近年来,科研人员对电弧DED技术在Al-Zn-Mg-Cu系合金上的应用展开研究。Yu等[11]通过非熔化极气体保护焊(GTA)多丝电弧沉积系统制造了Al-Zn-Mg-Cu合金部件,发现其微观组织主要由柱状晶组成,合金的抗拉强度仅有241 MPa,且力学性能具有典型的各向异性。Wang等[12]使用多丝电弧DED技术沉积了Al-5.7Zn-3.4Mg-1.6Cu合金部件,发现合金的力学性能远低于锻造的产品,极限抗拉强度(UTS)仅有234.9 MPa。对于Al-Zn-Mg-Cu合金,除了常见的氢气孔缺陷外,由于存在较宽凝固区间,在电弧DED工艺中还存在热裂纹缺陷[11,13]。因此,沉积合金的力学性能与航空航天领域的应用要求还有很大差距。在沉积合金中添加微合金元素是改善微观组织的一种有效方法,通过促进非均匀形核实现细化晶粒,可以抑制沉积缺陷从而提高成型件的力学性能。Ren等[14]的研究证明了Sc元素在电弧DED沉积Al-Mg合金中有均匀化微观组织的作用,并制备了无裂纹合金部件,增强了沉积合金的力学性能,其UTS从325 MPa增加到415 MPa,消除了各向异性。Xia等[15]采用GTA工艺沉积了Al-Mg-0.3Sc合金,发现Sc元素在熔池中以稳定的Al3Sc颗粒存在,促进了非均匀形核并细化晶粒,使合金的晶粒尺寸从425.71 μm减小到26.96 μm。Dong等[16]通过钨极气体保护电弧焊(GTAW)增材制造系统,采用Al-Mg-0.35Sc丝材和Al-Zn-Mg-Cu丝材同步送丝的方法制备了无裂纹的Al-Zn-Mg-Cu-0.15Sc合金部件,并分析了Sc元素对Al-Zn-Mg-Cu合金组织演变的影响;沉积态合金的屈服强度(YS)和UTS分别达到了234和326 MPa,比不添加Sc的合金提高了约30%。虽然通过成分合金化方法明显提高了沉积合金的力学性能,但与传统工艺制造的Al-Zn-Mg-Cu合金相比仍存在很大差异。

Al-Zn-Mg-Cu系合金作为典型的沉淀强化合金,可以通过热处理工艺调控第二相的存在形式,从而提高合金的力学性能。然而,电弧DED合金由于其特殊的微观结构无法直接应用传统铝合金热处理工艺,需要对沉积态合金的热处理工艺进行系统研究。Klein等[17]通过冷金属过渡(CMT)技术沉积了Al-7.72Zn-1.96Mg-2.16Cu合金,对沉积态合金进行470 ℃、5 h + 160 ℃、24 h的热处理后,UTS、YS和伸长率得到明显改善,分别达到477 MPa、431 MPa和3.9%。Dong等[16]采用GTA沉积Al-Zn-Mg-Cu-0.15Sc合金,再经300 ℃、2 h + 470 ℃、3 h + 120 ℃、21 h热处理后,晶界的粗大连续共晶相消失,YS、UTS和伸长率分别达到400 MPa、449 MPa和6%。因此,热处理在改善电弧DED铝合金的微观结构和力学性能方面有着显著效果。Miao等[18]研究了热处理过程中沉积合金的孔隙演变,发现孔隙率随固溶温度和时间的增加而增加,研究表明是由于Kirkendall效应导致的固溶缺陷。Hao等[19]使用自制的7B55丝材沉积了薄壁合金构件,发现固溶处理温度在480 ℃时固溶效果最好,且晶粒尺寸没有增大,为时效过程提供更多驱动力。Fu等[20]通过热丝技术沉积7055铝合金,经过400 ℃、4 h + 468 ℃、8 h + 473 ℃、6 h + 120 ℃、16 h的热处理,UTS和伸长率分别达到563 MPa和10%。然而,时效工艺参数的调控对析出相的形成以及力学性能有着决定性影响,上述研究缺乏对后续人工时效处理的最佳工艺的深入研究。

本工作基于7075铝合金焊丝,通过优化合金成分并添加Sc元素,设计并制备出一种高强度的Al-Zn-Mg-Cu-Sc焊丝,命名为7075-Sc。以7075-Sc丝材为原材料,采用CMT工艺沉积了Al-Zn-Mg-Cu-Sc厚壁合金构件。对沉积态合金在470 ℃下进行了不同时间的固溶处理,确定最佳固溶处理工艺参数。随后在120 ℃下研究了时效时间对微观组织和力学性能的影响,阐明其潜在机制,最终确定了最佳热处理工艺。本工作旨在为电弧DED制备优异性能的7系铝合金提供参考。

1 实验材料和方法

1.1 电弧DED和热处理

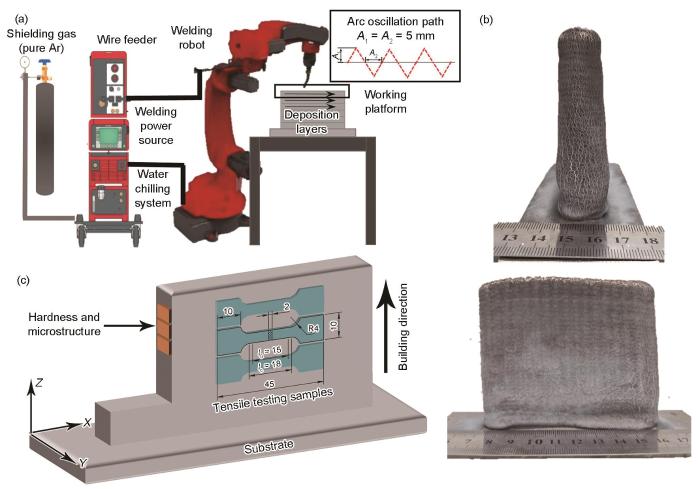

合金经熔炼、铸造、热挤压、冷拉及表面处理等工序,最终制成直径1.2 mm的7075-Sc盘绕丝材,并用于本次沉积实验。电弧DED系统主要由送丝机、KUKA KR30HA焊接机器人和CMT Advanced 4000 R焊接电源组成,示意图如图1a所示。沉积过程采用同向沉积策略,在10 mm厚的7075铝合金轧制板上进行。同时,每层沉积结束后设置120 s的停留时间对合金进行冷却。为了增加沉积合金的厚度,实验采用呈锯齿形电弧摆动的沉积路径,其中摆动幅度(A1)为5 mm,摆动长度(A2)为5 mm,摆动频率为1 Hz,以这种方式尝试沉积25层。实验使用的沉积电流为80 A,电压为12.2 V,送丝速率为4.9 m/min,沉积速率为0.3 m/min;保护气体为纯Ar气(99.99%),流量25 L/min。在此条件下制备平均尺寸为98 mm (长) × 20 mm (宽) × 83 mm (高)的厚壁构件(图1b)。采用ICAP7400型电感耦合等离子体发射光谱仪(ICP-OES)对丝材和沉积合金的化学成分进行分析,分析结果列于表1。

图1

图1

电弧定向能量沉积(DED)实验过程示意图、沉积样品的形貌与实验取样位置示意图

Fig.1

Schematic of the wire-arc directed energy deposition (DED) process (a), photos of the deposited sample (b), and schematic of the experimental sampling location (unit: mm) (c) (A1—amplitude, A2—length, l0—gauge length, lc—parallel length)

表1 材料的化学成分 (mass fraction / %)

Table 1

| Alloy | Zn | Mg | Cu | Sc | Cr | Fe | Si | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 7075-Sc wire | 5.52 | 2.56 | 1.62 | 0.25 | 0.11 | 0.32 | 0.25 | 0.14 | Bal. |

| As-deposited | 5.11 | 2.38 | 1.48 | 0.23 | 0.12 | 0.28 | 0.22 | 0.14 | Bal. |

1.2 表征技术

使用线切割对沉积合金构件进行精密切割,制备用于微观结构观察和力学性能表征的样品。将样品研磨、抛光和腐蚀处理,腐蚀剂为Keller试剂。采用VHX-2000超景深光学显微镜(OM)观察样品形貌,采用ULTRA 55扫描电子显微镜(SEM)表征第二相和微尺度缺陷的分布,使用电子背散射衍射(EBSD)技术观察晶粒形态和取向。EBSD样品在室温下使用5%HClO4 + 95%C2H6O (体积分数)溶液电解抛光,电压30 V,时间40 s,步长1.2 μm,并使用Channel 5软件进行后处理。使用D/max 2500 X射线衍射仪(XRD,CuKα )分析合金的相组成。使用Titan Themis 200透射电子显微镜(TEM)观察纳米尺度的第二相形态,并获取衍射斑点进行第二相定性分析。TEM样品为从沉积合金中切割出的10 mm × 10 mm × 1 mm薄片,用砂纸机械减薄至30 μm后,使用Gatan 691离子抛光机进行2 h减薄处理。使用Digital Micrograph软件对高分辨TEM (HRTEM)像进行快速Fourier变换(FFT)分析。

使用HVS 1000显微硬度计分别对沉积态和热处理后的样品进行显微硬度测试,载荷200 g,加载时间15 s。每个样品沿着高度方向测试10个点,取平均值。按照ISO 6892-1:2009测试方法,沿水平方向制备拉伸样品,取样位置和拉伸样品尺寸如图1c所示,标距长度为15 mm。使用AG-Xplus100KN拉伸试验机进行室温拉伸实验,拉伸速率为1 mm/min。

2 实验结果

2.1 固溶处理

从电弧DED Al-Zn-Mg-Cu-Sc合金构件的稳定段选取纵截面区域进行微观组织分析,其OM像如图2a所示。可以看出,沉积合金的微观组织由细等轴晶组成,沿沉积方向没有观察到DED铝合金中常见的分层现象。这种现象可能与电磁力的变化有关。在沉积过程中,CMT的电磁力对熔池形成搅拌效应,增加熔池内流体的运动,而摆弧的加入可以增强这种效应,导致形成较为均匀的微观组织[23]。此外,Sc元素在凝固过程中与Al基体形成的Al3Sc颗粒具有较强的稳定性,可以充当异质形核点促进异质形核,从而显著细化晶粒[24]。图2b为沉积合金的SEM像。可以看出,沉积过程中元素偏析导致晶界上形成连续的共晶相,晶粒内部析出较多点状的第二相。因此,为了提高时效强化,应先进行固溶处理,尽可能消除沉积合金凝固组织中的第二相。

图2

图2

沉积态Al-Zn-Mg-Cu-Sc合金及固溶处理后纵截面区域的OM和SEM像

Fig.2

OM (a) and SEM (b) images of the as-deposited Zn-Mg-Cu-Sc sample, and SEM images of solution-treated samples at 470 oC for 2 h (c), 4 h (d), and 6 h (e) (Insets in Figs.2c-e are locally enlarged images of the boxed areas; the arrows point to the pores)

图2c~e所示为沉积态样品经固溶处理不同时间后的第二相形貌。可以看出,固溶处理后,晶界第二相和晶内第二相明显减少,晶界特征较之前减弱,但仍有部分残余第二相没有溶解。使用ImageJ软件对多张SEM像进行处理以统计第二相的比例,结果显示,第二相的演化没有随着时间的延长而变快。固溶处理前第二相的初始占比为14.47%;固溶处理时间2 h后,第二相占比下降明显,较固溶处理前降低了63.7%;之后,第二相的溶解速率降低,在固溶处理时间为4和6 h时,第二相占比较固溶处理前分别降低了70.2%和74.4%。同时,在固溶处理过程中观察到几微米至几十微米的孔隙缺陷(如图2c~e箭头所示),并且在孔隙的边缘还存在少量第二相。由于固溶处理过程中第二相的溶解是通过元素浓度的差异进行的,而Zn和Mg等合金元素向基体的扩散速率比Al元素向第二相的扩散速率快,这种差异将导致空位聚集,形成Kirkendall孔隙缺陷[25]。并且随着固溶时间的延长,Kirkendall孔的数量也会增多。此外,在沉积态合金中的氢气孔也会在固溶过程中进一步扩散,形成更多的孔隙缺陷[26]。因此,根据第二相固溶效果和孔洞缺陷分布的综合考虑,确定最佳固溶处理时间为4 h。

2.2 时效处理

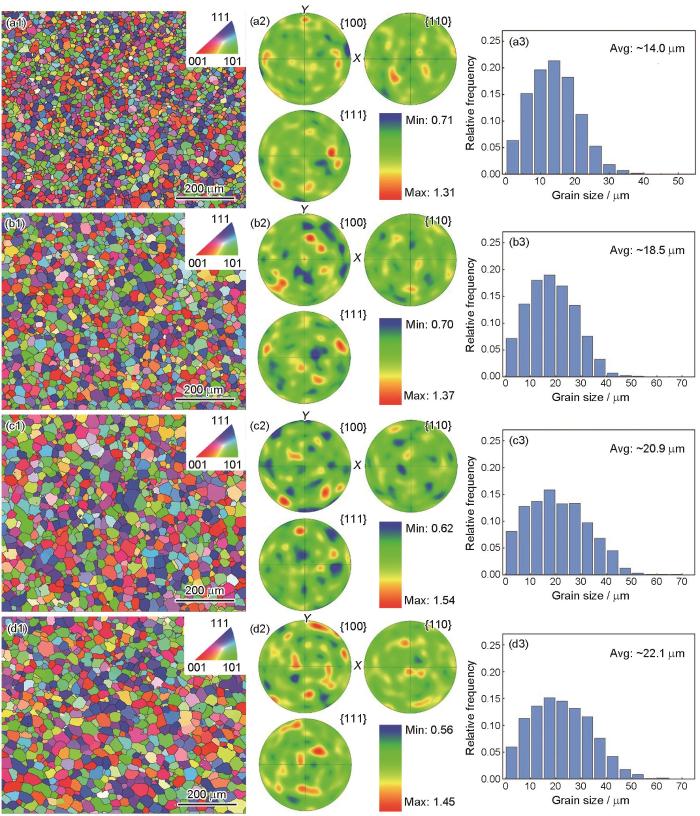

为了评估沉积态Al-Zn-Mg-Cu-Sc合金时效处理后的晶粒形态和织构,分别对不同时效时间的样品进行EBSD分析(时效态样品与沉积态样品的扫描位置相同),结果如图3所示。在沉积态下,Al-Zn-Mg-Cu-Sc合金的反极图(IPF)显示,晶粒形态为细小等轴晶,平均晶粒尺寸约为14.0 μm。同时,极图(PF)中的极投影点呈现出分散的特征,织构指数仅表现为1.45,表明沉积态合金取向均匀,见图3a1~a3。在Al-Zn-Mg-Cu-Sc合金的沉积过程中,熔池中的Al3Sc颗粒带来的异质形核作用获得了细小的等轴晶的微观组织,从而表现出随机的织构取向。经过固溶和时效热处理后,合金的晶粒取向并没有显著变化,仍然表现出非常弱的织构指数(图3b2~d2)。然而,时效后合金的晶粒有所长大,随着时效时间的延长增加4.5~8.1 μm (图3b3~d3)。这表明,热处理过程中的高温会导致沉积合金的晶粒粗化。根据热力学定律,晶粒长大的驱动力是晶界能的下降,晶粒变粗将使得晶界的总面积减小,晶界能降低,使合金处于低能量的稳定状态[27]。此外,固溶处理后晶界上连续的第二相溶解消失,导致对晶界移动的阻碍作用减弱,这是时效过程中晶粒长大的另一影响因素。

图3

图3

沉积态与时效态电弧DED合金的EBSD反极图、极图和晶粒尺寸统计图

Fig.3

EBSD inverse pole figures (a1-d1), pole figures (a2-d2), and grain size statistics (a3-d3) of the wire-arc DED alloys under the as-deposited state (a1-a3) and as-aged at 470 oC, 4 h + 120 oC, 12 h (b1-b3), 470 oC, 4 h + 120 oC, 18 h (c1-c3), and 470 oC, 4 h + 120 oC, 24 h (d1-d3)

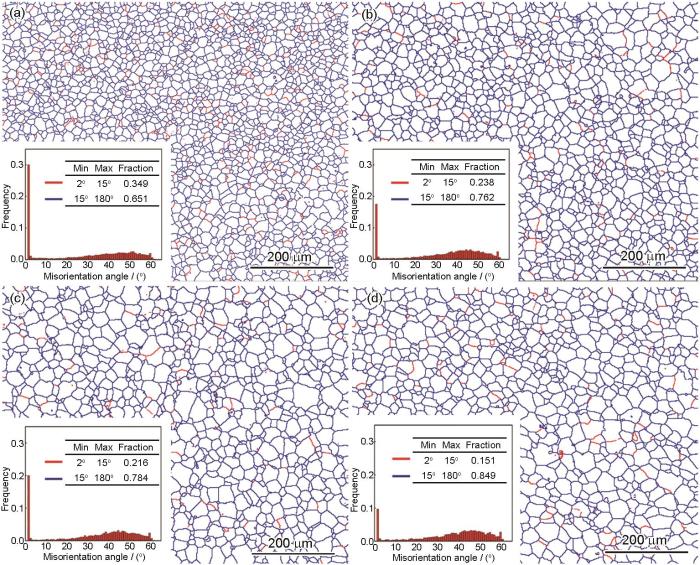

图4显示了沉积态和时效态电弧DED合金样品的晶界图和取向差分布直方图,其中,红色晶界和蓝色晶界分别表示了小角度晶界(LAGB)和大角度晶界(HAGB)。HAGB可以阻碍裂纹拓展,提高合金性能。结果显示,沉积态合金中LAGBs的占比较高,约为0.349,表明有较高的位错密度。在热处理过程中,晶粒生长的同时吸收了部分位错。随着时效时间的延长,沉积态合金中HAGBs占比逐渐增高,经过24 h时效处理后,HAGBs占比从0.651增加至0.849。

图4

图4

沉积态与时效态电弧DED合金的晶界图和取向差角统计结果

Fig.4

Grain boundary maps and misorientation angle statistical results (insets) of the wire-arc DED alloys under the as-deposited state (a) and as-aged at 470 oC, 4 h + 120 oC, 12 h (b), 470 oC, 4 h + 120 oC, 18 h (c), and 470 oC, 4 h + 120 oC, 24 h (d) (Red and blue grain boundaries represent low angle grain boundaries (LAGBs) and high angle grain boundaries (HAGBs), respectively)

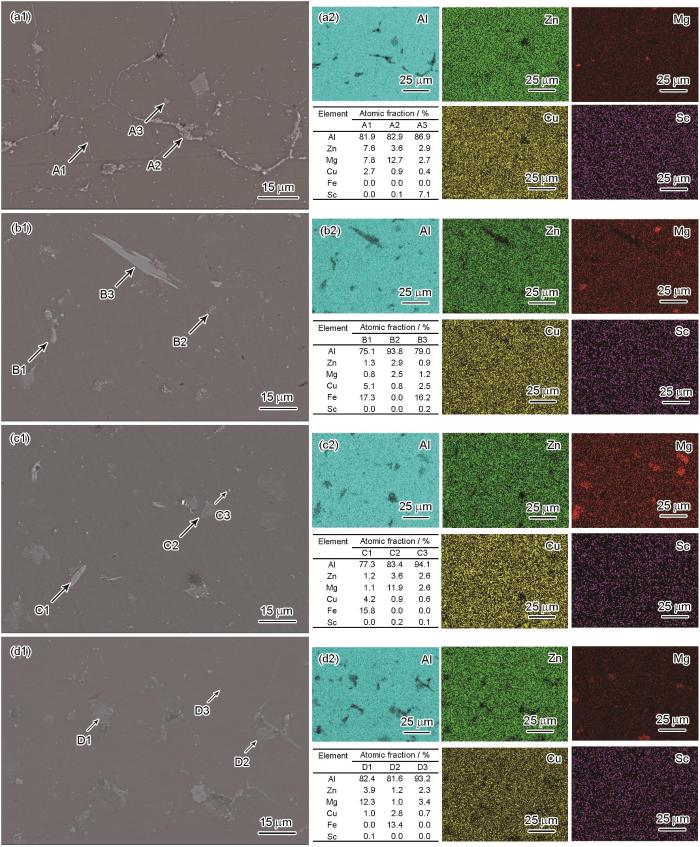

为了确定热处理后沉积合金的第二相形态和类型,对不同状态的样品进行了SEM和EDS分析,结果如图5所示。如图5a1所示,沉积态样品的第二相呈现出明显的沿着晶界分布特征,形状多为条状和块状。这是由于凝固过程中Mg、Zn和Cu等元素存在较为严重的偏析,并且在后续电弧增材的高温热循环下偏析程度加剧。EDS面扫描结果显示,由于Mg元素的扩散系数比Cu和Zn元素的高,导致Mg元素出现明显的聚集。沉积态样品中第二相EDS结果表明,晶界上条状相(A1点)的合金元素主要为Zn元素和Mg元素,其原子分数分别为7.6%和7.8%,Zn元素和Mg元素的原子比接近1.0,Fu等[20]确认其为η(MgZn2)相。同时,晶界上分布的絮状析出物(A2点)中Mg的原子分数较高,达到12.7%,表明其形成原因主要与Mg元素的偏析有关,根据原子比可以被识别为常见的富Mg相Al2Mg3Zn3 (T相)。此外,在沉积态样品的晶粒内部发现了直径约3 μm的块状第二相(A3点),EDS结果表明其含有较多的Sc元素。根据形貌和EDS的原子比,A3可以被确定为Al3Sc相,微米Al3Sc相通常来源于丝材熔化和凝固过程中形成的初生相[28]。由于Al3Sc颗粒熔点较高,且晶体结构为L12立方结构,与fcc结构Al基体仅有很小的晶格失配率(< 1.5%)[29],因此非常适合作为铝基固溶体晶粒的异质形核点,在改善合金微观结构上起到重要作用。随后,对不同状态样品进行XRD物相分析,除α-Al基体相外,只标定出了η(MgZn2)相的衍射峰(图6),其余第二相由于含量较低而无法被识别。在Al-Zn-Mg-Cu合金中,Zn原子很容易被Al和Cu原子取代,因此η(MgZn2)相通常以Mg(Al, Zn, Cu)2形式存在,有着相同的晶格结构,属于六方晶系[30]。结合SEM、EDS和XRD结果可以确定晶界连续第二相为η(Mg(Al, Zn, Cu)2)相。

图5

图5

沉积态和时效态电弧DED合金的SEM像及EDS分析

Fig.5

SEM images (a1-d1) and elemental EDS analyses (a2-d2) of the wire-arc DED alloy under the as-deposited state (a1, a2) and as-aged at 470 oC, 4 h + 120 oC, 12 h (b1, b2), 470 oC, 4 h + 120 oC, 18 h (c1, c2), and 470 oC, 4 h + 120 oC, 24 h (d1, d2)

图6

图6

沉积态和不同时效时间热处理后样品的微区XRD谱

Fig.6

Micro-area XRD spectra of as-deposited and heat-treated samples with different time

热处理后,沿晶界分布的第二相明显减少(图5b1~d1),但仍然有部分残余第二相没有在固溶处理中溶解。在经不同时间时效处理的合金中,通过一些典型第二相的EDS点扫描和面扫描可以看出,时效时间为24 h时合金没有明显出现过时效状态。不同时效工艺下,沉积合金的第二相类型相似,未溶解相主要为富Fe相和富Mg相。研究[21,31]表明,当固溶温度为470 ℃时,Zn和Mg原子的扩散速率相当,部分η(Mg(Al, Zn, Cu)2)在溶解过程中会首先转变为杂质相Al7Cu2Fe再进行溶解,且Al7Cu2Fe相的熔点较高导致溶解速率较低。因此,结合典型第二相(B1、B3、C1和D2处)含量分析可以确定富Fe相为热处理后合金的主要残余相。由于富Fe相硬度较高和界面的脆性,在受到拉伸载荷时裂纹优先在Al7Cu2Fe/Al基体界面处形核,促进了裂纹萌生,对试样延伸率产生不利影响。此外,由于T相的溶解速率非常缓慢,也会作为一部分残余第二相存在于合金中。

2.3 力学性能

通过测量所有样品的显微硬度以评估Al-Zn-Mg-Cu-Sc合金的时效响应,结果如图7所示。经过时效热处理后,沉积合金析出MgZn2强化相,导致硬度明显增加。研究[32,33]表明,Al-Zn-Mg-Cu合金硬度在120 ℃进行24 h时效能达到峰值,继续延长时间则可能过时效,因此本工作选择24 h为最长时效时间。在开始的12 h,时效硬度较沉积态样品增加了24%,平均硬度达到205.00 HV0.2。随着时效时间的延长,合金的硬度逐渐增加,但增速较之前明显减缓。在后面的12 h,合金元素经过析出物的消耗,基体的过饱和度已经逐渐降至最低,硬度仅增加了10%,平均硬度达到225.89 HV0.2,这与之前研究[32,33]的时效峰值接近。

图7

图7

沉积态和不同时效时间热处理后样品的硬度

Fig.7

Hardnesses of as-deposited and heat-treated samples with different time

图8显示了沉积态和不同时效时间热处理后合金的工程应力-应变曲线和拉伸性能。沉积态合金的平均屈服强度、极限抗拉强度和延伸率分别为311.0 MPa、397.2 MPa和3.8%。经过热处理后,由于纳米级η'相析出,通过Orowan强化机制显著提升了合金强度。

图8

图8

沉积态和不同时效时间热处理样品的工程应力-应变曲线和拉伸性能

Fig.8

Engineering stress-strain curves (a) and tensile properties (b) of as-deposited and heat-treated samples with different time

相比沉积态合金,时效态合金的力学性能得到了明显提升,并且屈服强度随着时效时间的延长而增加。当时效时间为24 h时,合金的屈服强度增加到482.5 MPa,与沉积态样品相比提高了约55%。然而,随着时效时间的延长,热处理样品的延伸率有所下降,在24 h时延伸率为3.9%,接近沉积态样品。时效热处理主要为合金提供析出强化,在时效初期强化相η' (MgZn2)的数量不断增多,析出相密度变大,对变形过程中的位错运动起到阻碍作用,因此合金性能得到提升。随着时效时间延长,析出相不断聚集和粗化,η'相的体积也逐渐变大,并且一部分可能转变为与Al基体不共格的η(Mg(Al, Zn, Cu)2相。析出相的生长造成的匹配性损失将会导致晶格变形,并使晶粒受到拉应力之后协调性降低,从而降低热处理样品的延伸率[34]。

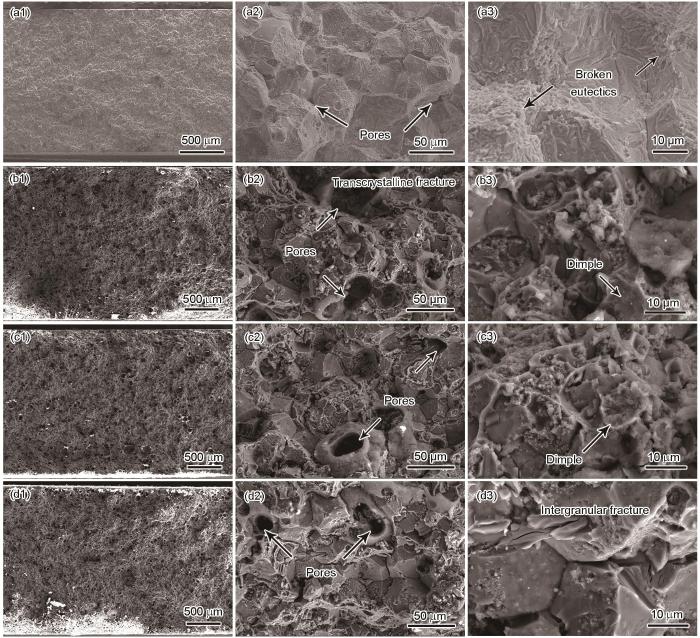

图9显示了沉积态和不同时效热处理时间下Al-Zn-Mg-Cu-Sc合金样品的典型拉伸断口形貌。如图9a1所示,沉积态样品的断裂表面十分平整,放大观察可发现近乎完整的晶粒,表明断裂模式为脆性断裂。同时,在晶界处可以看到许多微小的孔隙和破碎的共晶相特征(图9a2和a3)。当样品受到拉应力时,由于脆性析出相的变形协调性较差,将首先出现微裂纹并沿着晶界扩展,尤其在孔隙较多的区域。对于经过热处理后的拉伸样品,晶界上连续的第二相被溶解,断裂表面观察到明显的凹坑。在时效处理12和18 h的样品表面存在着一些韧窝和破碎的晶粒,表明此状态下的样品塑性较好,断裂模式为韧-脆混合断裂(图9b1~b3和c1~c3)。然而,当时效处理时间增加到24 h时,拉伸样品的断裂表面未见韧窝,显示出完整的等轴晶表面(图9d1~d3),与沉积态样品的断口形貌类似。由于MgZn2相的粗化导致延伸率显著降低,断裂模式转变为脆性断裂。此外,热处理后样品的断裂表面存在较多孔隙,且相比沉积态试样孔隙尺寸明显增加,这将显著影响合金的延伸率。

图9

图9

沉积态和不同时效热处理时间下电弧DED Al-Zn-Mg-Cu-Sc样品的拉伸断口形貌

Fig.9

Tensile fracture morphologies with different magnifications of the wire-arc DED alloys samples under the as-deposited state (a1-a3) and as-aged at 470 oC, 4 h + 120 oC, 12 h (b1-b3), 470 oC, 4 h + 120 oC,18 h (c1-c3), and 470 oC, 4 h + 120 oC, 24 h (d1-d3)

2.4 析出相

对沉积态样品开展进一步的TEM表征和分析,结果如图10所示。可见,在合金的晶界处发现了大约106 nm宽的无沉淀析出带(PFZ) (图10a),这将会降低合金的力学性能。形成原因可以从以下方面考虑:首先,根据溶质贫乏理论[35],粗大的晶界第二相的形成过度消耗了附近区域的溶质元素,导致附近区域无法析出第二相。其次,非相干性界面在一定温度下能够吸收空位原子,导致晶界第二相附近的空位浓度低于临界值,无法形成纳米析出相[36]。图10b明场像显示,晶粒内存在较多棒状和球状的纳米沉淀物。在沉积过程中,后续的热循环历史有助于这些沉淀物析出。对其中一些典型沉淀物进行放大观察,经过测量其长度约为30 nm (图10c)。进行FFT后可以确定该沉淀物为η' (MgZn2)相,与Al基体保持半共格关系,它们之间的晶面关系确定为(200)Al//(11

图10

图10

沉积态和热处理样品的TEM像和对应的快速Fourier变换(FFT)

Fig.10

TEM images (a, b, d, e) and high resolution TEM images and corresponding fast Fourier transform (FFT) (c, f) of as-deposited (a-c) and heat-treated (470 oC, 4 h + 120 oC,18 h) (d-f) samples (PFZ—precipitation free zone, d—spacing)

根据微观组织和力学性能分析,确定470 ℃下固溶处理4 h然后120 ℃下时效18 h为最佳的热处理工艺。对进行此热处理工艺后的样品进行TEM表征分析,结果如图10d所示。可见,热处理后由于晶界处粗大第二相的溶解,晶界的宽度降低至约32 nm,PFZ宽度降低至大约55 nm,但仍然存在连续的纳米沉淀物。这是由于合金元素在晶界处仍存在微观偏析[37],高浓度溶质原子更容易使析出相成核。同时晶界处的面缺陷可以降低形核能垒,促进析出相的形核,导致更容易在热处理中形成连续的第二相。合金在热处理后,高密度纳米级η'相析出,相比沉积态,其数量更多,体积分数达到0.095,通过Orowan强化机制显著提升强度。晶粒内的沉淀相形态主要为大的棒状(长度为105~280 nm)和小球状(直径为8~75 nm) (图10e)。放大观察可见直径约23 nm的球形第二相,对其进行FFT变换后可以确定为η'相,与Al基体的取向关系为(

3 分析与讨论

电弧DED沉积的Al-Mg-Zn-Cu-Sc合金在热处理后表现出优异的力学性能。根据上述分析,强化机制主要为晶界强化、固溶强化和沉淀强化。其中,晶界强化是由晶粒细化引起的。热处理后微观组织仍由等轴晶构成。细化晶粒带来的强度贡献(σGB)可以用Hall-Petch公式来计算[38]:

式中,σ0为晶格摩擦应力(20 MPa)[39],k为Hall-Petch系数(170 MPa·μm1/2),

由于在沉积过程中受到高温热循环影响,沉积态合金元素大量析出,形成粗大的第二相,相当于过时效,Al基体中溶质含量较低。热处理后,溶质扩散到基体中,通过剪切模量差产生局部应力场,从而获得固溶强化,其强度贡献(σss)可以表示为[40]:

TEM结果表明,η′ (MgZn2)相为电弧DED Al-Mg-Zn-Cu-Sc合金的主要强化相,且热处理后析出效果加强。根据Booth-Morrison等[42]的研究,Orowan位错旁路机制主导η′相带来强度贡献(σOrowan),可表示为:

式中,M表示Taylor因子(fcc晶格的M = 3.06),G表示Al基体的剪切模量(26.5 GPa)[41],b表示Burgers矢量模(0.286 nm),

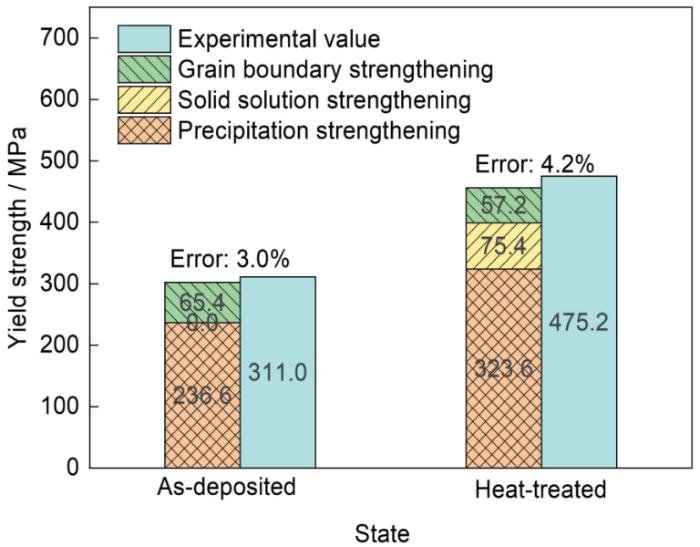

综上所述,图11显示了在沉积态和120 ℃、18 h时效态下Al-Mg-Zn-Cu-Sc合金中各强度机制的贡献程度。沉积态和热处理后合金的理论屈服强度(

图11

图11

沉积态和热处理后合金中强化机制的贡献

Fig.11

Contributions of strengthening mechanisms in as-deposited and heat-treated alloys

4 结论

(1) 在凝固过程中高熔点的Al3Sc颗粒可以促进异质形核,显著细化晶粒。沉积态Al-Mg-Zn-Cu-Sc合金由细小等轴晶组成,平均晶粒尺寸约为14.0 μm。合金元素存在严重的偏析,晶界分布着连续的第二相,主要为η(Mg(Zn, Al, Cu)2)相和富Mg相T(Al2Mg3Zn3)相。

(2) 在470 ℃下进行固溶处理,第二相的溶解速率随着时间的延长而降低,为了降低固溶孔隙缺陷,选择4 h为最佳固溶时间。在此固溶参数下,第二相溶解比例达到70.2%,残余第二相主要为杂质相Al7Cu2Fe和T(Al2Mg3Zn3)相。

(3) 在120 ℃时效时,合金的HAGBs比例和晶粒尺寸在热处理过程中增加,硬度随时效时间延长迅速增加,18 h后硬度趋于稳定,在24 h时平均硬度达到225.89 HV0.2。根据拉伸测试结果,强度随着时效时间的延长而增加,延伸率随时效时间延长先增加后降低,24 h时延伸率为3.9%接近沉积态,且屈服强度较18 h时效没有明显提升。因此,最佳的时效参数确定为120 ℃、18 h。

(4) 沉积合金的纳米析出相主要为η'相,热处理后析出效果加强,与Al基体的取向关系为(

参考文献

Progress in structural materials for aerospace systems

[J].

Development of ultrafine grained high strength age hardenable Al 7075 alloy by cryorolling

[J].

Recent developments in advanced aircraft aluminium alloys

[J].

Additive manufacturing of metallic components—Process, structure and properties

[J].

A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends

[J].Selective laser melting (SLM) is an attractive rapid prototyping technology for the fabrication of metallic components with complex structure and high performance. Aluminum alloy, one of the most pervasive structural materials, is well known for high specific strength and good corrosion resistance. But the poor laser formability of aluminum alloy restricts its application. There are problems such as limited processable materials, immature process conditions and metallurgical defects on SLM processing aluminum alloys. Some efforts have been made to solve the above problems. This paper discusses the current research status both related to the scientific understanding and technology applications. The paper begins with a brief introduction of basic concepts of aluminum alloys and technology characterization of laser selective melting. In addition, solidification theory of SLM process and formation mechanism of metallurgical defects are discussed. Then, the current research status of microstructure, properties and heat treatment of SLM processing aluminum alloys is systematically reviewed respectively. Lastly, a future outlook is given at the end of this review paper.

Experimental investigation of the effect of processing parameters on densification, microstructure and hardness of selective laser melted 7075 aluminium alloy

[J].

Fatigue analysis of wire arc additive manufactured (3D printed) components with unmilled surface

[J].

A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement

[J].

Effects of subsequent heat treatment on microstructure and high-temperature mechanical properties of laser 3D printed GH4099 alloy

[J].

后续热处理对激光3D打印GH4099合金微观组织和高温力学性能的影响

[J]激光粉末床熔融(LPBF) 3D打印技术具有跨维度多尺度成形的技术特点,同时表现出非平衡快速凝固的冶金特征,与传统制造工艺形成的微观组织存在明显差异。基于传统制造工艺发展而来的热处理工艺难以适用于LPBF制备的样品,因此,研究LPBF打印件专用的后续热处理制度对于其组织和性能调控具有重要的意义。本工作以LPBF制备的GH4099合金为研究对象,研究了后续热处理对3D打印高温合金非平衡微观组织和高温力学性能的影响。结果表明,固溶处理不仅影响打印组织的再结晶行为,而且也与碳化物和γ'相的析出行为密切相关,因而对GH4099合金的高温延伸率影响较大。LPBF制备GH4099合金中的多尺度异质结构使其组织热稳定性明显高于传统铸锻件,因此需要更高的固溶热处理温度以促进其完全再结晶。经1150 ℃固溶处理1.5 h后,GH4099打印件中柱状晶转变为等轴晶并形成大尺寸孪晶,同时晶界处M<sub>23</sub>C<sub>6</sub>碳化物的析出也受到抑制。在随后的时效热处理过程中,由于再结晶释放了3D打印晶粒内部储存的畸变能,使得基体中γ'相的析出受到了明显抑制。基于上述结果,通过优化热处理制度,GH4099合金打印件实现了高温强度和塑性的良好匹配。

Research progress on laser cladding of refractory high-entropy alloy coatings

[J].Refractory high-entropy alloys (RHEAs) have emerged as an innovative and promising class of high-entropy alloys that are primarily composed of multiple refractory elements, such as Ta, Nb, Mo, W, and Hf. These elements confer to the RHEAs with exceptional mechanical properties at high temperature, including excellent strength and stability. In addition to their desirable high-temperature performance, RHEAs also exhibit remarkable resistance to oxidation, wear, corrosion, and radiation. These resistance characteristics grant them potential as application materials in extreme environments, such as aerospace, nuclear reactors, and high-performance industrial machinery. As application materials, RHEAs have attracted evergrowing attention as the candidate materials to replace the traditional nickel-based superalloys due to their single solid solution phases and excellent stability in terms of structure and performance. Although they are promising, RHEAs fabricated using traditional methods, such as casting and powder metallurgy, present several shortcomings that limit their widespread application. It is often difficult to achieve a uniform composition in RHEAs that are prepared by conventional arc melting, which results in significant elemental segregation. Additionally, the size of the ingots prepared by this way is restricted to a small, button-like scale due to the limitations of the casting molds. These drawbacks significantly restrict the development, customization, and application of RHEAs in various industries, underscoring the need for advanced manufacturing techniques that can overcome these restrictions. Laser additive manufacturing (LAM) has emerged as a transformative approach to addressing the abovementioned challenges. By utilizing a high-energy density laser beam as a heat source, LAM enables a “discrete-stacking” or layer-by-layer forming process that can be precisely controlled through computer-aided design. This process offers exceptional flexibility in the manufacture of complex shapes, the fine-tuning of alloy composition, and the achievement of a uniform microstructure, thereby minimizing problems such as elemental segregation. Additionally, laser cladding (LC), which is a subset of LAM, provides the ability to deposit coatings that demonstrate superior mechanical and chemical properties to the surface of substrates, which further expands the application potential of RHEAs. This study presents a comprehensive review of current research on the LC of RHEAs while focusing on the unique microstructures and properties of RHEA coatings (RHEACs). It delves into the influences of alloy composition and processing parameters on the phase composition, microstructure, microhardness, as well as abrasion, oxidation, and corrosion resistances of RHEACs. Furthermore, this review discusses the evolution of RHEAC microstructure during the LC process and how it affects the performance of the coatings. Lastly, this review summarizes the current state of research on LC-RHEAs and outlines future development trends. It also highlights key challenges such as optimizing processing parameters, improving coating-substrate bonding, and tailoring microstructures for enhanced performance to guide future research studies and industrial applications.

激光熔覆难熔高熵合金涂层研究进展

[J]难熔高熵合金(RHEAs)是一种由多种难熔元素组成的新型合金,具有优异的高温力学、高温抗氧化、摩擦磨损、耐腐蚀和抗辐照等综合性能,有望应用于航空、航天、核能、石油化工和医疗器械等领域。受限于传统合金熔炼技术,目前制备的高熔点难熔高熵合金存在成型尺寸较小、元素偏析严重以及密度大等问题,极大地限制了难熔高熵合金的发展和应用。激光增材成形技术以高能量密度激光束为加热源,通过计算机辅助设计与控制实现金属材料“离散-堆积”成形过程,为突破难熔高熵合金的研究瓶颈提供了一条行之有效的途径。本文综述了近几年采用激光熔覆技术制备的难熔高熵合金涂层(RHEACs)的加工特性、显微结构和性能特点。重点讨论了合金成分、加工工艺对难熔高熵合金涂层相组成,显微形貌,显微硬度,以及耐磨损、耐腐蚀和抗氧化性能的影响,指出目前激光熔覆难熔高熵合金的研究现状、不足和挑战,并对其未来的发展趋势进行了展望。

Microstructure and mechanical properties of Al-Zn-Mg-Cu alloy fabricated by wire + arc additive manufacturing

[J].

A novel heterogeneous multi-wire indirect arc directed energy deposition for in-situ synthesis Al-Zn-Mg-Cu alloy: Process, microstructure and mechanical properties

[J].

Effects of deposition paramaters on the microstructure evolution of wire arc additive manufactured Al-Zn-Mg-Cu alloy

[J].

Effect of Sc content on the microstructure and properties of Al-Mg-Sc alloys deposited by wire arc additive manufacturing

[J].

Wire arc additive manufacturing of Al-Mg-Sc alloy: An analysis of the effect of Sc on microstructure and mechanical properties

[J].

Addition of Sc in wire-based directed energy deposition of Al-Mg-Zn-Cu alloy: Microalloying to refine grains and improve mechanical properties

[J].

Wire-arc additive manufacturing of a novel high-performance Al-Zn-Mg-Cu alloy: Processing, characterization and feasibility demonstration

[J].

Effect of solution treatment on porosity, tensile properties and fatigue resistance of Al-Cu alloy fabricated by wire arc additive manufacturing

[J].

Study on the solid solution temperature of achieving ultra-high strength in wire-arc additive manufactured Al-Zn-Mg-Cu aluminum alloy

[J].

Achieving high strength-ductility of Al-Zn-Mg-Cu alloys via hot-wire arc additive manufacturing enabled by strengthening precipitates

[J].

Evolution of second phases and mechanical properties of 7075 Al alloy processed by solution heat treatment

[J].

Microstructure and intermetallic phase evolution during the homogenization of an Al-Zn-Mg-Cu-Zr-Nd aluminum alloy

[J].

Effects of arc oscillation on microstructure and mechanical properties of AZ31 magnesium alloy prepared by CMT wire-arc directed energy deposition

[J].

Microstructure and mechanical properties of a novel Sc and Zr modified 7075 aluminum alloy prepared by selective laser melting

[J].

Effects of residual S on Kirkendall void formation at Cu/Sn-3.5Ag solder joints

[J].

Growth behavior of hydrogen micropores in aluminum alloys during high-temperature exposure

[J].

An intrinsic correlation between driving force and energy barrier upon grain boundary migration

[J].The migration of grain boundary (GB), which plays a key role in the microstructural evolution of polycrystalline materials, remains mysterious due to the unknown relationship between GB mobility associated with specific geometry and external conditions (e.g. temperature, stress, etc., hence the thermodynamic driving force). Combining the rate equation of GB migration with molecular dynamics simulations, an intrinsic correlation between driving force and energy barrier for the migration of various types of GBs (i.e. twist, symmetric tilt, asymmetric tilt, and mixed twist-tilt) is herein explored, showing the decrease of energy barrier with increasing thermodynamic driving force.

Effects of Zr, Ti and Sc additions on the microstructure and mechanical properties of Al-0.4Cu-0.14Si-0.05Mg-0.2Fe alloys

[J].The evolution of microstructure and mechanical properties of Al-0.4Cu-0.14Si-0.05Mg-0.2Fe (wt.%) alloys, micro-alloyed with Zr, Ti and Sc, were investigated. The addition of 0.2%Zr to base alloy accelerates the precipitation of Si-rich nano-phase in α-Al matrix, which plays an important role in improving the mechanical properties of an alloy. The tensile strength increases from 102 MPa for the base alloy to 113 MPa for the Zr-modified alloy. Adding 0.2%Zr + 0.2%Ti to base alloy effectively refines α-Al grain size and accelerates the precipitation of Si and Cu elements, leading to heavy segregation at grain boundary. By further adding 0.2%Sc to Zr + Ti modified alloy, the segregation of Si and Cu elements is suppressed and more Si and Cu precipitates appeared in α-Al matrix. Accompanied with the formation of coherent Al3Sc phase, the tensile strength increases from 108 MPa for the Zr + Ti modified alloy to 152 MPa for the Sc-modified alloy. Due to excellent thermal stability of Al3Sc phase, the Sc-modified alloy exhibits obvious precipitation hardening behavior at 350 °C, and the tensile strength increases to 203 MPa after holding at 350 °C for 200 h.

Nanoscale structural evolution of Al3Sc precipitates in Al(Sc) alloys

[J].

Transmission electron microscopy investigation of separated nucleation and in-situ nucleation in AA7050 aluminium alloy

[J].

Step solution treatment of a wire-arc directed energy deposited Al-Zn-Mg-Cu alloy: Defects suppression and mechanical property improvement

[J].

Effect of non-isothermal retrogression and re-aging treatment on microstructure evolution and mechanical properties of Al-Zn-Mg-Cu alloy

[J].

The effect of multistage ageing on microstructure and mechanical properties of 7050 alloy

[J].

Effect of post-weld heat treatment on microstructure and mechanical properties of 7055 aluminum alloy electron beam welded joint

[J].

On solute depletion zones along grain boundaries during segregation

[J].We propose a model for predicting the depletion zone arising next to grain boundaries during non-equilibrium segregation. The model directly links to distribution of segregation energies as provided by atomistic simulations. We expose the theoretical framework based on the thermodynamic extremal principle and propose an efficient algorithm to solve the underlying equations. The example of the W-25at%Re is discussed to illustrate the main features of the model. Multi-component segregation kinetics is discussed for segregation of B, C, and N in Mo to illustrate site-competition scenarios. Comparison with earlier results obtained without depletion illustrates the importance of this effects. Finally the depletion zones along GBs are investigated for many different compositions to asses for which material composition and heat treatments they may be observed experimentally. We find that extended depletion zones arise for very small solute concentrations. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

Atom probe tomography of nanoscale microstructures within precipitate free zones in Al-Zn-Mg(-Ag) alloys

[J].

Segregation assisted grain boundary precipitation in a model Al-Zn-Mg-Cu alloy

[J].

Comparison between dislocation dynamics model predictions and experiments in precipitation-strengthened Al-Li-Sc alloys

[J].

The microstructure and mechanical properties of 316L austenitic stainless steel prepared by forge and laser melting deposition

[J].

Effect of post-deposition heat treatment on laser-TIG hybrid additive manufactured Al-Cu alloy

[J].

Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy

[J].

Coarsening resistance at 400 oC of precipitation-strengthened Al-Zr-Sc-Er alloys

[J].