cp/6061Al复合材料在不同变形温度和应变速率下的真应力-真应变曲线如图3所示。可见,在较低应变时,应力随应变的增加而迅速增加,达到峰值应力后,真应力开始出现不同程度的下降,最后流变应力曲线趋于稳态。根据流变应力曲线的变化规律,可以将31%B4Cp/6061Al复合材料在不同变形条件下的流变应力曲线分为3个阶段:(I) 加工硬化阶段,该阶段位错密度在外力作用下急剧增加,导致变形初期真应力迅速增加,出现加工硬化现象;(II) 软化阶段,该阶段B4C颗粒的强化效果下降,动态软化同时发生,使真应力达到峰值后略有下降;(III) 稳态流变阶段,该阶段软化机理如动态回复(dynamic recovery,DRV)、动态再结晶(dynamic recrystallization,DRX)以及硬化机理如应变硬化(strain hardening)所产生的作用相互抵消,流变应力趋于稳态。从图3d可以看出,当应变速率为10 s-1时,流变应力曲线出现严重的波动,这是由于在高应变速率条件下,大量增强相的存在导致不均匀变形及微裂纹的萌生[19,20]。

图3

图3

不同热变形条件下31%B4Cp/6061Al复合材料的真应力-真应变曲线

Fig.3

True stress-true strain curves of 31%B4Cp/6061Al composites under different temperatures and strain rates (

(a)

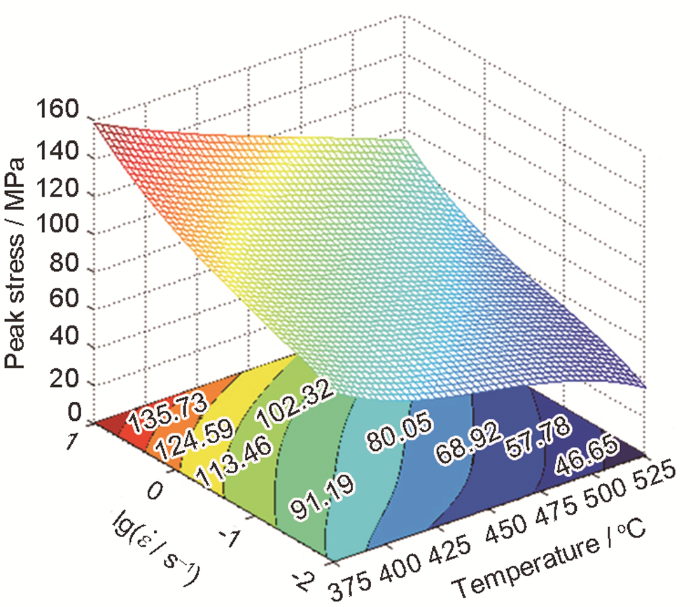

图4

图4

31%B4Cp/6061Al复合材料在不同变形条件下的峰值应力分布

Fig.4

Peak stress distributions of 31%B4Cp/6061Al composites under different deformation conditions

Color online

表1 31%B4Cp/6061Al复合材料在不同变形条件下的峰值应力 (MPa)

Table 1

| 375 ℃ | 400 ℃ | 425 ℃ | 450 ℃ | 475 ℃ | 500 ℃ | 525 ℃ | |

|---|---|---|---|---|---|---|---|

| 0.01 | 89.34 | 73.90 | 67.40 | 61.77 | 56.69 | 38.66 | 35.52 |

| 0.1 | 107.00 | 92.89 | 86.80 | 76.45 | 70.81 | 60.01 | 52.52 |

| 1 | 126.18 | 113.58 | 103.75 | 94.40 | 85.91 | 79.61 | 65.38 |

| 10 | 158.00 | 146.00 | 133.39 | 124.92 | 112.96 | 102.04 | 92.53 |

2.3 热加工图

式中,m为应变速率敏感指数,在m=1的理想条件下,J将达到最大值Jmax,这样功率耗散系数(η)可由下式求解:

式中,ξ为失稳因子。

由于DMM中材料应力与应变速率之间幂函数关系的限制,许多材料体系很难严格满足条件,因此,计算出的η将产生误差。Murty等[17]修正了DMM中G的求解方法,提出了MDMM,G可表示为:

式中,

式中,ε为应变,T为热力学温度。同样,结合Ziegler's失稳条件,得出MDMM失稳准则表达式如下:

该失稳准则适合于所有材料的本构关系,被认为是应用前景最好的一种失稳准则。

由

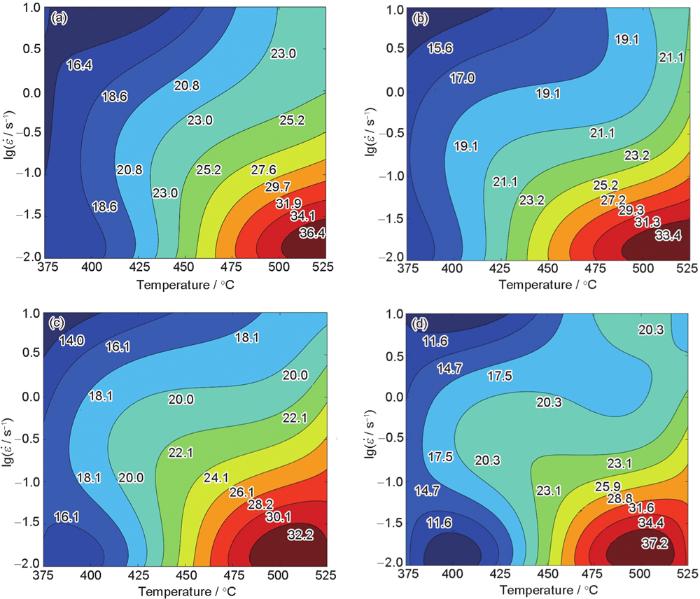

图5

图5

不同应变下31%B4Cp/6061Al复合材料的功率耗散图

Fig.5

Power dissipation maps of 31%B4Cp/6061Al composites at strains of 0.1 (a), 0.3 (b), 0.5 (c) and 0.7 (d) (The contour numbers represent coefficients of power dissipation (η)

Color online

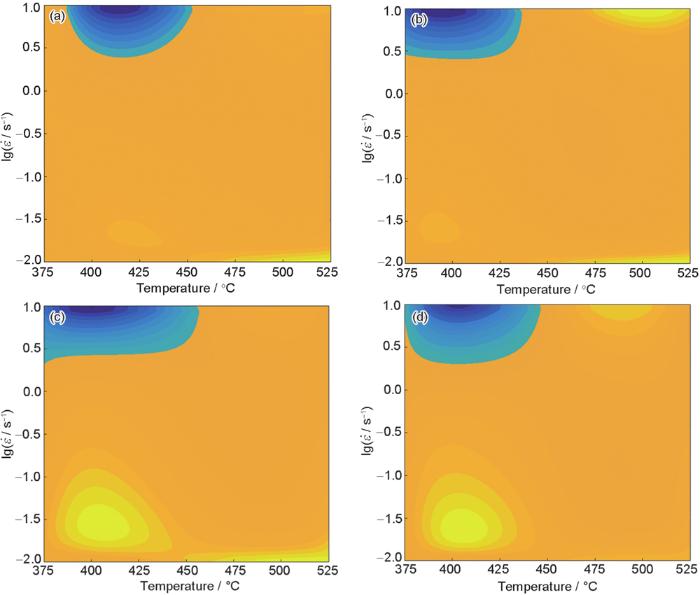

图6

图6

31%B4Cp/6061Al复合材料在不同应变下的失稳图

Fig.6

Instability zones of 31%B4Cp/6061Al composites at strains of 0.1 (a), 0.3 (b), 0.5 (c) and 0.7 (d) (The contours represent instability factors (ξ), and the blue regions less than zero are the unstable regions, while the yellow regions greater than or equal to zero are the stable regions)

Color online

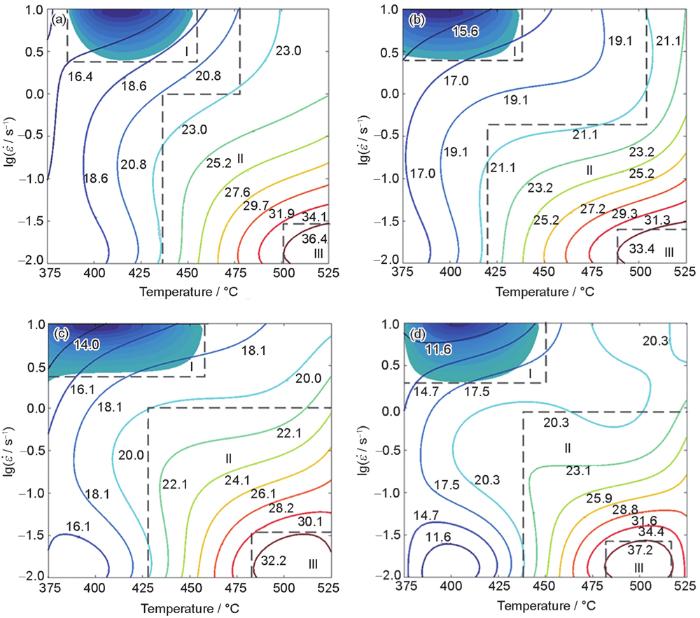

将功率耗散图与失稳图叠加到一起即为加工图,31%B4Cp/6061Al复合材料在应变为0.1、0.3、0.5和0.7时的加工图如图7所示。区域I为加工失稳区域,可以发现,不同应变下31%B4Cp/6061Al复合材料加工失稳区域的参数范围基本相似,主要集中在低温高应变速率区域,并且随着应变增大,加工失稳区域也随之增大。区域II为可加工区域,如果工件性能的要求不是十分严格,可以根据实际要求,选择这一区域的加工参数。区域III为最优加工区域,该区域不仅功率耗散率最高,而且避开了加工失稳区域。从加工图可以看出,31%B4Cp/6061Al复合材料最优加工区域的范围为应变速率0.01~0.04 s-1且变形温度为480~525 ℃。在不同应变条件下,31%B4Cp/6061Al复合材料的热加工工艺窗口如表2所示。

图7

图7

31%B4Cp/6061Al复合材料在不同应变下的加工图

Fig.7

Processing maps for 31%B4Cp/6061Al composites at strains of 0.1 (a), 0.3 (b), 0.5 (c) and 0.7 (d) (I—instability domain, II—machinable domain, III—optimal processing domain)

Color online

表2 31%B4Cp/6061Al复合材料的热加工工艺

Table 2

| Strain | Domain | T / ℃ | |

|---|---|---|---|

| 0.1 | I | 385~450 | 3.16~10 |

| II | 435~525 | 0.01~1 | |

| 475~525 | 1~10 | ||

| III | 500~525 | 0.01~0.031 | |

| 0.3 | I | 275~435 | 2.80~10 |

| II | 420~525 | 0.01~0.39 | |

| 505~525 | 0.39~10 | ||

| III | 490~525 | 0.01~0.025 | |

| 0.5 | I | 375~455 | 2.51~10 |

| II | 426~525 | 0.01~0.1 | |

| III | 480~525 | 0.01~0.039 | |

| 0.7 | I | 375~450 | 2.23~10 |

| II | 438~525 | 0.01~0.1 | |

| III | 480~520 | 0.01~0.021 |

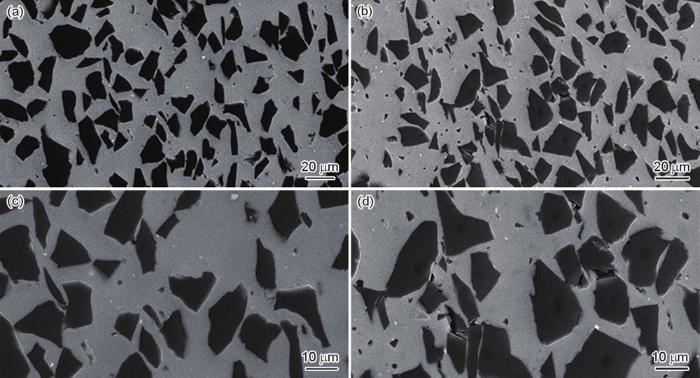

图8

图8

31%B4Cp/6061Al复合材料在最优加工区和失稳区热压后的SEM像

Fig.8

Low (a, b) and high (c, d) magnified SEM images of 31%B4Cp/6061Al composites at temperatures and strain rates of 500 ℃, 0.01 s-1 (a, c) and 400 ℃, 10 s-1 (b, d)

2.4 显微组织

利用DEFORM软件对试样的热压缩过程进行数值模拟,得到试样在温度为475 ℃、应变速率为10 s-1变形条件下压缩变形后的应变场分布,如图9所示,计算的详细过程见文献[27]。可以发现,试样内部变形很不均匀:试样顶部和底部的扇形区域(区域A)变形很小,应变不高于0.5;试样中心区域的变形最大,应变达最大值1.5;试样左、右两侧的“鼓肚”区域(区域C)的变形则介于两者之间,应变在0.5~1.0范围内。为了研究变形量对显微组织的影响,选取图9所示的3个区域进行微观组织观察。图10所示为31%B4Cp/6061Al复合材料在475 ℃、10 s-1变形条件下压缩变形后3个区域显微组织的OM像,与图9的模拟热压工艺相同。可以发现,各个区域的显微组织存在明显的差异,与原始形貌(图2)相比,区域C的晶粒都变成了细长状。因此,在热压缩过程中,31%B4Cp/6061Al复合材料不同区域由于应变的不同,基体晶粒会发生不同程度的变形,应变越大,则晶粒被“压”的越细长。此外,由于热压缩过程中应变速率较高,试样的压缩时间很短,图10所示的3个区域再结晶晶粒非常少。

图9

图9

31%B4Cp/6061Al复合材料在475 ℃、10 s-1变形条件下压缩变形后的应变场分布

Fig.9

Distribution of strain of 31%B4Cp/6061Al composites at temperature of 475 ℃ and strain rate of 10 s-1 after hot compression

Color online

图10

图10

31%B4Cp/6061Al复合材料在475 ℃、10 s-1热压缩条件下不同区域显微组织的OM像

Fig.10

OM images of 31%B4Cp/6061Al composites at temperature of 475 ℃ and strain rate of 10 s-1 at areas A (a), B (b) and C (c) in Fig.9

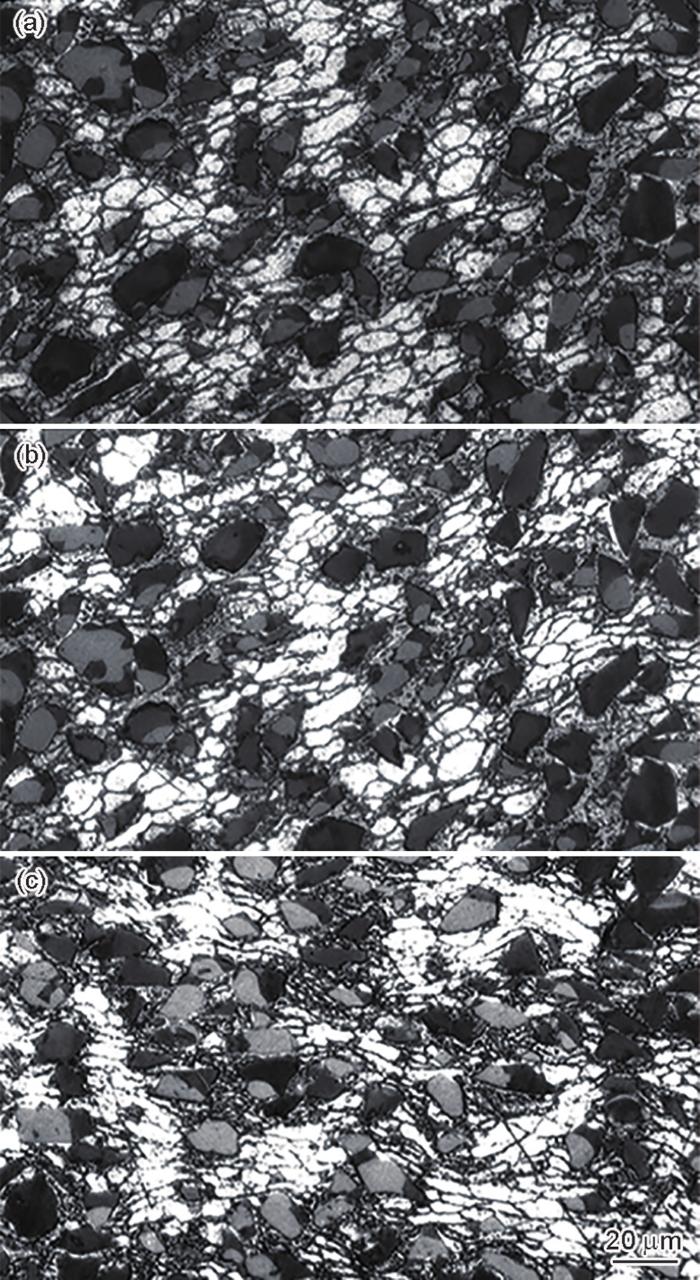

图11为31%B4Cp/6061Al复合材料在不同温度和应变速率下热压缩后试样中心区域显微组织的OM像。可以发现,在相同应变速率下,450 ℃时31%B4Cp/6061Al复合材料只有在B4C颗粒附近才出现再结晶晶核,而在500 ℃时复合材料内部出现了大量的再结晶晶核。因此可以得出,热压缩温度的升高,促进了B4Cp/6061Al复合材料基体的再结晶,这与功率耗散图得出的结论一致。在相同热变形温度下,当应变速率为0.01 s-1时,由于压缩时间较长,再结晶晶粒开始逐渐长大,而应变速率为1 s-1时,压缩时间短,限制了晶粒的长大。这表明B4Cp/6061Al复合材料热压缩变形中显微组织受应变速率的影响非常显著,较高的应变速率会使再结晶过程的形核和长大受到限制,这也可以从功率耗散图中得到进一步验证。

图11

图11

31%B4Cp/6061Al复合材料不同变形条件下试样中心区域显微组织的OM像

Fig.11

OM images of 31%B4Cp/6061Al composites at central area of specimen under temperatures and strain rates of 450 ℃, 0.01 s-1 (a), 450 ℃, 1 s-1 (b), 500 ℃, 0.01 s-1 (c) and 500 ℃, 1 s-1 (d)

3 结论

(1) 通过对31%B4Cp/6061Al复合材料在较宽的温度和应变速率范围内的热变形行为进行研究,表明该复合材料的流变应力对变形温度和应变速率非常敏感,流变应力随变形温度的降低或应变速率的升高而增加。

(2) 确定了31%B4Cp/6061Al复合材料的最优热加工参数所对应的变形温度和应变速率分别为480~525 ℃和0.01~0.04 s-1。而加工失稳区主要集中在低温高应变速率区域,并且该区域随应变的增大而增大。

(3) 热压过程中显微组织的演化与热变形条件密切相关,如应变、温度和应变速率。随着应变的增加,基体晶粒变形更加严重,且随着变形温度的升高或应变速率的降低,基体内动态再结晶晶粒尺寸明显增大。

参考文献

Size-dependent compression deformation behaviors of high particle content B4C/Al composites

[J].

Dynamic tensile deformation and damage of B4C-reinforced Al composites: Time-resolved imaging with synchrotron X-rays

[J].

Multi-scale study on the fracture behavior of hot compression B4C/6061Al composite

[J].4C/Al composites possess excellent physical and mechanical properties, especially the capacity of neutron absorption, and therefore are increasingly used in nuclear industry for storage and transportation of spent fuels. However, very little study has reported the fracture behavior of B4C/Al composite under hot compression. Therefore, at the present work, the hot compression fracture behavior of B4C/6061Al composite was studied by combining experimental and simulation methods, and the fracture model and damage parameters were determined. A unidirectional multi-scale finite element model was established to analyze the meso damage mechanism of B4C/6061Al composite. The results show that the shear damage model cannot predict the fracture behavior of B4C/6061Al composite because of the inhomogeneous microstructure, and the GTN damage model can accurately predict the hot compression fracture behavior of B4C/6061Al composite. At the same time, by comparing with the experimental results, the GTN damage parameters of 31%B4C/6061Al composite were determined, and then by applying the damage parameters, the calculated crack depth and load-displacement curves agree well with the experimental results. In addition, the micro-damage mechanism of B4C/6061Al composite during hot compression process was analyzed accurately with the unidirectional multi-scale finite element method, which was caused by brittle fracture of particles, debonding between matrix and interface, and ductile damage of matrix.]]>

B4C/6061Al复合材料热压缩断裂行为的多尺度研究

[J].4C/6061Al复合材料的热压缩断裂行为,确定了损伤模型及损伤参数。建立了单向多尺度有限元模型,分析了B4C/6061Al复合材料的细观损伤机理。结果表明,由于B4C/6061Al复合材料内部不均匀的细观结构,剪切损伤模型不能预测其断裂行为,而GTN损伤模型能准确预测B4C/6061Al复合材料的热压缩断裂行为。通过与实验结果的比较,确定了31%B4C/6061Al (质量分数)复合材料的GTN模型损伤参数,从而使模拟和实验获得的裂纹深度和载荷-位移曲线高度一致。此外,利用单向多尺度有限元法准确地分析了B4C/6061Al复合材料热压缩过程的细观损伤机理,即热压缩过程中出现的宏观裂纹是由颗粒的脆性断裂、基体和界面的脱黏以及基体的延性损伤导致的。]]>

Research on hot deformation behaviors of discontinuously reinforced aluminum composites

[J].This paper describes the research progress in hot deformation behaviors of discontinuously reinforced aluminum (DRA) composite, including research method, deformation mechanism and hot workability. The reliability of constitutive equation and processing map for description of flowing behaviors and deformation mechanisms in the previous studies were discussed. Based on that, the strain rate and temperature sensitivities of flow stress were introduced to further identify the deformation mechanisms. Deformation characteristics and microstructures of the composites with different reinforcements were illustrated. Finally, the future researches of hot deformation of DRA composite are suggested.

非连续增强铝基复合材料的热变形行为研究进展

[J].本文综述了非连续增强铝基复合材料的热变形行为理论研究方法,并描述了典型铝基复合材料的热变形机制和可加工性特征。对本构方程、加工图理论方法对流变行为和变形机制研究的可靠性进行了讨论,同时介绍了引入应变速率敏感指数和温度敏感指数作为基体合金变形机制演化辅助判据的方法。根据铝合金常见变形机制,讨论了不同类型增强体的铝基复合材料热加工变形行为特征。最后,对该领域未来的研究方向进行了展望。

Effect of whisker breakage on the forgeability and the tensile properties of the forged 2024Al/Al18B4O33w composite

[J].

Effect of rolling and heat treatment on tensile behaviour of wrought Al-SiCp composites prepared by stir-casting

[J].

Development of a processing map for use in warm-forming and hot-forming processes

[J].

Processing map for hot working of SiCp/7075 Al composites

[J].

Hot deformation behavior and processing map of SiCp/2024Al composite

[J].

Development of processing maps for 2124Al/SiCp composites

[J].

Hot deformation behaviors of 35%SiCp/2024Al metal matrix composites

[J].

Development of constitutive relationship and processing map for Al-6.65Si-0.44Mg alloy and its composite with B4C particulates

[J].

Hot deformation behaviors and processing maps of B4C/Al6061 neutron absorber composites

[J].

Constitutive flow behavior and hot workability of powder metallurgy processed 20 vol.%SiCp/2024Al composite

[J].

Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60

[J].

Hot deformation behavior of Mg2B2O5 whiskers reinforced AZ31B magnesium composite fabricated by stir-casting

[J].

On the evaluation of efficiency parameters in processing maps

[J].

Hot deformation mechanisms and microstructure evolution of SiCp/2014Al composite

[J].

Effects of strain rate on flow stress behavior and dynamic recrystallization mechanism of Al-Zn-Mg-Cu aluminum alloy during hot deformation

[J].

Effect of processing parameters on hot deformation behavior and microstructural evolution during hot compression of as-cast Ti60 titanium alloy

[J].

Dynamic materials model: Basis and principles

[J].

Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242

[J].

Processing map for hot working of alpha-zirconium

[J].

Recent advances in the science of mechanical processing

[J].

Hot deformation and processing maps of DC cast Al-15%Si alloy

[J].

Hot deformation and processing map of 15%SiCp/2009 Al composite

[J].

Constitutive equation and model validation for a 31 vol.% B4Cp/6061Al composite during hot compression

[J].