为了提高运行效率和降低燃油消耗,先进的涡扇发动机追求更高的涵道比,这对涡轮盘等关键热部件在使用温度和承受载荷方面都提出了更高的要求[1~3]。实际上,涡轮盘部件在服役时存在复杂的温度和应力环境,轮毂附近受到的应力较大,温度一般在500 ℃以下,而轮缘部分应力较小但温度较高,一般在650~815 ℃[4]。均匀细晶组织在中温和更低温度下能够保证合金具有足够的强度,但对于高温蠕变和裂纹扩展是不利的;均匀的粗晶组织能够满足合金高温蠕变和裂纹扩展的要求,但很难满足较低温度下的强度要求。因此,使用均匀的粗晶合金或者细晶合金都直接影响涡轮盘的寿命[3,5]。通过双组织热处理(DMHT)工艺制造的盘件,轮毂部分为高强度的细晶组织,轮缘部分为高蠕变抗力的粗晶组织,能够很好地符合盘件的服役特性[6]。通过粉末冶金工艺和变形热处理可得到宏观偏析少、组织均匀且晶粒较小的坯料,再由DMHT工艺获得这种具有梯度晶粒组织的材料,能够同时满足轮毂和轮缘不同温度和应力的要求[4,7]。

对于涡轮盘来说,在温度和应力作用下的蠕变损伤是影响部件寿命和安全运行的重要因素。因此,合金的蠕变行为受到了研究者的广泛关注。研究[8~11]表明,在镍基高温合金的蠕变过程中,位错和γ'相之间的相互作用通常体现在γ通道内位错的滑移和交滑移、位错攀移绕过γ'相和位错切割γ'相形成层错和反相畴界。一定温度下应力增加可能会导致不同的蠕变机制。Jia等[12]研究了一种涡轮盘用粉末高温合金在705 ℃不同应力条件下的蠕变变形机制,结果表明,应力相对较低时主要的变形机制为位错切割γ'相,而在高应力下堆垛层错和微孪晶共同主导了变形过程。Dong等[13]分析了低固溶高熔点(low-solvus high-refractory,LSHR)合金在700 ℃不同蠕变应力条件下的蠕变特性,发现在较低应力下蠕变行为由晶界滑移主导,而在高应力下微裂纹沿着晶内滑移带萌生。彭子超等[14]研究了FGH96合金的蠕变行为,发现在一定温度和应力范围内蠕变变形以位错滑移为主导机制,位错滑移过程中在(

本工作研究了一种先进镍基粉末高温合金FGH4108在700 ℃不同应力下的蠕变性能和断裂特性。通过控制固溶温度获得2种晶粒尺寸的组织。研究了蠕变曲线、蠕变变形亚结构和蠕变断口,明确了2种晶粒尺寸组织中加载应力对蠕变速率的影响以及应力变化对变形机制和蠕变断裂模式的影响。这对于全面理解双组织结构合金的蠕变特性和组织优化设计具有重要意义。

1 实验方法

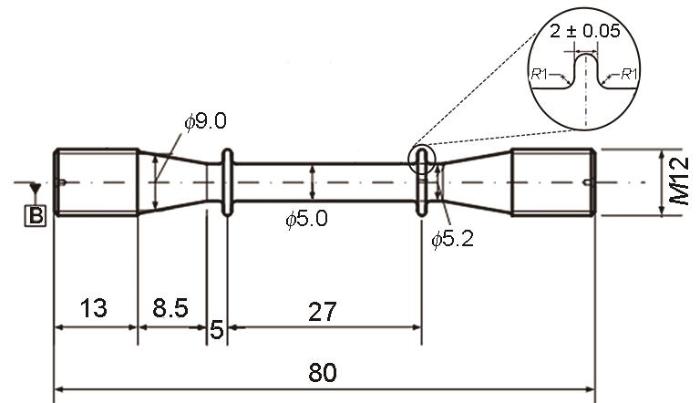

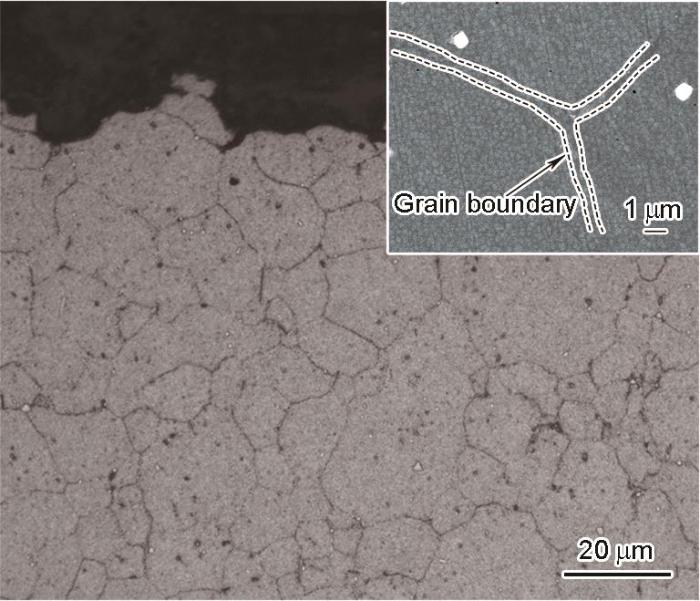

实验用镍基合金FGH4108的名义成分(质量分数,%)为:C 0.04~0.06,Co 17.5~18.5,Cr 11.5~12.6,Ta 4.5~5.0,Al 2.5~3.5,Mo 2.5~3.5,W 2.5~3.5,Ti 2.5~3.5,Nb 1.2~1.8,Hf 0.3~0.5,B + Zr 0.08~0.1,Ni余量。实验合金采用等离子旋转电极法(PREP)制备合金粉末,粉末粒度控制在50~150 μm。经过热等静压(HIP)、热挤压和锻造工艺成型,最后采用固溶处理+两级时效完成实验坯料的制备。通过HIP工艺(1180 ℃、120 MPa、4 h)压实,在1100 ℃挤压后在1120 ℃进行3火次锻造,获得直径160 mm、厚25 mm的圆盘形实验锭坯。经不同固溶温度(1180和1120 ℃)的热处理获得不同组织的试样,随后的两级时效制度均为870 ℃、4 h + 760 ℃、16 h、油冷。固溶温度为1180 ℃的热处理过程记为HT1,合金晶粒尺寸在20~40 μm之间;固溶温度为1120 ℃的热处理过程记为HT2,合金晶粒尺寸在2~5 μm之间。为了便于描述,将经过HT1处理后的试样称为粗晶试样,经过HT2处理后的试样称为细晶试样。所有蠕变试样在两块坯料的相同半径位置取样。单轴拉伸蠕变实验参照GB/T 2039—2012执行,实验条件为700 ℃、780 MPa,700 ℃、810 MPa和700 ℃、900 MPa。试样尺寸如图1所示。选择700 ℃是因为在该温度下细晶组织具有较好的屈服强度(粗晶试样为1027 MPa,细晶试样为1128 MPa),若选择更高温度,细晶粒的扩散蠕变可能对蠕变变形造成很大的不利影响。若选择更低的温度,在适当应力下,粗晶试样的蠕变时间可能较长,增加了实验成本。

图1

采用DSX1000体式光学显微镜(OM),JSM-7800F场发射扫描电子显微镜(FE-SEM)和Tecnai G2 F20透射电子显微镜(TEM)进行显微组织表征。SEM试样采用80%H2SO4 + 20%CH3OH溶液(体积分数)电解抛光(20 V、10 s)后,使用30 mL H3PO4 + 3 g CrO3 + 2 mL H2SO4溶液在5 V电压下腐蚀1~2 s。TEM试样取样位置为距离断口8~10 mm处,这是因为断口附近的变形较大,位错密度高,不利于亚结构的形貌观察,而距离断口过远处变形较小,不利于观察微孪晶。TEM试样通过砂纸将薄片磨至40~50 μm厚,并在-25 ℃、80 mA下采用10%HClO4 + 90%C2H5OH溶液(体积分数)电解双喷制备。析出相的体积分数通过统计其面积分数得到,取值为10张10000倍的SEM像统计的析出相面积分数的平均值。统计孪晶厚度时,选择在[011]正带轴下采用中心暗场成像的TEM像进行测量统计,被测量的孪晶数量大于50个,取平均值。孪晶密度的分析是通过Digital Micrograph软件对TEM图像进行衬度强度分析来体现,分析方向与孪晶的扩展方向垂直。

2 实验结果

2.1 初始显微组织

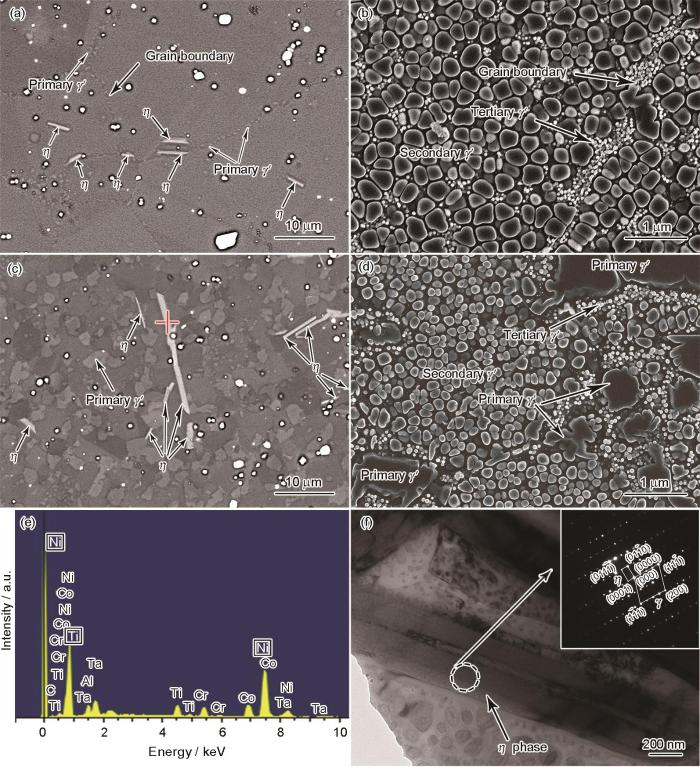

图2a和b为粗晶试样显微组织的SEM像。可见,粗晶试样的析出相主要为二次γ'相,较少的三次γ'相分布在晶界和二次γ'相的通道处。只观察到极少的小尺寸晶界一次γ'相,一次γ'相大部分被溶解。图2c和d为细晶试样显微组织的SEM像。发现少量主要沿着晶界分布的未溶解的η相和大量较大尺寸的一次γ'相,而少量的三次γ'相主要分布在一次γ'相周围和晶界处。粗晶试样和细晶试样中析出相的尺寸和体积分数如表1所示。可见,细晶组织中的一次γ'相体积分数接近二次γ'相。与粗晶相比,细晶组织中η相数量更多,尺寸更大,并且一些相邻的η相首尾相接,细长的η相不仅分布在晶界,还会连续穿过晶界。由于η相的形貌为棒状,因此本工作统计的η相尺寸为长度方向。η相是D024结构的hcp相(Ni3Ti型),对于η相的EDS分析如图2e所示,TEM像如图2f所示。

图2

图2

镍基粉末高温合金FGH4108的初始显微组织

Fig.2

Initial microstructures of the nickel-based powder metallurgy superalloy FGH4108

(a, b) low (a) and high (b) magnification backscattered secondary electron images of the coarse grain sample (c, d) low (c) and high (d) magnification backscattered secondary electron images of the fine grain sample (e) EDS analysis of the marked position in Fig.2c (f) TEM image of the η phase and its selected area electron diffraction (SAED) pattern (inset)

表1 粗晶和细晶试样中析出相的尺寸和体积分数

Table 1

| Heat treatment | Sample | Precipitate | Average size / nm | Volume fraction / % |

|---|---|---|---|---|

| HT1 | Coarse grain | Primary γ' | 597 | 0.6 |

| Secondary γ' | 241 | 51.2 | ||

| Tertiary γ' | 48 | 3.6 | ||

| η | 4 | 0.3 | ||

| HT2 | Fine grain | Primary γ' | 1107 | 22.0 |

| Secondary γ' | 146 | 28.0 | ||

| Tertiary γ' | 53 | 2.6 | ||

| η | 7 | 2.2 |

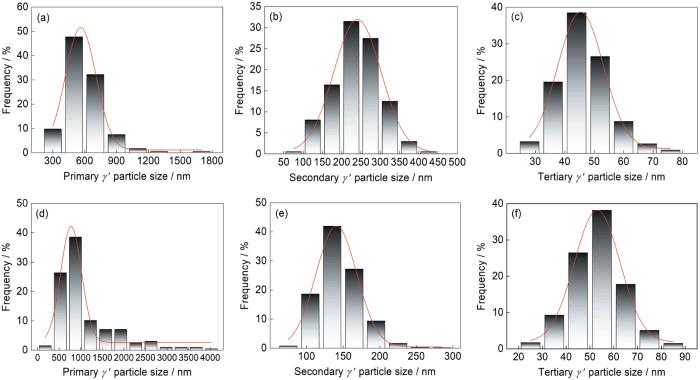

图3为粗晶和细晶试样中γ'相的尺寸分布情况。可见,2种热处理制度下,所有模态的γ'相都是单峰分布。二次γ'相和三次γ'相的正态分布特征比较明显,一次γ'相的分布峰位向左偏移,对于粗晶组织,一次γ'相的尺寸主要分布于400~600 nm范围,对于细晶组织,一次γ'相主要分布在500~1000 nm内。细晶组织中这些晶界处的大尺寸一次γ'相和η相可能会对合金的蠕变性能造成极大的不利影响。

图3

图3

粗晶和细晶试样中γ'相的等效粒径分布

Fig.3

Equivalent particle size distributions of γ' phase in the coarse grain (a-c) and fine grain (d-f) samples

(a, d) primary γ' phase (b, e) secondary γ' phase (c, f) tertiary γ' phase

2.2 蠕变曲线

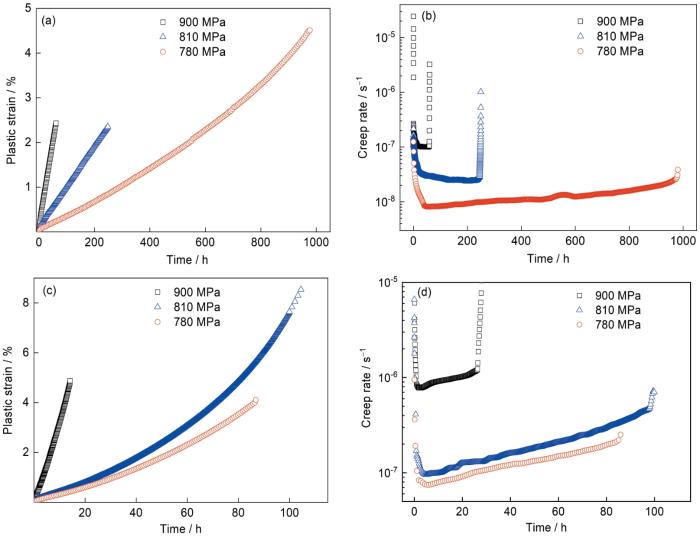

图4为粗晶和细晶试样在700 ℃不同应力条件下的蠕变寿命-应变曲线和蠕变寿命-蠕变速率曲线。从图4a和b可以看出,在较高应力下(900和810 MPa),粗晶试样没有明显的蠕变第一阶段和第三阶段,第二阶段占了变形过程的大部分。可见,在较高应力条件下蠕变变形迅速进入稳态蠕变阶段,应变持续累积,没有经历明显的加速累积过程即发生了断裂。但在700 ℃、780 MPa条件下,蠕变曲线能够区分出3个特征阶段,蠕变寿命与810 MPa应力时相比显著增加。细晶试样的蠕变曲线表现出明显不同的特点,如图4c和d所示,在700 ℃所选应力下,与粗晶试样相比,蠕变寿命非常短,这说明在此温度下,所选应力对于细晶组织来说较大,但蠕变曲线显示出了完整的3个阶段。根据图4的蠕变曲线可以计算出蠕变各阶段产生的应变、时间和对应占比,结果如表2所示。可见,所有曲线的蠕变第一阶段都非常短,对于具有完整蠕变三阶段的曲线,大部分的应变累积和寿命都发生在蠕变第三阶段。另外,随着蠕变应力从780 MPa增加到900 MPa,最小蠕变速率(

图4

图4

在700 ℃不同应力条件下粗晶试样和细晶FGH4108合金的蠕变性能

Fig.4

Creep properties of the coarse grain (a, b) and fine grain (c, d) samples under different stress conditions at 700 oC

(a, c) creep plastic strain curve (b, d) creep rate curve

表2 在700 ℃下粗晶和细晶FGH4108合金的最小蠕变速率和各蠕变阶段的应变和时间

Table 2

Sample | Stress MPa | s-1 | First stage | Second stage | Third stage | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

ε1 % | ε1 / ε % | t1 h | t1 / tr % | ε2 % | ε2 / ε % | t2 h | t2 / tr % | ε3 % | ε3 / ε % | t3 h | t3 / tr % | |||

| Coarse grain | 900 | 1.02 × 10-7 | 0.7 | 29.1 | 14.2 | 23.2 | 1.7 | 70.8 | 47.0 | 76.8 | - | - | - | - |

| 810 | 2.19 × 10-8 | 0.3 | 12.5 | 17.0 | 6.8 | 2.1 | 87.5 | 233.0 | 93.2 | - | - | - | - | |

| 780 | 8.15 × 10-9 | 0.5 | 10.2 | 145.5 | 14.8 | 0.6 | 12.2 | 166.3 | 16.9 | 3.8 | 77.6 | 670.2 | 68.2 | |

| Fine grain | 900 | 7.77 × 10-7 | 1.1 | 23.4 | 3.8 | 27.1 | 0.7 | 14.9 | 2.4 | 17.1 | 2.9 | 61.7 | 7.8 | 55.7 |

| 810 | 9.53 × 10-8 | 0.6 | 6.9 | 15.6 | 14.9 | 0.9 | 10.3 | 18.9 | 18.0 | 7.2 | 82.8 | 70.5 | 67.1 | |

| 780 | 7.61 × 10-8 | 0.4 | 9.3 | 11.6 | 13.4 | 0.4 | 9.3 | 13.7 | 15.8 | 3.5 | 81.4 | 61.5 | 70.8 | |

2.3 蠕变断口附近的变形组织

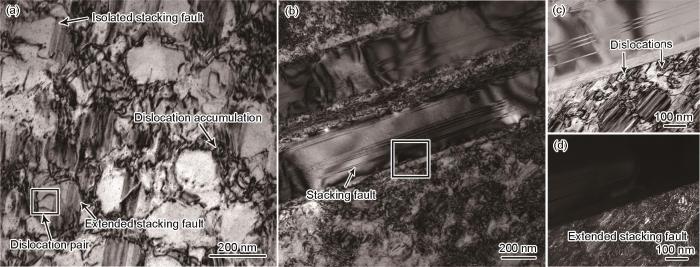

粗晶试样在700 ℃、900 MPa条件下蠕变断裂后位错组态的TEM像如图5所示。可见,大量位错在γ基体中滑移,被γ'相颗粒和晶界阻挡,在γ/γ'界面附近和晶界处塞积,这是γ'相和晶界抑制位错运动的体现。只有很少的位错进入γ'相,可观察到位错成对进入γ'相造成了切割,如图5a中方框区域所示。孤立层错被限制在γ'相内的,这是由于切割γ'相的位错被分解形成了不全位错和层错。还存在切割γ基体和γ'相的扩展层错。值得注意的是,在细晶组织中观察到η相不仅阻碍基体中的位错运动,还阻碍了层错的扩展,如图5b~d所示。相比于二次γ'颗粒,这种阻碍更强,更容易导致位错的塞积,对于含有较多大尺寸η相的细晶组织来说,蠕变过程中这些η相界面处可能会优先形成位错塞积,从而导致应力集中,促使裂纹形核,加快变形速率。另外,还在η相上观察到了层错,层错方向与η相的长度取向平行,如图5b所示,这说明η相也参与了变形。粗晶组织中也有少量小尺寸η相(表1),但由于尺寸小、含量少,η相的影响可不作考虑。

图5

图5

700 ℃、900 MPa条件下粗晶试样中位错组态的TEM像和细晶试样中η相附近亚结构形貌的TEM像

Fig.5

TEM image showing the dislocation configurations of the coarse grain sample (a), low (b) and high (c, d) magnification images of the substructural morphologies near η phase in fine grain sample under 700 oC and 900 MPa

(a, b) bright field images (c, d) bright field (c) and dark field (d) images of the partially enlarged zone in Fig.5b

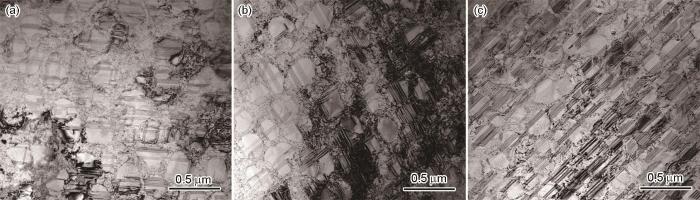

图6

图6

在700 ℃不同蠕变应力下粗晶试样中层错的TEM明场像

Fig.6

Bright field TEM images of stacking faults in the coarse grain sample under different creep stresses at 700 oC

(a) 780 MPa (b) 810 MPa (c) 900 MPa

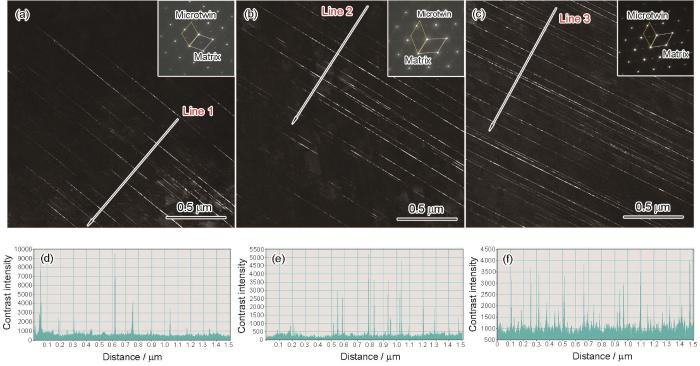

图7

图7

在700 ℃不同蠕变应力下粗晶试样晶粒内微孪晶的TEM暗场像、选区电子衍射(SAED)花样和孪晶密度分析 (<011>带轴)

Fig.7

Dark field TEM images (a-c) and density analyses (d-f) of microtwins in coarse grain sample at 700 oC under creep stresses of 780 MPa (a, d), 810 MPa (b, e), and 900 MPa (c, f) (<011> zone axis. Insets in Figs.7a-c show the corresponding SAED patterns. Line 1-line 3 show analyzing directions for analyzing microtwin density)

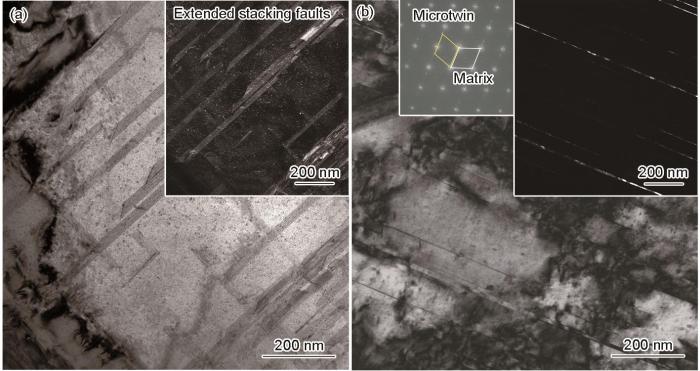

图8

图8

在700 ℃、780 MPa蠕变条件下细晶试样中的层错(<001>带轴附近)和微孪晶(<011>带轴)形貌的TEM像

Fig.8

TEM images of the stacking fault (near the <001> zone axis) (a) and microtwin (<011> zone axis) (b) in the fine grain sample at 700 oC and 780 MPa (Inset in Fig.8a shows the dark field TEM image of extended stacking faults. Insets in Fig.8b show the dark field TEM image and corresponding SAED pattern)

2.4 蠕变断口形貌

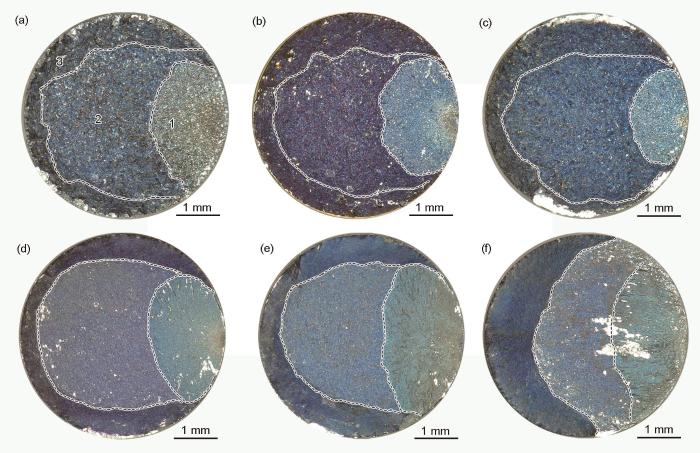

图9

图9

粗晶和细晶试样宏观断口的OM像

Fig.9

OM images showing the macroscopic fracture morphologies of coarse grain (a-c) and fine grain (d-f) samples under creep stresses of 780 MPa (a, d), 810 MPa (b, e), and 900 MPa (c, f) at 700 oC (Positions 1, 2, and 3 indicate the source region, expansion region, and shear region of the rupture section, respectively)

表3 在700 ℃不同应力条件下蠕变断口的裂纹源区和扩展区的面积占比

Table 3

Stress MPa | Coarse grain sample | Fine grain sample | ||

|---|---|---|---|---|

| Source region / % | Expansion region / % | Source region / % | Expansion region / % | |

| 780 | 23.0 | 47.8 | 22.2 | 48.6 |

| 810 | 21.9 | 45.4 | 27.6 | 39.6 |

| 900 | 12.9 | 53.4 | 27.3 | 38.4 |

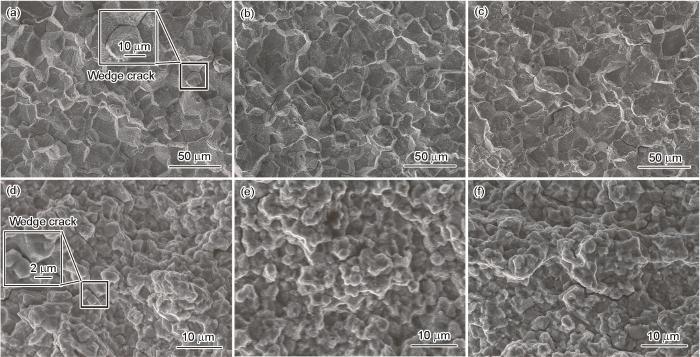

图10

图10

在700 ℃不同应力条件下粗晶和细晶试样断口断裂源区形貌的SEM像

Fig.10

SEM images showing the fracture surface of the fracture source regions of the coarse grain (a-c) and fine grain (d-f) samples under creep stresses of 780 MPa (a, d), 810 MPa (b, e), and 900 MPa (c, f) at 700 oC (Insets in Figs.10a and d show the enlarged images of square areas)

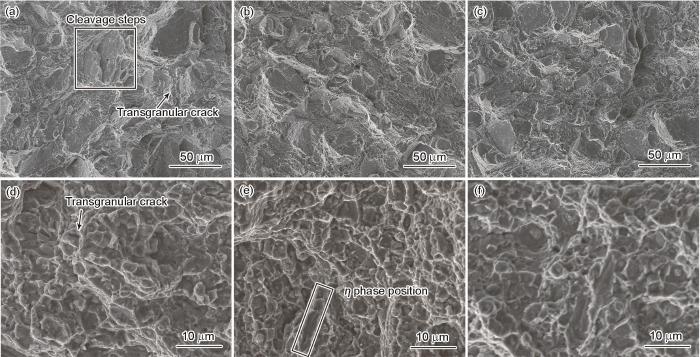

通过对扩展区形貌进行观察发现,不同应力下断口形貌依然近似,如图11所示。从图11a~c可以看出,粗晶试样的断口有明显的解理面和台阶,并存在大量穿晶裂纹。对于细晶试样断口,如图11d~f所示,可以发现不同应力下,断口形貌也是相似的,存在大量穿晶裂纹,此外还出现了类似塑坑的形貌,这表明该裂纹是延性的。以上观察结果表明,测试应力下不论是较粗晶粒还是细晶粒组织的合金,其断裂模式并未随着应力增加而发生较大的改变。另外,在细晶试样断口裂纹扩展区观察到了长条状的断裂痕迹,如图11e所示,结合形貌判断该位置是断裂后η相遗留的痕迹。断裂后η相周围的裂纹呈包围状,说明在断裂过程中裂纹沿着η相的轮廓扩展,根据图5c可知,η相周围存在位错塞积,这很可能导致了应力集中,从而成为裂纹的萌生起源,而η相界面为裂纹扩展提供了通道。

图11

图11

在700 ℃不同应力条件下粗晶和细晶试样断口断裂扩展区形貌的SEM像

Fig.11

SEM images showing the fracture surface of the fracture expansion regions of the coarse grain (a-c) and fine grain (d-f) samples under creep stresses of 780 MPa (a, d), 810 MPa (b, e), and 900 MPa (c, f) at 700 oC

3 分析讨论

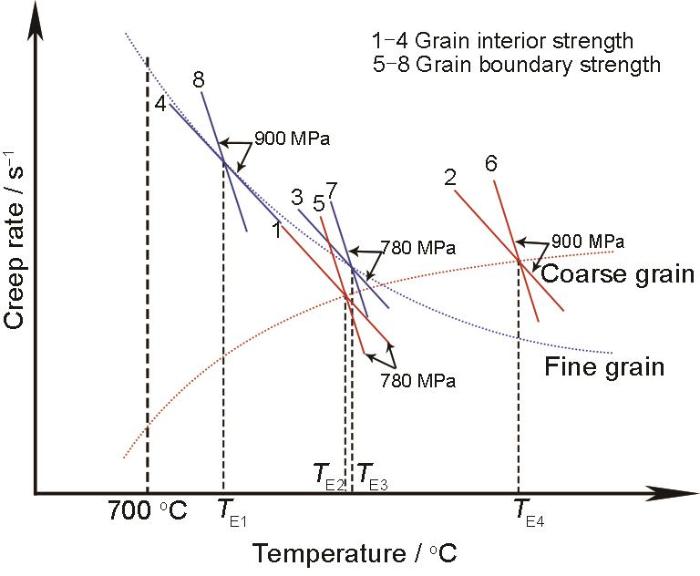

3.1 应力对蠕变速率的影响

在多晶高温合金中,晶粒尺寸对蠕变速率的影响比较复杂,同时晶粒取向、晶界结构等因素也会对蠕变速率产生一定的影响。一般对于多晶体而言,变形包括晶粒变形和晶界滑动。蠕变变形过程中,γ基体中的位错蠕变和晶界滑动是单独进行的[18]。高温时在切应力分量作用下晶界更容易滑动,细晶粒的晶界面积更大,这就导致晶界滑动对总变形量的贡献也越大,相应的蠕变速率也增大。只有当晶粒尺寸足够大时才可以忽略晶界的影响,因为在高温合金蠕变过程中大尺寸晶粒在变形时只在小范围滑移,此时蠕变速率将不再依赖于晶粒尺寸[13]。但在本工作中晶粒尺寸的影响不可忽视。Fang和Murty[19]通过研究18Cr-14Ni不锈钢建立了考虑晶粒尺寸的蠕变方程,并且考虑了晶粒尺寸小于亚晶粒尺寸时的情况,但对于多晶高温合金而言,蠕变速率还受γ′相间距、基体层错能等因素的影响。Kim等[20]建立了同时考虑位错蠕变和晶界滑动的镍基合金最小蠕变速率模型,需要强调的是该模型并未考虑碳化物钉扎晶界对晶界滑移的影响,也没有考虑细小晶粒的情况,由于本工作合金中的晶界碳化物极少[21],因此,Kim等[20]建立的模型适用于实验合金的粗晶组织,但是对细晶组织具有一定的局限性。

因此,利用文献[20]中的模型表示粗晶组织中考虑晶粒尺寸影响的最小蠕变速率贡献分量:

需要注意的是,Ag在不同合金中具有高度的传递性[20],在本工作中Ag / A

对于粗晶试样,将加载应力(780、810和900 MPa)依次代入

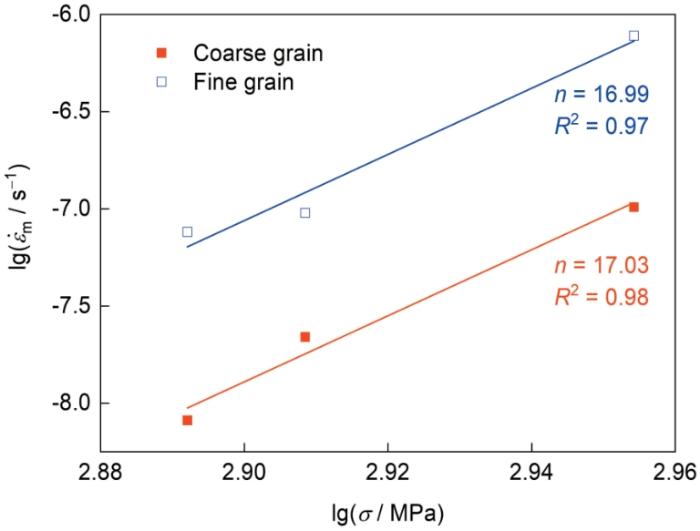

3.2 合金的蠕变应力敏感性和变形机制

式中,A为与材料有关的常数。将

图12

图12

粗晶和细晶组织合金的应力敏感指数

Fig.12

Stress sensitivity indexes (n) of the coarse grain and fine grain samples (σ—applied stress, R—relevance of the data)

本工作中较高的应力敏感指数表明合金的蠕变过程由位错切割机制主导。对于粗晶组织,在较低应力时(780 MPa),蠕变变形机制主要为位错切割γ'相形成孤立层错和微孪晶,此时的微孪晶密度相对较低,随着应力的提升,层错迅速扩展,贯穿基体和γ'相的扩展层错占主导。然而对于细晶组织,在测试应力范围内,扩展层错和微孪晶成为主要的蠕变变形组织。这些扩展层错在应力作用下可迅速增厚转变成微孪晶,导致微孪晶的数量显著增加。这种现象印证了该合金较高的应力敏感性。在变形过程中,由于这种高应力敏感性的特性,应力增高后孪生现象更频繁发生,这加快了塑性变形过程,使得合金发生软化,导致了蠕变速率的增加。这也侧面证明了孪生对变形具有较大的贡献。

3.3 应力对合金蠕变断裂模式的影响

前期研究[21]表明,本工作合金具有较好的组织稳定性。图13为粗晶试样在700 ℃、780 MPa条件下蠕变断裂后晶界形貌的SEM像。蠕变后的晶界未观察到拓扑密堆(TCP)相析出和明显的蠕变孔洞。显然,这对于蠕变过程中的晶界强度是有利的。通常晶界强度和晶内强度相等时的温度被称为等强温度(TE),在一些高温合金中通过高温拉伸实验证实了随着应变速率的增加TE也会升高[27~29]。在高温蠕变实验中发现了随着应力的增加蠕变速率增加,导致了TE升高的规律[28,30],但上述研究均是基于大尺寸的晶粒。从图10和11可以发现,沿晶断裂主要在断裂源区产生,因此可通过断裂源区的面积确认沿晶断裂的区域。这样可以假设当断裂源区面积占比为50%时,对应的测试温度为TE。结合表3可知,对于粗晶试样,当蠕变应力为780 MPa时,沿晶断裂源区域的面积占比为23.0%,此时TE高于测试温度700 ℃。当应力增加至900 MPa后,沿晶断裂源区域的面积占比降低至12.9%,说明TE与测试温度的差在增大,这能够表明TE随着应力的增加而升高。这个规律与Guan等[29]和Cui等[30]的研究结果相符。然而,对于细晶试样,呈现了相反的规律。应力为780 MPa时沿晶断裂源区域面积占比为22.2%,应力增加后沿晶断裂源区域面积占比明显增加,这表明TE在接近测试温度,因此对于细晶试样,随着蠕变应力增加,TE是降低的。因此根据以上分析,结合表2中的最小蠕变速率数据,可以绘制TE受蠕变速率影响的示意图,如图14所示。2种晶粒尺寸的试样在实验条件下沿晶断裂面积占比均远小于50%,表明在实验条件下晶界强度大于晶内强度,TE均大于700 ℃。2种热处理状态合金的TE受应力导致的蠕变速率影响的规律相反,这反映出了其断裂模式倾向性的不同。虽然在断裂初期都是沿晶断裂模式,但随着应变的加速累积,裂纹加速扩展,穿晶断裂成为主要的断裂模式,蠕变应力的增加导致了蠕变速率增大,对于粗晶试样,沿晶断裂的倾向性随着应力增加而减小,而对于细晶试样,应力增加后合金沿晶断裂的倾向性增大。这解释了粗晶粒在高应力下具有更好的蠕变断裂性能的原因。当然,除了应力和晶粒尺寸,合金的断裂模式还与温度、晶界相等因素有关,细晶试样中晶界处大尺寸的η相和包围晶界的一次γ'相都可能对合金的变形行为和断裂模式造成影响,这些问题将在今后的工作中展开进一步研究。

图13

图13

粗晶试样在700 ℃、780 MPa条件下蠕变断裂后晶界形貌的SEM像

Fig.13

SEM image of grain boundaries after creep rupture of the coarse grain sample at 700 oC and 780 MPa (Inset shows the enlarged image)

图14

图14

粗晶和细晶试样的蠕变速率和等强温度(TE)的影响关系示意图

Fig.14

Schematic of the relationship between the creep rate and the equal strength temperature (TE) of the coarse grain and fine grain samples

4 结论

(1) 700 ℃时,在粗晶和细晶组织中,晶界对最小蠕变速率的贡献比均随着蠕变应力的增加而迅速减小,这表明晶界对于最小蠕变速率的促进作用随着蠕变应力的增加而降低。

(2) 在700 ℃条件下,粗晶组织在780 MPa加载应力时的变形机制主要为位错切割γ'相形成孤立层错和微孪晶,随着应力增加到900 MPa,扩展层错和微孪晶成为主要的蠕变变形组织;对于细晶组织,在测试应力(780~900 MPa)下主要的变形组织为贯穿基体和γ′相的扩展层错和微孪晶。

(3) FGH4108合金具有较高的应力敏感性,在变形过程中,这种高应力敏感性导致应力增加后合金更容易发生孪生,加快了塑性变形过程,使得合金发生软化,从而增加了蠕变速率。这也能够反映出孪生对变形具有较大的贡献度。

(4) 在粗晶和细晶试样中断裂源区的断裂模式均为沿晶断裂,而扩展区由穿晶断裂主导。随着蠕变应力的增加,蠕变速率增大,对于较粗晶粒的合金,其沿晶断裂的倾向性减小,而对于细晶组织的合金,应力增加后其沿晶断裂的倾向性增大。

参考文献

Alloys-by-design: Towards optimization of compositions of nickel-based superalloys

[A].

Evolution of creep rupture mechanism in advanced powder metallurgy superalloys with tantalum addition

[J].

Microstructural evolution of a Ni-Co based superalloy during hot compression at γ′ sub-/super-solvus temperatures

[J].

Experimental and simulation study of the effect of precipitation distribution and grain size on the AD730TM Ni-based polycrystalline superalloy tensile behavior

[A].

Microstructural origin and control mechanism of the mixed grain structure in Ni-based superalloys

[J].

The effect of dual microstructure heat treatment on an advanced nickel-base disk alloy

[A].

Fatigue resistance of the grain size transition zone in a dual microstructure superalloy disk

[J].

Shearing mechanisms of stacking fault and anti-phase-boundary forming dislocation pairs in the γ′ phase in Ni-based single crystal superalloy

[J].

Effects of microstructure on the creep properties of a new Ni-Co base superalloy

[J].

Dislocation network with pair-coupling structure in {111} γ/γ′ interface of Ni-based single crystal superalloy

[J].

Creep deformation micro-mechanisms of CM 247 DS LC Ni-base superalloy under relevant service condition

[J].In order to meet the 21st century challenges, the need to improve the high temperature load bearing capabilities or creep properties of nickel base superalloys is more important than ever. Thorough understandings of creep deformation micro-mechanisms are essential for improving high temperature performance of these alloys. Therefore, in the present study, creep deformation micro-mechanisms of CM 247 DS LC alloy used for fabricating turbine blades and vanes under relevant service conditions have been explored. The creep deformation behaviour at the investigated temperatures has been divided into three temperature regimes. In the lower temperature regime, a classical three stage creep curve is observed, i.e., primary creep followed by steady-state creep and then an accelerating creep stage leading to failure. While, in the intermediate temperature creep regime a relatively shorter secondary creep region is seen, in contrast, secondary creep stage is almost missing in the high temperature regime. Transmission electron microscopic (TEM) studies revealed that the deformation micro mechanisms in the low temperature regime are dominated by gamma'-precipitates shearing of anti phase boundary (APB) coupled dislocations pair. In the high temperature regime, the deformation is dominated by the extensive dislocation networks formation and severe gamma'-rafting. In the intermediate temperature regime, the deformation micro-mechanisms are basically mixture of both low and high temperature deformation micro-mechanisms. The facts revealed by TEM observations were well supported by scanning electron based factographic and microstructural analysis.

The creep behavior of a disk superalloy under different stress conditions

[J].

Creep properties of a powder metallurgy disk superalloy at 700 oC

[J].

Creep behavior of FGH96 superalloy at different service conditions

[J].The FGH96 superalloy is extensively used as a gas turbine disk under high temperature due to its excellent tensile and creep properties. With recent developments in the aviation industry, the velocity of the aircraft has increased significantly, thereby increasing the temperature and stress on the turbine disk materials during their service. Therefore, creep deformation is crucial in the turbine disk superalloy. In this study, the creep characteristics of FGH96 superalloy were systematically studied at 650-750oC and 690-810 MPa and the creep mechanism of the alloy under different service conditions was investigated via SEM, EBSD, and TEM. For the creep temperature of 704oC, the creep properties of the alloy decreased with the increase in stress level. When the applied loading stress was 690 MPa, the creep properties of FGH96 alloy decreased significantly with the increase in temperature, and its steady-state creep strain rate was more sensitive to the service temperature. Further, every 30oC increase in the service temperature increased the creep rate by an order of magnitude. For the temperature in the range 650-750oC and the applied loading stress in the range 690-810 MPa, the creep deformation of the alloy was dominated by dislocation slip and resulted in various micro-twins on the continuous (111¯) planes. Moreover, the creep fracture of FGH96 alloy presented typical intergranular fracture under different service conditions in this study.

不同服役条件下FGH96合金的蠕变特征

[J].采用SEM、EBSD和TEM等手段研究了FGH96合金在650~750℃、690~810 MPa条件下的蠕变特征,揭示FGH96合金在不同服役条件下的蠕变机理。结果表明,当蠕变温度为704℃时,FGH96合金的蠕变性能随着应力水平的提高而降低;当加载应力为690 MPa时,FGH96合金的蠕变性能随着温度提高而显著降低,且FGH96合金的稳态蠕变速率对服役温度更为敏感,服役温度每提高30℃,将会导致蠕变速率提高一个数量级。当温度处于650~750℃范围、应力处于690~810 MPa范围时,FGH96合金的蠕变变形均以位错滑移为主,且位错在滑移过程中,会在(111¯)原子面上形成大量的微孪晶。在不同服役条件下,FGH96合金的蠕变断裂均呈现典型的沿晶断裂特征。

Creep behaviors of fine-grained Ni-base powder metallurgy superalloys at elevated temperatures

[J].

Is there an optimal grain size for creep resistance in Ni-based disk superalloys?

[J].

Dislocation motion in a Ni-Fe-based superalloy during creep-rupture beyond 700 oC

[J].

Effect of grain size on creep rate in type 316 stainless steel at 873 and 973 K

[J].

Grain-size-dependent creep of stainless steel

[J].

An intermediate temperature creep model for Ni-based superalloys

[J].

The evolution of γ′ precipitates and hardness response of a novel PM Ni-based superalloy during thermal exposure

[J].

Stress dependence of the creep behaviors and mechanisms of a third-generation Ni-based single crystal superalloy

[J].<p>Elevated temperature creep behaviors at 1100 °C over a wide stress regime of 120-174 MPa of a third-generation Ni-based single crystal superalloy were studied. With a reduced stress from 174 to 120 MPa, the creep life increased by a factor of 10.5, from 87 h to 907 h, presenting a strong stress dependence. A splitting phenomenon of the close- (about 100 nm) and sparse- (above 120 nm) spaced dislocation networks became more obvious with increasing stress. Simultaneously, <i>a</i><sub>0</sub><010> superdislocations with low mobilities were frequently observed under a lower stress to pass through γ′ precipitates by a combined slip and climb of two <i>a</i><sub>0</sub><110> superpartials or pure climb. However, <i>a</i><sub>0</sub><110> superdislocations with higher mobility were widely found under a higher stress, which directly sheared into γ′ precipitates. Based on the calculated critical resolved shear stresses for various creep mechanisms, the favorable creep mechanism was systematically analyzed. Furthermore, combined with the microstructural evolutions during different creep stages, the dominant creep mechanism changed from the dislocation climbing to Orowan looping and precipitates shearing under a stress regime of 137-174 MPa, while the dislocation climbing mechanism was operative throughout the whole creep stage under a stress of 120 MPa, resulting a superior creep performance.</p>

Creep behaviour of Ni-base single-crystal superalloys with various γ′ volume fraction

[J].

Effects of stress and temperature on creep behavior of a new third-generation powder metallurgy superalloy FGH100L

[J].

An investigation on the creep and fracture behavior of cast nickel-base superalloy IN738LC

[J].

Dislocation network formation during creep in Ni-base superalloy GTD-111

[J].

Tensile strengthening in the nickel-base superalloy IN738LC

[J].

Effect of strain rate on the tensile behavior of a single crystal nickel-base superalloy

[J].

The role of phosphorus in a newly developed Ni-Fe-Cr-based wrought superalloy

[J].

The creep deformation and fracture behaviors of nickel-base superalloy M951G at 900 oC

[J].