低活化铁素体/马氏体(reduced activation ferritic/martensitic,RAFM)钢如Eurofer 97、F82H、JLF-1、中国低活化马氏体(China low activation martensitic,CLAM)钢及中国低活化铁素体(China low activation ferrite steel-1,CLF-1)钢等[1~6]是未来聚变反应堆增殖包层首选结构材料。然而,由于回火马氏体组织的高温不稳定性导致材料强度急剧下降,其最高服役温度限制在大约550 ℃[7]。将适量Y2O3添加到基体中制备的氧化物弥散强化(oxide dispersion strengthened,ODS)钢,在提高抗中子辐照性能的同时提高了材料的组织稳定性,其最高服役温度可提高至650~700 ℃,从而有效提高了反应堆的热效率[8,9]。因此,ODS钢被认为是未来聚变反应堆更高设计参数下最具潜力的结构材料[7,10]。

1 实验方法

选用自主制备的低活化9Cr-ODS钢为研究对象。采用粉末冶金方法制备9Cr-ODS钢,通过预合金冶炼、气雾化制粉、机械球磨、热等静压固化成型、热锻造及轧制等系列工序,最终制备成厚度为16 mm的板材。其制备过程及具体参数可参见文献[21,22]。制备的9Cr-ODS钢化学成分(质量分数,%)为:C 0.10,Cr 9.31,W 2.04,Y 0.26,O 0.21,Ti 0.21,H < 0.0001,Fe余量。9Cr-ODS钢经过1050 ℃正火1 h 、空冷以及800 ℃回火1 h 、空冷的热处理工艺,最终获得回火马氏体组织,拉伸试样总长度为55 mm,螺纹段直径为6 mm,工作段直径为3 mm,其室温拉伸力学性能为:屈服强度972 MPa,抗拉强度1108 MPa,断裂延伸率14%,断面收缩率59%。硬度为336.6 HV (加载力为500 g)。

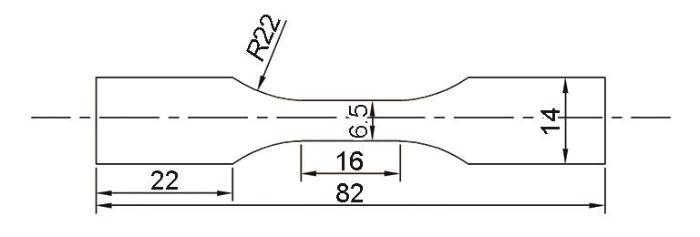

疲劳试样沿着材料轧制方向切取,在粗加工基础上再精加工成标距直径为6.5 mm、长度为16 mm、总长度为82 mm的圆柱形疲劳试样,符合国家标准GB/T 15248—2008中等截面试样要求(具体尺寸如图1所示),并对试样进行机械抛光,确保平行段的表面粗糙度Ra ≤ 0.15 µm。然后,按照国家标准GB/T 15248—2008,使用INSTRON 8801电液伺服疲劳试验机进行轴向应变控制疲劳实验。应变测试用引伸计的标距为10 mm,量程为±10%。疲劳实验采用的应变幅(Δεt / 2)范围为0.3%~0.8%,应变比为-1,波形为三角波,应变速率为4 × 10-3 s-1。将循环应力峰值下降25%所对应的循环周次定义为该试样的疲劳寿命(Nf),设定的条件寿命为5 × 104 cyc。

图1

图1

9Cr-ODS钢疲劳试样的尺寸

Fig.1

Specimen dimension of 9Cr-ODS steel for fatigue experiment (unit: mm. ODS—oxide dispersion strengthened)

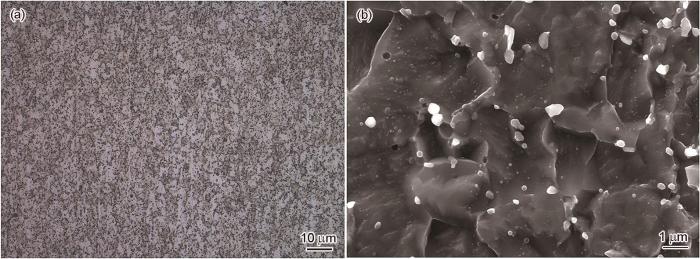

对热处理之后的轧板沿轧制方向切取10 mm × 10 mm × 5 mm的样品,磨抛之后,使用HAL100共聚焦光学显微镜(OM)和MIRA3场发射型扫描电子显微镜(SEM)进行组织观察。将疲劳断口放入酒精和丙酮的混合溶液中进行超声清洗后,使用Gemini 300型SEM对疲劳断口进行表征。然后,将疲劳试样沿着断口纵向切开,经过冷镶、研磨、机械抛光及振动抛光后采用电子背散射衍射(EBSD)方法进一步对疲劳过程中微观组织演化进行分析。EBSD观察采用的加速电压为20 keV,倾斜角度为70°,扫描步长为40 nm。

2 实验结果

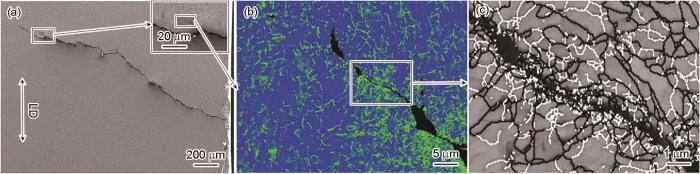

图2

图2

9Cr-ODS钢热处理后显微组织的OM像和SEM像

Fig.2

OM (a) and SEM (b) images of the heat-treated 9Cr-ODS steel

2.1 室温低周疲劳性能

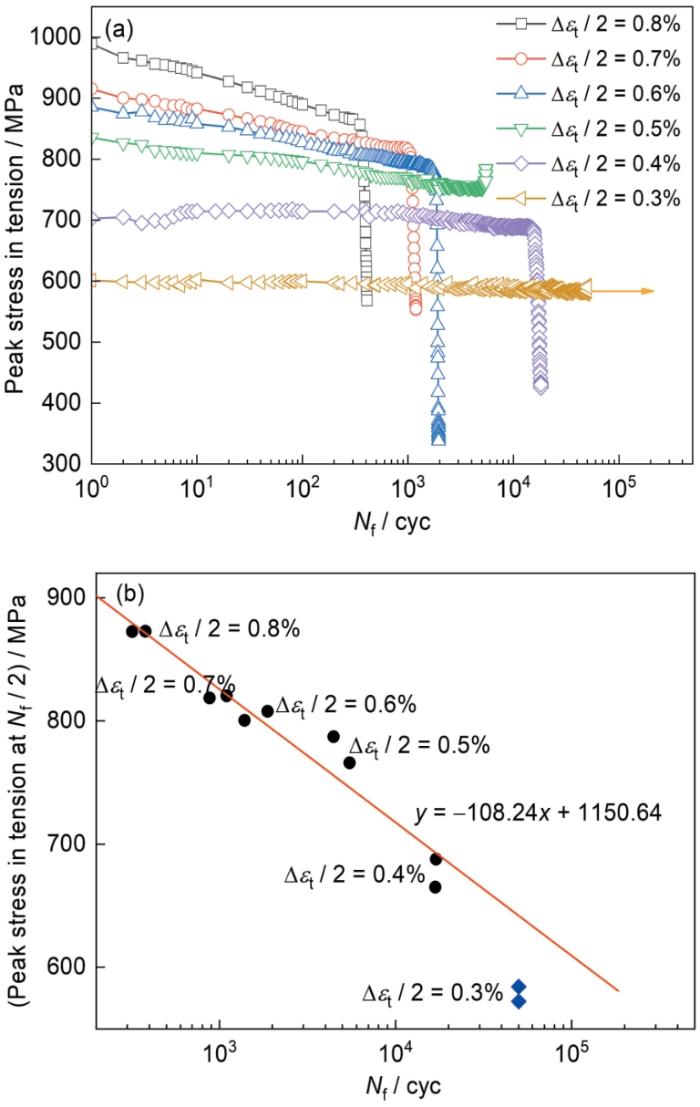

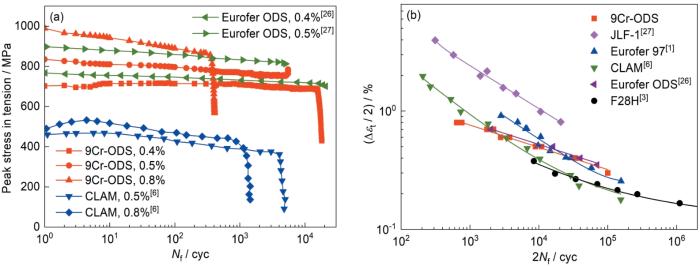

9Cr-ODS钢在室温不同应变幅下的疲劳响应曲线如图3所示。从图3a峰值拉应力与疲劳寿命的关系曲线可以看出,随Δεt / 2从0.8%降至0.3%,疲劳寿命逐渐增加。在0.5%~0.8%较高应变幅下,试样未出现循环硬化,而是呈现一定循环软化直至试样断裂。循环软化的斜率随Δεt / 2的降低而逐渐升高。在Δεt / 2 = 0.8%时断裂循环峰值应力较开始循环时降低约13%,在Δεt / 2 = 0.5%时降低6.8%,斜率由-49.87升高至-22.72。需要说明的是,Δεt / 2 = 0.5%的曲线在疲劳失效前发生上翘,结合Nishimura等[2]的研究发现,这可能由试样断裂位置处在引伸计边缘或引伸计外所致。当Δεt / 2降至0.4%时,在初期的轻微硬化后快速进入一个相对稳定的循环阶段,随后峰值拉应力缓慢下降而直至断裂。当Δεt / 2进一步降至0.3%时,试样循环直至5 × 104 cyc始终处于一个相对稳定的循环阶段而未出现循环软化及断裂,因此终止了实验。图3b显示9Cr-ODS钢中值寿命处(Nf / 2)的峰值拉应力与疲劳寿命的关系。可以看出,峰值拉应力与疲劳寿命的对数呈现明显的线性关系。随峰值拉应力降低,疲劳寿命逐渐延长。再次说明,Δεt / 2 = 0.3%时的疲劳实验在循环5 × 104 cyc后中止,因此曲线上对应的数据并非最终的疲劳寿命。

图3

图3

9Cr-ODS钢的循环应力响应曲线

Fig.3

Cyclic stress response curves of 9Cr-ODS steel

(a) relationship between peak stress in tension and fatigue life (Nf) (Arrow indicates not fractured sample, Δεt / 2—total strain amp-litude)

(b) relationship between peak stress in tension at Nf / 2 and Nf (Diamonds are data corres-ponding to the arrow in Fig.3a)

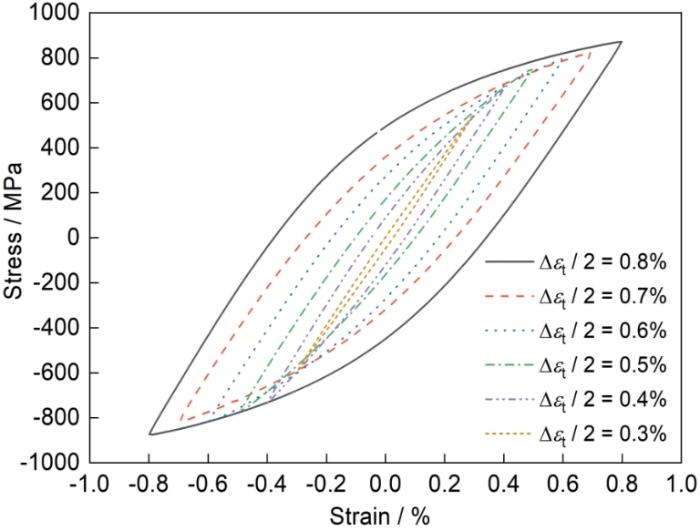

图4为9Cr-ODS钢在不同总应变幅下中值寿命处的滞后回线。可见,滞后回线对称性较好。随Δεt / 2从0.3%增加至0.8%,滞后回线宽度逐渐增加,滞回环所包围的面积相应增大,说明循环变形所消耗的塑性功增加。

图4

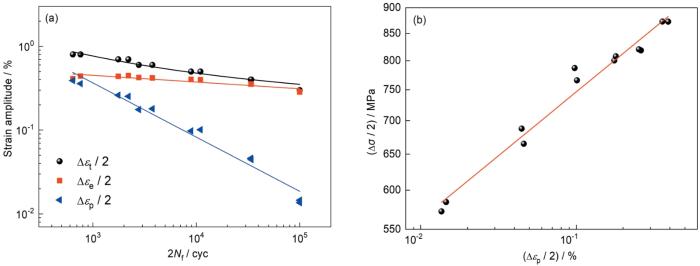

2.2 Coffin-Manson关系

式中,Δεe / 2和Δεp / 2分别为弹性应变幅和塑性应变幅,Δεp / 2为滞后回线与平均应力的交点;E为中值疲劳寿命或循环稳定时对应循环周次的拉伸卸载模量(ET)和压缩卸载模量(EC)的平均值;2Nf、σ

利用Coffin-Manson关系式(

将上述拟合得到的疲劳参数代入

由图5a中2条拟合曲线的相交处(Δεe / 2 = Δεp / 2)所对应的反向加载次数,得到过疲劳寿命(2Nf)t,大约在800 cyc。可见,过疲劳寿命的左侧,塑性应变幅起主导作用,将会对材料造成不可逆损伤。反之,在过疲劳寿命的右侧,弹性应变幅起主导作用,疲劳寿命由断裂强度决定。9Cr-ODS钢在较低Δεt / 2下弹性应变幅占主导。由于弹性变形是可逆的,因此变形功大多以热量的形式散发到环境中,对基体造成的疲劳损伤较小。随Δεt / 2的增加,9Cr-ODS钢塑性应变幅逐渐占主导。

图5

图5

循环应变幅与反向加载次数(2Nf)的关系及Nf / 2处的应力幅(Δσ / 2)与塑性应变幅(Δεp / 2)的关系

Fig.5

Relationship between cyclic strain amplitude and number of reversals to failure 2Nf (Δεe / 2—elastic strain amplitude, Δεp / 2—plastic strain amplitude) (a) and relationship between stress amplitude at Nf / 2 (Δσ / 2) and Δεp / 2 (b)

Nf / 2对应的应力幅(Δσ / 2)与Δεp / 2存在如下关系[23]:

式中,K'和n'分别为循环强度系数和循环应变硬化指数。根据

图5b为9Cr-ODS钢Δσ / 2与Δεp / 2的关系曲线。如图所示,在总应变幅控制实验期间,塑性应变连续变化,循环应力峰值随着Δεp / 2的增加呈线性增加。

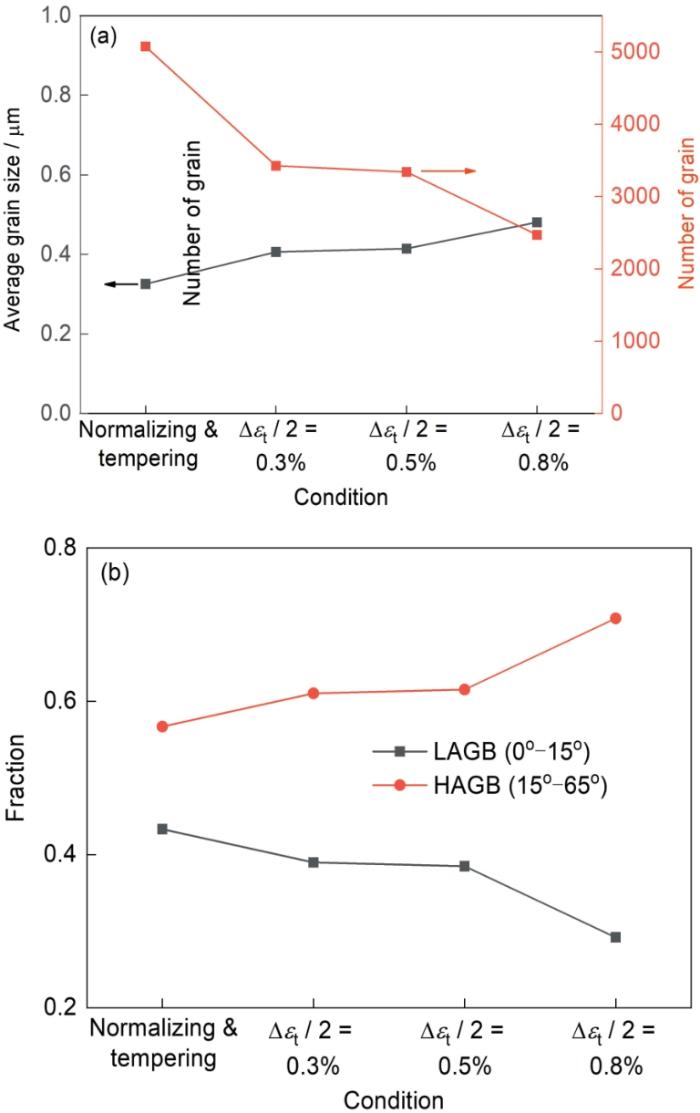

2.3 微观组织演变

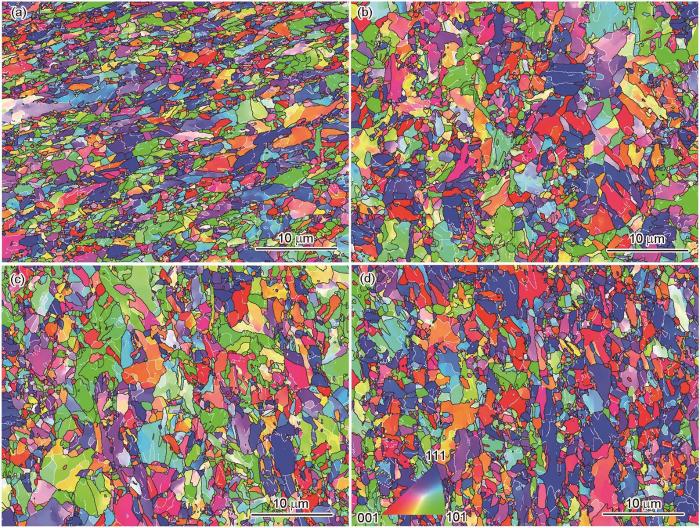

图6为反极图(inverse pole figure,IPF),其中黑色线为大于15°的大角度晶界(HAGBs),白色线为小于15°的小角度晶界(LAGBs)。可见,热处理态的9Cr-ODS钢沿轧向有一定的晶体学取向,但经循环应变之后晶粒无择优取向。同时,所有样品中均可观察到晶粒尺寸不同的混晶组织。热处理态9Cr-ODS钢中存在大量细小晶粒(尺寸< 0.5 μm),而随循环总应变幅增加,小尺寸晶粒数量逐渐减少、较大尺寸晶粒数量相应增加。

图6

图6

9Cr-ODS钢在热处理态和不同应变幅下的反极图

Fig.6

Inverse pole figures of 9Cr-ODS steel after normalizing & tempering treatment (a) and under Δεt / 2 = 0.3% (b), Δεt / 2 = 0.5% (c), and Δεt / 2 = 0.8% (d) (Black lines are large angle grain boundaries (HAGBs) greater than 15°, white lines are low angle grain boundaries (LAGBs) less than 15°, the same below)

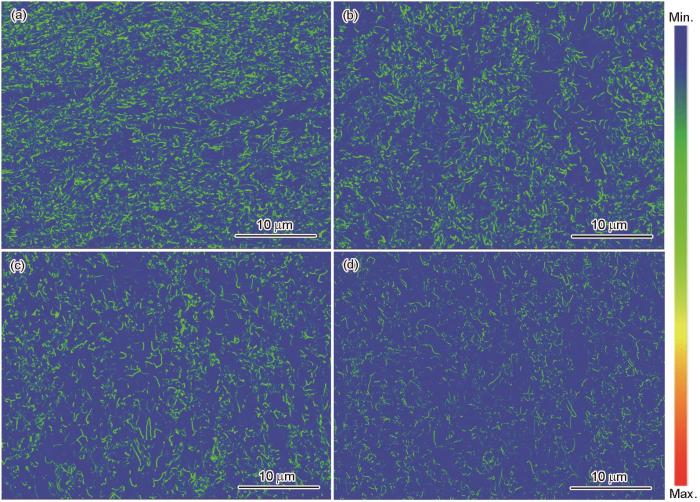

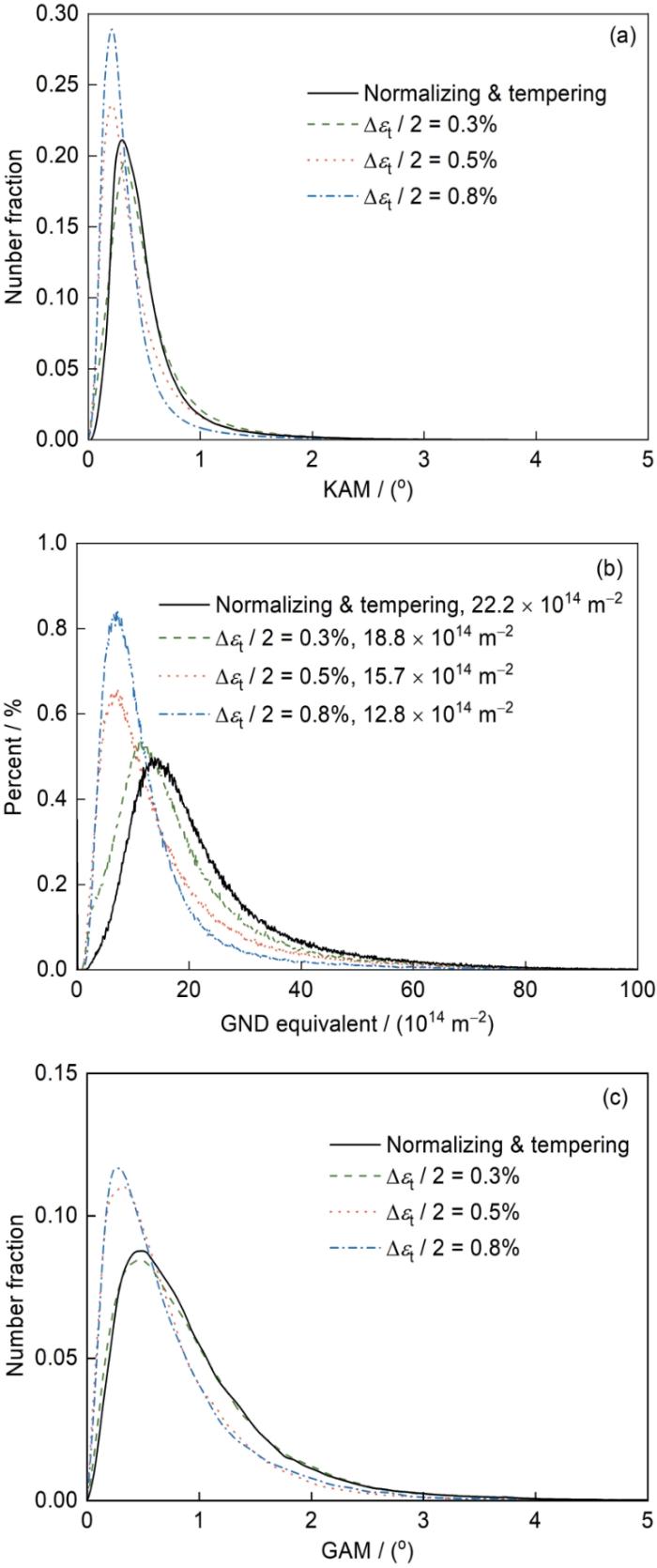

图7为局部取向差(kernel average misorientation,KAM)图。KAM图计算某个点及其3个相邻点之间的平均取向差,最大取向差为5°。由于考虑了较小局部区域的取向变化,通过KAM图可以观察局部塑性变形和局部应变。可见,随Δεt / 2增加,平均取向差逐渐降低,预示晶界滑移越容易发生。

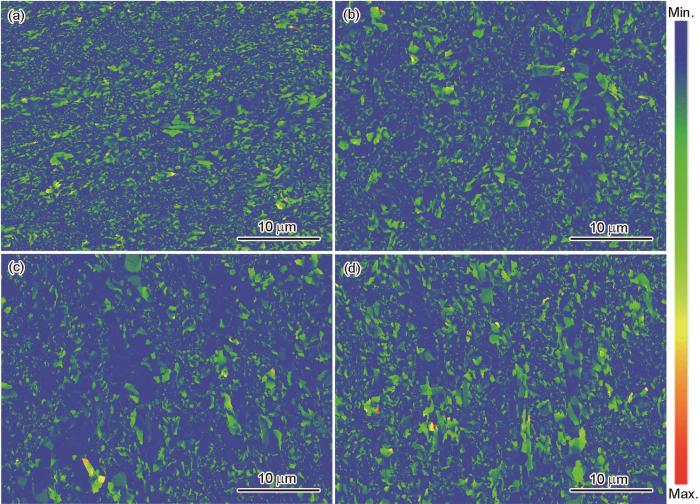

图8为对应的晶粒平均取向差分布(grain average misorientation,GAM)图。GAM图以晶粒为最小单元,将晶粒内每对相邻点之间的取向差汇总并均分,以体现晶粒尺度的局部变化。因此,GAM图是显示晶粒取向变化的典型方式。可见,随Δεt / 2增大至0.8%,高取向差晶粒数量有所增加。

图7

图7

9Cr-ODS钢在热处理态和不同应变幅下的局部取向差(KAM)图

Fig.7

Kernel average misorientation (KAM) maps of 9Cr-ODS steel after normalizing & tempering treatment (a) and under Δεt / 2 = 0.3% (b), Δεt / 2 = 0.5% (c), and Δεt / 2 = 0.8% (d)

图8

图8

9Cr-ODS钢在热处理态和不同应变幅下的晶粒平均取向差(GAM)图

Fig.8

Grain average misorientation (GAM) maps of 9Cr-ODS steel after normalizing & tempering treatment (a) and under Δεt / 2 = 0.3% (b), Δεt / 2 = 0.5% (c), and Δεt / 2 = 0.8% (d)

2.4 室温低周疲劳断裂行为

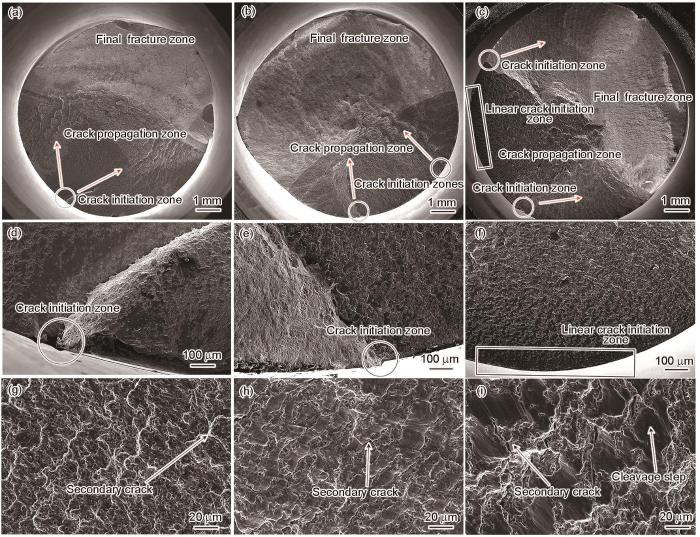

根据疲劳寿命的分布,选取9Cr-ODS钢在疲劳寿命为409、5488和18163 cyc的3个代表性疲劳样品进行断口分析,对应的Δεt / 2分别为0.4%、0.5%和0.8%,断口形貌如图9所示。

从图9a~c的宏观断口可观察到,材料疲劳断口主要由裂纹源区(圆圈所示)、裂纹扩展区和瞬断区3部分组成,它们分别代表疲劳破坏的不同进程。裂纹扩展区较为光亮,而最终断裂区呈灰黑色。当Δεt / 2 = 0.4%时(图9a),裂纹源有且仅有1个,裂纹扩展区2个方向的一次裂纹共同汇聚于裂纹源处,通过裂纹源断口表面的放射状起点,可以判断出裂纹起源于样品表面。其局部放大形貌(图9d)显示,可见裂纹起源于试样加工缺陷处。图9g的裂纹扩展区形貌显示,存在大量小而浅的韧窝,二次裂纹扩展曲折,说明以韧性断裂为主。当Δεt / 2增加至0.5%,疲劳裂纹源由1个增加至2个(图9b),但同样起源于试样加工缺陷处(图9e),而且扩展区的韧窝明显变浅、变少(图9h)。当Δεt / 2增加至0.8%时,在试样表面点状裂纹源附近垂直轴向应力方向有一条线性裂纹源(图9c),肉眼可观察到线性裂纹源区域比裂纹扩展区更明亮,同时,从线性裂纹源区的局部放大形貌(图9f)可观察到多条一次裂纹起源于试样表面且一次裂纹较密集,符合裂纹源的特征,但未观察到有大尺寸夹杂物及析出相。此时疲劳裂纹源由单一的点状裂纹源增加至线性裂纹源和点状裂纹源 (红色箭头所示为裂纹扩展方向),数量由1个增加到3个,但裂纹源位置仍然出现在试样表面。疲劳过程中,试样表面线性裂纹源萌生的一次裂纹逐渐向试样内部扩展,同时,附近的点状裂纹源萌发的一次裂纹也沿着箭头方向开始扩展。点状源区附近的稳态扩展区垂直裂纹扩展方向有较明显的疲劳条带,但条带宽度较宽。从线性裂纹源对应的稳态扩展区可以发现不太明显的疲劳条带且条带较密(图9c),说明线性裂纹源萌发的一次裂纹扩展速率远大于点状源区,故线性裂纹源为主源区,其余2个裂纹源为次源区。裂纹稳态扩展区二次裂纹数量明显较少,间距增宽,并出现较多的解理台阶(图9i)。由此说明,塑性应变增大到一定程度之后出现了解理断裂。

图9

图9

9Cr-ODS钢在不同应变幅下的宏观断口、裂纹源区及裂纹扩展区形貌的SEM像

Fig.9

SEM images of macrofractography (a-c), crack source zones (d-f), and crack propagation zones (g-i) under Δεt / 2 = 0.4% (a, d, g), Δεt / 2 = 0.5% (b, e, h), and Δεt / 2 = 0.8% (c, f, i) (Source of fatigue crack is the place where the circle and square circle arrive, the fatigue crack propagation directions are indicated by the red arrows)

3 分析讨论

3.1 与其他铁素体/马氏体钢的低周疲劳性能对比

9Cr-ODS钢的疲劳性能结果显示,随Δεt / 2的增加,其循环峰值应力呈线性增加,且循环响应特征与加载应变幅的大小密切相关(图3)。在0.3%应变幅下,材料承受600 MPa的拉压应力循环至5 × 104 cyc仍未发生断裂,表示该状态下仍有较长的服役寿命。在0.4%应变幅下,材料呈现较稳定的应力平台。当Δεt / 2从0.5%增加至0.8%,材料出现了一定的疲劳软化。图4的滞后环曲线显示,随Δεt / 2从0.3%增加至0.8%,滞后环面积逐渐增加。由于滞后环面积代表材料所吸收的变形能,其中一部分以塑性变形能的形式储存在材料中用以改变原子结构的排列,剩下部分则以热的形式向周围环境散逸。因此,滞后环面积越大,表明在外加载荷作用下材料的塑性变形越大,越容易发生损伤。在Δεt / 2 = 0.3%时,滞后环面积接近0,此时材料损伤不大。Δεt / 2 = 0.8%时,滞后环面积最大,此时材料所承受的峰值应力最大,吸收变形功最大,同时受损伤最严重。图5a进一步显示,随应变幅增加,材料总应变从以弹性应变为主逐渐转变为塑性应变控制。

9Cr-ODS钢与Eurofer ODS钢[26,27]及CLAM钢[6]在不同总应变幅下的疲劳响应曲线如图10a所示。其中,CLAM钢是中国RAFM钢的代表性牌号之一,Eurofer ODS则为欧盟ODS钢的典型代表。由图可知,与CLAM钢相比,9Cr-ODS钢具有相对更高的峰值拉应力。Δεt / 2 = 0.5%时,2者的疲劳寿命基本一致,但9Cr-ODS钢的峰值拉应力可达到CLAM钢的2倍。这是由于此时在9Cr-ODS钢整个循环应变的过程中弹性应变起主导作用,而疲劳损伤主要来源于塑性应变,因此在低Δεt / 2下拥有更长的服役寿命。随Δεt / 2增大至0.8%,9Cr-ODS钢的峰值拉应力仍然远高于CLAM钢。显而易见,9Cr-ODS钢具有比CLAM钢更高的疲劳强度,说明在反应堆设计中ODS钢的最高许用温度及应力可高于CLAM钢。当然,这还需要更多的实验研究来进一步验证。另一方面,在相同Δεt / 2 (0.4%和0.5%)下,当疲劳寿命基本一致时,9Cr-ODS钢所能承受的峰值拉应力略低于Eurofer ODS钢。

图10

图10

9Cr-ODS、中国低活化马氏体(CLAM)钢[6]及Eurofer ODS钢[26,27]在不同Δεt / 2下的疲劳响应曲线;室温下几种典型低活化铁素体/马氏体(RAFM)钢的循环总应变幅与反向加载次数的关系

Fig.10

Fatigue response curves of 9Cr-ODS, China low activation martensitic (CLAM)[6], and Eurofer ODS[26,27] steels under different Δεt / 2 (a); and relationship between Δεt / 2 and 2Nf of several typical reduced activation ferritic/martensitic (RAFM) steels[1,3,6,26,27] at room temperature (b)

图10b为室温下9Cr-ODS钢与几种典型RAFM钢[1,3,6,26,27]的Δεt / 2与反向加载次数的结果对比。结果显示,随Δεt / 2降低,RAFM钢反向加载次数增加得较小。在所有测试Δεt / 2下,9Cr-ODS钢的反向加载次数均高于F82H,略低于 Eurofer ODS钢。在Δεt / 2高于1%时,JLF-1钢的疲劳寿命高于其他RAFM钢和ODS钢,但低于F28H钢[1]。当总应变幅较高时(如Δεt / 2 > 0.8%),9Cr-ODS钢的疲劳寿命低于CLAM钢。当Δεt / 2介于0.6%~0.7%之间时,2者的疲劳寿命接近。当Δεt / 2低于0.5%时,9Cr-ODS钢的疲劳寿命高于RAFM钢,且Δεt / 2越小这种趋势越明显。由此说明,在反应堆材料设计中,9Cr-ODS钢在较低的许用应变下具有更长的疲劳寿命。这与ODS钢的特殊微观结构相关,即基体中存在的高密度弥散分布的纳米级氧化物,大幅提高了材料的疲劳强度,但同时也降低了材料的塑韧性。

表1总结了9Cr-ODS钢与几种RAFM钢[1,3,6,27]的室温低周疲劳参数。需要说明的是,这几种钢Cr含量(质量分数)均在7%~9%,均为回火马氏体组织。不同之处在于,ODS钢采用粉末冶金制备,而RAFM钢为传统熔炼方法制备。一般来说,塑性材料的c为-0.7~-0.5,b为-0.06~-0.14。与RAFM钢相比,9Cr-ODS钢的b和c值相差不大,但ε

表1 室温下9Cr-ODS钢与几种典型RAFM钢[1,3,6,27]的低周疲劳参数

Table 1

| Steel | T | σ | ε | b | c | K' | n' |

|---|---|---|---|---|---|---|---|

| K | MPa | ||||||

| 9Cr-ODS | 300 | 0.7331 | 12.12 | -0.0722 | -0.5268 | 1628.40 | 0.113 |

| CLAM[6] | 300 | 0.5396 | 59.18 | -0.0930 | -0.6154 | 514.66 | 0.128 |

| Eurofer 97[1] | 300 | - | - | - | -0.5520 | - | - |

| F82H[3] | 300 | 0.4722 | 67.72 | -0.0850 | -0.7805 | - | - |

| JLF-1[27] | 300 | 1.0230 | 91.02 | -0.0946 | -0.5956 | - | - |

此外,不同材料的室温循环硬化与软化行为也存在差异。Stubbins和Gelles[3]研究显示,当塑性变形参与疲劳损伤时,F82H钢的循环软化趋势增加。Hu等[28]研究显示,在所有循环应变幅下CLAM钢先发生循环硬化随后循环软化,随应变幅增加,循环硬化与软化行为更为明显。Kuběna等[26]研究显示,Eurofer 97钢的循环响应特征与CLAM钢类似。Li等[27]研究显示,在室温疲劳过程中JLF-1钢的峰值拉应力随循环周次的增加而降低,呈现明显的循环软化。Msolli[29]研究显示,JLF-1钢与F82H和Eurofer 97钢一样,在最初的几个循环中经历了非常快的循环软化,峰值拉应力急剧下降,持续至疲劳失效。与上述RAFM钢不同,Eurofer ODS钢[26]在室温低周疲劳过程中未发生循环硬化,而是仅发生了一定的循环软化。本工作9Cr-ODS钢在0.4%应变幅时出现了轻微的循环硬化。随总应变幅增加,与Eurofer ODS钢类似,9Cr-ODS钢发生循环软化,但循环软化程度较RAFM钢低。因此,在反应堆的材料设计中,相较于ODS钢,RAFM钢需要考虑更多的安全余量。

3.2 9Cr-ODS钢的循环应变对微观组织演变的影响

对不同总应变幅下的IPF图(图6)进行分析,其平均晶粒尺寸及数量的统计结果如图11a所示,大、小角度晶界占总晶界的百分比的统计结果如图11b所示。由图可知,随Δεt / 2增大,9Cr-ODS钢的平均晶粒尺寸逐渐增加,相应的晶粒数目减少。当Δεt / 2较低时,晶粒尺寸长大趋势较小。然而当Δεt / 2增至0.8%时,与热处理态相比,平均晶粒尺寸增大,晶粒数目减少约50%。这可能是由于此时塑性应变增大,材料可吸收的变形功增加,导致晶粒长大,晶粒数量相应减少。值得注意的是,虽然材料的晶粒尺寸随应变幅增大而有所增加,但平均晶粒尺寸仍然保持在500 nm以下。图11b进一步显示,随Δεt / 2增大,HAGBs的体积分数增大,LAGBs体积分数逐渐减少,说明部分亚结构发生了回复。

图11

图11

9Cr-ODS钢在热处理态及不同Δεt / 2下的平均晶粒尺寸和数目,以及大角度晶界(HAGBs)和小角度晶界(LAGBs)的体积分数

Fig.11

Results of microstructural evolution for 9Cr-ODS steel after normalizing & tempering and under different Δεt / 2

(a) average grain sizes and amounts

(b) volume fractions of HAGBs and LAGBs

图12a为KAM图(图7)中取向差分布的统计结果。结果显示,0.3%低应变幅的取向差分布与热处理态基本相似,仅峰值占比稍有降低。随Δεt / 2增大,取向差角度逐渐降低。Δεt / 2为0.8%时,0.2°的取向差占比接近30%。图12b为不同Δεt / 2下的几何必需位错(geometrically necessary dislocation,GND)密度图,X轴为位错当量,Y轴为体积分数,曲线与X轴围成的面积即为位错密度。热处理态峰值对应的横坐标最大、覆盖面积最广,说明此时位错密度最高。随Δεt / 2增加,峰值逐渐左移,面积减小,位错密度随Δεt / 2增加而逐渐降低。图12c为GAM图(图8)中取向差分布的统计结果。类似于KAM,与热处理态相比,Δεt / 2为0.3%时的GAM峰值位置及曲线形状未发生明显变化,随Δεt / 2增加至0.5%和0.8%时,取向差逐渐减小。

图12

图12

9Cr-ODS钢在热处理态及不同Δεt / 2下的微观结构演化结果

Fig.12

Results of microstructural evolution for 9Cr-ODS steel after normalizing & tempering and under different Δεt / 2

(a) KAM

(b) geometrically necessary dislocation (GND)

(c) GAM

材料的微观结构演化与疲劳行为有着密切的联系。Hu等[28]对CLAM钢的室温疲劳样品进行微观结构的演化分析,结果发现,循环塑性变形导致基体中位错大量增殖,密度升高,位错相互缠结并形成胞状亚结构,导致了循环硬化。随后CLAM 钢开始持续循环软化并直至疲劳失效,这是由于持续的局部塑性变形促使位错在原奥氏体三叉晶界处大量塞积,使显微裂纹能够在不额外吸收能量的情况下在晶界处萌生,并在循环加载的作用下相互联结,从而降低了CLAM 钢的承载能力。Chauhan等[15]发现,在温度和循环应变的联合作用下,9Cr-ODS钢中原始亚晶粒结构消除并产生了动态再结晶,在缺乏纳米级析出相的区域微观结构演变加快,因此认为位错重排和相互湮灭是循环软化及疲劳强度损失的主要原因。本工作9Cr-ODS钢不同于RAFM钢,未发生明显的循环硬化。这是由于材料采用粉末冶金方法制备,在前期球磨过程中已经引入了大量空位和位错,因此在外加应变幅的条件下不再具有较好的加工硬化能力。在0.3%较低的应变幅时,9Cr-ODS钢的循环响应曲线显示为较稳定的应力平台,此时晶粒尺寸、位错密度等均未发生明显的变化。在0.5%~0.8%较高应变幅时,9Cr-ODS钢出现了一定程度的循环软化,此时其晶粒尺寸与大角度晶界体积分数逐渐增加(图11),伴随亚晶界与位错密度逐渐降低(图12)。同时,部分晶界附近出现大量较高应力区域(图8),表明在较大应变能下晶粒吸收位错和亚晶得以长大,促使亚结构发生了回复,从而显示循环软化。需要说明的是,虽然9Cr-ODS钢在较高应变幅下显示了一定的循环软化,然而软化程度较RAFM钢低。其原因在于,材料基体中分布有大量弥散的纳米级氧化物,对晶界与位错具有强烈的钉扎作用,从而确保材料在循环应变过程中具有更优异的稳定性。下一步,将对疲劳过程中9Cr-ODS钢中纳米级氧化物及M23C6等析出相的演化进行深入分析,以明确析出相的稳定性行为。

3.3 疲劳断裂与裂纹扩展机制

疲劳裂纹通常萌生于材料的应力集中处,如夹杂物、析出相、脆性的晶粒边界及表面划痕或机加工刀痕等[30]。图9显示,在所有Δεt / 2下,9Cr-ODS钢的疲劳断口表面形貌均有3个主要特征,即疲劳源区、裂纹扩展区以及瞬断区。在较低Δεt / 2下,疲劳裂纹源大都起源于试样表面,为试样加工缺陷处,但附近未发现明显的夹杂物。在较高Δεt / 2下,疲劳裂纹起源行为呈现复杂化,裂纹源出现在表面与内部,对其内部裂纹源处的局部放大观察同样未发现到明显的夹杂物及粗大析出相。因此推测,9Cr-ODS钢的室温疲劳裂纹起源不是来自于粗大夹杂物与析出相。这是由于,本工作9Cr-ODS钢的预合金粉末采用真空感应熔炼及气雾化制备,在随后的粉末机械球磨过程采用高纯Ar气保护,因此最大限度地降低了杂质含量及夹杂物的形成。微观组织的低倍观察也进一步证明,材料中未发现尺寸较大的夹杂物。热处理后9Cr-ODS钢的析出相主要由纳米级氧化物和M23C6型碳化物组成:纳米级氧化物尺寸细小(约< 10 nm),且在基体中弥散分布,一般不会成为疲劳裂纹源;M23C6析出相的尺寸为100~300 nm,一般在晶界及板条界析出,有可能成为疲劳裂纹源。但本工作在裂纹源区未观察到M23C6存在,后续还将对M23C6析出相进行更深入的分析。由此,推测本工作9Cr-ODS钢疲劳裂纹的产生有如下几个方面原因:(1) 试样表面难免有加工痕迹(如切削刀痕),其薄弱部位容易萌生疲劳裂纹;(2) 试样表面本身处于平面应力状态,有利于塑性滑移的进行,并形成挤出和挤入滑移带,从而可能形成微裂纹核;(3) 采用粉末冶金制备的ODS钢可能存在粉末颗粒界面(PPB),其界面或晶界在较高应变幅下产生应力集中,在积累到一定程度时也将产生微裂纹进而发生断裂。

为进一步分析9Cr-ODS钢疲劳裂纹的起源和扩展方式,对Δεt / 2 = 0.8%下样品垂直于断口的剖面进行观察。图13a为断口附近一次裂纹形貌的SEM像。可见,裂纹由试样表面产生/萌生,长度达到毫米级。在较高的塑性应变下一次裂纹与轴向应变呈60°夹角向内扩展,并发生了多次偏转,且产生多条分叉的二次裂纹。二次裂纹末端的KAM图如图13b所示,裂纹附近呈现高亮色,其中较窄的部位尤为明显,显示有明显的应力集中。图13c为裂纹较窄区域的晶界+带衬度(grain boundary + band contrast,GB + BC)叠加图。GB图反映大、小角度晶界的分布情况,其中黑色线为大于15°的HAGBs,白色线为0°~15°的LAGBs。BC图反映样品在EBSD表征中的花样质量,花样越清晰,则缺陷或内应力越小。综合GB + BC叠加图,可观察二次裂纹的扩展情况。结果显示,二次裂纹未发生沿晶扩展,而是以穿过大角度晶界的方式扩展,与图9的断口分析结果一致。同时,9Cr-ODS钢细的原奥氏体晶界、马氏体板条界或析出相等均可诱导裂纹偏转,使裂纹走向曲折,从而可降低裂纹扩展速率,提高疲劳寿命。因此,9Cr-ODS钢具有比RAFM钢更高的低周疲劳强度与疲劳寿命。

图13

图13

9Cr-ODS钢在Δεt / 2 = 0.8%时的裂纹起源与扩展

Fig.13

Fatigue crack initiation and propagation morphology of 9Cr-ODS steel under Δεt / 2 = 0.8%

(a) SEM image of a main crack (Inset show the locally enlarged image. LD—loading direction)

(b) local magnified EBSD-KAM image of a secondary crack of square area in the inset of Fig.13a

(c) high magnified grain boundary + band contrast (GB + BC) image of square area in Fig.13b

4 结论

(1) 9Cr-ODS钢的循环应力响应和疲劳寿命与应变幅有关:在0.3%应变幅时一直保持稳定的应力平台直至50000 cyc仍未发生断裂;在0.4%应变幅时出现轻微的循环硬化后进入较长的稳定阶段,随后缓慢下降直至断裂;在0.5%~0.8%应变幅时未出现明显循环硬化,而是发生一定的循环软化。循环软化的主要原因在于亚结构发生回复,平均晶粒尺寸增大,大角度晶界体积分数增加,并伴随位错密度下降。

(2) 9Cr-ODS钢的疲劳寿命在低应变幅下主要由弹性应变控制,但在较高应变幅下转变为塑性应变控制。其低周疲劳性能符合Coffin-Manson应变寿命方程:

(3) 9Cr-ODS钢疲劳断口均包含裂纹源区、裂纹扩展区与瞬断区3个特征区域。疲劳裂纹起源于样品表面,但附近均未观察到明显的夹杂物或析出相。随总应变幅的增加,裂纹扩展区韧窝逐渐变浅、数量减少,且裂纹扩展率加快、二次裂纹的宽度增加。疲劳裂纹为穿晶扩展方式,细的原奥氏体晶界及亚晶界等对裂纹扩展具有阻碍作用。

(4) 在相同低循环应变幅、不降低疲劳寿命情况下,9Cr-ODS的峰值拉应力达到CLAM钢的约2倍,说明其具有更优异的疲劳强度。

参考文献

Low cycle fatigue properties of a low activation ferritic steel (JLF-1) at room temperature

[J].

Fatigue performance and cyclic softening of F82H, a ferritic-martensitic steel

[J].

Radiation effects on low cycle fatigue properties of reduced activation ferritic/martensitic steels

[J].

Present development status of EUROFER and ODS-EUROFER for application in blanket concepts

[J].

Low cycle fatigue properties of CLAM steel at room temperature

[J].

Study of the deformation and damage mechanisms of a 9Cr-ODS steel: Microstructure evolution and fracture characteristics

[J].

R&D on advanced cladding materials ODS alloys for fast reactor

[J].

快堆先进包壳材料ODS合金发展研究

[J].

Study on oxide strengthened dispersion alloys for Generation Ⅳ advanced nuclear systems

[D].

用于第四代先进核能系统的氧化物弥散强化合金的研究

[D].

Effect of mechanical alloying parameters on irradiation damage in oxide dispersion strengthened ferritic steels

[J].

Development and prospect of nano-structured ODS steels for fusion reactor first wall application

[J].

聚变堆第一壁用纳米结构ODS钢的发展与前瞻

[J].

Designing radiation resistance in materials for fusion energy

[J].

High chromium ferritic and martensitic steels for nuclear applications: R. Klueh and D. Harries

[J].

A review on the development of the structural materials of the fusion blanket

[J].

核聚变堆包层结构材料研究进展及展望

[J].

High-temperature low-cycle fatigue behavior of a 9Cr-ODS steel: Part 2 - hold time influence, microstructural evolution and damage characteristics

[J].

High-temperature low-cycle fatigue behavior and microstructural evolution of an ODS steel based on conventional T91

[J].

Research on microstructure and mechanical property of 15Cr-ODS ferritic alloys

[D].

15Cr-ODS铁素体合金微观结构及力学性能的研究

[D].

High-temperature low-cycle fatigue behavior of a 9Cr-ODS steel: Part 1 - pure fatigue, microstructure evolution and damage characteristics

[J].

Ferritic/martensitic steels—Overview of recent results

[J].

Development of oxide dispersion strengthened ferritic steels for fusion

[J].

Study on microstructure and mechanical properties of 9Cr-ODS steel prepared by a powder hot forging process

[J].110016, Liaoning, China) Abstract: ODS steel is considered as one of the most promising candidate structural materials for advanced nuclear reactors due to its excellent hightemperature mechanical properties and radiation tolerance. A low activation 9Cr-ODS steel was prepared by hot forging after powder mechanical alloying. The effects of mechanical milling on powder morphology and particle size were studied by scanning electron microscope (SEM) and Xray diffraction (XRD) analysis. The microstructure of 9Cr-ODS steel were observed by transmission electron microscope (TEM), and the mechanical properties were tested by tensile experiments. It is found that after ball milling for 50 h, the particle size, grain size and lattice distortion of the powders tended to be stable. The relative density of 9Cr-ODS steel was 99.4%, indicating that the excellent compactness had successfully obtained by hot forging method. After heat treatment, 9Cr-ODS steel exhibited tempered martensite structure with high density of dislocations and fine grains. There were two types of precipitates in the matrix of 9CrODS steel, M23C6 carbides with a size of 100-200nm and Y-Ti-O nanooxides with an average size of 102nm. The number density of nanooxides could reach about 1.3×1022m-3. The tensile strength and yield strength of 9CrODS steel were 910MPa and 750MPa at room temperature, and 200MPa and 160MPa at 700℃, respectively.

粉末热锻制备9Cr-ODS钢的微观组织和力学性能研究

[J].ODS钢因其优异的高温力学性能和抗辐照能力被认为是新一代核反应堆最具潜力的结构材料之一。在机械合金化后,通过粉末热锻成型的方法制备了一种低活化9Cr-ODS钢。采用SEM、XRD、TEM及拉伸实验等研究了粉末形貌和粒度随球磨时间的变化规律,以及热处理后9Cr-ODS钢的微观组织及力学性能。实验结果表明,球磨至50 h后,粉末的粒度、晶粒尺寸和晶格畸变趋于稳态。热处理后的9CrODS钢成功获得了具有高密度位错的回火马氏体组织,晶粒细小,析出相为M23C6碳化物及Y-Ti-O型氧化物。氧化物颗粒的平均直径为10.2nm,数密度约为1.3×1022m-3。粉末热锻成型的9Cr-ODS钢的致密度达到了99.4%,并具有优良的强塑性,其室温抗拉强度和屈服强度分别为910MPa和750MPa,700℃时分别为200MPa和160MPa。

Microstructure and mechanical properties of a novel designed 9Cr-ODS steel synergically strengthened by nano precipitates

[J].Oxide dispersion-strengthened (ODS) steels with nano-scale Y2O3 or Y-Ti-O oxides have been considered as potential structural materials used in advanced nuclear systems. In this work, a novel 9Cr-ODS steel, namely, MX-ODS steel, was designed by decreasing carbon content to eliminate conventional M23C6-type carbides and by increasing the content of nitrogen and vanadium to form MX-type precipitates. In addition, the MX-ODS steel was synergistically strengthened by nano-scale MX precipitates and oxides. After fabrication by powder metallurgy, microstructural observation, and mechanical property tests were conducted after different heat treatments. The density of the prepared materials using hot forging instead of hot isostatic pressing was about 98%. Results of the microstructure observation of the MX-ODS steel indicated that after normalizing and tempering, the tempered martensitic structure dominated, and the mean effective grain size was approximately 1 μm. Moreover, the preferential orientation of coarse-grained and fine-grained mixed grains was not detected. By diminishing carbon content, M23C6-type carbides precipitated at the grain and sub-grain boundaries were eliminated. By contrast, MX-type precipitates with a diameter of approximately 30-200 nm were formed in the matrix. Furthermore, nano-scale Y-rich oxides with an average size of approximately 3.0 nm were dispersed in the matrix, and a number density can reach to approximately 1.9 × 1023 m-3. Furthermore, “core-shell” structure precipitates were found, which were spherical in shape with a diameter ranging from 10 to 20 nm. Such precipitates also contained Y, Ta, and O as the core and V as the shell. The mechanical properties indicate that microhardness decreased from 372 to 320 HV with the increase of normalizing temperature from 980oC to 1200oC. In addition, microhardness decreased significantly after tempering but initially increased and then decreased with the increase of tempering temperature from 700oC to 800oC, with a peak microhardness at approximately 750oC. Excellent strength and ductility were obtained after normalizing at 1100oC for 1 h and then tempering at 750oC for 1 h. Yield strength, ultimate tensile strength, and total elongation were 1039 MPa, 1103 MPa, and 20.5% when tested at room temperature and 291 MPa, 333 MPa, and 16% at 700oC, respectively.

新型纳米复合强化9Cr-ODS钢的设计、组织与力学性能

[J].

A study of the effects of cyclic thermal stresses on a ductile metal

[J].

Low-activation ferritic and martensitic steels for fusion application

[J].

The tensile deformation, cyclic fatigue and final fracture behavior of dispersion strengthened copper

[J].

Fatigue behaviour of ODS ferritic-martensitic Eurofer steel

[J].

Low cycle fatigue behavior of JLF-1 steel at elevated temperatures

[J].

Microstructure evolution in CLAM steel under low cycle fatigue

[J].

Thermoelastoviscoplastic modeling of RAFM steel JLF-1 using tensile and low cycle fatigue experiments

[J].

Irradiation damage concurrent challenges with RAFM and ODS steels for fusion reactor first-wall/blanket: A review

[J].

Low-cycle fatigue behavior of 1100 MPa grade high-strength steel

[J].The low-cycle fatigue (LCF) behavior of 1100 MPa grade tempered high strength steel under symmetrical strain control conditions was studied at the strain amplitude ranges of 0.4%~1.2% in this work. The LCF properties of quenching and tempering high strength steel were examined by means of OM, SEM and TEM. The microstructure changes, fracture morphology, crack propagation characteristics and inclusion morphology were studied in detail. The results show that the cyclic hardening and cyclic softening depend on strain amplitude. At the low strain amplitude of 0.4%, rapid cyclic hardening occurs in initial 10 cyc, and then the stress remains almost unchanged until the sample breaks. While at the strain amplitude ranges of 0.5%~1.2%, the cyclic hardening reaches a peak at the first few cycles, followed by the remarkable cyclic softening until the sample fails. The cyclic softening is mainly due to the recovery of some martensite lath under low-cycle fatigue loading and the decrease of dislocation density in the laths. 1100 MPa grade high-strength steel is found to obey LCF Manson-Coffin relationship. The high-strength steel has excellent LCF performance for two main reasons, which is related with the shape and size of inclusions. One is that the shape of the inclusion is nearly circular, and the diameter is 2~5 μm, which is lower than the critical dimension of the inclusions causing fatigue crack initiation. The crack is initiated on the surface of the sample. This increases fatigue crack initiation life. The other one is that the original austenite grain boundary, the martensite packet/block boundary and the inclusions or cavities can induce the crack deflection, reducing the crack propagation rate and increasing fatigue crack propagation life.

1100 MPa级高强钢的低周疲劳行为

[J].研究了在对称应变控制条件下1100 MPa级调质态高强钢的低周疲劳性能,借助OM、SEM、TEM等手段对高强钢在低周疲劳载荷下的微观组织、断口形貌、裂纹扩展特性、夹杂物形态等进行了研究。结果表明,调质态1100 MPa高强钢具有优异的低周疲劳性能,主要有2个原因:一是由于夹杂物形态为近圆形,直径为2~5 μm,低于夹杂物引起疲劳裂纹萌生的临界尺寸,裂纹萌生于试样表面,提高了疲劳裂纹萌生寿命;二是原奥氏体晶界、马氏体板条包/束界、夹杂物/孔洞都会诱导裂纹偏转,使裂纹走向曲折,降低了裂纹扩展速率,提高了疲劳裂纹扩展寿命。