非晶合金内部原子排列呈现长程无序而短/中程有序的结构特征,与具有周期性规则排列的晶体结构材料形成鲜明对比[1~4]。这种独特结构赋予非晶合金优异的物理、化学和力学特性,例如高强度、高弹性极限、以及出色的抗腐蚀和耐磨性能。然而,当加载温度远低于其玻璃化转变温度时,块体非晶合金的塑性应变高度集中在狭窄的剪切带中,这些剪切带会不受阻碍地快速扩展,从而导致材料缺乏明显的宏观拉伸塑性并呈现脆性断裂行为,极大限制了非晶合金在工程中的应用[5~7]。针对非晶合金在室温下表现出的脆性问题,科研人员已经探索出多项策略以增强其塑性。其中,在非晶内部引入第二相增强的非晶复合材料备受关注[8]。第二相的加入,有效避免了剪切带的单一失稳传播,并促使多个剪切带参与到塑性形变中,从而显著提高了材料的室温塑性[9,10]。W丝增强非晶复合材料因具有高密度、高强度和优异的自锐性而广泛地应用在国防武器领域。研究人员[11]引入了W丝作为增强相,通过物理或化学方法将其均匀分布在非晶基体Vitreloy 1 (Zr41.2Ti13.8Cu12.5Ni10.0Be22.5,原子分数,%,下同)中,从而形成W丝增强的非晶复合材料。W丝的引入不仅增强了非晶合金的压缩强度,还显著提升了材料的塑性变形能力,使得这种复合材料能够在承受较大外力作用时,展现出更好的韧性[12~16]。而且W丝与非晶基体之间的良好界面结合能够有效地传递应力,避免了应力集中,从而提高了材料的整体性能[17~19]。此外,W丝的体积分数、分布状态以及尺寸等都是影响复合材料性能的重要因素[3],通过调控这些参数,可以进一步优化复合材料的性能。

W丝增强非晶复合材料制备过程中不可避免地会引入热残余应力[20~25],这些应力是由材料内部组分的热膨胀系数差异和冷却过程中的不均匀收缩引起的[22]。这些内部应力会显著影响复合材料的力学性能和长期稳定性,包括可能导致的微裂纹生成、材料失效以及性能下降。Conner等[23]利用同轴圆柱体模型(CCM)计算了W丝/金属玻璃复合材料中的热残余应力,结果表明W丝的热残余应力处于三轴压应力状态。相反,非晶基体中的热残余应力沿周向和轴向处于拉伸状态,而在径向则处于压应力状态。Dragoi等[21]的研究表明,W丝中的热残余应力随着W丝体积分数的增加而减小。Zhang等[20]利用高能同步X射线衍射方法测量了非晶复合材料中的残余应力,建立了W丝尺寸对残余应力状态的影响关系。

无损检测残余应力的方式主要包括X射线衍射技术、同步辐射X射线衍射技术、中子衍射技术等,其中,中子衍射技术因其独特的深入材料内部的能力,成为评估这些复合材料内部应力分布的理想工具[26~28]。 通过中子衍射能够检测铝合金等材料内部10 cm深的应力状态,并且对于高强钢、钛合金、镍基高温合金等,也可实现几厘米的测量深度。相较于其他表面或近表面应力测量技术,中子衍射空间分辨率高,能够提供整个样品体积内的应力分布信息,包括材料内部难以直接观察的区域。通过精确测量材料晶格参数的变化,可以定量分析材料内部的残余应力分布。中子衍射方法能够模拟不同的环境进行测试,如生产过程(如涡轮叶片的定向凝固过程)和实际使用条件(如温度、应力、时间等),从而在现场获得部件在制造和使用过程中的残余应力分布。同样地,热残余应力的大小和分布对于W丝增强非晶复合材料的力学性能至关重要[29,30]。适当的热处理和工艺优化可以显著减少不利的残余应力,从而提高材料的韧性和强度。烧氢处理是提高W丝性能的关键工艺,通过烧氢处理,W丝表面杂质可以被去除,从而净化W丝表面[31]。同时,高温下的H2环境有助于W丝内部晶格的重排和晶粒的细化,这会导致W丝的力学性能,如强度和韧性的提高,同时减少不利的内部应力。

自W丝增强锆基非晶复合材料问世以来,通过改变制备过程中W丝的排布方式、体积分数、直径、环境温度等因素来调控复合材料内部残余应力的效果显著,但缺乏热处理对复合材料内部应力分布状态的研究。本工作采用中子衍射技术深入分析了W丝的烧氢处理、热处理时间和W丝直径对非晶复合材料残余应力的影响。通过这种方法,能够精确地调控制备过程中W丝增强非晶复合材料内的热残余应力,为材料性能的优化和提升奠定基础。

1 实验方法

实验选用Vitreloy 1 (Zr41.2Ti13.8Cu12.5Ni10.0Be22.5)为非晶基体,采用直径约为0.2或0.3 mm、纯度为99.9%的W丝作为增强相制备非晶复合材料。W丝增强非晶复合材料的制备是通过熔体浸渗方法,首先将W丝放置在钢管中,然后通过施加气体压力使熔融非晶合金浸渗其中,之后钢管被迅速浸入水中以快速冷却,具体流程参见文献[32],最后获得长×宽×高分别为10 mm × 10 mm × 12 mm的长方体样品。本实验中的W丝采用2种处理方式,一种是经过拉拔成型的W丝不做任何处理,该工艺记为NA;另一种是经过烧氢处理,工艺记为AH,具体处理方式是将W丝加热至800℃,并在纯H2气氛中保持1 h,冷却到室温。另外,对这2种W丝增强非晶复合材料进行不同热处理,一部分直径0.2 mm未烧氢的W丝增强的非晶复合材料在200℃下回火处理30和60 min,另一部分不做热处理作为对比。对直径0.2 mm烧氢的W丝增强的非晶复合材料不做热处理。最后对一部分直径0.3 mm烧氢的W丝增强的非晶复合材料在200℃下回火处理30 min,另一部分不做热处理作为对比。在上述类似条件下经过热处理的松散W丝被用作残余应力测量中的“无应力”参考状态。具体制备工艺及参数见表1。

表1 样品制备工艺及参数

Table 1

| Process | Material | Specimen | Diameter of W / mm | Tempering process |

|---|---|---|---|---|

| NA | W | NA2-W | 0.2 | None |

| BMGCs | NA2-AC | 0.2 | None | |

| BMGCs | NA2-30 | 0.2 | 200oC, 30 min | |

| BMGCs | NA2-60 | 0.2 | 200oC, 60 min | |

| AH | W | AH2-W | 0.2 | None |

| BMGCs | AH2-AC | 0.2 | None | |

| W | AH3-W | 0.3 | None | |

| BMGCs | AH3-AC | 0.3 | None | |

| BMGCs | AH3-30 | 0.3 | 200oC, 30 min |

Note: NA—not annealed in hydrogen; AH—annealing in hydrogen: heat the W wire to 800oC, maintain it in the pure H2 atmosphere for 1 h, and then cool to room temperature; AC—as cast; BMGCs—bulk metallic glass composites

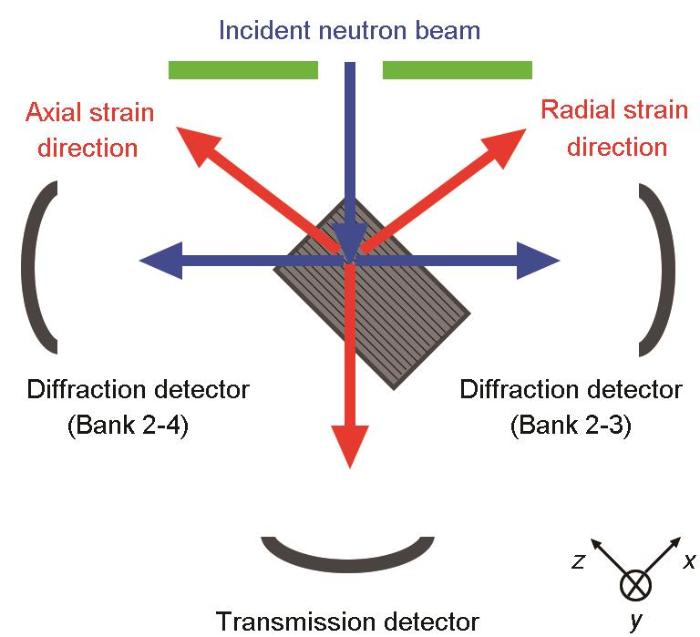

在上述的样品中切取试样,经过砂纸研磨和机械抛光后,利用Mira 3场发射扫描电子显微镜(SEM)进行组织观察。经机械抛光后的W丝样品,再进行数小时的振动抛光,随后在配有电子背散射衍射(EBSD)探头的SEM上进行W丝横截面和纵截面的结构表征,工作电压为20 kV,扫描步长为0.2 μm,样品倾斜角为70°。为了分析材料的结构特性,国内外学者采用了穿透力强的中子束进行衍射分析。这种中子束具有高强度和出色的空间分辨率等特点[33]。本工作在中国散裂中子源(CSNS)的通用粉末衍射仪(GPPD)上开展,实验装置示意图如图1所示。将样品放置于样品台中心,W丝横截面与入射中子束成45°,该谱仪上的2组探测器收集散射角为±90°的衍射谱,其中Bank 2-3的探测器负责测量材料的径向应变,Bank 2-4的探测器测量材料的轴向应变。结合飞行时间(TOF)技术,对每个样品进行了8 h的数据采集工作。为了深入解读衍射数据,采用GSAS-Ⅱ[34]对中子衍射全谱数据进行Rietveld精修处理,该方法是一种广为接受的精修分析技术,按照特定顺序对多个参数进行精修,包括比例因子、背景、晶格参数以及与材料织构相关的诸多因素。所有精修步骤均以获得准确的衍射结果为目标,包括晶面间距(d)、衍射峰强度(I)和半峰全宽(FWHM)等。Rwp为加权图形方差因子,通常该值小于10%即为精修结果准确[34]。这些结果及其对应的拟合曲线清晰地展示在图中,以此来验证衍射数据的可靠性和分析的准确性。

图1

式中,d0为无应力参考松散W丝的晶面间距,d为复合材料中W丝的晶面间距。

通过测量弹性应变,利用广义Hooke定律进行应力计算[24]:

式中,

2 实验结果与讨论

2.1 微观组织

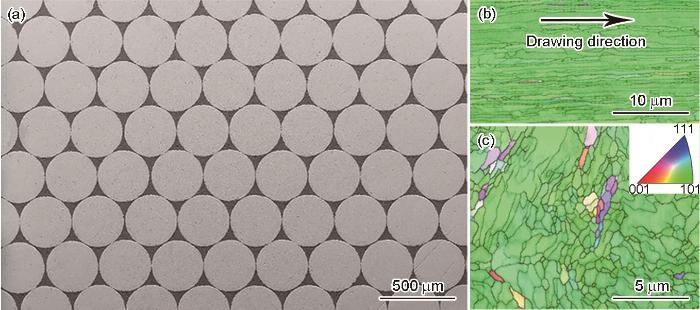

图2

图2

AH3-AC样品横截面的SEM像和AH3-W样品纵截面和横截面的EBSD像

Fig.2

SEM image of transverse section of AH3-AC specimen (a); and EBSD images of longitudinal section (b) and transverse section (c) of AH3-W specimen

2.2 热处理条件对非晶复合材料残余应力的影响

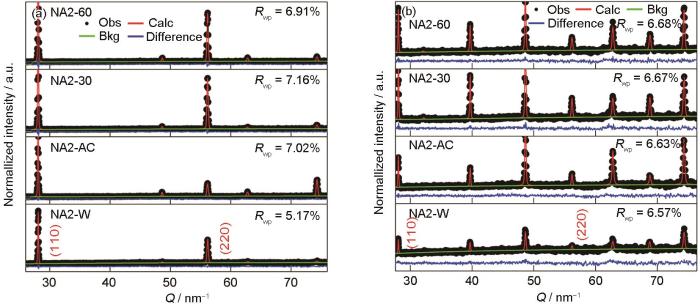

图3a和b为不同热处理工艺(铸态、200℃回火30和60 min)条件下,以直径0.2 mm未烧氢W丝作为增强相的非晶复合材料轴向和径向的中子衍射结果。可以看出,每个样品精修后的Rwp值均小于10%,表明Rietveld分析中模型的拟合度很好,精修结果准确。由图3a可见,每个样品轴向的(110)峰和(220)峰有较高的衍射强度,进一步表明了通过拉拔工艺制备的W丝轴向存在强烈的<110>织构。根据精修结果来确定W丝在不同状态下的晶格参数,进而计算出所受到的热残余应力,结果见表2。NA2-AC样品的轴向残余应力为-88.451 MPa,径向残余应力为50.182 MPa,表现出显著的残余应力。这种应力状态是由于W丝的热膨胀系数较小(4.5 × 10-6~4.7 × 10-6 K-1),而非晶基体的热膨胀系数较大(9.0 × 10-6~15 × 10-6 K-1),在冷却过程中W丝与非晶基体相比收缩较少所致,这种热膨胀系数的差异会使W丝处于轴向压缩和径向拉伸的状态。

图3

图3

不同热处理工艺条件下以直径0.2 mm未烧氢W丝作为增强相的非晶复合材料轴向和径向的中子衍射数据精修结果

Fig.3

Refinement results of axial (a) and radial (b) neutron diffraction data of metallic glass composites with 0.2 mm-diameter W wires not-annealed in hydrogen as reinforcement phase under different heat treatment process conditions (Q—scattering factor, Rwp—weighted graphical variance factor, Obs—observation, Calc—calculation, Bkg—background)

表2 不同热处理工艺下以直径0.2 mm未烧氢W丝作为增强相的非晶复合材料的残余应力分布

Table 2

| Specimen | Axial direction | Radial direction | ||||

|---|---|---|---|---|---|---|

| a / nm | ε / % | σ / MPa | a / nm | ε / % | σ / MPa | |

| NA2-W | 0.316594 | 0 | 0 | 0.316435 | 0 | 0 |

| NA2-AC | 0.316504 | -0.028 | -88.451 | 0.316482 | 0.0149 | 50.182 |

| NA2-30 | 0.316568 | -0.0082 | -35.315 | 0.316441 | 0.0019 | -2.936 |

| NA2-60 | 0.316473 | -0.038 | -184.866 | 0.316447 | 0.00379 | -50.297 |

Note: a—lattice parameter, ε—residual strain, σ—residual stress

回火处理作为一种常用的热处理方法,旨在减少或重新分布材料内部的应力状态。在200℃下回火30 min的非晶复合材料中(NA2-30),W丝的轴向残余应力降至-35.315 MPa,径向残余应力降至-2.936 MPa,表明回火处理有效减少了残余应力。这一现象是由于回火过程中,非晶基体和W丝界面处的应力得到了释放,以及W丝内部发生的微观结构重组,促使应力达到了新的平衡状态。然而,当回火时间延长至60 min时(NA2-60),轴向残余应力和径向残余应力的变化趋势发生了反转,分别增至-184.866和-50.297 MPa。这表明,随着回火时间的增加,材料内部发生了更复杂的结构变化,这些变化并不总是有利于减少残余应力。长时间的回火导致非晶基体和W丝之间的界面反应,或是促使W丝内部发生微观结构的调整,这些都会引入新的应力源。此外,回火处理还会改变非晶基体和W丝界面的化学和物理性质,如界面扩散和新相的形成,这些都对残余应力状态产生重要影响。因此,虽然回火可以作为一种手段来控制残余应力,但其效果受到回火温度、时间以及材料本身特性的共同影响。

通过测量和分析未经热处理以及不同回火条件下非晶复合材料中W丝的残余应力,可以看到回火处理对于控制残余应力的复杂效应。虽然短时间回火可以有效减少残余应力,但长时间回火会引起材料内部的复杂反应从而导致应力的重新积累。这些发现强调了在设计和优化复合材料的热处理过程中,需要综合考虑材料的微观结构、界面特性以及热处理参数,为制备具有优异性能的非晶复合材料提供指导。

2.3 烧氢处理对非晶复合材料残余应力的影响

图4

图4

以直径0.2 mm烧氢W丝作为增强相的非晶复合材料轴向和径向中子衍射数据的精修结果

Fig.4

Refined results of axial (a) and radial (b) neutron diffraction data of metallic glass composites with 0.2 mm-diameter W wires annealed in hydrogen as reinforcement phase

表3 以直径0.2 mm 烧氢W丝作为增强相的非晶复合材料的残余应力分布

Table 3

| Specimen | Axial direction | Radial direction | ||||

|---|---|---|---|---|---|---|

| a / nm | ε / % | σ / MPa | a / nm | ε / % | σ / MPa | |

| AH2-W | 0.316469 | 0 | 0 | 0.316439 | 0 | 0 |

| AH2-AC | 0.316443 | -0.0082 | -41.774 | 0.316441 | 0.000316 | -14.446 |

烧氢处理的W丝与未烧氢W丝最主要的差异在于表面状态和微观结构。烧氢处理是一种在高温下和H2环境中进行退火的热处理工艺,可以减少材料表面的氧化层和其他表面缺陷,并消除内应力,从而改善材料性能。针对W丝这种金属材料,烧氢处理可以有效去除W丝表面的氧化层和其他可能的杂质,从而减少表面缺陷,显著提高其表面质量,提高其与非晶基体的结合效果[36]。此外,烧氢过程中,材料会发生3种不同的微观结构变化:回复、再结晶和晶粒长大。这些变化有助于减少晶界处的应力。相比之下,未烧氢的W丝保留有更多的表面缺陷和氧化物,这些特性会在复合材料中引入额外的内部应力。在复合材料制备过程中,基体材料在凝固时会因为这些表面缺陷而在界面处产生不均匀的收缩或拉伸,从而导致较高的残余应力。此外,氧化物层的存在会阻碍W丝与基体材料之间有效的化学结合。这些因素加剧了增强相与基体之间的应力不匹配,导致更高的内部应力水平。这种应力不匹配在制备非晶复合材料过程中引入了残余应力,导致材料受到外部负载时性能下降。

通过对烧氢与未烧氢W丝增强的非晶复合材料中残余应力的比较分析,可以得出烧氢处理可以显著改善W丝的表面质量,减少非晶复合材料中的残余应力。这一发现表明烧氢处理技术在制备高性能复合材料中的重要性。因此,在设计和制备非晶复合材料时,考虑增强相的预处理,如烧氢,是优化材料性能和调控残余应力的一个关键步骤。

2.4 不同直径的W丝对非晶复合材料残余应力的影响

图5为以直径0.3 mm烧氢W丝作为增强相的非晶复合材料的中子衍射数据精修结果。从图中的Rwp值可以看出精修结果准确,并且在轴向方向有明显的<110>织构。表4为AH3-W、AH3-AC和AH3-30精修后的晶格参数和残余应力。可以看出,W丝直径增加到0.3 mm,AH3-AC轴向和径向的残余应力分别为-47.4731和-13.064 MPa,与AH2-AC的残余应力非常接近,这一结果表明本实验W丝直径对复合材料中的残余应力影响较小,只是随着直径增加残余应力略有增加,这与W丝与基体材料之间的界面作用、热膨胀系数差异有关。首先,W丝直径的增加意味着在单个W丝与非晶基体之间的接触面积有所增加。这种增加的接触面积会导致在界面处产生更多的应力集中,在冷却过程中,W丝与基体之间的热膨胀不匹配会导致界面处产生额外的应力,从而导致整体残余应力的增加。

图5

图5

不同热处理工艺条件下以直径0.3 mm烧氢W丝作为增强相的非晶复合材料轴向和径向中子衍射数据的精修结果

Fig.5

Refinement results of axial (a) and radial (b) neutron diffraction data of metallic glass composites with 0.3 mm-diameter W wires annealed in hydrogen as reinforcement phase under different heat treatment process conditions

表4 不同热处理工艺下以直径0.3 mm烧氢W丝作为增强相的非晶复合材料的残余应力分布

Table 4

| Process | Axial direction | Radial direction | ||||

|---|---|---|---|---|---|---|

| a / nm | ε / % | σ / MPa | a / nm | ε / % | σ / MPa | |

| AH3-W | 0.316504 | 0 | 0 | 0.316468 | 0 | 0 |

| AH3-AC | 0.316473 | -0.0098 | -47.4731 | 0.316471 | 0.000948 | -13.064 |

| AH3-30 | 0.316474 | -0.0095 | -43.241 | 0.316473 | 0.00158 | -7.819 |

对该非晶复合材料进行200℃的回火处理30 min (AH3-30),观察到轴向残余应力减小到-43.241 MPa,径向残余应力减小到-7.819 MPa,但这些变化的幅度相对较小。这主要与热膨胀系数差异以及回火处理对材料微观结构的影响有关。回火处理引起的热膨胀是影响残余应力变化的一个重要因素。由于W丝和基体材料具有不同的热膨胀系数,回火过程中材料加热会导致2者之间的热膨胀不匹配,从而影响残余应力的分布。在一定温度下,材料的膨胀或收缩会导致原有残余应力的重新分配,从而导致径向残余应力和轴向残余应力的减小。然而,在200℃下,虽然能够促使部分应力松弛发生,但由于温度并不高,特别是对于W这种高熔点材料,其结构重排的动力学相对缓慢,因此应力松弛作用有限,导致残余应力的变化幅度不大。回火处理还对复合材料的微观结构产生影响,包括W丝与非晶基体之间的界面结构。微观结构的微小变化会影响力的传递和分布方式,进而影响残余应力的状态。这表明,在设计和优化复合材料的热处理工艺时,需要综合考虑材料的热膨胀特性、应力松弛能力以及微观结构的稳定性,以实现预期的应力调控效果。

3 结论

(1) 中子衍射结果表明,精修残差均小于10%,说明Rietveld分析中数据拟合很好,精修结果准确,并且W丝轴向方向具有强烈的<110>织构。

(2) 非晶复合材料在制备过程中由于非晶基体和W丝之间热膨胀系数的不同产生了较高的热残余应力,200℃下回火处理30 min能有效降低非晶复合材料内部的残余应力,当回火时间增加到60 min时,会导致应力再次增加。

(3) 对W丝进行烧氢处理可以有效改善增强相与基体之间的结合,从而降低非晶复合材料整体的残余应力。

(4) 烧氢后的W丝的直径由0.2 mm增加到0.3 mm,非晶复合材料内部的残余应力略有减小,对材料内部残余应力的影响较小。因此,为了调控非晶复合材料中的残余应力并优化其性能,需要综合考虑回火工艺和烧氢处理等因素。通过精细调整这些参数,可以最大限度地调控残余应力的分布,从而提高材料的整体性能。

参考文献

A structural model for metallic glasses

[J].Despite the intense interest in metallic glasses for a variety of engineering applications, many details of their structure remain a mystery. Here, we present the first compelling atomic structural model for metallic glasses. This structural model is based on a new sphere-packing scheme-the dense packing of atomic clusters. Random positioning of solvent atoms and medium-range atomic order of solute atoms are combined to reproduce diffraction data successfully over radial distances up to approximately 1 nm. Although metallic glasses can have any number of chemically distinct solute species, this model shows that they contain no more than three topologically distinct solutes and that these solutes have specific and predictable sizes relative to the solvent atoms. Finally, this model includes defects that provide richness to the structural description of metallic glasses. The model accurately predicts the number of solute atoms in the first coordination shell of a typical solvent atom, and provides a remarkable ability to predict metallic-glass compositions accurately for a wide range of simple and complex alloys.

Tuning the microstructure and metastability of β-Ti for simultaneous enhancement of strength and ductility of Ti-based bulk metallic glass composites

[J].A parametric experimental study on the role played by the size, metastability, and volume fraction of the dendritic beta-Ti phase on the tensile properties of amorphous matrix composites is conducted. Towards this end, several bulk metallic glass composites (BMGCs) with varying compositions were synthesized, processed under different cooling rates and tensile tested. Results show that the stress induced martensitic transformation, from beta to alpha '', of the dendritic Ti phase enhances the resistance to shear band propagation and, in turn, imparts significant strain hardening capability to the composite. This transformation was found to be favored in BMGCs in which the size of the dendrites is relatively coarse and Co content is similar to 1 at.%. Furthermore, a volume fraction of the dendritic phase between 34% and 45% was found to result in optimum combination of strength and ductility. The utility of these microstructural design principles learned from this study was demonstrated by design, synthesis, and testing of a BMGC containing transformable beta-Ti with a volume fraction of-38% that simultaneously exhibits high strength and ductility. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

Effect of W fiber diameter on the compressive mechanical properties of the Zr-based metallic glass composites

[J].<p>The Zr-based metallic glass composite containing four kinds of W fibers with different diameters are prepared by infiltration casting method. The diameters of the W fibers are 1000, 700, 500 and 200<em>μ</em>m,respectively. The effect of fiber diameter on the quasi-static and dynamic compressive mechanical properties and deformation behaviors of the composites was investigated. The results show that the quasi-static compressive properties improve with the decrease of the W fiber diameters, which is attributed to the increasing interface area and the size effect of the metallic glass matrix. Under dynamic compressive loading, the strain rate changes with the variation of the W fiber diameter at the same bullet firing pressure. The dynamic compressive strength and strain rate sensitivity exponent of the metallic glass composite with a fiber diameter of 500<em>μ</em>m is the highest among the four W fiber/Zr-based metallic glass composites.</p>

W纤维直径对锆基非晶复合材料压缩力学性能的影响

[J].

The nature and properties of amorphous matter

[J].

非晶态物质的本质和特性

[J].

Advances in fracture behavior and strength theory of metallic glasses

[J].Owing to the unique amorphous structure, metallic glasses (MGs) exhibit quite distinctive deformation and fracture behaviors from the conventional crystalline materials. The high strength, brittleness and macroscopic homogenous and isotropic structural features make MGs ideal model materials for the investigations of the strength theory of high-strength materials. Hence the fracture behavior and strength theory of MGs have attracted very extensive interests of researchers from the fields of materials, mechanics and physics. This paper is based on the research works of the authors on the fracture and strength of MGs in the past decade, and concentrates on discussing the current knowledge and recent advances on the fracture behavior and strength theory of ductile and brittle MGs. Firstly, the fracture behaviors of ductile and brittle MGs including tension-compression strength asymmetry, fracture mechanism and ductile-to-brittle transition will be briefly elaborated. Then the strength theories of MGs will be discussed, with our emphasis on the foundation, validation, further development and application of the ellipse criterion. At last, some unsolved issues associated with the fracture and strength of MGs are proposed.

金属玻璃的断裂行为与强度理论研究进展

[J].由于特殊的非晶态结构, 金属玻璃表现出与传统晶体材料十分不同的变形与断裂行为. 金属玻璃具有高强、脆性和宏观均匀、各向同性的特点, 使其成为研究高强度材料强度理论的理想模型材料, 因而关于金属玻璃的断裂行为与强度理论研究至今仍然吸引着材料、力学和物理等学科研究人员的广泛兴趣. 本文基于作者十多年来关于金属玻璃断裂与强度方面的研究工作, 着重阐述对韧性和脆性金属玻璃的断裂行为和强度理论方面的最新认识和研究进展, 最后提出金属玻璃断裂与强度方面尚待解决的科学问题.

In situ transmission electron microscopy studies of shear bands in a bulk metallic glass based composite

[J].

Temperature-dependence of impact toughness of bulk metallic glass composites containing phase transformable β-Ti crystals

[J].

Improving plasticity and work-hardening capability of β-type bulk metallic glass composites by destabilizing β phases

[J].

Shear-band blunting governs superior mechanical properties of shape memory metallic glass composites

[J].

Design and mechanical properties of new β type titanium alloys for implant materials

[J].

Microstructure and interfacial shear strength in W/(Zr55Cu30Al10Ni5)100 - x Nb x composites

[J].

FEM analysis on the deformation and failure of fiber reinforced metallic glass matrix composite

[J].

Effect of W volume fraction on dynamic mechanical behaviors of W fiber/Zr-based bulk metallic glass composites

[J].

Anisotropic compressive deformation behaviors of tungsten fiber reinforced Zr-based metallic glass composites

[J].

Correlation of microstructure with mechanical properties of Zr-based amorphous matrix composite reinforced with tungsten continuous fibers and ductile dendrites

[J].

Deformation and fracture behavior of tungsten fiber-reinforced bulk metallic glass composite subjected to transverse loading

[J].

Effect of particle size on dynamic mechanical behaviors of W particles/Zr-based bulk metallic glass composites

[J].

Compressive yielding of tungsten fiber reinforced bulk metallic glass composites

[J].

Self-sharpening mechanism of kinetic energy penetrator nose constructed of tungsten-fiber-reinforced Cu-Zn matrix composite

[J].

Thermal residual stresses in W fibers/Zr-based metallic glass composites by high-energy synchrotron X-ray diffraction

[J].Thermal residual stresses in W fibers/Zr-based metallic glass composites were measured by <em>in situ</em> high energy synchrotron X-ray diffraction (HEXRD). The W fibers for the composites were 300, 500, and 700 μm in diameter, respectively. Coaxial cylinder model (CCM) and finite element model (FEM) were employed to simulate the distribution of thermal residual stress, respectively. HEXRD results showed that the selected diameters of W fiber had little influence on the value of thermal residual stresses in the present composites. Thermal residual stresses simulated by CCM and FEM were in good agreement with HEXRD measured results. In addition, FEM results exhibited that thermal residual stress concentrated on interface between the two phases and area where the two W fibers were the closest ones to each other.

Investigation of thermal residual stresses in tungsten-fiber/bulk metallic glass matrix composites

[J].

Residual stresses in a bulk metallic glass-stainless steel composite

[J].

Dynamic deformation behavior of tungsten-fiber/metallic-glass matrix composites

[J].

Multiscale residual stress evaluation of engineering materials/components based on neutron and synchrotron radiation technology

[J].Multiscale residual stress exists throughout the manufacturing process of engineering components, from design and production to processing and servicing. This stress can impact the machining accuracy, structural load capacity, and fatigue lifespan of these components. Therefore, accurate measurement and regulation of residual stress are critical for ensuring the longevity and reliability of engineering components. However, precise characterization of residual stress is challenging owing to its multilevel and cross-scale distribution traits and dynamic evolution under various conditions, such as temperature and load. Compared with laboratory X-ray measurement methods, neutron diffraction (ND), synchrotron-based high-energy X-ray diffraction (HE-XRD), and synchrotron-based X-ray microbeam diffraction (μ-XRD) techniques offer increased penetration depth and better time and spatial resolutions. In addition, the ability to attach environmental devices enables nondestructive and accurate in situ characterization of three types of residual stresses: macroscopic residual stress, intergranular or interphase microscopic stress, and intragranular ultramicroscopic stress. ND is currently the only nondestructive method capable of accurately measuring three-dimensional (3D) stress at centimeter-level depths within engineering components. HE-XRD, due to its high flux, excellent collimation, and millimeter-level penetration depth for metals, can be utilized for in situ studies of intergranular and interphase stress evolution and partitioning during deformation. The μ-XRD employs a submicron focused beam and differential aperture technology to analyze depth information of a sample. By conducting point-by-point scanning, it can capture 3D distribution of microscopic stress inside a single grain. Furthermore, our group has developed a novel method and device for depth stress characterization based on differential aperture technology under synchrotron-based high-energy monochromatic X-ray transmission geometry, and can measure stress gradients with high precision from the surface to the interior of engineering materials at millimeter-level depths. This study presents the measurement principles, application ranges, and applications of the above-mentioned multiscale stress characterization technologies based on the neutron/synchrotron facilities as well as envisaging the future development of related technologies.

基于中子与同步辐射技术的工程材料/部件多尺度残余应力评价

[J].多尺度残余应力贯穿于工程部件设计、生产、加工和服役的全生命周期,对工程部件的长寿命可靠服役具有重要意义。残余应力具有多层次、跨尺度的分布特征,在温度、载荷等服役环境作用下发生动态演化,给精确表征带来了很大困难。相较于传统实验室X射线残余应力测量方法,中子衍射、同步辐射高能X射线衍射和同步辐射微束衍射技术在穿透深度、时间分辨率、空间分辨率、环境装置等方面具有显著优势,能够实现宏观残余应力、晶间/相间微观应力、晶内超微观应力3类残余应力的原位无损精确表征。本文详细介绍了上述基于中子/同步辐射大科学装置的多尺度应力表征技术的测量原理、应用范围和典型应用案例,并对相关技术的发展进行了展望。

Dynamic compressive mechanical properties of the spiral tungsten wire reinforced Zr-based bulk metallic glass composites

[J].

Direct measurement of residual stresses and their effects on the microstructure and mechanical properties of heat-treated Si3N4 ceramics

[J].

Neutron diffraction measurements of residual stress in a powder metallurgy component

[J].

Depth profiles of macro residual stresses in thin shot peened steel plates determined by X-ray and neutron diffraction

[J].

Effect of residual stresses on the onset of yielding in a Zr-based metallic glass

[J].

Neutron diffraction measurements of time-dependent residual stresses generated by severe thermomechanical deformation

[J].

Hydrogen annealed silicon wafer

[J].

Melt infiltration casting of bulk metallic-glass matrix composites

[J].

Making ultrastrong steel tough by grain-boundary delamination

[J].Developing ultrahigh-strength steels that are ductile, fracture resistant, and cost effective would be attractive for a variety of structural applications. We show that improved fracture resistance in a steel with an ultrahigh yield strength of nearly 2 gigapascals can be achieved by activating delamination toughening coupled with transformation-induced plasticity. Delamination toughening associated with intensive but controlled cracking at manganese-enriched prior-austenite grain boundaries normal to the primary fracture surface dramatically improves the overall fracture resistance. As a result, fracture under plane-strain conditions is automatically transformed into a series of fracture processes in "parallel" plane-stress conditions through the thickness. The present "high-strength induced multidelamination" strategy offers a different pathway to develop engineering materials with ultrahigh strength and superior toughness at economical materials cost.Copyright © 2020 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

GSAS-II: The genesis of a modern open-source all purpose crystallography software package

[J].

Investigation of residual strains by neutron diffraction in an AZ31 direct chill cast billet

[J].

The effect of interface modification on fracture behavior of tungsten fiber reinforced copper matrix composites

[J].