高强铝合金的发展及其材料的制备加工技术

1

2015

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

高强铝合金的发展及其材料的制备加工技术

1

2015

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

800MPa级Al-Zn-Mg-Cu系合金

1

2018

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

800MPa级Al-Zn-Mg-Cu系合金

1

2018

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

多向锻造对改善7075铝合金性能的作用

1

2003

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

多向锻造对改善7075铝合金性能的作用

1

2003

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

强化固溶对Al-Zn-Mg-Cu合金力学性能和断裂行为的影响

1

2001

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

强化固溶对Al-Zn-Mg-Cu合金力学性能和断裂行为的影响

1

2001

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

高强7050铝合金超低温大变形加工与组织、性能调控

1

2017

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

高强7050铝合金超低温大变形加工与组织、性能调控

1

2017

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

固溶处理对7150铝合金组织和力学性能的影响

1

2010

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

固溶处理对7150铝合金组织和力学性能的影响

1

2010

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

两阶段轧制变形过程中高强铝合金析出相与晶粒结构演变及其对性能的影响

1

2016

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

两阶段轧制变形过程中高强铝合金析出相与晶粒结构演变及其对性能的影响

1

2016

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

Recent developments in advanced aircraft aluminium alloys

1

2014

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

Influence of second phases on mechanical properties of spray-deposited Al-Zn-Mg-Cu alloy

1

2012

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

Isothermal deformation of spray formed Al-Zn-Mg-Cu alloy

2

2013

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

... 不同时效工艺下超高强Al-Zn-Mg-Cu合金力学性能如表2所示.12+8合金的抗拉强度为(796±5) MPa,3%+12+8和4%+12+8合金的抗拉强度分别提高了17和11 MPa,相应的屈服强度也分别提高了14和9 MPa.同时合金伸长率也少量提高,3%+12+8和4%+12+8处理后合金的伸长率均超过了10%,高于同等强度的多数Al-Zn-Mg-Cu合金[10,24,25,26].经过12+10处理后的合金抗拉强度尽管较12+8处理略微提高,但延伸率开始下降. ...

Microstructure and mechanical properties of spray-deposited Al-Zn-Mg-Cu alloy processed through hot rolling and heat treatment

1

2009

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy

1

2014

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

Microstructural and mechanical characterization of various modified 7XXX series spray formed alloys

1

2008

... 超高强铝合金是指抗拉强度在800 MPa左右的Al-Zn-Mg-Cu合金[1,2],其合金元素含量较高,Zn含量通常大于10% (质量分数,下同).相较于500 MPa级的7075[3,4]、7050[5]和600 MPa级的7150[6]、7055[7]等合金,超高强Al-Zn-Mg-Cu合金强度可提升30%~60%.将超高强铝合金应用于航空航天结构件,可显著减轻结构重量,对实现轻量化具有重要意义[8].尽管具有明显的强度优势,但超高强Al-Zn-Mg-Cu合金的塑性与7055、7075等有较大差距,现阶段强度在750 MPa以上的Al-Zn-Mg-Cu合金伸长率普遍低于9%[9,10,11,12,13],部分甚至低于5%,影响了可加工性与使用可靠性. ...

Characterization and modeling of precipitation kinetics in an Al-Zn-Mg alloy

1

2000

... 作为典型的析出强化材料,析出相形态对铝合金的力学性能有直接的影响.超高强Al-Zn-Mg-Cu合金的元素含量接近Al固溶体极限,具有比7075、7055等合金更高的脱溶驱动力和原子扩散速率[14],析出相容易粗化,导致其塑性较低.为提高力学性能,需要采用合理的方式控制析出过程. ...

A conventional thermo-mechanical process of Al-Cu-Mg alloy for increasing ductility while maintaining high strength

2

2011

... 研究[15]发现,通过预变形引入一定量的位错,对析出方式改变有重要的影响.有学者[16,17,18]认为,预变形仅起到了析出相粗化和促进非共格的η相析出的作用,对强度与韧性造成了不利的影响.但上述工作通常在过时效态或较大的变形量下进行,对小变形量时效和欠时效以及峰时效的析出行为指导意义不强.赵建吉等[19]认为,2%和10%的变形量可提高Al-13.01Zn-3.16Mg-2.8Cu-0.20Zr-0.075Sr合金的强度,但对析出相的影响规律并未进行研究. ...

... 通常情况下,依靠合金元素浓度起伏形成析出相的过程被认为是均质形核[27],这种情况需要突破较高的能量势垒限制,只有部分能量较高的原子集团才能实现,在单位时间内形核数量有限.经过预变形后,合金基体内形成了大量的位错,由于位错附近位置储存了很高的弹性变形,使其处于热力学不稳定状态,相变驱动力大大增加,溶质元素容易向位错位置偏聚.因此,预变形为析出相提供了形核质点[28,29],形核过程由均质形核过渡为异质形核,形核能量势垒降低,析出加速加快,促进细小弥散的析出相在晶内形成.但当位错的含量较高时,析出相的形成速度过快[15],析出相开始粗化,尺寸增加. ...

预拉伸对7050铝合金断裂韧性的影响

5

2010

... 研究[15]发现,通过预变形引入一定量的位错,对析出方式改变有重要的影响.有学者[16,17,18]认为,预变形仅起到了析出相粗化和促进非共格的η相析出的作用,对强度与韧性造成了不利的影响.但上述工作通常在过时效态或较大的变形量下进行,对小变形量时效和欠时效以及峰时效的析出行为指导意义不强.赵建吉等[19]认为,2%和10%的变形量可提高Al-13.01Zn-3.16Mg-2.8Cu-0.20Zr-0.075Sr合金的强度,但对析出相的影响规律并未进行研究. ...

... Al-Zn-Mg-Cu合金时效过程中析出序列为[30]:α (过饱和固溶体)-GP区 (Guinier-Preston zone,脱溶原子偏聚区)-η′相(亚稳态MgZn2)-η相(稳定态MgZn2).关于预变形对析出序列的影响,韩念梅等[16]认为,预变形引入的位错降低了空位密度,不利于η′相形核析出,但有利于形成粗大的η相;而同时也有学者[29,30]认为,变形加工后析出序列与未进行预变形的合金相同.在本工作的实验结果中,既未在SAED图中观察到η相的衍射斑点,也未在高分辨图像中观察到不共格的析出相,故η相并未在晶内形成.本工作中,随变形量增加,η′相与基体的关系由共格转变成半共格.DSC实验结果(图5)显示,在4%+12+8与12+10处理合金的热分析曲线中,对应η'向η相转变的峰(235 ℃附近)强度[31]显著高于12+8和3%+12+8处理后的合金.这表明,增加变形量与延长时效时间均可以促进η′相的长大进程[32],二者的作用是一致的.继续增加预变形量或延长时间,会进一步促进η′相长大,当尺寸增加到一定程度,析出相与基体不再保持共格关系,形成不共格的η相[33],这与文献[16,17,18]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

... ,这与文献[16,17,18]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

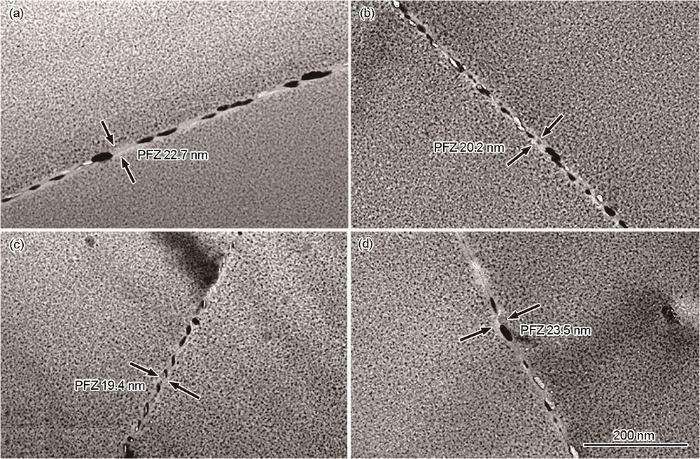

... 晶间析出相形态的变化是影响力学性能的另一个重要因素.如果晶间析出相尺寸较大,加载过程中容易在附近形成应力集中[16],导致开裂.另外,由于PFZ的存在,晶界的强度通常低于晶内的强度[16,36],裂纹易沿晶界扩展.所以晶界析出相尺寸与PFZ宽度越小,合金的强度与延伸率则越高.因此,经预变形处理后的合金较未经预变形处理的合金表现出更好的综合力学性能. ...

... [16,36],裂纹易沿晶界扩展.所以晶界析出相尺寸与PFZ宽度越小,合金的强度与延伸率则越高.因此,经预变形处理后的合金较未经预变形处理的合金表现出更好的综合力学性能. ...

预拉伸对7050铝合金断裂韧性的影响

5

2010

... 研究[15]发现,通过预变形引入一定量的位错,对析出方式改变有重要的影响.有学者[16,17,18]认为,预变形仅起到了析出相粗化和促进非共格的η相析出的作用,对强度与韧性造成了不利的影响.但上述工作通常在过时效态或较大的变形量下进行,对小变形量时效和欠时效以及峰时效的析出行为指导意义不强.赵建吉等[19]认为,2%和10%的变形量可提高Al-13.01Zn-3.16Mg-2.8Cu-0.20Zr-0.075Sr合金的强度,但对析出相的影响规律并未进行研究. ...

... Al-Zn-Mg-Cu合金时效过程中析出序列为[30]:α (过饱和固溶体)-GP区 (Guinier-Preston zone,脱溶原子偏聚区)-η′相(亚稳态MgZn2)-η相(稳定态MgZn2).关于预变形对析出序列的影响,韩念梅等[16]认为,预变形引入的位错降低了空位密度,不利于η′相形核析出,但有利于形成粗大的η相;而同时也有学者[29,30]认为,变形加工后析出序列与未进行预变形的合金相同.在本工作的实验结果中,既未在SAED图中观察到η相的衍射斑点,也未在高分辨图像中观察到不共格的析出相,故η相并未在晶内形成.本工作中,随变形量增加,η′相与基体的关系由共格转变成半共格.DSC实验结果(图5)显示,在4%+12+8与12+10处理合金的热分析曲线中,对应η'向η相转变的峰(235 ℃附近)强度[31]显著高于12+8和3%+12+8处理后的合金.这表明,增加变形量与延长时效时间均可以促进η′相的长大进程[32],二者的作用是一致的.继续增加预变形量或延长时间,会进一步促进η′相长大,当尺寸增加到一定程度,析出相与基体不再保持共格关系,形成不共格的η相[33],这与文献[16,17,18]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

... ,这与文献[16,17,18]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

... 晶间析出相形态的变化是影响力学性能的另一个重要因素.如果晶间析出相尺寸较大,加载过程中容易在附近形成应力集中[16],导致开裂.另外,由于PFZ的存在,晶界的强度通常低于晶内的强度[16,36],裂纹易沿晶界扩展.所以晶界析出相尺寸与PFZ宽度越小,合金的强度与延伸率则越高.因此,经预变形处理后的合金较未经预变形处理的合金表现出更好的综合力学性能. ...

... [16,36],裂纹易沿晶界扩展.所以晶界析出相尺寸与PFZ宽度越小,合金的强度与延伸率则越高.因此,经预变形处理后的合金较未经预变形处理的合金表现出更好的综合力学性能. ...

预拉伸对7085铝合金力学及局部腐蚀性能的影响

2

2018

... 研究[15]发现,通过预变形引入一定量的位错,对析出方式改变有重要的影响.有学者[16,17,18]认为,预变形仅起到了析出相粗化和促进非共格的η相析出的作用,对强度与韧性造成了不利的影响.但上述工作通常在过时效态或较大的变形量下进行,对小变形量时效和欠时效以及峰时效的析出行为指导意义不强.赵建吉等[19]认为,2%和10%的变形量可提高Al-13.01Zn-3.16Mg-2.8Cu-0.20Zr-0.075Sr合金的强度,但对析出相的影响规律并未进行研究. ...

... Al-Zn-Mg-Cu合金时效过程中析出序列为[30]:α (过饱和固溶体)-GP区 (Guinier-Preston zone,脱溶原子偏聚区)-η′相(亚稳态MgZn2)-η相(稳定态MgZn2).关于预变形对析出序列的影响,韩念梅等[16]认为,预变形引入的位错降低了空位密度,不利于η′相形核析出,但有利于形成粗大的η相;而同时也有学者[29,30]认为,变形加工后析出序列与未进行预变形的合金相同.在本工作的实验结果中,既未在SAED图中观察到η相的衍射斑点,也未在高分辨图像中观察到不共格的析出相,故η相并未在晶内形成.本工作中,随变形量增加,η′相与基体的关系由共格转变成半共格.DSC实验结果(图5)显示,在4%+12+8与12+10处理合金的热分析曲线中,对应η'向η相转变的峰(235 ℃附近)强度[31]显著高于12+8和3%+12+8处理后的合金.这表明,增加变形量与延长时效时间均可以促进η′相的长大进程[32],二者的作用是一致的.继续增加预变形量或延长时间,会进一步促进η′相长大,当尺寸增加到一定程度,析出相与基体不再保持共格关系,形成不共格的η相[33],这与文献[16,17,18]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

预拉伸对7085铝合金力学及局部腐蚀性能的影响

2

2018

... 研究[15]发现,通过预变形引入一定量的位错,对析出方式改变有重要的影响.有学者[16,17,18]认为,预变形仅起到了析出相粗化和促进非共格的η相析出的作用,对强度与韧性造成了不利的影响.但上述工作通常在过时效态或较大的变形量下进行,对小变形量时效和欠时效以及峰时效的析出行为指导意义不强.赵建吉等[19]认为,2%和10%的变形量可提高Al-13.01Zn-3.16Mg-2.8Cu-0.20Zr-0.075Sr合金的强度,但对析出相的影响规律并未进行研究. ...

... Al-Zn-Mg-Cu合金时效过程中析出序列为[30]:α (过饱和固溶体)-GP区 (Guinier-Preston zone,脱溶原子偏聚区)-η′相(亚稳态MgZn2)-η相(稳定态MgZn2).关于预变形对析出序列的影响,韩念梅等[16]认为,预变形引入的位错降低了空位密度,不利于η′相形核析出,但有利于形成粗大的η相;而同时也有学者[29,30]认为,变形加工后析出序列与未进行预变形的合金相同.在本工作的实验结果中,既未在SAED图中观察到η相的衍射斑点,也未在高分辨图像中观察到不共格的析出相,故η相并未在晶内形成.本工作中,随变形量增加,η′相与基体的关系由共格转变成半共格.DSC实验结果(图5)显示,在4%+12+8与12+10处理合金的热分析曲线中,对应η'向η相转变的峰(235 ℃附近)强度[31]显著高于12+8和3%+12+8处理后的合金.这表明,增加变形量与延长时效时间均可以促进η′相的长大进程[32],二者的作用是一致的.继续增加预变形量或延长时间,会进一步促进η′相长大,当尺寸增加到一定程度,析出相与基体不再保持共格关系,形成不共格的η相[33],这与文献[16,17,18]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

Effect of pre-strain on microstructure and stress corrosion cracking of over-aged 7050 aluminum alloy

3

2009

... 研究[15]发现,通过预变形引入一定量的位错,对析出方式改变有重要的影响.有学者[16,17,18]认为,预变形仅起到了析出相粗化和促进非共格的η相析出的作用,对强度与韧性造成了不利的影响.但上述工作通常在过时效态或较大的变形量下进行,对小变形量时效和欠时效以及峰时效的析出行为指导意义不强.赵建吉等[19]认为,2%和10%的变形量可提高Al-13.01Zn-3.16Mg-2.8Cu-0.20Zr-0.075Sr合金的强度,但对析出相的影响规律并未进行研究. ...

... Al-Zn-Mg-Cu合金时效过程中析出序列为[30]:α (过饱和固溶体)-GP区 (Guinier-Preston zone,脱溶原子偏聚区)-η′相(亚稳态MgZn2)-η相(稳定态MgZn2).关于预变形对析出序列的影响,韩念梅等[16]认为,预变形引入的位错降低了空位密度,不利于η′相形核析出,但有利于形成粗大的η相;而同时也有学者[29,30]认为,变形加工后析出序列与未进行预变形的合金相同.在本工作的实验结果中,既未在SAED图中观察到η相的衍射斑点,也未在高分辨图像中观察到不共格的析出相,故η相并未在晶内形成.本工作中,随变形量增加,η′相与基体的关系由共格转变成半共格.DSC实验结果(图5)显示,在4%+12+8与12+10处理合金的热分析曲线中,对应η'向η相转变的峰(235 ℃附近)强度[31]显著高于12+8和3%+12+8处理后的合金.这表明,增加变形量与延长时效时间均可以促进η′相的长大进程[32],二者的作用是一致的.继续增加预变形量或延长时间,会进一步促进η′相长大,当尺寸增加到一定程度,析出相与基体不再保持共格关系,形成不共格的η相[33],这与文献[16,17,18]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

... 关于预变形对晶间析出相的影响,之前的研究工作存在着争论,Wang和Ma[18]认为预变形有利于减小晶间析出相尺寸,降低PFZ宽度;Han等[34]认为预变形产生的位错加速了合金元素向晶界运动,促进了晶间析出相粗化与PFZ宽化.本工作支持了第一种观点.分析认为,预变形后晶界上的位错密度提高[27]、促进了晶界异质形核,有利于形成连续细小的晶间析出相;同时在位错作用下,晶内析出相形核速率加快、数量增多,晶内与晶界的元素扩散梯度减弱[25],向晶间扩散的合金元素减少,有利于晶间析出相尺寸与PFZ宽度降低,弱化晶间偏聚. ...

预变形对超高强铝合金Al-Zn-Mg-Cu-Zr-Sr组织与性能的影响

1

2016

... 研究[15]发现,通过预变形引入一定量的位错,对析出方式改变有重要的影响.有学者[16,17,18]认为,预变形仅起到了析出相粗化和促进非共格的η相析出的作用,对强度与韧性造成了不利的影响.但上述工作通常在过时效态或较大的变形量下进行,对小变形量时效和欠时效以及峰时效的析出行为指导意义不强.赵建吉等[19]认为,2%和10%的变形量可提高Al-13.01Zn-3.16Mg-2.8Cu-0.20Zr-0.075Sr合金的强度,但对析出相的影响规律并未进行研究. ...

预变形对超高强铝合金Al-Zn-Mg-Cu-Zr-Sr组织与性能的影响

1

2016

... 研究[15]发现,通过预变形引入一定量的位错,对析出方式改变有重要的影响.有学者[16,17,18]认为,预变形仅起到了析出相粗化和促进非共格的η相析出的作用,对强度与韧性造成了不利的影响.但上述工作通常在过时效态或较大的变形量下进行,对小变形量时效和欠时效以及峰时效的析出行为指导意义不强.赵建吉等[19]认为,2%和10%的变形量可提高Al-13.01Zn-3.16Mg-2.8Cu-0.20Zr-0.075Sr合金的强度,但对析出相的影响规律并未进行研究. ...

Nanocrystalline Al-Mg alloy with ultrahigh strength and good ductility

1

2006

... 拉伸预变形在Instron 5569电子万能试验机上进行,应变量控制为3%和4%.利用D8 Advance X射线衍射仪(XRD)测试不同变形量下试样的XRD谱,根据式(1)[20]和(2)[21]计算位错密度: ...

Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing

1

2004

... 拉伸预变形在Instron 5569电子万能试验机上进行,应变量控制为3%和4%.利用D8 Advance X射线衍射仪(XRD)测试不同变形量下试样的XRD谱,根据式(1)[20]和(2)[21]计算位错密度: ...

Precipitation behaviors and properties of solution-aging Al-Zn-Mg-Cu alloy refined with TiN nanoparticles

1

2018

... 选区电子衍射(SAED)花样如图2a、c、e和g中插图所示,根据文献[22]可知,析出相衍射斑点在[011]晶带上占据的位置与η'相的分布位置一致,故图2中析出相主要是η'相.η'相具有六方结构,其(0001)η'面与基体(111)Al面平行,以(111)Al面为惯习面呈盘状析出,当平行<011>Al晶带轴投影时,η'相4个变体中有2个形状呈短杆状,另2个呈近圆形[23]. ...

Characterisation of the composition and volume fraction of η′ and η precipitates in an Al-Zn-Mg alloy by a combination of atom probe, small-angle X-ray scattering and transmission electron microscopy

1

2005

... 选区电子衍射(SAED)花样如图2a、c、e和g中插图所示,根据文献[22]可知,析出相衍射斑点在[011]晶带上占据的位置与η'相的分布位置一致,故图2中析出相主要是η'相.η'相具有六方结构,其(0001)η'面与基体(111)Al面平行,以(111)Al面为惯习面呈盘状析出,当平行<011>Al晶带轴投影时,η'相4个变体中有2个形状呈短杆状,另2个呈近圆形[23]. ...

Investigation of precipitation behavior and related hardening in AA 7055 aluminum alloy

1

2009

... 不同时效工艺下超高强Al-Zn-Mg-Cu合金力学性能如表2所示.12+8合金的抗拉强度为(796±5) MPa,3%+12+8和4%+12+8合金的抗拉强度分别提高了17和11 MPa,相应的屈服强度也分别提高了14和9 MPa.同时合金伸长率也少量提高,3%+12+8和4%+12+8处理后合金的伸长率均超过了10%,高于同等强度的多数Al-Zn-Mg-Cu合金[10,24,25,26].经过12+10处理后的合金抗拉强度尽管较12+8处理略微提高,但延伸率开始下降. ...

Effects of Mg and Cu on microstructures and properties of spray-deposited Al-Zn-Mg-Cu alloys

2

2017

... 不同时效工艺下超高强Al-Zn-Mg-Cu合金力学性能如表2所示.12+8合金的抗拉强度为(796±5) MPa,3%+12+8和4%+12+8合金的抗拉强度分别提高了17和11 MPa,相应的屈服强度也分别提高了14和9 MPa.同时合金伸长率也少量提高,3%+12+8和4%+12+8处理后合金的伸长率均超过了10%,高于同等强度的多数Al-Zn-Mg-Cu合金[10,24,25,26].经过12+10处理后的合金抗拉强度尽管较12+8处理略微提高,但延伸率开始下降. ...

... 关于预变形对晶间析出相的影响,之前的研究工作存在着争论,Wang和Ma[18]认为预变形有利于减小晶间析出相尺寸,降低PFZ宽度;Han等[34]认为预变形产生的位错加速了合金元素向晶界运动,促进了晶间析出相粗化与PFZ宽化.本工作支持了第一种观点.分析认为,预变形后晶界上的位错密度提高[27]、促进了晶界异质形核,有利于形成连续细小的晶间析出相;同时在位错作用下,晶内析出相形核速率加快、数量增多,晶内与晶界的元素扩散梯度减弱[25],向晶间扩散的合金元素减少,有利于晶间析出相尺寸与PFZ宽度降低,弱化晶间偏聚. ...

双级时效处理对喷射沉积Al-Zn-Mg-Cu合金微观组织和力学性能的影响

1

2007

... 不同时效工艺下超高强Al-Zn-Mg-Cu合金力学性能如表2所示.12+8合金的抗拉强度为(796±5) MPa,3%+12+8和4%+12+8合金的抗拉强度分别提高了17和11 MPa,相应的屈服强度也分别提高了14和9 MPa.同时合金伸长率也少量提高,3%+12+8和4%+12+8处理后合金的伸长率均超过了10%,高于同等强度的多数Al-Zn-Mg-Cu合金[10,24,25,26].经过12+10处理后的合金抗拉强度尽管较12+8处理略微提高,但延伸率开始下降. ...

双级时效处理对喷射沉积Al-Zn-Mg-Cu合金微观组织和力学性能的影响

1

2007

... 不同时效工艺下超高强Al-Zn-Mg-Cu合金力学性能如表2所示.12+8合金的抗拉强度为(796±5) MPa,3%+12+8和4%+12+8合金的抗拉强度分别提高了17和11 MPa,相应的屈服强度也分别提高了14和9 MPa.同时合金伸长率也少量提高,3%+12+8和4%+12+8处理后合金的伸长率均超过了10%,高于同等强度的多数Al-Zn-Mg-Cu合金[10,24,25,26].经过12+10处理后的合金抗拉强度尽管较12+8处理略微提高,但延伸率开始下降. ...

Microstructures and properties evolution of spray-deposited Al-Zn-Mg-Cu-Zr alloys with scandium addition

2

2017

... 通常情况下,依靠合金元素浓度起伏形成析出相的过程被认为是均质形核[27],这种情况需要突破较高的能量势垒限制,只有部分能量较高的原子集团才能实现,在单位时间内形核数量有限.经过预变形后,合金基体内形成了大量的位错,由于位错附近位置储存了很高的弹性变形,使其处于热力学不稳定状态,相变驱动力大大增加,溶质元素容易向位错位置偏聚.因此,预变形为析出相提供了形核质点[28,29],形核过程由均质形核过渡为异质形核,形核能量势垒降低,析出加速加快,促进细小弥散的析出相在晶内形成.但当位错的含量较高时,析出相的形成速度过快[15],析出相开始粗化,尺寸增加. ...

... 关于预变形对晶间析出相的影响,之前的研究工作存在着争论,Wang和Ma[18]认为预变形有利于减小晶间析出相尺寸,降低PFZ宽度;Han等[34]认为预变形产生的位错加速了合金元素向晶界运动,促进了晶间析出相粗化与PFZ宽化.本工作支持了第一种观点.分析认为,预变形后晶界上的位错密度提高[27]、促进了晶界异质形核,有利于形成连续细小的晶间析出相;同时在位错作用下,晶内析出相形核速率加快、数量增多,晶内与晶界的元素扩散梯度减弱[25],向晶间扩散的合金元素减少,有利于晶间析出相尺寸与PFZ宽度降低,弱化晶间偏聚. ...

Effect of pre-strain and two-step aging on microstructure and stress corrosion cracking of 7050 alloy

1

2008

... 通常情况下,依靠合金元素浓度起伏形成析出相的过程被认为是均质形核[27],这种情况需要突破较高的能量势垒限制,只有部分能量较高的原子集团才能实现,在单位时间内形核数量有限.经过预变形后,合金基体内形成了大量的位错,由于位错附近位置储存了很高的弹性变形,使其处于热力学不稳定状态,相变驱动力大大增加,溶质元素容易向位错位置偏聚.因此,预变形为析出相提供了形核质点[28,29],形核过程由均质形核过渡为异质形核,形核能量势垒降低,析出加速加快,促进细小弥散的析出相在晶内形成.但当位错的含量较高时,析出相的形成速度过快[15],析出相开始粗化,尺寸增加. ...

Precipitation kinetics in a severely plastically deformed 7075 aluminium alloy

3

2014

... 通常情况下,依靠合金元素浓度起伏形成析出相的过程被认为是均质形核[27],这种情况需要突破较高的能量势垒限制,只有部分能量较高的原子集团才能实现,在单位时间内形核数量有限.经过预变形后,合金基体内形成了大量的位错,由于位错附近位置储存了很高的弹性变形,使其处于热力学不稳定状态,相变驱动力大大增加,溶质元素容易向位错位置偏聚.因此,预变形为析出相提供了形核质点[28,29],形核过程由均质形核过渡为异质形核,形核能量势垒降低,析出加速加快,促进细小弥散的析出相在晶内形成.但当位错的含量较高时,析出相的形成速度过快[15],析出相开始粗化,尺寸增加. ...

... Al-Zn-Mg-Cu合金时效过程中析出序列为[30]:α (过饱和固溶体)-GP区 (Guinier-Preston zone,脱溶原子偏聚区)-η′相(亚稳态MgZn2)-η相(稳定态MgZn2).关于预变形对析出序列的影响,韩念梅等[16]认为,预变形引入的位错降低了空位密度,不利于η′相形核析出,但有利于形成粗大的η相;而同时也有学者[29,30]认为,变形加工后析出序列与未进行预变形的合金相同.在本工作的实验结果中,既未在SAED图中观察到η相的衍射斑点,也未在高分辨图像中观察到不共格的析出相,故η相并未在晶内形成.本工作中,随变形量增加,η′相与基体的关系由共格转变成半共格.DSC实验结果(图5)显示,在4%+12+8与12+10处理合金的热分析曲线中,对应η'向η相转变的峰(235 ℃附近)强度[31]显著高于12+8和3%+12+8处理后的合金.这表明,增加变形量与延长时效时间均可以促进η′相的长大进程[32],二者的作用是一致的.继续增加预变形量或延长时间,会进一步促进η′相长大,当尺寸增加到一定程度,析出相与基体不再保持共格关系,形成不共格的η相[33],这与文献[16,17,18]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

... ]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

Accelerated precipitation and growth of phases in an Al-Zn-Mg-Cu alloy processed by surface abrasion

3

2017

... Al-Zn-Mg-Cu合金时效过程中析出序列为[30]:α (过饱和固溶体)-GP区 (Guinier-Preston zone,脱溶原子偏聚区)-η′相(亚稳态MgZn2)-η相(稳定态MgZn2).关于预变形对析出序列的影响,韩念梅等[16]认为,预变形引入的位错降低了空位密度,不利于η′相形核析出,但有利于形成粗大的η相;而同时也有学者[29,30]认为,变形加工后析出序列与未进行预变形的合金相同.在本工作的实验结果中,既未在SAED图中观察到η相的衍射斑点,也未在高分辨图像中观察到不共格的析出相,故η相并未在晶内形成.本工作中,随变形量增加,η′相与基体的关系由共格转变成半共格.DSC实验结果(图5)显示,在4%+12+8与12+10处理合金的热分析曲线中,对应η'向η相转变的峰(235 ℃附近)强度[31]显著高于12+8和3%+12+8处理后的合金.这表明,增加变形量与延长时效时间均可以促进η′相的长大进程[32],二者的作用是一致的.继续增加预变形量或延长时间,会进一步促进η′相长大,当尺寸增加到一定程度,析出相与基体不再保持共格关系,形成不共格的η相[33],这与文献[16,17,18]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

... ,30]认为,变形加工后析出序列与未进行预变形的合金相同.在本工作的实验结果中,既未在SAED图中观察到η相的衍射斑点,也未在高分辨图像中观察到不共格的析出相,故η相并未在晶内形成.本工作中,随变形量增加,η′相与基体的关系由共格转变成半共格.DSC实验结果(图5)显示,在4%+12+8与12+10处理合金的热分析曲线中,对应η'向η相转变的峰(235 ℃附近)强度[31]显著高于12+8和3%+12+8处理后的合金.这表明,增加变形量与延长时效时间均可以促进η′相的长大进程[32],二者的作用是一致的.继续增加预变形量或延长时间,会进一步促进η′相长大,当尺寸增加到一定程度,析出相与基体不再保持共格关系,形成不共格的η相[33],这与文献[16,17,18]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

... ,30]中的说法. ...

Improved bake-hardening response of Al-Zn-Mg-Cu alloy through pre-aging treatment

1

2018

... Al-Zn-Mg-Cu合金时效过程中析出序列为[30]:α (过饱和固溶体)-GP区 (Guinier-Preston zone,脱溶原子偏聚区)-η′相(亚稳态MgZn2)-η相(稳定态MgZn2).关于预变形对析出序列的影响,韩念梅等[16]认为,预变形引入的位错降低了空位密度,不利于η′相形核析出,但有利于形成粗大的η相;而同时也有学者[29,30]认为,变形加工后析出序列与未进行预变形的合金相同.在本工作的实验结果中,既未在SAED图中观察到η相的衍射斑点,也未在高分辨图像中观察到不共格的析出相,故η相并未在晶内形成.本工作中,随变形量增加,η′相与基体的关系由共格转变成半共格.DSC实验结果(图5)显示,在4%+12+8与12+10处理合金的热分析曲线中,对应η'向η相转变的峰(235 ℃附近)强度[31]显著高于12+8和3%+12+8处理后的合金.这表明,增加变形量与延长时效时间均可以促进η′相的长大进程[32],二者的作用是一致的.继续增加预变形量或延长时间,会进一步促进η′相长大,当尺寸增加到一定程度,析出相与基体不再保持共格关系,形成不共格的η相[33],这与文献[16,17,18]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

AA7055铝合金时效析出过程的小角度X射线散射定量表征

1

2017

... Al-Zn-Mg-Cu合金时效过程中析出序列为[30]:α (过饱和固溶体)-GP区 (Guinier-Preston zone,脱溶原子偏聚区)-η′相(亚稳态MgZn2)-η相(稳定态MgZn2).关于预变形对析出序列的影响,韩念梅等[16]认为,预变形引入的位错降低了空位密度,不利于η′相形核析出,但有利于形成粗大的η相;而同时也有学者[29,30]认为,变形加工后析出序列与未进行预变形的合金相同.在本工作的实验结果中,既未在SAED图中观察到η相的衍射斑点,也未在高分辨图像中观察到不共格的析出相,故η相并未在晶内形成.本工作中,随变形量增加,η′相与基体的关系由共格转变成半共格.DSC实验结果(图5)显示,在4%+12+8与12+10处理合金的热分析曲线中,对应η'向η相转变的峰(235 ℃附近)强度[31]显著高于12+8和3%+12+8处理后的合金.这表明,增加变形量与延长时效时间均可以促进η′相的长大进程[32],二者的作用是一致的.继续增加预变形量或延长时间,会进一步促进η′相长大,当尺寸增加到一定程度,析出相与基体不再保持共格关系,形成不共格的η相[33],这与文献[16,17,18]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

AA7055铝合金时效析出过程的小角度X射线散射定量表征

1

2017

... Al-Zn-Mg-Cu合金时效过程中析出序列为[30]:α (过饱和固溶体)-GP区 (Guinier-Preston zone,脱溶原子偏聚区)-η′相(亚稳态MgZn2)-η相(稳定态MgZn2).关于预变形对析出序列的影响,韩念梅等[16]认为,预变形引入的位错降低了空位密度,不利于η′相形核析出,但有利于形成粗大的η相;而同时也有学者[29,30]认为,变形加工后析出序列与未进行预变形的合金相同.在本工作的实验结果中,既未在SAED图中观察到η相的衍射斑点,也未在高分辨图像中观察到不共格的析出相,故η相并未在晶内形成.本工作中,随变形量增加,η′相与基体的关系由共格转变成半共格.DSC实验结果(图5)显示,在4%+12+8与12+10处理合金的热分析曲线中,对应η'向η相转变的峰(235 ℃附近)强度[31]显著高于12+8和3%+12+8处理后的合金.这表明,增加变形量与延长时效时间均可以促进η′相的长大进程[32],二者的作用是一致的.继续增加预变形量或延长时间,会进一步促进η′相长大,当尺寸增加到一定程度,析出相与基体不再保持共格关系,形成不共格的η相[33],这与文献[16,17,18]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

非等温回归再时效对Al-8Zn-2Mg-2Cu合金厚板组织及性能的影响

1

2018

... Al-Zn-Mg-Cu合金时效过程中析出序列为[30]:α (过饱和固溶体)-GP区 (Guinier-Preston zone,脱溶原子偏聚区)-η′相(亚稳态MgZn2)-η相(稳定态MgZn2).关于预变形对析出序列的影响,韩念梅等[16]认为,预变形引入的位错降低了空位密度,不利于η′相形核析出,但有利于形成粗大的η相;而同时也有学者[29,30]认为,变形加工后析出序列与未进行预变形的合金相同.在本工作的实验结果中,既未在SAED图中观察到η相的衍射斑点,也未在高分辨图像中观察到不共格的析出相,故η相并未在晶内形成.本工作中,随变形量增加,η′相与基体的关系由共格转变成半共格.DSC实验结果(图5)显示,在4%+12+8与12+10处理合金的热分析曲线中,对应η'向η相转变的峰(235 ℃附近)强度[31]显著高于12+8和3%+12+8处理后的合金.这表明,增加变形量与延长时效时间均可以促进η′相的长大进程[32],二者的作用是一致的.继续增加预变形量或延长时间,会进一步促进η′相长大,当尺寸增加到一定程度,析出相与基体不再保持共格关系,形成不共格的η相[33],这与文献[16,17,18]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

非等温回归再时效对Al-8Zn-2Mg-2Cu合金厚板组织及性能的影响

1

2018

... Al-Zn-Mg-Cu合金时效过程中析出序列为[30]:α (过饱和固溶体)-GP区 (Guinier-Preston zone,脱溶原子偏聚区)-η′相(亚稳态MgZn2)-η相(稳定态MgZn2).关于预变形对析出序列的影响,韩念梅等[16]认为,预变形引入的位错降低了空位密度,不利于η′相形核析出,但有利于形成粗大的η相;而同时也有学者[29,30]认为,变形加工后析出序列与未进行预变形的合金相同.在本工作的实验结果中,既未在SAED图中观察到η相的衍射斑点,也未在高分辨图像中观察到不共格的析出相,故η相并未在晶内形成.本工作中,随变形量增加,η′相与基体的关系由共格转变成半共格.DSC实验结果(图5)显示,在4%+12+8与12+10处理合金的热分析曲线中,对应η'向η相转变的峰(235 ℃附近)强度[31]显著高于12+8和3%+12+8处理后的合金.这表明,增加变形量与延长时效时间均可以促进η′相的长大进程[32],二者的作用是一致的.继续增加预变形量或延长时间,会进一步促进η′相长大,当尺寸增加到一定程度,析出相与基体不再保持共格关系,形成不共格的η相[33],这与文献[16,17,18]中较大预变形量或过时效态析出相形态相对应.所以,预变形量虽增加了析出相含量,加快了时效析出进程,但并未改变时效析出序列,支持了文献[29,30]中的说法. ...

Effects of pre-stretching and ageing on the strength and fracture toughness of aluminum alloy 7050

1

2011

... 关于预变形对晶间析出相的影响,之前的研究工作存在着争论,Wang和Ma[18]认为预变形有利于减小晶间析出相尺寸,降低PFZ宽度;Han等[34]认为预变形产生的位错加速了合金元素向晶界运动,促进了晶间析出相粗化与PFZ宽化.本工作支持了第一种观点.分析认为,预变形后晶界上的位错密度提高[27]、促进了晶界异质形核,有利于形成连续细小的晶间析出相;同时在位错作用下,晶内析出相形核速率加快、数量增多,晶内与晶界的元素扩散梯度减弱[25],向晶间扩散的合金元素减少,有利于晶间析出相尺寸与PFZ宽度降低,弱化晶间偏聚. ...

A process model for age hardening of aluminium alloys—I. The model

2

1990

... 上述析出相形态的改变,对超高强Al-Zn-Mg-Cu合金力学性能的变化具有重要影响.当析出相尺寸较小时,位错以切过方式作用于析出相.根据析出强化模型,铝合金屈服强度强化效果可以表示为[35]: ...

... 式中,为切过机制作用下的屈服强度强化效果,c1、m、n都为正常数,f为析出相体积分数,r为析出相半径.由式(3)可知,随着f和r增加,屈服强度增加.这种强化方式对于3%+12+8处理的Al-Zn-Mg-Cu合金完全适用,由于f的增加为主要因素,因此强度提高.而对于4%+12+8处理的Al-Zn-Mg-Cu合金,由于出现了较大尺寸的析出相,部分区域位错被认为是以绕过的方式作用于析出相,屈服强度强化效果可以表示为[35]: ...

Microchemical analysis of precipitate free zones in 7075-A1 in the T6, T7 and RRA tempers

1

1991

... 晶间析出相形态的变化是影响力学性能的另一个重要因素.如果晶间析出相尺寸较大,加载过程中容易在附近形成应力集中[16],导致开裂.另外,由于PFZ的存在,晶界的强度通常低于晶内的强度[16,36],裂纹易沿晶界扩展.所以晶界析出相尺寸与PFZ宽度越小,合金的强度与延伸率则越高.因此,经预变形处理后的合金较未经预变形处理的合金表现出更好的综合力学性能. ...