为此,研究人员提出通过添加稳定化元素Nb来调控相析出行为:一方面,Nb与C具有较高的亲和力,会优先与C结合形成NbC碳化物,以抑制晶界M23C6碳化物的析出;另一方面,在高温或应力的作用下,奥氏体中析出的细小弥散NbC能够有效阻碍位错运动,提高高温强度[9]。近年来,Nb稳定奥氏体不锈钢受到了广泛关注,如新型的TP347HFG、316Nb、TP310HCb、NF709、HT-UPS等合金[10~15],各合金对Nb含量的控制要求不尽相同,例如,TP347HFG合金规定Nb含量≥ 8[C] ([C]为C的质量分数),316Nb和TP310HCb合金规定Nb含量≥ 10[C],而NF709和HT-UPS合金的Nb含量控制在较低的水平。已有研究[16~18]表明,添加Nb会造成奥氏体不锈钢铸态组织中出现尺寸大且分布不均匀的初生NbC,对其力学性能和耐腐蚀性能造成不利影响。347型奥氏体不锈钢在316 ℃下的断裂韧性研究[16]表明,粗大的Nb(C, N)可作为孔洞的形核位置,增加裂纹扩展速率。25Cr-20Ni奥氏体不锈钢的拉伸性能研究[17]表明,凝固过程中形成的粗大Nb(C, N)周围存在明显的应力集中,促进了微裂纹的萌生和扩展,明显降低了延伸率。含Nb奥氏体不锈钢的Pb-Bi腐蚀性能研究[18]表明,初生NbC的氧化会伴随着体积膨胀和气体产生,降低了氧化层致密性,加快腐蚀速率。截至目前,Nb含量对奥氏体不锈钢微观组织和力学性能的影响尚不明晰。此外,粗大的初生NbC会消耗较多的Nb元素,降低热时效或蠕变过程中二次NbC的析出倾向[19]。然而,后续的热加工和固溶处理对初生NbC形貌和尺寸的影响较小,如何调控铸态样品中的初生NbC也是改善力学性能的关键。

为此,本工作制备了3种Nb含量的奥氏体不锈钢,研究Nb含量对奥氏体不锈钢铸态组织和力学性能的影响规律,在优化Nb含量的基础上,进一步研究了均质化处理对含Nb奥氏体不锈钢微观组织和力学性能的影响,为优化合金的Nb含量和均质化处理制度奠定理论基础。

1 实验方法

实验采用Nb含量分别为0.01%、0.30%和0.90%的奥氏体不锈钢,其他主要化学成分为:C 0.10%,Si 2.50%,Ni 9.00%,Cr 15.00%,Mn 0.60%,Fe余量,分别标记为0Nb、3Nb和9Nb钢。奥氏体不锈钢采用25 kg真空感应炉熔炼并浇注成直径为150 mm的铸锭。从9Nb铸锭切取样品进行均质化处理,即在1250 ℃下保温5 h,然后水淬。拉伸实验在RDL-50试验机上进行,拉伸试样的平行段直径5 mm、长30 mm。拉伸实验的温度范围为室温(20 ℃)~550 ℃,应变速率为2.78 × 10-4 s-1。采用Ferrite Determ SP10a铁素体仪测量拉伸断裂样品的铁素体数(ferrite number,FN),FN值可以通过下式转换为形变诱发α'马氏体的体积分数(

用于显微组织观察的样品依次经过水砂纸机械研磨、金刚石抛光膏抛光,再采用体积分数为10%的草酸水溶液进行电化学腐刻,电压为5 V,腐蚀时间30 s,随后利用GX51型光学显微(OM)和SEM3100扫描电镜(SEM)及其附带的能谱仪(EDS)进行观察和分析。透射电镜(TEM)样品采用体积分数为10%的高氯酸酒精溶液电解双喷减薄制得,温度约为-30 ℃,恒电压为20 V,随后利用Talos F200 TEM及其附带的高角环形暗场(HAADF)探测器和EDS探头进行观察和分析。此外,初生NbC在室温拉伸变形过程中容易发生碎裂,因此采用10%应变下的拉伸变形组织进行TEM观察。

2 实验结果

2.1 不同Nb含量奥氏体不锈钢的微观组织和拉伸性能

2.1.1 铸态组织

图1

图1

不同Nb含量奥氏体不锈钢铸态组织的OM像和SEM像

Fig.1

OM (a-c) and SEM (d-f) images of 0Nb (a, d), 3Nb (b, e), and 9Nb (c, f) steel samples

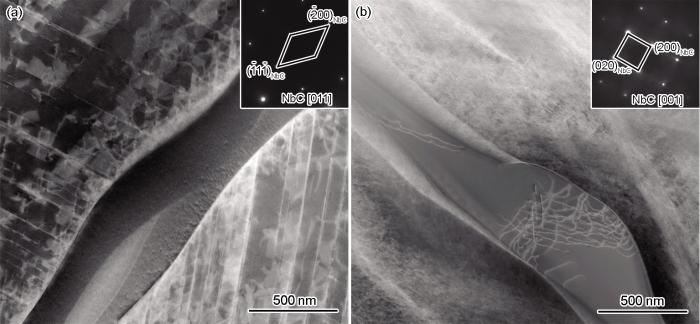

图2

图2

0Nb和9Nb奥氏体不锈钢铸态组织的TEM像、EDS面扫描图和选区电子衍射(SAED)花样

Fig.2

Bright field (BF) TEM images of 0Nb (a) and 9Nb (d) steel samples, the corresponding EDS Cr (b) and Nb (e) mappings, and selected area electron diffraction (SAED) patterns of M23C6 carbide and austenite matrix (c) and NbC (f)

2.1.2 拉伸性能

图3给出了不同Nb含量奥氏体不锈钢强度和延伸率随温度的变化曲线。可见,不同Nb含量合金拉伸性能随温度的变化呈现出相似的规律。室温~300 ℃范围内,屈服强度随温度升高而降低;300~550 ℃范围内,屈服强度随温度升高基本保持不变(图3a)。抗拉强度随温度的变化规律表现为:室温~100 ℃范围内,随温度升高而迅速降低;100~300 ℃范围内,随温度升高而缓慢降低;300~550 ℃范围内,随温度升高基本保持不变(图3b)。与强度不同,延伸率随温度升高呈现出先增加后下降的规律:室温~100 ℃范围内,随温度的升高而增加;100~300 ℃范围内,随温度升高而下降;300~550 ℃范围内,随温度升高基本保持不变(图3c)。

图3

图3

不同Nb含量和均质化处理态奥氏体不锈钢的拉伸性能随温度的变化曲线

Fig.3

Variations in yield strength (a), tensile strength (b), and elongation (c) as a function of tensile temperature of 0Nb, 3Nb, 9Nb, and homog-enized 9Nb steel samples

由图3a可见,室温~550 ℃范围内,合金的屈服强度随Nb含量的提高而不断提高,分别以室温、100 ℃和550 ℃下的屈服强度为例进行阐述。室温下的屈服强度由0Nb钢的约225 MPa 提高至3Nb钢的约241 MPa,并进一步提高至9Nb钢的约269 MPa;100 ℃下的屈服强度由0Nb钢的约172 MPa增加至3Nb钢的约191 MPa,并进一步增加至9Nb钢的约224 MPa; 550 ℃下的屈服强度由0Nb钢的约112 MPa提高至3Nb钢的约126 MPa,并进一步提高至9Nb钢的约159 MPa。由此可见,Nb含量提高至0.30%时,合金的屈服强度略有增加;Nb含量提高至0.90%时,屈服强度的增加幅度更大。

与屈服强度不同,Nb含量对抗拉强度的影响较小(图3b),分别以室温、100 ℃和550 ℃下的抗拉强度为例进行阐述。室温下,0Nb钢的抗拉强度约为822 MPa,3Nb钢的抗拉强度约为821 MPa,9Nb钢的抗拉强度略有增加至约855 MPa。当温度升到100 ℃时,0Nb钢的抗拉强度约为499 MPa,3Nb钢的抗拉强度约为505 MPa,9Nb钢的抗拉强度增加至约534 MPa。拉伸温度进一步升高到550 ℃时,0Nb、3Nb和9Nb钢的抗拉强度分别约为380、389和387 MPa,基本相当。因此,室温~100 ℃范围内,Nb含量提高至0.30%时,合金的抗拉强度基本不变;Nb含量提高至0.90%时,抗拉强度略有增加。但在更高温度下,不同Nb含量合金的抗拉强度基本不变。

由图3c可见,室温~550 ℃范围内,合金的延伸率随Nb含量的提高而发生显著变化,室温、100 ℃和550 ℃下延伸率随Nb含量的变化规律如下:室温下,0Nb钢的延伸率约为44.0%,3Nb钢的延伸率保持不变,但9Nb钢的延伸率大幅度降低至约24.0%。当温度升到100 ℃时,与延伸率约为68.5%的0Nb钢相比,3Nb钢的延伸率略有下降至约58.2%,9Nb钢的延伸率进一步降低至约48.7%。拉伸温度进一步升高到550 ℃时,0Nb钢的延伸率约为40.9%,3Nb钢的延伸率基本不变(约为39.6%),但9Nb钢的延伸率降低至约29.7%。可见,Nb含量提高至0.30%时,合金的延伸率变化较小;而Nb含量提高至0.90%时,合金延伸率显著降低。

2.1.3 断口特征

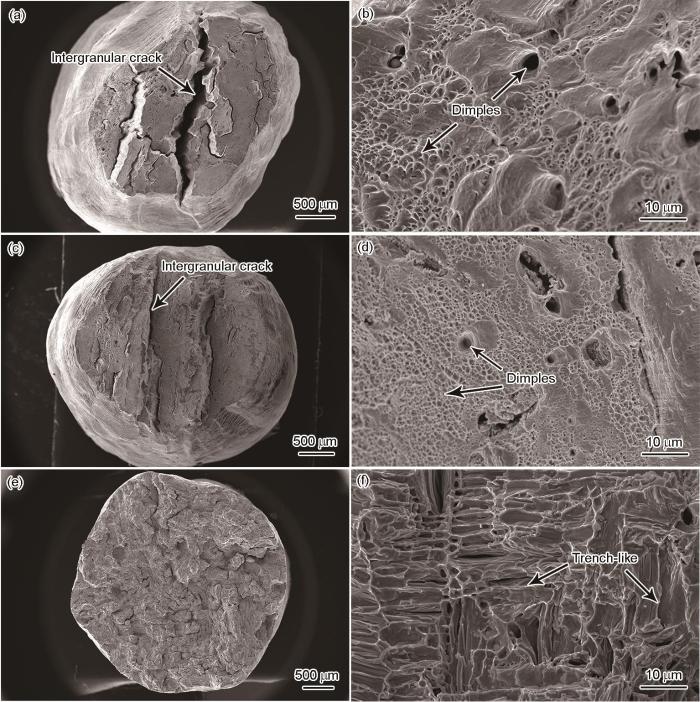

图4为不同Nb含量奥氏体不锈钢室温拉伸断口形貌的SEM像。可见,0Nb钢的拉伸断口表面可观察到许多平行分布的二次裂纹,部分二次裂纹贯穿整个截面(图4a);3Nb钢拉伸断口表面也存在平行分布的二次裂纹,但数量少于0Nb钢(图4c);9Nb钢拉伸断口表面仅观察到零星分布的细小二次裂纹(图4e)。高倍SEM像显示,0Nb钢拉伸断口呈现韧窝形貌,韧窝尺寸不均,大尺寸韧窝的深度较浅(图4b);3Nb钢的断口仍为韧窝形貌,韧窝更加均匀细小(图4d);9Nb钢的断口呈现沟壑状(trench-like)形貌(图4f)。SEM-EDS面扫描分析可见,沟壑状断口表面上可观察到Nb的明显富集,说明沟壑状断裂特征与NbC有关(图4f中插图)。

图4

图4

不同Nb含量奥氏体不锈钢室温拉伸断口形貌的SEM像

Fig.4

Low (a, c, e) and high (b, d, f) magnified SEM images of fracture surfaces of 0Nb (a, b), 3Nb (c, d), and 9Nb (e, f) steel samples after tensile test at room temperature (Inset in Fig.4f shows the EDS area scan mapping of rectangular zone)

图5

图5

不同Nb含量奥氏体不锈钢100 ℃拉伸断口形貌的SEM像

Fig.5

Low (a, c, e) and high (b, d, f) magnified SEM images of fracture surfaces of 0Nb (a, b), 3Nb (c, d), and 9Nb (e, f) steel samples after tensile test at 100 oC

图6

图6

不同Nb含量奥氏体不锈钢550 ℃拉伸断口形貌的SEM像

Fig.6

Low (a, c, e) and high (b, d, f) magnified SEM images of fracture surfaces of 0Nb (a, b), 3Nb (c, d), and 9Nb (e, f) steel samples after tensile test at 550 oC

图7

图7

0Nb奥氏体不锈钢在不同温度下拉伸断口纵剖面的SEM像

Fig.7

SEM images of the longitudinal section near fracture surface in 9Nb steel sample after tensile test at room temperature (a), 100 oC (b), and 550 oC (c)

图8

图8

9Nb奥氏体不锈钢在室温和550 ℃下拉伸断口纵剖面的SEM像

Fig.8

Low (a, c) and locally high (b, d) magnified SEM images of the longitudinal section near fracture surface in 9Nb steel sample after tensile test at room temperature (a, b) and 550 oC (c, d)

2.1.4 变形行为

图9

图9

9Nb奥氏体不锈钢经不同温度拉伸断裂后的TEM像和SAED花样

Fig.9

TEM images of the fractured 9Nb steel sample after tensile test at room temperature (a, b), 100 oC (c), and 550 oC (d) (Insets in Figs.9b and c show the corresponding SAED patterns)

2.2 均质化处理后的微观组织和拉伸性能

2.2.1 微观组织

图10

图10

9Nb奥氏体不锈钢经均质化处理后微观组织的OM像和SEM像

Fig.10

OM (a) and SEM (b) images of 9Nb steel sample after homogenization treatment at 1250 oC for 5 h

2.2.2 拉伸性能

图3还给出了9Nb钢经均质化处理后的拉伸性能随温度的变化曲线。可见,均质化处理未改变强度和延伸率随温度的变化规律,但在不同程度上提高了延伸率。同样以室温、100 ℃和550 ℃下的拉伸性能为例进行阐述,相较于铸态样品,均质化处理态9Nb钢样品室温下的屈服强度基本不变,但抗拉强度由约855 MPa升高到约933 MPa,延伸率由约24.0%大幅度提高到约46.8%。100和550 ℃下,均质化处理态样品的屈服强度略有降低,但抗拉强度基本不变,延伸率大幅度提高。由此说明,均质化处理在保证奥氏体不锈钢强度的基础上,显著提高了延伸率。

2.2.3 断口特征

图11

图11

均质化处理后9Nb奥氏体不锈钢在室温和550 ℃下拉伸断口纵剖面的SEM像

Fig.11

Low (a, c) and locally high (b, d) magnified SEM images of the longitudinal section near fracture surface in homogenized 9Nb steel sample after tensile test at room temperature (a, b) and 550 oC (c, d)

3 分析讨论

3.1 不同温度下的变形机制

式中,[M]为元素M的质量分数。计算可知,0Nb钢在室温下的γSFE为14.66 mJ/m2。fcc金属变形过程中,一个全位错分解为2个Shockley不全位错和夹带的层错区,层错能决定着层错宽度,并具有反比关系。本工作实验用钢具有较低的层错能,较大的层错宽度使得不全位错的束集难以发生,位错交滑移困难,从而发生了平面滑移,形成了平面滑移型位错组态(图9a)。基于Olson-Cohen马氏体形核模型[23],滑移带交叉引起的应变集中可降低奥氏体向马氏体转变的化学驱动力,有利于α'马氏体的形核(图9b)。奥氏体钢变形方式与层错能的经验关系亦表明,当γSFE ≤ 20 mJ/m2时,可发生形变诱发马氏体相变[21]。随着应变的增加,交叉滑移带数量增加,马氏体可在更多的滑移带交叉位置处形核。0Nb钢室温拉伸断裂样品中马氏体含量统计结果证实,马氏体含量可达约30% (图12)。

图12

图12

不同Nb含量和均质化处理态奥氏体不锈钢经不同温度拉伸断裂后形变诱发马氏体的体积分数

Fig.12

Volume fractions of deformation-induced martensite after tensile fracture at different temperature in 0Nb, 3Nb, 9Nb, and homogenized 9Nb steel samples

随着拉伸温度的升高,γSFE会随之增加,温度与γSFE的经验关系表明,温度每升高10 ℃对应于γSFE增加1 mJ/m2 [24]。γSFE的增加使得扩展位错的层错宽度减小,位错平滑滑移倾向降低,马氏体形核位置变少,造成形变诱发马氏体含量随拉伸温度的升高而不断降低,温度超过75 ℃时,0Nb钢中便不会发生形变诱发马氏体相变(图12)。温度提高至100 ℃时,计算获得的γSFE约为22.16 mJ/m2,变形方式与层错能的经验关系表明[21],当层错能> 20 mJ/m2时,变形方式主要为形变孪晶,因而出现了变形方式由形变诱发马氏体相变向形变孪晶的转变(图9c)。随着温度的进一步提高,0Nb钢在550 ℃下的层错能约为67.16 mJ/m2,全位错分解成2个不全位错的难度显著增加,促进交滑移的发生,因而出现了散乱分布的位错组态(图9d)。与此同时,高温下原子扩散明显加快,还可发生垂直于滑移面的攀移,位错攀移可促使2个相反方向运动的位错相互湮灭,这可能是位错密度显著降低的主要原因。

3.2 Nb含量对微观组织和力学性能的影响

从Nb含量对奥氏体不锈钢铸态组织的影响结果可见,Nb含量的变化一方面会影响NbC的形成,另一方面会改变M23C6的析出行为。未添加Nb的0Nb钢晶界上析出了连续分布的M23C6碳化物(图1d),Thermo-Calc热力学计算结果表明M23C6碳化物的析出温度≤ 1050 ℃[25],因此可推断晶界M23C6碳化物是在凝固后的冷却过程中析出的。Nb作为一种强碳化物元素,其与C的亲和力比Cr强,Nb会优先与C结合形成NbC。Nb含量为0.30%的3Nb钢中形成了初生NbC +奥氏体的共晶组织(图1e)。Thermo-Calc热力学计算结果表明初生NbC的开始形成温度约为1360 ℃[18],略高于液相线温度。在凝固过程中,首先结晶出γ奥氏体,Nb为正偏析元素,易于在枝晶间偏聚[26],该处液相中Nb含量的增加满足了共晶反应的成分条件,因而在凝固末期发生了L→NbC + γ的共晶反应。3Nb钢的Nb/C原子比为0.38,无法完全固定C原子,在凝固后的冷却过程中,晶界仍析出了M23C6碳化物(图1b和e)。Nb含量提高至0.90%时,Nb/C原子比为1.16,基本上能固定C原子,因此抑制了M23C6的析出。Nb含量的提高有利于达到L→NbC + γ共晶反应的成分条件,使共晶组织的数量显著增加。与此同时,Nb在先共晶奥氏体中呈过饱和状态,在凝固后的冷却过程中,二次NbC在奥氏体固溶体中脱溶析出(图1f)。

室温~550 ℃范围内的拉伸性能结果显示,添加Nb提高了合金的屈服强度。通常来说,奥氏体不锈钢的屈服强度(

式中,σ0为纯Fe的晶格阻力,在一定温度下为定值[28];σs、σg、σp和σd分别为固溶强化、晶界强化、沉淀强化和位错强化对屈服强度的贡献。与0Nb钢相比,3Nb钢中M23C6的析出倾向降低,降低了碳化物析出消耗的Cr含量,奥氏体中较高的Cr含量提高了固溶强化效果,因此屈服强度略有增加。9Nb钢中M23C6的析出被完全抑制,奥氏体中更高的Cr含量提高了固溶强化效果,与此同时,Nb元素的固溶强化、晶粒细化带来的晶界强化以及二次NbC析出产生的沉淀强化,使得屈服强度显著增加。随着拉伸温度的提高,晶格阻力、固溶强化作用以及晶界强化作用减弱,造成了屈服强度随温度升高而下降。然而,添加Nb带来的强化作用未发生明显变化,因此Nb含量对屈服强度的影响规律未改变。

室温~100 ℃范围内的拉伸过程中,当应力超过屈服强度后,合金中会发生形变诱发马氏体相变,可显著提升应变硬化能力,从而提高抗拉强度。添加Nb一方面通过形成NbC以固定C元素,另一方面抑制M23C6析出而提高了基体的Cr含量,由

然而,Nb含量的提高会显著改变断裂行为,降低延伸率。室温变形过程中,位错运动方式主要为平面滑移,位错运动至晶界处,会被晶界阻碍,造成应力集中。由于0Nb和3Nb钢晶界处存在连续分布的M23C6碳化物,削弱了晶界的变形能力,不足以协调相邻晶粒的变形,因而产生了沿晶开裂(图4a和c)。9Nb钢中晶界M23C6的析出被抑制,在塑性变形过程中,相邻晶粒可相互协调变形,避免了沿晶开裂(图4e)。然而,9Nb钢中大尺寸的初生NbC与奥氏体之间的变形协调性较差。图13a为9Nb奥氏体不锈钢在10%应变下室温拉伸变形后的HAADF像和SAED花样。可见,初生NbC未发生变形,NbC/奥氏体界面处塞积了大量位错。随着界面处应力集中程度的增加,易诱发微裂纹的萌生,并沿着网状分布的NbC快速扩展,造成了沟壑状的脆性断裂形貌(图4f),使得9Nb钢具有较低的延伸率。拉伸温度升高至100 ℃后,变形过程中发生了形变孪晶,由于孪晶诱发塑性(TWIP)效应使奥氏体的应变硬化能力得到改善,从而提高了延伸率。但是,0Nb和3Nb钢仍呈现因晶界碳化物引起的沿晶开裂形貌,9Nb钢呈现沿网状分布NbC扩展的沟壑状断裂形貌(图5f)。随拉伸温度进一步升高到550 ℃,位错由于发生了交滑移而易发生湮灭,导致晶界处的位错塞积减弱,0Nb和3Nb钢中不会发生沿晶开裂(图6a和c),9Nb钢未出现沿网状分布NbC扩展的沟壑状断裂形貌,转变为韧窝断裂(图6f)。从9Nb奥氏体不锈钢经550 ℃拉伸断裂后初生NbC附近的微观组织(图13b)可见,初生NbC中仅存在少量的位错,证明其塑性变形能力差。550 ℃拉伸变形过程中,初生NbC与奥氏体之间的变形不协调仍导致了部分初生NbC开裂的现象(图8d),造成延伸率的降低。

图13

图13

9Nb奥氏体不锈钢分别经10%应变的室温拉伸变形和550 ℃拉伸断裂后的高角环形暗场(HAADF)像和SAED花样

Fig.13

High-angle annular dark field (HAADF) images of 9Nb steel sample deformed to a true strain of 10% at room temperature (a) and fracture at 550 oC (b) (Insets show the corresponding SAED patterns of NbC)

3.3 均质化处理对微观组织和力学性能的影响

在均质化处理过程中,Nb、C在NbC和周围奥氏体的化学势差异为NbC的回溶提供了驱动力,即NbC的回溶行为与奥氏体中Nb和C的溶解度有关。Nb—C化学键断裂解体为游离的Nb和C原子是NbC发生回溶的前提,因此选择NbC在奥氏体中的平衡固溶度积([Nb]·[C])来确定NbC的回溶温度,如下式所示[29]:

均质化处理虽然会促进初生NbC的回溶从而提高Nb元素的固溶强化效果,但是会造成晶粒粗化和二次NbC的回溶,降低了晶界强化和沉淀强化效果,使得屈服强度略有降低。结合前文讨论,初生NbC与奥氏体之间变形不协调引起的开裂是9Nb钢塑性降低的主要原因。初生NbC与奥氏体界面处微裂纹形成所需的临界应力(σf)与NbC的形貌和尺寸有关[32]:

式中,E为Young's模量,γf为奥氏体与初生NbC的有效界面能,C0为初生NbC的尺寸,ν为Poisson比。可见,均质化处理使得初生NbC尺寸减小,提高了临界应力。与铸态样品的骨架状初生NbC相比,均质化处理态样品中球状初生NbC与奥氏体间的有效界面能更高[33],其临界应力更高。对比可见,在塑性变形过程中,均质化处理态样品中初生NbC与奥氏体界面处微裂纹形成需要更大的应力,即微裂纹的萌生更困难。此外,均质化处理将连续网状分布的初生NbC改变为断续分布,有效阻止了微裂纹沿初生NbC的扩展,从而显著提高了延伸率。

4 结论

(1) 0Nb钢晶界析出连续分布的M23C6碳化物;3Nb钢形成了初生NbC +奥氏体的共晶组织,但晶界仍析出M23C6;当Nb含量进一步增加到0.90%时,可完全抑制M23C6的析出,但初生NbC +奥氏体的共晶组织数量显著增加。

(2) 随着Nb含量增加到0.90%,M23C6析出被抑制,使Cr元素固溶强化、Nb元素固溶强化、晶粒细化带来的细晶强化以及二次NbC的沉淀强化作用提高,从而提高了屈服强度。虽然9Nb钢抑制了晶界M23C6引起的沿晶开裂,但是初生NbC与奥氏体间较差的变形协调性易诱发微裂纹的萌生,裂纹沿网状分布的NbC快速扩展而造成了沟壑状的脆性断裂,显著降低了延伸率。

(3) 1250 ℃均质化处理可在不引入δ-铁素体的基础上,实现9Nb钢中初生NbC分布、形貌和尺寸的调控,初生NbC由骨架状转变为球状或椭球状,由网状分布转变为断续分布。

(4) 均质化处理后,9Nb钢中初生NbC与奥氏体界面处微裂纹形成所需的临界应力提高,抑制了微裂纹的萌生,同时断续分布的初生NbC阻止了微裂纹沿初生NbC的扩展,大幅度提升了延伸率。

参考文献

Temperature dependence of fracture behavior and mechanical properties of AISI 316 austenitic stainless steel

[J].

Research advance on liquid lead-bismuth eutectic corrosion resistant Si enhanced ferritic/martensitic and austenitic stainless steels

[J].Structural materials are one of the major factors that restrict the lead-cooled fast reactor construction due to metallic elements that can dissolve in the liquid lead-bismuth eutectic (LBE), which may affect the structure's safety. T91 steel and 316 stainless steel are the leading structural materials for critical equipment such as fuel cladding, reactor vessels, and reactor core internals. The environmental compatibility of those steels with the liquid LBE needs to be systematically evaluated. However, T91 steel and 316 stainless steel suffer from rapid oxidation corrosion in oxygen-saturated LBE at 550oC. T91 steel's corrosion resistance in liquid LBE can be improved by decreasing the oxygen concentration (1.26 × 10-6%, mass fraction), but dissolved corrosion occurred at dissolved oxygen concentration below 1 × 10-6% for T91 steel and 316 stainless steel. T91 steel is sensitive to liquid metal embrittlement, significantly reducing its corrosion fatigue life in the liquid LBE. Compared to the standard (9%-12%)Cr ferritic/martensitic steel and 316 stainless steel, the microalloyed Si enhanced (9%-12%)Cr ferritic/martensitic steel (9Cr-Si and 12Cr-Si) and 316 stainless steel (ASS-Si) have good microstructural stability and comprehensive mechanical properties. The Si-rich oxide formation in liquid LBE improves the oxide film compactness and corrosion resistance. The dissolution corrosion was inhibited in static oxygen-saturation and oxygen-controlled (10-6%-10-7%) flowing liquid LBE (0.3 m/s) at 550oC for 9Cr-Si, 12Cr-Si, and ASS-Si. These alloys are expected to meet the design requirements for a lead-cooled fast reactor.

耐Pb-Bi腐蚀Si增强型铁素体/马氏体钢和奥氏体不锈钢的研究进展

[J].结构材料是制约铅冷快堆建设的关键因素之一,原因是其组成元素在液态Pb-Bi共晶(LBE)中会发生不同程度的溶解,影响结构安全。候选结构材料铁素体/马氏体钢T91与不锈钢316在550℃饱和氧LBE环境中发生快速氧化腐蚀;溶解氧浓度降至1.26 × 10<sup>-6</sup>% (质量分数)可减轻T91的液态LBE腐蚀,但低于1 × 10<sup>-6</sup>%时,T91与316钢发生溶解腐蚀;T91液态LBE脆化敏感性高,导致其在350℃液态LBE中腐蚀疲劳寿命显著降低。与商用的(9%~12%)Cr铁素体/马氏体钢和316型奥氏体不锈钢相比,经微合金化的Si增强型铁素体/马氏体钢(9Cr-Si和12Cr-Si)和奥氏体不锈钢(ASS-Si),具有较好的组织稳定性和综合力学性能,且在液态LBE中形成的富Si氧化物提高了氧化膜的致密性,改善了其耐腐蚀性能,在550℃下静态饱和氧和动态控氧LBE环境中的溶解腐蚀受到抑制,有望满足铅冷快堆的设计需求。

Tailoring microstructure of austenitic stainless steel with improved performance for generation-IV fast reactor application: A review

[J].

First-principles evaluation of the effect of alloying elements on the lattice parameter of a 23Cr25NiWCuCo austenitic stainless steel to model solid solution hardening contribution to the creep strength

[J].

The effect of the carbon and nitrogen contents on the fracture toughness of Type 347 austenitic stainless steels

[J].

Determination of susceptibility to intergranular corrosion and electrochemical reactivation behaviour of AISI 316L type stainless steel

[J].

Precipitation in AISI 316L (N) during creep tests at 550 and 600 oC up to 10 years

[J].

Evolution of secondary phases in austenitic stainless steels during long-term exposures at 600, 650 and 800 oC

[J].

Precipitation strengthening of Nb-stabilized TP347 austenitic steel by a dispersion of secondary Nb(C, N) formed upon a short-term hardening heat treatment

[J].

The evolution of primary and secondary niobium carbonitrides in AISI 347 stainless steel during manufacturing and long-term ageing

[J].

Microstructural evolution of NF709 (20Cr-25Ni-1.5MoNbTiN) under neutron irradiation

[J].

In-situ high-energy X-ray characterization of neutron irradiated HT-UPS stainless steel under tensile deformation

[J].

In situ monitoring of isothermal phase transformation in two Nb stabilized austenitic stainless steels (316Nb) by neutron diffraction

[J].

Investigation on elastic and thermodynamic properties of Fe25Cr20NiMnNb austenitic stainless steel at high temperatures from first principles

[J].

Creep behavior at 1273 K (1000 oC) in Nb-bearing austenitic heat-resistant cast steels developed for exhaust component applications

[J].

Correlation of chemistry, microstructure and ductile fracture behaviours of niobium-stabilized austenitic stainless steel at elevated temperature

[J].

The influence of niobium on the plastic deformation behaviors of 310s austenitic stainless steel weld metals at different temperatures

[J].

Corrosion behavior of NbC and its effect on corrosion layer formation in liquid lead-bismuth eutectic of Nb-containing austenitic stainless steel

[J].The lead-cooled fast reactor is considered one of the promising Generation IV nuclear energy systems. Structural materials used in the construction of pressure vessels and internals for this reactor include 300 series austenitic stainless steels. Nb-containing austenitic stainless steels are developed to improve corrosion properties, mechanical properties, and irradiation resistance. However, coarse primary NbC carbides are formed during solidification in these steels and cannot be eliminated through subsequent hot working and heat treatment. Recently, researchers have found different oxidation behaviors between secondary phase particles and the matrix, which affect the material's corrosion properties. However, the oxidation behaviors of primary NbC are rarely reported. This study analyzes the corrosion behaviors of a solution-treated Nb-containing austenitic stainless steel plate after exposure to oxygen-saturated liquid lead-bismuth eutectic (LBE) at 550 and 600 oC using SEM, EPMA, XRD, and TEM. The results show that the oxidation probability of NbC is correlated with its location in the samples at 550 oC. NbC at the initial surface is easily oxidized, while NbC within the interior is difficult to oxidize due to the low equilibrium oxygen partial pressure in the inner oxide layer, which suppresses the oxidation of NbC. However, NbC at the initial surface and within the interior are prone to be oxidized as the temperature increases to 600 oC. Compared to the matrix, NbC oxidizes into Nb2O5, resulting in a higher Pilling-Bedworth ratio (PBR). This leads to high compressive stress and resultant microcrack formation in the surrounding oxide layer. Additionally, the presence of CO2 generated during the oxidation of NbC within the interior reduces the compactness of the oxide layer, leading to a higher growth rate.

含铌奥氏体不锈钢中NbC的液态Pb-Bi共晶腐蚀行为及其对氧化层形成的影响

[J].

Homogenization temperature dependent microstructural evolution and mechanical properties in a Nb-stabilized cast austenitic stainless steel

[J].

Comparison of different methods for measuring strain induced α-martensite content in austenitic steels

[J].

Deformation-induced martensite in austenitic stainless steels: A review

[J].

Composition-dependence of stacking fault energy in austenitic stainless steels through linear regression with random intercepts

[J].

Kinetics of strain-induced martensitic nucleation

[J].

Dynamic strain aging induced by synergistic effects of deformation-induced martensite and deformation twins in Fe-Cr-Ni metastable austenitic stainless steel

[J].

Effect of Nb content on microstructure, welding defects and mechanical properties of NiCrFe-7 weld metal

[J].Ni-based filler metal is one of the most important filler metals in building the key components of nuclear power plants, however, ductility-dip-cracking (DDC) and inclusion defects form easily in the weldment and need to be repaired afterward. The precipitation of M23C6 (M=Cr, Fe) at grain boundaries will promote the nucleation and propagation of DDC. Adding Ti can form Ti(C, N) and reduce M23C6 precipitate at grain boundaries, which reduces DDC in the weld metal. However, the increase of Ti content in filler metal will cause the inclusion defects. Nb replacing part of Ti in Ni-based filler metal is proposed in this work. The reduction of Ti in filler metal is to reduce the sensitivity of inclusion defects in the weld metal. Nb can form MX (M=Nb, Ti, X=C, N) precipitates to reduce the M23C6 and DDC in weld metal. The effect of Nb on the size, number, and location of MX and M23C6 in Ni-based weldment has been investigated systematically in this work. Phase diagram calculations show that Nb is an element forming high temperature MX precipitate, and its affinity with oxygen is poor and not easy to form oxide. According to the phase diagram calculations, five different filler metals are designed and made with 0, 0.4%, 0.7%, 0.85%, 1.1%Nb content. The results show that the intragranular precipitates are distributed along sub grain boundaries. The intragranular precipitate for the Nb-free weld metal is Ti(C, N), whereas the intragranular precipitate in the Nb-bearing weld metals is MX. For the increased Nb in weld metals, more MX is produced, and more C is fixed within the grain. As the Nb content increased in weld metals, the initial precipitation temperature of M23C6 decreases, the intergranular M23C6 precipitate decreases and M23C6 turns discreted at grain boundaries. As Nb content increases in weld metals, the total crack length of DDC decreases. When the Nb content is over 0.85%, little DDC is found in the weld metals. The addition of Nb can improve the tensile strength, plasticity and bending property of the weld metals。

Nb含量对NiCrFe-7焊缝金属组织、缺陷和力学性能的影响

[J].采用相图计算、焊材设计、焊材制备、现场焊接和焊缝金属解剖的方法, 研究Nb含量对NiCrFe-7焊缝金属组织、缺陷和力学性能的影响. 结果表明, 随焊缝金属中Nb含量增加, 焊缝金属晶内MX (M=Nb, Ti, X=C, N)析出相增加, 晶界M<sub>23</sub>C<sub>6</sub>(M=Cr, Fe)的初始析出温度降低, 晶界M<sub>23</sub>C<sub>6</sub>析出相减少, 且M<sub>23</sub>C<sub>6</sub>由多列连续分布转变为单列离散分布; 焊缝金属中的高温失延裂纹(ductility-dip-cracking, DDC)的数量和尺寸减少; 焊缝金属的强度、塑性和弯曲性能显著提高。

Microstructure and segregation behaviour of directionally solidified tungsten bearing 25Cr-35Ni-Nb heat-resistant stainless steels

[J].

Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures

[J].

Solubility of niobium carbide in austenite

[J].

δ-ferrite formation and its effect on the mechanical properties of heavy-section AISI 316 stainless steel casting

[J].

Role of δ-ferrite in fatigue crack growth of AISI 316 austenitic stainless steel

[J].

Isothermal aging embrittlement in an Fe-22Cr-25Ni alloy

[J].

Effect of precipitated phases on the mechanical properties and fracture mechanisms of Inconel 718 alloy

[J].