涡轮盘是航天发动机的关键耐热部件,随着航空发动机向大型化、高推重比和高效率的方向发展,涡轮前燃气温度不断提高,零部件的负荷不断增大,工作状况越趋恶劣,对涡轮盘的性能要求越来越苛刻。GH4720Li (美国牌号Udimet720Li)合金是一种典型涡轮盘用沉淀强化型镍基高温合金,合金中主要强化相γ'的体积分数高达45%;主要用于制作650~750 ℃下使用的压气机盘和涡轮盘以及在900 ℃短时使用的涡轮盘[1]。按照材料成形方式,高温合金的制备工艺可分为铸造、变形、粉末冶金3大类。目前国内一方面利用粉末冶金工艺制备无宏观偏析、晶粒均匀细小、塑性好、抗疲劳性强的新型FGH4720Li涡轮盘用高温合金[2];另一方面,在熔炼和热加工技术高速发展的推动下,仍利用生产流程相对简单、成本相对较低的传统铸锻工艺进一步探索高性能变形GH4720Li涡轮盘用高温合金的制备工艺[3]。

国外对于Udimet720Li合金的研究起步较早,已获得比较成熟的熔炼-铸造-锻造成形和热处理工艺,并形成了相对完备的工业制备体系。而国内的相关研究起步较晚,虽然在变形GH4720Li合金熔炼和棒材制备技术上取得了一定成就,但锻造成形及热处理过程中的组织控制仍存在困难。由此导致GH4720Li合金在大尺寸棒材制备、热加工成材率及批次稳定性等方面存在一定问题。因此,国内学者[4,5]主要针对铸锻型GH4720Li合金铸锭开坯、热加工及热处理工艺参数的优化以及各阶段组织调控开展研究,为解决γ'相体积分数高带来的难变形问题提供指导。对于新型粉末FGH4720Li高温合金的研究,国外学者[6~9]多探究该粉末高温合金显微组织对疲劳裂纹扩展行为及疲劳寿命的影响;国内研究[8~10]则主要集中在该合金的热加工行为、热处理工艺优化以及服役过程中γ'相的析出规律等方面。

为探究实际生产过程中采用粉末冶金工艺和传统铸锻工艺制备的相同成分的高温合金涡轮盘组织和力学性能的异同性,本工作详细对比了FGH4720Li和GH4720Li合金的微观组织特征,总结了2种合金的晶粒尺寸和取向、γ'相和孪晶的分布以及孪晶界及大/小角度晶界的数量等特点,并结合以往研究系统分析了2种合金组织的异同点,及其对合金的硬度、屈服强度和抗拉强度的影响,以期为难变形高温合金涡轮盘的实际生产和服役安全提供一定理论参考。

1 实验方法

实验对象分别为采用粉末冶金工艺(粉末制备(Ar气雾化法)、粉末固结(热等静压+热挤压)、等温锻造、热处理)制备的FGH4720Li合金盘件,以及采用传统铸锻工艺(三联熔炼(真空感应熔炼+电渣重熔+真空自耗重熔)、均匀化处理、开坯、锻造成形、热处理)制备的变形GH4720Li合金盘件。2种合金的化学成分(质量分数,%)均为:Cr 15.50~16.50,Co 14.00~15.50,Ti 4.75~5.25,Mo 2.75~3.25,Al 2.25~2.75,W 1.00~1.50,C 0.01~0.02,B 0.01~0.02,Zr 0.025~0.05,Ni 余量。利用JmatPro软件计算合金的平衡相图。

分别从FGH4720Li和GH4720Li合金盘坯靠近盘心处的3个不同位置进行取样(图1),同一位置的2种合金试样分为一组,共3组,编号为FGH-1、GH-1,FGH-2、GH-2,FGH-3、GH-3。对样品进行磨抛处理后再进行电解抛光和电解腐蚀处理。电解抛光液:20 mL H2SO4 + 80 mL CH3OH,电抛参数:20 V,5~10 s;电解腐蚀液:150 mL H3PO4 + 10 mL H2SO4 + 15 g CrO3,电解参数:3 V,5~10 s。之后利用SUPRA 55 型场发射扫描电子显微镜(SEM)观察2种合金中γ

图1

图1

FGH4720Li和GH4720Li合金盘坯及取样示意图

Fig.1

Schematic of billet disc and sampling positions of FGH4720Li (FGH) and GH4720Li (GH) alloys (1—FGH-1/GH-1, 2—FGH-2/GH-2, 3—FGH-3/GH-3)

2 实验结果

2.1 γ' 相

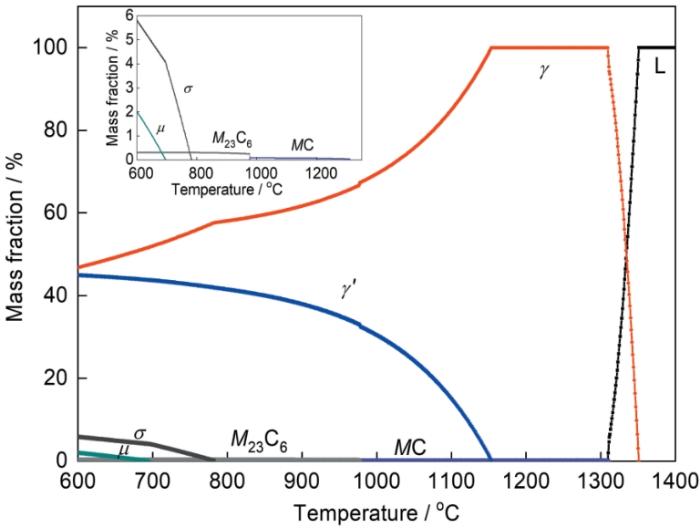

GH4720Li合金的平衡相图如图2所示。由图可知,600 ℃时GH4720Li合金中γ'相质量分数在45%左右,合金中可能析出的其他的相(σ、µ、M23C6和MC)的质量分数较小。GH4720Li合金中的γ′相主要为钉扎在晶界的一次γ′ (γ

图2

图2

GH4720Li合金平衡相图

Fig.2

Equilibrium phase diagram of GH4720Li alloy (Inset shows the partial enlarged view. L—liquid)

图3

图3

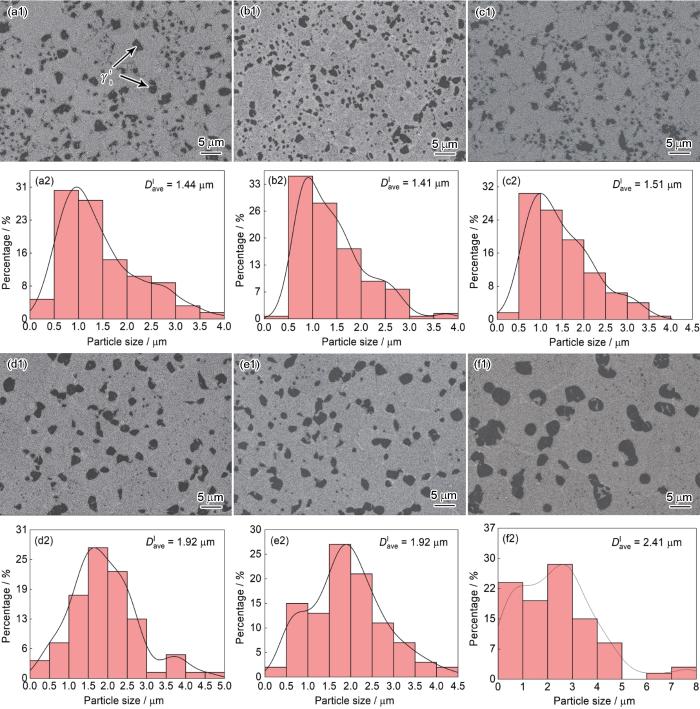

FGH4720Li和GH4720Li合金中γ

Fig.3

SEM images (a1-f1) and particle size distributions (a2-f2) of γ

(a1, a2) FGH-1 (b1, b2) FGH-2 (c1, c2) FGH-3 (d1, d2) GH-1 (e1, e2) GH-2 (f1, f2) GH-3

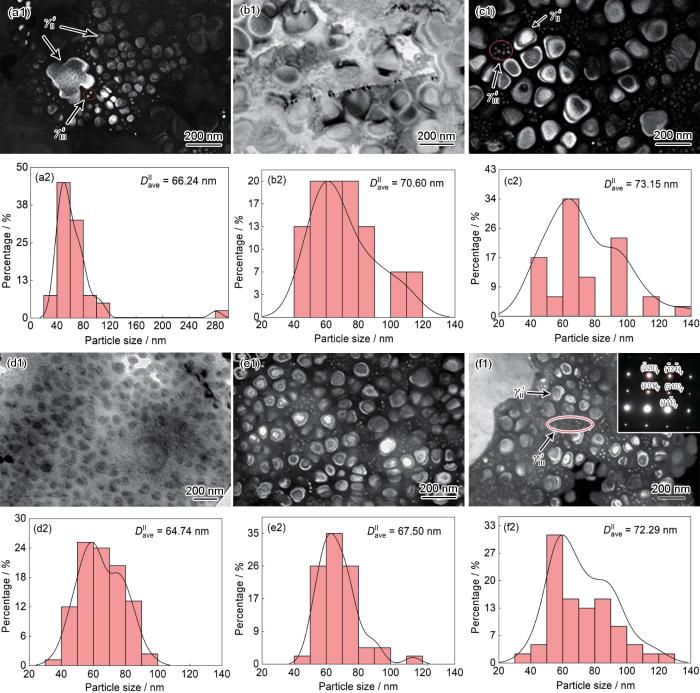

图4为FGH4720Li和GH4720Li合金中γ

图4

图4

FGH4720Li和GH4720Li合金中γ

Fig.4

SEM images (a1-f1) and particle size distributions (a2-f2) of γ

(a1, a2) FGH-1 (b1, b2) FGH-2 (c1, c2) FGH-3 (d1, d2) GH-1 (e1, e2) GH-2 (f1, f2) GH-3

2.2 位错和孪晶分布

图5

图5

FGH4720Li和GH4720Li合金中位错分布的TEM像

Fig.5

TEM images of dislocation distributions in FGH4720Li and GH4720Li alloys

(a) FGH-1 (b) FGH-2 (c) FGH-3 (d) GH-1 (e) GH-2 (f) GH-3

图6

图6

FGH4720Li和GH4720Li合金中孪晶分布的TEM像

Fig.6

TEM images of twins in FGH4720Li and GH4720Li alloys (Inset in Fig.6f shows the typical SAED pattern of twin. T—twin)

(a) FGH-1 (b) FGH-2 (c) FGH-3 (d) GH-1 (e) GH-2 (f) GH-3

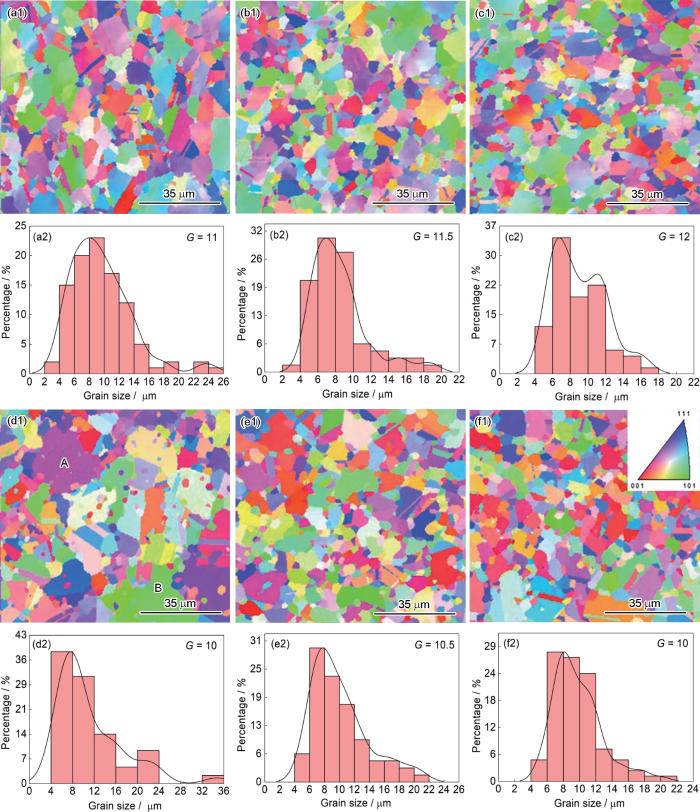

2.3 晶粒取向及尺寸

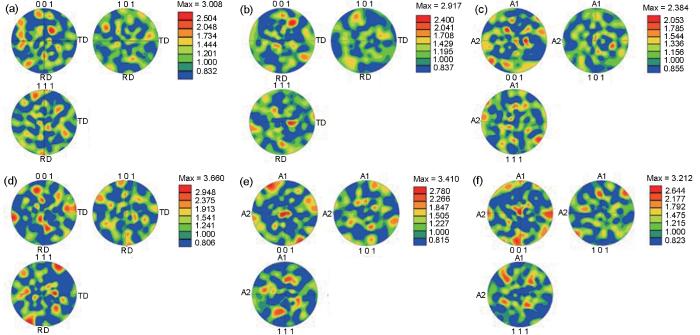

塑性变形会引起晶内位错运动或晶界滑动,导致原本取向相同取向成像的晶粒在不同区域产生取向差,晶粒取向分布图可以展现出合金的塑性变形情况以及不同晶粒取向的集中程度。极图中的等高线可清楚显示各织构的强度差别和锋锐程度。图7和图8a1~f1分别为2种合金的极图和晶粒取向分布图。图中没有出现大面积的同种颜色,颜色分布没有特定规律,较分散,表明晶粒取向分布比较均匀。GH4720Li合金晶内无明显取向差,FGH4720Li合金中部分晶粒内存在明显取向差,表明其塑性变形主要集中在晶粒内部。由图7可见,虽然2种合金极图存在小面积的晶体学取向高密度区域,但最高密度强度处仅为3.66,表明2种合金的晶向呈随机分布,未发现明显的择优取向。

图7

图7

FGH4720Li和GH4720Li合金的极图

Fig.7

Pole figures of FGH4720Li and GH4720Li alloys (TD—transverse direction, RD—rolling direction, A1—axis 1, A2—axis 2)

(a) FGH-1 (b) FGH-2 (c) FGH-3 (d) GH-1 (e) GH-2 (f) GH-3

图8

图8

FGH4720Li和GH4720Li合金中的晶粒取向分布图及晶粒尺寸分布图

Fig.8

Grain orientation distribution maps (a1-f1) and grain size distributions (a2-f2) of FGH4720Li and GH4720Li alloys (G—grain grade)

(a1, a2) FGH-1 (b1, b2) FGH-2 (c1, c2) FGH-3 (d1, d2) GH-1 (e1, e2) GH-2 (f1, f2) GH-3

2.4 晶界分布

FGH4720Li和GH4720Li合金中大、小角度晶界分布及孪晶界分布的统计结果如表1所示。由表可知,2种合金中大角度晶界所占比最大,在83.2%~92.0%之间,小角度晶界占比较低;且3组试样中FGH4720Li合金的小角度晶界占比均略高于GH4720Li合金。上述结果表明,FGH4720Li合金中存在更多的小角度晶界,因此晶内取向差更明显,上述小角度晶界通常由动态再结晶过程中的位错增殖形成。此外,2种合金中均存在大量的Σ3孪晶界。Σ = 3是fcc点阵绕[111]轴转动60°得到的相符点阵,这种取向关系即为孪晶取向关系[20]。FGH4720Li与GH4720Li合金中Σ3孪晶界占比相差不大,在22.9%~28.3%之间。由此表明,粉末冶金和铸锻2种工艺所制备的合金的孪晶界数量差异不大。

表1 FGH4720Li和GH4720Li合金中大、小角度晶界和孪晶界的数量分数 (%)

Table 1

| Alloy | Grain boundary misorientation | Twin boundary | ||||

|---|---|---|---|---|---|---|

| 2°-10° | 10°-180° | Σ3 | Σ9 | Σ27a | Σ27b | |

| FGH-1 | 16.2 | 83.8 | 27.5 | 0.9 | 0.2 | 0.4 |

| GH-1 | 9.0 | 91.0 | 28.3 | 1.5 | 0.1 | 0.6 |

| FGH-2 | 15.6 | 84.4 | 25.2 | 0.8 | 0.2 | 0.2 |

| GH-2 | 9.9 | 90.1 | 24.3 | 1.2 | 0.2 | 0.3 |

| FGH-3 | 16.8 | 83.2 | 24.6 | 0.8 | 0.1 | 0.3 |

| GH-3 | 8.0 | 92.0 | 22.9 | 0.8 | 0.1 | 0.4 |

2.5 力学性能

表2为FGH4720Li和GH4720Li合金在500、650和720 ℃下的屈服强度和抗拉强度及室温Vickers硬度的测试结果。可见,在高温拉伸实验中,随温度的升高,2种合金的屈服强度和抗拉强度降低,但FGH4720Li合金的屈服强度(1058~1098 MPa)和抗拉强度(1153~1530 MPa)始终略高于GH4720Li合金的屈服强度(1020~1083 MPa)和抗拉强度(1133~1513 MPa),表明FGH4720Li合金的高温拉伸性能优于GH4720Li合金。此外,FGH4720Li合金的室温Vickers硬度(580 HV)显著高于GH4720Li合金(494 HV)。

表2 FGH4720Li和GH4720Li合金高温拉伸性能以及室温Vickers硬度

Table 2

Alloy | 500 oC | 650 oC | 720 oC | Vickers hardness (RT) HV | |||

|---|---|---|---|---|---|---|---|

YS MPa | UTS MPa | YS MPa | UTS MPa | YS MPa | UTS MPa | ||

| FGH4720Li | 1098 | 1530 | 1068 | 1363 | 1058 | 1153 | 580 |

| GH4720Li | 1083 | 1513 | 1048 | 1350 | 1020 | 1133 | 494 |

Note: YS—yield strength, UTS—ultimate tensile strength, RT—room temperature

3 分析与讨论

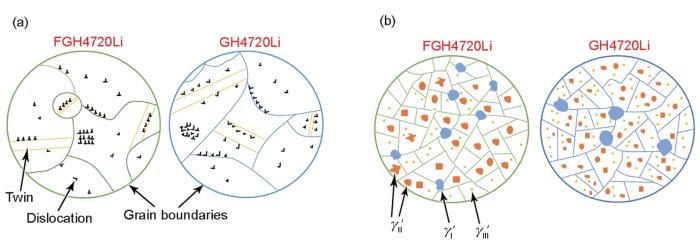

由实验结果总结出FGH4720Li和GH4720Li合金显微组织的异同如图9所示。采用粉末冶金和铸锻工艺所制备的2种合金的位错和孪晶亚结构形态分布、晶粒取向及孪晶界分布均相似。FGH4720Li和GH4720Li合金中均存在位错墙及高位错密度区处的位错网、位错缠结等组态;2种合金中的孪晶均由宽孪晶(0.5~1 µm之间)和部分窄孪晶(< 100 nm)构成,孪晶界类型主要为Σ3;2者的晶粒组织中均未出现明显的择优取向。FGH4720Li和GH4720Li合金显微组织的差异主要体现在晶粒尺寸、晶内取向差、析出相形态及分布和大/小角度晶界数量占比。动态再结晶过程是大角度晶界向高密度位错区迁移的过程[21],2种合金中的大角度晶界占比均高于83%,但FGH4720Li合金中的小角度晶界占比略高于GH4720Li合金,其晶内取向差也更明显,表明在位错滑动机制作用下其动态再结晶完成后部分晶粒内部仍存在位错。此外,GH4720Li合金中还会出现含有局部粗晶的混晶组织。在析出相形态及分布方面,GH4720Li合金中的γ

图9

图9

FGH4720Li和GH4720Li合金微观组织异同的示意图

Fig.9

Schematics showing microstructure similarities (a) and differences (b) of FGH4720Li and GH4720Li alloys

服役态合金的组织及变形行为与合金初始组织状态密切相关。在高温服役阶段,FGH4720Li和GH4720Li合金组织差异导致材料力学性能有所不同。镍基高温合金中主要的强化机制为细晶强化、固溶强化和γ′相析出强化[22]。一方面,合金的硬度、强度及塑性与晶粒尺寸密切相关,晶粒越细,晶界的面积分数越大,积累的位错障碍越多,材料塑性变形的抗力就越大,最终导致合金硬度和强度高而塑性低。已有研究[23~25]表明,合金的屈服强度和抗拉强度随着平均晶粒尺寸的增加而逐渐降低。另一方面,在高温合金服役过程中,不同形态和分布的γ′相必然会导致不同的变形行为[10,26]。在合金变形过程中,大尺寸的γ

4 结论

(1) FGH4720Li和GH4720Li合金的位错和孪晶亚结构分布、晶粒取向及孪晶界分布均相似,显微组织的不同主要体现在晶粒尺寸、晶粒内取向差、析出相形态及分布和大/小角度晶界占比。

(2) 2种合金的γ

(3) 2种合金内的晶粒尺寸均分布在4~12 µm之间。GH4720Li合金内晶粒尺寸在12~24 µm之间的晶粒占比略高于FGH4720Li合金,且GH4720Li合金组织中含有少量粗晶(32~36 µm)。GH4720Li合金晶粒度级别(10~10.5)略低于FGH4720Li合金(11~12)。2种合金中的大角度晶界占比均超过83%,但FGH4720Li合金中的小角度晶界占比略高于GH4720Li合金,且晶内取向差更明显。

(4) FGH4720Li和GH4720Li合金的屈服强度FGH4720Li合金的室温Vickers硬度和高温(500~720 ℃)拉伸性能均高于GH4720Li合金。以上性能差异主要是由2种合金的晶粒尺寸差异造成的。

参考文献

An optimization method of upsetting process for homogenized, nickel-based superalloy Udimet 720Li ingot considering both cracking and recrystallization

[J].

Microstructure and property stability of powder metallurgy nickel-based U720Li superalloy during long-term aging

[J].

粉末镍基U720Li高温合金长期时效下的组织与性能稳定性

[J].

A novel short-process manufacturing method of γ′-strengthened superalloy: Modulation of nano-scaled γ′ precipitates during hot deformation

[J].

Research progress of precipitated phases in GH4720Li superalloy

[J].

GH4720Li合金中析出相的研究进展

[J].GH4720Li高温合金因其具有良好的高温强度、抗疲劳和抗腐蚀性能以及长期组织稳定性,被广泛应用于高性能航空发动机涡轮盘等转动部件。本文归纳了GH4720Li高温合金中γ'相的作用机理和演变规律,并分析了γ'相与高温性能之间的关联性和γ'相与残余应力的交互影响规律。此外,还综述了GH4720Li高温合金的改型研究进展,展望了未来分区控冷技术和双组织双性能盘制备技术在高温合金中的应用。

Effect of micron-sized particles on the crack growth behavior of a Ni-based powder metallurgy superalloy

[J].

Strain localization and crack initiation behavior of a PM Ni-based superalloy: SEM-DIC characterization and crystal plasticity simulation

[J].

Precipitation behavior of γ′ phase in P/M superalloy Udimet720Li

[J].

粉末高温合金Udimet720Li γ′强化相析出行为

[J].

Microstructure evolution behavior of powder superalloy FGH4720Li at near service temperature

[J].GH4720Li is used for turbine disks in a large number of civil and military propulsion systems because of its excellent mechanical properties and corrosion resistance. GH4720Li turbine disk is mainly manufactured through cast and wrought conventionally, but the addition of a high mass fraction of Ti, Al, and Mo can cause severe element segregation and more difficult microstructure control, which can become more severe as the turbine disk gets larger. Owing to this difficulty, the turbine disk quality cannot be guaranteed if the GH4720Li turbine disk is still in cast and wrought form, and the manufacturing process will be more complex, resulting in increased costs. However, the powder metallurgy method can efficiently eliminate element segregation and produce a more uniform microstructure than the cast and wrought methods. GH4720Li alloys manufactured using the powder metallurgy method are called FGH4720Li alloys. As there has been limited research on FGH4720Li and no report on the microstructure evolution during long-term ageing for FGH4720Li to date, it is necessary to study the microstructure evolution behavior during long-term ageing for FGH4720Li to obtain improved microstructure stability. In this study, field emission scanning electron microscopy and extractive phase analysis were used to investigate the microstructure evolution of FGH4720Li in the temperature range of 600-730oC up to 3000 h. The results showed that primary gamma prime was the most stable; whereas, secondary and tertiary gamma prime microstructure evolutions were comparatively complex. At 600oC, there was no microstructure change. At 650oC, only the tertiary gamma prime grew, but there was no microstructure change for the other gamma primes up to 3000 h. When the ageing temperature increased to 730oC, the tertiary gamma prime grew faster before coarsening rapidly. After 200 h, the secondary gamma prime coarsened noticeably, but the big secondary gamma prime coarsened by Ostwald ripening first, absorbing a large amount of tertiary gamma prime and splitting up between 300 and 500 h, before ageing with further processing. Big secondary gamma prime mainly coarsens by amalgamation; whereas, small secondary gamma prime always coarsens by amalgamation during ageing. The divergence between these two types of secondary gamma prime is related to the distribution characteristics of the tertiary gamma prime.

粉末高温合金FGH4720Li在近服役温度下的组织演变规律

[J].

Effect of solution cooling rate on the γ′ precipitation behaviors of a Ni-based P/M superalloy

[J].

Tensile properties of Ni-based GH4720Li superalloys with different microstructures at 650 oC

[J].

GH4720Li镍基合金显微组织对650 ℃拉伸性能影响

[J].

Creep-fatigue behavior of turbine disc of superalloy GH720Li at 650 oC and probabilistic creep-fatigue modeling

[J].

Deformation and recrystallization behavior of a coarse-grain, nickel-base superalloy Udimet720Li ingot material

[J].

Deformation mechanisms in a fine-grained Udimet 720LI nickel-base superalloy with high volume fractions of γ′ phases

[J].

Deformation mechanisms of primary γ′ precipitates in nickel-based superalloy

[J].

Hot deformation behavior of nickel-based superalloy GH4720Li

[J].

Hot deformation behaviors and three-dimensional processing map of a nickel-based superalloy with initial dendrite microstructure

[J].

Influence of microstructure on mechanical property of GH4720 Li alloy

[J].

微观组织对GH4720 Li合金力学性能的影响

[J].

Multiple twinning in cubic crystals: Geometric/algebraic study and its application for the identification of the Σ3 n grain boundaries

[J].

Competition between work-hardening effect and dynamic-softening behavior for processing as-cast GH4720Li superalloys with original dendrite microstructure during moderate-speed hot compression

[J].

Effect of mixed grain structure on high temperature stress rupture property of Ni-based GH4720Li superalloy

[J].

GH4720Li镍基合金混晶组织对高温持久性能的影响

[J].

Cooling precipitation and strengthening study in powder metallurgy superalloy U720LI

[J].

Effects of cooling rate and γ′ morphology on creep and stress-rupture properties of a powder metallurgy superalloy

[J].

Creep behaviour of Ni-base single-crystal superalloys with various γ′ volume fraction

[J].

Effect of standard heat treatment on the microstructure and mechanical properties of hot isostatically pressed superalloy Inconel 718

[J].

Investigation of creep deformation mechanisms at intermediate temperatures in René 88 DT

[J].

Deformation and strength behavior of two nickel-base turbine disk alloys at 650 oC

[J].