随着新能源和汽车工业的快速发展,压铸技术在汽车行业的应用越发广泛。压铸模具通常形状复杂且需多道制造工序,利用传统制造技术制备复杂模具时存在技术难度大、耗时长、制造成本高和使用寿命短等问题。近年来具有高自由度、可一体化成型的增材制造技术在模具制造领域中受到广泛关注。选区激光熔化(selective laser melting,SLM)是目前主要使用的一种增材制造技术,SLM基于离散-堆积原理,采用高能激光束结合计算机辅助设计对金属粉末进行选择性熔化,通过分层制造、逐层叠加的成型方式构造出三维实体[1],具有生产周期短、一体化成型、加工精度高、成型速度快、材料利用率高、自由度高和力学性能优异等优点[2]。

SLM的冷却速率非常高(103~108 K/s[5]),具有快热快冷的热循环效应,重复的加热和冷却循环导致试样存在很高的残余应力[6]。18Ni300马氏体时效钢的性能提升主要通过Ni、Ti、Mo和Co等元素的协同作用形成纳米级金属间化合物,而较高的冷却速率导致金属间化合物来不及析出[7]。热处理可以消除残余应力、均匀化学成分以及促进金属间化合物的析出,有效提高材料的热稳定性和综合力学性能。18Ni300马氏体时效钢的热处理主要分为直接时效和固溶时效2种工艺。固溶处理温度一般高于奥氏体转化的终了温度,在快速淬火中形成过饱和马氏体[5,8],固溶处理有利于残余应力的释放,提高成分的均匀性[9,10],可以获得全马氏体基体,有利于后续时效过程中金属间化合物的析出[11,12]。时效过程中过饱和的马氏体基体析出大量弥散分布的金属间化合物,这些金属间化合物可以阻碍位错的运动[10],从而提升强度。

18Ni300马氏体时效钢的力学性能受合金中析出相种类、尺寸、分布以及奥氏体含量的协同作用影响[13]。时效处理促使基体析出高密度镍基和少量钼基金属间化合物[12,14],同时促使马氏体逆转变生成奥氏体[15]。Mei等[16]对不同时效温度处理后SLM成型18Ni300马氏体时效钢进行了研究,发现直接时效处理后析出相主要为棒状的η-Ni3Ti。当时效温度进一步提升,还会析出球状的Laves相(Fe2Mo),然而该研究的侧重点在于析出相的类型和结构,并未对奥氏体的形成机理进行深入探讨。Tekin等[8]对直接时效和固溶时效处理后SLM成型18Ni300马氏体时效钢进行了研究,认为材料力学性能的差异是由于奥氏体的含量不同,直接时效处理后,Ni富集在晶界处,奥氏体含量上升,但其并未对打印态和固溶时效态试样的奥氏体进行详细表征。奥氏体对于性能的提升具有重要作用,部分尺寸细小的奥氏体对位错运动具有阻碍作用[17],提升强度,同时由于奥氏体的相变诱导塑性(TRIP)效应,在塑性变形过程中奥氏体会转变为马氏体,这种转变有利于减缓变形区域的扩张,推迟颈缩现象,提升材料韧性[18]。随着时效温度和时间的增加,奥氏体含量增加,塑性上升,但是析出相的尺寸、析出相间的距离也随之增加,析出相阻碍位错运动的能力下降,造成强度的下降[19]。合适的热处理工艺应当获得高强度和不低的塑性,因此时效处理的温度和时间不宜过长。打印态试样仅存在少量尺寸细小的奥氏体,合适的热处理后奥氏体含量仍较少且尺寸细小[15,16],这对研究不同热处理工艺下奥氏体的形成机理带来了挑战。目前,大部分研究仅关注不同热处理对奥氏体含量和力学性能的影响[14,15,20],鲜少对打印态、直接时效态和固溶时效态试样奥氏体的形成机理进行全面深入的研究。

本工作分析了直接时效和固溶时效2种热处理工艺对SLM成型18Ni300马氏体时效钢的微观组织和力学性能的影响。讨论了不同热处理状态下析出相的类型和结构、微观组织演变及奥氏体的形成机理,阐明不同热处理状态试样的力学性能强化机理,探讨SLM成型18Ni300马氏体时效钢的最佳热处理工艺,为实现SLM成型18Ni300马氏体时效钢的强塑性匹配提供理论基础和工艺参考。

1 实验方法

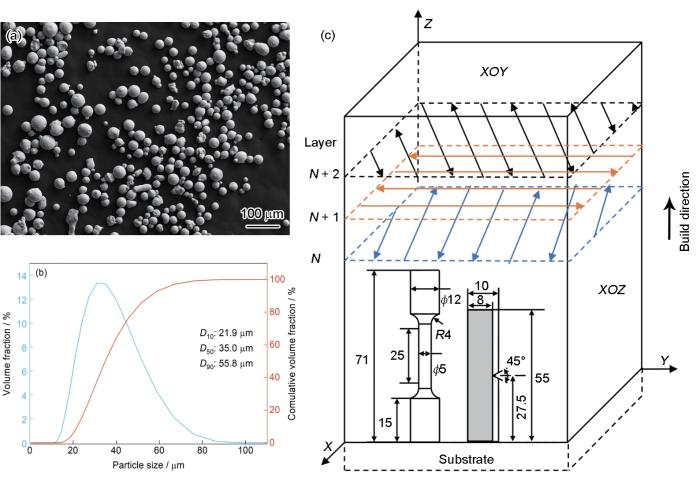

实验原材料为真空气雾化法生产的18Ni300马氏体时效钢粉末,粉末的化学成分(质量分数)为:Ni 17.22,Co 8.79,Mo 4.74,Ti 0.66,Al 0.089,Cr 0.0067,Mn 0.0093,C 0.0053,Fe余量。粉末的微观形貌如图1a所示,粉末呈现近球形,卫星粉较少。粉末的粒径分布如图1b所示,其中,D10、D50和D90分别表示粉末的累计粒度分布数达到10%、50%和90%时所对应的粒径。粉末粒径在15~53 μm之间,中值粒径为31 μm。实验采用FS273 M型SLM打印设备,光斑尺寸为85 μm。样品制备时的激光功率、扫描速率和扫描间距分别为300 W、900 mm/s和0.08 mm,层厚为50 μm,层间旋转角度为67°,成型过程的扫描策略如图1c所示。

图1

图1

18Ni300马氏体时效钢粉末形貌和粒径分布,拉伸试样和冲击试样的成型和尺寸示意图以及选区激光熔化(SLM)成型时使用的扫描策略示意图

Fig.1

Morphology of 18Ni300 maraging steel powder (a), powder particle size distribution (D10, D50, and D90 are the particle sizes of the powder at 10%, 50%, and 90% cumulative distribution, respectively) (b), and schematics of tensile specimen dimensions, impact specimen dimensions, and the scanning strategy employed during selective laser melting (SLM) process (unit: mm) (c)

为探究热处理工艺对SLM成型18Ni300马氏体时效钢的影响,使用高温气氛炉对成型试样(打印态,试样用AB表示)进行直接时效(试样用DA表示)和固溶时效(试样用SA表示)热处理。经过前期热处理工艺的探索[21],发现:直接时效处理的时效温度为490 ℃、保温时间为6 h、随炉冷却,固溶时效处理的固溶温度为820 ℃、保温时间为1.5 h、空冷,时效温度为490 ℃、保温时间为6 h、随炉冷却,此时可以获得最佳的强塑性结合。

使用D8 ADVANCE型X射线衍射仪(XRD)进行物相分析,Cu靶(波长λ = 0.15418 nm),扫描速率2°/min,扫描范围20°~100°,奥氏体的体积分数(VA)使用公式[22]:VA= 1.4ΙA/ (1.4ΙA + ΙM)进行计算(其中,IA为(111)A和(200)A峰的综合强度,IM为(110)M、(200)M、(211)M和(220)M峰的综合强度,其中下标A和M分别代表奥氏体和马氏体)。金相试样经砂纸研磨后,使用50 nm SiO2溶胶抛光到表面无划痕,选用4% (体积分数)硝酸酒精溶液为刻蚀剂,使用Axio Imager.M2m金相显微镜(OM)、Gemini SEM 460场发射扫描电子显微镜(SEM)和Talos F200X 透射电子显微镜(TEM)观察和分析显微组织。电子背散射衍射(EBSD)试样经砂纸研磨后,使用50 nm SiO2溶胶抛光去除表面应力层,使用JXA-iHP200F电子探针显微分析仪(EPMA)进行分析,测试步长为0.07 μm,加速电压为20 keV,加速电流为15 nA。使用Qness 3000CS洛氏硬度计测量硬度,每个测试面测量5组数据,取平均值。拉伸和冲击试样均沿构建方向成型,成型和尺寸示意图如图1c所示,使用Zwick/Roell Z250SH万能试验机根据GB/T 228.1—2021《金属材料 拉伸试验 第1部分:室温试验方法》进行室温拉伸实验,屈服前的应变速率为0.00025 s-1,屈服后的应变速率为0.0067 s-1。为保证数据的可重复性,每组力学性能测试至少设置3组平行试样,并使用Apreo 2S场发射SEM观察拉伸断口形貌。使用LZ22.452 Charpy摆锤冲击试验机依据GB/T 229—2020《金属材料 夏比摆锤冲击试验方法》进行室温冲击实验,每组冲击测试至少设置3组平行试样。其中,XRD、EBSD和硬度测试试样均选取与构建方向平行的面进行测试。

2 实验结果

2.1 显微组织

图2为不同状态18Ni300试样的XRD谱。试样主要由马氏体和少量奥氏体组成。打印态试样主要为马氏体组织,存在约1.4%体积分数的残余奥氏体;直接时效后,奥氏体含量上升,逆转奥氏体生成,奥氏体体积分数约6.4%。固溶时效后获得全马氏体组织,未检测到奥氏体。

图2

图2

不同热处理状态SLM 18Ni300试样的XRD谱

Fig.2

XRD spectra of SLM 18Ni300 samples after different heat treatments (VA—volume fraction of austenite; AB—as-built, DA—direct aging, SA—solution aging; A—austenite, M—martensite)

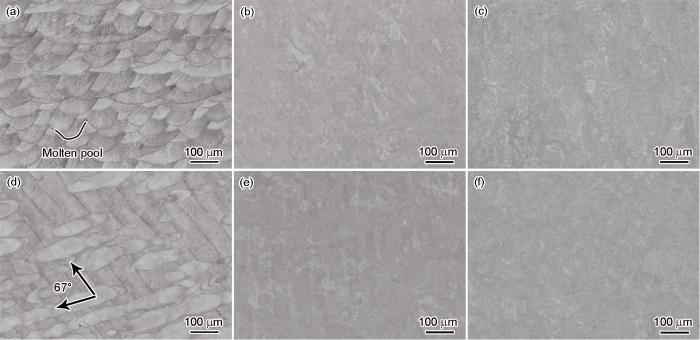

图3

图3

不同热处理状态SLM 18Ni300试样的OM像

Fig.3

OM images of SLM 18Ni300 samples after different heat treatments (a-c) XOZ surface images of AB (a), DA (b), and SA (c) samples (d-f) XOY surface images of AB (d), DA (e), and SA (f) samples

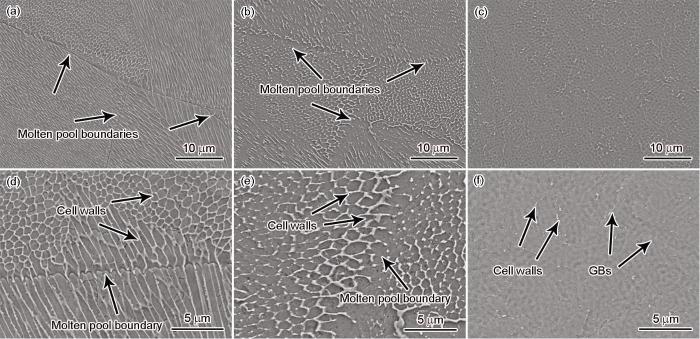

图4

图4

不同热处理状态SLM 18Ni300试样的SEM像

Fig.4

Low (a-c) and high (d-f) magnified SEM images of SLM 18Ni300 samples after different heat treatments (GB—grain boundary) (a, d) AB (b, e) DA (c, f) SA

图5为不同热处理状态18Ni300试样的EBSD像。如图5a所示,AB试样的晶粒尺寸不均,存在许多不规则长条状的大晶粒和许多细小晶粒;其残余奥氏体含量较少且尺寸细小,主要分布在晶界处,如图5d所示,且与图5a中部分细小晶粒具有良好的对应关系,这些细小晶粒与马氏体基体具有明显的不同取向。如图5b所示,DA试样保留了AB试样不规则的长条状晶粒形态,较低温度的热处理并不能完全消除激光加工的影响;DA试样的逆转奥氏体呈片状,如图5e所示,其含量和尺寸上升,主要分布在晶界处,且逆转奥氏体与图5b中部分细小晶粒具有良好的对应关系,这些细小晶粒同样与马氏体基体具有明显的不同取向。如图5c和f所示,SA试样存在许多相互平行的条状晶粒,晶粒尺寸更加均匀,试样中基本不存在奥氏体。

图5

图5

不同热处理状态SLM 18Ni300试样的EBSD像

Fig.5

Inverse pole figures (IPFs) (a-c) and phase distribution maps (d-f) of SLM 18Ni300 samples after different heat treatments (a, d) AB (b, e) DA (c, f) SA

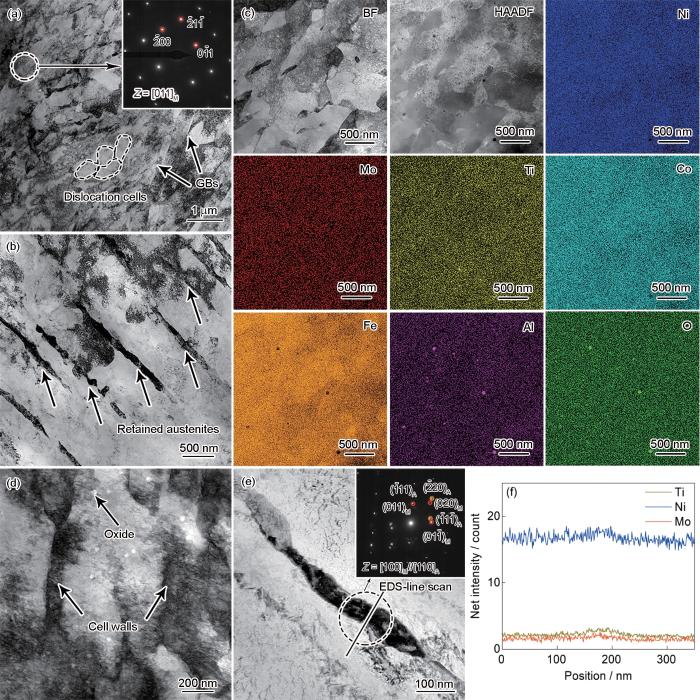

图6

图6

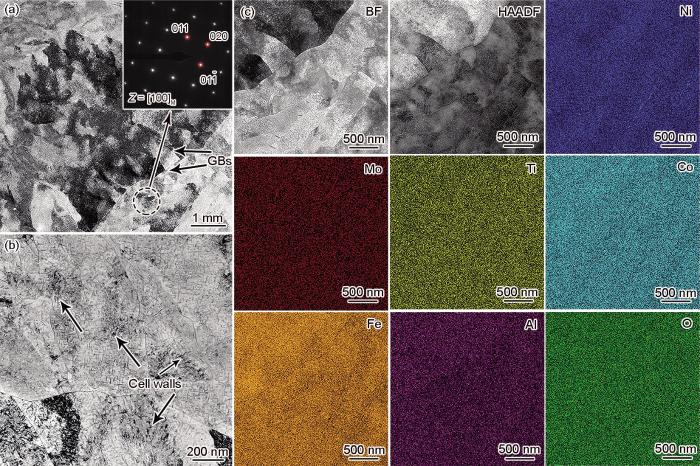

AB试样的TEM表征结果

Fig.6

TEM characteristics of AB sample

(a) bright-field (BF) image (Inset is the selected area electron diffraction (SAED) pattern)

(b) retained austenite

(c) TEM images and EDS maps (HAADF—high-angle annular dark field)

(d) detailed view of the cell structure

(e) detailed view of the retained austenite (Inset is the SAED pattern)

(f) EDS line scan result of Fig.6e

图7

图7

DA试样的TEM表征结果

Fig.7

TEM characteristics of DA sample

(a) BF image (Inset is the SAED pattern)

(b) reverted austenite

(c) TEM images and EDS maps

(d) detailed view of the cell structure

(e) detailed view of the reverted austenite (Inset is the SAED pattern)

(f) EDS-line scan result of Fig.7e

图8为SA试样的TEM表征结果。如图8a所示,SA试样主要为马氏体组织,没有明显的奥氏体组织,存在少量胞壁(图8b),残留的胞壁仍然由位错缠结组成。EDS分析结果如图8c所示,SA试样存在少量Ni或Mo的富集区域。如图9a所示,SA试样在部分马氏体晶界处存在厚度约50 nm、长度约200 nm的逆转奥氏体。该区域的EDS结果(图9b)表明,晶界存在明显的Ni、Ti和Mo的富集,Fe和Co含量则较少。而逆转奥氏体区域存在Ni富集,其他元素分布均匀,对该区域进行高分辨TEM (HRTEM)分析,结果如图9c和f所示。由于析出相的影响,其快速Fourier变换(FFT)结果较为复杂,如图9d和e所示。可见,该区域存在与马氏体基体呈现N-W取向关系的奥氏体。

图8

图8

SA试样的TEM表征结果

Fig.8

TEM characteristics of SA sample

(a) BF image (Inset is SAED pattern) (b) detailed view of the cell structure (c) TEM images and EDS maps

图9

图9

SA试样逆转奥氏体的TEM表征结果

Fig.9

TEM characteristics of the reverted austenite of SA sample, including BF image (a), TEM image and EDS maps (b), HRTEM image of Fig.9a (c), fast Fourie transform (FFT) of regions d (d) and e (e) in Fig.9c, and FFT of Fig.9c (f)

图10

图10

DA和SA试样中析出相的TEM像和相应区域的EDS元素分析,及单个析出相的EDS线扫描结果

Fig.10

BF images, HAADF images and EDS maps of the precipitated phase, and the EDS-line scan results of a nanoparticle in the DA (a) and SA (b) samples

图11为DA和SA试样纳米析出相的HRTEM像和FFT结果。如图11a和c所示,DA和SA试样析出相的(11

图11

图11

DA和SA试样析出相的HRTEM像和快速Fourier变换(FFT)结果

Fig.11

HRTEM images (a, c) and corresponding FFT (b, d) of the precipitated phase in DA (a, b) and SA (c, d) samples (The precipitated phases of DA and SA samples are η-Ni3Ti)

2.2 力学性能

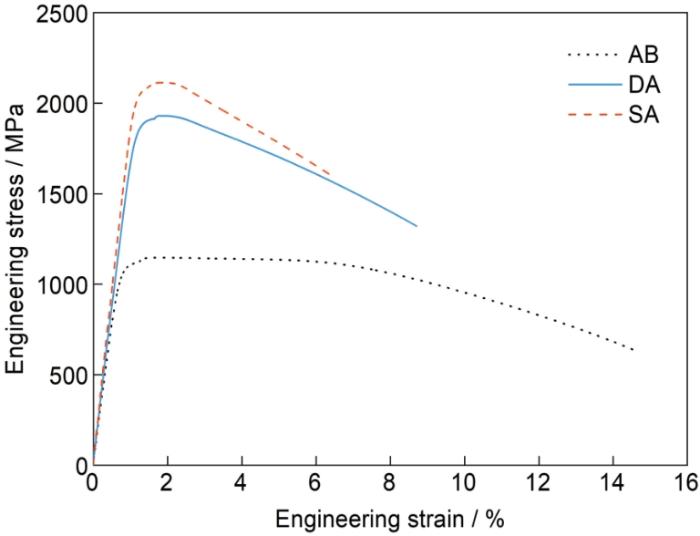

图12为不同状态18Ni300试样的工程应力-应变曲线,具体数值如表1所示。AB试样的强度最低,屈服强度为(1090 ± 1.5) MPa,抗拉强度为(1147 ± 1.5) MPa,断后伸长率为14.5% ± 1.4%,塑性最好,硬度为(36.6 ± 0.6) HRC。SA试样的强度最高,屈服强度为(2059 ± 9.9) MPa,抗拉强度为(2114 ± 9.0) MPa,断后伸长率为6.0% ± 1.4%,塑性最低,硬度为(54.7 ± 0.4) HRC。DA试样的强度较SA试样的低,屈服强度为(1854 ± 13.2) MPa,抗拉强度为(1931 ± 8.1) MPa,断后伸长率为8.5% ± 1.0%,塑性较好,硬度为(52.3 ± 0.3) HRC。DA和SA试样的Charpy冲击实验结果表明,DA试样的冲击吸收功为(18.3 ± 0.6) J,SA试样的冲击吸收功为(17.3 ± 0.6) J,可见DA试样具有较高的冲击韧性。

图12

图12

不同热处理状态SLM 18Ni300试样的工程应力-应变曲线

Fig.12

Engineering stress-strain curves of SLM 18Ni300 samples after different heat treatments

表1 不同状态SLM 18Ni300试样的力学性能

Table 1

| State | YS / MPa | UTS / MPa | El / % | Hardness / HRC |

|---|---|---|---|---|

| AB | 1090 ± 1.5 | 1147 ± 1.5 | 14.5 ± 1.4 | 36.6 ± 0.6 |

| DA | 1854 ± 13.2 | 1931 ± 8.1 | 8.5 ± 1.0 | 52.3 ± 0.3 |

| SA | 2059 ± 9.9 | 2114 ± 9.0 | 6.0 ± 1.4 | 54.7 ± 0.4 |

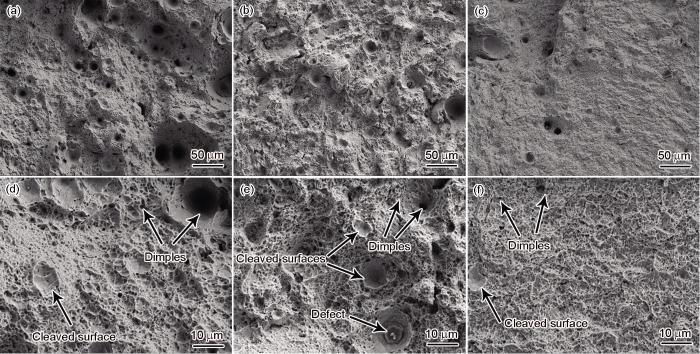

图13

图13

不同热处理状态SLM 18Ni300试样的拉伸断口形貌SEM像

Fig.13

Low (a-c) and high (d-f) magnified SEM images of tensile fractures of SLM 18Ni300 samples after different heat treatments (a, d) AB (b, e) DA (c, f) SA

SLM成型过程中不可避免会产生未融合的粉末、氧化物和气孔等缺陷,大尺寸的缺陷很可能是裂纹的萌发点[24],对材料的性能具有重要影响,选取合适的工艺参数可以减少缺陷,试样中只存在少量小尺寸的缺陷,证明是较为合适的工艺参数。

3 分析与讨论

3.1 微观组织演变

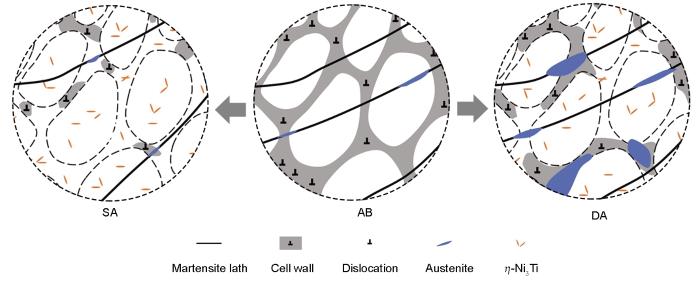

根据前文分析可知,AB试样存在许多连续胞状和柱状的组织,胞壁上具有较高密度的位错,胞内具有较低的位错密度,部分晶界处存在少量残余奥氏体。DA试样的胞状组织部分溶解,胞壁不再连续,残留的胞壁仍然由位错组成。部分晶界和残留的胞壁处有逆转奥氏体生成,奥氏体含量上升,基体存在高密度的Ni3Ti析出相。SA试样的胞状组织基本溶解,存在少量胞壁残留,残留的胞壁仍然由位错组成,晶粒尺寸增大,部分晶界处存在微量逆转奥氏体,基体存在高密度的Ni3Ti析出相。不同状态18Ni300试样的微观组织演变如图14所示。

图14

图14

不同热处理状态SLM 18Ni300试样的微观组织演变示意图

Fig.14

Schematic of microstructure evolution of SLM 18Ni300 samples after different heat treatments

胞状组织在增材制造中广泛存在,这是由于激光加工的超高冷却速率所造成的微观组织形貌[25]。通常认为,胞状组织是由位错缠结形成的,位错的来源一般认为是激光加工过程中的重复加热导致已凝固部分再次受热发生膨胀而引起的塑性变形[26,27]。如图4a和d所示,胞状组织呈胞状或柱状形貌,其形态演变主要由温度梯度(G)与凝固速率(R)之比(G / R)决定[9],G / R越大,越倾向于形成柱状晶,且柱状晶的生长方向为主要热流方向[26];G / R越小,越倾向于形成胞状晶。熔池底部的热输入较小,G最大,而R接近于0,G / R较大,组织为柱状晶;热输入从熔池底部开始上升,R逐渐增大,G逐渐减小,G / R逐渐减小,由柱状晶逐渐向胞状晶演变。由于高能激光束和小尺寸的熔池,SLM存在远大于熔池尺寸的热影响区,复杂的热流使胞状组织的形态分布更加复杂[27]。胞状组织可以作为软屏障阻碍位错的运动,提高强度,同时可以促进加载过程中的塑性流动,从而提高塑性,还可以作为溶质元素偏聚的优先位置[27]。如图4e和f所示,经过热处理后胞状组织发生不同程度的溶解,使其呈现不连续的形貌,胞状组织的溶解主要通过位错的迁移和湮灭实现[16],胞状组织减少会对材料的强度和延展性产生不利影响[14,26]。

AB、DA和SA试样具有不同含量的奥氏体。AB试样在部分晶界处存在少量呈长条状且无明显化学成分偏析的奥氏体(图6),这很可能是由于马氏体形成过程中马氏体相互挤压,导致晶界处部分奥氏体没有足够的空间进行马氏体转变而残留的残余奥氏体[28],残余奥氏体可以作为时效过程中逆转奥氏体生成的形核点[12]。时效处理使Ni在部分晶界和胞壁处富集(图7),Ni含量的提升可以增加马氏体转变生成奥氏体的相变驱动能,促使逆转奥氏体生成,同时可以降低马氏体初始转化温度,稳定生成的逆转奥氏体[29]。固溶时效处理使残余奥氏体全部转化成马氏体(图8),胞状组织基本溶解,合金元素分布均匀,Ni难以富集,逆转奥氏体难以生成,但是长时间的时效处理依旧使Ni在部分晶界处富集,生成逆转奥氏体,由于这些逆转奥氏体数量极少、尺寸极小,很难被EBSD和XRD捕获。因此DA试样具有最高含量的奥氏体,SA试样具有最低含量的奥氏体。

如图11所示,DA和SA试样都在时效过程中析出高密度的棒状纳米级Ni3Ti金属间化合物。通常认为,时效过程中Ni和Ti的相互作用是最快速的,Ni3Ti可以快速生成[9],是主要的析出相。Co在Ni3Ti析出相中溶解度较低,会扩散到基体中。基体中Co的富集会降低Mo的溶解度,导致Mo优先偏析到已经形成的Ni3Ti析出相中。Mo可以降低Ti在α-Fe中的溶解度,促进Ni3Ti的形成,而随着Ni3Ti的形成Mo会被排斥到Ni3Ti界面处,随着时效时间和温度的增加,Ni3Ti析出相表面的Mo富集最终会形成钼基析出相[12,16,19]。这些纳米级析出相可以阻碍位错的运动,材料强度获得提升,塑性下降。固溶处理使元素分布更加均匀、基体的过饱和度增加,进而析出相成核点的数量密度增加[12],因此SA试样析出相具有较高的密度。

3.2 力学性能强化机制

式中,σ0 = 50 MPa,为晶格摩擦应力[33]。

式中,θ为平均KAM;μ = 70 nm,为EBSD测试步长。AB、DA和SA试样的KAM统计图如图15所示。其中,AB、DA和SA试样的ρ分别为1.54 × 10-3、1.44 × 10-3和1.3 × 10-3 nm-2。

图15

图15

不同热处理状态SLM 18Ni300试样的局部取向差(KAM)统计图

Fig.15

Kernel average misorientation (KAM) statistics of SLM 18Ni300 samples after different heat treatments

(a) AB (b) DA (c) SA

Δσss可以通过Fleischer关系计算,如

式中,xi 为基体中元素i的原子分数(%);βi 为元素i的固溶强化常数,其值分别为:Ni 355,Co 292,Mo 2127,Ti 2388,Al 134 MPa/at (at代表原子分数)[33]。

式中,a'为析出相长径比,DA和SA试样的a'分别为6.2和6.9;rp为析出相等效圆半径,DA和SA试样的rp分别为6.3和6.1 nm;fp为析出相体积分数,DA和SA试样的fp分别为27.9%和36.8%。本工作中a'、rp和fp均使用TEM像统计获得。

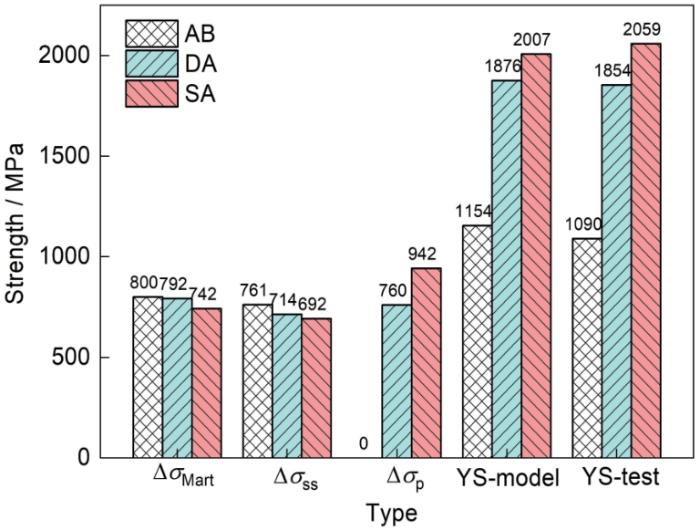

AB、DA和SA试样的屈服强度理论值和实际测试值如图16所示。理论值和测试值差距较小,具有较好的一致性。AB试样具有最高的固溶强化和马氏体相变强化数值。直接时效处理后位错密度下降,而由于逆转奥氏体的生成,晶粒尺寸下降,因此DA试样的马氏体相变强化数值与AB试样差距较小。而固溶处理能降低位错密度并促进晶粒的结晶再生长,因此SA试样的位错密度最低,晶粒尺寸上升,其马氏体相变强化数值最低。DA和SA试样的固溶强化数值相差不大,与AB试样相比发生了较为明显的下降。SA试样析出相具有更高的密度和长径比,具有更高的析出强化数值,因此拥有更高的强度。SA和DA试样的屈服强度差距较小,只进行时效处理就可以获得不低的强度。而DA试样具有较高含量的逆转奥氏体,逆转奥氏体的生成会使晶粒平均尺寸下降,促进细晶强化,部分尺寸细小的奥氏体对位错的运动具有阻碍作用[17],有利于强度的提升。奥氏体具有TRIP效应,在塑性变形过程中奥氏体会向马氏体发生转变,这种转变有利于减缓变形区域的扩张,推迟颈缩现象,有效地改善了材料的力学性能[8,18]。

图16

图16

不同热处理状态SLM 18Ni300试样屈服强度的理论值和测试值

Fig.16

Estimated and experimental results of yield strength of SLM 18Ni300 samples after heat treatments (ΔσMart—phase transformation streng-thening, Δσss—solid solution strengthening, Δσp—precipitation strengthening)

4 结论

(1) 18Ni300打印态试样具有典型熔池特征,存在连续的胞状组织和少量残余奥氏体。直接时效态试样的熔池边界变得平整,胞状组织部分溶解,逆转奥氏体在晶界和胞壁处生成,基体存在高密度析出相。固溶时效态试样的熔池结构基本消失,胞状组织基本溶解,晶界处存在微量逆转奥氏体,基体存在高密度析出相。胞状组织由位错缠结组成,不同的热处理工艺促使胞状组织发生不同程度的溶解,胞状组织的边界不再连续。打印态、直接时效态和固溶时效态试样的奥氏体均与马氏体基体存在N-W的取向关系。

(2) 打印态试样的残余奥氏体主要分布在晶界处,呈长条状,无明显元素偏析。时效处理后,Ni、Ti和Mo等元素在部分晶界和残留胞壁处发生不同程度的富集,其中Ni元素的富集促使马氏体转变生成逆转奥氏体并使其稳定存在,有利于塑性的提升。固溶时效处理后,元素分布均匀,胞状组织基本溶解,逆转奥氏体难以生成。

(3) 直接时效和固溶时效处理后,基体均析出大量长度20~50 nm、宽度5~10 nm的棒状η-Ni3Ti金属间化合物,强度提升,固溶时效态试样的析出相具有更高的密度和长径比,具有更好的析出强化效果。

(4) 固溶时效态试样的屈服强度可达(2059 ± 9.9) MPa,硬度为(54.7 ± 0.4) HRC,但是由于较低含量的奥氏体和胞状组织,塑性和冲击吸收功较低,断后伸长率为6.0% ± 1.4%,冲击吸收功为(17.3 ± 0.6) J。直接时效态试样的屈服强度可达(1854 ± 13.2) MPa,硬度为(52.3 ± 0.3) HRC,由于较高含量的奥氏体和胞状组织,具有更高的塑性和冲击吸收功,断后伸长率为8.5% ± 1.0%,冲击吸收功为(18.3 ± 0.6) J。直接时效处理具有简单的工艺和较低的能源消耗,可以获得与固溶时效处理相差较小的强度,同时具有较高的塑性和冲击韧性,是更为合适的热处理工艺。

参考文献

Progress in selective laser melted aluminum alloy

[J].

选区激光熔化铝合金的研究进展

[J].

Research progress of metal powder for additive manufacturing

[J].

增材制造用金属粉末研究进展

[J].

Research on composition optimization of maraging steel and its selective laser melting process

[D].

马氏体时效钢成分优化及其激光选区熔化成型工艺研究

[D].

The influence of aging temperature and aging time on the mechanical and tribological properties of selective laser melted maraging 18Ni-300 steel

[J].

Progress on additive manufacturing of maraging steel

[J].

增材制造马氏体时效钢的研究进展

[J].

Effect of heat treatment on low-cycle fatigue properties of selective laser melted IN718 at room temperature

[J].

热处理对激光选区熔化IN718合金室温低周疲劳性能的影响

[J].

Research progress of laser additive manufacturing of maraging steels

[J].Additive manufacture is recognized as a world-altering technology which triggered a world-wide intensive research interest. Here the research progress and application of the laser additive manufacturing maraging steel (MS) are systematically outlined. The advantages of selective laser melting (SLM) additive manufacture of MS is emphasized. The processing parameter and properties optimizations, build orientation based anisotropies, age hardening mechanism, gradient materials, and applications in die and moulds of SLM-processed MS are reviewed in detail. Achieving relative density of >99% in SLM-processed MS is effortless, owing to the wide SLM process window of MS. Mechanical properties of MS produced with optimized SLM processing parameters and post heat treatments are comparable to traditionally wrought parts. The build orientation hardly affects the property anisotropies of MS. The age hardening behaviour in MS follows Orowan bowing mechanism. MS-based gradient multi-materials (such as MS-Cu, MS-H13, etc.) with high bonding strength are fabricated by SLM, which provides a new approach to produce high-performance functionally gradient multi-materials components. Lastly, the application in conformal cooling moulds of SLM-processed MS is elucidated, and future research interests related to MS are also proposed.

激光增材制造成型马氏体时效钢研究进展

[J].本文较全面地综述了国内外激光增材制造成型马氏体时效钢(MS)的研究和应用现状。分析了选区激光熔化(SLM)制备MS特有的优势,并从SLM成型MS参数与性能优化、成型各向异性、时效强化机理、梯度材料和模具应用5个方面进行了系统介绍。研究表明,SLM成型MS的工艺窗口较宽,易获得成型致密度>99%的试样;经过激光和热处理工艺参数优化后,其力学性能可达标准锻件水平。MS时效强化遵循Orowan位错绕过机制,成型方向对MS力学性能影响较小。此外,SLM能够制备高结合强度MS基梯度材料(MS-Cu和MS-H13等)零件,为制备梯度材料功能件开辟了新途径。最后,介绍了SLM成型MS面向随形冷却模具的应用,并提出了今后的研究展望。

Effect of a direct aging heat treatment on the microstructure and the tensile properties of a 18Ni-300 maraging steel produced by laser powder bed fusion

[J].

Microstructural evolution, nanoprecipitation behavior and mechanical properties of selective laser melted high-performance grade 300 maraging steel

[J].

Influence of pore defects on the mechanical property and corrosion behavior of SLM 18Ni300 maraging steel

[J].

Tuning process parameters to optimize microstructure and mechanical properties of novel maraging steel fabricated by selective laser melting

[J].

Tailoring the nanostructure of laser powder bed fusion additively manufactured maraging steel

[J].

Effect of heat treatment on the microstructure and mechanical properties of maraging steel by selective laser melting

[J].

Effect of heat treatment on the strength and fracture resistance of a laser powder bed fusion-processed 18Ni-300 maraging steel

[J].

Effect of solution annealing and precipitation hardening at 250 oC-550 oC on microstructure and mechanical properties of additively manufactured 1.2709 maraging steel

[J].

Effect of aging temperature on microstructure evolution and strengthening behavior of L-PBF 18Ni(300) maraging steel

[J].

Tailoring the metastable reversed austenite from metastable Mn-rich carbides

[J].

Transformation-induced plasticity (TRIP) in advanced steels: A review

[J].

Synergistic alloying effects on nanoscale precipitation and mechanical properties of ultrahigh-strength steels strengthened by Ni3Ti, Mo-enriched, and Cr-rich co-precipitates

[J].

Aging behaviour and mechanical performance of 18-Ni 300 steel processed by selective laser melting

[J].

Effect of heat treatment on microstructure and mechanical properties of selective laser melting 18Ni300 maraging steel

[J].

热处理对选区激光熔化18Ni300马氏体时效钢微观组织和力学性能的影响

[J].

Enhanced mechanical properties of a high-carbon martensite steel processed by heavy warm rolling and tempering

[J].

The mechanisms of the fcc-bcc martensitic transformation revealed by pole figures

[J].

Microstructural characterisation and in-situ straining of additive-manufactured X3NiCoMoTi 18-9-5 maraging steel

[J].

Influence of post heat treatment condition on corrosion behavior of 18Ni300 maraging steel manufactured by laser powder bed fusion

[J].

About metastable cellular structure in additively manufactured austenitic stainless steels

[J].

Origin of dislocation structures in an additively manufactured austenitic stainless steel 316L

[J].In this experiment, the origin of dislocation structures in AM stainless steels was systematically investigated by controlling the effect of thermal stress through geometric constraints for the first time. Stainless steel 316L parts were produced in the form of "1D" rods, "2D" walls, and "3D" rectangular prisms to evaluate the effect of constraints to thermal expansion/shrinkage on the development of defect microstructures and to elucidate the origin of additively manufactured (AM) dislocation microstructures. Dislocation density, organization, chemical micro-segregation, precipitate structures, and misorientations were analyzed as a function of increasing constraints around solidifying material in 1D, 2D, and 3D components built using both directed energy deposition (DED) and powder-bed selective laser melting (SLM). In DED parts, the dislocation density was not dependent on local misorientations or micro-segregation patterns, but evolved from approximately rho(perpendicular to)approximate to 10(12) m(-)(2) in 1D parts to rho(perpendicular to) approximate to 10(14) m(-2) in 3D parts, indicating that it is primarily thermal distortions that produce AM dislocation structures. In DED 3D parts and SLM parts, dislocation densities were highest (rho(perpendicular to) approximate to 10(14) m(-2)) and corresponded to the formation of dislocation cells approximately 300-450 nm in diameter. Dislocation cells overlapped with dendrite micro-segregation in some but not all cases. The results illustrate that dendritic micro-segregation, precipitates, or local misorientations influence how the dislocations organize during processing, but are not responsible for producing the organized cell structures. This work shows that AM dislocation structures originate due to thermal distortions during printing, which are primarily dictated by constraints surrounding the melt pool and thermal cycling. (C) 2020 Acta Materialia Inc. Published by Elsevier Ltd.

Study on fine composition regulation and stabilization of retained austenite in low carbon high strength steels

[D].

低碳高强钢中残余奥氏体的成分精细调控及稳定性研究

[D].

Effects of reversed austenite on the cryogenic impact toughness of 0Cr16Ni5Mo1 super martensitic stainless steel

[J].The reversed austenite obtained through a tempering process can effectively improve the toughness and ductility of super martensitic stainless steel (SMSS). Overcoming the trade-off between thermal stability and quantity of the reversed austenite is the key to improving the cryogenic impact toughness of SMSS. In this study, the mechanical properties at room temperature and cryogenic impact toughness at -196 oC of 0Cr16Ni5Mo1 SMSS after quenching and tempering (QT) were investigated, along with quenching, intercritical annealing, and tempering (QIT) processes. Reverse transformation behavior during the heat treatment was studied using a thermal dilatometer, and the microstructure evolution was characterized by XRD, EBSD, and TEM. Additionally, the effect of reversed austenite on cryogenic impact toughness was extensively analyzed. The results showed that full martensite was obtained in 0Cr16Ni5Mo1 SMSS after quenching at 1100 oC. The volume fraction of reversed austenite in the QT samples tempered at 620 oC was found to be 16.4%, which decreased to 5.0% after cryogenic treatment with liquid nitrogen, and the cryogenic impact toughness of the QT samples was obtained to be only 36.4 J/cm2. The microstructure of samples after intercritical annealing at 680 oC mainly consisted of Ni-poor tempered martensite and Ni-rich fresh martensite. Furthermore, the volume fraction of reversed austenite in the QIT samples increased to 23.8% during the subsequent tempering process at 620 oC while the plasticity increased by 6% and the strength decreased by 7% at room temperature. The average Ni content of reversed austenite in the QIT samples reached 13% (mass fraction), which considerably improved the thermal stability of reversed austenite. Moreover, ~18.3% (volume fraction) reversed austenite remained stable in QIT samples at -196 oC, thereby substantially improving the cryogenic impact toughness to 115.4 J/cm2 by absorbing the impact energy through transformation into martensite. The impact fracture of the QIT samples was dominated by dimples, but there remained a little quasicleavage morphology indicating a mixed fracture mode.

逆转变奥氏体对0Cr16Ni5Mo1超级马氏体不锈钢低温冲击韧性的影响

[J].逆转变奥氏体对超级马氏体不锈钢的韧塑性协同具有重要作用,其热稳定性和含量的调控是提高材料低温韧性的关键。本工作以0Cr16Ni5Mo1超级马氏体不锈钢为研究对象,测试了淬火+回火(QT)和淬火+临界区退火+回火(QIT)工艺处理后的室温力学性能以及-196 ℃低温冲击韧性,利用热膨胀仪研究热处理过程中的逆相变行为,利用XRD、EBSD和TEM表征显微组织,深入研究了逆转变奥氏体对低温冲击韧性的影响。结果表明,0Cr16Ni5Mo1超级马氏体不锈钢经1100 ℃淬火可以得到全马氏体组织;直接进行620 ℃回火后的QT试样在马氏体板条界面处形成体积分数为16.4%的逆转变奥氏体,经-196 ℃深冷处理后逆转变奥氏体的体积分数下降至5.0%,低温冲击韧性仅有36.4 J/cm<sup>2</sup>,表现为准解理断裂。QIT工艺热处理过程中,680 ℃临界区退火后的室温组织主要由贫Ni的回火马氏体和富Ni的新鲜马氏体组成,经后续620 ℃回火可形成体积分数为23.8%的逆转变奥氏体,与QT试样相比,室温下塑性提升了6%,而强度仅降低7%。临界区退火使得后续回火过程中形成的逆转变奥氏体内平均Ni含量提高至13% (质量分数),具有更优异的热稳定性,经-196 ℃处理后仍有18.3% (体积分数)的逆转变奥氏体可以稳定存在。这部分逆转变奥氏体在冲击过程中会发生马氏体相变而吸收冲击能量,使经过QIT工艺处理后的0Cr16Ni5Mo1超级马氏体不锈钢在-196 ℃拥有高达115.4 J/cm<sup>2</sup>的冲击韧性,其冲击断口以韧窝为主,同时存在少许准解理形貌,呈混合断裂模式。

The segregation of transition metals to iron grain boundaries and their effects on cohesion

[J].

Precipitate evolution and strengthening behavior during aging process in a 2.5 GPa grade maraging steel

[J].

Understanding the factors controlling the hardness in martensitic steels

[J].

A model for the microstructure behaviour and strength evolution in lath martensite

[J].

Predicting microstructure and strength of maraging steels: Elemental optimisation

[J].

Strength-ductility synergy through tailoring heterostructures of hot-rolled ferritic-martensitic steels containing varying Si contents

[J].

A high-entropy alloy with dislocation-precipitate skeleton for ultrastrength and ductility

[J].