9Cr铁素体/马氏体耐热钢不仅具有良好的室温和高温强度,还因具有较高的热导率、较低的热膨胀系数和较低的辐照肿胀率[1],在火电和核电领域得到了广泛应用,其中核电领域主要用于堆芯、包壳和换热管等结构部件的制备[2,3]。随着先进核电系统的发展,结构材料在服役时所面临的服役环境变得更加苛刻。比如在采用液态Pb (Pb-Bi)作为冷却剂的铅冷快堆中,结构材料除了要经受高温和辐照外,还需要直接接触流动的液态金属,因此还要求结构材料具有优良的耐液态金属腐蚀的性能[4,5]。然而传统的9Cr铁素体/马氏体钢与液态金属的兼容性较差,研究[6~8]表明,与液态金属接触后其表面生成疏松多孔的氧化膜,不能有效阻碍合金元素穿过氧化膜,导致氧化膜快速生长,造成9Cr铁素体/马氏体钢面临失效的风险。Si因与O有较强的结合能力,且生成的致密氧化物对合金元素的扩散具有良好的阻碍作用,因此常通过提高铁素体/马氏体钢中的Si含量,来提高其耐液态金属腐蚀性能。如Wang等[9]的研究表明,随着Si含量的增加,9Cr铁素体/马氏体钢在Pb-Bi共晶溶液中氧化层的厚度逐渐减小,原因在于Si含量增加后,内氧化区生成的SiO2层的连续性和致密性增加,其阻碍原子扩散的能力也得到了提升,从而显著提高了合金钢的耐腐蚀性能。然而值得注意的是,Si作为较强的铁素体形成元素,加入Si会对铁素体/马氏体钢的微观组织和力学性能产生影响。比如Chen和Rong[10]发现在低活化铁素体/马氏体钢中增加Si含量后,提高了铁素体向奥氏体转变的温度,从而细化了原始奥氏体晶粒,提高了合金钢的室温拉伸强度。Zhang等[11]对不同Si含量的9Cr铁素体/马氏体钢进行550℃时效后,发现当Si含量达到1.0% (质量分数)时,调质态合金钢中会出现δ铁素体,且时效后析出的Laves相数量会随Si含量的增加而增加;Si含量的增加会提高调质态9Cr铁素体/马氏体钢的室温拉伸强度,且时效后析出的Laves相也会在一定程度上提高合金钢的拉伸强度。周军等[12]研究了不同Si含量9Cr铁素体/马氏体钢经600℃时效后冲击功变化,发现调质态合金钢的室温冲击功随Si含量的增加先增加后降低,而时效后高硅合金钢由于析出了数量较多的Laves相,因此冲击功显著下降。综上可知,Si虽然可以显著提升9Cr铁素体/马氏体钢的耐液态金属腐蚀性能,但对合金钢的微观组织和力学性能等都会产生较大影响。

针对铅冷快堆中换热管用耐液态Pb-Bi腐蚀耐热钢的研发需求,前期工作在ASME标准中P91钢成分的基础上,结合Cr、Ni当量的计算,对其成分进行了优化调整,研制开发了一种Si增强型的9Cr铁素体/马氏体钢(记为H-Si钢)。研究结果表明,H-Si钢的耐Pb-Bi腐蚀性能明显优于P91钢。作为可能应用于铅冷快堆建设的结构材料,H-Si钢除了增加Si含量外,还对Ni、Mn、Mo元素含量进行了调整,但元素含量调整对合金钢的微观组织和力学性能(尤其是长时时效后)的影响尚不清楚。本工作选用H-Si和P91合金钢作为研究对象,通过对比回火态和550℃时效3000 h 2种状态下合金钢微观组织和力学性能的变化,揭示元素含量调整后(尤其是Si含量)对Si增强型9Cr铁素体/马氏体钢显微组织和力学性能的影响机制,为耐Pb-Bi腐蚀9Cr铁素体/马氏体钢的研制开发提供理论指导。

1 实验方法

本实验冶炼制备了2种成分的9Cr铁素体/马氏体钢,其中P91为ASME标准成分,主要用于对比研究。而Si增强型的9Cr铁素体/马氏体钢是在P91钢成分基础上,提高了Si、Ni、Nb等元素含量,同时对Mo、Mn等元素含量进行了微调,该高硅型合金钢记为H-Si钢。合金钢采用真空感应炉熔炼,浇铸成25 kg的钢锭。铸锭先进行均质化处理,均质化温度为1150℃,保温12 h后空冷至室温。然后将钢锭在1150℃保温2 h后进行锻造,再将锻造后的锻坯在1150℃保温1 h后进行轧制。终锻与终轧温度均不低于900℃,最终轧制的板材厚度为12 mm。从轧板上取样进行热处理,其中正火工艺为:1050℃保温0.5 h,然后空冷至室温。回火工艺为:760℃保温1.5 h,然后空冷至室温。铁素体/马氏体钢在核电服役过程中将面临高温环境,为了考察Si增强后合金钢在高温长时间保温后的组织稳定性和力学性能变化,将回火态合金钢放置在烘箱中进行时效处理,时效温度为550℃,保温3000 h后取出,然后进行组织观察和力学性能测试。

沿着回火态和时效态板材的轧制方向分别取拉伸和冲击试样,每种状态下均取2个平行试样进行力学性能的测试,测试结果取其平均值。拉伸实验采用圆棒试样,其尺寸为:螺纹段直径10 mm,平行段直径5 mm、长30 mm,室温拉伸实验在AK-1000KNG拉伸试验机上进行,拉伸速率为0.5 mm/min (屈服前)和3.5 mm/min (屈服后)。冲击实验采用标准Charpy-V型缺口试样,其尺寸为10 mm × 10 mm × 55 mm,室温冲击实验在RKP450冲击试验机上进行。

金相样品分别从铸锭、回火态和时效态板材上取样,经过机械研磨、抛光后,用Vilella试剂(1 g C6H3N3O7 + 5 mL HCL + 95 mL C2H5OH)进行腐蚀,然后在GX51型金相显微镜(OM)上进行微观组织观察,并用线性截距法(GB/T 6394—2017)统计原始奥氏体晶粒尺寸。使用配备Ultim MaxN硅漂移型能谱仪(EDS)的MIRA3型场发射扫描电镜(FESEM)进行微观组织观察,并用Image-Pro Plus软件对FESEM像中的析出相尺寸进行统计,每种析出相的统计照片不少于10张。电子背散射衍射(EBSD)样品经过机械研磨、振动抛光后,用MERLIN Compact FESEM中集成的Nordlys F+系统进行数据收集,基体和断口截面进行数据收集时采用的步长分别为0.03 和0.05 μm,再使用HKL Channel 5软件进行数据分析。透射电镜(TEM)样品经机械研磨至厚度为50 μm的薄片,然后冲孔成直径3 mm的圆片,最后进行双喷电解减薄(双喷液为10% (体积分数)的高氯酸酒精溶液、电解温度为-20℃、电压为20 V),最后使用F200X TEM进行观察。

2 实验结果

2.1 力学性能

表1给出了回火态和时效态P91和H-Si合金钢的室温拉伸性能对比。可见,回火态下P91钢的屈服强度(YS)和抗拉强度(UTS)分别为560和714 MPa。Si增强后的H-Si钢强度均有增加,其YS和UTS分别提高到628和759 MPa。时效后,P91钢的强度变化不明显,YS和UTS分别为554和716 MPa。而H-Si钢的强度则有所增加,其YS和UTS分别为644和782 MPa,分别较回火态提高了16和23 MPa,增加幅度较小。因此,时效后H-Si钢的强度仍高于P91钢。回火态2种合金钢的延伸率(A)和断面收缩率(Z)均相同,其中A为23.5%,Z为74%。时效处理后2种合金钢的A和Z均出现了一定程度的下降,但2种合金钢之间并没有明显差异。表1还列出了回火态和时效态2种合金钢的室温冲击功对比。回火态P91和H-Si钢的室温冲击功基本相同,分别为216和211 J。冲击功较高,说明回火态2种合金钢均具有较好的冲击韧性。经过550℃、3000 h时效处理后,2种合金钢的冲击功均出现了下降,此时P91和H-Si钢的冲击功分别为163和114 J。与回火态相比,2种合金钢的冲击功分别下降了25%和46%,说明Si增强后的H-Si钢冲击韧性下降幅度更大。值得注意的是,虽然时效后2种合金钢的冲击功出现了下降,但冲击功均高于100 J,说明时效后2种合金钢仍具有较好的冲击韧性。由此可见,与P91钢相比,Si增强型H-Si钢的强度有一定程度的增加,但塑性和韧性基本保持不变。经550℃长时时效后,Si增强型H-Si钢的强度略有增加,其强度显著高于P91钢;塑性则有不同程度的下降,但延伸率和断面收缩率均与P91钢相当,而冲击功则明显低于P91钢。

表1 回火态和时效态P91和H-Si合金钢的室温拉伸性能和冲击功

Table 1

| Steel | Tempered state | Aged state | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| YS | UTS | A | Z | Impact energy | YS | UTS | A | Z | Impact energy | |

| MPa | MPa | % | % | J | MPa | MPa | % | % | J | |

| P91 | 560 | 714 | 23.5 | 74 | 216 | 554 | 716 | 22.3 | 68 | 163 |

| H-Si | 628 | 759 | 23..5 | 74 | 211 | 644 | 782 | 21.5 | 67 | 114 |

2.2 微观组织

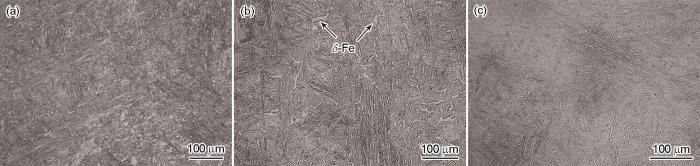

图1所示为P91和H-Si合金钢的铸态组织和均质化后H-Si钢显微组织的OM像。可见,在铸态P91钢中未观察到有δ铁素体的存在(图1a)。而Si增强后的H-Si钢中则出现了一定数量的δ铁素体(图1b),其形状不规则,呈弥散分布,含量约为3.9% (体积分数)。对9Cr铁素体/马氏体钢而言,δ铁素体属于有害相,因此需要避免出现或者将其消除。本工作对含有δ铁素体的H-Si钢铸锭采用均质化处理,以期消除δ铁素体。由图1c可见,均质化处理后H-Si钢中未观察到δ铁素体,说明铸态时存在的δ铁素体已被完全消除。由此可见,虽然Si增强后会在铸态组织中引入一定量的δ铁素体,但采用均质化处理可以将其完全消除,从而获得了不含δ铁素体的H-Si钢。

图1

图1

铸态P91和H-Si钢以及均质化处理后H-Si钢显微组织的OM像

Fig.1

OM images of as-cast P91 (a) and H-Si (b) steels and homogenized H-Si steel (c)

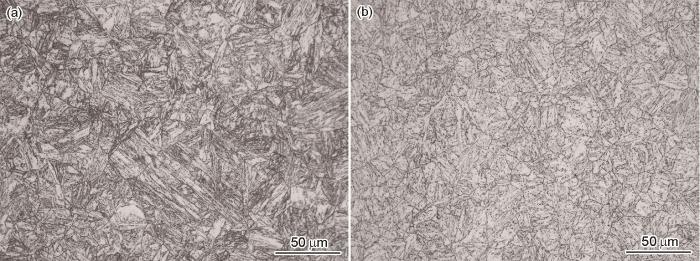

对均质化处理后的钢锭进行热锻、热轧,然后采用正火和回火处理。图2所示为回火态P91和H-Si合金钢显微组织的OM像。由图可见,回火处理后2种合金钢均为典型的回火马氏体组织,同时可以观察到析出了数量较多的第二相。值得注意的是,在合金钢中均未观察到δ铁素体的存在。由图还可以看出,合金钢的原始奥氏体晶界清晰可见,其中P91钢的晶粒尺寸为24 μm,H-Si钢的晶粒尺寸为17 μm。

图2

图2

回火态P91和H-Si钢显微组织的OM像

Fig.2

OM images of tempered P91 (a) and H-Si (b) steels

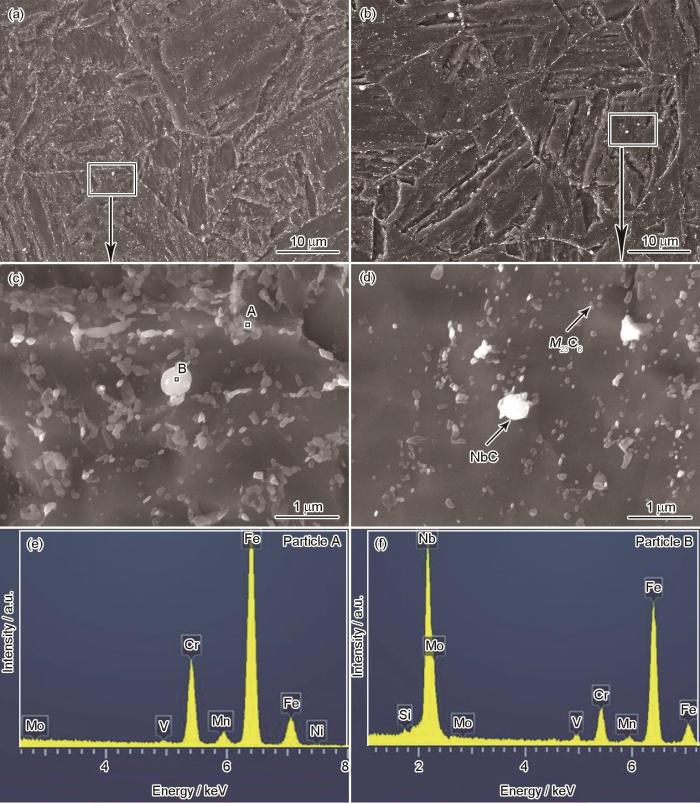

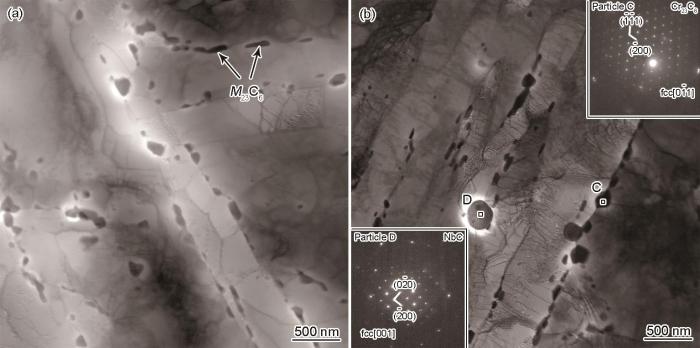

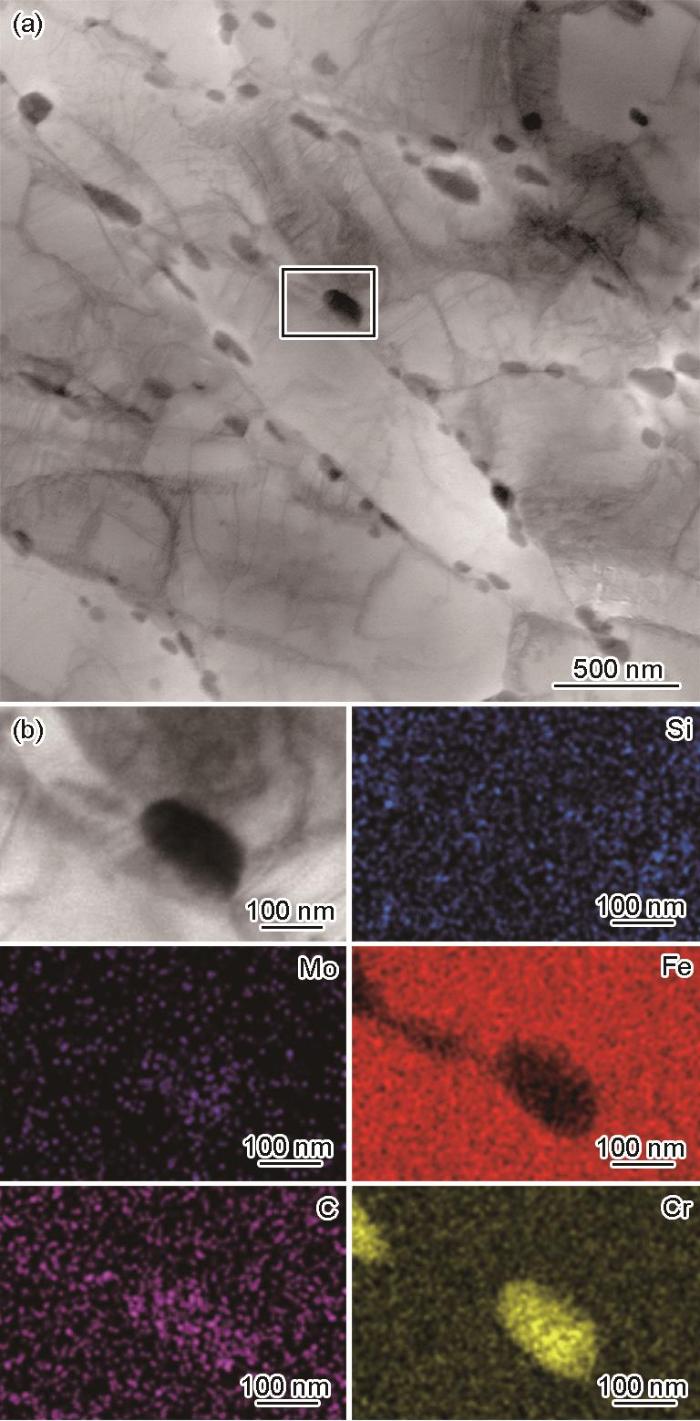

为了进一步观察第二相的析出特征和马氏体亚结构,对回火态的P91和H-Si合金钢进行了SEM观察,并利用EDS对第二相进行成分分析,如图3所示。由图可见,2种合金钢中都可以清晰观察到原始奥氏体晶界和马氏体板条(图3a和b),且在界面(包括原始奥氏体晶界和板条界)和基体内均析出了大量的第二相,其中沿界面析出的数量更多。值得注意的是,原始奥氏体晶界上析出相的数量虽然较多,但析出相与析出相之间仍有间隙,并未成串分布。从高倍SEM像(图3c和d)可以看出,2种合金钢中的析出相类型相同,均存在2类第二相:一种第二相为外形为短杆状或椭球状的析出相,其数量较多,除了在基体内大量析出外,沿界面析出数量更多,通过EDS分析可知,这是一种富Cr的碳化物(图3e);另一种第二相尺寸较大,外形为近球状,主要分布在基体内部,EDS分析表明其为富Nb的析出相(图3f)。对比2种合金钢中析出相的尺寸可知,P91钢中富Cr析出相尺寸明显大于H-Si钢,2种合金钢中富Nb析出相的尺寸则基本相近。对回火态的2种合金钢进行了TEM观察,如图4所示。由图可见,2种合金钢中存在数量较多的析出相,且明显看出有沿板条析出的特征。多数析出相为短杆状,这种析出相的尺寸较小。与此同时还存在数量较少、尺寸较大的近球状析出相,这与SEM观察到的2类析出相结果相一致。通过选区电子衍射(SAED)分析可知,尺寸较小的析出相为fcc结构的M23C6 (图4b右上角),结合SEM结果可知为富Cr的碳化物。而尺寸较大的析出相为fcc结构的NbC (图4b左下角)。由此可见,2种回火态合金钢内均存在大量的碳化物,分别为主要分布在界面处的M23C6 (短杆状、椭球状)和基体内部的NbC (近球状),2种合金钢中NbC的尺寸相近,但P91钢中M23C6尺寸大于H-Si钢。

图3

图3

回火态P91和H-Si钢的SEM像以及P91钢中析出相的EDS分析

Fig.3

SEM images of tempered P91 (a, c) and H-Si (b, d) steels at lower (a, b) and higher (c, d) magnifications, and the EDS analyses (e, f) of particles A (e) and B (f) in tempered P91 steel as shown in Fig.3c

图4

图4

回火态P91和H-Si钢的TEM像

Fig.4

TEM images of tempered P91 (a) and H-Si (b) steels (Insets in Fig.4b show the selected area electron diffraction (SAED) patterns of particles C and D )

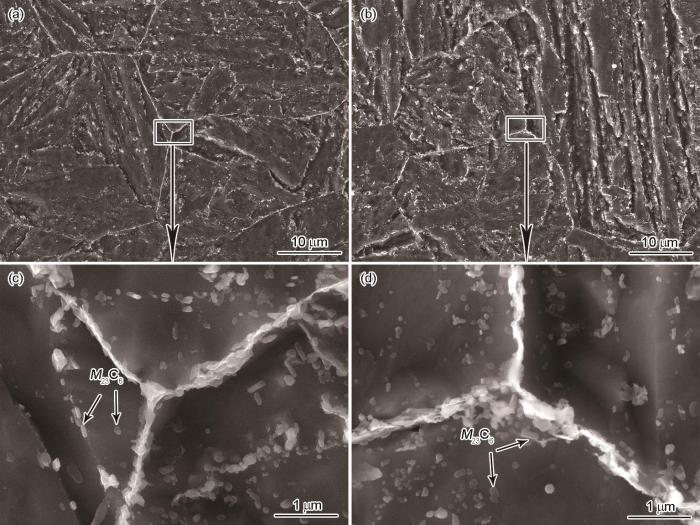

图5所示为时效态P91和H-Si合金钢的SEM像。可见,时效处理后2种合金钢仍保持典型的板条马氏体结构特征,其板条和原始奥氏体晶界清晰可见,P91和H-Si钢的原始奥氏体晶粒尺寸分别为25和22 μm,其尺寸与回火态差别不大。由此可见,550℃时效处理3000 h后合金钢的基体组织保持稳定,且在界面和基体中同样都析出了大量的第二相。值得注意的是,与回火态晶界析出相不连续相比,时效后2种合金钢晶界处析出相数量明显增多,部分晶界处的析出相成串分布,说明时效处理促进了第二相的析出。从高倍SEM像(图5c和d)可以清晰观察到该现象,晶界处析出相之间基本没有间隙,出现了相互连接的现象。与回火态合金钢相比可以发现,2种时效态合金钢中析出相均发生了粗化。

图5

图5

时效态P91和H-Si钢的SEM像

Fig.5

SEM images of aged P91 (a, c) and H-Si (b, d) steels at lower (a, b) and higher (c, d) magnifications

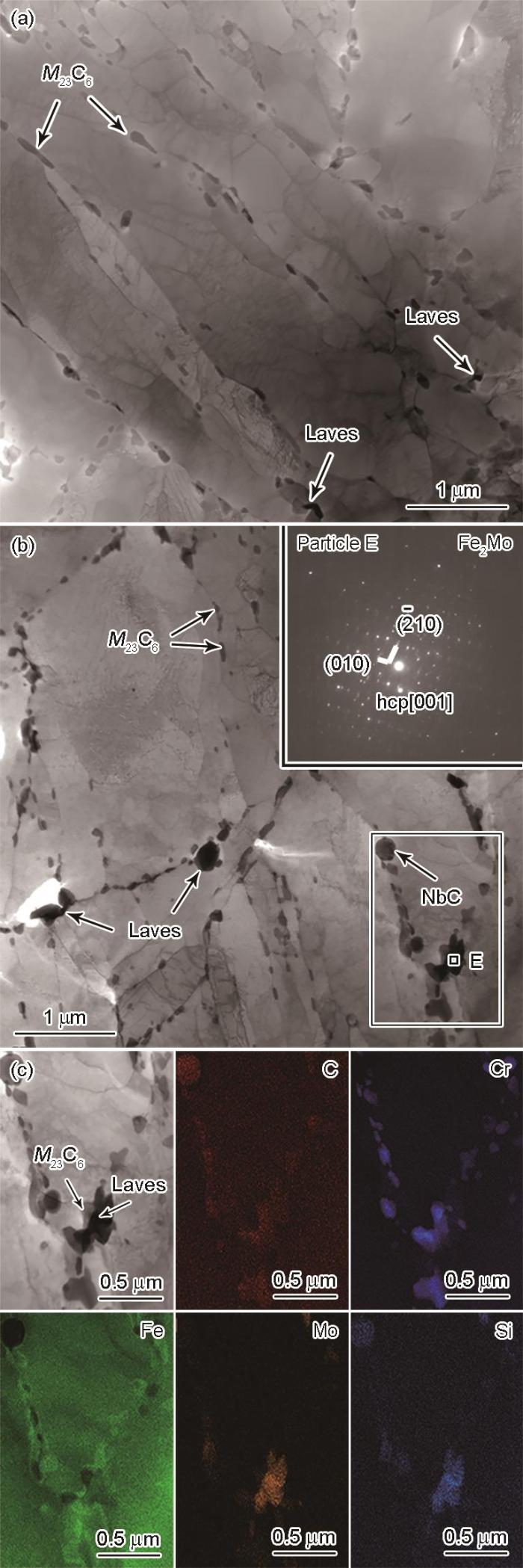

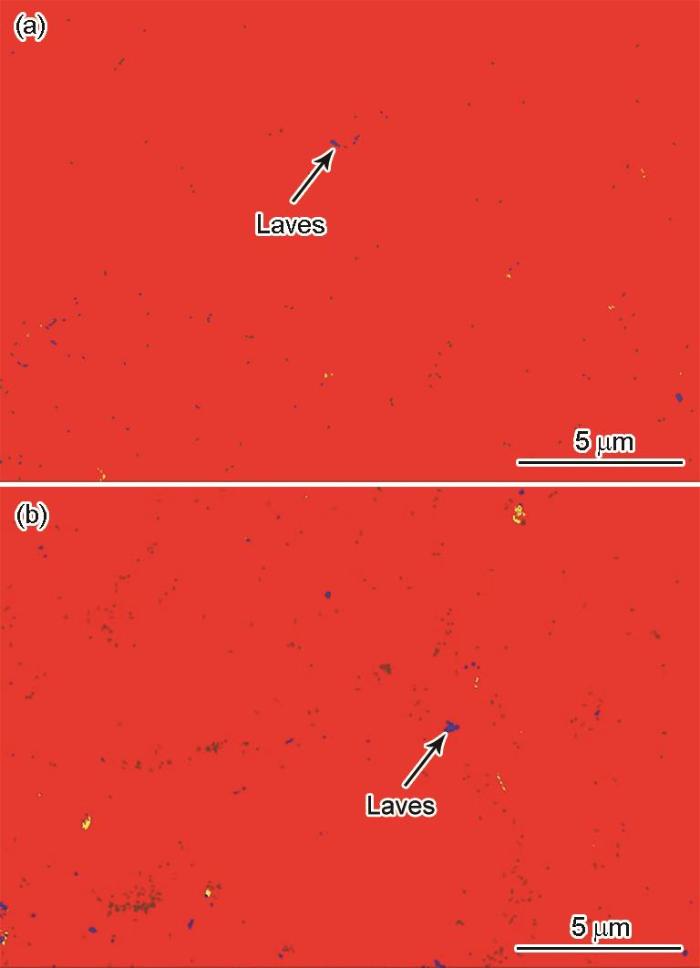

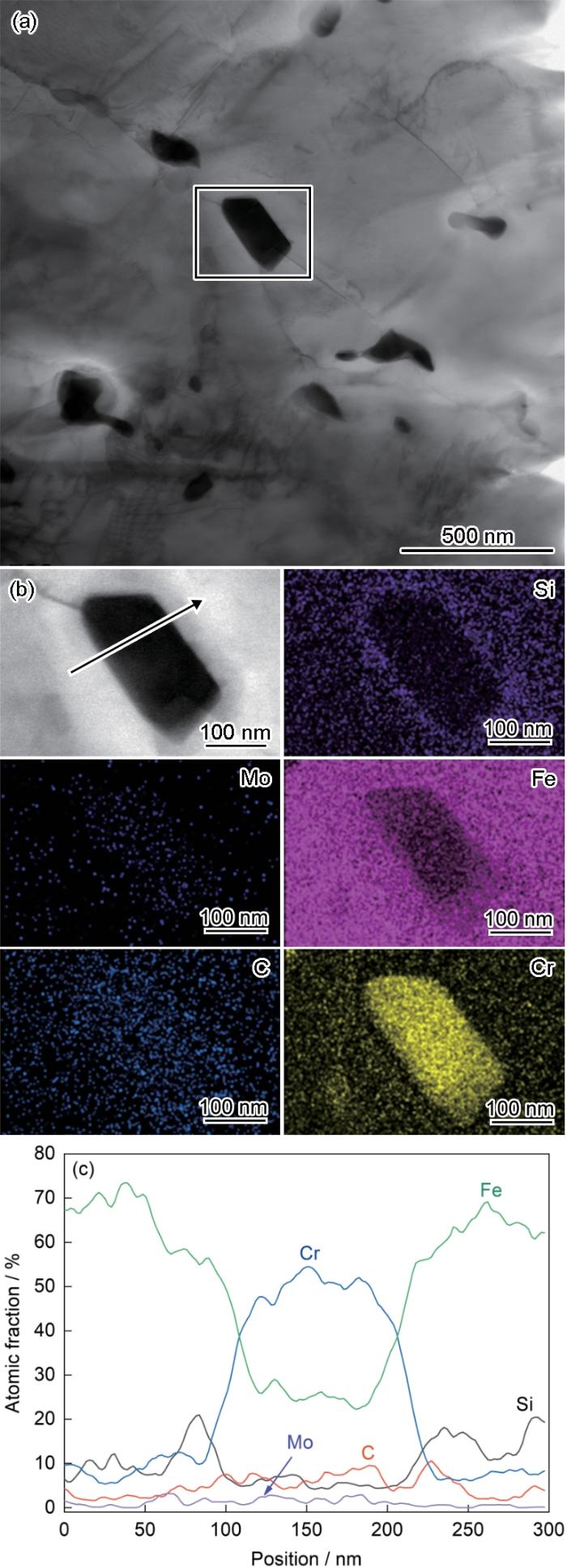

对时效态P91和H-Si合金钢进行了TEM观察,如图6所示。可以清楚地观察到原始奥氏体晶界、板条界和基体内部都分布着大量的析出相,且界面处析出相的数量明显多于基体内部。与回火态合金钢的TEM像相比,可以发现时效后2种合金钢板条界面上的析出相数量明显增多,部分界面处析出相成串分布(图6a、b),与SEM观察结果一致。界面上的析出相主要为短杆状和椭球状,对其进行面扫描可以发现,这些析出相为富Cr的碳化物(图6c),应为富Cr的M23C6。值得注意的是,在个别富Cr的区域附近,还存在富Mo、Si的现象(图6c),且这2种元素的富集与Cr的富集并不完全重叠,这说明有新的第二相析出。与M23C6对比可以发现,该富Mo、Si的析出相衬度较暗,其尺寸较大且形状不规则(图6b)。SAED花样(图6b插图)表明,该富Mo、Si的第二相为hcp结构的Laves相。该相衬度较暗是因为原子质量较大的Mo含量较高。Laves相在其他位置也有分布(图6b),但其数量相对较少,主要在晶界上分布,且在Laves相附近通常有衬度较浅的M23C6。与H-Si钢相比,在时效态P91钢中也同样发现了大量的M23C6和少量的Laves相,其中Laves相的存在形式与H-Si钢一样。值得注意的是,H-Si钢中Laves相的尺寸明显大于P91钢,且其数量也较多。这从时效态P91和H-Si合金钢的EBSD相分布结果(图7)可以看出,H-Si钢中Laves相尺寸明显更大,其含量约为0.22% (体积分数),明显高于P91钢中Laves相的含量(0.13%)。值得注意的是,这种Laves相的形态并不都是规则的棒状或球状,往往具有尖角或棱角(图6a和b),这对合金钢的韧性不利。通过TEM观察,在时效态合金钢中也观察到NbC的存在(图6b),其尺寸和外形都与回火态合金钢相一致,说明NbC比较稳定,不容易粗化长大。

图6

图6

时效态P91和H-Si钢的TEM像以及H-Si钢中析出相的EDS面扫描成分分析和Laves相的选区电子衍射(SAED)花样

Fig.6

TEM image of aged P91 (a) and H-Si (b) steels and the elements mapping of the area denoted by the rectangle in Fig.6b (c) (Inset in Fig.6b is the SAED pattern of particle E)

图7

图7

时效态P91和H-Si合金钢的EBSD相分布图

Fig.7

EBSD phase distribution images of aged P91 (a) and H-Si (b) steels

3 分析讨论

3.1 Si对微观组织的影响

Si是一种较强的铁素体形成元素,增加Si含量会提高铁素体/马氏体钢中δ铁素体的析出倾向。铁素体/马氏体钢中δ铁素体的析出倾向可用Cr当量(Creq)来表征,其公式如下[13]:

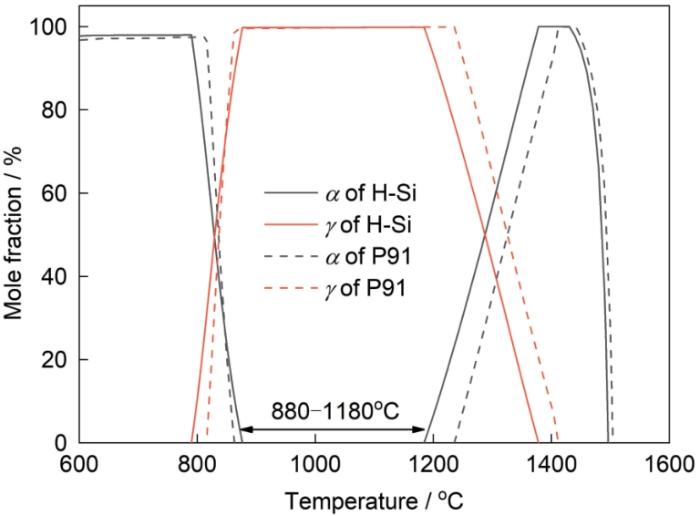

式中,[M]为元素M的质量分数。Creq的值越大,δ铁素体的析出倾向越强。一般认为当Creq > 10时,在铁素体/马氏体钢中就会析出δ铁素体。本工作中的H-Si钢采用了Si增强的设计,由上式可知Si含量的提高明显会增大Creq,因此在合金化设计时主要通过同时提高Ni含量,以达到适当降低Creq的目的。通过计算可知,P91和H-Si合金钢的Creq分别为9.24和10.92。显然Si增强后合金钢的Creq超过了临界值10,从而导致铸态H-Si钢中析出了δ铁素体(图1b)。δ铁素体作为一种有害相,需要将其含量减少或者完全消除。利用Thermo-Calc计算了P91和H-Si合金钢平衡态下的相组成,如图8所示。可见,高温液相在冷却过程中首先会析出高温铁素体(即δ铁素体),随着温度的下降,δ铁素体完全转变成奥氏体,随后又完全转变成铁素体。说明平衡态下,2种合金钢均不会出现δ铁素体。实际钢锭在浇铸凝固冷却过程中,冷速相对较快,往往δ铁素体来不及析出,温度已经进入奥氏体温度区间,从而观察不到δ铁素体的存在,比如本工作中的P91钢。然而由于Si含量的增加,导致H-Si钢中高温铁素体存在的温度区间扩大,随着在该温度区间停留时间的延长,显然会增加δ铁素体的析出倾向,这也是本工作中铸态H-Si钢存在少量δ铁素体的原因。然而Si增强后H-Si钢仍存在完全奥氏体温度区间,为880~1180℃,说明在该温度区间δ铁素体会发生溶解。因此本工作选用的均质化温度为1150℃,保温一定时间后达到了完全消除δ铁素体的目的。此外,本工作H-Si钢选取的锻造、轧制和正火温度分别为1150、1150和1050℃,均不在δ铁素体的析出温度区间内,不会发生δ铁素体析出的现象,因此可以获得完全无δ铁素体的回火态H-Si钢。

图8

图8

P91和H-Si合金钢相转变温度的变化

Fig.8

Changes of phase transition temperature of P91 and H-Si alloy steels

由图8还可以看出,增加Si含量仅改变了各基体组织(δ铁素体、奥氏体和铁素体)的相转变温度,H-Si钢仍可以通过常规的正火处理获得奥氏体高温相,然后空冷获得亚结构丰富的板条马氏体组织。然而,Si含量增加后对合金钢的第二相析出有较大影响。表2所示为回火态和时效态P91和H-Si钢中析出相尺寸的统计结果。可见,2种合金钢中NbC的尺寸基本相同,均约为510 nm,且时效后未发生明显的粗化,表明该碳化物有着较高的稳定性。一般而言,固溶后回火过程中析出的NbC较小,其尺寸在20~50 nm[14]。而本工作观察到的NbC尺寸明显较大,比回火过程中析出的M23C6尺寸还大。这是因为本工作合金钢中出现的NbC属于一次碳化物,是在铸锭凝固时从液态金属中直接析出的,在高温液相中由于元素扩散速率较快,因此析出的NbC尺寸较大,类似的现象在文献[15,16]中也有报道。一次析出的NbC在轧制和热处理过程中能够有效钉扎晶界从而细化晶粒[17],这也是本工作2种合金钢晶粒尺寸较细的原因。与P91钢相比,H-Si钢中Nb含量较高,导致其析出的NbC数量较多,从而使得H-Si钢晶粒尺寸相对较小。

表2 回火态和时效态P91和H-Si合金钢的析出相尺寸 (nm)

Table 2

| Precipitate | Tempered state | Aged state | ||

|---|---|---|---|---|

| P91 | H-Si | P91 | H-Si | |

| M23C6 | 106 ± 35 | 82 ± 32 | 135 ± 38 | 98 ± 38 |

| NbC | 515 ± 12 | 512 ± 14 | 512 ± 14 | 514 ± 21 |

| Laves phase | - | - | 79 ± 32 | 129 ± 47 |

与NbC不同,一方面回火态P91钢中M23C6的尺寸要明显大于H-Si钢,分别为106和82 nm。另一方面,时效处理后2种合金钢中M23C6均发生了粗化,尺寸分别为135和98 nm,与回火态相比分别增长了27%和20%,显然P91钢中M23C6的粗化更明显。2种合金钢中M23C6的这种差异,一方面与H-Si钢中Nb含量较高有关,因为Nb是一种强碳化物形成元素,优先在凝固过程中析出的NbC将会占据较多的C,从而使得正火固溶的C含量减少,最终导致回火过程中析出的M23C6尺寸较小。相同的现象在9CrWVTi钢中也被观察到,Ti通过与C结合形成TiC从而细化了M23C6的尺寸[18];另一方面与H-Si钢中Si含量的增加有关。图9所示为回火态H-Si钢界面处M23C6的TEM像及其EDS面扫描和线扫描元素分析结果。可见,界面上析出了若干碳化物,从形貌可以判断其为M23C6型碳化物(图9a),EDS面扫描结果也证实了这一点。值得注意的是,在该碳化物的周围存在着明显的富Si层,呈现出富Si层包裹M23C6的现象(图9b)。从EDS成分线扫结果可以清晰地观察到,在中间富Cr的碳化物两边,Si呈现明显的富集(图9c)。采用同样的方法对回火态P91钢中的M23C6进行了EDS面扫元素分析,如图10所示。可见,在P91钢中界面处M23C6的四周并未观察到富Si现象(图10b)。Si不是碳化物形成元素,因此并不参与M23C6的析出,所以M23C6生长过程中会发生往外排Si的现象[19],由于Si在铁素体中的扩散速率较慢,因此来不及扩散的Si元素会在M23C6与基体的界面处富集,并最终形成Si包裹M23C6的现象。显然,这种Si包裹碳化物的行为,阻碍了元素的扩散,从而有效地阻碍了M23C6的粗化长大,这也是回火态H-Si钢中M23C6尺寸较小的原因。值得注意的是,这种Si在M23C6周边富集的行为,在时效过程中也会起到2方面的作用,其一是该现象同样会阻碍元素扩散,并减缓M23C6的粗化长大。这是本工作H-Si钢时效3000 h后,M23C6粗化相对较慢的原因;其二,这种Si在碳化物周边富集的行为,为Laves相的析出创造了有利条件。Laves相的成分主要为Fe2Mo,且Laves相的析出需要有Mo的富集才能完成形核然后长大[20,21]。而550℃下Mo原子在铁素体/马氏体钢中的扩散速率相对较慢,因此Laves相的形核往往需要较长的孕育期[11,22],所以通常都在较长时间时效后Laves相才析出。有研究[21,23]表明,当铁素体/马氏体钢中存在Si的富集后,Laves相形核所需Mo含量下降,从而有利于Laves相的析出。本工作中回火态H-Si钢中由于M23C6周边存在Si的显著富集,促进了Laves相的析出。因此与P91钢相比,在H-Si钢中观察到的Laves相尺寸较大、数量较多。值得注意的是,实验中观察到的Laves相多在晶界上的M23C6旁边分布,这是由于晶界能量较高,合金元素通过晶界扩散相对更容易。同时紧邻M23C6形核可以提高形核率,降低临界形核功[11],因此对Laves相的形核和长大更有利。

图9

图9

回火态H-Si钢界面处M23C6的TEM像及其EDS面扫描和线扫描元素分析结果

Fig.9

TEM image of M23C6 precipitated at boundaries of tempered H-Si steel (a), elements mapping image of the area denoted by the rectangle in Fig.9a (b), and line scanning image of M23C6 along the line in Fig.9b (c)

图10

图10

回火态P91钢界面处M23C6的形貌及其EDS面扫描元素分析结果

Fig.10

TEM image of M23C6precipitated at boundaries of tempered P91 steel (a) and elements mapp-ing image of the area denoted by the rectangle in Fig.10a (b)

3.2 Si对力学性能的影响

与P91钢相比,Si增强后的H-Si钢强度明显提高,而延伸率、断面收缩率和冲击功变化不大。时效3000 h后,H-Si钢的强度略有上升,而P91钢的强度变化不大,时效后2种合金钢的延伸率和断面收缩率均略有下降,但冲击功下降较明显。值得注意的是H-Si钢的冲击功下降幅度更大。由此可见,Si增强后合金钢的力学性能发生了较大的变化。合金钢的力学性能主要取决于其成分、组织和第二相等。由组织观察和分析可知,Si增强后合金钢的基体组织并未发生改变,均为板条马氏体结构,且合金钢的晶粒尺寸变化不大,显然基体组织不是造成力学性能变化的原因。与P91钢相比,Si增强型H-Si钢主要提高了Si、Ni含量,并微调了Nb、Mo和Mn等合金元素,而C、Cr等元素并未调整。可见,元素含量变化较大的为Si和Ni等元素,其中Ni的固溶强化作用相对较弱,且Ni的调整并不影响第二相的析出行为,因此Ni对力学性能的影响可以不考虑。显然,Si含量的增加对合金钢力学性能的变化起主导作用:一方面,Si具有较强的固溶强化作用,增加Si含量会提高固溶强化作用[10,11],对合金钢的强度有利;另一方面,Si的加入改变了析出相(包括M23C6和Laves相)的析出行为,从而影响了合金钢的力学性能。合金钢的析出强化效果可用下式表示[24]:

式中,Δσps为析出相强化增量;G为剪切模量(76 GPa[24]);b为Burgers矢量模(2.85 × 10-10 m[24]);dp为析出相尺寸;fv为析出相体积分数。从

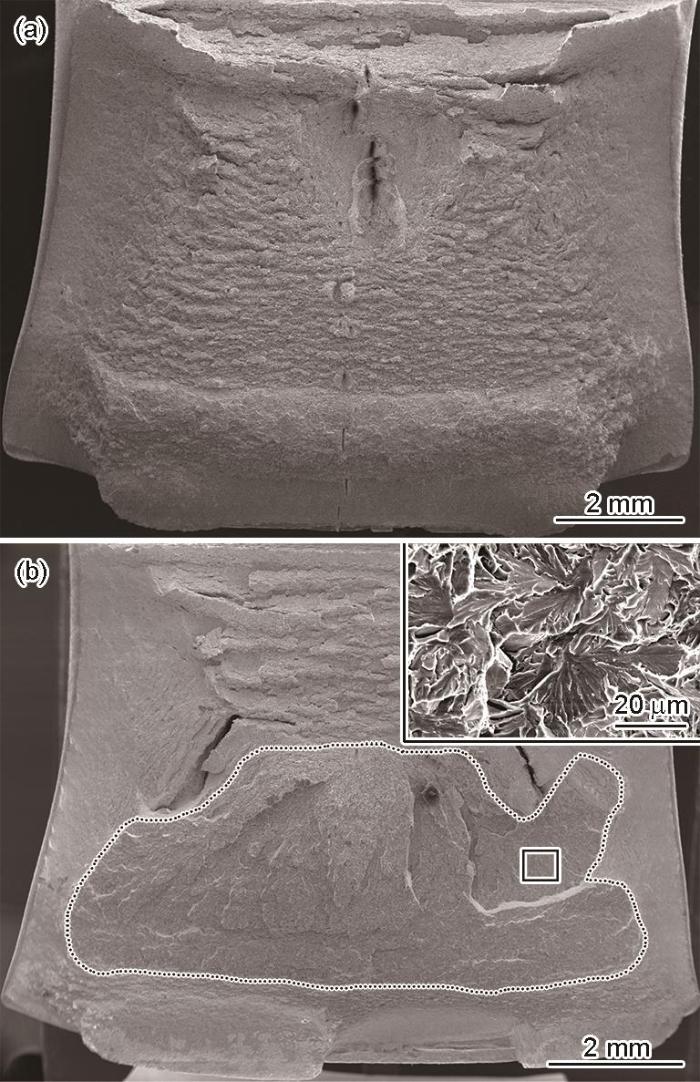

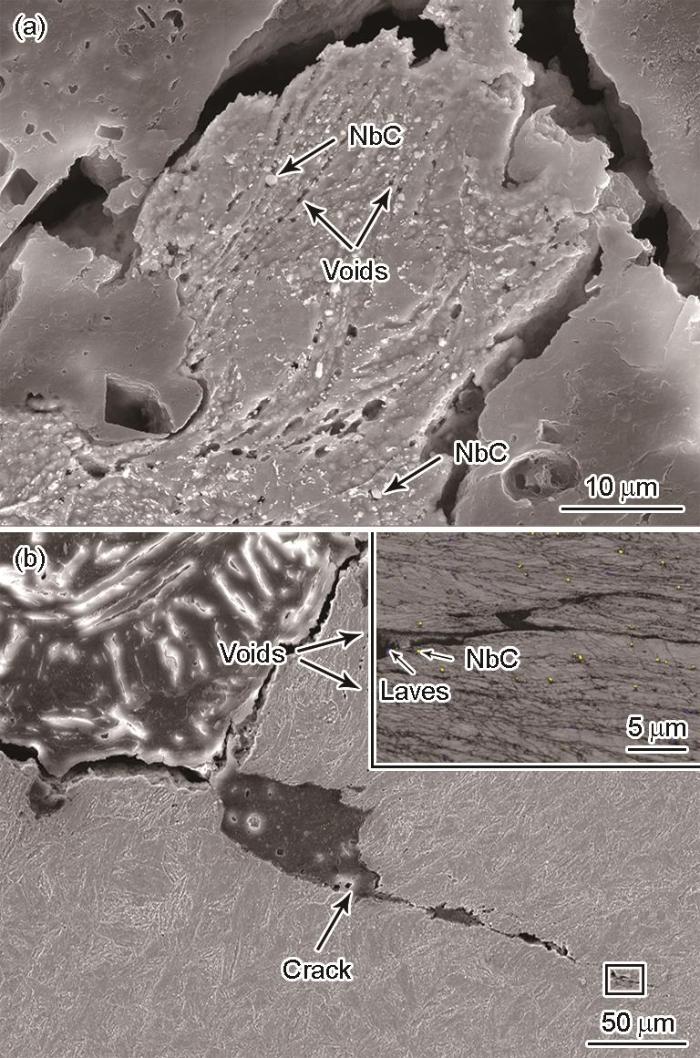

与塑性类似,由于2种回火态合金钢具有相近的微观组织,因此2种合金钢均具有较好的冲击韧性,且均为韧性断裂,而时效后2种合金钢的冲击韧性均下降。图11所示为时效态P91和H-Si合金钢冲击断口形貌的SEM像。可以发现,P91钢冲击断口呈现的是纤维状断口形貌(图11a),说明发生的仍是韧性断裂。而H-Si钢的冲击断口则为混合断裂模式,除了纤维区之外,还存在较大比例的解理区(图11b虚线所示),呈现典型的河流花样(图11b插图)。这也说明时效处理后H-Si钢的冲击韧性不如P91钢,与2种合金钢冲击功的测试结果相一致(表1)。时效后H-Si钢冲击功的下降和冲击断裂模式的改变,主要与Si含量增加引起的Laves相析出有关。对时效态P91和H-Si合金钢的室温冲击断口截面进行了观察,如图12所示。可以发现,P91钢断口附近存在一定数量的连续性孔洞,而在孔洞上往往都存在着球状碳化物(图12a),结合前文的组织观察结果(图3c),可知该碳化物为NbC。NbC由于尺寸较大,在冲击变形过程中容易引起应力集中[26],当应力集中到一定程度就会形成孔洞,孔洞相互连接从而形成裂纹。2种回火态合金钢只含有M23C6和NbC 2种析出相,在受力过程中较大尺寸的NbC则成为萌生裂纹的裂纹源。时效态H-Si钢断口截面附近则存在明显的二次裂纹(图12b),表明其冲击韧性较低,显然NbC并不是造成该合金钢冲击时出现二次裂纹的原因。图12b 插图为时效态H-Si钢冲击断口截面中二次裂纹尖端的EBSD相分布图,可以观察到裂纹周围往往存在大尺寸的Laves相。与近球状的NbC相比,Laves相不仅是脆性相,而且外形不规则,带有锐利尖角(图6a和b),这种相与基体的结合力较差,在冲击变形受力过程中不仅易于裂纹萌生,且裂纹会沿着脆性相快速扩展[25,27],从而导致合金钢的冲击韧性急剧下降,其断裂模式也由韧性断裂转变成混合断裂模式。值得注意的是,时效态P91钢中虽然也出现了Laves相,但其断裂模式仍为韧性断裂,说明该合金钢中的Laves相并未造成断裂模式的改变。仅因为Laves相的出现增加了裂纹集中的位置,从而导致了冲击功的下降。造成这种现象的原因可能与Laves相的尺寸有关,Lee等[28]在P92钢的蠕变实验中就发现当Laves相尺寸大于某一临界值(130 nm)时,合金钢会发生韧性断裂向脆性断裂的转变。本工作中时效态H-Si钢中Laves相的尺寸明显大于P91钢,推测该合金钢中Laves相也存在某一临界尺寸,当实际Laves相大于临界尺寸时,将会发生韧性断裂向脆性断裂的转变。值得注意的是,时效态H-Si钢中Laves相尺寸为129 nm,与文献[28]报道的临界尺寸130 nm接近,这说明对于本工作合金钢冲击过程而言Laves相的临界尺寸较小,这可能与冲击断裂过程中变形速率较快有关。变形速率越快,对脆性相的尺寸越敏感,因此冲击实验下使断裂模式发生转变的Laves相临界尺寸可能会小于130 nm。

图11

图11

时效态P91和H-Si钢室温冲击断口的SEM像

Fig.11

SEM images of impact fracture surfaces of aged P91 (a) and H-Si (b) steels at room temperature (Inset in Fig.11b is the magnified image of the rectangle area, and dotted line shows the cleavage zone)

图12

图12

时效态P91和H-Si钢冲击断口截面的SEM像

Fig.12

Cross section SEM images of aged P91 (a) and H-Si (b) steels near the impact fracture surfaces (Inset in Fig.12b is the EBSD phase distribution image of the impact fracture surface denoted by rectangle)

4 结论

(1) Si含量增加后,扩大了δ铁素体存在的温度区间,增加了δ铁素体的析出倾向,从而导致H-Si钢铸态组织中出现了少量δ铁素体。这些δ铁素体可通过均质化处理完全消除。Si含量的增加并未改变合金钢的基体组织,对合金钢的晶粒尺寸基本没有影响,因此回火处理后可以获得没有δ铁素体的完全马氏体H-Si钢。

(2) Si增强后会在M23C6周边形成富Si层,从而阻碍了M23C6的长大,使得回火态H-Si钢中M23C6的尺寸小于P91钢。这种M23C6周围富集的Si,在时效过程中也会起到限制M23C6粗化的作用,使得M23C6的粗化速率小于P91钢;同时也为Laves相的形核生长提供了有利条件,使得H-Si钢中Laves相的尺寸较大且数量较多。

(3) 回火态H-Si钢一方面因增加了Si含量,提高了固溶强化作用,另一方面因其M23C6尺寸更小,析出强化作用更明显,从而其强度明显高于P91钢,但塑性、韧性与P91钢相当。时效处理后,因Laves相析出导致H-Si钢的强度增加,而延伸率和断面收缩率均下降。同时2种合金钢时效过程中析出的Laves相都造成了合金钢冲击功的下降,但因H-Si钢中Laves相的尺寸较大、数量更多,导致其冲击断裂时发生了部分解理断裂,从而造成冲击功下降更显著。

参考文献

Material performance in lead and lead-bismuth alloy

[J].

Ferritic-martensitic steels for fission and fusion applications

[J].Compared to austenitic stainless steels, largely employed in the early fission reactors, high chromium Ferritic/Martenstic (FM) steels, developed since the first half of the 20th century for fossil-fuel power-plants, have a number of advantageous properties among which lower thermal expansion, higher thermal conductivity and better void swelling resistance. At the beginning of the 1970s, FM steels found their first nuclear application as wrapper and fuel cladding materials in sodium-cooled fast reactors. They are now the reference materials for in-vessel components of future fusion reactors, and are considered for in-pile and out-of-pile applications in Generation IV reactors as well as for various other nuclear systems. In this paper, after an introductory historical overview, the challenges associated with the use of FM steels in advanced reactors are addressed, including fabrication, joining and codification issues. The long term evolution of mechanical properties such as the creep and creep-fatigue behaviors is discussed and the degradation phenomena occurring in aggressive environments (lead alloys, high temperature gases, super-critical water and CO2, molten salts) are detailed. The paper also provides a brief overview of the radiation effects in FM steels. The influence of the key radiation parameters e.g. temperature, dose and dose rate on the microstructure and mechanical properties are discussed. The need to better understand the synergistic effects of displacement damage and helium produced by transmutation in fusion conditions is highlighted. (C) 2019 Elsevier B.V.

Environmental degradation of structural materials in liquid lead- and lead-bismuth eutectic-cooled reactors

[J].

The lead fast reactor: An opportunity for the future?

[J].

Development of a novel structural material (SIMP steel) for nuclear equipment with balanced resistances to high temperature, radiation and liquid metal corrosion

[J].

核用新型耐高温、抗辐照、耐液态金属腐蚀结构材料——SIMP钢的研究进展

[J].

Oxidation mechanism of a Fe-9Cr-1Mo steel by liquid Pb-Bi eutectic alloy (Part I)

[J].

Oxidation mechanism of a Fe-9Cr-1Mo steel by liquid Pb-Bi eutectic alloy (Part III)

[J].

Oxidation mechanism of an Fe-9Cr-1Mo steel by liquid Pb-Bi eutectic alloy at 470°C (Part II)

[J].

Effect of silicon on the oxidation resistance of 9wt.% Cr heat resistance steels in 550oC lead-bismuth eutectic

[J].

Effect of silicon on the microstructure and mechanical properties of reduced activation ferritic/martensitic steel

[J].

Evolution of microstructure and mechanical properties of 9Cr ferrite/martensite steels with different Si content after long-term aging at 550oC

[J].

Effect of Si content on precipitation behavior of Laves phase and impact performance of 9%Cr ferritic martensitic steel

[J].

Si含量对9%Cr铁素体马氏体钢Laves相析出行为和冲击性能的影响

[J].

A new equation for the Cr equivalent in 9 to 12 pct Cr steels

[J].

Investigation of the microstructure and strength in G115 steel with the different concentration of tungsten during creep test

[J].

Effects of alloying elements and thermomechanical treatment on 9Cr reduced activation ferritic-martensitic (RAFM) steels

[J].

Effect of carbon and niobium on the microstructure and impact toughness of a high silicon 12% Cr ferritic/martensitic heat resistant steel

[J].

Study on the microstructural evolution and strength degradation of 9% chromium ferritic/martensitic heat resistant steels

[D].

9%Cr铁素体/马氏体耐热钢的组织演化和强度退化研究

[D].

Effects of Ti and a twice-quenching treatment on the microstructure and ductile brittle transition temperature of 9CrWVTiN steels

[J].

Mo-rich Laves phase in a 9.5Cr-1.5MoCoVNbNB heat-resistant steel during long-term aging at 620oC

[J].

The nucleation of Mo-rich Laves phase particles adjacent to M23C6 micrograin boundary carbides in 12% Cr tempered martensite ferritic steels

[J].

On the nucleation of Laves phase particles during high-temperature exposure and creep of tempered martensite ferritic steels

[J].

Laves phase evolution in P92 steel during ageing

[J].ASME P92 (9Cr-0.5Mo-1.8WVNb) is a key material for the main steam pipe and header with larger diameter and thick wall in ultra-supercritical (USC) plant, because of its low thermal expansion coefficient, good corrosion resistance, good fabricability and especially its high creep rupture strength. The Laves phase (Fe2M) precipitates in service and plays complicated and controversial role in affecting and/or determining the creep strength of the P92 steel. The fine Laves phase particles may contribute to precipitation strengthening and decrease the creep rate in the primary and transient creep region, however, the subsequent coarsening of Laves phase reduces the precipitation strengthening. Thus, in order to provide a systematic and definite understanding of the creep properties, it is necessary to investigate the precipitation and coarsening behavior of the Laves phase in P92 steel. In this work, the Laves phase parameters of P92 steel, including volume fraction, mean diameter and number density, were measured using SEM-BSE and quantitative metallography methods during aging at 650 ℃ for 0~8000 h. The precipitate and coarsening kinetics were investigated based on the quantification of Laves phase in P92 steel. Furthermore, the martensitic lath stability during aging was observed by OM and TEM. Lastly, the influence of Laves phase evolution on the creep rupture strength was estimated from the change of Orowan stress during aging. The results indicate that SEM-BSE is a suitable method for measurement of Laves phase precipitates, and can achieve significantly statistical data when characterizing large particles comparing with the EFTEM, so that evaluate the kinetics of precipitation and coarsening of Laves phase. The Laves phase precipitates at grain boundaries preferentially during the 0~2000 h of aging and its final volume fraction is around 0.95%. Obvious coarsening of Laves phase is observed after aging for 3000 h and its rate is much greater than that of M23C6 carbides. Grain boundary diffusion may play significant role in much rapider coarsening of Laves phases than that of M23C6 carbides. The Laves phase has the most precipitate hardening in the P92 steel aged up to 1000~3000 h and this hardening would drop remarkably due to its fast coarsening after aging for 3000 h. The contribution of Laves phase particles to creep strength is much less than that of M23C6 carbides. The P92 steel has a sub-microstructure with clear lath and high density dislocations after aging at 650 ℃ for 8000 h due to the stable M23C6 carbides on sub-boundaries.

P92钢时效的Laves相演化行为

[J].

On the effect of long-term creep on the microstructure of a 12% chromium tempered martensite ferritic steel

[J].

Micromechanical behavior of a fine-grained China low activation martensitic (CLAM) steel

[J].Micromechanical behavior of a fine-grained China Low Activation Martensitic (CLAM) steel under nanoindentation was studied in this work. The grain size of the as-prepared 0.1Ti-CLAM steel is $\widetilde{5}$ μm and the average diameter of the spherical precipitates is $\widetilde{5}$ nm. Both elastic modulus and hardness decrease with increasing contact depth of the nanoindenter, following an exponential decreasing function. The abnormally large contact depths should be resulted from defect concentration under the indenter. The effect of nanosized precipitates on hardness is responsible for the pop-ins occurring in the load-depth curves, corresponding to the blockage of nanosized precipitates to the dislocation movement. Nanosized VC and M23C6precipitates with the volume fractions of 0.32% and 1.21% can be identified, respectively. Different strengthening mechanisms originated from the two types of nanosized precipitates. The blockage of dislocations by VC particles leads to an Orowan strengthening whilst dislocations could cut through theM23C6particles because of the large size of the particles. The strengthening effects originated from the VC and M23C6 precipitates lead to the strength increase of $\widetilde{4}$48 MPa and $\widetilde{2}$54 MPa, respectively.

The effect of microstructure evolution on the mechanical properties of martensite ferritic steel during long-term aging

[J].

Effect of large-size carbides on the anisotropy of mechanical properties in 11Cr-3Co-3W martensitic heat-resistant steel for turbine high temperature blades in ultra-supercritical power plants

[J].

Toughness evolution of 9Cr-3W-3Co martensitic heat resistant steel during long time aging

[J].

Causes of breakdown of creep strength in 9Cr-1.8W-0.5Mo-VNb steel

[J].