美国Tesla汽车公司率先布局了大尺寸汽车后地板的一体成形,将传统汽车生产所需冲压焊装的70余个零件,以及1000余次的焊接工序,一次压铸得到成品,大幅提升了车身结构稳定性。我国正稳步推动镁合金一体化压铸技术的发展,如重庆博奥镁铝金属制造有限公司、浙江万丰镁瑞丁新材料科技有限公司等采用中大型压铸机可以稳定生产长1.6 m的大型仪表盘支架,零部件数量从20多个集成为1个。重庆大学国家镁合金材料工程技术研究中心联合镁利信科技股份有限公司、博奥镁铝金属制造有限公司,使用8800T压铸机成功试制了后地板和电池箱盖2类超大型新能源汽车结构件,2个产品的投影面积均超过2.2 m2,是目前世界上最大的镁合金汽车压铸结构件[21]。与铝合金铸件相比,镁合金一体化压铸件减重32%,展现出巨大的轻量化应用前景。力劲集团、海天集团、伊之密股份有限公司等均具备研制和生产超大吨位压铸机的能力。雄厚的产业基础为镁合金一体化压铸产品的大规模生产与应用打下了坚实基础[22,23]。

但是由于镁合金一体化压铸件尺寸大、壁厚薄、几何形状更加复杂,铸造过程中温度分布不平衡,而且熔体高速流动容易卷入气体,在成形过程中容易出现气孔、缩松、热裂、冷隔、变形等各种缺陷,极大地影响了压铸件性能,限制了镁合金一体化压铸在工业上的进一步应用。目前,国内外针对镁合金一体化压铸车身结构的研究刚起步,参考资料较少。本工作在简述压铸镁合金缺陷形成原因和防治措施的基础上,针对孔洞、缺陷带和热裂3种典型压铸缺陷,系统阐述了缺陷特征及其影响因素。围绕大体积熔体处理、高性能压铸镁合金材料开发、压铸工艺优化和压铸结构设计等,概述了镁合金一体化压铸缺陷控制方面的进展和挑战,最后对高性能镁合金一体化压铸缺陷的预测和控制进行了展望,旨在为控制镁合金一体化压铸缺陷提供参考,进一步推动镁合金在大型复杂结构领域的大规模应用,推动汽车轻量化技术的进一步应用和发展,助力一体化压铸技术引领汽车行业变革。

1 镁合金一体化压铸缺陷分类

镁合金一体化压铸技术的节能减排效益明显。在力学性能与免热处理铝合金相媲美甚至更优的情况下,镁合金一体化压铸件相较于铝合金一体化压铸件可以实现超过30%的减重效果。然而,压铸过程中产生的缺陷会恶化铸件性能,限制铸件的使用。

表1从缺陷特征、缺陷产生原因及防治措施等方面简述了镁合金压铸过程中常见的缺陷类型,如压铸过程液态金属充型速率快、流动不稳定、容易卷入气体;压射速率不合理、合金熔体流动性不足等会造成毛刺及欠铸等缺陷;浇注温度、模具温度以及脱模剂的不当使用会造成黏膜及冷隔等缺陷。这些缺陷会导致材料性能恶化,降低材料的可加工性和使用性。

表1 压铸中常见的缺陷类型

Table 1

| Defect | Characteristic | Cause | Prevention measure |

|---|---|---|---|

Gas porosity | Round and oval shape with smooth surface | Gas trapped during die casting process and gas generated by the decomposition of mold release agent | Equipping vacuum system, reasonable selection of process parameters and coating, and control of the amount of spraying |

Adhesion | Strip-shaped scratches along the mold-opening direction on the casting surface | Damaged or rough mold surface, high casting temperature or mold temperature, and bad release agent effect | Repair the damaged part of the mold surface, adjust the balance of the ejector rods, use the release agent with good release effect, and adjust the pouring and mold temperatures |

Cold shut | Irregular sunken linear lines on the casting surface | Poor fluidity of the alloy melt, low filling rate, low pouring temperature, and low mold temperature | Increase the pouring temperature, shorten the filling time, enhance the fluidity of the liquid metal, and improve the injection rate |

Defect band | A band of pores with solute segregation, distributed near the casting surface and some also in the core area | The shear force in the solid-liquid two-phase region causes the fragmentation, remelting, and coalescence of externally solidified crystals. It is difficult for liquid metal to fill at late solidification, resulting in a large number of pores | Increase the shear force, by increasing the injection rate and adjusting the vacuum time, to break externally solidified crystals |

Undercasting | Insufficient filling parts or incomplete casting contour | Poor fluidity, low pouring temperature, low mold temperature, too much involved gas, and poor operation | Optimize the alloy composition and improve pouring and mold temperatures |

Flow mark | Clearly visible, non-directional stripes that differ in color from the metal matrix | Low mold temperature, splashing due to too small cross-section area and inappropriate position of the inner gate, insufficient pressure on the metal, and too much coating | Raise the mold temperature, adjust the cross-sectional area and position of the inner gate, adjust the injection rate and pressure, and use appropriate amount of coating |

Deformation | Overall or partial deformation of the casting | Poor structural design, insufficient casting rigidity due to premature mold opening, uneven force during ejection caused by unreasonable setting of ejector rods | Improve casting structure, adjust mold opening time, reasonably set the number and position of ejector rods, and eliminate mold pulling problem |

Burr | Metal flakes appear on the edge of the parting surface | High injection rate, insufficient locking force, high pouring temperature, and worn and deformed hinge of die casting machine | Check the locking force, correct the mold, clean the cavity and parting surface, and reduce poring temperature and the injection rate |

| Slag inclusion | Irregular impurities on the casting surface and inside the casting | Unclean furnace materials, insufficient alloy purification, unclean casting mold, and slag and oxides brought into melt | Ensure the cleanliness of furnace materials, refine melt, and promptly clean the mold |

Crack | Network-like protrusions or indentations resembling hairs on the casting surface | Cracks on the surface of the mold cavity, high pouring temperature, rough surface of the mold cavity | Select high-quality mold materials, avoid too high pouring temperature, and sufficient and uniform mold preheating |

Drawing die | Difficult to smoothly demold | Insufficient mold surface roughness, carbon deposits and oxidation on the mold surface, improper or insufficient use of lubricants, unreasonable design of mold structure | Spray special coatings, perform surface treatment on the mold surface, select appropriate lubricants, and minimize mold deformation and wear |

2 典型压铸缺陷特征及影响因素

与重力铸造等工艺不同,镁合金压铸缺陷形成过程更为复杂,影响因素更加多变。本节将针对孔洞、缺陷带和热裂3种典型压铸缺陷,围绕缺陷特征及其影响因素等进行概述。

2.1 孔洞

2.1.1 孔洞缺陷特征

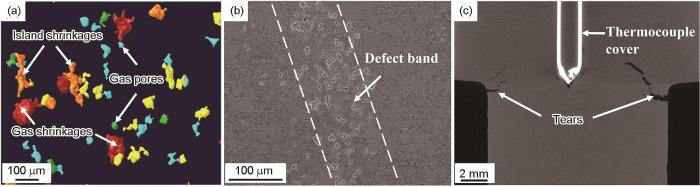

气孔主要包括由卷气现象导致的卷入性气孔和气体溶解度降低导致的析出性气孔。由于压铸时液态金属充型速率快,易产生紊流现象,卷入性气孔更为常见,即使加装真空装置也难以完全消除。气孔尺寸较大,等效直径一般为20~100 µm,其形成和分布受样品厚度、尺寸等因素影响,没有明显规律。

缩松源于镁合金凝固收缩过程中的液体补缩不足,形貌不规则,主要分布在最后凝固区域。液态金属依附于压室内壁优先形核,形成预结晶组织(externally solidified crystals,ESCs),充型阶段的合金由ESCs的半固态熔体所构成,受冷凝固收缩后,晶粒间容易形成空隙。压铸界面换热行为复杂,凝固速率快[27,28];压铸件壁厚较薄,各部位凝固速率接近,液态金属对空隙的补缩难度较大;且内浇口一般先于铸件凝固,阻断了压室与型腔间的液相补缩通道,使得高压补缩阶段的作用时间较短,效果甚微。此外,镁合金易氧化产生氧化薄膜,在液态金属中形成褶皱,成为孔洞缺陷的形核点。因此,熔体内氧化薄膜的分布、尺寸及含量也会影响孔洞缺陷的分布、形貌及数量。

图1

2.1.2 孔洞影响因素

目前主要通过工艺参数优化对孔洞缺陷进行控制。在压铸过程中,浇注压力、浇注速率等工艺参数会显著影响液态金属的流动。而压铸件中孔洞缺陷的形成与充型阶段液态金属的流动、合金的凝固过程等密切相关。增大增压压力可以减少孔洞含量,尤其是大尺寸气孔缺陷;改变浇口速率及浇注温度会影响气孔及缩松缺陷的数量和尺寸。

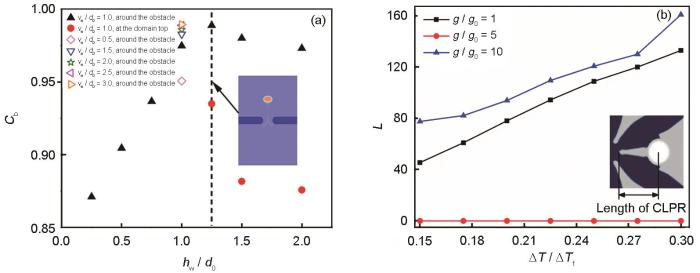

为减少孔洞缺陷,本团队[35~38]通过数值模拟研究了熔体中气泡的动力学行为,并通过在熔体中预设障碍物,对比分析了不同流场参数和障碍物几何参数对气泡动力学的影响,发现气泡形貌与障碍物几何参数密切相关,有着尖角过渡的单边矩形障碍物会使气泡发生最大程度的变形,如图2[35,39]所示。在此基础上,研究人员考虑凝固过程中的组织生长,研究了不同流场作用下的组织特征[40~43]及枝晶-气泡间的相互作用[39,44~46]。Cheng等[39]通过统计分析由枝晶和气泡组成的封闭液相区的长度,评估了孔洞缺陷的形成倾向,发现枝晶臂因气泡碰撞形成扭结结构时,孔洞形成倾向最低。固、液、气多相模拟为减少孔洞缺陷提供了一定的理论指导。

图2

Fig.2

Simulations of bubble dynamics and dendrite-bubble interaction

(a) changes of dimensionless shape parameter Cb with hw / d0 of the obstacle[35] (Cb—revised Blaschke coefficient, hw—dimensionless horizontal interval width, d0—dimensionless bubble diameter, vw—dimensionless vertical obstacle width; inset shows the rising bubble in the bilateral arc obstacle cases)(b) changes of the length (L, mesh in unit) of the closed liquid phase region (CLPR) with the dimensionless undercooling (ΔT / ΔTf)[39] (ΔTf—undercooling, K; ΔTf—the freezing temperature range, K; g—given gravita-tional acceleration, m/s2; g0—gravitational acceleration benchmark, m/s2; inset shows the definition of the length CLPR)

2.2 缺陷带

2.2.1 缺陷带特征

基于压室预结晶理论可以基本解释单缺陷带的形成原因[50]:在充型凝固过程中,ESCs向中心聚拢,并从中心向表层逐渐凝固;而由于金属液和模具之间存在温度梯度,金属液也会从表层向中心进行凝固。在这2个凝固前沿相遇的区域,由于凝固收缩未能得到有效补缩,导致在压铸件内部形成沿截面轮廓分布的带状组织。

2.2.2 缺陷带影响因素

缺陷带的形成和分布与压铸工艺参数密切相关。压铸速率会改变金属液的流动形态,影响ESCs含量,进而影响缺陷带宽度。随着压射低速速率的提高,铸件中的缺陷带愈加靠近中心区域,其宽度逐渐减小,内部孔洞更加聚集;压射高速速率越大,ESCs组织分布愈弥散,缺陷带愈向心部靠拢;当无高速压射速率时,铸件中会出现双缺陷带[47]。增压压力可以改变金属液的供料能力,从而影响压铸件的补缩能力[56]。施加高真空辅助系统后,熔体流动能力加大,缺陷带宽度减小[57]。此外,不同部位的缺陷带分布具有明显差异。在铸件近浇口端和近溢流槽端,缺陷带的分布与铸件外轮廓关联度较小,而与金属液的液流轮廓一致;在铸件中部,缺陷带的分布与铸件外轮廓及金属液的液流轮廓一致。

在一体化压铸过程中,更大的模具结构、复杂的金属液流动会使压铸件凝固不均匀,容易出现孔洞、偏析等缺陷,影响缺陷带的形貌和分布,进而影响压铸件的整体性能和合格率。相较于铸造压力,压铸速率对缺陷带位置、宽度及其内部孔洞形貌的影响更明显。除此之外,内浇口的形状及位置也会影响金属液的流动形态,进而影响缺陷带的形成和分布。

2.3 热裂

2.3.1 热裂缺陷特征

2.3.2 热裂影响因素

镁合金热裂倾向受合金成分、铸造工艺、模具结构等因素影响。合金成分直接影响合金的收缩应力、凝固温度区间、共晶反应前的液相占比等。改变合金成分会改变合金的凝固路径,影响脆弱温度区间和合金的第二相分布,最终影响凝固末期残余液相的占比。如向Mg-4Zn-0.3Zr合金中添加Ca元素,当添加量为2.0% (质量分数,下同)时,会在晶界处形成脆性富钙相,削弱基体合金的高温强度,降低合金的抗凝固收缩应力,增加合金的热裂倾向[60];在Mg-1Ca合金中添加0.6%Sr时,会形成大量宽片层状共晶,并缩短脆弱温度区间,降低合金的热裂倾向[61];在Mg-6Zn-1Cu-0.6Zr合金中添加Y元素时,不仅晶粒细化效果显著,补缩通道还会被优化,最终提升了合金的抗热裂能力[62]。

铸造工艺,如浇注温度、模具温度等,会显著影响液态金属的流动性,进而影响合金的热裂倾向。过高的浇注温度会促进第二相的析出,并粗化晶粒,削弱凝固后期残余液相的补缩效果,增加了合金的热裂倾向[63]。但若适当提升模具的预热温度,可有效提升合金的抗热裂能力,如在Mg-2Ca-xZn合金中,当模具温度从250 ℃提升至450 ℃后,合金凝固收缩应变减小,抗热裂倾向增大[64]。然而,在实际生产中,工艺参数的可选范围较窄,因此该方法需结合实际生产条件进行考量。模具结构设计以及铸件结构优化也是控制铸件热裂倾向的重要手段。模具结构主要影响浇注系统的退让性,其通常与合金的补缩性相关。在模具设计阶段,不仅应避免过多的热节点,还应防止铸件在截面变化处或厚薄不均处出现收缩受阻现象,以避免限制性收缩结构的出现。

热裂还与孔洞、氧化夹杂等缺陷相互影响。孔洞缺陷容易在铸件内部形成应力集中,这些应力集中会在冷却过程中诱发或加剧热裂的形成。孔洞缺陷还会削弱铸件的整体强度,在相同热应力作用力下,更易产生裂纹。因此,孔洞越多、尺寸越大,铸件内部的应力分布越不均匀,形成热裂的风险就越高。氧化夹杂通常会导致材料局部的性能不均匀,引起局部应力增大。应力集中使得存在氧化夹杂的区域在冷却阶段更易出现裂纹,增加热裂形成的风险。氧化夹杂处的金属与基体金属的黏结力较弱,甚至存在微小的间隙,这些弱黏结区在应力作用下极有可能扩展成明显的裂纹,加速热裂的形成。

2.4 缺陷对合金性能的影响

压铸缺陷会导致合金性能明显恶化,主要体现在降低合金的强度和耐腐蚀性能,影响合金的使用寿命、安全性和外观质量,降低合金的美观度和市场竞争力等。

缺陷带部位一般存在大量聚集的孔洞,在试样断裂过程中起2方面作用,一是降低有效受力面积,促使裂纹的起源及扩展;二是聚集的孔洞可能作为裂纹源,裂纹向试样表层及中心扩展,导致试样断裂。在无缺陷带的试样中,裂纹主要萌生于尺寸较大的孔洞处。而在含有缺陷带的试样中,裂纹的起源则与缺陷带中ESCs的含量和尺寸有关。当ESCs尺寸较小且含量较少时,与无缺陷带试样类似,缺陷带内组织较为致密,缺陷带内部的孔洞主要作用是减少试样有效受力面积;当ESCs尺寸较大且含量较多时,缺陷带中的孔洞较大且形貌复杂,显微组织较为粗大,孔洞会作为裂纹萌生起点并随之进行扩展。如在压铸低速速率较低时,ESCs增多且尺寸增大,枝晶化现象更为显著,缺陷带中的孔洞数量增多且尺寸增大,裂纹在缺陷带及非缺陷带处尺寸较大的孔洞处同时萌生;随着拉伸应力的增加,这2个裂纹相向扩展,最终相互连接导致试样断裂。

为构建孔洞缺陷与力学性能之间的关系模型,需引入多项参数(包括孔洞面积分数、孔洞平均体积分数、断面孔洞面积分数、断面最大孔面积分数等)以量化孔洞缺陷含量,相应的预测模型包括经验公式[69]、临界应变模型[70]等。Zhou等[71]发现孔洞含量处于较低水平时,其对合金抗拉强度的负面影响较缓和;然而,当孔洞缺陷含量较高时,合金性能则出现明显的下降;基于经验公式实现了对压铸试样力学性能的预测,但该经验公式是否可以直接推广到更广泛的镁合金体系中仍需进一步验证。在临界应变模型中,通过将所有孔洞缺陷等效为一个具有相同面积的孔洞缺陷,考虑应变强化作用,建立了真实抗拉强度与断面孔洞面积分数的定量关系,但该模型更加适用于试样中含有规整形貌(如气孔)且三维体积较小的孔洞缺陷[72]。

在实际一体化压铸过程中,铸件内孔洞缺陷分布随机,形貌、尺寸差异显著,且孔洞缺陷与热裂、氧化夹杂等缺陷间存在相互作用。因此,未来还需深入探索孔洞缺陷的形貌特征和分布规律,并考虑镁合金一体化压铸件内不同类型缺陷间的相互作用机制。在此基础上,进一步深化对孔洞缺陷与试样力学性能间关系的理解,从而提高模型预测压铸镁合金力学性能的准确性。

3 一体化压铸镁合金铸件缺陷控制

当前,镁合金一体化压铸件主要应用于汽车和新能源汽车等领域中,具体应用于电池包壳体、汽车后地板和后掀背门等部件。这些铸件结构复杂、尺寸大,金属液在大型模具内流程长、不平稳,导致铸件容易产生气孔、缩松、热裂等缺陷,严重影响铸件品质。本节从熔体处理、合金开发、工艺优化和结构设计等方面简述如何开发低缺陷、高质量镁合金一体化压铸件。

3.1 大体积高质量镁合金熔体处理

镁合金一体化压铸件轮廓尺寸大、总浇注量大、熔体处理量大、处理时间长,熔体纯净化若不达标,铸件容易产生各种严重缺陷。因此,需开发大体积镁合金熔体纯净化技术以提高熔体质量。

Mg元素化学性质活泼,易形成MgO等夹杂,净化难度较大;当前熔炼工艺中镁合金均与铁质工具接触,由此引发的电偶腐蚀严重恶化了其耐腐蚀性能[73]。因此,在研究和生产过程中,需去除氧化物夹杂及Fe杂质等,以改善镁合金纯净度,进而提高镁合金的品质与使用性能。目前,镁合金熔体纯净化技术在国内外均已取得重要进展。依据是否使用熔剂,该技术可分为熔剂法和无熔剂法2大类。

熔剂法通过向镁熔体中添加熔剂,实现夹杂物的完全润湿和团聚,进而与熔剂结合成大颗粒并沉积在坩埚底部,以此有效去除镁熔体中的各类金属和非金属夹杂物。熔剂主要包含氯盐和氟盐,其主要成分为MgCl2。然而,由于环境污染、助焊剂夹杂物和金属损失,这种精炼方法在工业应用中受到一定限制[74]。

无熔剂法包括静置法、吹气法、过滤法等。静置法是利用镁熔体与夹杂物之间的密度差,当熔体在高温静置时,2者将自动分离,静置法一般需与熔剂法结合使用。吹气法是向镁熔体中通入惰性气体,气体分散成多个细小气泡后,在搅拌过程中将润湿黏附轻质夹杂物,并在气泡上浮过程中将轻质夹杂物带到熔体表面,然后经打渣工序去除。工艺参数对脱气效果具有显著影响,具体而言,当注入气体压力过高、气泡上升速率过快时,气泡与熔体之间的接触时间会相应减小,气体逸出时会损坏熔体表面保护膜,导致脱气效果降低。目前,各参数的最优取值范围尚未确定,仍需进一步研究[75]。

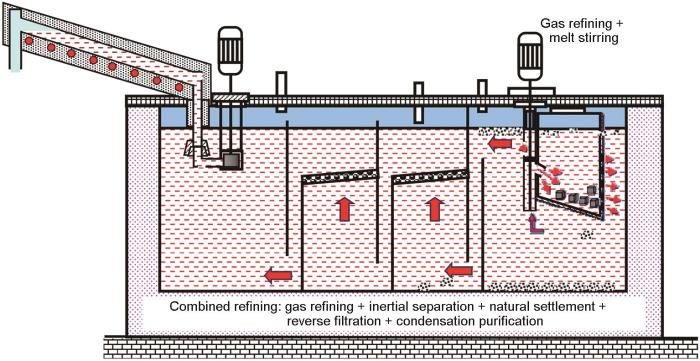

过滤法是使熔体通过由中性或活性材料制造的多孔过滤器,以分离悬浮在熔体中的固态夹杂物的净化方法。过滤器长期使用后极易发生堵塞,导致过滤效率降低,因此需要经常清洗或更换过滤器以保证过滤效果。针对过滤法的缺陷,本团队开发了镁熔体非陶瓷介质反重力过滤技术,解决了传统方法无法连续净化熔体的国际难题,镁合金中Fe杂质含量降至5 × 10-6,过滤介质寿命提高20倍以上。熔体的逆向流动将固态夹杂物分离思路从传统的“截留”调整为“阻挡”,被阻挡的夹杂物将聚集而自然沉降到过滤板的下方,使过滤板不易被堵塞进而具备自净化效果。为提高过滤效率,设计了多级逆向过滤装置,使镁合金熔体逐次通过孔径逐渐减小的过滤孔板,实现逐级过滤从而有效净化夹杂物。通过集气体精炼、自然沉降、惯性分离、过滤净化、凝析降铁技术为一体,实现了镁熔体无熔剂连续纯净化,如图3[76]所示。首创的镁合金熔体绿色纯净化技术及其配套装备为提高大体积镁熔体的净化效率开辟了新的途径,在国内外镁合金生产企业中得到了广泛的推广和应用。

图3

近年来,出现许多复合净化新方法,例如低压脉冲电磁技术、超声波Ar气净化技术等[76]。多种精炼方法的组合可以克服单一精炼方法的局限性,实现优势互补,为进一步提高大体积镁熔体的净化效率提供了契机。

3.2 高性能镁合金材料开发

镁合金一体化压铸件充型距离长,熔体凝固速率快,常用镁合金的铸造流动性难以满足一体化压铸工艺的要求,铸件易产生浇不足、冷隔等缺陷。除良好的流动性外,一体化压铸还要求镁合金具备良好的铸造性能和高强韧性,以满足车用结构件的安全要求。目前应用最为广泛的压铸镁合金系是Mg-Al系,包括Mg-Al-Zn、Mg-Al-Mn、Mg-Al-Si和Mg-Al-RE系等,典型商用牌号有AM50、AM60和AZ91等[77]。Al元素对镁合金的铸造性能有积极影响,而RE元素则有利于提高镁合金的强度和高温性能。在此基础上,通常还会添加Ca、Sr、Sn等元素[78~81],以优化合金性能。目前,适用于压铸工艺的Mg-RE系合金处于研发阶段[82],由于受成本因素制约,该类合金尚未在汽车领域实现应用。

近几年新开发的Mg-Al系压铸镁合金中,力学性能较好的有AX73[83]、AXT710[84] (X:Ca,T:Sn)等,如AXT710镁合金的抗拉强度、屈服强度和延伸率分别达到了258 MPa、188 MPa和10.2%,微量Sn元素在其中起到了固溶强化、第二相强化和细晶强化作用。Mg-Al-RE系合金中,具有优异综合力学性的代表性商用镁合金是AE44,该合金力学性能优异且高温抗蠕变能力强。Yang等[85]从降低AE44成本角度出发,通过Ca元素代替部分RE元素制备了AEX422压铸镁合金,发现屈服强度大幅度提升,达到了204 MPa,但延伸率却降至4%,抗拉强度亦有所下降。若采用价格相对低廉的La或Sm等稀土元素替代AE44镁合金中的天然混合RE元素,可进一步改善合金性能,如ALa43-2Sm合金抗拉和屈服强度分别达到266和170 MPa,延伸率达到11.2%[86]。添加合金元素可以有效调控第二相的形态及分布,从而提高合金性能。但通过添加合金元素进而优化合金性能需满足如下条件:添加合金元素后形成的金属化合物不能损害基体的延展性;其熔点要高于变质处理后的第二相;与第二相之间要存在良好的晶体学匹配关系,以确保实现第二相的变质处理及均匀化。

镁合金的流动性与熔体黏度密切相关,而黏度大小除了与合金熔体成分有关外,还与熔体中夹杂物的含量及形态有关。RE元素一方面可以通过净化熔体、减小凝固温度区间等提高合金流动性;一方面又会造成晶粒粗化、形成Al-RE等第二相使黏度增加而降低熔体流动性。当不同影响因素占主导时,熔体流动性展现出不同的结果,如本团队发现在AZ91中加入RE元素后,合金流动性排序为:AZ91 > AZ91 + Y > AZ91 + La > AZ91 + Ce;在AM60中加入微合金化元素后,合金流动性排序为:AM60 + La > AM60 + Mn > AM60 + Ce > AM60。樊晓泽等[75]发现La/Ce混合稀土元素可以提高AZ91压铸合金熔体流动性,若进行精炼降低夹杂物,合金流动性进一步提高约10.0%。李潇[87]发现在压铸Mg-4.2Al-4Ce合金中,当用1%的La或Nd元素部分替换Ce元素时,熔体流动性会降低;若添加0.3%Bi元素,熔体流动长度增大约2.4%;但若添加0.3%的Sn或Ca元素,熔体流动性会降低。

合金流动性与原子集团间的结合力及熔体的有序结构密切相关。一般认为,当原子集团变小时,相邻原子成键概率变小,系统中的原子排列密集程度减小,有序结构减少(即熔体有序度减小,无序度增大),原子集团之间的内摩擦力减小,因此熔体黏度变小,流动性变好。本团队发现,Ca、Sr等快扩散元素可以改变第二相的形成过程,影响镁合金熔体中原子间的结合能力,降低熔体的黏度,进而极大地提高合金的流动性。通过调控熔体结构以改变熔体黏度,为高流动性压铸镁合金的开发提供了新的思路。鉴于压铸工艺中ESCs等组织结构的存在,开发高流动性压铸镁合金时还应考虑金属液流动过程中Magnus效应对熔体流动行为的影响[88]。

3.3 压铸工艺参数优化

压铸工艺参数是影响压铸过程的重要因素,包括压射速率、压射比压、浇注温度、模具温度等。压射速率直接影响合金的充模时间和液态金属的流动速率。压铸速率过低可能导致浇不足,过高则可能导致液态金属在填充时产生喷溅,甚至在内浇口的位置产生雾化,使液体发生翻卷,在内部造成卷气。压射比压通常由铸件强度或铸件壁厚决定,对于强度要求高的铸件,为确保其良好的致密度,需要采用高压射比压。提高浇注温度有助于增强合金熔体流动性,优化铸件表面质量,但会导致更大的收缩率及模具寿命的降低。反之,浇注温度太低则会造成冷隔等缺陷。为了防止熔融金属的过度激冷,浇注温度和模具温度均应控制在合理的区间内。此外,为避免模具因激热而张裂,应缩小模具的冷热交变温差以延长其寿命。

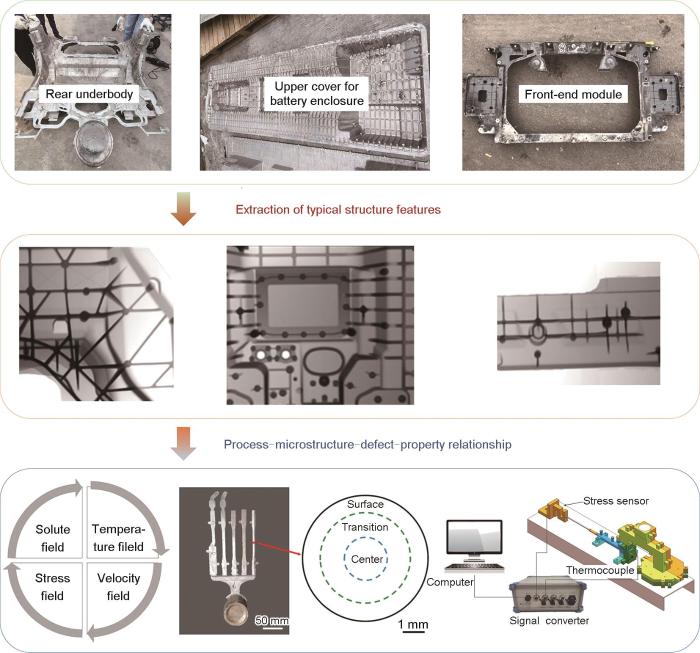

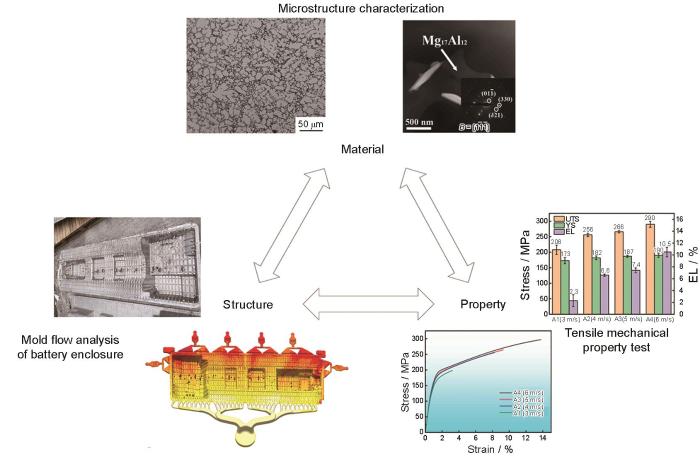

鉴于镁合金一体化压铸件尺寸较大,为优化压铸工艺参数,可依据实际应用需求,提取其典型结构特征进行分析,如图4所示。构建与镁合金一体化压铸件关键局部结构相似且凝固环境相同的小型特征样件,开展特征试件压铸实验,研究压铸充型过程中流场、温度场、应力场的演变特征,研究不同压铸工艺参数下的微观组织、缺陷和力学性能,分析各缺陷的分布特征和形成规律。将数值模拟与铸造实验相结合,建立特征试件的压铸工艺参数-组织-缺陷-性能之间的关系,提出压铸缺陷与性能调控措施,为从整体和宏观上控制镁合金一体化压铸缺陷提供理论依据和工艺指导,实现“局部”与“整体”的有机协同。

图4

图4

基于典型结构特征的“局部”-“整体”协同设计

Fig.4

“Partial”-“whole” collaborative design based on typical structural features

在特征试件研究基础上,首先采用工艺仿真研究大型一体化压铸件材料特性-结构参数-工艺参数与温度场、应力场、缺陷的对应关系,初步优化得到模具结构、浇注系统和压铸工艺参数等。然后开展镁合金一体化压铸实验,分析镁合金一体化压铸件典型部位的组织、缺陷、几何尺寸精度特征,结合溶质场、温度场和应力场数值模拟,揭示铸件组织和缺陷的形成机制,获得镁合金一体化压铸件的缺陷控制准则,建立工艺参数-组织缺陷特征-综合性能之间的映射关系,实现外形、组织、缺陷和性能的有效调控和大型复杂镁合金一体化压铸件的高效制备。

3.4 结构优化设计

在结构设计方面,一体化镁合金铸件展现出空间跨度大、几何结构复杂、热节点多、壁薄且厚度不均匀等特点,易导致服役应力分布复杂;铸件充型顺序复杂、流动距离长、冷却不均匀,加之铸件不同部位对材料强度、塑性要求不同,若直接沿用现有复杂铸件的空间结构、模具和浇注系统设计,易引发缺陷增多、铸件性能不达标等问题。因此,在大型镁合金一体化铸件设计及制备过程中,需要对镁合金零部件进行再设计,在深入揭示镁合金压铸缺陷控制方法和充分掌握大型铸件铸造要求的基础上,将铸件空间结构、模具和浇注系统与材料综合性能充分结合,从镁合金的材料特性和工艺特性出发,开展大型一体化压铸镁合金产品模具参数设计、过程仿真和结构优化等,实现大型铸件材料-结构-性能一体化设计,如图5所示。

图5

图5

材料-结构-性能一体化优化设计

Fig.5

Optimization designs of material-structure-property integration (UTS—utimate tensile strength, YS—yield strength, EL—elongation)

在进行结构设计时,需充分考虑型腔的数量、尺寸、壁厚以及分型面的位置,以确保产品外观、质量、成本和生产周期等符合要求,如压铸模具上必须有排气槽和溢流槽,避免加工过程中产生气蚀、缩松等缺陷,并排除混有气体和被残余涂料、润滑剂污染的前端冷凝金属液,保证铸件质量,延长压铸模使用寿命;需根据产品结构特点和铸件质量要求,优化浇口位置和浇口尺寸,并对模具结构进行合理设计;压铸模结构需保证精度和刚度,避免出现变形等。

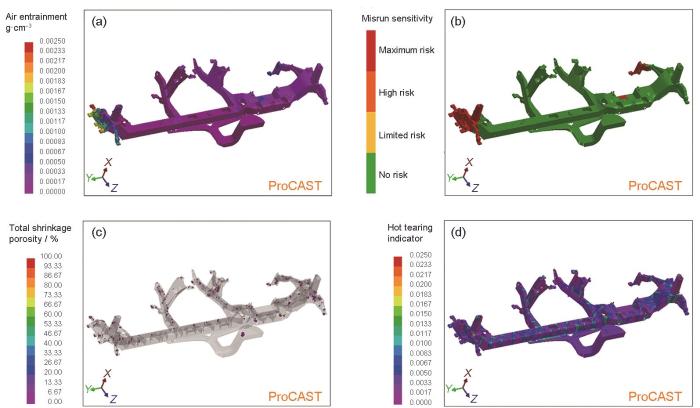

在对镁合金零部件进行设计时,可以采用数值模拟软件进行零部件结构的初步设计,再通过计算机辅助工程(computer aided engineering,CAE)分析和工艺分析优化结构[91]。以汽车仪表盘支架为例,由于结构优化和轻量化减重,仪表盘支架背部区域设计了结构加强筋,薄厚相接区域较多且壁厚不均匀。通过模流分析,发现镁合金仪表盘支架在压铸过程中2侧远端区域存在卷气和浇不足问题,缩孔主要在仪表盘支架的远端区域和厚大区域,如图6所示。这些区域存在孤立液相区,金属液无法及时补充,薄厚相接区域和圆角过渡区域存在应力集中,容易产生热裂。为此,设计时需进一步优化结构,尽可能避免极大圆角及曲面的造型设计,使壁厚分布更加均匀,以减少容易产生缺陷的区域,提高铸件质量。

图6

图6

镁合金仪表盘支架压铸缺陷模拟预测

Fig.6

Simulations and predictions of die-casting defects of magnesium alloy dashboard bracket

(a) air entrainment

(b) misrun sensitivity

(c) total shrinkage porosity

(d) hot tearing indicator

4 结论和展望

镁合金一体化压铸技术通过将多构件生产、多构件连接的复杂工艺集成于一体,极大地节约了时间成本和生产制造成本,在汽车轻量化方面具有巨大的潜力。本工作综述了镁合金一体化压铸中的孔洞、缺陷带和热裂等典型缺陷的特征及影响因素,并从熔体处理、合金开发、工艺优化和结构设计等角度探讨了缺陷的控制措施。面对一体化压铸中的各种缺陷,应在深入分析各种缺陷的形成原因、分布特征及影响因素的基础上,结合热动力学计算、模流分析、压铸试验等,建立压铸工艺参数-组织-缺陷-性能之间的关系,并搭配大体积、高质量熔体处理技术和成熟的压铸工艺参数及合理的模具结构,以降低或消除缺陷对构件性能的影响,进而助力大尺寸镁合金一体化压铸件的高质量生产。镁合金一体化压铸缺陷控制方法的发展将为各类大型零部件的一体化生产提供借鉴和指导,为颠覆汽车及相关行业的传统生产制造模式提供可能。

随着工业数字化、智能化的进程不断加快,基于数据驱动的缺陷智能检测、智能系统优化和智能制造等也为压铸缺陷的检测和控制提供了新的思路和方法。在面临一体化铸件各部位铸造条件不均匀、铸造参数与铸件质量映射关系复杂等问题时,基于机器学习的缺陷目标检测等智能算法可以有效提升缺陷的检测精度和准确率。此外,大型、智能化压铸单元的研发和使用将进一步提升铸件的质量与生产效率,相应高端压铸产品带来的更高要求也将进一步刺激镁合金一体化压铸技术的发展,推动镁合金在大型复杂结构领域的进一步大规模应用,加速汽车等领域轻量化目标的实现,助推压铸行业不断螺旋上升。

参考文献

Development and application of plastic processing technologies of magnesium alloys

[J].

镁合金塑性加工技术发展及应用

[J].我国是世界上镁资源最为丰富的国家,镁及镁合金具有质轻、比强度高、阻尼减振、电磁屏蔽性能优良、储能特性好等优点,是最有潜力的轻量化材料之一,其推广应用对节能减排和能源转型战略具有重要意义。但镁合金具有密排六方晶体结构,塑性变形能力较差。如何改善镁合金的塑性变形能力是扩大镁合金应用的瓶颈问题之一。本文综述了10多年来,世界各国在改善镁合金塑性、提升镁合金塑性变形能力等方面所做的大量工作,及在镁合金塑性加工技术等方面取得的重要进展。发展了“固溶强化增塑”新型镁合金设计理论和“熔体变温自纯化”等关键制备技术,形成了一批高塑性变形镁合金材料和牌号,其中杂质Fe含量可降到10 × 10<sup>-6</sup>以下,超高塑性镁合金延伸率可达到60%以上,超高强度(抗拉强度大于550 MPa)镁合金延伸率可以达到10%以上;开发了非对称挤压、非对称轧制、非对称改性、往复循环多道次镦挤开坯技术、扩收控制大比率锻造技术、挤锻复合成形技术等一批镁合金新型塑性加工技术。这些合金和技术使变形镁合金基面织构显著弱化,明显提高了变形镁合金板材、管型材和锻件的塑性成形能力和制品质量,产品成本大幅度降低,在板材、管型材和锻件制备加工中实现了成功应用。

Research advances of magnesium and magnesium alloys worldwide in 2022

[J].

Recent advances of high strength Mg-RE alloys: Alloy development, forming and application

[J].

Recent advances in micro-alloyed wrought magnesium alloys: Theory and design

[J].

Research advances of magnesium and magnesium alloys worldwide in 2021

[J].

One developed finite element model used in nano-layered flaky Ti2AlC MAX ceramic particles reinforced magnesium composite

[J].

Optimizing mechanical properties of magnesium alloys by philosophy of thermo-kinetic synergy: Review and outlook

[J].

Recent developments in high-pressure die-cast magnesium alloys for automotive and future applications

[J].

Recent research and development on forming for large magnesium alloy components with high mechanical properties

[J].

Development and application of magnesium alloy parts for automotive OEMs: A review

[J].

Magnesium research and applications: Past, present and future

[J].

Applications of magnesium alloys for aerospace: A review

[J].

Magnesium casting technology for structural applications

[J].

A review of magnesium die-castings for closure applications

[J].Vehicle mass reduction in the automotive industry has become an industry-wide objective. Increasing fuel efficiency and greenhouse gas emission targets for engine-powered vehicles, and ambitions for extended range electric vehicles have motivated these reductions in vehicle mass. Mass reduction opportunities in structural automotive applications are increasingly realized through lightweight alloy castings, such as magnesium, primarily due to the ease of component substitution. The traditional benefits of magnesium die-castings including lightweighting and associated compounded mass savings, excellent strength-to-weight ratio, part consolidation, near net-shape forming, dimensional repeatability, and integration of additional components can be realized in closure applications. One recent example is the application of a magnesium die-casting for the structural inner of the liftgate in the 2017 Chrysler Pacifica, replacing nine parts in the previous generation and resulting in a liftgate assembly weight reduction of nearly 50%. The work presented here reviews past and current developments of magnesium die-castings in closure applications and discusses the benefits and challenges of magnesium alloys for these applications, including casting design, corrosion and fastening strategies, and the manufacturing design and assembly methodologies. (C) 2019 Published by Elsevier B.V. on behalf of Chongqing University.

Characterization on the formation of porosity and tensile properties prediction in die casting Mg alloys

[J].

On the deformation behavior of heterogeneous microstructure and its effect on the mechanical properties of die cast AZ91D magnesium alloy

[J].

Re-evaluation of the mechanical properties and creep resistance of commercial magnesium die-casting alloy AE44

[J].

The role and significance of Magnesium in modern day research-A review

[J].

Transformation and development of subverting traditional automotive manufacturing model

[J].

颠覆传统汽车制造模式的变革发展

[J].

Integrated die casting promotes the innovation and development of aluminum alloy materials

[J].

一体化压铸促进铝合金材料创新与发展

[J].

Progress and prospects in Mg-alloy super-sized high pressure die casting for automotive structural components

[J].

Large die-casting die is the key technology to realize integrated die-casting

[J].

大型压铸模是实现一体化压铸的关键技术

[J].

“Jin” precedes “opportunity” leading the new era of die casting

[J].

“劲”占先“机”引领压铸新时代

[J].

Recent advances in numerical simulation of solidification process in cast magnesium alloys

[J].

铸造镁合金凝固过程数值模拟研究进展

[J].

Phase-field modeling of microstructure and gas porosity evolution during solidification of alloys: A review

[J].

合金凝固组织和气孔演变相场模拟研究进展

[J].

Multi-physical phase-field modeling of microstructure and hydrogen porosity evolution during solidification of aluminum alloys

[D].

铝合金多物理场凝固组织和氢气孔演变的相场建模研究

[D].

Characterization and modeling study on interfacial heat transfer behavior and solidified microstructure of die cast magnesium alloys

[J].

镁合金压铸过程界面传热行为及凝固组织结构的表征与模拟研究

[J].本文系统介绍了镁合金压铸界面换热行为以及凝固微观组织结构的实验表征及计算模拟方面的研究进展,包括:(1) 一种基于换热系数的边界设定模型,由此发现了压铸界面换热系数可以分为初始升高、高值维持、快速下降及低值保持4个阶段;(2) 压室预结晶流动分布预测模型,据此得到了压室预结晶组织的主要分布规律及其对镁合金铸件缺陷带形成的影响;(3) 考虑压室预结晶组织的压铸镁合金形核模型及生长模型;(4) 结合离异共晶形核及生长机制建立的镁合金压铸工艺条件下微观组织演变的数学模型;(5) 镁合金枝晶组织的三维形貌和生长取向的研究,发现镁合金枝晶组织呈现十八个分支的形貌特征,分别沿着基面的112?0>方向和非基面的112?3>方向生长,由此建立了镁合金枝晶各向异性的生长模型,实现了镁合金枝晶组织的三维模拟研究。

A study of metal/die interfacial heat transfer behavior of vacuum die cast pure copper

[J].

Fast shot speed induced microstructure and mechanical property evolution of high pressure die casting Mg-Al-Zn-RE alloys

[J].

2D and 3D characterization of pore defects in die cast AM60

[J].

Correlation between porosity and fracture mechanism in high pressure die casting of AM60B alloy

[J].X-ray tomography was used to characterize the porosity in high pressure die casting of AM60B alloy. <em>In situ</em> tensile deformation was performed to observe the change of porosities and their influences on crack initiation, propagation and subsequent fracture of specimen. Results showed that four types of porosities, including gas-shrinkage pore, gas pore, net-shrinkage and island-shrinkage, could be identified according to the formation mechanism and morphology characterization. During tensile deformation, it was shown that the gas-shrinkage pore and net-shrinkage, rather than gas pore or island-shrinkage, were the main sources for crack initiation. In addition, the crack propagated by interconnecting the porosities at the cross section with minimum efficient force bearing area. At these locations where externally solidified crystals (ESCs) were present, the crack would propagate along the ESC boundaries in an inter-granular mode, while at these locations without ESCs, the crack would propagate roughly along the direction perpendicular to the tensile stress in a combination of trans-granular and inter-granular modes.

Correlation of 3D defect-band morphologies and mechanical properties in high pressure die casting magnesium alloy

[J].

Comparison on hot tearing behavior of binary Mg-Al, Mg-Y, Mg-Gd, Mg-Zn, and Mg-Ca alloys

[J].

Shrinkage porosity in thin walled AM60 HPDC magnesium alloy U-shaped box

[J].

Investigation of bubble dynamics in a micro-channel with obstacles using a conservative phase-field lattice Boltzmann method

[J].

Three-dimensional phase-field lattice-Boltzmann simulations of a rising bubble interacting with obstacles: Shape quantification and parameter dependence

[J].

Three-dimensional numerical simulation of bubble rising in viscous liquids: A conservative phase-field lattice-Boltzmann study

[J].

Conservative phase-field method with a parallel and adaptive-mesh-refinement technique for interface tracking

[J].

Interaction between growing dendrite and rising bubble under convection

[J].

Solution to multiscale and multiphysics problems: A phase-field study of fully coupled thermal-solute-convection dendrite growth

[J].

Dendritic growth under natural and forced convection in Al-Cu alloys: From equiaxed to columnar dendrites and from 2D to 3D phase-field simulations

[J].

Phase-field-lattice Boltzmann study for lamellar eutectic growth in a natural convection melt

[J].

Numerical investigation of eutectic growth dynamics under convection by 3D phase-field method

[J].

Multiphase and multiphysics modeling of dendrite growth and gas porosity evolution during solidification

[J].

Phase-field modeling of microstructure evolution in the presence of bubble during solidification

[J].

Multiphase-field modelling of hydrogen pore evolution during alloy solidification

[J].

Microstructure characteristics and formation mechanism of defect band in die cast magnesium alloy

[J].

压铸镁合金缺陷带的组织特征及形成机理

[J].研究了压铸镁合金缺陷带的组织形貌及分布特征,建立缺陷带与压室预结晶(ESCs)、气缩孔及压铸工艺参数之间的对应关系,在此基础上探讨了缺陷带的形成及演化机理。结果表明,压铸镁合金截面凝固组织以缺陷带为界可划分为3个有明显组织特征差异的区域。随着压铸低速速度提高,镁合金凝固组织中ESCs含量逐渐降低,而缺陷带组织愈加明显并向压铸件中心靠拢,缺陷带宽度减小,其内部孔洞更加聚集;高速速度越大,压铸镁合金凝固组织中ESCs越分散,缺陷带向压铸件中心靠拢,压铸在无高速速度情况下,镁合金凝固组织横截面出现双缺陷带现象。压铸充型过程中金属液流的形态决定了缺陷带的分布位置和发展趋势,在高速金属液的剧烈冲刷及增压压力的作用下,靠近金属液流外轮廓的晶粒发生破碎或转动,在晶粒间形成大于剩余金属液体积的间隙,随着凝固的进行,形成沿液流轮廓分布孔洞聚集的缺陷带组织。

Dilatant shear bands in solidifying metals

[J].

Influence of melt flow on the formation of defect band in high pressure die casting of AZ91D magnesium alloy

[J].

Development of the as-cast microstructure in magnesium-aluminium alloys

[J].

The influence of al content and thickness on the microstructure and tensile properties in high-pressure die cast magnesium alloys

[J].

The skin effect and the yielding behavior of cold chamber high pressure die cast Mg-Al alloys

[J].

Characterization of the grain structures in vacuum-assist high-pressure die casting AM60B alloy

[J].

Characteristics and formation mechanisms of defect bands in vacuum-assisted high-pressure die casting AE44 alloy

[J].

The thickness of defect bands in high-pressure die castings

[J].

The effect of different high pressure die casting parameters on 3D microstructure and mechanical properties of AE44 magnesium alloy

[J].

Effect of different casting techniques on the microstructure and mechanical properties of AE44-2 magnesium alloy

[J].

Influence of alloying elements on hot tearing susceptibility of Mg-Zn alloys based on thermodynamic calculation and experimental

[J].

Effect of Al content on hot-tearing susceptibility of Mg-10Zn-xAl alloys

[J].

Effect of Ca content on hot tearing susceptibility of Mg-4Zn-xCa-0.3Zr (x = 0.5, 1, 1.5, 2) alloys

[J].

Optimized hot tearing resistance of VW63K magnesium alloy

[J].

Effect of Yttrium on hot tearing susceptibility of Mg-6Zn-1Cu-0.6Zr alloys

[J].

Effect of pouring and mold temperatures on hot tearing susceptibility of WE43 magnesium alloy

[J].

Hot tearing characteristics of Mg-2Ca-xZn alloys

[J].

The ductility variation of high-pressure die-cast AE44 alloy: The role of inhomogeneous microstructure

[J].

Porosity quantification for ductility prediction in high pressure die casting AM60 alloy using 3D X-ray tomography

[J].

Improved mechanical properties in vacuum-assist high-pressure die casting of AZ91D alloy

[J].

The effect of slow shot speed and casting pressure on the 3D microstructure of high pressure die casting AE44 magnesium alloy

[J].

Effect of strain rate on the defect susceptibility of tensile properties to porosity variation

[J].

Effect of microporosity on the tensile properties of AZ91 magnesium alloy

[J].

Characterization of porosity and its effect on the tensile properties of Mg-6Gd-3Y-0.5Zr alloy

[J].Microstructure investigations and static uniaxial tensile tests of Mg-6Gd-3Y-0.5Zr (GW63) alloys containing varied content of porosity were carried out to disclose the relationship between porosity and tensile properties. Here, a qualitative analysis was performed by relating the tensile properties with porosity level, which was relevant to porosity content and assessed by X-ray detector. Besides, both analytical (i.e., critical local strain model) and empirical methods were applied to quantitatively investigate the influence of porosity on tensile properties, based on the projected area of porosity on the fracture surface. The results showed that two types of porosity and three typical regions on the fracture surface were identified. Both ultimate tensile strength (UTS) and elongation-to-failure (EL) decreased with porosity level increasing. Besides, a great scatter of EL of each porosity level was observed. The critical local strain model was testified not applicable for GW63 alloys to calculate the tensile properties. Instead, strong quantitative correlations between tensile properties and porosity area fraction were obtained through the empirical approach.

The effects of casting porosity on the tensile behavior of investment cast 17-4PH stainless steel

[J].

A corrosion study of the main constituent phases of AZ91 magnesium alloys

[J].

Research progress of purification technology in magnesium alloy melt

[J].

镁合金熔体净化技术研究进展

[J].

Effect of mixed-RE on fluidity and mechanical properties of die casting AZ91D magnesium alloy

[J].

混合稀土对AZ91D压铸镁合金流动性及力学性能的影响

[J].

A study on Mg melt continuous non-flux purification theory and key techniques

[D].

镁熔体无熔剂连续精炼理论及关键技术研究

[D].

Exploring the concept of castability in magnesium die-casting alloys

[J].This paper provides a summary of the recent work completed and history of the measure of manufacturability in the magnesium diecasting industry. The most popular die-casting alloys utilized in this industry are based on the Mg-Al system, including AZ91, AM60 and AM50. These are well-established alloys, and are generally considered to be highly tastable. However, the concept of castability in magnesium die-casting is not a well-defined characteristic or quantitative material property. As a result, the author investigates the subject of castability for magnesium die-cast alloys and how it relates to the development of alloys for innovative applications or improved properties. This paper provides a summary of some key findings in literature on the castability of magnesium die-cast alloys, how castability is defined and evaluated, the impact of different alloying elements on the castability of magnesium alloys, and suggestions for future work. (C) 2020 Published by Elsevier B.V. on behalf of Chongqing University.

Study of Mg-Al-Ca magnesium alloy ameliorated with designed Al8Mn4Gd phase

[J].

A review on thermal conductivity of magnesium and its alloys

[J].

Development of high-strength magnesium alloys with excellent ignition-proof performance based on the oxidation and ignition mechanisms: A review

[J].

Ordering in liquid and its heredity impact on phase transformation of Mg-Al-Ca alloys

[J].

A novel die-casting Mg alloy with superior performance: Study of microstructure and mechanical behavior

[J].

A high performance Mg-Al-Ca alloy processed by high pressure die casting: Microstructure, mechanical properties and thermal conductivity

[J].

Microstructure, tensile properties, and corrosion behavior of die-cast Mg-7Al-1Ca-xSn alloys

[J].

Microstructures and tensile properties of a high-strength die-cast Mg-4Al-2RE-2Ca-0.3Mn alloy

[J].

Influence of trace Sr additions on the microstructures and the mechanical properties of Mg-Al-La-based alloy

[J].

Research on microstructures and properties of moderate or high strength and high thermal conductivity Mg-Al-Ce series die-cast magnesium alloys

[D].

中强高导热Mg-Al-Ce系压铸镁合金组织与性能研究

[D].

Fluidity of alloys under high-pressure die casting conditions: Flow-choking mechanisms

[J].

Quantitative experimental study of defects induced by process parameters in the high-pressure die cast process

[J].

Numerical simulation and die casting process optimization of magnesium alloy vehicle head-up display bracket (HUD)

[J].

镁合金汽车抬头显示支架压铸工艺模拟与优化

[J].

A complete computer aided engineering (CAE) modelling and optimization of high pressure die casting (HPDC) process

[J].The application of computer aided engineering (CAE) has become a trend in manufacture industry due to its great efficiency and reliability. In casting industries, numerical modelling of the casting process based on CAE has replaced traditional trial-and-error R&D procedures in many aspects. With advanced parallel computing techniques and numerous calculation models, the fluid flow, heat transfer, solidification and defect formation behaviours under different casting conditions may be examined in detail. Based on this idea, component design and the optimization of casting parameters may be carried out to produce products for subsequent microstructural and mechanical characterization. In this way, a direct link between process condition, casting quality, and cast mechanical properties may be established in a manner that is practical, economical and energy efficient for such processes as gravity die casting, high pressure die casting (HPDC) and continuous casting.