在建设“航天强国”等战略目标的牵引下,以行星探测器、舰载机为代表的空天装备快速更新迭代,对DRA的性能提出了更严苛的要求。高比强度是实现轻量化的基础,但现役DRA多以2xxxAl (Al-Cu-Mg)和6xxxAl (Al-Mg-Si-Cu)等强度相对较低的铝合金为基体[4],难以满足装备升级换代的需求。7xxxAl (Al-Zn-Mg-Cu)合金在铝合金家族中具有最高的强度[5],以其为基体是开发新一代超高强DRA的必然趋势。然而,DRA中常用的SiC、B4C等陶瓷颗粒增强相对7xxxAl合金的强化效果较差,有时DRA的强度甚至低于未增强的7xxxAl合金[6]。尽管Chen等[7]在大量工艺探索的基础上开发出了强度超600 MPa、弹性模量约100 GPa、延伸率约5%的超高强7xxxAl基DRA产品,但仍然没有改变颗粒增强相强化效果不佳的现状,材料的强韧化潜力尚没有充分发挥。

7xxxAl合金属于沉淀强化型铝合金,时效过程中形成的纳米析出相是其强度的主要来源[8]。然而,DRA中颗粒增强相与Al基体在物理、化学以及力学性质方面均存在巨大差异,不仅会引发增强相/Al基体间的化学反应从而改变微区成分,还会因增强相与Al基体的弹性错配(弹性模量差异)与热错配(热膨胀系数差异)导致位错萌生、空位湮灭等[9]。现有研究[6,10]普遍认为,上述因素会改变析出相的尺寸、含量和分布等,进而削弱沉淀强化能力,由此冲淡了增强颗粒的强化效应,导致DRA较未增强的7xxxAl合金无法表现出强度优势。显然,阐明DRA中增强相对沉淀强化能力的影响规律与内在机制,是进一步释放其强韧性潜力的基础。尽管已有许多学者[6,7]利用透射电子显微镜(TEM)对比研究了7xxxAl基DRA与未增强7xxxAl合金中析出相的差异,但由于受到表征手段的限制,现有研究一般是选取特征时效时间点对观测微区中的析出相进行定性描述,无法准确反映时效析出特征。此外,目前多是基于单一时效温度研究7xxxAl基DRA的时效析出特性,不同温度下颗粒增强相对沉淀强化能力的影响是否存在区别尚不清楚。参照7xxxAl合金常用的时效温度[11~13],本工作选择100和160℃对7xxxAl基DRA在2种时效温度下的时效析出行为与沉淀强化能力进行了研究。

本工作采用粉末冶金法制备了15%SiC颗粒(体积分数)增强7085Al复合材料及不含SiC的7085Al合金,结合SANS与TEM技术研究了不同时效温度下2种材料时效析出行为与沉淀强化能力的差异,并探讨了相关机制,以期为7xxxAl基DRA的时效工艺改进与力学性能提升提供指导。

1 实验方法

1.1 材料制备

7085Al合金的名义成分为Al-7.5Zn-1.8Mg-1.7Cu (质量分数,%),金属粉末与SiC粉末的平均粒径分别约为13和7 μm。将粉末置于双轴混料机中机械混合6 h,混合均匀的粉末在真空环境下热压烧结成致密坯锭,热压温度为560℃。热压后的坯锭在420℃下挤压成棒材,挤压比为16∶1,挤压速率为1 mm/s。挤压棒取样后在450℃固溶2 h并迅速淬入室温水中,对淬火后的样品立刻进行时效处理。时效工艺分为2种:(1) 在100℃下人工时效0~3 h;(2) 在160℃下人工时效0~3 h。采用相同的工艺制备7085Al合金样品作为对比。

1.2 力学性能测试及析出相观测

使用Instron 5982拉伸试验机在室温下对人工时效后的样品进行单轴拉伸测试。拉伸样品呈狗骨状,平行段长度为23 mm且平行于挤压方向,拉伸应变速率为1 × 10-3 s-1。每种工艺参数测试3个平行样品,并计算强度和延伸率的平均值。

使用F200X型TEM观察析出相,该电镜同时装备有高角环形暗场(HAADF)探头及X射线能量色散谱(EDS)探头。明场(BF)像及高分辨透射电镜(HRTEM)像观测时电子束入射方向均平行于[110]Al晶带轴。TEM样品首先机械打磨至50 μm厚,然后冲成直径为3 mm的圆片。复合材料圆片凹坑后进行离子减薄。铝合金圆片在-25℃、12 V恒电压下进行双喷减薄,双喷液为HNO3 + CH3OH溶液(体积比为7∶3)。

1.3 SANS测试及数据拟合

在中国散裂中子源开展SANS测试,实验采用直径为6 mm的圆形光阑,样品与探测器距离为4 m。SANS样品为12 mm (平行于挤压方向) × 10 mm × 5 mm的方块,经固溶及淬火处理后先置于-80℃的冷冻箱中保存,待SANS实验开始时取出。首先在室温下测试20 min,以此作为固溶态样品的散射数据,之后以10℃/min的升温速率升至指定时效温度进行保温,并同步获取散射信号。散射信号通过二维探测器(由120根直径8.5 mm、长1 m的3He管横向排列组成)进行采集,从而获得二维散射数据。对二维散射数据进行径向积分,可以得到散射强度I(Q)与散射矢量 Q 的一维散射曲线[16]。Q是散射角θ和入射中子束波长λ的函数,λ的范围为0.1~0.98 nm,对应Q的范围为0.048~8.8 nm-1。一维散射曲线经透过率和标准样品校正后采用IGOR Pro软件的Irena程序包进行拟合分析,过程描述如下。

式中,A为椭球体的长径比(A < 1);α为椭球体长轴与散射矢量之间的夹角,变化范围为0~π/2。

通过上述模型拟合散射曲线可以得到A、R1和Rs的定量信息。fv则可以通过Porod积分不变量Q0来计算,Q0是Kratky曲线(IQ2-Q)与坐标轴包围的积分面积[21]:

当fv很小时,1 - fv ≈ 1。因此:

对于SiC/7085Al复合材料,由于SiC颗粒不参与散射,因此计算fv时需将其占比(15%)扣除,即复合材料中析出相的体积分数

2 实验结果及讨论

2.1 时效温度对15%SiC/7085Al复合材料析出行为及力学性能的影响

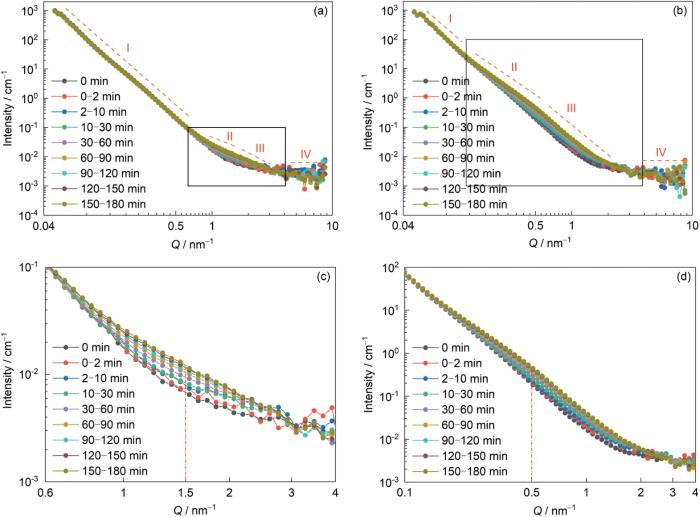

2.1.1 原位SANS测试

将SiC/7085Al复合材料的原位SANS数据按照时效时间进行切分,得到代表该时间段内析出相平均信息的散射曲线,如图1所示。根据斜率的不同,可以将时效态的散射曲线分为4部分。I主要来源于晶界散射,IV是由非相干散射造成的散射背底,这2部分散射信号在时效过程中不发生变化。II和III包围形成的“鼓包” (如图1a和b中方框所示)代表纳米级析出相的散射信号。随着时效进行析出相发生演变,“鼓包”位置也在不断变化。其中,“鼓包”上移代表析出相含量增加,“鼓包”左移代表析出相尺寸增大[22]。比较2种时效温度下“鼓包”的位置,可以看出其均随时效时间的延长而上移,说明析出相含量增加。不同之处在于,100℃时效时“鼓包”位于Q = 1.5 nm-1附近,而160℃时效时“鼓包”位于Q = 0.5 nm-1附近。即时效温度升高,“鼓包”位置向左移动,表明高温时效时析出相的尺寸更大。

图1

图1

15%SiC/7085Al复合材料在100和160℃不同时效时间段的散射曲线

Fig.1

Scattering curves of 15%SiC/7085Al composites at 100oC (a, c) and 160oC (b, d) for various aging periods (Figs.1c and d are the local magnification diagrams of the rectangular regions in Figs.1a and b, respectively. Q—scattering vector modulus)

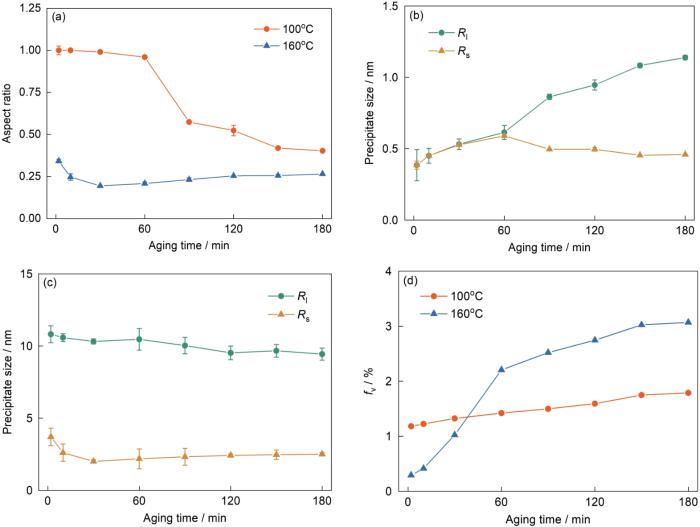

为得到析出相尺寸、含量等参量的量化数据,对散射曲线进行拟合分析,结果如图2所示。图2a展示了析出相长径比随时效时间的演变。可以看出,100℃时效初期析出相的长径比接近1,表明析出相的形貌近似为球状。时效1 h后,长径比显著降低,析出相由球状转变为片状或棒状。而160℃时效时,析出相的长径比稳定在0.25左右,表明析出相的形貌始终以片状或棒状为主。析出相尺寸随时效时间的演变(图2b和c)进一步展示了不同温度下析出相形貌变化的特点。100℃时效时,析出相尺寸的演变主要体现为随时效时间延长R1增大,但Rs变化很小(图2b)。而160℃时效时,R1与Rs均比较稳定,R1甚至略有减小(图2c)。2种时效温度下析出相的体积分数(图2d)均随时效时间的延长而增加。但100℃时效时析出相体积分数增长缓慢,始末态仅相差0.6%;而160℃时效时则增长较快,始末态相差2.8%。

图2

图2

散射曲线的拟合结果

Fig.2

Fitting results of scattering curves

(a) aspect ratio of precipitates

(b) size of precipitates at 100oC (R1 and Rs are the long and short axis radii of precipitates, respectively)

(c) size of precipitates at 160oC

(d) volume fraction of precipitates (fv)

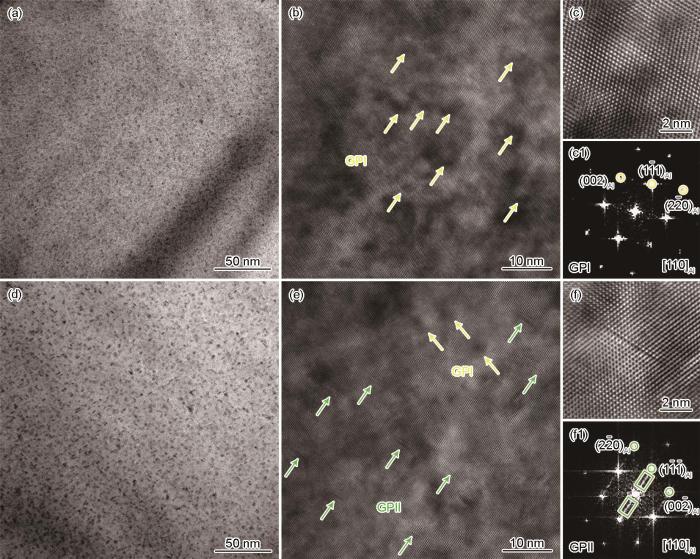

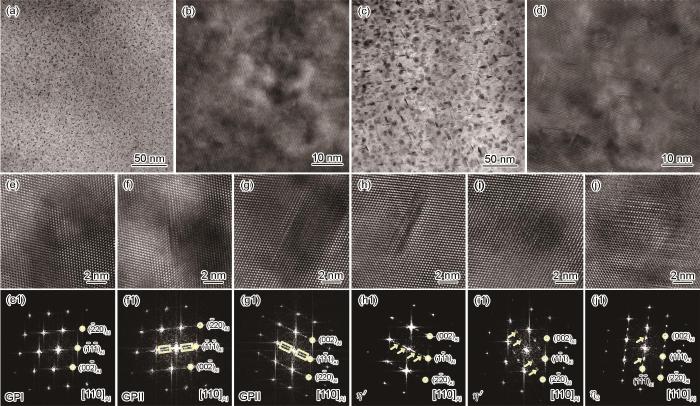

2.1.2 TEM观测

图3为SiC/7085Al复合材料在100℃时效不同时间后晶内析出相形貌和结构的TEM分析。时效时间为0.5 h时,复合材料晶粒内部分布着大量细小的近球状析出相(图3a和b)。通过图3c所示的高倍HRTEM像可以看出该析出相与Al基体之间是完全共格的,相应的快速Fourier变换(FFT,图3c1)中除Al基体的衍射斑点之外未观测到其他斑点,这与文献[23,24]中报道的GPI区的特征一致,表明复合材料在100℃时效0.5 h后析出相主要为GPI区。随着时效时间延长至3 h,复合材料中除GPI区外,还出现了大量的针状析出相(图3d和e)。由图3f所示的高倍HRTEM像可知其长度约3 nm,厚度仅2~3个原子层。相应FFT (图3f1)中沿<1

图3

图3

15%SiC/7085Al复合材料在100℃时效不同时间后析出相的TEM分析

Fig.3

TEM bright field images (a, d), low (b, e) and high (c, f) magnified HRTEM images of precipitates in 15%SiC/7085Al composites after aging at 100oC for 0.5 h (a-c) and 3 h (d-f); and corresponding fast Fourier transform (FFT) (c1, f1) of Figs.3c and f, respectively (Various types of precipitates are indicated by arrows with different colors, and the characteristic streaks are highlighted with green boxes)

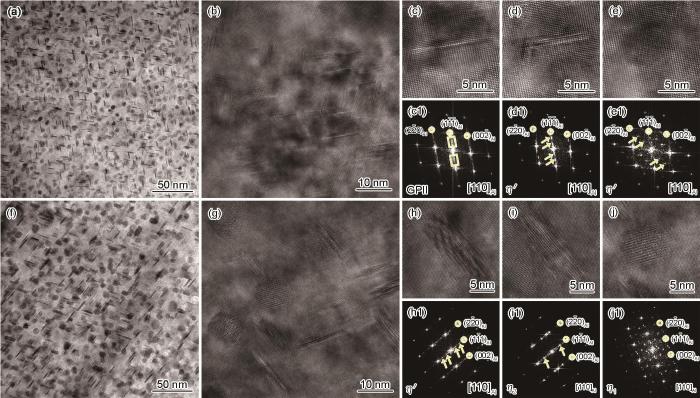

SiC/7085Al复合材料在160℃时效不同时间后晶内析出相形貌和结构的TEM分析如图4所示。时效0.5 h后,TEM明场像(图4a)和低倍HRTEM像(图4b)中既存在针棒状析出相也存在圆点状析出相。结合高倍HRTEM像和相应的FFT可知,针棒状析出相分为2类:一类厚度较薄(< 1 nm),FFT显示沿<1

图4

图4

15%SiC/7085Al复合材料在160℃时效不同时间后析出相的TEM分析

Fig.4

TEM bright field images (a, f), low (b, g) and high (c-e, h-j) magnified HRTEM images of precipitates in 15%SiC/7085Al composites after aging at 160oC for 0.5 h (a-e) and 3 h (f-j), and corresponding FFT (c1-e1, h1-j1) of Figs.4c-e and h-j, respectively (The characteristic streaks and spots are highlighted with yellow boxes and arrows, respectively)

随着时效时间延长至3 h,析出相进一步长大,但在TEM明场像(图4f)和低倍HRTEM像(图4g)下析出相形貌仍然为针棒状和圆点状。由高倍HRTEM像和相应FFT图所示的晶格结构可知,图4h中的析出相是η'相,图4i和j中的析出相均符合η相的特征,是该相2种不同形貌的变体。图4i所示的η相常被称为η2相[25],其与Al基体的取向关系和η'相相同,即

一般认为,7xxxAl合金及其复合材料的时效析出序列为过饱和固溶体(SSS)→GP(I, II)区→η'相(Mg2Zn5 - x Al2 + x,x > 0)→η相(MgZn2)[30,31]。其中,GPII区和η'相是主要强化相,而平衡相η相强化效果不佳。析出相的形成包括形核与生长2个阶段。随着时效温度的升高,析出相形核的临界尺寸减小,形核越容易发生。此外,时效温度越高,合金元素的扩散速率越大,析出相的生长速率也越大。因此,在本工作所涉及的时效时间里,160℃时效时析出相的平均尺寸和体积分数均比100℃时效时大,体积分数的增幅也更明显。然而,160℃时由于析出相的形成速率过快,仅时效0.5 h便出现了大量η'相,而100℃时效相同时间后析出相仍以GPI区为主。η'相稳定性较好,且即便演变为η相尺寸增幅也不大。而GPI区稳定性不佳,随着时效过程的推进极易向尺寸更大的GPII区演变。因此100℃时效时析出相尺寸的增幅反而大于160℃时效时。圆盘状GPII区在直径方向与Al基体之间的界面能远小于厚度方向[32],故析出相在长大过程中主要以R1的增加为主。

2.1.3 力学性能测试及强化机制分析

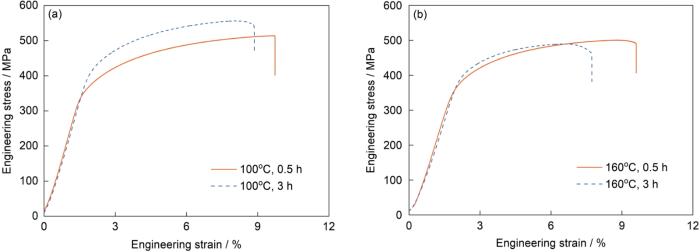

图5

图5

15%SiC/7085Al复合材料在100和160℃时效不同时间后的工程应力-应变曲线

Fig.5

Engineering stress-strain curves of 15%SiC/7085Al composites after aging at 100oC (a) and 160oC (b) for different time

表1 15%SiC/7085Al复合材料在100和160℃时效不同时间后的拉伸力学性能

Table 1

| Aging temperature / oC | Aging time / h | YS / MPa | UTS / MPa | EL / % |

|---|---|---|---|---|

| 100 | 0.5 | 362 ± 0.9 | 512 ± 1.6 | 7.6 ± 0.4 |

| 3 | 424 ± 0.5 | 559 ± 1.5 | 6.1 ± 0.3 | |

| 160 | 0.5 | 374 ± 0.8 | 501 ± 0.5 | 7.2 ± 0.3 |

| 3 | 403 ± 2.4 | 490 ± 1.2 | 5.2 ± 0.1 |

Note: YS—yield strength, UTS—ultimate tensile strength, EL—elongation

沉淀强化是SiC/7085Al复合材料的主要强化机制,析出相的类型、尺寸以及体积分数等参量直接影响其与位错的作用方式,进而导致不同的沉淀强化效果。当析出相尺寸较小、自身强度较弱时,位错以切过方式作用于析出相,由此带来的沉淀强化被称为切过型强化,这种强化方式又可以通过共格应变强化、模量强化和有序强化等机制进行描述[33]。当析出相尺寸较大、自身强度较强时,位错难以切过,从而选择以绕过方式作用于析出相,由此带来的沉淀强化被称为绕过型强化,也称为Orowan强化。Poole等[34]通过计算发现,铝合金中位错能够切过析出相的临界半径为2.5 nm。结合不同温度下复合材料中析出相的SANS和TEM分析可知,100℃时效时复合材料中析出相的主要强化机制为切过型沉淀强化,而160℃时效时则是绕过型沉淀强化。

式中,M为Taylor因子;χ为与基体晶体结构有关的常数;ε为析出相与基体之间的共格应变;G为基体的剪切模量;b为位错Burgers矢量模;ΔG为析出相与基体之间的剪切模量差;n为与位错类型有关的常数;r和γAPB分别为析出相的等效半径和反向畴界自由能。r可以表示为[38]:

Orowan强化对屈服强度的贡献(Δσorowan)可以用下式来表达[39]:

2.2 15%SiC/7085Al复合材料与7085Al合金对时效温度响应的差异

2.2.1 析出相表征

对7085Al合金在100和160℃时效3 h后的样品进行了SANS测试,采用与SiC/7085Al复合材料相同的数据处理方法获得了析出相的定量信息,并与相同时效状态下复合材料的析出相信息共同列于表2。可以看出,100℃时效3 h后7085Al合金中析出相的长径比和尺寸(R1和Rs)与复合材料相差不大,但析出相的体积分数比复合材料高50%。而160℃时效3 h后7085Al合金中析出相的体积分数与复合材料相当,但尺寸却小很多。

表2 100和160℃时效3 h后15%SiC/7085Al复合材料与7085Al合金中析出相的定量信息

Table 2

| Aging temperature / oC | Material | A | R1 / nm | Rs / nm | fv / % |

|---|---|---|---|---|---|

| 100 | SiC/7085Al | 0.403 | 1.139 | 0.459 | 1.788 |

| 7085Al | 0.323 | 1.465 | 0.473 | 2.682 | |

| 160 | SiC/7085Al | 0.265 | 9.435 | 2.505 | 3.096 |

| 7085Al | 0.450 | 3.240 | 1.458 | 2.861 |

Note: A—aspect ratio

图6

图6

7085Al合金在100和160℃时效3 h后析出相的TEM分析

Fig.6

TEM bright field images (a, c), low (b, d) and high (e-j) magnified HRTEM images of precipitates in 7085Al alloy after aging at 100oC (a, b, e, f) and 160oC (c, d, g-j) for 3 h, and corresponding FFT (e1-j1) of Figs.6e-j (The characteristic streaks and spots are highlighted with yellow boxes and arrows, respectively)

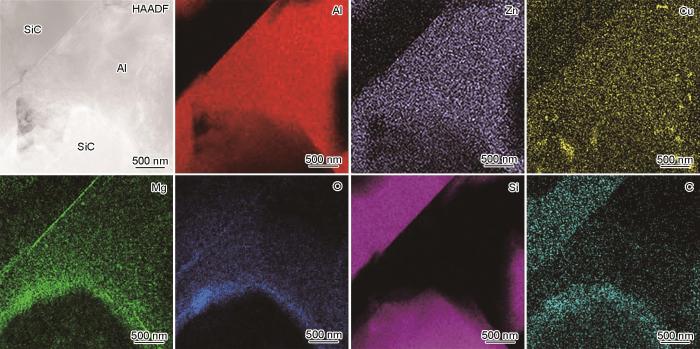

图7为100℃时效3 h的SiC/7085Al复合材料中SiC/Al界面的HAADF像及相应的EDS元素分布图。可见,Mg元素和O元素在SiC/Al界面处偏聚,且分布十分接近。前期研究[6]已表明,原始SiC粉末中通常存在SiO2和Si杂质,在复合材料的制备过程中,Mg元素与SiO2之间容易发生化学反应生成MgO或MgAl2O4。由于该种元素偏聚通常发生在热压等高温处理过程,并不会随时效时间和温度而改变[31],故其他时效工艺样品的界面微观结构不再给出。100℃时效时上述化学反应对Mg元素的消耗抑制了析出相的形成,导致复合材料中析出相的体积分数低于7085Al合金。而该温度下元素扩散较慢,析出相的生长和演变本就困难,故Mg消耗对析出相尺寸和类型的影响不大。160℃下时效动力学大幅加快,补偿了Mg消耗对析出相形成的抑制,因此复合材料与7085Al合金中析出相的体积分数相差不大。然而,此时复合材料中析出相的尺寸反而大于7085Al合金,原因可以归结为:复合材料中大量的界面和淬火位错(因SiC颗粒与Al基体热膨胀系数不同而产生)会湮灭空位,导致析出相的有效形核位点减少[40],进而使得单个析出相的尺寸更加粗大。

图7

图7

15%SiC/7085Al复合材料中SiC/Al界面的高角环形暗场(HAADF)像及相应的EDS元素分布图

Fig.7

High angle annular dark field (HAADF) image of SiC/Al interface in 15%SiC/7085Al composites and corresponding EDS elemental distribution maps

2.2.2 力学性能差异及强化机制分析

表3展示了100和160℃时效3 h后7085Al合金的拉伸性能。对比表1和3可见,与7085Al合金相比,复合材料的强度和延伸率均存在不同程度的削弱,但2种时效温度下削弱的幅度不同。100℃时效3 h后,复合材料的YS、UTS和EL分别低43 MPa、7 MPa和11.0%;160℃时效3 h后,复合材料的YS、UTS和EL分别低96 MPa、37 MPa和4.9%,即高温时效对复合材料沉淀强化能力的削弱比低温时效大。由表2可知,100℃时效3 h后复合材料与7085Al合金中析出相的尺寸接近,但复合材料中析出相的体积分数更低。此时沉淀强化机制为切过型强化,析出相的强化效果与其尺寸和体积分数均呈正相关(式(

表3 100和160℃时效3 h后7085Al合金的拉伸力学性能

Table 3

Aging temperature oC | YS MPa | UTS MPa | EL % |

|---|---|---|---|

| 100 | 467 ± 4.1 | 566 ± 3.7 | 17.1 ± 0.1 |

| 160 | 499 ± 8.4 | 527 ± 9.0 | 10.1 ± 0.5 |

综上,SiC/7085Al复合材料的力学性能难以与7085Al合金相媲美主要归因于其较弱的沉淀强化能力。本研究发现,复合材料沉淀强化能力被削弱一方面是由于SiC/Al界面反应消耗了Mg元素,另一方面是因为复合材料在时效后期或高温时效下的析出相粗化比7085Al合金更快。因此,进一步提升SiC/7085Al复合材料的力学性能可以从以下2个方面着手:(1) 通过界面修饰或Al基体成分设计,减轻界面反应或补偿界面反应对Mg元素的消耗;(2) 开发适当的低温时效工艺或者低温长时间+高温短时间复合时效工艺,减弱析出相的粗化。

3 结论

(1) 100℃时效0.5 h后15%SiC/7085Al复合材料中的析出相主要是GPI区,随着时效时间延长至3 h,析出相转变为GPI区+ GPII区。SANS结果表明,100℃时效0~3 h期间析出相的尺寸显著增大、体积分数略有增加,这使得位错切过析出相的阻力增大,进而促使复合材料的屈服强度随时效时间的延长而明显提高。

(2) 160℃时效0.5 h后15%SiC/7085Al复合材料中的析出相主要是GPII区+ η'相,时效3 h后则以η'相+ η相为主。160℃时效0~3 h期间析出相的尺寸和体积分数均增大。此时沉淀强化机制为绕过型强化,尽管析出相体积分数的增加有利于强度的提高,但析出相的粗化和平衡相η相的出现却会削弱强化效果,故复合材料的屈服强度随时效时间的延长仅出现小幅度提高。

(3) 与7085Al合金相比,15%SiC/7085Al复合材料在100和160℃时效3 h后强度均降低,但相关机制并不相同。100℃时效时复合材料沉淀强化能力的削弱主要是由于SiC/Al界面反应消耗了Mg元素,使得析出相的体积分数减少。而160℃时效时复合材料与7085Al合金中析出相的体积分数接近,但前者的析出相尺寸更大,再加上复合材料中η相占比增加,这2方面的原因共同导致了复合材料较弱的沉淀强化能力。

参考文献

The production and application of metal matrix composite materials

[J].

Overview of research and development for aluminum matrix composites driven by aerospace equipment demand

[J].Tianwen-1 is China's first planetary probe. Its core, the rover Zhurong, undertook the task of tour and survey, and had extended the mission over the designed 90-Martian-day period limit on Mars. The rover was equipped with various silicon-carbide-particle-reinforced aluminum matrix composites for its bearing structure, motion system, and detectors to meet design requirements, such as lightweight, wear resistance, impact resistance, and dimensional stability. The use of these composites has set a new record for the proportion of aluminum matrix composites used in Chinese spacecraft. This paper discusses the research and development process of the four types of aluminum matrix composites used for the rover Zhurong: property simulation, material design, preparation, and processing. Additionally, the paper introduces new research and development paradigms based on material genetic engineering and the use of synchrotron radiation or neutron scattering facilities. The future development of aluminum matrix composites for high-tech equipment is also discussed.

航天装备牵引下的铝基复合材料研究进展与展望

[J].天问一号是我国第一个行星探测器,其核心祝融号火星车承担着星面巡视和探测重任,已圆满完成预定90个火星日的探测并进入拓展任务。火星车上使用了多种SiC颗粒增强铝基复合材料,分别满足承载结构、运动机构、探测器结构的轻量化、耐磨损、耐冲击、尺寸稳定等苛刻服役要求,用量刷新了我国航天器铝基复合材料占比记录。本文介绍了针对火星车需求的4种铝基复合材料的研发历程,尤其是性能仿真、材料成分设计与制备加工等。在此基础上,针对未来飞行器等先进装备更苛刻服役工况对材料性能的更高要求,对低成本、高效制备和快速响应的需求,介绍了基于材料基因工程思想与大科学装置的研发新模式,展望了铝基复合材料未来的发展方向。

The Aluminum matrix composites team of the Institute of Metal Research, Chinese Academy of Sciences, embraces the stars and sea, using new independent and controllable materials for basic and applied linked uses

[J].

中国科学院金属研究所铝基复合材料团队 基础应用联动 用自主可控新材料拥抱星辰大海

[J].

Research and application of powder metallurgy particle reinforced aluminum matrix composite used in aviation

[J].

航空用粉末冶金颗粒增强铝基复合材料研制及应用

[J].

An investigation on particle weakening in T6-treated SiC/Al-Zn-Mg-Cu composites

[J].

Effects of solution temperatures on microstructures and mechanical properties of B4C/7A04Al composites: A comparison study with 7A04Al alloys

[J].

Quantitative study of nanoscale precipitates in Al-Zn-Mg-Cu alloys with different chemical compositions

[J].

Microstructure and microchemistry of an Al-Zn-Mg-Cu alloy matrix-20 vol.% SiC composite

[J].

Effect of SiC particles on ageing behaviour of SiCp/7075 composites

[J].

HR-STEM investigation of atomic lattice defects in different types of η precipitates in creep-age forming Al-Zn-Mg-Cu aluminium alloy

[J].

Effect of pre-ageing treatment on second nucleating of GPII zones and precipitation kinetics in an ultrafine grained 7075 aluminum alloy

[J].

Precipitation behaviour of Al-Zn-Mg-Cu alloy and diffraction analysis from η′ precipitates in four variants

[J].

Use of SANS and SAXS in study of nanoparticles

[J].

China spallation neutron source small-angle scattering spectrometer

[J].

中国散裂中子源小角散射谱仪

[J].

Precipitate characterisation in metallic systems by small-angle X-ray or neutron scattering

[J].

Quantitative study on dynamic instantaneous dissolution of precipitated phases in 2195-T6 Al-Li alloy based on characterizations with SANS and TEM

[J].

Spinodal decomposition coupled with a continuous crystal ordering in a titanium alloy

[J].

Precipitation behavior of ω phase and ω→α transformation in near β Ti-5Al-5Mo-5V-1Cr-1Fe alloy during aging process

[J].

Form factors of block copolymer micelles with spherical, ellipsoidal and cylindrical cores

[J].

Characterisation of the composition and volume fraction of η′ and η precipitates in an Al-Zn-Mg alloy by a combination of atom probe, small-angle X-ray scattering and transmission electron microscopy

[J].

Quantitative characterization on the precipitation of AA 7055 aluminum alloy by SAXS

[J].AA 7055 aluminum alloy is a newly advanced Al-Zn-Mg-Cu alloy. It has been wide applied in aviation and aerospace field due to its attractive combined properties, such as high strength, high fracture toughness, good resistance to the growth of fatigue cracks and good stress corrosion resistance, and so on. It is generally believed that the optimum ageing precipitates are responsible for these good properties. However, the detailed information, such as size and its distribution, volume fraction, and morphology of precipitate in this alloy is still not clear. Although TEM is used to determine these information, the results are mostly qualitative. Small angle X-ray scattering (SAXS) provides a direct technique to determine the size, morphology and volume fraction of nano-scale particles and the sampling size is much larger than that in TEM. In this work, the evolution of the precipitates during ageing at 120 and 160 ℃ in AA 7055 aluminum alloy were investigated systematically and quantitatively by SAXS technique. The results show that, when ageing at 120 ℃, the average radius of the precipitates increases with increasing the ageing time. After ageing for 5 h and later, the average radius of the precipitates is 3.3 nm, and its distribution almost keeps stably. The volume fraction of the precipitates is also increased with increasing the ageing time. When ageing from 5 h to 60 h, the volume fraction increases from 2.4% to 5.2%. When ageing at 160 ℃, however, the average radius of the precipitates increases from 3.1 nm to 11.7 nm with increasing the ageing time from 0.5 h to 72 h. The volume fraction of the precipitates increases from 1.4% to 5.4% with increasing the ageing time from 0.5 h to 16 h. After ageing for 16 h and later, the volume fraction of the precipitates keeps stably. Both ageing at 120 and 160 ℃, the morphology of the precipitates is similar to a flat ellipsoid with an axis ratio between 0.2 and 0.3. Based on these quantitative results of the precipitates, the strength models during ageing will be built possibility.

AA 7055铝合金时效析出过程的小角度X射线散射定量表征

[J].利用小角度X射线散射(SAXS)技术系统、定量地研究了AA 7055铝合金在120和160 ℃时效过程中析出相的演变规律。结果表明,在120 ℃时效时,随时效时间延长析出相半径不断增加,时效5 h后半径基本稳定,约为3.3 nm,且尺寸分布基本不变;析出相的体积分数随着时效时间的延长不断增加,由时效5 h时的2.4%增加到时效60 h时的5.2%。在160 ℃时效时,随时效时间延长析出相半径不断增加,由时效0.5 h时的3.1 nm增加到时效72 h时的11.7 nm,尺寸分布范围也随着时效时间的延长而逐渐增加;析出相的体积分数随着时效时间的延长先不断增加,由时效0.5 h时的1.4%增加到时效16 h时的5.4%,时效16 h后趋于平衡。在120和160 ℃时效时,析出相均属于轴比介于0.2~0.3之间的扁椭球状,即为盘状。

Precipitation in an Al-Zn-Mg-Cu alloy during isothermal aging: Atomic-scale HAADF-STEM investigation

[J].

Characterization of precipitate evolution in an artificially aged Al-Zn-Mg-Sc-Zr alloy

[J].

Transmission electron microscopy investigation of separated nucleation and in-situ nucleation in AA7050 aluminium alloy

[J].

GP-zones in Al-Zn-Mg alloys and their role in artificial aging

[J].

The effect of minor addition of Mn in AA7075 Al-Zn-Mg-Cu aluminum alloys on microstructural evolution and mechanical properties in warm forming and paint baking processes

[J].

An atomic scale structural investigation of nanometre-sized η precipitates in the 7050 aluminium alloy

[J].

The time-of-flight small-angle neutron spectrometer at China spallation neutron source

[J].

Revisiting the precipitation sequence in Al-Zn-Mg-based alloys by high-resolution transmission electron microscopy

[J].

Fabrication, microstructure and mechanical properties of SiC/Al-Zn-Mg-Cu composites

[D].

SiC/Al-Zn-Mg-Cu复合材料的制备、微观组织和力学性能

[D].

The study on phase transformation of hardening precipitates in Al-Zn-Mg-(Cu) alloys during aging

[D].

Al-Zn-Mg-(Cu)合金时效中纳米析出相结构及演变规律研究

[D].

Aging precipitation behavior and mechanical properties of AA 7055 aluminum alloy

[D].

AA 7055铝合金的时效析出行为与力学性能

[D].

The shearable-non-shearable transition in Al-Mg-Si-Cu precipitation hardening alloys: Implications on the distribution of slip, work hardening and fracture

[J].

Precipitation strengthening in naturally aged Al-Zn-Mg-Cu alloy

[J].

Precipitation strengthening at ambient and elevated temperatures of heat-treatable Al(Sc) alloys

[J].

Strengthening mechanisms in a high-strength bulk nanostructured Cu-Zn-Al alloy processed via cryomilling and spark plasma sintering

[J].

Effects of natural aging on precipitation behavior and hardening ability of peak artificially aged SiCp/Al-Mg-Si composites

[J].

Effect of variable rate non-isothermal aging on microstructure and properties of Al-Zn-Mg-Cu alloy

[J].

Enhanced precipitate strengthening in particulates reinforced Al-Zn-Mg-Cu composites via bimodal structure design and optimum aging strategy

[J].