金属材料在高于0.6Tm (Tm为合金熔点)的使役温度下会发生明显的结构软化现象[1,2],传统铁基、钴基和镍基等高温合金在高温、摩擦、氧化和腐蚀等极端环境下易过早失效。提高合金在极端环境下的高温耐磨损、耐腐蚀和抗氧化性能对提升结构材料的服役寿命具有重要的实际意义。合金化是改善金属材料性能最普遍和有效的方法,传统合金通常以1种或2种元素为主元,通过添加多种微量元素来提高合金的服役性能。目前为止,研究人员利用合金化方法开发了大量具有性能优异的传统合金。然而,这些合金的成分通常位于相图的边缘位置,极大地限制了材料设计的自由度。2004年Yeh等[3]制备了由10种等摩尔元素组成的新型合金,该合金不仅相结构简单,而且性能优于传统的单主元合金,并正式提出了“高熵合金”的设计理念。

合金的高温力学性能受其熔点影响较大。当温度≥ 0.6Tm时,位错攀移机制得以激活,合金的变形机制由非扩散性变形转变为扩散性变形,屈服强度将急剧下降。因此,通过加入高熔点元素以提高扩散性变形的阈值温度是改善合金高温力学性能最简单、有效的方法。基于此,2011年Senkov等[4,5]采用高熔点的难熔元素制备了MoNbTaW和MoNbTaWV高熵合金,发现2种合金在1600 ℃下仍保持405和477 MPa的超高屈服强度,并提出了“难熔高熵合金(refractory high-entropy alloys,RHEAs)”的概念。相比于传统的fcc相Cantor合金,由bcc相组成的RHEAs普遍具有较高的高温强度和显微硬度[6]。近年,各国学者分别对RHEAs的高温力学性能[7~9]、相稳定性[10,11]、抗辐照性能[12,13]和抗氧化性能[14,15]等开展了广泛研究。作为高温材料,RHEAs相比于传统的镍基高温合金表现出更为优异的高温力学性能[5],有望成为下一代高温结构材料。然而,大多数RHEAs在室温下表现出明显的脆性,可加工性较差。RHEAs中常见的第V副族和第VI副族组元具有较高的熔点,目前普遍使用的真空电弧熔炼法受限于炉腔尺寸,仅能制备出纽扣大小的合金锭[16],且合金锭存在组织粗大和成分偏析严重等问题。此外,Mo、W、Nb、Ta和Hf等难熔元素具有较高的密度,制备得到的合金通常密度较大。上述问题极大地限制了RHEAs在结构材料方面的应用,因此,探索更为先进的成形制造技术迫在眉睫。

激光熔覆(laser cladding,LC)是近些年快速发展起来的一种基于数字化控制制备涂层、实现金属材料表面强化的先进技术手段。相比于传统的表面强化技术,LC技术具有能量密度高、加工速度快及材料浪费少和工艺环保等特点,有助于涂层与基体合金间形成较强的冶金结合,涂层具有均匀而细小的显微组织[17~19]。研究表明,LC成形难熔高熵合金涂层(refractory high-entropy alloys coatings,RHEACs)有望突破目前RHEAs的研究瓶颈。首先,高能量密度激光源可快速熔化Mo、Nb、Ta、W、Hf、Zr、Cr和V等难熔元素,并通过快冷沉积对熔融金属进行精确成形,有效解决了RHEAs因室温脆性而难以加工以及成形尺寸受限的问题。此外,简单的“二维”涂层可有效解决RHEAs作为结构材料时的高密度问题[20],同时增强基体合金的表面性能,为实现RHEAs低成本、高效率的应用提供有效途径。

目前,国内外研究人员已采用LC技术制备了部分RHEACs,提高了M2钢、316L钢、IN718和TC4等基体合金耐磨损、耐腐蚀和抗氧化等性能。本文主要综述了LC技术的加工特性,RHEACs的微观组织,显微硬度,以及耐磨损、耐腐蚀和抗氧化性能等的研究进展。总结了目前研究存在的问题和挑战,并对未来发展趋势进行了展望,以期为后续LC-RHEACs的研究提供借鉴和参考。

1 激光熔覆难熔高熵合金成分设计

多主元作为高熵合金区别于传统合金的最主要特点,为开发高性能材料提供了广阔的成分设计空间,然而其成分复杂且组织多变,同时又为合金的元素和成分筛选带来了一定的挑战。研究初期,人们倾向于设计等摩尔成分的合金以期获得最大混合熵值,从而提高合金中单相固溶体的成型性和稳定性。随着研究的深入,人们发现混合熵在大部分的合金体系中并没有足够的驱动力抑制金属间化合物的产生,而成分改变带来的混合焓变化在一定程度上决定着固溶体合金的成形性和服役性能。因此,激光熔覆难熔高熵合金成分设计的目的与传统难熔高熵合金类似,主要是优化物相组成和微观组织从而实现合金的预期性能。不同的是,激光熔覆过程中涂层成分会受基体合金中元素的稀释,涂层成分设计的重点是研究主元种类与含量对固溶体成形情况和合金特性的影响。此外,激光熔覆过程中涉及快速加热和冷却,成分设计时需要选择具有合适热膨胀系数、热导率和熔点的合金元素,以避免快热快冷过程中,熔覆层内部以及熔覆层与基材之间因产生较大的热应力而导致涂层开裂或脱落。激光熔覆需要确保熔覆层与基材有良好的冶金结合,设计成分时需要考虑元素间的相容性,确保2者之间的界面结合良好,避免形成脆性相或界面缺陷。RHEACs通常包含Ta、Zr和Hf等昂贵金属元素,采用传统的“炒菜式”成分设计方法不仅实验周期长,且研究成本高。基于此,研究人员开发了多种理论模型和模拟计算方法用于RHEAs成分设计。

1.1 经验参数法

经验参数法属于通过模型或归纳进行研究的理论范式。经验参数法的特点是可以简单快捷地通过理化参数对合金的物相结构进行预测。Zhang等[21]通过分析大量实验数据发现,合金中的固溶体形成能力与其体系内的混合焓(ΔHmix)和原子尺寸差(δ)有关。混合焓的绝对值代表元素之间形成无序固溶体结构的阻力,较正的混合焓表示元素之间的排斥力较大,合金倾向于发生调幅分解或形成有序结构;较负的混合焓表示元素之间相互吸引,合金倾向于形成金属间化合物;而混合焓越接近于零,合金越容易形成无序固溶体。此外,原子尺寸差越小表明各元素越容易相互置换形成无限固溶体。因此,Zhang等[21]提出了合金体系中-15 kJ/mol ≤ ΔHmix ≤ 5 kJ/mol、δ ≤ 6.5%是合金形成简单固溶体结构的条件。随着研究的深入,Yang和Zhang[22]认为ΔHmix-δ判据条件忽略了混合熵对固溶体稳定性的影响,并提出了新的判据参数(Ω)来表示高熵合金凝固时的固溶体形成能力:

1.2 计算模拟法

计算模拟法属于应用计算机进行仿真模拟研究的计算范式。目前应用在激光熔覆成分设计的计算模拟法主要为第一性原理和相图计算法。第一性原理计算法以原子和电子间的相互作用为基础,通过密度泛函理论等近似假设求解薛定谔方程从而获得物质的物理、化学和力学等性质[23]。第一性原理计算首先根据合金晶格点阵构建晶体模型。在此基础上,对晶体模型进行结构优化以得到合金体系在计算环境中的最稳定结构,该结构主要包含合金体系的波函数。最终通过提取波函数信息得到合金的相关性质。

目前激光熔覆涂层研究领域主要采用第一性原理计算进行熔覆层元素筛选和成分优化。穆永坤[24]采用第一性原理方法计算了Cr和Al元素对TiVMoNb RHEAs结合能、生成焓、弹性模量和体积模量等热物性参数的影响。结果表明,TiVMoNb-X (X = Cr、Al、CrAl) RHEAs均为单一的bcc结构,且Cr元素使合金的生成焓趋近于零;而Al元素则导致合金生成焓变得更负,这一结果表明Al元素有助于稳定合金的bcc相;Cr元素则会导致bcc相产生失稳倾向。此外,分别添加Al和Cr元素时合金的弹性模量变小,而同时添加Al和Cr元素时合金的弹性模量增大,表明合金化在一定程度上影响了材料的刚度。

第一性原理计算虽然可以在原子尺度上观察和获得合金体系内部的晶体结构信息,并从电子结构角度分析和理解物质本质和相关机理,但其晶体结构建模方法和密度泛函理论采用了大量的近似假设,导致模拟结果存在一定误差[25]。此外,晶胞是进行第一性原理计算的基础,研究成分对合金物理和化学性质的影响时需要建立庞大的晶体结构模型数据库,第一性原理计算在处理多原子的超胞结构优化时通常计算效率较低,难以满足材料设计领域对高通量的需求[25]。相图计算法是一种使相平衡和热力学信息参数化的方法,该方法的实质是通过迭代拟合实验和理论计算的数据,进而优化得到目标体系的低阶热力学参数,通过外推法建立高阶体系的热力学描述,该热力学描述可以快速建立合金成分-相结构-温度之间的关系[26]。采用相图计算实现准确的合金成分设计需要充分的低阶热力学信息和大量的关键实验信息验证,因此采用相图计算法迭代拟合基于第一性原理计算所得的热力学信息和实验数据以构建完善的高熵合金热力学和动力学数据库,是目前实现激光熔覆高熵合金涂层成分快速优化和材料开发的可行方案。

2 激光熔覆难熔高熵合金涂层的加工特性

2.1 LC-RHEACs原材料的制备方法和送粉系统

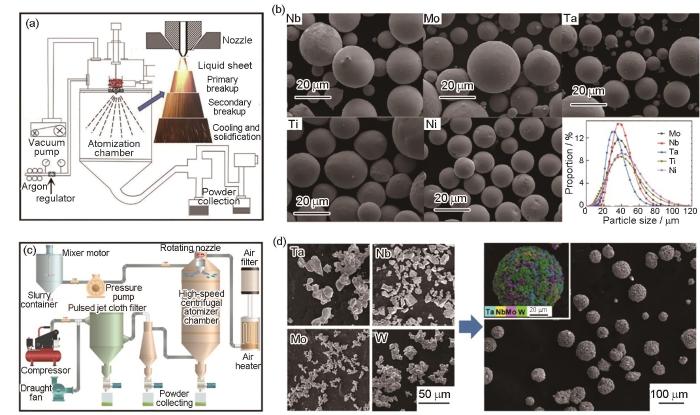

LC本质上是属于粉末冶金范畴的加工技术,成形的原材料通常为规则的球形金属粉末。为了制备形貌和质量较好的涂层,粉末必须满足低O含量、高球形度和高纯度的要求。目前制备合金粉末常用方法[27,28]的原理示意图及粉末形貌如图1[27,29~31]所示。图1a[27]为真空等离子雾化法的基本原理图,熔融态金属在雾化室的高压气体下被破碎成细小的液滴,并不断冷却、球化成金属粉末。如图1b[29]所示,真空等离子雾化法制备的金属粉末颗粒为规则的球形,且具有良好的流动性,适用于同轴送粉激光增材制造,是目前制备RHEACs常用的金属粉末类型。图1c[30]为喷雾造粒法的基本原理图,该方法采用聚乙烯醇或蒸馏水将非规则形状的金属原材料调制成预制合金浆料,浆料在喷雾热风的作用下干燥、团聚,最终得到球状合金粉末。如图1d[31]所示,喷雾造粒法可以将非规则形状的纯金属粉末制备成球形度良好的预制合金粉末,其中高熔点元素颗粒具有较小的尺寸,在激光束的辐照下可以充分熔化,该方法适用于元素熔点差异较大合金粉末的增材制造。研究表明,喷雾造粒粉末成形的高熔点RHEACs相比于等离子雾化合金粉末制备的涂层组织更均匀,涂层中高熔点的W和Mo颗粒完全熔化,但由于喷雾造粒法制得的合金粉末致密性较差,以及受到聚乙烯醇中杂质C元素的污染,制备的涂层存在明显的气孔以及杂质陶瓷相等缺陷[31]。

图1

2.2 LC-RHEACs的常见缺陷

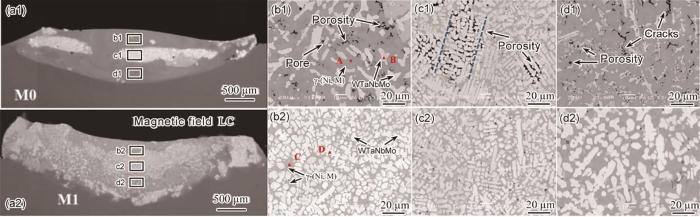

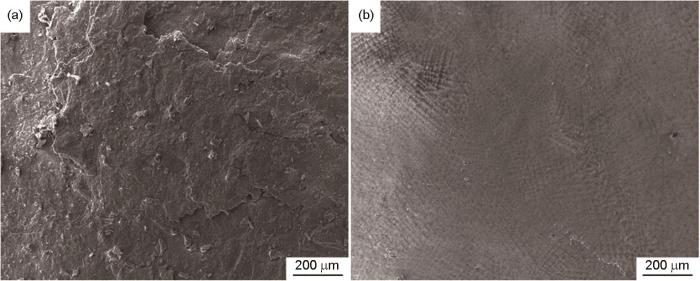

激光加工过程中熔池具有较高的加热和冷却速率,由此产生的热内应力导致涂层中存在一定量宏观和显微缺陷。RHEAs组成元素的熔点普遍高于1650 ℃,Ta和W元素的熔点甚至达到了3000 ℃左右,因此激光加工过程中需要输入更高的能量密度以保证元素充分熔化。由于部分元素的熔点甚至高于其他元素的沸点,熔覆过程中会出现低熔点元素蒸发或高熔点元素不充分熔化的现象。当低熔点元素蒸发产生的过饱和气体溢出速率小于凝固速率时,气泡将滞留在涂层中形成孔洞等缺陷[35,36]。此外,高熔点元素的不充分熔化会降低熔池内熔体的流动性,导致气泡难以“逃离”熔池,甚至在内应力的作用下沿未熔化粉末周围产生裂纹等缺陷[35,36]。研究[35,37]表明,熔覆过程中外接辅助场可以有效改善涂层的成形质量,凝固后的涂层组织更加均匀,气孔和裂纹等缺陷消失。图2[35]为LC和磁场-LC制备MoNbTaW RHEACs的SEM像。如图2a[35]所示,未增加辅助磁场制备的涂层组织不均匀,并存在明显的孔隙和裂纹(图2a1~d1[35]),而增加辅助磁场制备的涂层组织变得均匀,气孔和裂纹消失(图2a2~d2[35])。这主要归因于外加辅助场提升了熔池内Marangoni流体的流速,因此过饱和气体可以快速到达熔体表面并溢出熔池。除外加辅助场外,合理优化加工工艺参数也可有效改善涂层中未熔化的金属粉末和气孔等缺陷。涂层中的缺陷随着激光功率的增大逐渐消失[38]。这主要归因于增大激光功率可提高熔池内的熔化温度,使得高熔点的元素颗粒充分熔化。此外,熔池温度的提高有效延长了熔体的凝固时间,熔化产生的气泡有充足的时间溢出熔池。除优化激光功率外,加快激光扫描速率可以降低粉末的送分比率,同样会减少涂层成形后未熔化粉末的比例,降低涂层中的缺陷[38]。

图2

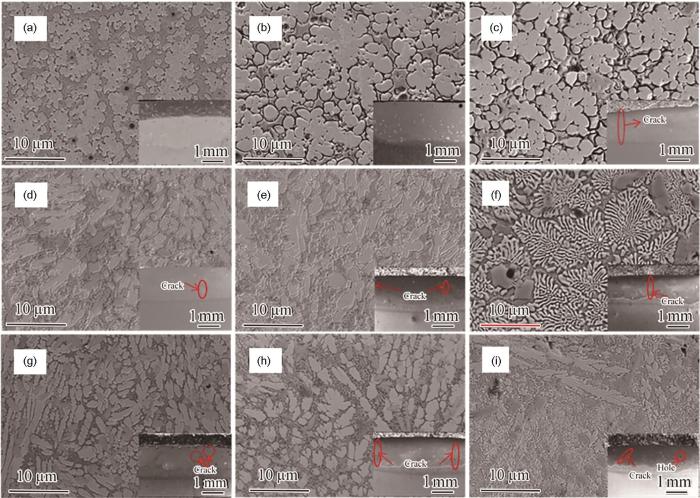

除气孔和未熔化的颗粒外,RHEAs由于其本征脆性和激光加工过程中连续加热与冷却产生的内应力[39,40],在涂层在成形过程中容易产生微裂纹。图3[41]为激光熔覆MoFe x CrTiWAlNb y RHEACs的SEM像。图3a和b[41]所示的Fe1Nb1和Fe1.5Nb1涂层中未产生明显的裂纹。当Fe和Nb含量较高时(图3c~i[41]),涂层中生成大量的Laves_Fe2Nb硬质相,提高了涂层的裂纹敏感性进而产生了大量的微裂纹。然而添加Cu元素后,涂层中微裂纹明显消失[42],这主要归因于Cu元素提高了涂层的抗塑性变形能力,有效抑制了裂纹的萌生和扩展。此外,Cu元素具有更低的熔点,可以延长涂层的凝固时间,使残余液体能有效填补凝固组织的空隙,从而进一步抑制了裂纹的形成。减少Mo、W等元素的含量也可有效降低涂层的脆性倾向,提高涂层的抗裂纹敏感性。Sun等[31]在Mo基体合金上激光熔覆了3层MoNbTaW RHEACs。结果显示,涂层中的裂纹随着涂层厚度增加逐渐消失。分析原因表明,裂纹减少主要是因为涂层稀释率随厚度增大而降低,减少Mo元素含量从而抑制了微裂纹的产生。综上所述,激光加工的工艺参数和合金成分共同决定着RHEACs的成形质量,建立完善的成形调控机制对提升RHEACs的可加工性,实现涂层的良好制备具有重要的意义。

图3

3 激光熔覆难熔高熵合金涂层的结构特点

合金的微观结构,比如相组成、晶粒尺寸、晶粒结构和位错密度等决定着材料的预期性能和改性方法。因此全面了解激光熔覆涂层成形过程中的微观结构演变行为至关重要。RHEACs的显微组织主要由合金成分和加工工艺决定。本节将对LC-RHEACs的组织结构研究进展进行综述,分析合金成分和加工工艺对RHEACs物相组成和组织形貌的影响机制。

3.1 物相组成

高熵合金通常具有等摩尔或近似等摩尔的元素组成。根据经典的Boltzmann公式[3]可知,组元数越多的高熵合金系统内混合熵越高,高的混合熵有利于降低体系自由能,促进固溶体相生成[43,44]。RHEAs主要由第IV副族、第V副族和第VI副族的难熔元素组成,其中第V副族和第VI副族元素均为bcc结构,而第IV副族中Ti、Zr和Hf元素的参考态为hcp相,在高温下会发生同素异构体转变,从而转换成bcc结构。据统计,截至目前,已报道的400余种RHEAs大都为单一的bcc物相结构[45],有时也会析出hcp相、B2相和Laves金属间化合物等第二相。不同于块状合金,RHEACs的成分由于受到基体元素的稀释,也会形成碳化物和氮化物等物相。表1[31,36~38,41,42,46~63]列出了近年LC-RHEAs的涂层种类、物相结构以及基体合金种类。

表1 LC-RHEACs的基体合金种类和物相结构[31,36~38,41,42,46~63]

Table 1

| Coating | Substrate | Phase | Ref. |

|---|---|---|---|

| TiMoWNbZr | 45 steel | bcc + Ti x W1 -x | [46] |

| CrTiMoWNb x Fe y Al | M2 steel | bcc + Fe2Nb + (Nb, Ti)C*+ W | [41,47,48] |

| (TiZrNb)14SnMo | TC4 alloy | bcc | [49] |

| TiTaZr | Zr | bcc | [50] |

| TiNbTaZr | Zr | bcc | [50] |

| FeCrAlTiMoWNb3 | M2 steel | bcc + Fe2M + (Nb, Ti)C* | [51] |

| NiTiCrNbTa x | TC4 alloy | bcc + Cr2Nb + NiTi2 + B2 | [52] |

| AlNbTaZr x | TC4 alloy | bcc + hcp* | [53] |

| AlTiVMoNb | TC4 alloy | bcc | [54] |

| MoNbTaW | IN-718 | bcc + Laves + fcc_(Ni, M)* | [36] |

| AlMoNbTaCu x | TC4 alloy | bcc + hcp_Ti(Al, Cu)2* + fcc_AlCu2Ti* + TiN* | [42] |

| Al0.2CrTiVNb | TC4 alloy | bcc | [55] |

| AlCoCrMoV x | SS 904L | bcc + sigma | [56] |

| TiMoNbZr | SS 316 | bcc | [57] |

| TiMoNbTaW | TC4 alloy | bcc#1 + bcc#2 | [58] |

| Si3N4 + TiMoNbTaW | TC4 alloy | bcc + (Nb, Ti)5Si3 + TiN | [59] |

| TiMoNbZr | TC4 alloy | bcc + hcp + Mo | [38] |

| TiNiMoNbTa | GTD-111 | bcc + fcc + MC | [37] |

| TiNbTaZr | SS 316 | bcc#1 + bcc#2 + Fe2Nb* | [60] |

| Y2O3 + MoNbTaW | IN-718 | bcc#1 + bcc#2 + fcc_(Fe, Ni)* | [61] |

| MoNbTaW | Mo | bcc + fcc + WC | [31] |

| AlTiNbZr | TC4 alloy | bcc + AlTi3 + AlNb3 | [62] |

| TiVNbTa | TC4 alloy | bcc#1 + bcc#2 | [63] |

| TiVNbTaCr | TC4 alloy | bcc#1 + bcc#2 + Laves | |

| TiVNbTaZr | TC4 alloy | bcc | |

| TiVNbTaW | TC4 alloy | bcc#1 + bcc#2 + bcc#3 |

从表1[31,36~38,41,42,46~63]可以看出,由难熔元素组成的合金涂层物相结构为单一的bcc固溶体,而添加Al、Cr和Fe等与难熔元素间具有较负混合焓的元素,涂层中易生成Laves等金属间化合物。此外,采用LC技术制备金属涂层时,涂层的成分受到基体合金元素的稀释会形成新的物相。Guo等[47]和Kuang等[51]在M2高速钢上采用LC分别制备了CrTiMoWNbFeAl和MoFeCrTiWAlNb3 RHEACs。X射线衍射(XRD)检测结果显示,Nb和Ti元素因与基体合金中的C元素具有较强的结合能力而形成了(Nb, Ti)C相[64]。类似地,Liu等[42]在TC4合金表面激光熔覆AlNbMoTaCu x RHEACs时发现,TC4基体中大量的Ti元素稀释进入涂层,与涂层中的Cu和Al元素形成了AlCu2Ti和Ti(Al, Cu)2化合物,与大气中的N元素形成了TiN硬质相。因此,为了提高涂层成分设计的准确性,优化激光加工工艺以降低其稀释率至关重要。

3.2 显微形貌特征

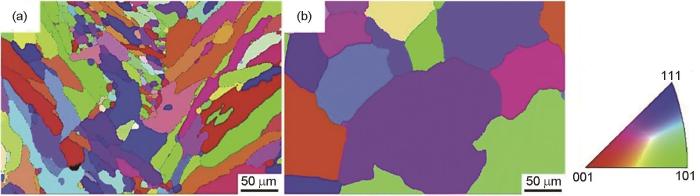

在激光熔覆难熔高熵合金过程中,激光束熔化金属粉末的时间极短,涂层具有高达106 K/s的加热和冷却速率,远远大于传统真空电弧熔炼合金的冷却速率(10~102 K/s)[65]。高冷却速率可以有效地提高合金的凝固形核率,有利于合金中产生超细的纳米级晶粒[66,67]。Li等[68]采用电子背散射衍射(EBSD)技术对比了激光熔化沉积和真空电弧熔炼MoNbTa合金的显微组织,结果如图4[68]所示。图4a[68]中激光沉积制备的合金主要由柱状晶组织组成,晶粒尺寸约为13.18 μm,明显小于图4b[68]中真空电弧熔炼制备的等轴晶晶粒(112.52 μm)。Guan等[50]采用激光熔覆技术制备了TiNbZr RHEACs,涂层由平均晶粒尺寸为24.5 μm的不规则状等轴晶组成,而传统真空电弧熔炼制备的合金其晶粒尺寸约为100 μm[69]。由此可见,激光加工技术在制备高性能的超细晶涂层方面具有巨大的潜力。

图4

图5

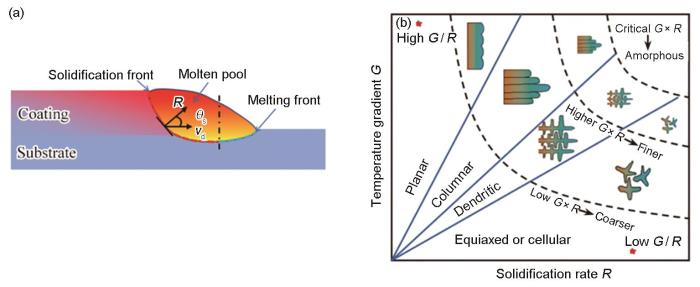

凝固角从熔池表面到底部逐渐增大,在激光扫描速率(vd)恒定的条件下,凝固速率将逐渐减小。图5b[60]为金属凝固过程中温度梯度(G)、凝固速率与凝固组织晶粒尺寸和形貌之间的关系示意图。众所周知,晶粒的生长方向受温度梯度的影响,晶粒的凝固尺寸由凝固速率决定。从构建的凝固图中可以看出,G · R决定着凝固组织的晶粒尺寸,G / R决定着凝固组织的晶粒形状。当熔池底部温度梯度足够大时,固液界面前沿难以形成成分过冷区,凝固组织将以界面光滑、无溶质偏析的平面晶胞形式长大。随着平面晶的生长,凝固界面处释放潜热,熔池内G逐渐减小,而R逐渐增大,在凝固前沿形成了本构过冷,凝固组织沿温度梯度方向外延生长为柱状晶粒。随着温度梯度的减小和凝固速率的持续增大,G / R不足以维持柱状晶的正常长大,局部区域会形成具有轻微分支的柱状枝晶结构。最终,凝固组织在凝固速率的驱动下形成胞状和等轴晶晶粒。

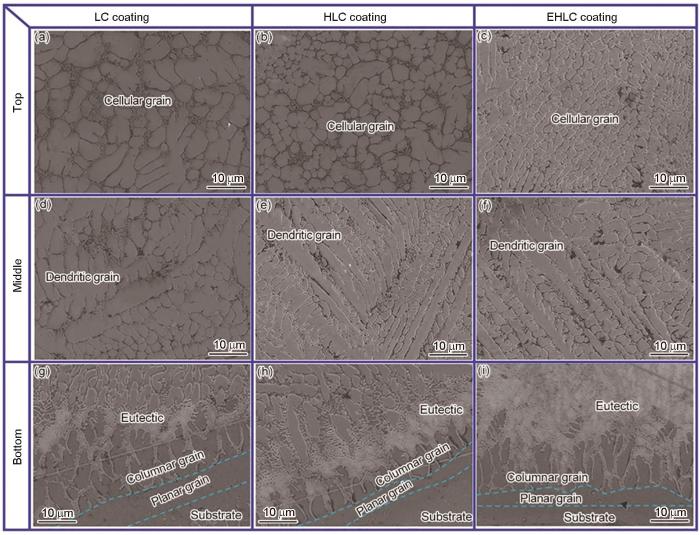

激光熔覆制备金属涂层的显微组织主要由加工参数决定。Zhou等[60]研究了LC、高速LC (high-speed laser cladding,HLC)和超高速LC (extreme high-speed laser cladding,EHLC)对TiNbTaZr RHEACs温度场的影响。结果表明,随着扫描速率的增大,熔池的凝固速率明显加快。图6[60]为采用不同扫描速率LC制备所得涂层微观组织形貌的SEM像。涂层顶端(图6a~c[60])、中部(图6d~f[60])和底部(图6g~i[60])分别由胞状晶、树枝晶和柱状晶组成。在熔池冷却过程中,晶粒通过吸收周围熔融金属液体进行形核和长大,当凝固速率较快时,晶粒生长的时间变短,形成致密细小的晶粒。因此,随着扫描速率的增大,涂层顶端的胞状晶产生了明显的细化效应,晶界变窄,中部树枝晶的二次枝晶臂变得短而致密。

图6

4 激光熔覆难熔高熵合金涂层的性能特点

采用激光增材技术制备的合金和涂层通常组织细小,结构均匀,具有优异的综合性能。此外,优异的高温力学性能是RHEAs区别于其余合金的主要优势。因此,由LC技术制备的RHEACs在热端部件表面防护领域具有广阔的应用前景。目前国内外对RHEACs的研究还处于工艺、成分优化的初步阶段。本节将对已报道RHEACs的显微硬度及耐磨损、耐腐蚀和抗氧化性能进行分析和总结。

4.1 激光熔覆难熔高熵合金涂层的显微硬度

| System | Treatment | Hardness | Ref. |

|---|---|---|---|

| TiMoWNbZr | As-cladded | 700 HV0.5 | [46] |

| Annealing | 1300, 1000, 1050 HV0.5 (800, 1000, 1200 oC for 20 h) | ||

| CrTiMoWNbFeAl | As-cladded | 1050 HV0.2 | [47] |

| CrTiMoWNb x Fe1.5Al | As-cladded | 810, 851, 873, 910 HV0.2 (x = 1.5, 2.0, 2.5, 3.0) | [48] |

| CrTiMoWNb1Fe1.5Al | As-cladded | 913.5 HV0.2 | [41] |

| Annealing | 923, 954, 822.3 HV0.2 (600, 650, and 800 oC for 4 h) | ||

| (TiZrNb)14SnMo | As-cladded | 551.4 HV0.2 | [49] |

| TiTaZr | As-cladded | (510 ± 22) HV | [50] |

| TiNbTaZr | As-cladded | (550 ± 26) HV | [50] |

| FeCrAlTiMoWNb3 | As-cladded | 694 HV0.2 | [51] |

| Annealing | 635, 512, 432 HV0.2 (750, 850, and 950 oC for 4 h) | ||

| Annealing | 432, 494, 639, 614 HV0.2 (950 oC for 4, 6, 8, and 10 h) | ||

| NiTiCrNbTa x | As-cladded | 922.8, 985.1, 851.3, 825.4 HV0.3 (x = 0.1, 0.3, 0.5, 1.0) | [52] |

| AlNbTaZr x | As-cladded | 594, 596, 611, 624, 654 HV0.5 (x = 0.2, 0.4, 0.6, 0.8, 1.0) | [53] |

| AlTiVMoNb | As-cladded | 888.5 HV0.2 | [54] |

| MoNbTaW | As-cladded | 753, 980 HV0.5 (with and without ultrasound vibrations) | [36] |

| AlMoNbTaCu x | As-cladded | ~836, ~568, ~519, ~430 HV0.2 (x = 0, 0.4, 0.6, 0.8) | [42] |

| Al0.2CrTiVNb | As-cladded | 477, 405 HV0.2 (with dilutions of 3.1% and 31.9%) | [55] |

| AlCoCrMoV x | As-cladded | 867.7, 832.5, 890.4, 910.9, 925.8, 942.6 HV0.1 (x = 0, 0.2, 0.4, 0.6, 0.8, 1.0) | [56] |

| TiMoNbZr | As-cladded | 410 HV0.1 | [57] |

| TiMoNbTaW | As-cladded | 600 HV | [58] |

| Si3N4 + TiMoNbTaW | As-cladded | 502.52, 537.34, 628.07 HV0.1 (correspondent to Si3N4 mass fractions of 1.0%, 1.5%, and 2.0%) | [59] |

| TiMoNbZr | As-cladded | 521.79 HV | [38] |

| TiNiMoNbTa | As-cladded | ~1000, ~650 HV0.2 (with and without ultrasound vibrations) | [37] |

| TiNbTaZr | As-cladded | 577.5, 487.8, 545.2 HV0.3 (LC, HLC, EHLC) | [60] |

| Y2O3 + MoNbTaW | As-cladded | 1007.5, 1163.9, 1218.5, 1274.6 HV0.3 (correspondent to Y2O3 mass fractions of 0%, 1%, 2%, and 3%) | [61] |

| MoNbTaW | As-cladded | 351, 488, 604, 655 HV0.1 (C1, C2, C3, C3-R*) | [31] |

| TiZrAlNb | As-cladded | ~530 HV | [62] |

| TiVNbTa | As-cladded | 372.8 HV0.2 | [63] |

| TiVNbTaCr | As-cladded | 532.4 HV0.2 | [63] |

| TiVNbTaZr | As-cladded | 455.2 HV0.2 | [63] |

| TiVNbTaW | As-cladded | 546.3 HV0.2 | [63] |

LC-RHEACs的强化机制包括细晶强化、固溶强化、沉淀强化和弥散强化。其中,细晶强化和固溶强化是激光制备合金中最普遍的强化机制。Chen等[54]对比了激光熔覆AlTiVMoNb RHEACs和电弧熔炼铸态合金的显微硬度。结果显示,RHEACs的显微硬度为888.5 HV0.2,显著高于铸态合金的536.6 HV0.2。分析结果表明,RHEACs具有较小的晶粒尺寸,细晶强化作用提高了涂层的显微硬度。同时,激光熔覆加工过程中频繁加热和冷却产生的拉应力使得涂层晶格点阵发生严重畸变,产生了一定量弹性应力场,通过钉扎作用阻碍了位错的运动,起到显著的强化作用。除加工过程产生的内应力强化作用外,添加Zr和Ta等大尺寸元素也会增强涂层的固溶强化效应[53,63,70],显著提高涂层的显微硬度。

hcp相、Laves相和MC化合物等是RHEACs中常见的第二相,会在涂层中产生显著的沉淀强化作用。涂层中含Ti、Zr和Hf等元素时容易存在hcp物相。研究[53]表明,合金涂层的显微硬度随着Zr等hcp结构元素的添加而逐渐增大。这主要归因于Zr元素含量的增加提高了hcp相的稳定性[71,72],涂层基体bcc相中逐渐析出针状hcp强化相。此外,根据难熔元素的二元相图可知[73],Cr元素的原子半径较小,容易与Zr、Ta和W等大原子半径元素形成Laves化合物。Laves化合物(晶体结构为MgZn2型的C15相结构和MgCu2型的C14相结构)是一种典型的拓扑密排相,具有较高的显微硬度及耐腐蚀和抗氧化性能[74]。合理地优化合金成分和加工工艺,调控Laves相的相分数可以实现高显微硬度RHEACs的制备。Wang等[48]研究了Nb元素含量对CrTiMoWNb x Fe1.5Al RHEACs组织形貌和显微硬度的影响。结果显示,随着Nb元素的添加,涂层中原位生成的Laves_Fe2Nb化合物逐渐增多,显微硬度由810 HV0.2逐渐提升至910 HV0.2,涂层经650 ℃退火后逐渐析出了Laves_Fe2W化合物,显微硬度达到了954 HV0.2。

4.2 激光熔覆难熔高熵合金涂层的耐磨损性能

金属材料的耐磨损性能依据材料的综合性能进行评价。良好的耐磨损性能首先要求材料具有较高的显微硬度,用来抵抗高硬度物料压入金属材料而造成的体积切削磨损。此外,强韧性兼具的材料具有优异的抗变形能力,可以有效降低材料因弹性失效而造成的疲劳剥落。金属材料在高温下会产生明显的结构软化现象,其强度会发生抛物线式下降。因此,金属结构材料的耐磨损性能通常与温度也存在较大关系。RHEAs作为典型的bcc结构高温合金通常具有较高的显微硬度和优异的抗高温软化性能,由其制备的涂层在室温和高温下均展现出优异的耐磨损性能。表3[36~38,41,42,47,49,51,53,56,58,59,61,63]总结了已报道LC-RHEACs的耐磨损性能。

表3 LC-RHEACs的耐磨性能[36~38,41,42,47,49,51,53,56,58,59,61,63]

Table 3

| Coating | Counterpart | Wear time | Load | Temperature | Wear loss | Wear rate | Ref. |

|---|---|---|---|---|---|---|---|

| min | N | oC | mm3·N·m-1 | ||||

| CrTiMoWNbFeAl | GCr15 | 15 | 50 | 0.0787 mm3 | [47] | ||

| CrTiMoWNb3Fe1.5Al | GCr15 | 15 | 50 | 0.045 mm3 | [47] | ||

| CrTiMoWNb1Fe1.5Al | GCr15 | 15 | 50 | 0.019 mm3 | [41] | ||

| (TiZrNb)14SnMo | Si3N4 | 15 | 40 | 0.368 mm3 | [49] | ||

| FeCrAlTiMoWNb3 | GCr15 | 15 | 50 | 0.630 mm3 | [51] | ||

| AlNbTaZr0.8 | Si3N4 | 120 | 10 | 1.16 × 10-4 | [53] | ||

| MoNbTaW | Si3N4 | 30 | 10 | RT | 1.17 × 10-5 | [36] | |

| 600 | 1.20 × 10-5 | ||||||

| 800 | 1.25 × 10-5 | ||||||

| 1000 | 1.48 × 10-5 | ||||||

| AlMoNbTaCu0.4 | WC | 60 | 20 | 0.41 mm3 | [42] | ||

| AlCoCrMoV0.8 | Si3N4 | 20 | 50 | 0.63 × 10-5 | [56] | ||

| TiMoNbTaW | GCr15 | 10 | 1.37 × 10-4 | [58] | |||

| TiMoNbTaW-2(Si3N4) | GCr15 | 30 | 20 | 9.5 × 10-3 mm3 | 1.31 × 10-4 | [59] | |

| TiMoNbZr | Si3N4 | 50 | 4 | 1.2 mg | [38] | ||

| TiNiMoNbTa | GCr15 | 15 | 60 | 3.8 × 10-6 mm3 | 0.32 × 10-6 | [37] | |

| MoNbTaW-3(Y2O3) | Si3N4 | 30 | 5 | RT | 3.33 × 10-5 | [61] | |

| 600 | 1.42 × 10-5 | ||||||

| 800 | 1.08 × 10-5 | ||||||

| TiVNbTa | Si3N4 | 60 | 5 | 1.06 mg | [63] | ||

| TiVNbTaCr | Si3N4 | 60 | 5 | 0.04 mg | |||

| TiVNbTaZr | Si3N4 | 60 | 5 | 0.87 mg | |||

| TiVNbTaW | Si3N4 | 60 | 5 | 0.06 mg |

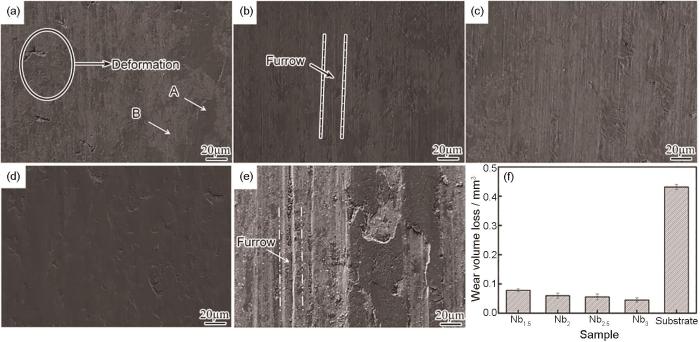

通常,金属材料的磨损机制为磨粒磨损、黏着磨损、氧化磨损和疲劳磨损等。其中磨粒磨损和黏着磨损机制较为普遍。当摩擦副表面细小而尖锐的突起接触涂层表面时,会对涂层表面进行微切割造成磨粒磨损。此外,随着摩擦副与涂层表面反复摩擦,接触点温度逐渐升高形成“焊接”反应[75],在摩擦副与试样反复运动产生的剪切力作用下,强度较低的涂层表面焊接点会被撕裂,形成局部黏着磨损。由此可见,显微硬度越高的涂层,其抵抗摩擦副表面的微切割能力越强,理论上具有更为优异的耐磨损性能[76]。Wang等[48]采用往复式磨损试验机对CrTiMoWNb x Fe1.5Al RHEACs的室温耐磨损性能进行研究。结果显示,随着Nb元素含量(x = 1.5~3.0)的增加,涂层的摩擦系数从0.72降低至0.52,磨损体积量从0.078 mm3降低至0.045 mm3,明显小于M2钢基体的摩擦系数和磨损体积量(0.87和0.4314 mm3),表明CrTiMoWNb x Fe1.5Al RHEACs具有优异的耐磨损性能。这主要是因为随着Nb含量的添加,涂层中原位生成的Laves_Fe2Nb金属间化合物逐渐增多,提高了涂层的显微硬度,有效增强了涂层对摩擦微切割的抵抗能力。图7[48]为涂层表面磨损形貌的SEM像,Nb1.5涂层的磨损形貌由因弹性失效而产生的撕裂变形和磨粒磨损产生的窄小犁沟组成,区域A为变形区域,区域B为磨损区域,如图7a[48]所示。随着Nb含量的添加(图7b~d[48]),涂层表面的犁沟变细变浅,表现出以磨粒磨损为主导的磨损机制。而硬度较低的M2钢基体被高硬度的摩擦副刺穿,表现出伴随黏着磨损机制的塑性失效特征,表面磨损形貌由大量宽而深的犁沟和大面积的剥落组成,如图7e[48]所示。除Laves金属间化合物外,RHEACs中hcp固溶体和TiN化合物等高硬度物相的存在也会显著降低摩擦副对涂层的磨粒磨损,提高涂层的耐磨损性能。

图7

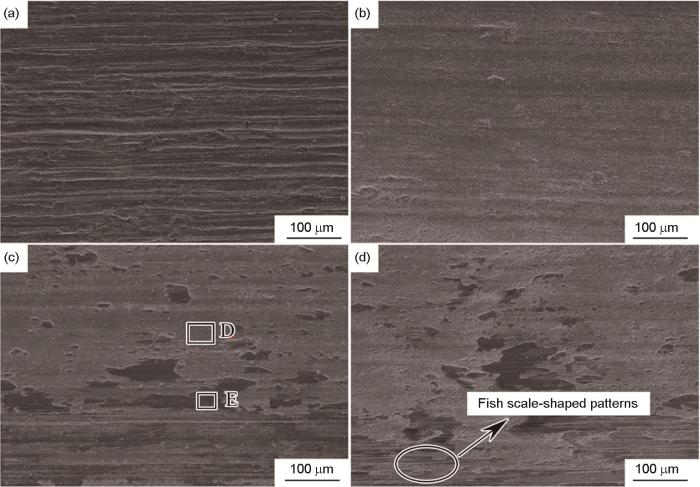

涂层的耐磨损性能不仅与其显微硬度有关,也与其强-塑性的匹配程度密切相关。RHEAs通常在室温下表现出较为明显的脆性倾向。涂层显微硬度随着hcp相和Sigma化合物含量增多而升高的同时,塑性也迅速降低,导致涂层在载荷作用下容易发生显微裂纹萌生和扩展,在摩擦副附加水平剪切应力的作用下,开裂区逐渐剥落。Zhao等[53]研究Zr元素对AlNbTaZr x RHEACs耐磨损性能的影响,发现随着Zr元素的添加,涂层中逐渐析出了hcp强化相,导致其显微硬度逐渐增大,增加了对微切割的抵抗作用。涂层表面磨损形貌的SEM像如图8[53]所示,随着Zr含量的增大,涂层表面因磨损产生的犁沟(区域D)逐渐减少(图8a~c[53]),并产生大量氧化釉层(区域E)。而当Zr含量继续增大至1.0时,涂层中大量hcp相的析出导致其韧性急剧下降,磨损过程中的抗脆性脱黏能力变弱,局部表面出现“鱼鳞状”的剥落区(图8d[53])。因此,向涂层中添加少量韧性元素可有效降低涂层在高应力摩擦下的开裂敏感性,提升涂层的耐磨损性能。Liu等[42]研究了Cu元素对AlNbMoTaCu x 难熔高熵合金涂层耐磨损性能的影响。结果显示,添加少量Cu元素(x = 0.4)后涂层的磨损体积由5.54 mm3减小至0.41 mm3,显著提高了涂层的耐磨损性能。这归因于AlNbMoTa涂层具有较大的脆性倾向,随着Cu元素的添加,虽然涂层的显微硬度从836 HV0.2下降至568 HV0.2,但由于bcc相和hcp相周围产生了fcc物相,有效降低了涂层的脆性,抑制了裂纹的萌生和扩展以及剥落层的形成,从而显著提升了涂层的耐磨损性能。

图8

合金涂层的磨损机制除磨粒磨损和黏着磨损外,还有易在高温下发生的氧化磨损。RHEAs中常见的Mo、Nb和Ta等元素在高温下难以形成致密的氧化层,通常表现出较差的抗氧化性能。然而由其制备的涂层在高温下形成的氧化膜会在高应力作用下被压实[77],形成致密的氧化膜釉层,通过抵抗摩擦副的切割进一步降低了涂层的磨损量。Wang等[61]研究了Y2O3陶瓷颗粒复合的MoNbTaW RHEACs的高温耐磨损性能。结果显示,涂层的耐磨损性能随着温度的升高而显著提升。分析结果表明,随着温度升高,合金涂层表面的氧化釉层在摩擦磨损过程中能起到较好的润滑作用,降低了涂层的磨损量。Zhao等[36]研究MoNbTaW RHEACs高温耐磨损性能发现,涂层的耐磨损性能随着温度升高而降低。这主要因为涂层成分被In718基体合金稀释,涂层中存在大量强度较低的fcc_(Ni, M)相,随着温度升高,fcc_(Ni, M)相明显软化,无法为氧化层提供结构支撑,导致氧化层大面积剥落。

由此可见,RHEACs具有优异的室温和高温耐磨损性能,显微硬度和强塑性是否匹配是决定其室温耐磨损性能的关键,而RHEACs的高温耐磨损性能主要由其抗高温软化性能决定。

4.3 激光熔覆难熔高熵合金涂层的耐腐蚀和抗氧化性能

腐蚀是金属最为常见的失效形式之一。合金腐蚀可分为均匀腐蚀、局部腐蚀和电偶腐蚀。其中,局部腐蚀是金属结构材料在工业应用领域中最主要的腐蚀失效形式,局部腐蚀产生的主要原因是合金中不同物相或不同成分区域之间存在明显电位差,在局部区域构成了电解池,导致材料发生快速腐蚀。RHEAs通常由简单的bcc固溶体组成,bcc固溶体在Cl-和酸性溶液中具有比fcc固溶体更为优异的耐腐蚀性能。其次,激光快速凝固可以有效消除元素的晶间偏析,有助于获得更均匀的显微组织。因此,RHEACs通常展现出较优异的耐腐蚀性能。动态电位极化曲线是表征材料耐腐蚀性能的标准电化学技术,表4[49,52,56,57,62,63,70,78]总结了采用电化学技术对LC-RHEACs耐腐蚀性能评价的结果。

表4 LC-RHEACs的耐腐蚀性能[49,52,56,57,62,63,70,78]

Table 4

| Coating | Substrate | HEAC | Ref. | |||

|---|---|---|---|---|---|---|

Type | Corrosion potential V | Corrosion current density A·cm-2 | Corrosion potential V | Corrosion current density A·cm-2 | ||

| (TiZrNb)SnMo | TC4 alloy | -1.15 | 3.89 × 10-6 | -1.0 | 1.10 × 10-6 | [49] |

| NiTiCrNbTa1.0 | TC4 alloy | -0.233 | 1.63 × 10-7 | [52] | ||

| TiMoNbZr | SS 316L | -0.736 | 1.002 × 10-5 | -0.474 | 2.939 × 10-6 | [57] |

| TiZrAlNb | TC4 alloy | -0.3853 | 4.53 × 10-8 | [62] | ||

| NbTaTiV | TC4 alloy | -0.458 | 9.198 × 10-8 | [63] | ||

| NbTaTiVCr | -0.390 | 6.262 × 10-8 | ||||

| NbTaTiVZr | -0.418 | 2.275 × 10-7 | ||||

| NbTaTiVW | -0.378 | 4.294 × 10-8 | ||||

| AlCoCrMo | SS 904L | -0.159 | 1.14 × 10-4 | -0.179 | 1.44 × 10-3 | [56] |

| AlCoCrMoV | -0.145 | 2.80 × 10-5 | ||||

| TiMoNbCr | TC4 alloy | -0.397 | 2.797 × 10-9 | -0.230 | 1.722 × 10-10 | [70] |

| TiMoNbTa | -0.248 | 1.695 × 10-9 | ||||

| TiMoNbZr | -0.277 | 1.788 × 10-9 | ||||

| WVTaTi | 42CrMo | -0.7783 | 6.466 × 10-6 | [78] | ||

| WVTaTiCr | -0.3198 | 4.337 × 10-7 | ||||

在由电化学方法测量得到的合金动态极化曲线中,腐蚀电位越大,腐蚀电流密度越小,表明材料具有更低的腐蚀敏感性和更少的腐蚀位置,耐腐蚀性能更好[79]。从表4[49,52,56,57,62,63,70,78]可以看出,RHEACs相比于TC4、SS 316等基体合金具有更大的腐蚀电位和更小的腐蚀电流,展现出更优异的耐腐蚀性能。RHEACs中Ti、Cr、Mo和W元素在NaCl溶液中腐蚀时会形成稳定的高价态TiO2、Cr2O3、MoO3和WO3钝化膜[63],防止金属的持续腐蚀,减缓涂层的腐蚀速率。而Ta和Nb元素则形成不稳定的多价钝化膜,Zr和V元素基本不会发生钝化。因此,添加易形成稳定钝化膜的元素是提高涂层耐腐蚀性能的有效方式。

除添加钝化元素外,通过成分设计改善涂层的物相组成可有效降低涂层的电偶腐蚀,提升其耐腐蚀性能。Liao等[56]采用CALPHAD方法研究了相组成对AlCoCrMoV x 难熔高熵合金涂层耐腐蚀性能的影响。动态极化曲线和阻抗图谱显示,当V元素含量为0.8时,涂层具有最低的腐蚀电流密度和最大的Nyquist半径,表明涂层耐腐蚀性能最佳。分析原因表明,随着V元素含量的增加,AlCoCrMoV x 涂层的微观结构逐渐转变为单一bcc相,有效地降低了电偶腐蚀速率,提高了涂层的耐腐蚀性能。而当V元素含量增大至1.0时,涂层的腐蚀电流密度则会小幅度增大。X射线光电子能谱(XPS)分析结果表明,涂层中Mo、Cr和Al等钝化元素的含量随着V元素的添加而降低,导致钝化膜中MoO3、Cr2O3和Al2O3等化合物含量降低,增大了腐蚀速率。总体来说,LC-RHEACs相比于传统的镍基、铁基和钛基合金均展现出优异的耐腐蚀性能,但目前文献中关于LC-RHEACs腐蚀行为的报道相对较少。为了加快涂层在极端腐蚀环境下的应用,探究激光加工工艺对RHEACs在各种腐蚀环境下腐蚀机理的影响是今后的研究重点。

涂层的抗氧化性能与氧化产物的稳定性相关。氧化产物的稳定性可通过PBR (Pilling-Bedworth ratio)值进行评估[83]。PBR值表示金属原子氧化前后的体积变化比,PBR值为1~2时金属氧化物膜较为致密,具有良好的隔绝大气作用,更高的PBR值表示金属原子氧化时体积膨胀较大,氧化膜容易破裂,抗氧化性能较差。Zhao等[53]研究AlNbTaZr x RHEACs在1000 ℃下氧化50 h后的氧化性能发现,ZrO2具有较小的PBR值,随着Zr含量的增加,涂层的氧化增重逐渐减小。图9[53]为涂层表面的氧化层形貌,Zr0.2涂层上形成的氧化层可以清楚地观察到一些细小的裂纹,部分区域发生了明显的剥落(图9a[53]),Zr1.0涂层上形成的氧化层较为平整(图9b[53])。由此可见,选择合适的组元以形成致密的氧化层对提升难熔高熵合金涂层的抗氧化性具有重要意义。此外,如何通过成分设计充分利用不同元素之间的协同作用是进一步提升难熔高熵合金涂层抗氧化性能的关键。

图9

5 总结与展望

激光熔覆作为一种先进的增材制造技术,为解决难熔高熵合金制备难、成本高及密度大等瓶颈问题提供了一条行之有效的途径。目前研究人员采用激光熔覆技术制备出了成分均匀、组织细小、界面结合力强及成形质量良好的难熔高熵合金涂层,并且涂层表现出优异的综合性能。首先,难熔高熵合金涂层在高温应用领域展现出优异的高温稳定性和抗氧化性能,有望广泛应用于保护航空发动机和燃气轮机的涡轮叶片和燃烧室等高温部件。其次,在能源领域,含有Zr和W等元素的难熔高熵合金涂层由于其优异的抗辐照性能、较低的中子吸收截面和低溅射率,被认为是核电站反应堆包壳的理想材料。在石油化工领域,难熔高熵合金涂层可以用于化工反应器、管道和储罐内壁,显著提高其耐腐蚀性能和耐磨损性能。此外,含有Ti元素的难熔高熵合金涂层因其良好的生物相容性和抗菌性能,可用于保护医疗植入物和手术器械表面,从而延长植入物的使用寿命。总体而言,激光熔覆难熔高熵合金涂层在极端应用领域具有可观的应用前景。但目前对激光熔覆难熔高熵合金涂层的研究还处于工艺优化、成分调控的实验室研究阶段,距工程实际应用仍存在一定的距离,亟待进一步完善基础理论性研究工作,主要表现在以下几个方面。

(1) 至今已开发的难熔高熵合金有400余种,但理论上的合金体系远超过31000种。因此应发挥材料基因组计划关于高通量材料集成计算数据库的作用,实现对具有预期性能合金材料的快速筛选。此外,有必要结合激光熔覆同轴送粉的优势,基于高通量设计进行原位合金化制备成分梯度涂层,通过对涂层显微组织和服役性能的快速表征,实现对合金成分的高效筛选,缩短新材料研发周期、降低研发成本。

(2) 目前开发的难熔高熵合金涂层的合金体系主要由难熔元素和强化元素组成。O、N和C等非金属元素和CeO2、Al2O3和WC等陶瓷颗粒往往会使铸态合金表现出优异的强-韧性协同作用。因此,未来可着重于非金属元素和陶瓷颗粒强化难熔高熵合金涂层的相关研究。此外,激光成形过程中高凝固速率可有效抑制晶体的形核和长大,有利于合金中形成非晶相结构,而非晶相结构具有优异的力学性能,尤其是耐磨损和耐腐蚀性能,但目前相关领域的研究仍较为匮乏。因此,应加快激光表面非晶化技术在制备难熔高熵合金涂层领域应用的相关研究。

(3) 目前,难熔高熵合金涂层普遍存在稀释率高(大于30%)的问题。稀释率过高会恶化涂层的显微硬度及耐腐蚀和抗氧化等性能,甚至影响难熔高熵合金涂层中固溶体的成形性。稀释率过低会降低涂层与基体之间的冶金结合力。此外,由于基体合金和涂层具有不同的物相组成,这种冶金结合使得结合区域呈现复杂的微观形貌,在激光加工过程中热应力、相变应力和约束应力的影响下,结合区域容易形成微裂纹,导致涂层在使用过程中出现裂纹扩展并最终失效。因此,获得具有良好冶金结合性和优异表面性能的难熔高熵合金涂层,控制稀释率以及深入研究结合区的微观形貌和物相组成对涂层结合强度的影响规律,是未来研究亟需攻克的主要难题。

(4) 难熔高熵合金涂层作为新一代的高温表面防护材料,未来应用瞄准的是航空航天、核能化工和军事装备等对高温服役性能要求较高的领域。但目前对其高温服役性能的研究还不够深入和全面,需进一步了解激光增材制造难熔高熵合金涂层的高温服役行为和失效机制,如高温蠕变、耐疲劳等性能。此外,目前针对难熔高熵合金涂层的抗辐照性能、生物相容性等方面仍缺乏系统性研究。应尽快形成和完善相应理论体系研究,以扩大难熔高熵合金涂层的应用范围。

参考文献

High temperature strength of refractory complex concentrated alloys

[J].Thermodynamic and mechanical properties of 15 single-phase and 11 multi-phase refractory complex concentrated alloys (RCCAs) are reported. Using the CALPHAD approach, phase diagrams for these alloys are calculated to identify the solidus (melting, T-m) temperatures and volume fractions of secondary phases. Correlations were identified between the strength drops at 1000 degrees C and 1200 degrees C and the alloy compositions, room temperature properties, melting temperatures and volume fractions of secondary phases. The influence of alloy density on the temperature dependence of specific yield strength was also explored. The conducted analysis suggests that the loss of high-temperature strength of single-phase BCC RCCAs is related to the activation of diffusion-controlled deformation mechanisms, which occurs at T >= 0.6 T-m, so that the alloys with higher T-m retain their strength to higher temperatures. On the other hand, a rapid decrease in strength of multi-phase RCCAs with increasing temperature above 1000 degrees C is probably due to dissolution of secondary phases. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

Multiplicity of dislocation pathways in a refractory multiprincipal element alloy

[J].Refractory multiprincipal element alloys (MPEAs) are promising materials to meet the demands of aggressive structural applications, yet require fundamentally different avenues for accommodating plastic deformation in the body-centered cubic (bcc) variants of these alloys. We show a desirable combination of homogeneous plastic deformability and strength in the bcc MPEA MoNbTi, enabled by the rugged atomic environment through which dislocations must navigate. Our observations of dislocation motion and atomistic calculations unveil the unexpected dominance of nonscrew character dislocations and numerous slip planes for dislocation glide. This behavior lends credence to theories that explain the exceptional high temperature strength of similar alloys. Our results advance a defect-aware perspective to alloy design strategies for materials capable of performance across the temperature spectrum.Copyright © 2020 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes

[J].

Refractory high-entropy alloys

[J].

Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys

[J].

Phase selection, lattice distortions, and mechanical properties in high-entropy alloys

[J].

Temperature-dependent tensile behavior of the HfNbTaTiZr multi-principal element alloy

[J].

Effects of Mo, Nb, Ta, Ti, and Zr on mechanical properties of equiatomic Hf-Mo-Nb-Ta-Ti-Zr alloys

[J].

Toughening pathways and regulatory mechanisms of refractory high-entropy alloys

[J].Alloying has long been used to improve the properties of metals. Typically, the design concept starts with two metal elements as the foundation and small quantities of other elements are added to change or optimize the alloy properties. Recently, a new alloy has emerged, which combines several main elements to form new alloys, known as high-entropy alloys. Among them, refractory high-entropy alloys (RHEAs) made by mixing five or more refractory metal elements that have similar atomic ratios have wide application prospects in the field of high-temperature materials because of their stable phase structures and excellent high-temperature properties. This paper reviews the mechanical properties and microstructure of typical RHEAs, mechanism of toughening and mechanical property regulation of RHEAs, and prospects for the future development of RHEAs, starting with the current research status of RHEAs. The first section delves into the classification of RHEAs based on their constituent phases, and the microstructure and phase composition of the RHEAs are investigated. The second section summarizes the mechanical properties, strengthening, and toughening mechanisms of RHEAs at room and high temperatures. The third section illustrates and discusses three different strengthening and toughening schemes that have been used to modulate the mechanical properties of RHEAs, namely, chemical composition, process, and phase structure modulations. Finally, the future development of RHEAs have been forecasted and the following recommendations are made for key RHEA research trends in the future: simulating and calculating the materials properties and formation phases using computers and other technologies, development of a research platform and database for RHEAs, accelerating the screening of new RHEAs using combinatorial experimental methods, and acquiring top-down and bottom-up experimental methods to explore RHEAs systems with excellent properties.

难熔高熵合金的强韧化途径与调控机理

[J].在众多高熵合金中,由5种或5种以上的难熔金属元素,按照等原子比或者近等原子比混合形成的难熔高熵合金,凭借稳定的相结构和优异的高温性能,在高温材料领域具有广阔的应用前景。本文从难熔高熵合金的研究现状出发,综述典型难熔高熵合金的微观组织和相组成、室温和高温力学性能、强韧化机理与力学性能调控,并对未来难熔高熵合金的研究开发进行展望。首先,将难熔高熵合金按照组成相进行分类,分析了难熔高熵合金的微观组织和相组成,然后总结了难熔高熵合金的室温和高温力学性能与强韧化机理,并讨论了3种不同的强韧化方案,即化学成分调控、工艺调控和相结构调控。最后对未来难熔高熵合金的发展进行了展望,并对其未来重点研究方向提出了如下建议:借助计算机等技术,模拟与计算材料的性能与形成相,构建难熔高熵合金的研究平台与数据库;借助组合实验方法,加快筛选新的难熔高熵合金;掌握自上而下和自下而上的实验方法,探究性能优异的新型难熔高熵合金体系。

CALPHAD-aided design for superior thermal stability and mechanical behavior in a TiZrHfNb refractory high-entropy alloy

[J].

On phase stability of Mo-Nb-Ta-W refractory high entropy alloys

[J].

A quinary WTaCrVHf nanocrystalline refractory high-entropy alloy withholding extreme irradiation environments

[J].In the quest of new materials that can withstand severe irradiation and mechanical extremes for advanced applications (e.g. fission & fusion reactors, space applications, etc.), design, prediction and control of advanced materials beyond current material designs become paramount. Here, through a combined experimental and simulation methodology, we design a nanocrystalline refractory high entropy alloy (RHEA) system. Compositions assessed under extreme environments and in situ electron-microscopy reveal both high thermal stability and radiation resistance. We observe grain refinement under heavy ion irradiation and resistance to dual-beam irradiation and helium implantation in the form of low defect generation and evolution, as well as no detectable grain growth. The experimental and modeling results-showing a good agreement-can be applied to design and rapidly assess other alloys subjected to extreme environmental conditions.© 2023. This is a U.S. Government work and not under copyright protection in the US; foreign copyright protection may apply.

Enhanced resistance to helium irradiations through unusual interaction between high-entropy-alloy and helium

[J].

Oxidation behavior of the Ti38V15Nb23Hf24 refractory high-entropy alloy at elevated temperatures

[J].

Natural-mixing guided design of refractory high-entropy alloys with as-cast tensile ductility

[J].

Additive manufacturing of ductile refractory high-entropy alloys via phase engineering

[J].

Research and progress of laser cladding on engineering alloys: A review

[J].

Research progress of laser cladding technology

[J].

激光熔覆技术研究进展

[J].

Recent research and development status of laser cladding: A review

[J].

Recent advances in tribology of high entropy alloys: A critical review

[J].

Solid-solution phase formation rules for multi-component alloys

[J].

Prediction of high-entropy stabilized solid-solution in multi-component alloys

[J].

Finding density functionals with machine learning

[J].

Design and fabrication of refractory multicomponent high entropy alloys coating with laser cladding

[D].

激光熔覆难熔多组元高熵合金涂层设计与制备

[D].

Composition design and property optimization of high entropy alloys based on machine learning

[D].

基于机器学习的高熵合金成分设计与性能优化

[D].

Accelerated exploration of multi-principal element alloys with solid solution phases

[J].Senkov, O. N.; Miller, J. D.; Miracle, D. B.; Woodward, C. Air Force Res Lab, Mat & Mfg Directorate, Wright Patterson AFB, OH 45433 USA.

Atomization simulation and preparation of 24CrNiMoY alloy steel powder using VIGA technology at high gas pressure

[J].

Fabrication of spherical MoNbTaWZr refractory high-entropy powders by spray granulation combined with plasma spheroidization

[J].

Development of high strength high plasticity refractory high entropy alloy based on Mo element optimization and advanced forming process

[J].

Laser additive manufacturing of melt-grown Al2O3/GdAlO3 eutectic ceramic composite: Powder designs and crack analysis with thermo-mechanical simulation

[J].

Design of heterogeneous structure for enhancing formation quality of laser-manufactured WTaMoNb refractory high-entropy alloy

[J].

Instantaneous powder flux regulation system for laser metal deposition

[J].

Laser metal deposition of compositionally graded TiZrNbTa refractory high-entropy alloys using elemental powder blends

[J].In the present study, laser metal deposition (LMD) was used to produce compositionally graded refractory high-entropy alloys (HEAs) for screening purposes by in-situ alloying of elemental powder blends. A compositional gradient from Ti25Zr50Nb0Ta25 to Ti25Zr0Nb50Ta25 is obtained by incrementally substituting Zr powder with Nb powder. A suitable strategy was developed to process the powder blend despite several challenges such as the high melting points of the refractory elements and the large differences in melting points among them. The influence of the LMD process on the final chemical composition was analyzed in detail and the LMD process was optimized to obtain a well-defined compositional gradient. Microstructures, textures, chemical compositions and mechanical properties were characterized using SEM, EBSD, EDX, and microhardness testing, respectively. Compositions between Ti25Zr0Nb50Ta25 and Ti25Zr25Nb25Ta25 were found to be single-phase bcc solid solutions with a coarse grain microstructure. Increasing the Zr to Nb ratio beyond the equiatomic composition results in finer and harder multiphase microstructures. The results shown in the present study clearly show for the first time that LMD is a suitable processing tool to screen HEAs over a range of chemical compositions.

High-throughput additive manufacturing and characterization of refractory high entropy alloys

[J].

Microstructure of WTaNbMo refractory high entropy alloy coating fabricated by dynamic magnetic field assisted laser cladding process

[J].

Microstructure and high temperature properties of laser cladded WTaNbMo refractory high entropy alloy coating assisted with ultrasound vibration

[J].

Microstructure of NbMoTaTiNi refractory high-entropy alloy coating fabricated by ultrasonic field-assisted laser cladding process

[J].

Multi-objective optimization for laser cladding refractory MoNbTiZr high-entropy alloy coating on Ti6Al4V

[J].

Residual stress determination by neutron diffraction in powder bed fusion-built Alloy 718: Influence of process parameters and post-treatment

[J].

Residual stresses in additively manufactured AlSi10Mg: Raman spectroscopy and X-ray diffraction analysis

[J].

Microstructure evolution and strengthening mechanism of laser-cladding MoFe x CrTiWAlNb y refractory high-entropy alloy coatings

[J].

Design and characterization of AlNbMoTaCu x high entropy alloys laser cladding coatings

[J].

A critical review of high entropy alloys and related concepts

[J].

Research progress in composition design, microstructure and properties of refractory high entropy alloys

[J].

难熔高熵合金成分设计微观组织及性能研究进展

[J].高熵合金被定义为含有4种或4种以上主要元素的合金,主要元素的原子分数大于5%且不超过35%,具有高强度、高耐磨性、高耐腐蚀性等优异的性能。难熔高熵合金是基于难熔元素的高熵合金而设计开发的一种新型高温合金,其在航空航天、石油化工等领域具有广阔的应用前景,有望取代传统的高温合金。本文综述了难熔高熵合金一般是从元素选择和添加微量的元素等方面进行成分设计,其相组成有单相组织和双相组织等结构,研究了难熔高熵合金的制备方法和性能特点,并且在文章最后指出了难熔高熵合金目前所面临的问题与挑战。希望通过本文综述,可以为科研工作者在难熔高熵合金的组分设计,微观组织调控以及性能开发等方面提供有价值的参考。

Research progress in refractory high-entropy alloys

[J].

难熔高熵合金的研究进展

[J].

Synthesis and characterization of refractory TiZrNbWMo high-entropy alloy coating by laser cladding

[J].

MoFeCrTiWAlNb refractory high-entropy alloy coating fabricated by rectangular-spot laser cladding

[J].

MoFe1.5CrTiWAlNb x refractory high-entropy alloy coating fabricated by laser cladding

[J].

A novel biomedical high-entropy alloy and its laser-clad coating designed by a cluster-plus-glue-atom model

[J].

Microstructure and hardness of NbTiZr and NbTaTiZr refractory medium-entropy alloy coatings on Zr alloy by laser cladding

[J].

Annealing-induced microstructure and properties evolution of refractory MoFeCrTiWAlNb3 eutectic high-entropy alloy coating by laser cladding

[J].

Microstructure evolution and properties of NiTiCrNbTa x refractory high-entropy alloy coatings with variable Ta content

[J].

Wear and high-temperature oxidation resistances of AlNbTaZr x high-entropy alloys coatings fabricated on Ti6Al4V by laser cladding

[J].

Lightweight refractory high entropy alloy coating by laser cladding on Ti-6Al-4V surface

[J].

Microstructure and properties of lightweight Al0.2CrNbTiV refractory high entropy alloy coating with different dilutions deposited by high speed laser cladding

[J].

Effect of V on microstructure, wear and corrosion properties in AlCoCrMoV x high entropy alloy coatings by laser cladding

[J].

Microstructure and properties of TiNbZrMo high entropy alloy coating

[J].

Wear-resistant NbMoTaWTi high entropy alloy coating prepared by laser cladding on TC4 titanium alloy

[J].

Microstructure and wear resistance of in-situ TiN/(Nb, Ti)5Si3 reinforced MoNbTaWTi-based refractory high entropy alloy composite coatings by laser cladding

[J].

Solidification characteristics and microstructure of TaNbZrTi refractory high entropy coating by extreme high-speed laser cladding

[J].

Effect of Y2O3 on the microstructure and tribology property of WMoTaNb refractory high entropy alloy coating prepared by laser cladding

[J].

A novel high-entropy alloy coating on Ti-6Al-4V substrate by laser cladding

[J].

Microstructure evolution and performance enhancement of NbTaTiV-(Cr, Zr, W) single-phase refractory high-entropy alloy coatings: Role of additional elements

[J].

Microstructure and mechanical properties of in situ (Ti, Nb)Cp/Fe-based laser composite coating prepared with different heat inputs

[J].

Refractory high-entropy alloys fabricated using laser technologies: A concrete review

[J].

Strong yet ductile nanolamellar high-entropy alloys by additive manufacturing

[J].

A novel rapid alloy development method towards powder bed additive manufacturing, demonstrated for binary Al-Ti, -Zr and -Nb alloys

[J].

Comparative study of the microstructures and mechanical properties of laser metal deposited and vacuum arc melted refractory NbMoTa medium-entropy alloy

[J].

A body-centered cubic Zr50Ti35Nb15 medium-entropy alloy with unique properties

[J].

Corrosion behavior of TiMoNbX (X = Ta, Cr, Zr) refractory high entropy alloy coating prepared by laser cladding based on TC4 titanium alloy

[J].

Phase-transformation ductilization of brittle high-entropy alloys via metastability engineering

[J].

Novel metastable engineering in single-phase high-entropy alloy

[J].

Structure and stability of Laves phases. Part I. Critical assessment of factors controlling Laves phase stability

[J].

Study of dry sliding wear of cast iron as a function of surface temperature

[J].

Synthesis and mechanical characterization of a CuMoTaWV high-entropy film by magnetron sputtering

[J].

Corrosion and wear resistance characterization of environmentally friendly sol-gel hybrid nanocomposite coating on AA5083

[J].<p>Environmentally friendly organic–inorganic hybrid nanocomposite films have been developed by sol–gel method for corrosion protection of AA5083 alloy. The hybrid nanocomposite coatings have been synthesized from tetraethylorthosilicate (TEOS) and 3-glycidoxypropyltrimethoxysilane (GPTMS) precursors. The multilayer coatings were prepared by dip-coating technique. Attenuated total reflectance–Fourier transform infrared (ATR–FTIR) spectroscopy was carried out to show the formation of the Si–O–Si structural backbone of the hybrid coatings. Structure and surface morphology of the coatings were studied by optical microscopy (OM), scanning electron microscopy (SEM) and atomic force microscopy (AFM). Characterization of the coatings with respect to pencil scratch hardness, adhesive and abrasion resistance was performed. The corrosion protection performance of these coatings was examined by using cyclic potentiodynamic polarization technique in Persian Gulf water. The results revealed that crack-free films with smooth surface were obtained. With increasing the number of sol–gel coated layers, corrosion resistance increased from 81 to 419 kΩ cm2, while the abrasion wear resistance did not change significantly. However, the triple sol–gel coated layer offered excellent protection against corrosion.</p>

Effect of Cr on microstructure and properties of WVTaTiCr x refractory high-entropy alloy laser cladding

[J].

New studies on wear and corrosion behavior of laser cladding FeNiCoCrMo x high entropy alloy coating: The role of Mo

[J].

On the oxidation mechanism of refractory high entropy alloys

[J].

Designing NbTiTa-Cr/Al refractory complex concentrated alloys with balanced strength-ductility-oxidation resistance properties: Insights into oxidation mechanisms

[J].

Opportunity and challenge of refractory high-entropy alloys in the field of reactor structural materials

[J].Exploitation of traditional reactor structural materials tends to limits; thus, the development of novel materials is urgent. Alloying has long been used to obtain materials with desirable properties. In recent decades, a new alloying technique that combines multiple principal elements in high concentrations to fabricate new materials, termed high-entropy alloys (HEAs), has gained popularity. Refractory HEAs (RHEAs) consist of several principle refractory elements and are an important subset of HEAs. RHEAs have attracted immense attention owing to their unique mechanical, physical, and chemical properties, particularly their excellent high-temperature mechanical properties and radiation resistance. RHEAs are expected to be utilized in cladding materials for fourth-generation fission reactors and plasma-facing materials for fusion reactors. Combined with representative literature, this paper focuses on mechanical, radiation resistance, and oxidation resistance properties of RHEAs. Further, strengthening and radiation resistance mechanisms of RHEAs are explored, and the development evolution and prospects of RHEAs are proposed.

难熔高熵合金在反应堆结构材料领域的机遇与挑战

[J].传统反应堆结构材料性能已趋于极限,亟需开发新型材料。难熔高熵合金是以多种难熔元素作为主元的新型金属材料,具有独特的力学、物理和化学性质,尤其在高温力学、抗辐照等方面表现出优异的性能。难熔高熵合金在第4代核裂变反应堆包壳材料、核聚变堆面向第一壁材料等关键领域具有广阔的应用前景。本文结合具有代表性的文献,围绕难熔高熵合金的力学性能、抗辐照性能、抗氧化性能阐述了其强化机制与抗辐照机理,梳理了难熔高熵合金的发展脉络,在此基础上展望了难熔高熵合金在反应堆结构材料领域的应用前景。

Pilling-Bedworth ratio for oxidation of alloys

[J].