选区激光熔化(selective laser melting,SLM)技术由于具有较高的冷却速率(106~108 K/s)、较大的温度梯度和独特的热循环等特点,可以制备具有超细微观结构和高体积分数强化相的材料,为新一代抗蠕变铝合金的开发提供了可能[11~14]。Bahl等[15]通过SLM技术构建了体积分数高达~27%的连续致密Al-Ce共晶组织,通过共晶组织的载荷传递有效降低了合金总应力水平,使Al-Ce-Ni-Mn-Zr合金具有良好的抗蠕变性能。Griffiths等[16]系统研究了共格L12-Al3Zr析出相对Al-Mg-Zr合金蠕变行为的影响,发现Al3Zr相降低了细小等轴晶粒的晶界迁移能力,晶界迁移和位错滑移为合金的主要蠕变机制。这些结果表明,共晶网络与高体积分数析出相的结合,是SLM成形抗蠕变铝合金的一种有效设计策略。Al-Si系合金由于具有良好的可焊性和淬透性在SLM成形中展现出显著优势,如AlSi10Mg和AlSi7Mg[17,18]。大体积分数的Al-Si共晶组织是Al-Si系合金的主要特点。在此基础上,添加少量成本低廉的慢扩散元素,如Fe、Mn和Ni,可以形成高度互联且具有良好热稳定性的金属间化合物(intermetallic compound,IMC)[19,20]。优化合金成分并结合IMC强化有望提高Al-Si系合金的高温蠕变性能。

Al-Si系合金的蠕变变形过程主要受位错蠕变机制控制[21~24]。IMC/基体的界面关系对位错蠕变阈值应力有较大影响。当位错绕过IMC时,界面上的晶格错配会在偏离侧捕获位错,阈值应力随晶格错配的增加而增大。这种现象在共格L12析出相强化的合金中被广泛报道[22]。非共格IMC也存在类似的机制,即由于晶界处较大失配导致位错运动受阻[23]。此外,载荷传递行为在具有大体积分数第二相强化的合金中不可忽略。从基体到第二相的载荷传递降低了体系的长程应力,使合金的蠕变速率减小,但也导致第二相/基体界面处的应力水平有所增大[24]。因此,塑性应变将主要集中在该界面上,可能诱发界面空化或脱黏。目前,大多数传统耐热析出相有限的体积分数和晶格错配,限制了Al-Si合金在极端环境下的蠕变性能表现。对于IMC强化的Al-Si系合金的高温蠕变行为尚需进一步研究。

本工作采用SLM技术制备了一种新型Al-Si-Fe-Mn-Ni合金。通过拉伸蠕变实验研究了该合金在300~400 ℃的高温蠕变行为,分析合金的微观组织演变规律及变形机理,以期为抗蠕变铝合金的组织设计与调控提供数据参考。

1 实验方法

实验采用气雾化法制备平均粒径为(42.9 ± 5) μm的Al-Si-Fe-Mn-Ni合金球形粉末。合金粉末的化学成分为Al-9.0Si-2.8Fe-2.1Mn-1.1Ni (质量分数,%)。采用EP-M150金属3D打印机在Ar气环境下(O含量低于11.2 mg/m³)以相邻层旋转67°的扫描策略制备块体材料。为了保证粉末的充分熔化、稳定的能量输入和熔池结构的均匀性,确定了最优SLM工艺,具体参数为:激光功率390 W、扫描速率1800 mm/s、搭接距离0.13 mm、层厚0.03 mm。激光输入能量密度约为55.5 J/mm³。研究[25]表明,过高或过低的能量密度会造成熔融飞溅和熔化不完全,降低样品致密度。为了降低块体材料中的残余应力,将铝基板温度保持在150 ℃。

采用RDL-50高温蠕变试验机在300、350和400 ℃下对打印态合金分别进行单轴拉伸蠕变实验,加载应力在33~132 MPa之间。各温度下的加载应力为相应温度下合金屈服强度的35%、45%、55%和65%。拉伸蠕变实验采用狗骨形试样,标距尺寸为10 mm × 4 mm × 2 mm。通过2个引伸计对样品的变形进行测量,分辨率为1 μm。实验结束后,将样品快速浸入水中,以保留高温组织特征。采用Gemini Supra 40扫描电子显微镜(SEM)和NordlysMax电子背散射衍射仪(EBSD)对样品的初始组织和变形组织进行表征,扫描步长为0.3 μm。利用AZtecCrystal软件对EBSD数据进行分析。采用Talos F200s透射电子显微镜(TEM)及附带的X射线能谱仪(EDS)观察合金的初始组织和断口附近组织以及析出相元素分布。TEM样品分别从均匀的初始组织和试样断口附近约1 mm处取切。将这些样品机械研磨至30~40 μm,制备出直径为3 mm的圆箔。随后对圆箔进行离子减薄,减薄倾角为6°,加速电压为3 kV。

2 实验结果与讨论

2.1 初始组织

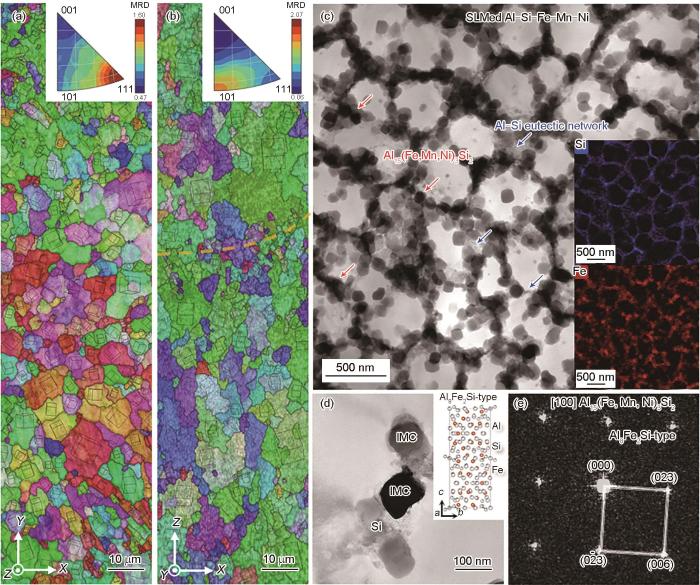

图1a和b分别为打印态Al-Si-Fe-Mn-Ni合金在XY和XZ方向上的反极图(inverse pole figure,IPF)。可以看到,XY平面呈等轴晶形态,平均晶粒尺寸为(6.7 ± 0.5) μm;XZ平面则具有较明显的柱状晶组织,晶粒较为粗大((9 ± 1.4) μm),但在熔体轨迹的重叠区域形成细小等轴晶((2 ± 0.7) μm)。为进一步观察合金晶粒内部的微观结构,对其进行TEM表征,如图1c所示。晶粒内观察到大量平均尺寸为(500 ± 50) nm的连续Al-Si共晶网络,以及平均尺寸为(72 ± 35) nm、体积分数约13.4%的IMC。大部分IMC沿共晶网络分布,图1d给出了局部放大图像。根据数据库(PDF:41-0894)中的Al8Fe2Si相[26]识别出[100]带轴下IMC的晶面参数,表明该相具有与Al8Fe2Si相较为相似的六方晶体结构,如图1e所示。因此,推测该相的结构式为Al15(Fe, Mn, Ni)3Si2,图1d插图内显示了其可能的原子占位信息。显然,通过慢扩散元素合金化的共晶组织设计理念,采用SLM方法获得了大体积分数的共晶组织和IMC。

图1

图1

选区激光熔化(SLM)成形Al-Si-Fe-Mn-Ni合金的初始组织

Fig.1

Initial microstructure of selective laser melted (SLMed) Al-Si-Fe-Mn-Ni alloy (MRD—multiples of random distribution)

(a) inverse pole figure (IPF) map in XY plane

(b) IPF map in XZ plane (Yellow dashed line represents the melt pool boundary)

(c) TEM image (Insets show the corresponding EDS results)

(d) high magnification bright field (BF) image of intermetallic compounds (IMCs) and Si phases (Inset shows the possible atomic occupancy information in IMC)

(e) selected area electron diffraction (SAED) image of IMC

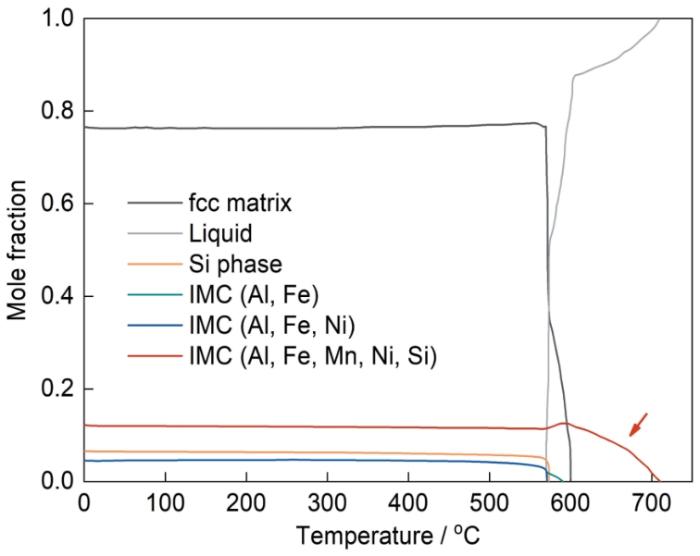

图2

图2

SLM成形Al-Si-Fe-Mn-Ni合金的模拟相图

Fig.2

Simulated phase diagram of SLMed Al-Si-Fe-Mn-Ni alloy (Red arrow represents IMC phase formation)

2.2 蠕变性能

最小蠕变速率可用来反映合金的蠕变性能,其与温度和应力之间的关系可用幂律方程表示[29]:

式中,

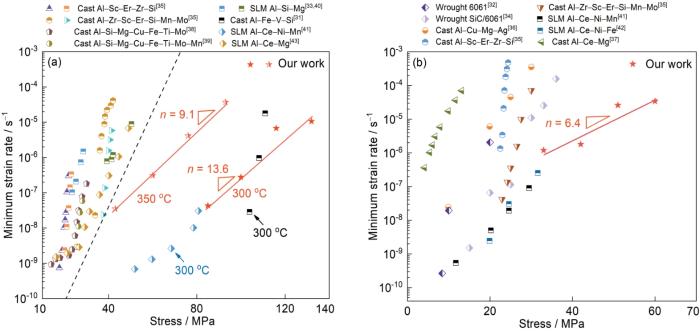

图3[31~43]为打印态Al-Si-Fe-Mn-Ni合金在不同温度下最小蠕变速率与应力之间的关系曲线。最小蠕变速率随加载应力的增加而显著增大。随着变形温度的升高,合金所能承受的应力逐渐降低。在350 ℃、43 MPa的条件下,合金的蠕变寿命约为140 h,最小蠕变速率约为3 × 10-8 s-1。一般来讲,蠕变应力指数可以反映合金的蠕变机制。对于纯Al,其n值通常为4.4[30]。在本工作中,打印态Al-Si-Fe-Mn-Ni合金在300~400 ℃区间均具有较高的蠕变应力指数(6.4~13.6),表明蠕变变形过程受位错蠕变机制控制[15],同时也说明,该合金内形成的共晶组织和IMC相增强了合金的抗蠕变性能。图3[31~43]还对比了与传统工艺和其他SLM工艺制备铝合金的抗蠕变性能。可以看到,打印态Al-Si-Fe-Mn-Ni合金表现出良好的抗蠕变性能,在400 ℃下优势也较为明显。

图3

2.3 变形组织及蠕变机制

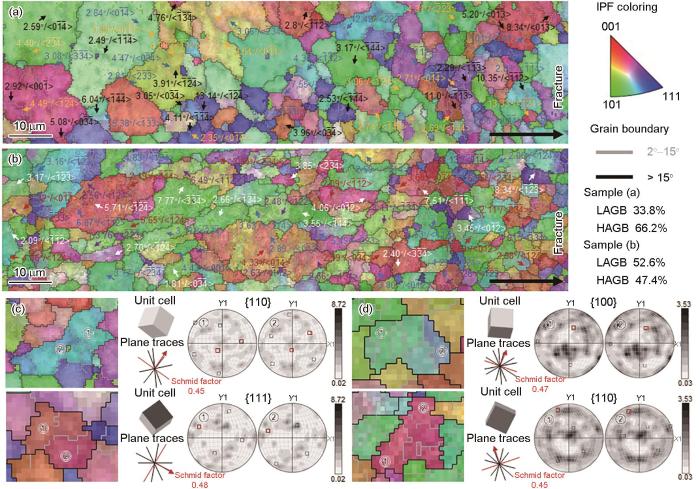

图4a和b为合金在温度350 ℃、应力60和93 MPa条件下蠕变断裂后XY面断口附近的显微组织。为确保数据对比的有效性,样品选取于距离断口1 mm处。可以看到,合金在蠕变过程中形成了大量小角度晶界(low angle grain boundaries,LAGBs,2°~15°)。随着应力的增加,LAGBs的数量从33.8%增大到52.6%。合金中原晶界均呈凸起状,并且LAGBs频繁地出现在凸起处附近,形成封闭区域,表明亚晶粒沿着凸起的晶界区域形成。在变形过程中,LAGBs通过吸收存储的位错促进晶界迁移,并逐渐向大角度晶界(high angle grain boundaries,HAGBs,> 15°)演化,促进等轴晶组织形成,以适应蠕变变形。通过分析LAGBs的失向角和旋转轴,发现应力的增加使合金中LAGBs的失向角减小,LAGBs的迁移程度下降。因此,在60 MPa的低应力条件下,大量LAGBs通过位错的有序化排列已完成向HAGBs的转变。

图4

图4

SLM成形Al-Si-Fe-Mn-Ni合金在温度350 ℃、应力60和93 MPa条件下蠕变后断口附近的EBSD像

Fig.4

EBSD images near the fracture of SLMed Al-Si-Fe-Mn-Ni alloy after creeping at temperature of 350 oC and stresses of 60 (a, c) and 93 MPa (b, d) (LAGB—low angle grain boundary, HAGB—high angle grain boundary; red arrows in Figs.4c and d represent slip directions)

(a, b) IPF images (c, d) slip trace analysis of the same oriented grains

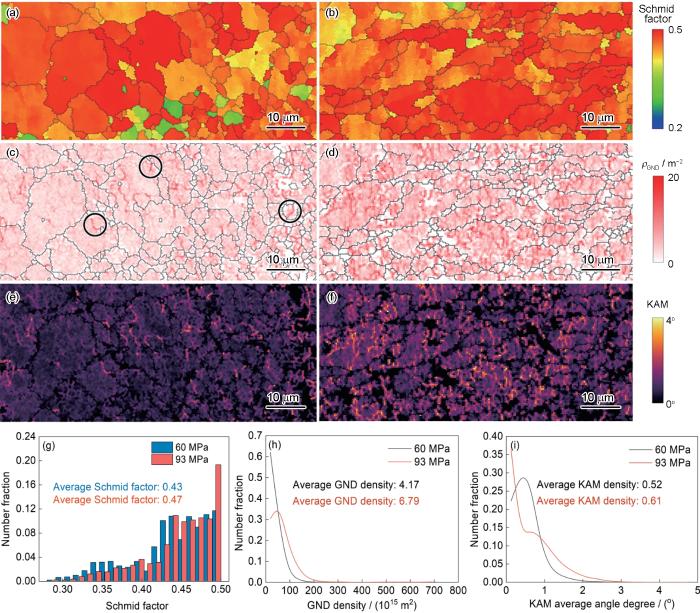

图5a和b分别为不同加载应力下合金在{111}<110>滑移方向的Schmid因子分布图。加载应力为93 MPa时,合金呈现出较高的平均Schmid因子(图5g),表明合金内位错滑移系增加。图5c~f分别为不同加载应力下合金的几何必需位错(geometrically necessary dislocation,GND)密度及局部取向差(kernel average misorientation,KAM)分布,其量化数据在图5h和i中显示。通常,GND密度为样品发生塑性变形的最小位错密度[10]。而KAM可以作为评价样品局部变形程度的参考量,也可表示为样品内位错密度的总和[44]。可以看出,低应力条件下,高密度位错主要集中在界面或晶粒内某些位置附近(如图5c中的黑色圆圈标记所示);而对于高应力条件,位错密度明显增大(平均GND密度和平均KAM密度分别由4.17 × 1015 m-2和0.52°增加至6.79 × 1015 m-2和0.61°),且在界面和晶粒内部分布也较为均匀。

图5

图5

SLM成形Al-Si-Fe-Mn-Ni合金在温度350 ℃、应力60和93 MPa条件下蠕变后的Schmid因子、几何必需位错(GNDs)密度和局部取向差(KAM)分布及统计结果

Fig.5

Schmid factors (a, b), geometric necessary dislocations (GNDs) density (ρGND represent GND density) (c, d), kernel average misorientations (KAMs) (e, f), average Schmid factor statistics (g), average GND statistics (h), and average KAM statistics (i) of SLMed Al-Si-Fe-Mn-Ni alloy after creeping at 350 oC (Black circles represent local high-density dislocation regions)

(a, c, e) under stress of 60 MPa (b, d, f) under stress of 93 MPa

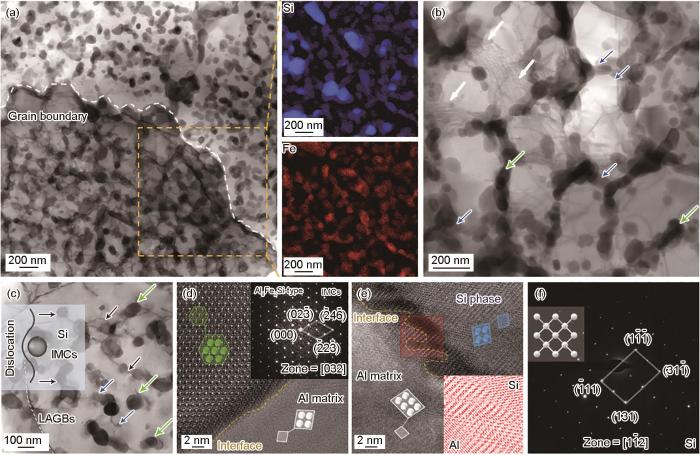

图6a显示了350 ℃和60 MPa条件下合金断口附近变形组织的TEM像。基体内大体积分数的第二相有效地阻碍了位错运动并稳定基体晶粒结构,特别是具有连续特征的网络化组织。这种大体积分数的连续第二相将通过载荷传递过程吸收合金的部分加载应力,例如之前所报道的具有约25% IMC (体积分数,下同)的Al-Fe-V-Si合金[31]和约27%共晶组织的Al-Ce-Ni-Mn-Zr合金[15]。载荷传递的作用机制为:(1) 载荷从基体转移至第二相;(2) 第二相承受载荷,进而提高合金的蠕变阈值应力。在蠕变变形过程中,载荷由强度较低的α-Al基体通过界面传递至强度较高的第二相,导致第二相承受更大的外部施加应力,此过程降低了基体的局部内应力,从而产生载荷传递强化效应。通过载荷的传递行为,合金的抗蠕变性能得到提升。合金内部沿共晶网络分布的大体积分数IMC有效地阻碍了位错和界面的迁移,导致晶内大量位错胞生成(图6b和c),与EBSD结果相吻合。IMC的平均尺寸为(105 ± 35) nm,体积分数约为15.7%。IMC发生一定程度的长大,但仍具有较好的热稳定性。而部分Si相则以分散体形式存在,平均尺寸为(55 ± 12) nm。图6d~f为IMC和分散Si相的高分辨TEM (HRTEM)像和SAED结果,表明分散Si相与合金内原位形成的IMC相同,均与基体呈非共格关系。

图6

图6

SLM成形Al-Si-Fe-Mn-Ni合金在350 ℃、应力60 MPa条件下断口附近变形组织的TEM像

Fig.6

TEM images of the deformed microstructures near the fracture of SLMed Al-Si-Fe-Mn-Ni alloy under conditions of 350 oC and 60 MPa (White arrows represent dislocation cells, blue arrows represent Si phases, green arrows represent Al15(Fe, Mn, Ni)3Si2, black arrows represent dislocations; green, white, and blue areas are the corresponding high magnified images of IMC phase, Al matrix, and Si phase)

(a) microscopic morphology and corresponding EDS results

(b) BF image of the Al-Si eutectic structure and IMCs

(c) interaction behavior of IMCs and dispersed Si phases with dislocations

(d) high resolution TEM (HRTEM) image of IMCs (Inset shows SAED result of the IMC)

(e) HRTEM image of the Si phase (Inset shows magnification of local interface structure)

(f) SAED image of the Si phase (Inset shows atomic occupancy information)

常温变形下,若滑移面上的位错运动受阻产生塞积,滑移便难以进行,只有在更大的分切应力下才能重新激活位错的运动和增殖[45]。而在高温下,位错可通过热激活和空位扩散克服短程阻碍,从而使变形持续进行[46]。本工作中,位错的攀移受大体积分数连续网状的Al-Si共晶组织抑制[47],主要通过滑移以绕过非共格第二相(图6c)。因此,位错与析出相的相互作用是Al-Si-Fe-Mn-Ni合金蠕变强化的主要原因之一。合金在350 ℃下蠕变应力指数为9.1,明显高于纯Al (4.4),表明存在抑制位错蠕变的阈值应力(σth)。在持续外应力的作用下,合金中析出相与位错的相互作用提供了σth。在

式中,

式中,σOrowan为Orowan应力,

由于大体积分数的Al-Si共晶组织呈连续特征,其体积分数和平均尺寸难以确定,故仅对IMC进行了定量计算。IMC的理论Orowan强化贡献约为104 MPa。合金内第二相的大体积分数和明显晶格失配有效提升了位错蠕变阈值应力和Orowan强化作用。此外,位错之间的相互作用(位错强化)也不可忽视。随外应力的持续加载,合金内大量位错通过第二相增殖,部分位错又通过基体的软化行为而消失(图4),以保持样品内部稳定的位错密度,为合金提供持续的蠕变抗力。体系内大体积分数IMC和共晶网络的协同作用导致合金在350 ℃下具有良好的抗蠕变性能。Carreño和Ruano[50]分析了Al-Fe-V-Si合金中基体和第二相对蠕变性能的贡献。在蠕变过程中,亚晶的旋转与合并导致基体软化,合金内第二相充当位错运动的物理屏障,从而产生长程背应力。因此,高应力下样品较短的蠕变寿命归因于体系内大量非共格第二相处的位错纠缠所导致的塑性失稳。

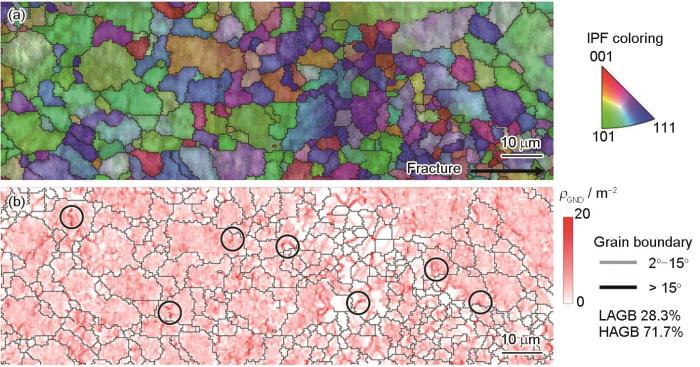

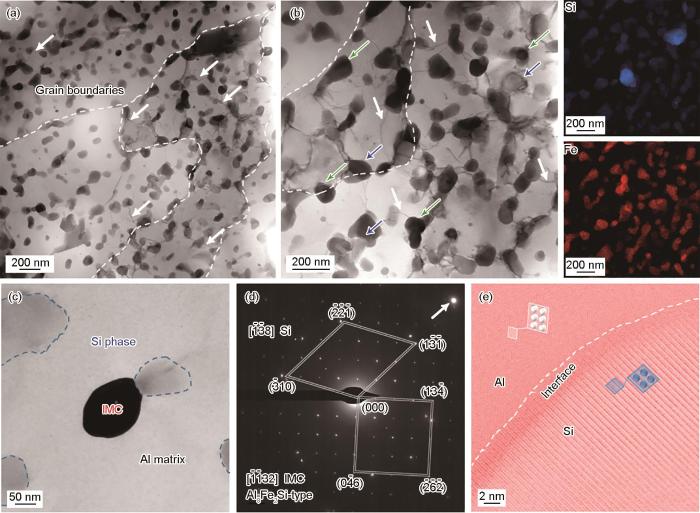

温度对合金的蠕变性能有重要影响。从图3[31~43]可以看出,合金的蠕变应力指数随测试温度的升高而减小,相同加载应力下的最小蠕变速率也显著提升。图7a为400 ℃和60 MPa条件下合金变形组织的EBSD像。与350 ℃相比(图4),400 ℃时合金中LAGBs的含量明显减少,表明更多的LAGBs向HAGBs发生了转化。图7b为相应的GND分布特征,大量位错出现在晶粒内,导致晶内形成部分高密度位错区(如图中黑色圆圈标记所示)。图8a和b显示了400 ℃和60 MPa条件下合金变形组织的TEM像。与350 ℃相比(图6),较高温度下合金的共晶网络呈非连续性。Si相已经粗化至(175 ± 12) nm,其数量明显减少。同时,IMC与Si相存在依附生长关系,如图8c所示,其相应的SAED结果见图8d。图8e为分散体Si相的HRTEM像,其与基体的晶格失配增加。这表明随着共晶网络的非连续转变,Si相/基体的总界面能也随之降低,促进了界面处的原子扩散。在高温和外应力作用等环境下,Al-Si共晶组织可由于总界面能的降低而发生Ostwald熟化。具体而言,由于体系中尺寸较小的Si相具有更高的表面能,导致其拥有更高的溶解度。被溶解的Si原子将通过扩散机制在体系中移动,迁移至较大的Si颗粒表面。大颗粒进一步长大,同时小颗粒逐渐消失。这个过程持续进行,有效降低了系统的总自由能[51]。合金内连续的Al-Si共晶组织被破坏,从而转变为分散Si相。显然,受本征热稳定性有限的Al-Si共晶组织的影响,温度的升高将导致合金内部载荷传递行为减弱,即外加应力重新由第二相转移至基体,这导致了基体内部的位错运动更为活跃(图7)。在蠕变变形阶段,第二相承载的总应力水平为周围基体所传递的外加应力和储存的残余应力之和。第二相/基体界面的弥散性质量流动是引起载荷传递失效等应力松弛行为的主要原因。Liu等[49]提出了一种扩散松弛机制,当基体通过位错蠕变变形时,在第二相/基体界面周围将产生应力梯度和化学势梯度。导致第二相相对于加载方向发生弥散性质量流动。这种传递行为减少了外加载荷向第二相的传递行为,在极端情况下,当弥散性质量流动和基体蠕变以相同速率发生时,可以完全消除载荷传递。此外,弥散性质量流动还可能同时使第二相的残余应力松弛。随着基体的蠕变变形,第二相通过弥散性质量流动将外加载荷和残余应力重新传递给基体,类似的行为在其他研究中也有报道[52~55]。

图7

图7

SLM成形Al-Si-Fe-Mn-Ni合金在温度400 ℃、应力60 MPa条件下蠕变后断口附近的EBSD像

Fig.7

EBSD images of SLMed Al-Si-Fe-Mn-Ni alloy after creeping at temperature of 400 oC and stress of 60 MPa (Black circles in Fig.7b represent local high-density dislocation regions)

(a) IPF image (b) GND distribution

图8

图8

SLM成形Al-Si-Fe-Mn-Ni合金在温度400 ℃、应力60 MPa条件下蠕变后断口附近的TEM像

Fig.8

TEM images of the deformed microstructure near the fracture of SLMed Al-Si-Fe-Mn-Ni alloy after creeping under conditions of 400 oC and 60 MPa (White arrows represent dislocations, blue arrows represent Si phases, green arrows represent Al15(Fe, Mn, Ni)3Si2)

(a) BF image

(b) interaction behavior of IMCs and dispersed Si phases with dislocation and corresponding EDS results

(c) high-magnification morphology of IMC and Si phase

(d) SAED results of IMC and Si phase

(e) HRTEM image of the dispersed Si phase

合金在不同条件下蠕变行为的差异表明,在具有连续或非连续共晶组织的微观结构中存在着2种截然不同的蠕变机制。在连续情况下,合金将通过共晶组织的载荷传递行为降低总应力水平。由于位错的攀移在连续的网状结构中较为困难,耐热IMC主要通过Orowan机制施加位错阻抗,进而提升合金的高温蠕变性能。随着温度的升高,Al-Si共晶网络发生非连续转变,本征热稳定性有限的Al-Si共晶网络将发生破碎并熔解。载荷传递行为减弱,非共格第二相(IMC和分散Si相)对位错滑移-攀移的阻碍作用是蠕变强化的主要机制。同时,温度升高导致位错运动活跃,合金基体软化程度增大。因此,如何提升高温下共晶组织的稳定性将成为未来研究的重点。

3 结论

(1) 合金在300~400 ℃下表现出良好的蠕变性能。最小蠕变速率随加载应力和温度的增加而增大。合金具有较高的应力指数(6.4~13.6),且应力指数随温度的升高而显著降低。

(2) 较低温度下,合金内连续的Al-Si共晶网络可通过载荷传递行为降低总应力水平,同时大体积分数耐热IMC-Al15(Fe, Mn, Ni)3Si2通过Orowan机制阻碍位错运动。当温度升高至400 ℃,Al-Si共晶网络发生破碎和回熔,IMC和分散Si相的协同强化是主要强化机制。

(3) 随着加载应力的增加,合金内的位错滑移系增多,位错与第二相作用加剧,促进了合金组织失稳与变形。

参考文献

Stacking fault formation in perovskite Ti3AlC carbides in a TiAl based alloy during creep at 800 oC

[J].

Creep behavior of Al-Cu-Mg-Ag heat-resistant alloy at elevated temperature

[J].

Al-Cu-Mg-Ag耐热铝合金高温蠕变行为

[J].在100-210℃和150-300 MPa的条件下, 研究了Al-5.3Cu-0.8Mg-0.5Ag-0.3Mn-0.15Zr耐热铝合金的蠕变行为, 探讨了时效状态对合金高温性能的影响. 结果表明: 在相同蠕变条件下, 欠时效态合金的稳态蠕变速率远远低于峰时效态合金. 在210℃/200 MPa下, 欠时效态合金的蠕变断裂时间为75 h, 而峰时效态合金的蠕变断裂时间仅为21 h. 蠕变过程中, 合金中的析出相长大. 峰时效态合金中析出相尺寸的增大速率高于欠时效态合金. 欠时效态合金中还发生了动态析出, 这些细小的析出相在蠕变过程中阻碍了位错的运动, 使得合金蠕变速率降低. 在100-150℃下合金的稳态蠕变速率保持在较低水平. 当温度升高到180℃时, 合金的稳态蠕变速率急剧增大. 合金稳态蠕变速率随着蠕变温度的升高和应力的提高均有增大趋势, 3者之间的关系可用一本构方程来表示, 其表观激活能为102 kJ/mol.

Recent progress in alloy design and creep mechanism of γ'-strengthened Co-based superalloys

[J].

γ'相强化钴基高温合金成分设计与蠕变机理研究进展

[J].

Creep behavior of an Al-6061 metal matrix composite produced by liquid metallurgy processing

[J].

Effects of heat treatment process on the microstructure and properties of a new cast nickel-based superalloy

[J].

热处理工艺对一种新型铸造镍基高温合金的组织和性能影响

[J].通过改变固溶热处理温度、保温时间和固溶后冷却方式, 研究了不同固溶热处理工艺对一种新型铸造高温合金组织和性能的影响. 结果表明, 将合金在不同温度固溶处理2 h后空冷, 合金在760 ℃, 660 MPa和 980 ℃, 180 MPa条件下的持久寿命随热处理温度的升高先升高而后降低; 固溶处理温度为 1220 ℃时, 760 ℃, 660 MPa条件下的持久寿命达到最高; 固溶处理温度为1180 ℃时, 980 ℃, 180 MPa条件下的持久寿命最高; 当热处理温度从1120 ℃升高到1220 ℃时, 拉伸强度随温度升高而增加, 继续升温到1240 ℃, 拉伸强度下降. 当固溶热处理温度为1120℃, 处理时间在2---8 h范围内变化时, 合金在760 ℃, 660 MPa条件下的持久寿命随时间延长而降低, 而在980 ℃, 180 MPa条件下的持久寿命随处理时间延长而升高; 当热处理时间为2和4 h时, 拉伸强度较高; 延长到6和8 h时, 拉伸强度下降. 当冷却方式不同时, 合金持久性能也发生变化. γ'相和γ/γ'共晶组织在尺寸、形态、分布和数量上的变化是导致合金力学性能变化的关键因素.

Temperature-dependent cyclic response and microstructure of AlSi10Mg(Cu) alloy

[J].

Microstructure, heat treatment and mechanical properties of TiB2/Al-7Si-Cu-Mg alloy fabricated by selective laser melting

[J].

Highly stable coherent nanoprecipitates via diffusion-dominated solute uptake and interstitial ordering

[J].

Heat-resistant super-dispersed oxide strengthened aluminium alloys

[J].

Towards the work hardening and strain delocalization achieved via in-situ intragranular reinforcement in Al-CuO composite

[J].

Damage modes and response mechanisms of AlSi10Mg porous structures under different loading strain rates

[J].AlSi10Mg is a frequently utilized aluminum alloy known for its low density, high specific strength, strong energy absorption capability, and good impact resistance. It holds significant appeal in the aviation, automotive, and machinery sectors and is particularly used as protective structures for critical aerospace components. In particular, in complex application scenarios, these protective structures are often subjected to impacts from foreign objects at different loading rates. This leads to diverse forms of damage and unpredictable damage patterns, ultimately jeopardizing key components and disrupting the normal operation of associated parts. Herein, through extensive research into the preparation, properties, and factors influencing AlSi10Mg porous structures, an understanding of the intrinsic relationship between the porous metal structure and its properties is revealed. This is important for improving material properties, expanding application possibilities, and promoting scientific and technological advancement. Exploring the application potential of AlSi10Mg porous structures across various fields offers theoretical support and technical guidance for its practical utilization. Moreover, this will provide new insights and methodologies for the future development of aluminum alloys with porous structures. By conducting a series of experimental studies, theoretical analyses, and numerical simulations, the load-bearing capacity, damage modes, and damage mechanisms of the optimized AlSi10Mg porous structures under different loading strain rates were examined. The rusults showed that the predominant damage modes in AlSi10Mg porous structures are fracture and shear damages, and the mechanical behavior is unaffected by the loading strain rates. The combination of structural damage analysis and high-precision numerical simulations revealed that under axial compressive loading, the AlSi10Mg porous structures experiences shear damage caused by relative misalignment along the diagonal cross section. This failure mode is the direct cause of the fracture damage of the structure. Furthermore, combined experimental and theoretical analyses indicated that the energy absorption properties of the AlSi10Mg porous structures are maintained at low and medium strain rates when the strain of the structures is less than 10%. When the strain exceeds 10%, the energy absorption properties at medium strain rates slightly improve compared to those at low strain rates. The energy absorption properties of the AlSi10Mg porous structures remain almost unchanged under different strain rates ranging from 378 to 1639 s-1.

AlSi10Mg多孔结构在不同加载应变率下的损伤模式及响应机制

[J].为探明AlSi10Mg多孔结构在不同加载应变率条件下的承载能力、破坏模式及破坏机理,展开了一系列实验研究、理论分析和数值模拟。通过实验研究明确了该AlSi10Mg多孔结构的损伤破坏模式主要表现为损伤断裂和剪切破坏,且其力学行为对加载应变率不敏感。结合结构损伤分析和高精度数值模拟研究,发现AlSi10Mg多孔结构在轴向压缩载荷作用下沿斜截面相对错动而发生剪切破坏,这一失效模式是导致其结构发生断裂破坏的最直接原因。结合实验研究和理论分析表明,当AlSi10Mg多孔结构应变小于10%时,其在低应变率和中应变率下的吸能特性十分接近;当结构应变大于10%时,其在中应变率下的吸能特性略高于低应变率加载时。在不同高应变率(378~1639 s-1)加载条件下,该AlSi10Mg多孔结构吸能特性十分接近。

Effect of pre-straining on the aging behavior and mechanical properties of an Al-Cu-Mg-Ag alloy

[J].

Current situation and prospect of computationally assisted design in high-performance additive manufactured aluminum alloys: A review

[J].Additive manufacturing technology has greatly increased opportunities in the production of high-strength aluminum alloy complex parts. However, current additive manufactured aluminum alloy systems are still limited to castable and weldable Al-Si alloys. This impedes the development of high-performance additive manufactured aluminum alloys. Recently, various computational techniques at different scales have been gradually used to promote the development of high-performance additive manufactured aluminum alloys. This paper summarizes the research achievements in the field of computationally-assisted design of additive manufactured aluminum alloys and their preparation from domestic and foreign scholars and presents representative cases from atomic, mesoscopic, and macroscopic scales and machine learning. The different calculation methods used to assist alloy designs are analyzed and their shortcomings are presented. Finally, the prospect on how to improve the application of multi-scale computation techniques in the development of high-performance additive manufactured aluminum alloys is presented, and some specific development directions are also clarified.

计算辅助高性能增材制造铝合金开发的研究现状与展望

[J].增材制造技术为高强铝合金复杂零部件的制造带来了前所未有的机遇,但目前增材制造铝合金体系仍局限于可铸造和可焊接的Al-Si系合金,制约了高性能增材制造铝合金的快速发展。近年来,不同尺度的计算方法逐步用于辅助高性能增材制造铝合金的开发。本文详细综述了国内外学者在计算辅助增材制造铝合金设计与制备领域的研究成果,列举了原子、介观和宏观尺度计算模拟及机器学习等计算方法辅助增材制造铝合金设计的代表性案例,分析了不同计算方法辅助合金设计的策略,并指出其不足。最后,针对如何推动多尺度计算在高性能增材制造铝合金开发中的应用进行了展望,并指出其发展方向。

Enhancement of microstructure and mechanical property of AlSi10Mg-Er-Zr alloys fabricated by selective laser melting

[J].

选区激光熔化AlSi10Mg-Er-Zr合金微观组织及力学性能强化

[J].采用气雾化制粉技术原位合金化制备了AlSi10Mg-Er-Zr粉末,研究了选区激光熔化(SLM)成形AlSi10Mg-Er-Zr试样的相对密度、微观组织和力学性能。结果表明,SLM成形AlSi10Mg-Er-Zr试样的相对密度为99.20%,显微硬度为156.5 HV,室温抗拉强度达到461 MPa,屈服强度为304 MPa,相对于常规AlSi10Mg试样显微硬度提升了25.8%,抗拉强度和屈服强度分别提高了22.6%和26.7%。这是由于Er、Zr元素的加入,细化了SLM成形AlSi10Mg-Er-Zr试样的晶粒尺寸,并且使α-Al基体中Si元素的固溶度增加,由细晶强化和固溶强化机制共同作用提高了AlSi10Mg-Er-Zr合金的力学性能。

An additively manufactured near-eutectic Al-Ce-Ni-Mn-Zr alloy with high creep resistance

[J].

Coarsening- and creep resistance of precipitation-strengthened Al-Mg-Zr alloys processed by selective laser melting

[J].The coarsening behavior of Al3Zr precipitates during aging was investigated for two Al-Mg-Zr alloys (Al-3.6Mg-1.2Zr and Al-2.9Mg-2.1Zr, wt%) processed by selective laser melting (SLM). Scanning transmission electron microscopy (STEM) investigations of peak-aged (400 degrees C, 8 h) samples reveal both continuous (similar to 2 nm in diameter) and discontinuous (similar to 5 nm wide and hundreds of nanometers in length) coherent, secondary L1(2)-Al3Zr precipitates. In-situ STEM experiments showed that aging at 400 degrees C results in the appearance and growth of both grain-boundary Al3Zr precipitates, and intragranular nanometer-sized spherical Al3Zr precipitates in Zr-rich dendritic arms. Heating to 500 degrees C resulted in the disappearance of most Al3Zr precipitates and oxide particles. This microstructural evolution sheds light on the evolution of the alloy strength at elevated temperature. For short-term yield tests, as-fabricated samples displayed higher yield strengths than peak-aged samples at temperatures above 150 degrees C (e.g., 87 vs 24 MPa at 260 degrees C). This is attributed to coarsening of grain-boundary precipitates during aging, decreasing their ability to inhibit grain-boundary sliding (GBS) of the fine equiaxed grains (similar to 1 mu m). For longer term creep tests at 260 degrees C, both asfabricated and peak-aged samples displayed near-identical creep behavior during a long-duration (168 h) creep test; by contrast, during a shorter duration creep test (8 h), as-fabricated samples are more creep-resistant than samples previously aged at 260 degrees C (threshold stresses of similar to 40 vs. similar to 14 MPa, respectively). Again, the creep behavior is consistent with coarsening of grain-boundary precipitates, occurring now during long-duration creep tests at 260 degrees C. An exact creep mechanism could not be isolated due to microstructural changes during testing but is believed to be a combination of GBS and dislocation motion. (C) 2020 Acta Materialia Inc. Published by Elsevier Ltd.

Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development

[J].

Microstructure and properties of AlSi7Mg alloy fabricated by selective laser melting

[J].The AlSi7Mg alloy was fabricated by selective laser melting (SLM), and its microstructure and properties at different building directions after heat treatment were analyzed. Results show that the microstructure of SLM AlSi7Mg samples containes three zones:fine grain zone, coarse grain zone, and heat affected zone. The fine-grain regions locate inside the molten pool, and the grains are equiaxed. The coarse-grain regions locate in the overlap of molten pools. After T6 treatment, the microstructure at the molten pool boundary is still the network eutectic Si, but the network structure becomes discrete, and is composed of intermittent, chain-like eutectic Si particles. The yield strength at three directions (xy, 45°, z direction) of the AlSi7Mg alloy samples fabricated by SLM is improved after T6 heat treatment. The fracture mechanism of the samples is a mixed ductile and brittle fracture before heat treatment and ductile fracture after heat treatment.

Microstructure and strength of selectively laser melted AlSi10Mg

[J].

A novel Al-Si-Ni-Fe near-eutectic alloy for elevated temperature applications

[J].

Creep of metals containing high volume fractions of unshearable dispersoids: II. Experiments in the Al Al2O3 system and comparison to models

[J].

Creep resistance of cast and aged Al-0.1Zr and Al-0.1Zr-0.1Ti (at.%) alloys at 300-400 oC

[J].

Pursuing ultrastrong and ductile medium entropy alloys via architecting nanoprecipitates-enhanced hierarchical heterostructure

[J].

Geometric factors affecting the internal stress distribution and high temperature creep rate of discontinuous fiber reinforced metals

[J].

Recent developments and opportunities in additive manufacturing of titanium-based matrix composites: A review

[J].

The structure of α-(AlFeSi) by anomalous-dispersion methods

[J].

The coarsening behaviour of θ″ and θ′ precipitates in two Al-Cu alloys

[J].

3D printing of high-strength aluminium alloys

[J].

On the threshold stress for dislocation creep in particle strengthened alloys

[J].

Mechanisms of creep deformation in a rapidly solidified Al-Fe-V-Si alloy

[J].

Creep strengthening in a discontinuous SiC-Al composite

[J].

High-temperature mechanical properties of AlSi10Mg specimens fabricated by additive manufacturing using selective laser melting technologies (AM-SLM)

[J].

Steady-state creep of a particulate SiC/6061 Al composite

[J].

Mn and Mo additions to a dilute Al-Zr-Sc-Er-Si-based alloy to improve creep resistance through solid-solution- and precipitation-strengthening

[J].

Precipitate stability in Al-Cu-Mg-Ag alloys aged at high temperatures

[J].

Aging- and creep-resistance of a cast hypoeutectic Al-6.9Ce-9.3Mg (wt.%) alloy

[J].

Development of creep-resistant Al-Si cast alloys strengthened with nanoscale dispersoids

[D].

Interaction between molybdenum and manganese to form effective dispersoids in an Al-Si-Cu-Mg alloy and their influence on creep resistance

[J].

Selective laser melting of Al and AlSi10Mg: Parameter study and creep experiments

[J].

A creep-resistant additively manufactured Al-Ce-Ni-Mn alloy

[J].

Microstructure and strengthening of Al-6Ce-3Ni-0.7Fe (wt%) alloy manufactured by laser powder-bed fusion

[J].

Solidification microstructure, aging evolution and creep resistance of laser powder-bed fused Al-7Ce-8Mg (wt%)

[J].

Tensile deformation dominated by matrix dislocations at intermediate temperatures revealed using in-situ EBSD in superalloys

[J].

Effect of strain rate on dynamic deformation behavior of DP780 steel

[J].<p>Tensile properties and deformation behavior of DP780 steel were studied using servo-hydraulic high-speed material testing machine, SEM and TEM. The effects of strain rate and the mechanism were investigated. The results showed that the strength and ductility of DP780 steel remained almost unchanged as the strain rate increased at strain rates lower than 100 s-1. When the strain rate was over 101 s-1, the strength and the strain-hardening coefficient increased remarkably. Ductility of DP780 steel increased significantly at the strain rates ranging from 3~101 to 5~102 s-1. The deformation resistance increased with increasing the strain rate due to the stronger short range resistance induced by the acceleration of dislocation motion in the ferrite matrix. Increasing strain rate up to 3~101 s-1 resulted in a considerable increase of the amount of mobile dislocation, which was the main reason for the increasing uniform elongation and fracture elongation of DP780 steel at the strain rate ranging from 3~101 to 5~102 s-1. Interface of ferrite-martensite in DP780 steel was the main location for pile-up of dislocation, crack initiation and propagation. The ability of inhomogeneous plastic deformation of DP780 steel increased due to the decreasing plastic strain energy difference between the ferrite matrix and ferrite-martensite interface and the consequent delaying initiation and propagation of microvoids at ferrite-martensite interface induced by the increasing work hardening degree of ferrite matrix with the increasing strain rate.</p>

应变速率对DP780钢动态拉伸变形行为的影响

[J].利用电液伺服高速试验机对DP780钢进行不同应变速率下的拉伸变形, 结合SEM和TEM等手段, 研究了应变速率对DP780钢拉伸性能及变形行为的影响规律及机制. 结果表明, 在较低应变速率(0 s-1)条件下, 随应变速率增加, DP780钢的强度、塑性等力学性能均未见显著变化. 当应变速率超过101 s-1后, DP780钢的强度和应变硬化指数n明显提高; 塑性在3~101-5~102 s-1范围内出现大幅度增加的现象. 高应变速率的变形过程中, 铁素体基体中位错运动速度加快, 导致“近程阻力”增大, 使DP780钢的变形抗力随应变速率的增加而增大.在应变速率达到3~101 s-1之后, 铁素体中可动位错数量的大幅度提高, 是DP780钢均匀伸长率和断后伸长率在3~101-5~102 s-1范围内得以明显增加的主要原因. DP780钢中的铁素体/马氏体界面是塑性变形过程中位错塞积、微裂纹形核及扩展的主要位置, 而随应变速率的增加, 铁素体基体中的形变强化程度增大, 可降低铁素体基体与铁素体/马氏体界面之间塑性应变能差异, 延缓铁素体/马氏体界面处微裂纹的形成和扩展, 一定程度上提高了DP780钢非均匀塑性变形能力.

High temperature creep behavior of Mg-9Gd-4Y-1Zn-0.5Zr alloy

[J].

Mg-9Gd-4Y-1Zn-0.5Zr合金的高温蠕变行为

[J].采用光学显微镜和蠕变实验机研究Mg-9Gd-4Y-1Zn-0.5Zr合金在不同温度和应力下的高温蠕变行为。结果表明:在应力为70~130 MPa范围内,200℃时Mg-9Gd-4Y-1Zn-0.5Zr合金的蠕变应力指数n=1.63,蠕变机制为晶界滑动,250℃时蠕变应力指数n=2.63,蠕变机制为位错滑移;在蠕变温度为200~250℃范围内,应力分别为70、90、110和130 MPa时,合金的蠕变激活能Qc分别为108.5、118.9、127.6和134.3 kJ/mol;随着温度和应力的增加,合金晶粒长大,合金的蠕变机制由晶界滑动控制转变为位错滑移控制。

On the high-temperature stability of the Al8Cu3Ce intermetallic in an additively manufactured Al-Cu-Ce-Zr alloy

[J].

Phase precipitation and strengthening behavior of a novel polycrystalline Ni3Al-based intermetallic alloy at 1100 oC

[J].

Cast near-eutectic Al-12.5wt.% Ce alloy with high coarsening and creep resistance

[J].

Separated contribution of particles and matrix on the creep behavior of dispersion strengthened materials

[J].

Evaluation of the creep properties of an Al-17Si-1Mg-0.7Cu alloy

[J].

The effects of diffusional relaxation on the creep strength of composites

[J].

Atomistic modeling of metal-nonmetal interphase boundary diffusion

[J].

Microstructure and mechanical properties of (B4C + Al2O3)/Al composites designed for neutron absorbing materials with both structural and functional usages

[J].

In-situ tailoring microstructure well-balanced strength and ductility in Al-Cu alloy

[J].

Effect of metastable Mg2Si and dislocations on α-Al(MnFe)Si dispersoid formation in Al-Mn-Mg 3xxx alloys

[J].