热加工是钢铁产品制备中应用最广泛的加工方式之一。在钢铁材料热变形过程中,大量位错会在变形基体内累积,在材料内部形成高应变区域[1,2,3,4,5,6]。当应变储能达到某临界值时,新的无畸变晶核开始出现,这些新晶核在随后的变形过程中会不断长大并逐渐消耗变形基体内的变形组织。这种通过新晶粒形核及长大的方式实现变形基体晶粒组织重构的过程称为动态再结晶(DRX)[2,4]。在实际生产中,钢铁材料的热加工过程通常分多道次进行,不同道次之间会经历一定时间的停留,此过程中,材料的微观组织会发生明显变化,变形抗力降低,出现明显的软化现象。因此,详细了解变形道次间隔内发生的微观结构演变行为及其软化机制,对有效实施热加工工艺控制,调整热加工产品的组织和性能具有非常重要的意义。

在钢铁材料多道次热加工的道次间隔内出现的软化行为通常被称之为亚动态软化。亚动态软化过程中可能出现的软化机制主要有3种:静态回复(SRV)、静态再结晶(SRX)和亚动态再结晶(P-DRX)[1,7,8]。其中,SRV过程中主要发生位错的重排和湮灭;SRX过程为变形后保温阶段发生的再结晶的形核及晶粒生长;P-DRX则是指热变形过程中形成的DRX晶核在保温过程中继续长大成为新的无畸变晶粒的再结晶过程[8,9,10]。对钢中的奥氏体而言,因其层错能较低,位错在其内部的交滑移运动较为困难,因此有一些研究[1,11]发现,在热变形后的保温过程中,SRV的作用很小,其亚动态软化主要通过SRX和P-DRX进行。Kugler和Turk[12]研究发现,变形后的间隔时间内,材料的亚动态软化机制与前期变形阶段的变形量相关:当变形阶段的变形量低于动态再结晶形核的临界应变时,材料内部无动态再结晶形核发生,后续保温过程的材料软化以SRX而主;而当变形阶段的变形量高于动态再结晶形核的临界应变时,动态再结晶形核已经发生,在随后的保温过程中,这些再结晶晶核会迅速长大,这种情况下材料的亚动态软化以P-DRX方式进行,而且P-DRX过程没有孕育期,通常比SRX具有更快的软化速率。Cho等[13]进一步提出,由于静态再结晶形核需要孕育期,在P-DRX已开动的条件下SRX将难以继续发生。

变形条件(如温度、应变速率、变形量等)会影响奥氏体在热变形后保温过程中的亚动态软化机制。Sun和Hawbolt[14]认为,变形温度和应变速率对奥氏体P-DRX的发生有明显影响,但变形量的影响较小。当变形量超过某临界值(一般为达到峰值应力时的应变),变形量对P-DRX几乎无影响。而Dehghan-Manshadi等[8]的研究则表明,变形间隔内材料的软化机制比较复杂,并非只存在一种软化机制,可能会同时出现2种甚至3种软化机制的复合作用,不同软化机制的发生取决于热变形条件的变化。迄今为止,变形条件对奥氏体热变形后的亚动态软化机制影响的研究仍缺乏统一认识。目前已有的关于奥氏体亚动态软化行为的结论大多是基于应力-应变曲线及组织形态整体特征分析而获得的,即通过分析材料经历不同保温时间后,其平均晶粒尺寸和第2次变形时的应力的变化来推导材料的亚动态软化机制,缺乏对不同亚动态软化机制背后的微观组织行为的详细阐述,对奥氏体亚动态软化行为的微观机理研究也有待进一步深化。

本工作利用电子背散射衍射(EBSD)和透射电镜(TEM)对Ni-30%Fe (质量分数)合金经热变形后保温过程中奥氏体晶粒内部的亚晶界及取向差的演变及微观亚结构进行表征,分析不同特征的变形亚结构在保温过程中的演变规律,阐述微观亚结构演变行为对奥氏体亚动态软化机制的影响。

1 实验方法

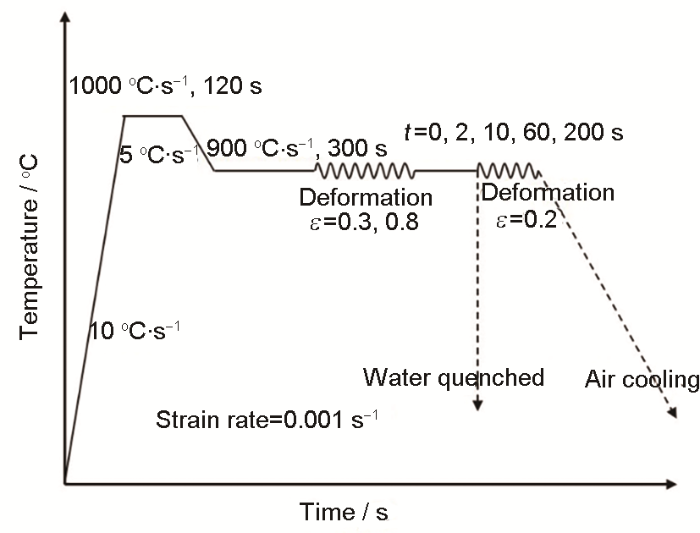

本工作采用的Ni-30%Fe合金是一种典型的奥氏体模型合金,化学成分(质量分数,%)为:Fe 30.5,C 0.02,Mn 0.04,Ni余量。Ni-30%Fe模型合金奥氏体的层错能与普碳钢奥氏体的层错能相近,但在快速冷却中不会发生任何相变[15,16],可通过淬火将高温变形组织保留至室温,可实现对高温奥氏体变形结构的分析及其热变形行为的研究。因此,Ni-30%Fe合金是研究钢中奥氏体热变形及后续保温过程中组织演变行为的理想材料,其研究结果可直接作为碳钢中奥氏体热变形微观组织演变行为研究的参考[11,17],且对其它奥氏体合金,如奥氏体不锈钢、高温合金等,同样具有借鉴意义。本工作中,Ni-30%Fe合金铸锭热锻后在1200 ℃下保温12 h,获得平均晶粒尺寸约为300 μm的无变形等轴状晶粒组织。随后,将退火试样加工成直径8 mm、高15 mm的圆柱形压缩试样,在Gleeble-3500热力模拟试验机上进行单轴等温热压缩实验,实验方案如图1所示。先将试样以10 ℃/s的速率加热至1000 ℃,保温2 min后以5 ℃/s的速率冷却至900 ℃,均温5 min后以应变速率

图1

图1

双道次热压缩实验工艺流程图

Fig.1

Diagram of the double-pass hot compression test (t—time, ε—strain)

材料的亚动态软化程度可通过分析两道次变形中的流动应力变化进行评估,通常使用0.2%应力补偿法[8]来确定,软化分数(X)可通过下式计算:

式中,σm为第一道次变形结束时的流动应力,σ1和σ2分别为第一道次压缩和第二道次压缩时的屈服应力,通常使用0.2%残余塑性变形所对应的应力作为材料的屈服应力,其确定方式如图2所示。

图2

图2

材料亚动态软化分数测量方法示意图

Fig.2

Schematic of the post-dynamic softening fraction measurement (σm is the stress at the end of the first deformation, σ1 and σ2 are the 0.2% offset yield stresses for the first and the second deformations, respectively)

将淬火后的试样平行于压缩轴方向对剖,分别利用EBSD及TEM对试样剖面中心区域进行微观组织表征。EBSD试样先经机械研磨抛光后,再使用离子刻蚀去除其表面的应力层。EBSD表征在装有NordlysMax EBSD探测器的Nova NanoSEM 430扫描电子显微镜(SEM)上进行,操作电压为20 kV, 并利用HKL-Channel 5软件进行后续数据处理。TEM试样先经机械研磨至约50 μm后通过电解双喷减薄而制成,电解液为10%HClO4+90%C2H5OH (体积分数)溶液,电解温度约为-30 ℃,电解电压为15 V。形貌观察在Tecnai G2 F20型TEM上进行,操作电压为200 kV。

2 实验结果

2.1 应力-应变曲线及软化速率

Ni-30%Fe合金在

图3

图3

Ni-30%Fe合金在应变速率

Fig.3

Flow curve of the hot deformation of the Ni-30%Fe model alloy at temperature T=900 ℃, strain rate

为方便对比,分别选取了峰值应变(ε=0.3)和稳态应变(ε=0.8)作为初始应变进行两道次压缩实验,并根据两道次变形中流动应力的变化计算材料的软化分数。两道次压缩实验的应力-应变曲线如图3中的实线所示。可以发现,经历不同保温时间,第二道次热压缩时的应力-应变曲线存在明显差别。经短时间保温(如t=2和10 s) 后,第二道次变形时的流动应力基本承继了第一道次变形结束时的应力,说明在短时间保温过程中材料内部亚动态软化程度较小。当保温时间增长至60 s时,第二道次变形时的初始流动应力明显小于第一道次变形结束时的应力;当保温时间延长至200 s时,第二道次变形初始应力下降更加明显,说明热变形试样在较长时间的保温过程中发生了明显软化。

图4

图4

不同初始应变下Ni-30%Fe合金经过不同保温时间后的软化分数

Fig.4

The softening fractions as a function of annealing time for the Ni-30%Fe alloy at different initial strains

2.2 变形态微观组织

图5a和d分别为Ni-30%Fe奥氏体合金变形至ε=0.3和ε=0.8时微观组织的EBSD像。当ε=0.3时,材料内部的动态再结晶已开始发生,再结晶晶核沿着原始晶界大量形成。当应变增至ε=0.8时,材料内部的动态再结晶已完成,原始变形晶粒已完全被动态再结晶晶粒所取代。与静态再结晶不同,动态再结晶生成的再结晶晶粒在后续变形中会继续经历变形,晶粒内部因此会继续生成变形亚结构。图5b和e分别为与图5a和d相对应的局部取向差分布图,其中蓝色区域为低取向差区域,红色区域为高取向差区域。可以看出,变形至ε=0.3时样品内部的局部取向差高于变形至ε=0.8时样品内部的局部取向差。图5c和f分别给出了2种应变下的局部取向差统计结果,曲线的峰值越靠右表示平均取向差越大。可以看出,变形至ε=0.3时样品内的平均取向差明显大于变形至ε=0.8时样品内中的平均取向差。一般认为,局部取向差越大,材料内部局部变形的累积程度越高,形变储能也越大[25,26]。通常,材料内部的形变储能会直接影响热变形后亚动态再结晶的发生速率[2,3]。

图5

图5

不同变形状态下Ni-30%Fe 合金微观组织的EBSD像、局部取向差分布图及取向差角度分布曲线

Fig.5

EBSD maps (a, d), the corresponding local misorientation maps (b, e) and the angular distributions of the local misorientations (c, f) of the Ni-30%Fe alloy after the hot deformation under T=900 ℃,

Color online

2.3 变形至峰值应变后保温过程中的奥氏体软化行为

Ni-30%Fe合金奥氏体在

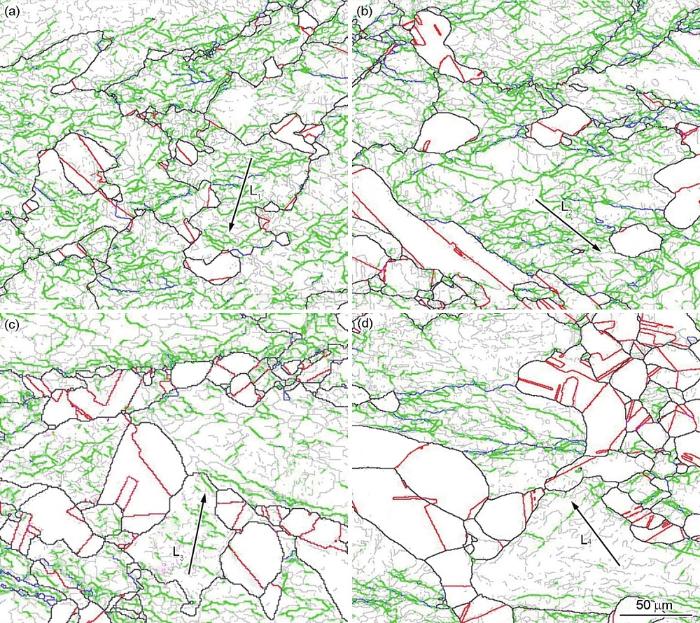

图6

图6

Ni-30%Fe 合金在T=900 ℃、

Fig.6

EBSD maps of the Ni-30%Fe alloy at different annealing time of 0 s (a), 2 s (b), 10 s (c) and 60 s (d) after the hot deformation under T=900 ℃ and

Color online

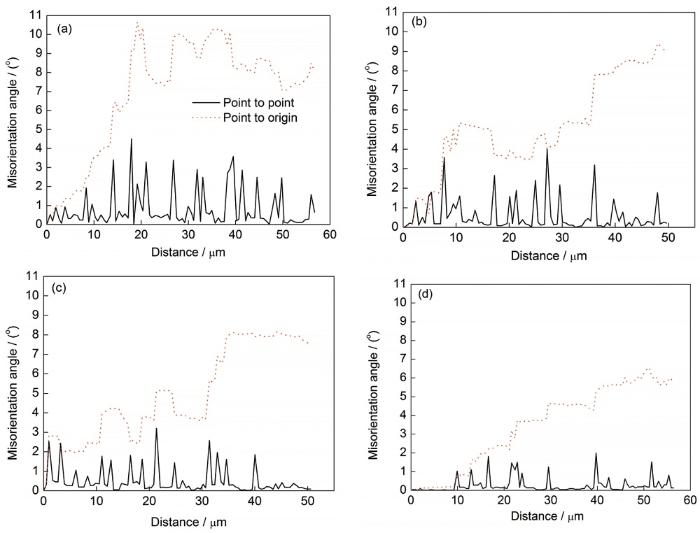

为进一步了解变形基体内变形亚结构在保温过程中的演变行为,对不同保温时间后晶粒内部的取向差分布进行了分析,结果如图7所示。其中,点对点取向差为2个相邻扫描点之间的取向差,累积取向差为第N个扫描点与第一个扫描点之间的取向差。在热变形样品中,晶粒内部形成了较为丰富的亚晶结构,大量亚晶界的取向差角度处于3°~5°之间,晶粒内的累积取向差约为11° (图7a);经2 s保温后,晶粒内部的亚晶界取向差角度略有降低,大部分亚晶界的取向差降低至3°左右(图7b);当保温时间延长至10 s时,晶粒内亚晶界的点对点取向差进一步降低(图7c);而当保温时间延长至60 s时,晶粒内部亚晶界的数量显著减少,留存的亚晶界的取向差绝大部分降低至2°以下,累积取向差也降低至6°左右(图7d)。可见,变形基体内存在的亚晶界的取向差随着保温时间的延长而逐渐减小,亚晶界数量也随之降低,即发生了变形亚结构的恢复。

图7

图7

沿图6中直线L1、L2、L3和L4的取向差变化规律

Fig.7

Misorientation profiles measured along the lines L1 (a), L2 (b), L3 (c) and L4 (d) in Fig.6

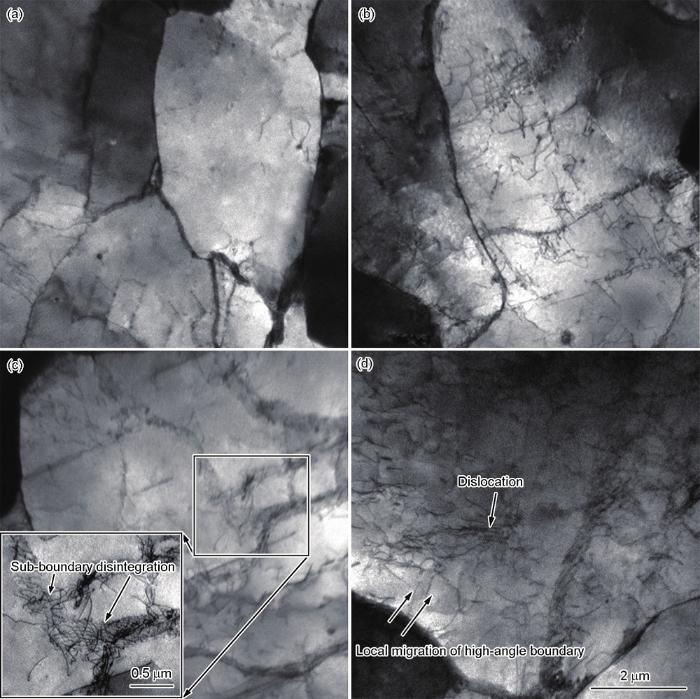

通过TEM分析变形态原始晶粒内部的位错亚结构特征后发现,变形至ε=0.3时,晶粒内的变形亚结构主要由发育良好的亚晶组成,这些亚晶通常由一些位错组成的中低角度亚晶界分割开来,内部的位错密度较低(图8a)。在随后保温过程中,少量位错开始从亚晶界中脱离(图8b),且随保温时间的延长,从亚晶界中挣脱的位错数量逐渐增加(图8c);而当保温时间延长至60 s时,大量位错从亚晶界中脱离出来,部分亚晶界已开始分解(图8d)。由此可见,变形过程中形成的亚结构在保温过程中通过位错运动而逐渐分解。这进一步说明当变形至峰值应变后继续保温,变形过程中在奥氏体内部产生的亚结构不仅会通过P-DRX的方式被消耗,也可通过自身恢复作用逐渐分解。

图8

图8

在T=900 ℃、

Fig.8

TEM images of the Ni-30%Fe alloy at different annealing time of 0 s (a), 2 s (b), 10 s (c) and 60 s (d) after the hot deformation under T=900 ℃ and

2.4 变形至稳态应变后保温过程中奥氏体的组织演变

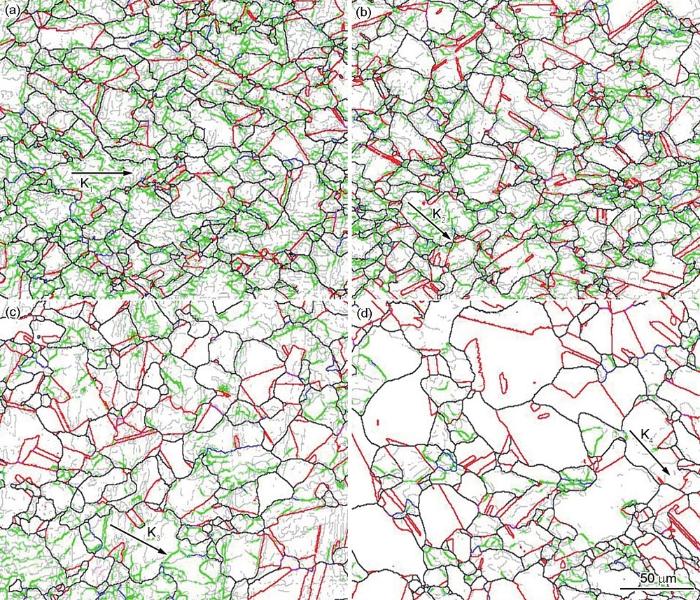

当Ni-30%Fe合金奥氏体变形至ε=0.8时,其动态再结晶过程已达稳态。此时,微观组织实际在经历一个连续的动态演变过程:再结晶晶粒内部因持续变形会继续累积应变;当形变储能累积到临界值时,新一轮再结晶会继续发生,新一轮再结晶晶核的长大也会再次吞并已发生变形的再结晶晶粒,从而实现再结晶持续发生与形变储能持续累积之间的动态平衡。由于弯曲的大角度晶界大量存在,新一轮再结晶的形核相对容易。此时,晶粒内部的形变储能较低,内部的亚结构呈现相对随机的分布特征,且内部亚晶界的取向差一般较小,如图9a所示。对变形后的试样分别保温2、10和60 s后发现:当保温2 s时,微观组织主要由已发生变形的动态再结晶晶粒组成,晶粒内部存在一定数量的位错亚结构,且晶界普遍较为弯曲,仍表现为典型的动态再结晶达到稳态时的组织特征,此时材料内部的软化分数极小(图4)。当保温时间延长至10 s,晶粒结构仍未发生明显变化,但晶粒内部的亚结构明显减少。当保温时间进一步延长到60 s时,晶粒结构开始发生变化,部分晶粒明显粗化,说明亚动态软化机制已发生显著改变。

图9

图9

Ni-30%Fe 合金在T=900 ℃、

Fig.9

EBSD maps of the Ni-30%Fe alloy at different annealing time of 0 s (a), 2 s (b), 10 s (c) and 60 s (d) after the hot deformation under T=900 ℃ and

Color online

图10分别给出了经过不同保温时间后材料内部的取向差分布情况。可以看出,晶粒内部亚晶界的取向差角度随保温时间的延长逐渐减小,意味着该条件下亚晶界也会通过恢复作用而逐渐分解。对比图10和7的结果可以发现,变形至稳态应变的样品中亚晶界取向差及累积取向差均小于变形至峰值应变时样品内的取向差;且在短时间保温过程中,变形至稳态应变的样品晶粒内部的亚晶界取向差角度的降低幅度更大,即在相同保温时间内,变形至稳态应变时晶粒内部的亚晶界分解更明显。通过TEM表征可以发现,当动态再结晶达到稳态时,晶粒内部的亚结构主要由一些较为分散的小角度亚晶界组成,亚晶内的位错密度较低(图11a)。在随后的保温过程中,晶粒内的亚结构会发生明显变化:保温2 s时,位错开始从亚晶界中脱离,在亚晶内部生成随机分布的位错(图11b);当保温10 s后,大量位错开始从小角度晶界中脱离,原本致密的亚晶界开始转变为较为松散的位错网结构(图11c);随着保温时间进一步延长到60 s,大量亚晶界已完全分解,晶粒内的局部区域因此生成了高密度且分布随机的自由位错(图11d)。 这些自由位错的出现,为大角度晶界的迁移提供了有利条件,这种情况下,大角度晶界容易发生局部的迁移而使晶粒粗化,如图9d所示。此过程中并未发现静态再结晶的形核发生,此过程并非静态再结晶过程,而是在自由位错作用下的晶粒粗化过程。

图10

图10

沿图9中直线K1、K2、K3 和K4的取向差变化规律

Fig.10

Misorientation profiles measured along the lines K1 (a), K2 (b), K3 (c) and K4 (d) in Fig.9

图11

图11

在T=900 ℃、

Fig.11

TEM images of Ni-30%Fe alloy at different annealing time of 0 s (a), 2 s (b), 10 s (c) and 60 s (d) after the hot deformation under T=900 ℃ and

3 分析讨论

由以上结果可以看出,热变形后奥氏体的亚动态软化行为是与热变形中形成的组织状态直接相关的。当奥氏体变形至峰值应变时,奥氏体中的动态再结晶已开动,大量再结晶晶核沿原始大角度晶界形成,但材料内部的再结晶体积分数总体较低,已再结晶区域与未再结晶区域间存在较大的应变储能差。在变形后的保温过程中,预先形成的动态再结晶晶核的大角度晶界会以应变驱动界面迁移(SIBM)的方式进行快速迁移[3,30],进而促使晶核生长成为较大尺寸的无畸变再结晶晶粒,此过程是典型的P-DRX过程,此时材料的快速软化是以P-DRX实现的,如图6所示。而当变形至稳态应变时,奥氏体内部的动态再结晶已发生充分,再结晶晶粒会因持续变形作用继续累积应变,但此时晶粒内部的局部应变大多分布于大角度晶界的两侧,如图5e所示。在这种情况下,大角度再结晶晶界两侧并不存在较大的应变储能差,无法提供晶界迁移所需的有效驱动力。虽然热变形中通过动态再结晶已形成了大量大角度的可动晶界,这些晶界在后续保温初期并不会发生大规模迁移,此时P-DRX是受限的,材料无法通过P-DRX实现快速软化,而只能通过其它软化机制进行软化。

实验结果表明,热变形中形成的微观亚结构的恢复也是一种潜在的亚动态软化机制,如图8和11所示。通常,金属材料热变形中会发生2种形式的位错运动:位错的交滑移和攀移。一方面,位错可通过交滑移形成位错墙以及亚晶界,并形成内部干净的较稳定的亚晶结构;另一方面,位错可通过攀移导致亚晶界分解或位错湮灭,促进亚晶的合并或粗化。在奥氏体热变形过程中,位错较容易滑移聚集并缠结形成位错墙,进一步发展可形成亚晶界,这是一个能量降低的过程。这些亚晶界会不断吸收周围新生成的位错使晶界取向差逐渐变大,其稳定性也会随之增加[3]。在动态再结晶过程中,这种亚结构的行为会影响再结晶的形核与生长,尤其在再结晶的初期阶段,甚至会改变再结晶的发生模式[2,3,31,32]。但在变形后的保温过程中,因无持续应变的作用,基体内不会有新的位错生成,原本形成的非稳定的亚晶界会在热激活作用下通过位错的攀移运动而逐渐分解,发生亚结构恢复。

当样品变形至峰值应变时,除已发生再结晶的区域外,在原始变形晶粒内部生成了复杂的微观亚结构。此时生成的亚晶界取向差较大,亚晶界的稳定性较好。在变形后的保温过程中,一方面,这些亚结构发生恢复的速率相对较慢;而另一方面,亚结构恢复导致位错从亚晶界中脱离,形成可移动位错,但在粗大的原始变形晶粒内部,由于没有大角度晶界的存在,这些自由位错仅能通过运动过程中与其它异号位错相遇而湮没。在这种情况下,亚结构恢复引起的亚动态软化速率较慢。且随着保温时间的延长,亚结构恢复所引起的亚晶界分解及位错湮没会降低原始变形晶粒内部的形变储能,降低大角度晶界长程迁移的驱动力,使P-DRX晶粒的进一步长大受到限制。而当初始变形达到稳态应变时,动态再结晶已完成。在此情况下,细化后的再结晶晶粒内部重新生成的亚结构相对较少(图9a),晶粒内亚晶界取向差也小于峰值应变时的取向差(图5),亚晶界的稳定性也相应较差。因此,在保温过程中,亚结构的恢复速度明显快于初始应变为峰值应变时的样品。此时,晶粒内的亚晶界很容易因位错的攀移运动而分解,如图11所示,此过程会使材料出现部分软化,但软化程度不及P-DRX过程。另一方面,亚晶界的大规模分解容易引起局部位错密度的快速增加,且不同晶粒内部位错密度的分布不均,在动态再结晶过程中形成的大角度晶界两侧形成储能差,从而为大角度晶界的局部迁移提供了有效的驱动力。在此过程中,局部高密度自由位错的出现会促进周围大角度晶界的局部迁移[3],在促进晶粒粗化的同时,大角度晶界局部迁移过程中会迅速吸收基体内的位错,带来材料的快速软化。即对于变形至稳态应变的样品,随着保温时间的延长,亚结构恢复的发生会加速再结晶晶粒粗化,同时提高材料的软化速率。由以上分析可见,变形亚结构恢复是一种潜在的软化机制,同时会影响其它软化机制的发生。

4 结论

(1) 在变形后保温过程中,Ni-30%Fe合金奥氏体亚动态再结晶和亚结构恢复2种不同的机制均可能成为其主要软化方式。亚结构恢复的速率与变形过程中形成的亚晶界特征相关,亚晶界取向差角度越小,保温过程中亚结构恢复的速率就越快。

(2) 当热变形中奥氏体内发生部分动态再结晶时,再结晶晶粒与变形基体储能差较大,亚动态软化首先通过亚动态再结晶进行;同时,亚结构的恢复也在不断发生,随着保温时间的延长,亚结构的恢复逐渐占据主导,成为主要的软化机制。

(3) 当热变形中奥氏体内动态再结晶达到稳态时,变形亚结构取向差角度较小,亚结构恢复会优先发生;随着保温时间的延长,亚结构的快速恢复引起的亚晶界大量分解所产生的高密度位错会促进大角度晶界的局部迁移,大大促进晶粒的粗化,进而引起材料的加速软化。

参考文献

Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions

[J].

Microstructure and mechanical properties of austenitic stainless steels after dynamic and post-dynamic recrystallization treatment

[J].

Recrystallization and Related Annealing Phenomena

[M].

A review of dynamic recrystallization phenomena in metallic materials

[J].

A study on the effect of strain rate on the dynamic recrystallization mechanism of alloy 617B

[J].

Evolution of twins and sub-boundaries at the early stage of dynamic recrystallization in a Ni-30%Fe austenitic model alloy

[J].

Grain boundary character distribution during the post-deformation recrystallization of Incoloy 800H at elevated temperature

[J].

Hot deformation and recrystallization of austenitic stainless steel: Part II. Post-deformation recrystallization

[J].

Metadynamic recrystallization in C steels

[J].

New insight into the mechanism of metadynamic softening in austenite

[J].

Comparison of 304 stainless steel and Ni-30 wt.% Fe as potential model alloys to study the behaviour of austenite during thermomechanical processing

[J].The applicability of a 304SS austenitic stainless steel and a Ni-30 wt.% Fe alloy as model materials to study the behaviour of austenite during the thermomechanical processing of a C-Mn steel has been investigated. The latter alloy has a stacking-fault energy (SFE) closer to that of a C-Mn steel. The crystallographic texture evolution is similar for both materials, being characterized by gradual crystallite rotations towards the stable end orientations typical of fcc metals. The deformation structures observed in both materials are principally similar, with these structures showing the same orientation dependence. However, at the lowest temperature studied the 304SS starts to form stacking faults in the deformation structure. Overall, it has been concluded that at higher temperatures both materials might be appropriate model alloys for the austenite phase in a C-Mn steel. However, at lower temperatures the Ni-30Fe would be the more appropriate alloy because at these temperatures the low SFE energy of 304SS significantly changes the deformation behaviour of the material. (C) 2011 Acta Materialia Inc. Published by Elsevier Ltd.

Modeling the dynamic recrystallization under multi-stage hot deformation

[J].AbstractThe kinetics of the restoration processes that take place during the isothermal annealing of metals for the case when the critical strain for the onset of dynamic recrystallization is reached and exceeded were modeled using the Cellular Automata approach. The model enables both quantitative and topographic simulations of microstructural evolution before and during metadynamic recrystallization. It allows the simulation of multi-stage deformation. It was observed that two kinds of transition between the strain-dependent and strain-independent range are possible: the first is smooth, whereas the second is oscillatory. The post-dynamic softening is shown to be weakly dependent on strain and temperature, but strongly dependent on strain rate, as has been observed in published experimental work.]]>

The dynamic, static and metadynamic recrystallization of a Nb-microalloyed steel

[J].

Comparison between static and metadynamic recrystallization—An application to the hot rolling of steels

[J].

The production of ultrafine ferrite during hot torsion testing of a 0.11 wt pct C steel

[J].

Serration of grain boundary in Ni-30Fe alloy through high temperature deformation

[J].

The effect of carbon and nickel upon the stacking-fault energy of iron

[J].

Dynamic recrystallization of ferrite with particle-stimulated nucleation in a low-carbon steel

[J].

Softening and microstructural change following the dynamic recrystallization of austenite

[J].

Research on dynamic recrystallization behavior of Incoloy 800H

[J].In order to optimize the hot working technology of Incoloy 800H, the dynamic recrystallization (DRX) behavior of Incoloy 800H at temperatures ranging from 850 V to 1100 V and strain rates from 0.01 s(-1) to 10 s(-1) was investigated by single-pass compression tests on MMS-300 thermo-mechanical simulator. The evolutions of microstructure and nucleation mechanisms of DRX were analyzed combined with the technique of EBSD and TEM. The results show that when the deformation temperature is below 950 degrees C, the behavior of DRX is obviously restrained by precipitation of Cr23C6 and Ti(C,N). Therefore the hot deformation constitutive equations in two temperature intervals (from 850 degrees C to 950 degrees C and from 950 degrees C to 1100 degrees C) were established by regression analysis with the deformation activation energy of 465.394 kJ/mol and 427.360 kJ/mol respectively. The inflection points were determined by fitting a third order polynomial to the ln theta-epsilon curves, which makes the prediction for the ratios of critical stress to peak stress and critical strain to peak strain more accurately. Accordingly, the mathematical models of critical stress and critical strain vs Z parameter were deduced. The DRX nucleation mechanisms of Incoloy 800H during hot deformation mainly include strain induced grain boundary migration, grain fragmentation and subgrain coalescence.

800H合金动态再结晶行为研究

[J].-1变形条件下的动态再结晶行为. 结果表明, 当变形温度低于950 ℃时, 析出了大量Cr23C6和Ti(C,N)析出相, 其对动态再结晶行为产生明显的抑制作用. 建立了2段温度区间内(850-950 ℃和950-1100 ℃)800H合金的热变形本构方程; 采用lnθ-ε曲线的三次多项式拟合求解拐点的方法, 较准确地预测了800H合金动态再结晶临界应力/峰值应力和临界应变/峰值应变的比值, 并建立了临界应力、临界应变与$Z$参数的关系;800H合金在热变形过程中动态再结晶形核机制主要包括应变诱导晶界迁移、晶粒碎化以及亚晶合并形核机制.]]>

Static softening in a Ni-30Fe austenitic model alloy after hot deformation: Microstructure and texture evolution

[J].

Correlation between grain size and flow stress during steady-state dynamic recrystallization

[J].

Analysis of steady-state dynamic recrystallization

[J].The steady-state behavior of dynamic recrystallization (DRX) was studied in commercially pure copper and the austenitic steel alloy 800H. Investigations on the flow stress behavior during strain-rate and temperature-change tests in the steady-state regime regarding the grain size sensitivity of the flow stress were analyzed. The results confirmed the predicted connection of DRX grain size and deformation-induced subgrain size. Furthermore, the grain size distribution during steady-state DRX was evaluated and found to remain constant. A continuity equation of the growing and shrinking grain distributions is proposed which allows the steady-state flow stress to be calculated. (C) 2013 Acta Materialia Inc. Published by Elsevier Ltd.

A grain scale approach for modeling steady-state discontinuous dynamic recrystallization

[J].AbstractDiscontinuous dynamic recrystallization (DDRX) generally occurs in low-stacking-fault-energy metals. New grains nucleate and grow at the expense of the strain-hardened older grains. A steady-state flow stress independent of initial conditions is experimentally observed. A general model is proposed to describe these phenomena. While the transient behavior can be addressed only numerically, a steady state is described in detail by closed-form relationships. The approach includes strain hardening and dynamic recovery, nucleation, growth and shrinkage of grains. Furthermore, the strain-hardening equation can be supplemented to account for the effect of boundary-migration-induced softening (BMIS). The present paper first states the general equations of the model; some simple strain-hardening laws neglecting BMIS are then discussed. Finally, a method for evaluating the material parameters is described and illustrated by the example of 304L stainless steel.]]>

Microstructure and flow stress evolution during hot deformation of 304L austenitic stainless steel in variable thermomechanical conditions

[J].

Evolution of microstructure and texture during cold deformation of hot-extruded GH3625 alloy

[J].θˉL) increases with the increase of cold deformation, which can reflect the increase of dislocation density. With the increase of cold deformation, the uniformity of grain deformation gradually becomes better, and the stress concentration distribution gradually changes to the stress uniform distribution. With the cold deformation increases, the type of deformation texture remains basically unchanged, while the strength of the Copper texture {112} with stable orientation is slightly reduced. Meanwhile, the Rotated-cube texture {001} generated by inhomogeneous plastic deformation is reduced in strength. In addition, the formation of deformation twin results in a decrease in the strength of the Goss texture {110} and the Brass-R texture {111}.]]>

挤压态GH3625合金冷变形过程中的组织和织构演变

[J].θˉL)升高,位错密度增加;同时,晶粒变形均匀性逐渐变好,应力集中分布逐渐向应力均匀分布转变。随着冷变形量的增加,其形变织构的类型基本保持不变,而具有稳定取向的Copper织构{112}的强度略有降低;同时,由不均匀变形产生的Rotated-cube织构{001}的强度降低;此外,形变孪晶的形成导致Goss织构{110}和Brass-R织构{111}的强度降低。]]>

Study of annealing twins in fcc metals and alloys

[J].

An investigation of the origin and growth of annealing twins

[J].

Investigation of annealing twins in F.C.C. metals

[J].

Nucleation and microtexture development under dynamic recrystallization of copper

[J].

Dynamic recrystallization mechanisms operating in a Ni-20%Cr alloy under hot-to-warm working

[J].

Continuous dynamic recrystallization during the transient deformation in a Ni-30%Fe austenitic model alloy

[J].