作为难熔元素,Hf或Ta被广泛添加到镍基粉末高温合金中以改善合金的组织和力学性能。例如第二代镍基粉末高温合金N18中添加了0.5Hf (质量分数,%,下同)[3],第三代镍基粉末高温合金René104中添加了2.4Ta[4],Alloy 10中添加了0.9Ta[5],N19中添加了0.3Hf[6],RR1000中添加了0.5Hf + 2.0Ta[7]。正在研究的第四代镍基粉末高温合金中,同时添加Hf和Ta变得更为常见,并且添加量进一步提高,如ME501中添加了0.4Hf + 4.8Ta[8],TSNA-1中添加了0.37Hf + 4.8Ta[9],RRHT3和RRHT4中分别添加了0.36Hf + 3.0Ta和0.42Hf + 3.0Ta[10]。可以看出,同时添加Hf和Ta已成为新型镍基粉末高温合金成分设计的趋势之一,研究Hf和Ta同时添加对合金蠕变断裂特征和性能的影响具有重要意义。

然而,过去的研究主要集中在Hf或Ta单独添加对蠕变性能的影响上。如Cochardt等[11]在专利中公开报道了在镍基变形高温合金中添加0.5Hf能够显著提高合金的蠕变断裂时间和断后伸长率。Zhao等[12]发现在镍基单晶高温合金中添加0.4Hf,可以通过增加γ和γ′相晶格错配度的方式促进更加致密的γ/γ′相界面位错网络的形成,从而降低最小蠕变速率、延长蠕变断裂时间。张义文和胡本芙[13]发现在镍基粉末高温合金中添加0.3Hf能显著提高合金的持久寿命和抗蠕变性能,降低裂纹扩展速率并消除缺口敏感性。杨志昆等[14]发现在镍基粉末高温合金中添加2.4Ta可以显著降低层错能,在蠕变过程中促进层错向形变孪晶转化,从而降低最小蠕变速率、延长蠕变断裂时间。Bai等[15]发现Ta能显著提高镍基粉末高温合金的承温能力,尤其是在较低温度和较高应力下,比如2.4Ta合金在1000和550 MPa应力下500 h蠕变断裂所对应的温度,要比0Ta合金分别高出23和15 ℃;Ta还有助于阻碍晶间裂纹扩展,从而降低裂纹源区的面积。但是,对于Hf和Ta同时添加对合金蠕变断裂特征和性能的影响,国内外的相关研究较少,作用机理也不明确。

本工作以4种只有(Hf + Ta)含量变化的镍基粉末高温合金作为研究对象,研究Hf和Ta对不同温度和应力条件下蠕变断裂特征和性能的影响。通过观察显微组织变化与层错结构特征,总结Hf和Ta对蠕变性能的影响规律,分析Hf和Ta对蠕变断裂特征的影响机理,从而为新型镍基粉末高温合金的成分设计和元素调整提供思路和理论依据。

1 实验方法

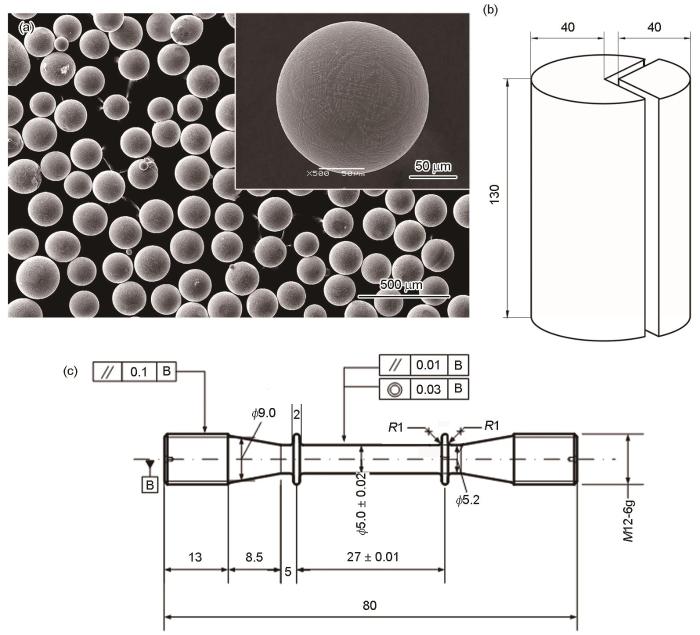

4种实验用镍基粉末高温合金的Hf和Ta的名义成分依次变化(根据成分分别记为0Hf + 0Ta、0.5Hf + 0Ta、0Hf + 2.4Ta、0.5Hf + 2.4Ta合金),其他元素名义成分相同,实测成分见表1。采用真空感应法熔炼合金棒料,利用等离子旋转电极法(PREP)制粉,经筛分与去除夹杂物后得到粒度范围为50~150 μm的合金粉末,如图1a所示。将合金粉末装入碳钢包套进行热等静压(HIP)成形,HIP制度为1200 ℃、120 MPa、4 h,经HIP后获得直径80 mm、长130 mm的圆柱形实验锭坯,将每个锭坯切出1/4份进行热处理(HT),如图1b所示。HT制度包括1180 ℃、2 h + 600 ℃盐浴、30 min +空冷(AC)的过固溶处理和760 ℃、16 h + AC的时效处理。所有实验样品均从这些1/4锭坯上切取和加工。参照GB/T 2039—2012《金属材料单轴拉伸蠕变试验方法》进行蠕变实验,实验条件分别为650 ℃、970 MPa,700 ℃、770 MPa,及750 ℃、580 MPa。由于粉末高温合金显微组织的均匀性,蠕变试样的取样位置没有严格的规定,蠕变试样的尺寸如图1c所示。在距离蠕变断口10 mm处垂直于应力方向切取透射电镜(TEM)试样。

表1 4种实验用镍基粉末高温合金的实测成分 (mass fraction / %)

Table 1

| Alloy | Cr | Co | W | Mo | Al | Ti | Nb | C | B | Zr | Hf | Ta | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0Hf + 0Ta | 15.7 | 12.9 | 4.0 | 4.1 | 2.2 | 3.9 | 0.8 | 0.05 | 0.01 | 0.04 | 0 | 0 | Bal. |

| 0.5Hf + 0Ta | 15.6 | 12.9 | 4.0 | 4.1 | 2.2 | 3.9 | 0.9 | 0.05 | 0.01 | 0.04 | 0.52 | 0 | Bal. |

| 0Hf + 2.4Ta | 15.6 | 13.2 | 4.0 | 4.0 | 2.3 | 3.9 | 0.8 | 0.06 | 0.01 | 0.04 | 0 | 2.41 | Bal. |

| 0.5Hf + 2.4Ta | 15.7 | 13.2 | 4.0 | 4.0 | 2.4 | 3.9 | 0.8 | 0.06 | 0.01 | 0.04 | 0.52 | 2.40 | Bal. |

图1

图1

等离子旋转电极法(PREP)制备粉末形貌,热等静压(HIP)和热处理(HT)锭坯尺寸,及蠕变试样尺寸

Fig.1

Morphology of powders obtained by plasma rotating electrode process (PREP) (Inset shows one typical PREP powder) (a), the size of ingot after hot isostatic pressing (HIP) and heat treatment (HT) (unit: mm) (b), and the size of creep specimen (unit: mm) (c)

试样显微组织由DSX1000体式镜、GX71光学显微镜(OM)、JSM-7800F扫描电镜(SEM)和配备Symmetry S2电子背散射衍射(EBSD)探头的JSM-7200F场发射SEM,以及Talos F200X TEM和配备XFlash 5030能谱仪(EDS)的Tecnai G2 F20 TEM进行表征。OM试样采用20 g CuCl2 + 100 mL HCl + 100 mL C2H5OH化学腐蚀15 s制备。SEM试样采用20%H2SO4 + 80%CH3OH (体积分数)电解抛光(20 V、10 s)制备,并采用30 mL H3PO4 + 3 g CrO3 + 2 mL H2SO4电腐蚀解(5 V、2 s)以观察γ′相。TEM试样在-25 ℃、80 mA下采用10%HClO4 + 90%C2H5OH (体积分数)电解双喷制备。EBSD试样采用20%H2SO4 + 80%CH3OH (体积分数)电解抛光(20 V、5 s)制备。采用JMatPro 12软件计算层错能,因为合金在蠕变后没有观察到拓扑密堆(TCP)相的析出,所以计算时选择了除TCP相以外所有的相。

2 实验结果

2.1 蠕变前的显微组织

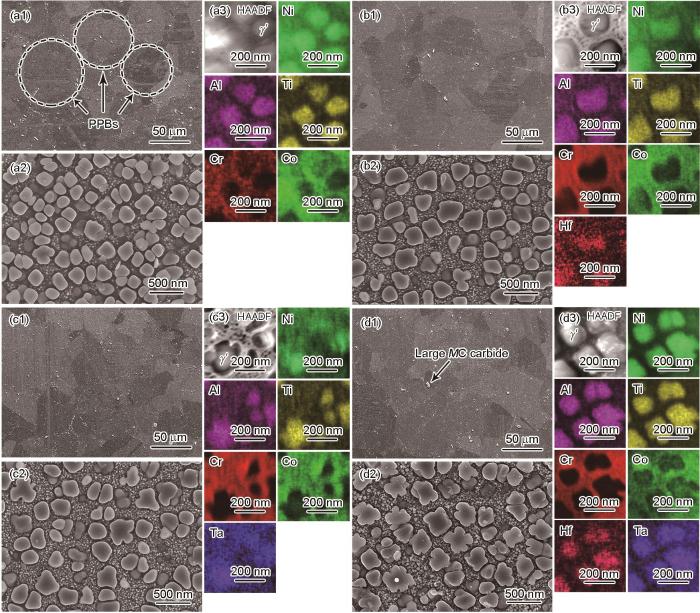

图2

图2

热处理后不同Hf和Ta含量合金的显微组织及元素分布

Fig.2

Microstructures and element distributions of 0Hf + 0Ta (a1-a3), 0.5Hf + 0Ta (b1-b3), 0Hf + 2.4Ta (c1-c3), and 0.5Hf + 2.4Ta (d1-d3) alloys

(a1-d1) distributions of MC carbides (PPB—prior particle boundary) (a2-d2) morphologies of γ′ phase (a3-d3) element distribution mappings of γ and γ′ phases (HAADF—high angle annular dark field)

2.2 蠕变断口形貌

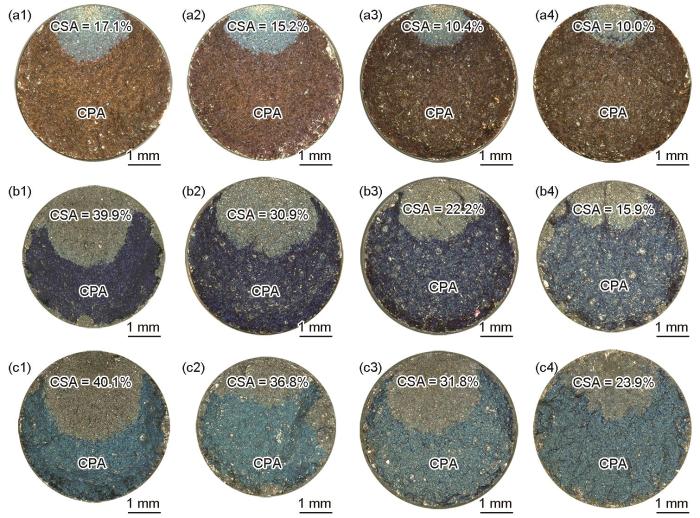

图3给出了不同Hf和Ta含量合金蠕变断口的体式镜照片,先断裂的裂纹源区(CSA)和后断裂的裂纹扩展区(CPA)因为氧化程度不同而呈现出不同的颜色。对裂纹源区、裂纹扩展区和2者交界处的断口形貌进行观察,如图4所示。可见在各温度下裂纹源区均为典型的沿晶断裂,裂纹扩展区均为沿晶和穿晶混合断裂,裂纹源区与裂纹扩展区交界处均出现了清晰的沿晶断裂和混合断裂的分界线(如图4中虚线所示)。在图3中对裂纹源区占断口总面积的面积分数进行了统计,可得对于同一合金,随着温度升高,由于晶界强度相比于晶内强度降低得更快[18],所以沿晶断裂的裂纹源区的面积分数不断增大。而在相同的温度下,合金中添加Hf和Ta显著降低了裂纹源区的面积分数,这说明Hf和Ta的添加显著抑制了沿晶断裂。

图3

图3

不同Hf和Ta含量合金在不同蠕变条件下的断口体视镜照片

Fig.3

Stereoscopic images of the fracture morphologies of the alloys under different creep conditions of 650 oC, 970 MPa (a1-a4),700 oC, 770 MPa (b1-b4), and 750 oC, 580 MPa (c1-c4), showing the area fraction of crack source area (CSA) (CPA—crack propagation area) (a1-c1) 0Hf + 0Ta (a2-c2) 0.5Hf + 0Ta (a3-c3) 0Hf + 2.4Ta (a4-d4) 0.5Hf + 2.4Ta

图4

图4

0Hf + 0Ta合金的裂纹源区、裂纹源区与裂纹扩展区交界及裂纹扩展区的断口形貌

(a1-a3) 650 oC, 970 MPa (b1-b3) 700 oC, 770 MPa (c1-c3) 750 oC, 580 MPa

Fig.4

Fracture morphologies of the CSA (a1-c1), the boundaries of CSA and CPA (indicated by the dotted yellow line) (a2-c2), and the CPA (a3-c3) of 0Hf + 0Ta alloy

2.3 蠕变实验结果

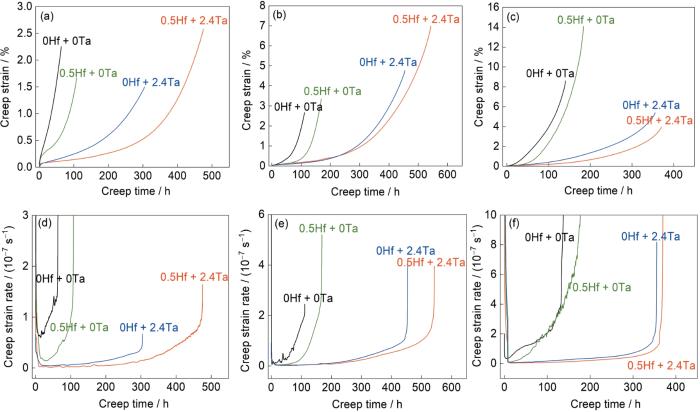

图5

图5

不同Hf和Ta含量合金在不同蠕变条件下的蠕变曲线和蠕变速率曲线

Fig.5

Creep strain curves (a-c) and creep strain rate curves (d-f) of the alloys

(a, d) 650 oC, 970 MPa (b, e) 700 oC, 770 MPa (c, f) 750 oC, 580 MPa

表2 各蠕变条件下不同Hf和Ta含量合金的蠕变断裂时间和最小蠕变速率

Table 2

| Creep condition | Alloy | tr / h | |

|---|---|---|---|

| 650 oC, 970 MPa | 0Hf + 0Ta | 64 | |

| 0.5Hf + 0Ta | 108 | ||

| 0Hf + 2.4Ta | 305 | ||

| 0.5Hf + 2.4Ta | 475 | ||

| 700 oC, 770 MPa | 0Hf + 0Ta | 112 | |

| 0.5Hf + 0Ta | 169 | ||

| 0Hf + 2.4Ta | 454 | ||

| 0.5Hf + 2.4Ta | 543 | ||

| 750 oC, 580 MPa | 0Hf + 0Ta | 140 | |

| 0.5Hf + 0Ta | 184 | ||

| 0Hf + 2.4Ta | 355 | ||

| 0.5Hf + 2.4Ta | 370 |

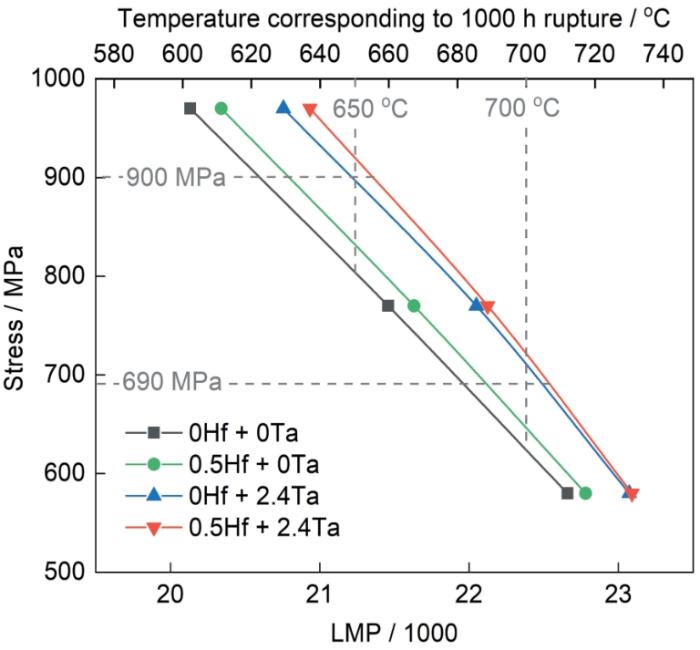

图6为不同Hf和Ta含量合金的Larson-Miller曲线,其中Larson-Miller参数LMP =

图6

图6

不同Hf和Ta含量合金的Larson-Miller曲线

Fig.6

Larson-Miller curves of alloys with varying Hf and Ta contents (Larson-Miller parameter LMP =

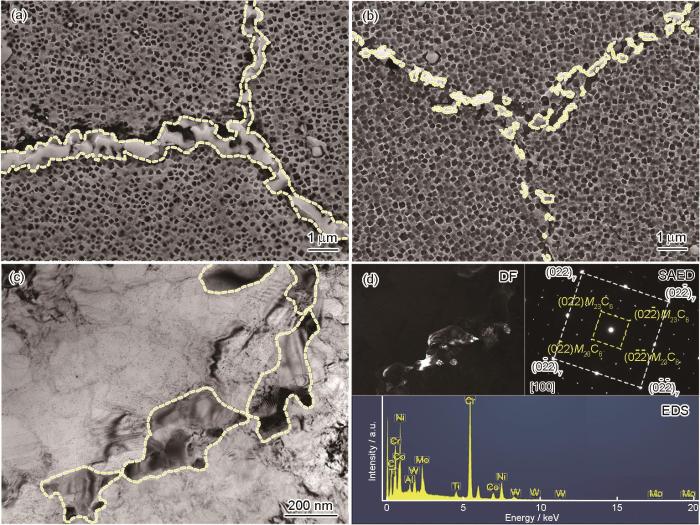

2.4 蠕变断裂后显微组织的TEM分析

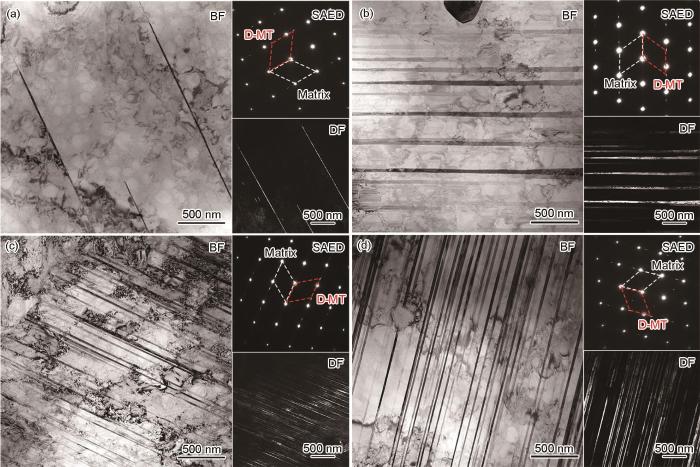

不同Hf和Ta含量合金在650 ℃、970 MPa蠕变断裂后显微组织的TEM像及选区电子衍射(SAED)花样如图7所示。在各合金中均可以观察到贯穿γ′相和γ基体的扩展层错。在其SAED花样中可观察到清晰的孪晶衍射斑点,所以可判断这些扩展层错已演变为变形微孪晶(D-MT)。因此,合金在650 ℃、970 MPa下的蠕变变形机制以微孪晶剪切为主导,这与文献[19,20]中的结果一致。从变形微孪晶的TEM暗场像中可以清楚地看出,0Hf + 0Ta合金的D-MT密度较低(图7a),0.5Hf + 0Ta合金的D-MT密度略微提高(图7b),而0Hf + 2.4Ta合金(图7c)和0.5Hf + 2.4Ta合金(图7d)的D-MT密度明显提高。700 ℃、770 MPa蠕变断裂后,不同Hf和Ta含量合金的D-MT密度规律与650 ℃、970 MPa蠕变断裂后相似。

图7

图7

不同Hf和Ta含量合金在650 ℃、970 MPa蠕变断裂后显微组织的TEM像及选区电子衍射(SAED)花样

Fig.7

Bright-field (BF) TEM images, selected area electron diffraction (SAED) patterns, and dark-field (DF) TEM images of microstructures of the alloys after creep rupture at 650 oC, 970 MPa (D-MT—deformation microtwin)

(a) 0Hf + 0Ta (b) 0.5Hf + 0Ta (c) 0Hf + 2.4Ta (d) 0.5Hf + 2.4Ta

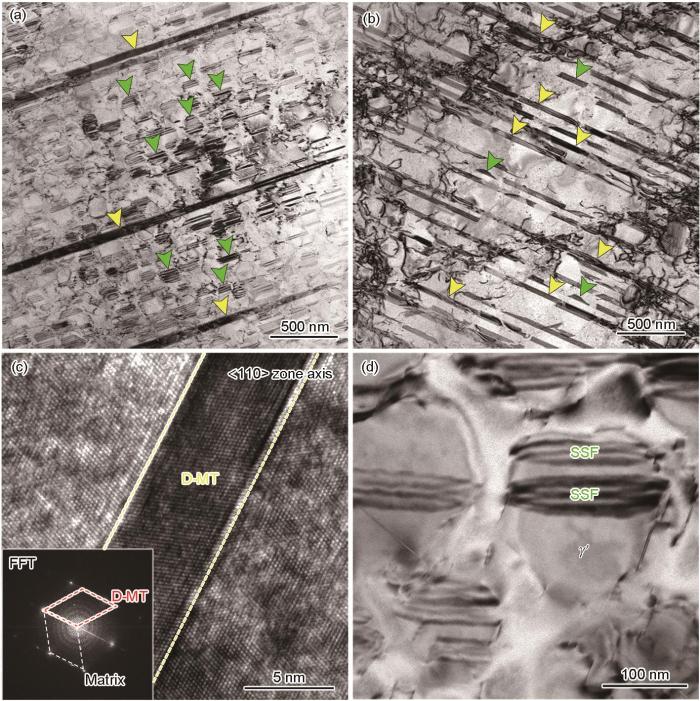

0Hf + 0Ta合金和0.5Hf + 2.4Ta合金在750 ℃、580 MPa蠕变断裂后显微组织的TEM像如图8a和b所示。与650 ℃、970 MPa相比,在750 ℃、580 MPa蠕变断裂后的显微组织中除了可以看到黄色箭头所指的贯穿γ′相和γ基体的变形微孪晶,还观察到了绿色箭头所指的γ′相中的孤立的超点阵层错(SSF),这与文献[21,22]中的发现一致。图8c是变形微孪晶的高分辨TEM像,可以看到其宽度为纳米级别,与γ基体呈共格、镜面对称的位向关系,在快速Fourier变换(FFT)插图中可观察到清晰的孪晶衍射斑点。图8d是SSF的高倍TEM像,可以看到SSF被限制在γ′相颗粒内。因此合金在750 ℃、580 MPa下的蠕变变形机制为微孪晶剪切和超点阵层错剪切共同主导。同时还可见,相比于0Hf + 0Ta合金,0.5Hf + 2.4Ta合金的D-MT密度明显较高,但SSF密度明显较低。

图8

图8

0Hf + 0Ta和0.5Hf + 2.4Ta合金在750 ℃、580 MPa蠕变断裂后显微组织的TEM像

Fig.8

TEM images of microstructures of 0Hf + 0Ta and 0.5Hf + 2.4Ta alloys after creep rupture at 750 oC, 580 MPa (The yellow arrows indicate D-MTs and the green arrows indicate superlattice stacking faults (SSFs))

(a) TEM image of 0Hf + 0Ta alloy

(b) TEM image of 0.5Hf + 2.4Ta alloy

(c) high-resolution TEM image of deformation microtwins (Inset shows the corresponding fast Fourier transform (FFT))

(d) TEM image of SSFs

3 分析讨论

晶界、相界、层错等界面是合金中重要的缺陷,所以在研究Hf和Ta对蠕变断裂特征和性能的影响时,界面的变化是需要重点关注的因素之一。在实验结果中也证实了添加Hf和Ta的合金断口形貌和层错特征发生了明显的变化,因此,下面从多尺度分析和讨论界面对于蠕变性能的影响。

3.1 退火孪晶界对蠕变性能的影响

基于Brandon准则[23]利用EBSD对不同Hf和Ta含量热处理态合金的退火孪晶界(A-TB)进行表征,如图9所示。由于EBSD的角分辨率在1°~2° [24],所以本工作不考虑小于2.5°的晶界取向差,小角度晶界(2.5° ≤ θ < 10°)、大角度晶界(θ ≥ 10°)和退火孪晶界分别用绿色、黑色和红色标出。对晶界长度进行统计发现,0Hf + 0Ta、0.5Hf + 0Ta、0Hf + 2.4Ta和0.5Hf + 2.4Ta合金中退火孪晶界的长度占整个晶界长度的比例分别为44%、38%、35%、和21%,即Hf和Ta均显著降低了退火孪晶界的密度。Tang等[25]指出合金中退火孪晶界的密度随着MC型碳化物含量的提高而降低,因为晶粒内部分散的MC型碳化物可以产生Zener钉扎效应,有效降低了退火孪晶界迁移的驱动力,抑制退火孪晶的形核,同时MC型碳化物还可有效阻挡Shockley位错的滑移,从而使退火孪晶界的生长受阻。由于Hf和Ta的添加提高了合金中MC型碳化物的含量,且使MC型碳化物由沿PPB分布转变为较均匀分布[16],因此显著降低了退火孪晶界的密度。

图9

图9

Hf和Ta对热处理态合金中退火孪晶界密度的影响

Fig.9

Effects of Hf and Ta addition on the density of annealing twin boundaries (A-TB) of HT alloys (θ—misorientation)

(a) 0Hf + 0Ta (b) 0.5Hf + 0Ta (c) 0Hf + 2.4Ta (d) 0.5Hf + 2.4Ta

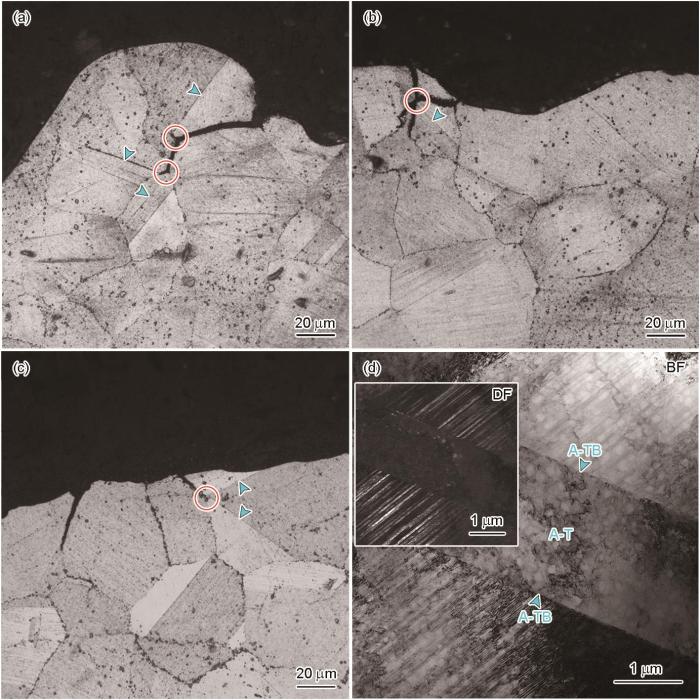

图10a~c给出了0Hf + 0Ta合金在不同蠕变条件下断裂后,断口纵剖面处的二次裂纹照片。经腐蚀后退火孪晶界清晰可见,其中蓝色箭头所指为退火孪晶界,红圈所示为二次裂纹源头。可以看到,在各蠕变条件下,均观察到了二次裂纹在退火孪晶界与晶界交叉处形核的现象,这与文献[26,27]中退火孪晶界易成为裂纹源的结论一致。图10d给出了650 ℃、970 MPa蠕变断裂后退火孪晶的TEM像,其宽度为微米级别。可以看到退火孪晶界中断了层错的扩展,产生了位错塞积,因此在蠕变变形过程中容易造成较大的应力集中,成为二次裂纹的形核源。所以,Hf和Ta通过降低退火孪晶界的密度,有效抑制了二次裂纹的形核,从而提高了蠕变性能。

图10

图10

0Hf + 0Ta合金在650 ℃、970 MPa,700 ℃、770 MPa和750 ℃、580 MPa蠕变断裂后的二次裂纹,及650 ℃、970 MPa蠕变断裂后退火孪晶的TEM像

Fig.10

Secondary cracks of 0Hf + 0Ta alloy after 650 oC, 970 MPa (a), 700 oC, 770 MPa (b), and 750 oC, 580 MPa (c) creep ruptures; and BF TEM image of an annealing twin (A-T) after 650 oC, 970 MPa creep rupture (d) (Inset in Fig.10d shows the corresponding DF TEM image; the blue arrows indicate A-TB, and the red circles indicate the sources of secondary cracks)

3.2 晶界上 M23C6 析出相对蠕变性能的影响

图11

图11

750 ℃、580MPa蠕变断裂后晶界上析出的M23C6相

Fig.11

M23C6 phase on grain boundaries after 750 oC, 580 MPa creep rupture (Yellow lines indicate M23C6 phase)

(a) 0Hf + 0Ta alloy

(b) 0.5Hf + 2.4Ta alloy

(c) BF TEM image of M23C6 phase in 0.5Hf + 2.4Ta alloy

(d) DF TEM image, SAED pattern, and EDS corresponding to Fig.11c

晶界上M23C6相的来源主要有2种途径,一是由于晶界上存在碳偏析而直接析出M23C6相,二是通过MC相的退化反应:MC + γ→M23C6 + γ′而生成M23C6相[28]。Hf和Ta是强MC相形成元素,起到固定C的作用,Hf和Ta进入(Ti, Nb)C形成热力学上更加稳定的(Ti, Nb, Hf, Ta)C[16]。因此Hf和Ta的添加不仅减弱了晶界上的碳偏析,而且抑制了MC相的退化反应,从而减缓了M23C6相的形成,使其在晶界上的析出量变少、尺寸细化、分布更加分散。晶界上的M23C6相对蠕变性能的影响与其析出情况有关,如果M23C6相呈连续分布,会促进裂纹的萌生与扩展[29],降低合金的蠕变性能[30,31],但如果M23C6相尺寸较小且呈不连续分布,则有助于强化晶界、阻碍晶界迁移、钉扎位错[32],从而提高合金的蠕变性能。所以,Hf和Ta通过改变M23C6相在晶界上的析出情况,促进其细化和不连续析出,从而强化了晶界,抑制了沿晶断裂,提高了合金的蠕变性能。这也与图3中观察到的添加Hf和Ta会减小蠕变断口的裂纹源区面积分数的现象相符。

3.3 层错能对蠕变变形机制和性能的影响

通过热力学计算,得到各温度下不同Hf和Ta含量合金的层错能,如表3所示。可以看出,随着温度的升高,各Hf和Ta含量合金的层错能均显著提高,而随着Hf和Ta的添加,各温度下合金的层错能均显著降低。

表3 各温度下不同Hf和Ta含量合金的层错能 (mJ·m-2)

Table 3

| Alloy | 650 oC | 700 oC | 750 oC |

|---|---|---|---|

| 0Hf + 0Ta | 113.4 | 117.0 | 120.6 |

| 0.5Hf + 0Ta | 109.7 | 113.3 | 116.9 |

| 0Hf + 2.4Ta | 96.1 | 99.7 | 103.4 |

| 0.5Hf + 2.4Ta | 91.6 | 95.2 | 98.9 |

层错能随温度的变化影响了蠕变变形机制。在650 ℃下,由于蠕变温度较低,层错能相对较低,变形微孪晶易于扩展,因此蠕变变形机制以贯穿γ基体和γ′相的微孪晶剪切为主导。而在750 ℃下,由于蠕变温度的提高,合金的层错能提高,抑制了层错的扩展,导致一部分a / 2<101>全位错分解为a / 3<112>部分位错剪切γ′相形成超点阵层错[33],因此蠕变变形机制转变为微孪晶剪切和超点阵层错剪切共同主导。

层错能的变化影响了蠕变性能。在各温度下,Hf和Ta的添加都显著降低了合金的层错能,使得γ基体中的a / 2<101>全位错更容易在γ′相和γ基体的界面处分解为a / 6<112>Shockley部分位错,连续剪切γ′相和γ基体的{111}滑移面[34],并通过原子重排形成D-MT[35,36]。所以Hf和Ta的添加显著提高了合金中D-MT的密度,在纳米尺度上引入了高密度的共格界面[37],有效降低了蠕变变形过程中位错运动的平均自由程,增大了位错运动的阻力[38],因此可以有效降低蠕变速率[39,40],提高蠕变抗力[14,35,41]。所以Hf和Ta通过降低层错能,提高D-MT密度,从而提高了蠕变性能。

3.4 γ′相对蠕变性能的影响

表4 热处理态合金中二次γ′相的体积分数、平均直径、平均间距以及γ与γ′相晶格错配度[16]

Table 4

(1) γ′相的体积分数对蠕变性能的影响。合金的蠕变强度主要来源于γ/γ′相共格界面的强化作用,过低或过高的γ′相体积分数都会使γ/γ′相共格界面的总面积减少,一般认为当γ′相体积分数低于60%时,增加γ′相的体积分数会增强γ/γ′相共格界面的强化作用,延长蠕变断裂时间[42]。本工作中合金的γ′相体积分数低于60%,因此,通过添加Hf和Ta提高γ′相体积分数的方式,可以提高合金的蠕变性能。

(2) γ′相的平均尺寸对蠕变性能的影响。在本工作的蠕变条件下,层错(微孪晶)剪切γ′相为主要的变形机制,在此变形机制下,较大尺寸的γ′相颗粒可以有效阻碍位错的切过,提高蠕变抗力[43]。因此,通过添加Hf和Ta提高γ′相平均尺寸的方式,可以提高合金的蠕变性能。

(4) 综合分析γ′相的体积分数、平均间距和合金层错能对蠕变性能的影响。在相同蠕变条件下,不同Hf和Ta含量合金的最小蠕变速率的比值可由下式计算[46]:

式中,Γ为合金的层错能;下标1和2分别代表不同Hf和Ta含量的合金。

如将0Hf + 0Ta合金在650 ℃、970 MPa,700 ℃、770 MPa和750℃、580 MPa下的最小蠕变速率分别设为a1、a2、a3,则可以利用

表5 各蠕变条件下不同Hf和Ta含量合金最小蠕变速率的计算值

Table 5

| Alloy | 650 oC, 970 MPa | 700 oC, 770 MPa | 750 oC, 580 MPa |

|---|---|---|---|

| 0Hf + 0Ta | a1 | a2 | a3 |

| 0.5Hf + 0Ta | 0.93a1 | 0.94a2 | 0.94a3 |

| 0Hf + 2.4Ta | 0.68a1 | 0.69a2 | 0.70a3 |

| 0.5Hf + 2.4Ta | 0.64a1 | 0.66a2 | 0.67a3 |

4 结论

(1) 向镍基粉末高温合金中添加Hf和Ta可以显著延长蠕变断裂时间,降低最小蠕变速率,提高合金的承温能力和持久强度。

(2) Hf和Ta通过提高合金中MC型碳化物的含量,显著降低了退火孪晶界的密度,有效抑制了二次裂纹的形核,从而提高了合金的蠕变性能。

(3) Hf和Ta通过细化晶界上的M23C6相,促使其由连续析出转变为不连续析出,强化了晶界,抑制了沿晶断裂,减小了蠕变断口的裂纹源区面积分数,从而提高了合金的蠕变性能。

(4) 由于层错能随着温度的升高而增加,蠕变变形机制由650 ℃下的微孪晶剪切为主导转变为750 ℃下的微孪晶剪切和超点阵层错剪切共同主导。Hf和Ta通过降低合金在各温度下的层错能,提高了变形微孪晶的密度,增大了位错运动的阻力,从而提高了合金的蠕变性能。

(5) Hf和Ta通过增加二次γ′相的体积分数增强了γ/γ′相共格界面的强化作用,通过增大二次γ′相的平均尺寸提高了蠕变抗力,通过增大γ和γ′相的晶格错配度降低了蠕变速率,从而提高了合金的蠕变性能。

参考文献

Research progress in powder metallurgy superalloys and manufacturing technologies for aero-engine application

[J].The research progress in powder metallurgy (PM) superalloys and manufacturing technologies are reviewed. The key control factors of Ar gas atomization (AA) powder manufacturing are introduced, including the aspects of the equipment development, atomization process, particle size, oxygen content, powder morphology and inclusion control. For the turbine disk manufacturing technology, the research progress of dual-property turbine disk, dual-alloy integral turbine wheel technologies and isothermal forging die materials are summarized. In the field of basic research, high-throughput experiment, advanced characterization and creep behavior of PM superalloys were introduced. According to the current major demand for aero-engines and 3D printing, the future of PM superalloys manufacturing technology is prospected.

航空发动机用粉末高温合金及制备技术研究进展

[J].本文概述了我国粉末高温合金及制备技术的研究进展。在粉末制备方面,重点介绍了Ar气雾化制粉技术关键因素,包括设备、雾化过程、粒度控制、O含量控制、粉末形貌控制和夹杂控制等。针对涡轮盘件制备技术,总结了双性能涡轮盘、双合金整体叶盘技术和等温锻造模具用材料的研究进展。此外,还介绍了在粉末高温合金高通量实验和表征以及蠕变行为等方面的研究进展。结合当前航空发动机、3D打印等高端工程用材料重大需求,对我国粉末高温合金制备技术和发展方向进行了展望。

The structure of N18

[A].

Microstructure, cracking behavior and mechanical properties of René 104 superalloy fabricated by selective laser melting

[J].

Precipitation model validation in 3rd generation aeroturbine disc alloys

[A].

Metallurgical optimisation of PM superalloy N19

[J].

The oxidation characteristics of the nickel-based superalloy, RR1000, at temperatures of 700-900 oC

[J].

Advanced supersolvus nickel powder disk alloy DOE: Chemistry, properties, phase formations and thermal stability

[A].

Utilizing local phase transformation strengthening for nickel-base superalloys

[J].

Design of modern high Nb-content γ-γ′ Ni-base superalloys

[D].

High temperature alloys

[P].

Effects of Hf and B on high temperature low stress creep behavior of a second generation Ni-based single crystal superalloy DD11

[J].

Function of microelement Hf in powder metallurgy nickel-based superalloys

[J].Hafnium (Hf) is one of the most important microelements in powder metallurgy (P/M) superalloy. Hf modifies the microstructure and drastically improves mechanical properties in P/M superalloy. The effect of Hf in a nickel-based P/M superalloy was systematically studied by means of FEG-SEM, TEM, AES, EDS and physical and chemical phase analysis. Hf mainly distributes at interdendritic region of the solidification powder in form of solid solution, which is helpful to reduce prior particle boundary (PPB). Hf facilitates morphology of g′ phase to be unstable and enhances the large cubic g′ phase to split into smaller ones, so the g′ phase turns into a stable state with a lower energy faster. Hf is mainly distributed in g′ phase and MC carbides, which changes the distribution of element between the g′ phase, MC and g solid solution, which is beneficial to eliminate notch sensitivity and improves overall mechanical properties of the alloy.

镍基粉末高温合金中微量元素Hf的作用

[J].

Effect of Ta content on high temperature creep deformation behaviors and properties of PM nickel base superalloys

[J].The nickel base powder superalloy prepared by modern powder metallurgy (PM) technology is selected because it has the characteristics of compatibility with strength and damage tolerance. Moreover, it is the preferred material for the fabrication of a new generation of aero-engine turbine disks. In this study, experimental techniques, such as FESEM and TEM, are used to systematically evaluate the creep properties of powder metallurgy nickel base superalloys with different Ta contents under the conditions of 750°C and 600 MPa. Additionally, the characteristics of microstructure and defosrmation behavior during creep and the effect of stacking fault energy of the alloy on creep property are also investigated. The results show that with increase in Ta content, the energy associated with alloy stacking fault decreases, demonstrating a nonlinear relationship. The deformation behavior and dislocation configuration changes in each creep deformation stage are closely related to the stacking fault energy. The stacking fault energy of alloys with low Ta content is relatively high, the matrix dislocation a/2<110> is prevented at the γ/γ' interface, and the dislocation is not easy to decompose. Furthermore, it can directly enter the γ' phase to form antiphase boundary or to bypass the γ' phase through the Orowan ring bow bending mode. If the alloy contains a moderate amount of Ta, the stacking fault energy of the alloy is reduced, promoting the decomposition of matrix dislocations at the γ/γ' interface. This results in a/6<112> Shockley incomplete dislocations and starts to shear the γ' phase, forming superlattice stacking faults (superlattice intrinsic stacking faults (SISFs) or superlattice extrinsic stacking faults (SESFs)) and extended stacking faults (ESFs), which are then transformed into deformation twins. Therefore, presenting the co-strengthening effect of stacking faults and deformation twins, which improves the creep property. The stacking fault energy of alloys with high Ta content is very low, which is favorable to the simultaneous formation of wide-sized ESFs on different {111} slip planes. The occurrence of inter-crossing stacking faults inhibits the formation of deformation twins and accelerates the development of creep deformation cracks. These experimental results demonstrate that the addition of an appropriate amount of Ta to the alloy can effectively reduce the stacking fault energy, improve the ability to form both partial dislocation shear γ' phase and micro-twins, increase creep resistance, and effectively improve the alloy creep property.

Ta含量对镍基粉末高温合金高温蠕变变形行为和性能的影响

[J].采用FESEM、TEM等实验技术,系统研究了750℃、600 MPa条件下,不同Ta含量的镍基粉末高温合金的蠕变性能和蠕变过程中显微组织和变形行为特征以及合金层错能对蠕变行为的影响。结果表明,随着Ta含量的增加,合金层错能呈非线性关系降低。蠕变变形各阶段的变形行为和位错组态的变化与层错能密切相关。低Ta含量合金层错能相对较高,基体位错a/2<110>滑移被阻止在γ/γ'内界面处,不易发生位错分解,可直接进入γ'相中形成反相畴界(APB)或通过Orowan环弓弯模式绕过γ'相;当合金中Ta含量中等时,合金层错能降低,促进在γ/γ'内界面处基体位错发生分解,产生a/6<112> Shockley不全位错开始剪切γ'相,形成超点阵层错(超点阵内禀层错(SISF)或超点阵外禀层错(SESF))和扩展层错(ESF)进而转化形成形变孪晶,呈现层错和形变孪晶共同强化效应,提高蠕变性能;而高Ta含量合金层错能很低,有利于位错在不同{111}滑移面上同时形成尺寸较宽的扩展层错,并出现相互交结的交叉层错抑制形变孪晶的形成,加快蠕变形变裂纹发展。因此,合金中加入适量Ta能有效降低层错能,提高形成不全位错剪切γ'相能力和形成显微孪晶能力,增加蠕变抗力,有效改善合金蠕变性能。

Evolution of creep rupture mechanism in advanced powder metallurgy superalloys with tantalum addition

[J].

Effect of hafnium and tantalum on the microstructure of PM Ni-based superalloys

[J].

Effect of Hf and Ta on the tensile properties of PM Ni-based superalloys

[J].

Effects of grain refinement on the microstructure and tensile behavior of K417G superalloy

[J].

Investigation of creep deformation mechanisms at intermediate temperatures in René 88 DT

[J].

Deformation mechanisms at intermediate creep temperatures in the Ni-base superalloy René 88 DT

[J].

Temperature dependence of tensile deformation mechanisms in a powder metallurgy Ni-Co-Cr based superalloy with Ta addition

[J].

Creep deformation behavior of a novel precipitate-hardened Ni-Fe-base superalloy at 750 oC

[J].

The structure of high-angle grain boundaries

[J].

Characterisation of fine-scale microstructures by electron backscatter diffraction (EBSD)

[J].

Effect of hafnium on annealing twin formation in as-hot isostatically pressed nickel-based powder metallurgy superalloy

[J].

Small crack behavior and fracture of nickel-based superalloy under ultrasonic fatigue

[J].

Crystallographic fatigue crack initiation in nickel-based superalloy René 88DT at elevated temperature

[J].

Effect of Ta on the microstructure of high performance Ni-based powder metallurgy superalloys

[J].

Precipitation behavior of grain boundary M23C6 and its effect on tensile properties of Ni-Cr-W based superalloy

[J].

Effect of carbon on microstructure and mechanical properties of HR3C type heat resistant steels

[J].

Creep deformation and rupture mechanism of an advanced wrought Ni Fe-based superalloy for 700 oC class A-USC steam turbine rotor application

[J].

M23C6 precipitation behavior in a Ni-base superalloy M963

[J].

Tensile deformation mechanisms at various temperatures in a new directionally solidified Ni-base superalloy

[J].

Dislocation decorrelation and relationship to deformation microtwins during creep of a γ′ precipitate strengthened Ni-based superalloy

[J].

Effects of stacking fault energy on the creep behaviors of Ni-base superalloy

[J].

The high temperature decrease of the critical resolved shear stress in nickel-base superalloys

[J].

Strengthening materials by engineering coherent internal boundaries at the nanoscale

[J].Strengthening materials traditionally involves the controlled creation of internal defects and boundaries so as to obstruct dislocation motion. Such strategies invariably compromise ductility, the ability of the material to deform, stretch, or change shape permanently without breaking. Here, we outline an approach to optimize strength and ductility by identifying three essential structural characteristics for boundaries: coherency with surrounding matrix, thermal and mechanical stability, and smallest feature size finer than 100 nanometers. We assess current understanding of strengthening and propose a methodology for engineering coherent, nanoscale internal boundaries, specifically those involving nanoscale twin boundaries. Additionally, we discuss perspectives on strengthening and preserving ductility, along with potential applications for improving failure tolerance, electrical conductivity, and resistance to electromigration.

Creep mechanisms of a new Ni-Co-base disc superalloy at an intermediate temperature

[J].

Creep mechanisms of U720Li disc superalloy at intermediate temperature

[J].

Inhibiting creep in nanograined alloys with stable grain boundary networks

[J].Creep, the time-dependent deformation of materials stressed below the yield strength, is responsible for a great number of component failures at high temperatures. Because grain boundaries (GBs) in materials usually facilitate diffusional processes in creep, eliminating GBs is a primary approach to resisting high-temperature creep in metals, such as in single-crystal superalloy turbo blades. We report a different strategy to inhibiting creep by use of stable GB networks. Plastic deformation triggered structural relaxation of high-density GBs in nanograined single-phased nickel-cobalt-chromium alloys, forming networks of stable GBs interlocked with abundant twin boundaries. The stable GB networks effectively inhibit diffusional creep processes at high temperatures. We obtained an unprecedented creep resistance, with creep rates of ~10<sup>-7</sup> per second under gigapascal stress at 700°C (~61% melting point), outperforming that of conventional superalloys.

Stress rupture properties and deformation mechanisms of Nimonic 105 alloy at intermediate temperature

[J].

Creep behaviour of Ni-base single-crystal superalloys with various γ′ volume fraction

[J].

Microstructural evolution and creep mechanisms in Ni-based single crystal superalloys: A review

[J].

Effect of initial gamma prime size on the elevated temperature creep properties of single crystal nickel base superalloys

[J].

The effect of lattice misfit on the dislocation motion in superalloys during high-temperature low-stress creep

[J].

An intermediate temperature creep model for Ni-based superalloys

[J].