Hf和Ta对镍基粉末高温合金蠕变断裂特征和性能的影响

Effect of Hf and Ta on Creep Rupture Characteristics and Properties of Powder Metallurgy Ni-Based Superalloys

Hf和Ta对镍基粉末高温合金蠕变断裂特征和性能的影响 |

| 张浩鹏, 白佳铭, 李新宇, 李晓鲲, 贾建, 刘建涛, 张义文 |

|

Effect of Hf and Ta on Creep Rupture Characteristics and Properties of Powder Metallurgy Ni-Based Superalloys |

| ZHANG Haopeng, BAI Jiaming, LI Xinyu, LI Xiaokun, JIA Jian, LIU Jiantao, ZHANG Yiwen |

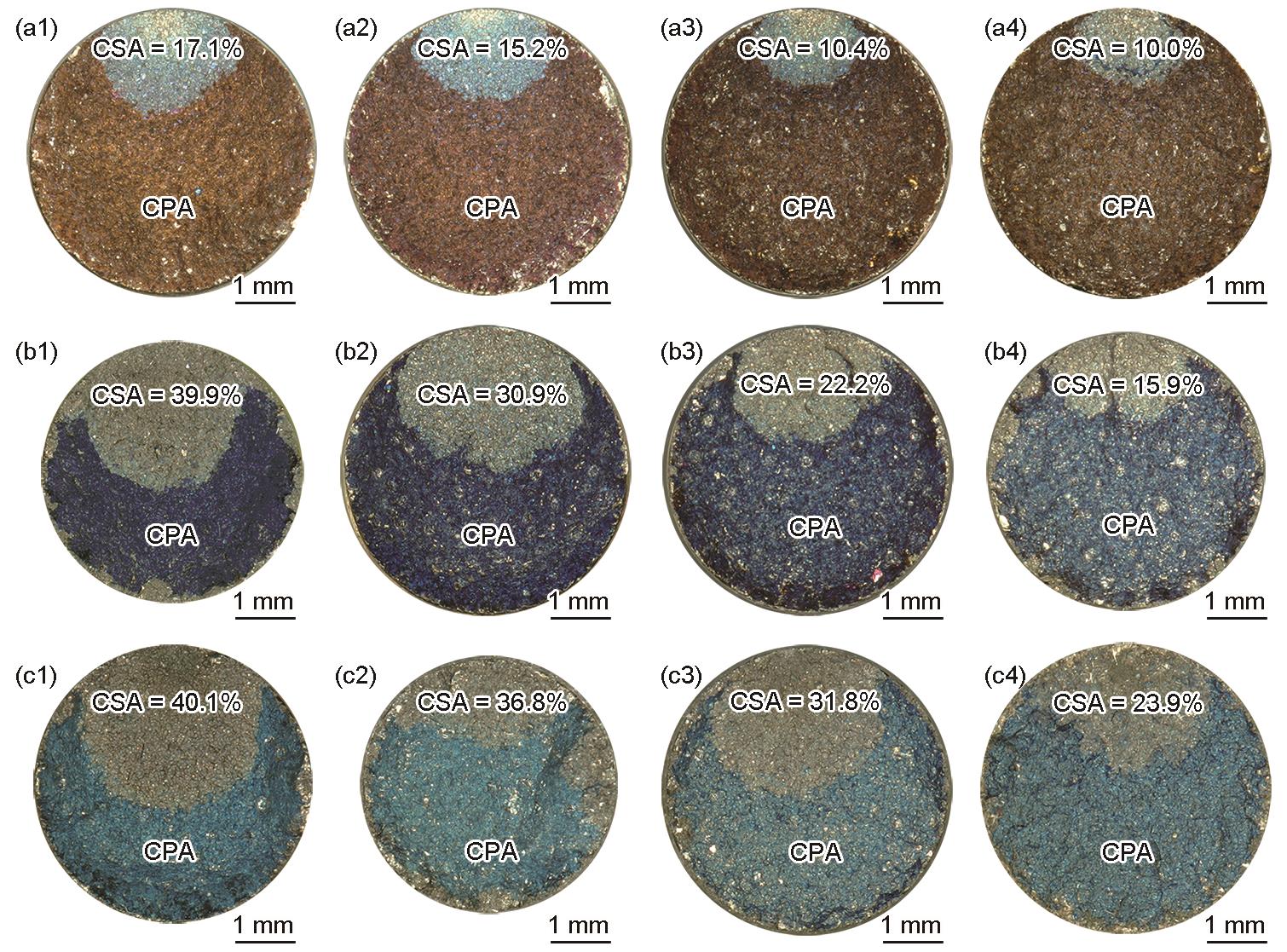

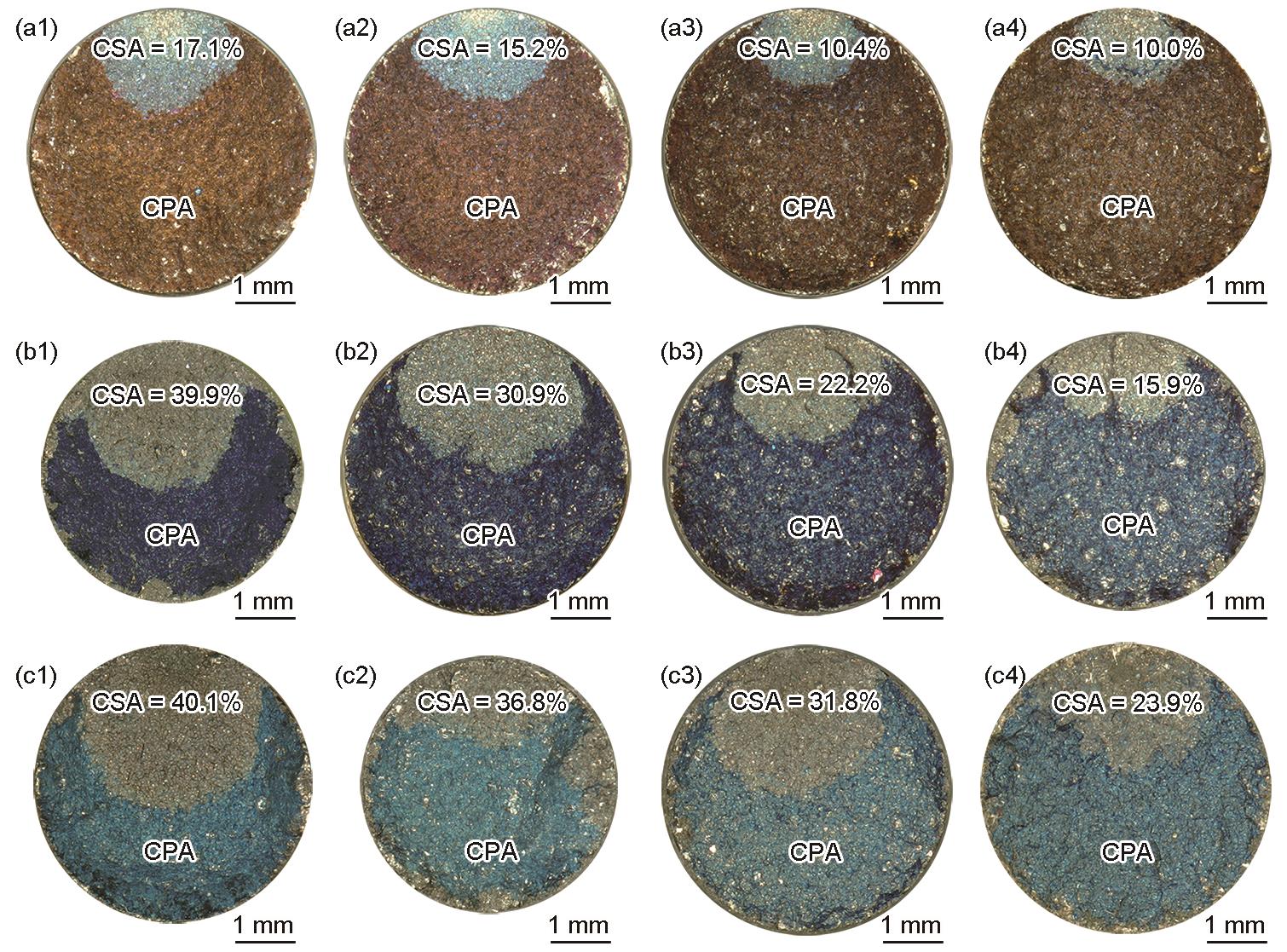

| 图3 不同Hf和Ta含量合金在不同蠕变条件下的断口体视镜照片 |

| Fig.3 Stereoscopic images of the fracture morphologies of the alloys under different creep conditions of 650 oC, 970 MPa (a1-a4),700 oC, 770 MPa (b1-b4), and 750 oC, 580 MPa (c1-c4), showing the area fraction of crack source area (CSA) (CPA—crack propagation area) (a1-c1) 0Hf + 0Ta (a2-c2) 0.5Hf + 0Ta (a3-c3) 0Hf + 2.4Ta (a4-d4) 0.5Hf + 2.4Ta |

|