钛合金具有比强度高、耐腐蚀性能优异、高温性能好、生物相容性好等优点,被广泛应用在航空航天、汽车、海洋、医疗等领域[1,2]。其中,TC4钛合金(Ti-6Al-4V)是一种典型的α + β双相钛合金,具有良好的力学性能和加工性能[3,4]。钛合金的力学性能与其微观组织及织构密切相关,例如α和β相的形貌、相比例、晶粒取向、晶粒尺寸、织构强度等,而钛合金的成形工艺及工艺参数会直接决定其微观组织的变化。钛合金在高温塑性成形的过程中易形成α相织构,甚至“宏区”[5]。这是由于在β→α的相变过程中,β相和α相严格遵循Burgers取向关系,即(0001) α //{110} β 、<

目前,关于β相区或α + β相区热变形对钛合金α相织构演变影响的研究已有很多。李东宽等[9]在α + β相区对双态组织TC4钛合金进行热压缩实验,发现随着变形温度的升高,组织中等轴α相减少,片状α相增加;随着形变速率和形变量的增加,α相晶粒内位错密度和畸变能增大,促进动态再结晶的发生及晶粒尺寸的减小。Zheng等[10]研究了具有等轴组织和随机织构的Ti6242S钛合金棒材在α + β相区热压缩过程中的织构演变,发现随形变量的增加,柱面滑移系被激活,初生α相(αp)晶粒在应力作用下发生弯曲、旋转,同时在动态回复或动态再结晶的作用下发生晶粒细化;在所有变形条件下,在热压缩过程中主要形成了平行于压缩方向的<

综上,钛合金在高温塑性成形的过程中易形成α相织构。此外,热加工前的β织构会对α相织构的形成产生较大的影响。当相邻的β晶粒具有相同或相近的<110>晶向时,c轴平行于<110> β 方向的α变体将优先在β/β晶界的两侧析出[12,13]。同时,β晶界平面的倾斜度也会对α变体选择产生影响,即所形成的α变体的主要低能界面与β晶界平面具有最小角度差[14]。Leo Prakash等[15]研究发现,β相织构和变体选择共同决定热轧及热处理过程中α相织构及“宏区”的产生。αp晶粒的取向与β→α相变中产生变体的取向相对应,且因为片层αs相在αp晶粒上形核,αs的织构也基本遵循αp织构的取向。此外,β相织构强度同样影响后续α相织构的形成。Zhao等[16]指出,β相(110)织构强度直接影响相变过程中的α相织构的形成,具有强(110) β 织构的合金中相邻β晶粒具有相近<110>晶向的概率增大,进而加剧了相变过程中的变体选择,导致强α相织构的形成。β晶粒尺寸也会影响钛合金α相织构和“宏区”的形成,Obasi等[17]发现,随着晶粒尺寸增加,Euler角为{90°, 30°, 0°}的α织构强度逐渐增加;在晶粒尺寸更大的β晶粒中,变体选择更强,且具有共同<110>取向的相邻β晶粒,在其晶界两侧形核的α板条优先形成,促进强织构的形成。研究[18]发现,可以通过跨相区连续热压缩变形的方法调控β相晶粒取向并抑制后续α + β两相区变形过程中α相织构的形成。然而,目前对钛合金热变形过程中组织和织构演变的研究主要集中在α + β两相区或β单相区热变形,工艺参数对跨相区连续热压缩变形过程中α相织构的作用规律尚不明晰。

本工作以TC4钛合金为研究对象,通过热压缩实验、光学显微镜(OM)和电子背散射衍射(EBSD)技术研究了TC4钛合金在α + β相区、β相区以及跨相区连续热压缩实验中α相组织和织构的演变规律,分析了形变量、形变速率等变形参数对α相织构演变的作用机理,进而为钛合金高温塑性成形α相织构的调控提供了一种可行的思路。

1 实验方法

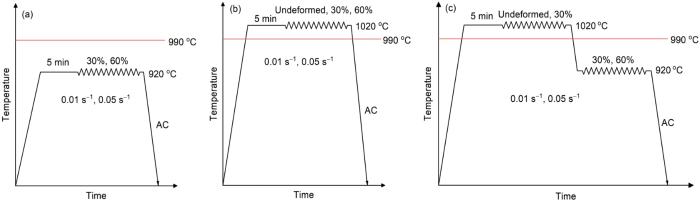

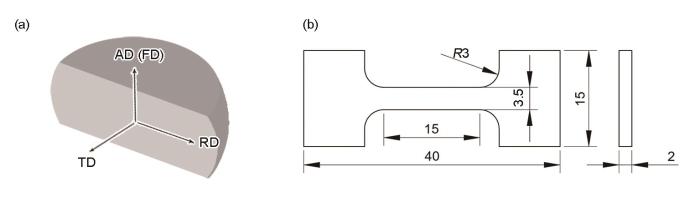

实验材料为挤压态TC4钛合金,其具体成分为Ti-6.36Al-4.15V-0.30Fe-0.10C-0.05N (质量分数,%),合金相变温度约为990 ℃。在配备有电加热炉的DNS200电子万能试验机上沿试样轴向(AD)进行热压缩实验,圆柱体试样尺寸为直径8 mm、长12 mm (用于微观组织分析)和直径40 mm、长60 mm (用于力学性能测试)。试样的变形参数及路线分别如表1和图1所示。α + β相区热压缩变形工艺路线为:将试样从室温(约20 ℃)升温至920 ℃后保温5 min,随后分别以0.01和0.05 s-1的形变速率压缩30%和60% (图1a)。β相区保温或热压缩变形的工艺路线为:将试样从室温升温至1020 ℃后保温5 min,不变形或分别以0.01和0.05 s-1的形变速率压缩30%和60% (图1b)。跨相区连续热压缩变形工艺路线为:将试样从室温升温至1020 ℃后保温5 min,不变形或分别以0.01和0.05 s-1的形变速率压缩30%,随后降温至920 ℃,不经过保温直接以相同形变速率压缩30%和60% (图1c)。所有试样变形完成后均空冷(AC)至室温。变形后用DK7735电火花线切割机将试样沿压缩方向(FD)切开,如图2a所示,经标准金相程序研磨、抛光后,使用3 mL HF + 1 mL HNO3 + 7 mL H2O溶液对样品表面进行腐蚀,采用DM2700M 型OM对试样径向(RD)和FD平面进行微观组织观察。采用配有EBSD系统的TESCAN-8000G扫描电子显微镜(SEM)对试样RD-FD面进行EBSD表征,加速电压为20 kV,扫描区域为950 μm × 700 μm,扫描步长为1.8 μm。通过HKL CHANNEL 5软件对EBSD数据进行分析。通过MATLAB软件及MTEX开源工具[19],基于室温下的α相晶粒取向分布图实现高温β相晶粒取向的重建。

表1 TC4钛合金在不同相区内的变形参数

Table 1

| Sample No. | Process | Deformation parameter |

|---|---|---|

| 1 | α + β phase field compression | 920 oC, 30%, 0.01 s-1 |

| 2 | 920 oC, 30%, 0.05 s-1 | |

| 3 | 920 oC, 60%, 0.01 s-1 | |

| 4 | 920 oC, 60%, 0.05 s-1 | |

| 5 | β phase field holding or compression | 1020 oC, 5 min (undeformed) |

| 6 | 1020 oC, 30%, 0.01 s-1 | |

| 7 | 1020 oC, 60%, 0.01 s-1 | |

| 8 | 1020 oC, 30%, 0.05 s-1 | |

| 9 | Continuous through-transus compression | 1020 oC, 30%, 0.01 s-1 + 920 oC, 30%, 0.01 s-1 |

| 10 | 1020 oC, 30%, 0.05 s-1 + 920 oC, 30%, 0.05 s-1 | |

| 11 | 1020 oC, 30%, 0.01 s-1 + 920 oC, 60%, 0.01 s-1 | |

| 12 | 1020 oC, 30%, 0.05 s-1 + 920 oC, 60%, 0.05 s-1 | |

| 13 | 1020 oC, 5 min (undeformed) + 920 oC, 60%, 0.01 s-1 |

图1

图1

TC4钛合金热压缩加工路线示意图

Fig.1

Schematics of TC4 titanium alloy thermal compression processes (AC—air cooling)

(a) α + β phase field compression

(b) β phase field holding or compression

(c) continuous through-transus compression

图2

图2

TC4钛合金试样和室温拉伸试样示意图

Fig.2

Schematics of sampling position (a) and tensile specimen size (b) of TC4 titanium alloy at room temperature (AD—axial direction, FD—forging direction, TD—transverse direction, RD—radial direction; unit: mm; 990 oC is the (α + β)/β transformation temperature)

在试样RD-FD截面上沿RD方向加工出如图2b所示的室温拉伸试样,室温拉伸实验在UTM4304微机控制电子万能试验机上按照GB/T 228.1—2010进行。

2 实验结果

2.1 合金初始微观组织

图3

图3

原始TC4钛合金的OM像,α相的EBSD取向图、极图和反极图

Fig.3

OM image (a), EBSD orientation map (b), pole figure (PF) (c), and inverse pole figure (IPF) (d) of α phase in as-received TC4 titanium alloy

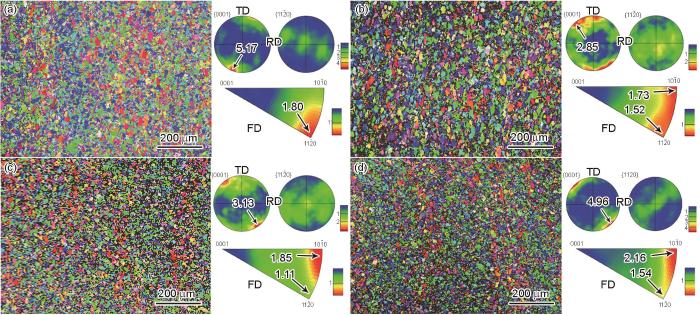

2.2 α+ β 相区压缩变形组织和织构演变

图4

图4

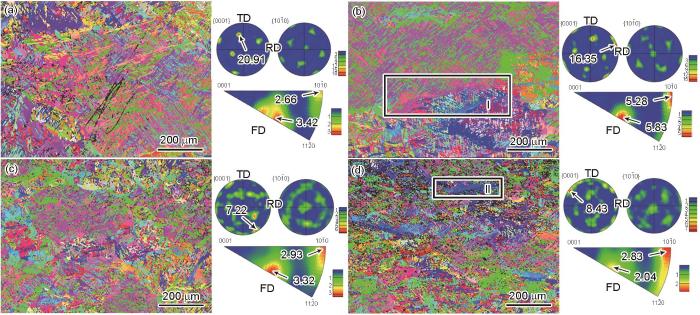

TC4钛合金在α + β相区压缩后α相的EBSD取向图、极图和反极图

Fig.4

EBSD orientation maps, PFs, and IPFs of α phase in TC4 titanium alloys compressed in α + β phase field

(a) sample No.1 (b) sample No.2 (c) sample No.3 (d) sample No.4

当试样以0.01 s-1速率压缩30%时(No.1试样),晶粒的{0001}晶面法向集中在横向(TD)附近,形成{

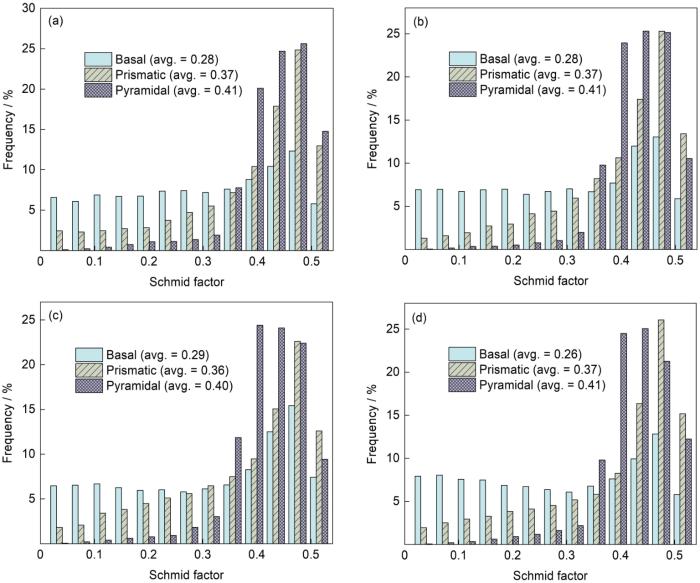

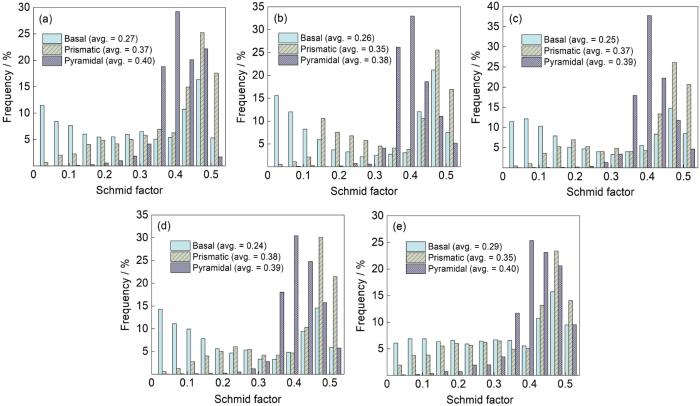

试样经过不同条件压缩实验后形成的形变织构在强度上有所差别,而形变织构的形成与不同滑移系的开动情况有关。图5为TC4钛合金在α + β相区压缩后α相{0001}<

图5

图5

TC4钛合金在α + β相区压缩后α相的{0001}<

Fig.5

Schmid factor (SF) distributions of {0001}<

(a) sample No.1 (b) sample No.2 (c) sample No.3 (d) sample No.4

2.3 β 相区压缩变形组织和织构演变

图6为TC4钛合金在β相区保温或压缩后α相的EBSD取向图、极图和反极图。在β相变点以上温度保温时β晶粒很容易长大,在随后的冷却过程中,α相优先在β晶界上形核并向β晶粒内生长,形成相互交叉的针状α相,即网篮组织[23,24]。在β相区未经处理变形(仅保温5 min)的试样(No.5试样)主要由细片层α相组成,α相晶粒取向非常集中,主要形成平行于压缩方向的{

图6

图6

TC4钛合金在β相区保温或压缩后α相的EBSD取向图、极图和反极图

Fig.6

EBSD orientation maps, PFs, and IPFs of α phase in TC4 titanium alloys held or compressed in β phase field

(a) sample No.5 (b) sample No.6 (c) sample No.7 (d) sample No.8

由于冷却过程中β→α的相变遵循Burgers取向关系,通过MATLAB软件和MTEX开源工具包根据相变后α相的取向重建高温β晶粒的取向,其结果如图7所示。由图可见,β晶粒呈等轴状或带状,晶粒尺寸较大,在原始β晶界处发现部分再结晶晶粒。在β相区保温未变形的试样(No.5试样),其β晶粒尺寸较大且呈等轴状(图7a)。在β相区经过压缩变形后,原始β晶粒沿压缩方向被压扁且晶粒尺寸减小,β晶界清晰完整,在外力的作用下发生弯折,是钛合金β热变形的典型显微组织特征[25] (图7b)。随着形变量增加至60% (No.7试样),β晶粒晶界处存在较多的等轴状动态再结晶晶粒,晶粒尺寸明显减小(图7c)。试样以0.05 s-1压缩30%时(No.8试样),β晶粒被压扁呈条带状,出现动态再结晶晶粒,晶粒尺寸相比No.6试样明显减小(图7d)。

图7

图7

TC4钛合金在β相区保温或压缩后β相的EBSD取向图

Fig.7

EBSD orientation maps of β phase in TC4 titanium alloys held or compressed in β phase field

(a) sample No.5 (b) sample No.6 (c) sample No.7 (d) sample No.8

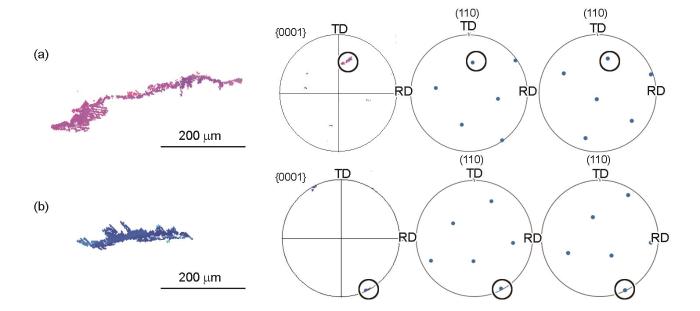

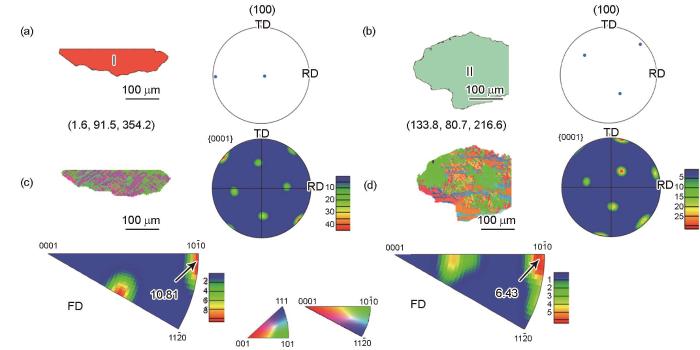

图8

图8

图6中方框位置I和II的α“宏区”EBSD取向图、{0001}极图和相邻β晶粒的{110}极图

Fig.8

EBSD orientation maps and {0001} PFs of α-“macrozones” and {110} PFs of adjacent β grains in the areas I (a) and II (b) in Figs.6b and d

2.4 跨相区连续热压缩变形组织和织构演变

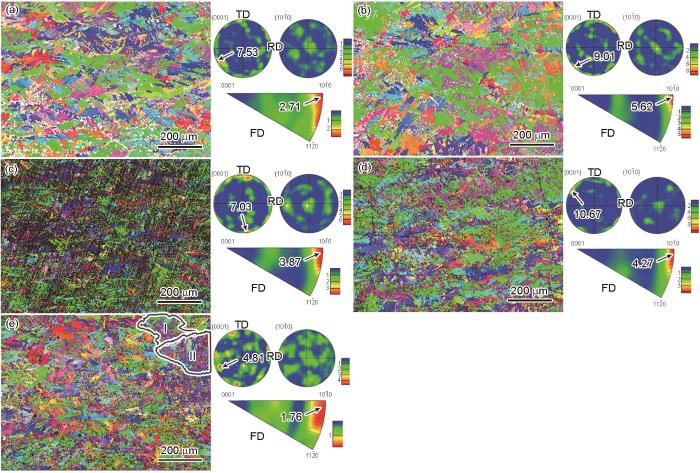

图9

图9

TC4钛合金跨相区连续热压缩后α相的EBSD取向图、极图和反极图

Fig.9

EBSD orientation maps, PFs, and IPFs of α phase in TC4 titanium alloys after through-transus thermal compression

(a) sample No.9 (b) sample No.10 (c) sample No.11 (d) sample No.12 (e) sample No.13

试样以0.01 s-1的形变速率分别在β相区和α + β相区压缩30%时(No.9试样),α相晶粒取向分散,{

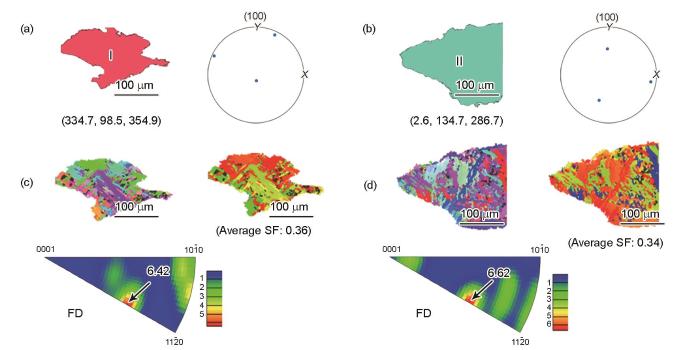

图10

图10

TC4钛合金跨相区连续热压缩后α相{0001}<

Fig.10

SF distributions of {0001}<

(a) sample No.9 (b) sample No.10 (c) sample No.11

(d) sample No.12 (e) sample No.13

结合α + β相区变形产生的形变织构,对于跨相区连续热压缩变形试样,试样在从β相区冷却至α + β相区时,{

2.5 室温力学性能

在实际生产过程中,通常采用β锻造的方法以获得具有良好断裂韧性的片层组织钛合金,而传统的β相区热变形易导致合金强{

表2 TC4钛合金在不同热压缩工艺下以0.01 s-1形变速率总压缩60%后的室温拉伸性能

Table 2

| Sample No. | Tensile strength / MPa | Elongation / % |

|---|---|---|

| 7 | 933.4 | 14.9 |

| 9 | 938.8 | 13.6 |

| 13 | 926.6 | 16.0 |

3 分析与讨论

由以上结果可知,α + β相区热压缩、β相区热压缩以及跨相区连续热压缩后的TC4钛合金的组织和织构存在一定的差异。其中,α + β相区热压缩后的试样由于未经历α→β相转变,其微观组织与合金初始组织相似,由等轴α相组成。在α + β相区变形时,α相滑移系的开动引起α晶粒转动,此外在应力作用下条状α晶粒破碎并发生再结晶,转变为细小的等轴α晶粒。由SF分布图(图5)可知,{

β相区热压缩的试样在冷却过程中发生β→α相变,α相从β基体中析出形成片层组织,并形成平行于压缩方向的{

图11

图11

图6中方框位置I和II中不同取向β晶粒的重构取向图和{001}极图、相应区域内α晶粒取向图、{0001}极图和反极图

Fig.11

Orientation maps and {001} PFs of β grains with different orientations (a, b); and orientation maps, {0001} PFs, and IPFs of α grains (c, d) in the areas I (a, c) and Ⅱ (b, d) in Figs.6b and d

综上,β相区热压缩易导致α相{

跨相区连续热压缩工艺可以明显弱化α织构,这是由于β相区压缩导致β相晶粒向

图12

图12

图9区域I和II中不同取向β晶粒的重构取向图和

Fig.12

Orientation map and {001} PFs of β grains with different orientations (a, b); and orientation maps, IPFs and SF maps of {

跨相区连续热压缩的No.13试样与No.7、No.9试样相比具有最高的延伸率,这是α相织构强度和晶粒形貌共同决定的。

对于传统的β相区热压缩(No.7试样),β相{001}//FD织构的增强促进了后续冷却过程中α相的变体选择,导致了较强α织构的形成。对于跨相区连续热压缩的No.9试样,虽然其在β相区30%的变形导致了β晶粒向{001}//FD取向转动,但同样促进了α + β相区变形时α相柱面滑移系开动,导致α相{

除织构强度的影响外,α相晶粒形貌及晶粒尺寸也会对试样力学性能产生一定的影响。No.13试样在较低温度下变形了60%,流动应力较大,因此其组织的变形程度最大,β相晶粒被严重压扁,片层α晶粒尺寸最为细小。No.9试样{

4 结论

(1) TC4钛合金在α + β相区热压缩后主要由等轴α相组成,变形中{

(2) 在β相区热压缩的试样在冷却过程中发生β→α相变,主要形成{

(3) 对于跨相区连续热压缩变形的试样,β相区压缩导致β晶粒向{001}//FD取向转动,进而促进了压缩过程中α + β相区中α相{

(4) 以不同条件进行热压缩变形后,TC4钛合金的室温抗拉强度相近,而延伸率有所区别。以1020 ℃、5 min (未变形) + 920 ℃、60%、0.01 s-1条件变形的试样具有最高的延伸率,这是因为该试样组织的变形程度最大,板条α晶粒尺寸较小、取向分散,{

参考文献

Experimental investigation on dwell-fatigue property of Ti-6Al-4V ELI used in deep-sea manned cabin

[J].

An overview on the use of titanium in the aerospace industry

[J].

Progresses of R&D on Ti-alloy materials in recent 5 years

[J].

近五年钛合金材料研发进展

[J].

Deformation behavior and microstructure evolution of titanium alloys with lamellar microstructure in hot working process: A Review

[J].Titanium alloys have been widely used in many industrial clusters such as automotive, aerospace and biomedical industries due to their excellent comprehensive properties. In order to obtain fine microstructures and favorable properties, a well-designed multi-step thermomechanical processing (TMP) is critically needed in manufacturing of titanium components. In making of titanium components, subtransus processing is a critical step to breakdown lamellar microstructure to fine-structure in hot working process and thus plays a key role in tailoring the final microstructure and properties. To realize this goal, huge efforts have been made to investigate the mechanisms of microstructure evolution and flow behavior during the subtransus processing. This paper reviews the recent experimental and modelling progresses, which aim to provide some guidelines for the process design and microstructure tailoring for titanium alloy research community. The characteristics of the initial lamellar microstructure are presented, followed by the discussion on microstructure evolution during subtransus processing. The globularization of lamellar α is analyzed in detail from three aspects, i.e., globularization mechanism, heterogeneity and kinetics. The typical features of flow behaviors and the explanations of significant flow softening are then summarized. The recent advances in modelling of microstructure evolution and flow behaviors in the subtransus processing are also articulated. The current tantalized issues and challenges in understanding of the microstructure evolution and flow behaviors of the titanium alloys with lamellar microstructure are presented and specified in future exploration of them.

The origin of coarse macrograin during thermo-mechanical processing in a high temperature titanium alloy

[J].

Anisotropy of mechanical properties of β processed TC17 titanium Alloy

[J].

β锻TC17钛合金力学性能各向异性研究

[J].

The effect of grain orientation on fracture morphology during high-cycle fatigue of Ti-6Al-4V

[J].

The effect of forging texture and machining parameters on the fatigue performance of titanium alloy disc components

[J].

Thermal deformation behavior and microstructure of TC4 titanium alloy in two-phase region

[J].

TC4钛合金两相区的热变形行为及微观组织

[J].

Evolution of microstructure and texture of a near α titanium alloy during forging bar into disk

[J].

Microstructures and textures of TA15 titanium alloy after hot deformation

[J].

TA15钛合金的热变形微观组织与织构

[J].

Crystallographic variant selection in Ti-6Al-4V

[J].

The role of crystallographic and geometrical relationships between α and β phases in an α/β titanium alloy

[J].

Experimental assessment of variant selection rules for grain boundary α in titanium alloys

[J].

The effect of β phase on microstructure and texture evolution during thermomechanical processing of α + β Ti alloy

[J].

Effect of β

Effect of β grain growth on variant selection and texture memory effect during α→β→α phase transformation in Ti-6Al-4V

[J].

β-texture evolution during α precipitation in the two-step forging process of a near-β titanium alloy

[J].

Texture analysis with MTEX—Free and open source software toolbox

[J].

Hot deformation behavior and microstructure evolution of TC11 titanium alloy

[J].Deformation behavior and microstructure evolution of the TC11 titanium alloy at high temperatures were investigated. The results show that the flow stress of the alloy decreases as the deformation temperature increases and the strain rate decreases during deformation, and the degree of softening of the flow stress increases as the strain rate increases. By analysis of the processing map at true strain of 0.6, the highest energy dissipation rate is found at 940 ℃ and 0.001 s<sup>-1</sup> and reaching 0.71. The plastic instability zone is found in the range of 920-930 ℃ and 0.9-10 s<sup>-1</sup>. The dynamic recrystallization of the α-phase during hot deformation of the TC11 titanium alloy is promoted by increase of the strain rate, the deformation volume and the deformation temperature.

TC11钛合金热变形行为及微观组织演变

[J].研究了TC11钛合金在高温下的变形行为以及显微组织变化。结果表明,在变形过程中,合金的流动应力随着变形温度的升高以及应变速率的降低而降低;同时合金的流动应力软化程度随着应变速率的升高而增加。通过真应变为0.6的热加工图分析可知,能量耗散率最高出现在940℃,0.001 s<sup>-1</sup>的条件下,达到0.71;塑性失稳区出现在920~930℃、0.9~10 s<sup>-1</sup>的变形工艺参数范围。TC11钛合金在热变形过程中,应变速率的增加、变形量的增加以及变形温度的升高都有利于促进α相的动态再结晶。

Texture and anisotropy in magnesium alloys

[J].

镁合金织构与各向异性

[J].

Anisotropy of the hot plastic deformation of Ti-6Al-4V single-colony samples

[J].

Microstructural formation in Ti Alloys: In-situ characterization of phase transformation kinetics

[J].

Hot deformation behavior and microstructure of TA15 titanium alloy in β field

[J].

TA15钛合金β热变形行为及显微组织

[J].

Analysis of the active slip mode during compression of the near-α titanium alloy in the α + β phase-field: Insights from the results of electron backscattered diffraction

[J].

Understanding the role of local texture variation on slip activity in a two-phase titanium alloy

[J].

Influence of β-forging on texture development in Ti 6246 alloy

[A].

Dynamic recrystallization mechanism of Ti-6554 alloy during high-temperature deformation

[J].

The effect of microstructure and texture on mechanical properties of Ti6-4

[J].

Influence of processing on microstructure and mechanical properties of (α + β) titanium alloys

[J].