目前汽车领域面临的主要挑战包括提高燃油效率、减少温室气体排放和提高汽车碰撞安全性。汽车若能大量使用低密度高强钢实现轻量化,可有效解决上述问题[1]。现有关于低密度钢的研究,一般是通过Al合金化来降低汽车钢的密度。钢中每添加1%Al (质量分数),质量密度可下降1.3%[2],但钢中Al含量的增加会导致强度或塑性的损失[3]。Huang等[4]研究发现,Fe-28Mn-(10, 12)Al-1C (质量分数,%,下同)钢中Al含量由10%增加到12%,钢中的铁素体分数由1.87%增加到9.14%,导致其断后延伸率由45.1%降至13.4%。Sutou等[5]研究发现,Fe-20Mn-(11, 12)Al-1.8C-5Cr钢中Al含量由11%增加到12%时,钢中高温δ铁素体的形成使得其抗拉强度和断后延伸率分别由1192 MPa和29%降至1148 MPa和1.6%。Chen等[6]发现Fe-30Mn-10Al-2C钢经固溶+时效处理后,κ-碳化物在奥氏体晶界析出并长大为片层状,导致其断后延伸率降至3%以下。为了提升低密度钢的强度和塑性,Kim等[7]采用Al + Ni复合添加的手段开发出Fe-16Mn-10Al-0.86C-4.9Ni钢,其比抗拉强度(抗拉强度/密度,SUTS)和断后延伸率达到227 MPa·cm3/g和20.3%;高的比抗拉强度归因于金属间化合物B2类型NiAl相的析出;但是大量Ni的添加大幅提高了合金的密度和成本。

降低密度或提高强度可提升低密度钢的比强度,但会导致塑性大幅降低,如何通过经济的手段同时提升比强度和塑性是低密度钢研究的难点。本工作拟通过提高Fe-Mn-Al-C钢中Al、C元素的含量并调控Al / C元素配比,在降低材料密度的同时得到单相奥氏体基体组织;采用Cr合金化抑制κ-碳化物在晶界的析出,以期保证材料塑性并提高材料比强度。

1 实验方法

1.1 材料制备

实验用新型高强奥氏体低密度钢的化学成分为Fe-30.1Mn-11.0Al-1.34C-4.61Cr。真空感应炉熔炼后获得约30 kg铸锭,在1200 ℃均匀化4 h后锻造成尺寸为120 mm (长) × 80 mm (宽) × 40 mm (厚)的板坯,终锻温度950 ℃。锻坯在1200 ℃均匀化处理2 h,经6道次热轧至6 mm,终轧温度为950 ℃,总热轧压下量为85%。热轧板在1050 ℃固溶处理0.5 h后空冷至室温,进行酸洗和冷轧。冷轧压下量分别设定为35%和75%,所得冷轧板分别记为35CR和75CR。上述冷轧钢在450 ℃时效1.5 h后空冷至室温,分别记为35CR-T和75CR-T。另外,将75CR冷轧钢在925 ℃退火10 s后水冷至室温,然后在450 ℃时效1.5 h,空冷至室温,获得样品记为75CR-AT。所制备钢的密度通过排水法测得为6.50 g/cm³。

1.2 力学性能检测和显微组织表征

在钢板上沿轧向切取25 mm标距的拉伸试样,机械磨光后在WDW-200D型万能试验机上以1 × 10-3 s-1的应变速率进行室温单向拉伸测试。采用D8 Discover A25X射线衍射仪(XRD)、PHI 710电子背散射衍射仪(EBSD)、JEM-2200FS透射电子显微镜+能谱仪(TEM + EDS)、Titan ETEM Themis环境气氛球差校正电子显微镜(ETEM)等进行样品表征。XRD和EBSD样品经机械磨抛后在20% (体积分数)高氯酸酒精溶液中电解抛光;TEM样品经机械减薄至50 μm后,冲压成直径3 mm的圆片,之后在-20 ℃下5% (体积分数)高氯酸酒精溶液中进行电解双喷。

2 实验结果

2.1 拉伸力学性能

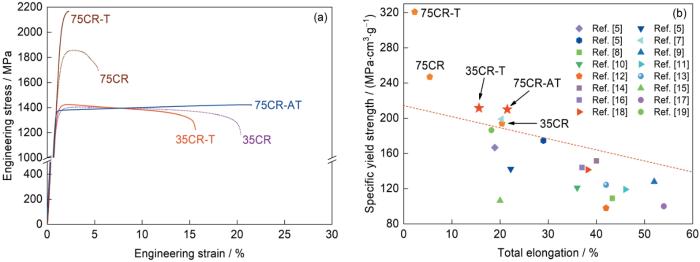

低密度钢板在冷轧和热处理后的工程应力-应变曲线如图1a所示。表1总结了该钢在各种加工条件下的屈服强度(YS)、比屈服强度(SYS)、抗拉强度(UTS)、SUTS和总延伸率(TE)。对比可以看出,随冷轧压下量由35%增加至75%,冷轧样品的屈服强度和抗拉强度显著增加,但塑性从20.4%大幅降低至5.4%,呈现显著脆性,这是因为冷轧引入大量位错等缺陷使得强度显著增加,且压下量越大强化越显著,但塑性恶化严重。35CR和75CR样品在450 ℃时效后,屈服强度和抗拉强度增加,总延伸率显著降低。尤其是75CR-T样品,虽然比屈服强度高达320.8 MPa·cm3/g,但塑性只有2.3%;相比之下,35CR-T比屈服强度降低至211.5 MPa·cm3/g但塑性大幅改善至15.6%。冷轧退火后的时效样品75CR-AT与35CR-T比强度相当但塑性更高,塑性改善至21.5%。图1b对比了实验用钢与文献[5,7~19]报道的其他Fe-Mn-Al-C低密度钢的比屈服强度和总延伸率。可以看出,本工作开发的新型高强奥氏体低密度钢在未添加Ni等昂贵合金元素的条件下,可以获得193.9~320.8 MPa·cm3/g范围的比屈服强度和2.3%~21.5%范围的塑性,尤其是75CR-AT样品,其比屈服强度和塑性达到了210.0 MPa·cm3/g和21.5%,综合力学性能超过了目前几乎已知的低密度钢,说明本工作设计的实验用钢有较大应用潜力。

图1

图1

不同工艺处理后钢的拉伸力学性能及与文献[5,7~19]结果的对比

Fig.1

Tensile properties of experimental steel subjected to the different processing routes and comparision with literature data[5,7-19]

(a) engineering stress-strain curves

(b) comparison on tensile properties of the steel and other alloy[5,7-19], including Cr-alloyed[5,9], Ni-alloyed[7], and Si-alloyed[13] Fe-Mn-Al-C low-density steels

表1 实验用钢经不同工艺处理后的拉伸力学性能

Table 1

| Specimen | Processing route | YS MPa | SYS MPa·cm3·g-1 | UTS MPa | SUTS MPa·cm3·g-1 | TE % |

|---|---|---|---|---|---|---|

| 35CR | CR by 35% | 1260 | 193.9 | 1405 | 216.2 | 20.4 |

| 35CR-T | CR by 35% + aging at 450 oC for 1.5 h | 1375 | 211.5 | 1425 | 219.2 | 15.6 |

| 75CR | CR by 75% | 1605 | 246.9 | 1855 | 285.4 | 5.4 |

| 75CR-T | CR by 75% + aging at 450 oC for 1.5 h | 2085 | 320.8 | 2210 | 340.0 | 2.3 |

| 75CR-AT | CR by 75% + annealing at 925 oC for 10 s + | 1365 | 210.0 | 1425 | 219.2 | 21.5 |

| aging at 450 oC for 1.5 h |

2.2 显微组织表征

图2为所得各样品的EBSD相分布图和晶粒参考取向差(grain reference orientation deviation,GROD)图。GROD图可以评估研究样品中奥氏体的再结晶晶粒分数,其中GROD为0°~2°的区域代表完全再结晶的晶粒[20,21]。根据EBSD检测结果统计得到的相分数、奥氏体尺寸和再结晶晶粒分数如表2所示。可以看出,各样品组织以奥氏体为基体,含有少量的铁素体(< 8%)。随冷轧压下量从35%增加至75%,缺陷密度逐渐增大,同时奥氏体平均晶粒尺寸由6.51 μm减小到1.48 μm。此外,35%冷轧样品在450 ℃时效后其奥氏体晶粒尺寸和再结晶晶粒分数基本无变化,说明时效未发生再结晶;而75%冷轧样品时效后再结晶晶粒分数有所提高,说明大压下量冷轧导致局部应变集中区域在时效时发生了有限的再结晶;但经925 ℃退火10 s后,再结晶晶粒分数提升至98.6%。且奥氏体晶粒的平均尺寸依然细小,只有1.65 μm,因此引入的高温短时退火使得冷轧奥氏体完全再结晶并获得细小晶粒。

图2

图2

EBSD相分布图与晶粒参考取向差图

Fig.2

EBSD phase distribution (a-e) and grain reference orientation deviation (GROD) (f-j) maps (Note that the red areas in Figs.2c and d are the highly dislocated regions that cannot be indexed; RD, TD, and ND represent rolling direction, transverse direction, and normal direction, respectively)

(a, f) 35CR (b, g) 35CR-T (c, h) 75CR (d, i) 75CR-T (e, j) 75CR-AT

表2 根据EBSD结果得出的各样品组织成分统计结果

Table 2

| Specimen | Austenite area fraction / % | Ferrite area fraction / % | Austenite grain size μm | Recrystallization austenite fraction % |

|---|---|---|---|---|

| 35CR | 98.9 | 1.1 | 6.51 | 10.6 |

| 35CR-T | 98.2 | 1.8 | 6.02 | 13.3 |

| 75CR | 96.2 | 3.8 | 1.48 | 1.8 |

| 75CR-T | 96.8 | 3.2 | 1.20 | 12.5 |

| 75CR-AT | 92.6 | 7.4 | 1.65 | 98.6 |

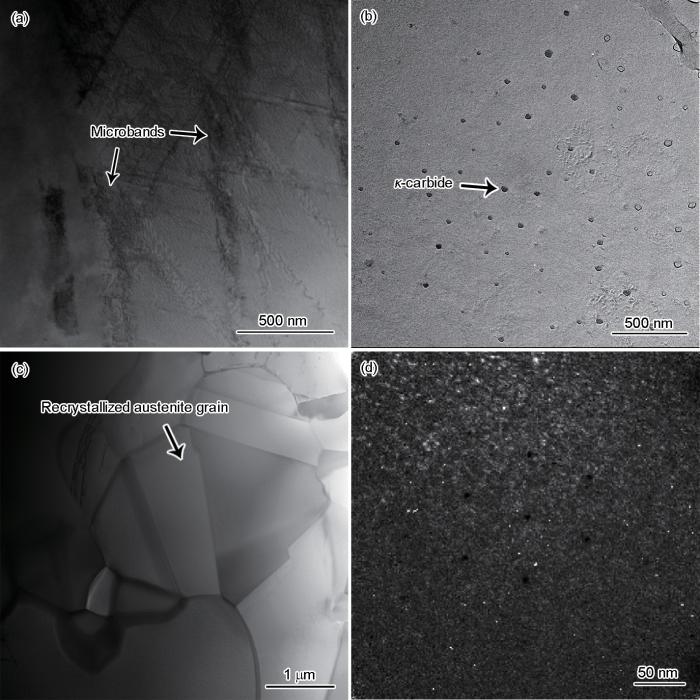

图3a和c分别为35CR-T和75CR-AT样品显微组织的TEM明场像。可以看出,35CR-T中奥氏体晶内存在明显的位错结构,即微带(microbands),说明该样品未发生完全再结晶,这与EBSD结果一致(表2);冷轧时产生大量位错,而时效时经过一定回复形成这些位错结构。75CR-AT样品由于在高温退火时发生了完全再结晶,因此没有发现位错。图3b和d分别是35CR-T和75CR-AT样品中析出相形貌的TEM明场像和暗场像。κ-碳化物均在2者晶内析出,未发现晶界κ-碳化物。35CR-T样品中的κ-碳化物尺寸和面积分数分别为17.02 nm和1.95%;75CR-AT样品中的κ-碳化物尺寸和面积分数分别为9.26 nm和6.07%。对比可以看出,再结晶退火+时效处理促进了更多、更细小的κ-碳化物在晶粒内析出。

图3

图3

35CR-T和75CR-AT样品显微组织的TEM明场像和暗场像

Fig.3

Brigth-field TEM images showing the microbands (a), κ-carbides (b), and the recrystallized austenite grains (c); and dark-field TEM image showing κ-carbides (d) of specimens

(a, b) 35CR-T (c, d) 75CR-AT

3 分析讨论

3.1 新型奥氏体低密度钢的强化机制研究

通过CR-T和CR-AT 2种工艺路径都可以制备出比屈服强度> 210 MPa·cm3/g、总延伸率> 15%的高强度高塑性低密度钢。但是2者的晶粒尺寸、位错密度和κ-碳化物的尺寸和面积分数均存在明显区别。基于此,量化细晶强化、位错强化和沉淀强化对各自屈服强度的贡献才能澄清这2个样品的强化机理。

细晶强化增量(Δσg)通过Hall-Petch公式进行计算[22]:

在奥氏体低密度钢中,位错强化增量(Δσd)可通过下式进行估算[23]:

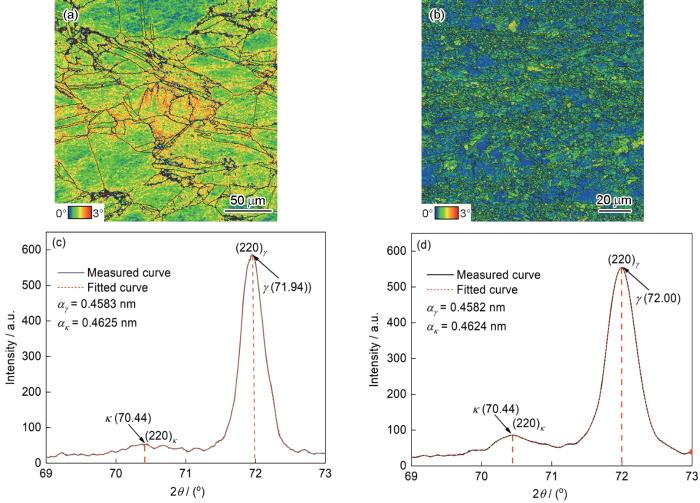

图4

图4

35CR-T和75CR-AT样品EBSD的核平均取向差(KAM)图,以及样品中奥氏体和κ-碳化物(220)晶面的对应XRD衍射峰与拟合曲线

Fig.4

EBSD-KAM maps (a, b) and XRD spectra (c, d) of 35CR-T (a, c) and 75CR-AT (b, d) specimens (The color in Figs.4a and b represents the kernel average misorientation (KAM). αγ —austenite lattice constant; ακ —κ-carbide lattice constant)

在奥氏体低密度钢中,沉淀强化增量(Δσp)在屈服强度中占主导地位,主要沉淀相为κ-碳化物。位错以剪切形式作用在κ-碳化物上时,Δσp可分为2部分:一是共格应变强化增量(Δσcoh),这一强化增量来源于κ-碳化物与奥氏体γ之间的晶格错配;二是κ-碳化物和奥氏体γ之间剪切模量不同带来的强化增量Δσmod,计算如下[25]:

式中,αγ 和ακ 分别为奥氏体和κ-碳化物的晶格常数,其计算公式为:

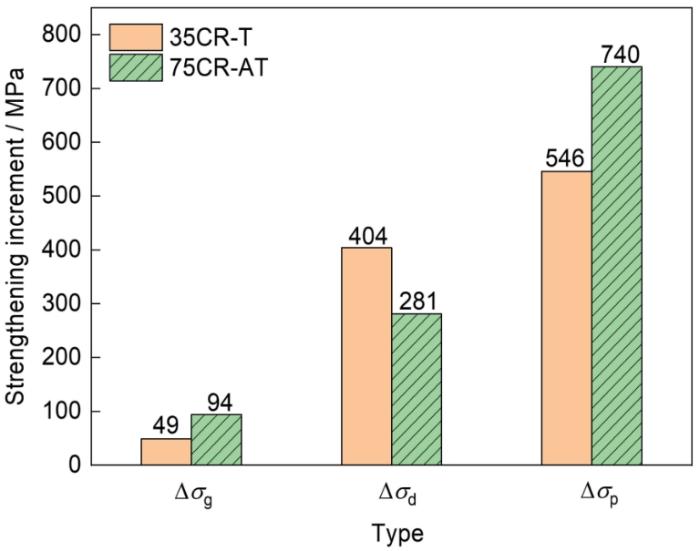

图5对比了以上计算得出的各种强化方式对35CR-T和75CR-AT样品屈服强度的贡献值。计算得到3种强化方式对以上2种样品的贡献之和分别为999和1115 MPa,再考虑到还有高浓度C、Mn、Al的固溶强化贡献(这部分与析出强化相斥且难以量化),则总强化增量接近各自的实际屈服强度。35CR-T样品可量化的细晶强化和沉淀强化增量分别为49和546 MPa,低于75CR-AT样品的94和740 MPa;但前者的位错强化增量较后者高了123 MPa,同时由于后者更高的C、Mn、Al析出κ-碳化物强化而固溶强化低于前者,所以综合各强化机制导致2者的屈服强度相似。

图5

图5

35CR-T和75CR-AT样品中3种强化机制对屈服强度增量贡献的对比

Fig.5

Comparison on the contribution of three strengthening mechanisms to increment of yield strength in 35CR-T and 75CR-AT specimens (Δσg—grain refinement strengthening increment, Δσd—dislocation hardening increment, Δσp—precipitation hardening increment)

3.2 新型奥氏体低密度钢的塑性变形机制

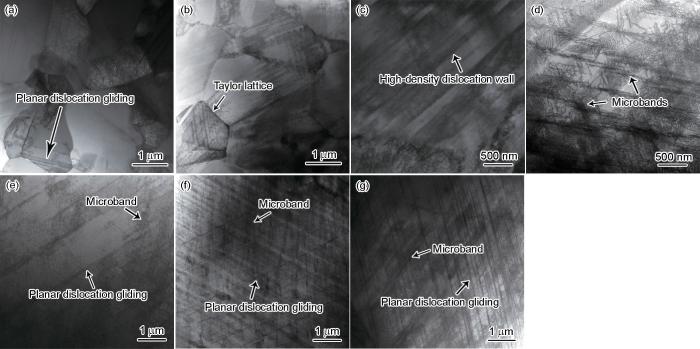

35CR-T和75CR-AT样品均表现出超高的比强度,但是后者的总延伸率比前者高5%。为了分析2者的塑性变形机制,采用中断拉伸结合TEM表征的方法探究了2者拉伸变形过程中的显微组织演变。图6是75CR-AT和35CR-T样品中断拉伸至真应变0.02、0.08、0.11和0.20后显微组织的TEM明场像。对于75CR-AT样品,拉伸变形前奥氏体已经完全再结晶,在奥氏体晶粒内没有观察到位错(图3c);拉伸过程中形成的位错沿不同的方向进行平面滑移。在拉伸变形至0.02真应变时,只观察到一个方向的平面滑移位错(图6a);随真应变增加至0.08、0.11和0.20,依次形成Taylor晶格(图6b)、高密度位错墙(图6c)和微带(图6d)。另外,微带上位错的交滑移能够有效泯灭位错,抑制应变局部化的发生,提高材料的塑性[26,27]。由于塑性变形过程位错交滑移和各种位错结构的形成,75CR-AT样品在1365 MPa的高屈服强度下仍有21.5%的塑性。

图6

图6

75CR-AT和35CR-T样品拉伸变形至不同真应变时显微组织的TEM明场像

Fig.6

Bright-field TEM images of the microstructures of 75CR-AT (a-d) and 35CR-T (e-g) specimens tensile deformed to different true strains

(a, e) 0.02 (b, f) 0.08 (c, g) 0.11 (d) 0.20

对于35CR-T样品,由于未发生再结晶,在变形前奥氏体内就已经有位错形成的交叉的微带(图3a),因此位错的增殖能力有限[28]。随着拉伸变形的进行,新产生的位错穿过微带进行平面滑移,形成平面位错滑移痕迹[29]。在拉伸变形至0.02真应变时,平面位错滑移痕迹之间的间距为1.42 μm (图6e);随真应变增加至0.08和0.11,平面位错滑移痕迹逐渐增多,晶内平面滑移痕迹之间的间距逐渐降低至0.72和0.29 μm (图6f和g),并最终在未形成其他位错亚结构前就断裂。这是因为变形前奥氏体中存在的微带占据了一定的滑移方向,导致35CR-T样品内拉伸变形时位错进行平面滑移的方向受限,因此在尚未形成Taylor晶格等多滑移方向对应的位错亚结构[15,30]时就由于位错增殖能力缺失而发生断裂。

4 结论

(1) 开发出一种新型含Cr高强奥氏体低密度钢,密度为6.50 g/cm³,经冷轧+时效(CR-T)和冷轧+退火+时效(CR-AT)制备出的35CR-T和75CR-AT 2种样品的比屈服强度和总延伸率分别达到211.5 MPa·cm3/g、15.6%和210.0 MPa·cm3/g、21.5%,2种制备工艺均可获得超高比强度和优良塑性。

(2) 冷轧时效钢35CR-T主要是由未再结晶组织中的高密度位错提供强化,而冷轧退火时效钢75CR-AT由于发生完全再结晶获得了细小晶粒和更多、更细小的κ-碳化物,因而细晶强化和析出强化更高,但固溶强化降低;综合起来导致2者屈服强度相当。

(3) 75CR-AT样品中的再结晶奥氏体内位错增殖能力强,可在拉伸变形时依次形成平面滑移位错、Taylor晶格、高密度位错墙和微带等位错亚结构;35CR-T样品未再结晶奥氏体内已经存在微带,限制了其拉伸变形过程中多种位错亚结构的形成,因此比前者的拉伸塑性更低。

参考文献

Effect of Mo and Cr additions on the microstructure, mechanical properties and pitting corrosion resistance of austenitic Fe-30Mn-10.5Al-1.1C lightweight steels

[J].

Research situation of Fe-Mn-Al-C system low-density high-strength steel

[J].

Fe-Mn-Al-C系列低密度高强钢的研究现状

[J].

Current state of Fe-Mn-Al-C low density steels

[J].

Rietveld refinement, microstructure, mechanical properties and oxidation characteristics of Fe-28Mn-xAl-1C (x = 10 and 12 wt. %) low-density steels

[J].

High-strength Fe-20Mn-Al-C-based alloys with low density

[J].

Aging hardening response and β-Mn transformation behavior of high carbon high manganese austenitic low-density Fe-30Mn-10Al-2C steel

[J].

Brittle intermetallic compound makes ultrastrong low-density steel with large ductility

[J].

Factors influencing the tensile behavior of a Fe-28Mn-9Al-0.8C steel

[J].

Microstructures and mechanical properties of high-strength Fe-Mn-Al-C light-weight TRIPLEX steels

[J].

Alloy design, combinatorial synthesis, and microstructure-property relations for low-density Fe-Mn-Al-C austenitic steels

[J].

Tensile deformation of low density duplex Fe-Mn-Al-C steel

[J].

Tensile deformation of a duplex Fe-20Mn-9Al-0.6C steel having the reduced specific weight

[J].

Tensile deformation of a low density Fe-27Mn-12Al-0.8C duplex steel in association with ordered phases at ambient temperature

[J].

Synergistic strengthening effect induced ultrahigh yield strength in lightweight Fe-30Mn-11Al-1.2C steel

[J].

Microband-induced plasticity in a high Mn-Al-C light steel

[J].

Influence of Al content and precipitation state on the mechanical behavior of austenitic high-Mn low-density steels

[J].

Simulation of κ-carbide precipitation kinetics in aged low-density Fe-Mn-Al-C steels and its effects on strengthening

[J].

Influence of Al content on the strain-hardening behavior of aged low density Fe-Mn-Al-C steels with high Al content

[J].

Microstructure and properties of a low-density steel with high strength of 1350 MPa

[J].

一种1350 MPa级低密度高强度钢的组织性能

[J].开发了一种1350 MPa级低密度Fe-29Mn-10Al-1.0C钢。采用光学显微镜、X射线衍射、高分辨电镜等方法对不同热处理状态下低密度钢的力学性能和组织演变规律进行研究。结果表明:实验钢在固溶、时效过程中发生了调幅分解,形成了L′12结构有序相κ′碳化物;实验钢经950 ℃固溶处理后,尺寸为2~5 nm的κ′碳化物弥散分布在奥氏体基体上;随后的时效过程中,随着时效温度提高,κ′碳化物尺寸增大,趋向于沿<100>方向分布,长大粗化择优取向,最终形成规则的“方格阵”调制组织;在有序强化和调幅组织强化的共同作用下,实验钢具有良好的强塑性配合,抗拉强度高达1350 MPa,密度小于6.80 g/cm3。

In situ SEM-EBSD observations of the hcp to bcc phase transformation in commercially pure titanium

[J].

Review Grain and subgrain characterisation by electron backscatter diffraction

[J].

A low-alloy high-carbon martensite steel with 2.6 GPa tensile strength and good ductility

[J].

High dislocation density-induced large ductility in deformed and partitioned steels

[J].A wide variety of industrial applications require materials with high strength and ductility. Unfortunately, the strategies for increasing material strength, such as processing to create line defects (dislocations), tend to decrease ductility. We developed a strategy to circumvent this in inexpensive, medium manganese steel. Cold rolling followed by low-temperature tempering developed steel with metastable austenite grains embedded in a highly dislocated martensite matrix. This deformed and partitioned (D and P) process produced dislocation hardening but retained high ductility, both through the glide of intensive mobile dislocations and by allowing us to control martensitic transformation. The D and P strategy should apply to any other alloy with deformation-induced martensitic transformation and provides a pathway for the development of high-strength, high-ductility materials.Copyright © 2017 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Ultrastrong lightweight compositionally complex steels via dual-nanoprecipitation

[J].

Anomalous precipitate-size-dependent ductility in multicomponent high-entropy alloys with dense nanoscale precipitates

[J].

Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys

[J].Alloy design based on single-principal-element systems has approached its limit for performance enhancements. A substantial increase in strength up to gigapascal levels typically causes the premature failure of materials with reduced ductility. Here, we report a strategy to break this trade-off by controllably introducing high-density ductile multicomponent intermetallic nanoparticles (MCINPs) in complex alloy systems. Distinct from the intermetallic-induced embrittlement under conventional wisdom, such MCINP-strengthened alloys exhibit superior strengths of 1.5 gigapascals and ductility as high as 50% in tension at ambient temperature. The plastic instability, a major concern for high-strength materials, can be completely eliminated by generating a distinctive multistage work-hardening behavior, resulting from pronounced dislocation activities and deformation-induced microbands. This MCINP strategy offers a paradigm to develop next-generation materials for structural applications.Copyright © 2018 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Formation mechanism of κ- carbides and deformation behavior in Si-alloyed FeMnAlC lightweight steels

[J].

Designing duplex, ultrafine-grained Fe-Mn-Al-C steels by tuning phase transformation and recrystallization kinetics

[J].

Origin of extended tensile ductility of a Fe-28Mn-10Al-1C steel

[J].