全面掌握材料宏微观静态特点及动态行为是深入认识材料机理的物理本质,建立和细化微观结构参数和宏观性能之间关系,从而实现关键构件“按需设计”的重要途径[1~3]。为此,不仅需要发展跨尺度的力-热耦合模型,同时也依赖可靠的定量分析技术来提供模型验证、迭代优化所需的基本实验数据。长期以来,人们发展了基于可见光、电子、软/硬X射线、中子等与材料发生弹性/非弹性作用的特征化实验技术以获得物相、晶粒、缺陷、晶格应变、织构、界面等关键信息,这些技术已经成为材料微观表征与性能评价的基本方法[4~10]。为了进一步建立材料宏微观性能关联,需要完整掌握覆盖几个数量级的空间和时间尺度的信息。其中,材料纵深区域微结构的量化分析是材料表征的难点,也是工程构件服役寿命评价中不可或缺的重要环节。

中子呈电中性、轻元素灵敏并且具有自旋磁矩,对于大部分材料,其穿透能力相比于Cu靶X射线提高近3个数量级[9]。基于中子源大科学装置发展的中子衍射技术,其空间分辨率和探测深度可达毫米至厘米尺度,能无损、定量获取材料内部具有统计意义的微结构信息,对于工程材料及部件残余应力的精确测量具有无可比拟的优势[8~10]。半个多世纪以来,中子衍射技术不断深入到凝聚态物理、材料科学、生物医学、无损检测等各个研究领域,逐步带动了航空航天、轨道交通、核电能源以及军事装备等高端制造业的进步和发展[8,9]。世界范围内,发展平台型大科学装置是支撑前沿科技创新和核心技术突破,实现社会经济快速发展与国家安全稳定的重要任务。

多维度、跨尺度分析是现阶段材料研究的重要方向,同时也面临诸多挑战。经过多年探索和发展,基于同步辐射光源、中子源大科学装置的衍射技术在外场环境、测量空间和时间维度上有效弥补了低能粒子分析技术的不足,成为建立物质微观、介观和宏观结构与性能内在联系的重要表征手段。例如,同步辐射X射线衍射适合材料内部微区晶体取向、缺陷密度及弹性应变分布的无损分析,为各种热-力耦合模型提供重要验证工具与基本实验数据,同时可以用于揭示关键工程材料与部件服役失效模式和机理[11~13];中子衍射能够无损、定量获得材料厘米级深部的三维应变/应力与织构信息,对大尺寸晶粒也具有良好的统计性,配合微区类、有损类测试方法能够实现全尺度分析,带来新的进展突破。

1 中子衍射技术

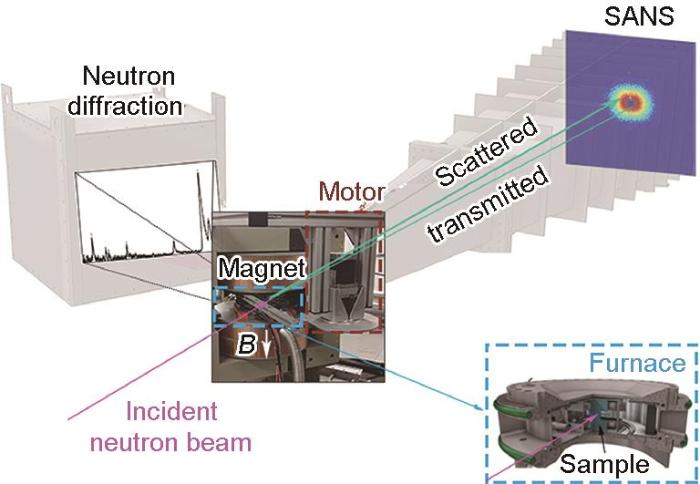

近半个多世纪以来,国际上先后建立了美国橡树岭国家实验室散裂中子源(Spallation Neutron Source,SNS)、法国劳厄-朗之万研究所(Institut Laue-Langevin,ILL)、德国高通量研究堆(Forschungs-Neutronenquelle Heinz Maier-Leibnitz,FRM II)、英国散裂中子源ISIS、日本大强度质子加速器设施(Japan Proton Accelerator Research Complex,J-PARC)、澳大利亚核科学与技术机构(Australia's Nuclear Science and Technology Organisation,ANSTO)等大型中子源,同时配套建设了各类中子衍射谱仪及原位装置,为中子衍射技术研究和应用提供了必备的实验条件[18~23],但由于中子源稀缺、机时紧张,很大程度上限制了中子衍射技术的拓展和应用。近几年,随着中国先进研究堆(China Advanced Research Reactor,CARR)、中国绵阳研究堆(China Mianyang Research Reactor,CMRR)和中国散裂中子源(Chinese Spallation Neutron Source,CSNS)三大中子源陆续建成并投入使用,我国先后建成一批功能丰富、指标先进的中子衍射谱仪装置,例如,北京先进研究堆的残余应力谱仪、中子织构谱仪,绵阳研究堆中子衍射应力分析谱仪、冷三轴谱仪、散裂中子源工程应力谱仪等[24~27]。材料科学研究专用的平台型大科学装置为中子衍射无损表征技术提供了快速发展的重要契机。2019年,作者所在团队依托CMRR启动建设了国内首台冷中子应力-织构一体化衍射谱仪“河图”,如图1所示。针对工程材料研究设计了专用的可切换双单色器、原位高/低温与力学实验平台等设备,并使用了高灵敏度3He二维位敏探测器[28,29]。其中,可切换单色器由双聚焦完美弯曲的单晶Si和高定向热解石墨(highly oriented pyrolytic graphite,HOPG)组成,根据实验需求提供高通量或高精度模式。在中子探测方面,由一维线探测器发展到大尺寸二维探测器,通过开发相应的衍射数据分析方法,使得材料织构、应力的中子衍射测试效率和精度都具有极大的提升潜力。

图1

1.1 基本原理与技术特点

中子衍射技术以Bragg定律作为物理基础,即:2dhkl sinθhkl = nλ (其中,λ为入射中子波长,dhkl 为Miller指数为hkl的晶面间距,θhkl 为衍射角,n为正整数)。不同中子源所提供的连续或脉冲中子特性决定了谱仪布局、实验效率、测量技术及其适用性以及相应的解谱方法等。通常由连续中子源筛选的单一中子波长适合角度色散类谱仪,其主要特点是每次只测量某一晶面的衍射,在大多数工程材料检测中,从单峰得到的衍射信息已经足够用于残余应力分析;基于能量色散法的飞行时间谱仪通常在脉冲中子源上,充分发挥它高效率的优势,单次测量就可以得到整套衍射信息图谱,更多用于多相材料及微应力的分析。

1.2 应变/应力分析方法

由于内应变导致晶面间距产生变化Δdhkl,对于特定的晶面(hkl),通过已知的入射中子束波长以及实验测得的衍射角2θ,即可计算出该晶面的间距dhkl。当样品无应变时,晶面间距为d0,hkl,衍射峰峰位偏移Δθ = (Δdhkl / d0,hkl )tanθ,根据衍射峰角度的变化可确定弹性应变(εhkl )[8]:

式中,θ0,hkl 和θhkl 分别为无应力样品和待测样品的衍射半角。在飞行时间(time of flight,TOF)中子衍射模式下,由于衍射角θ固定,中子飞行时间thkl ∝ sinθ × dhkl,因此,弹性应变的计算公式为:

式中,t0,hkl 为中子在无应力样品中的飞行时间。

为了计算一个既定位置上的应力张量,至少需要进行6次独立取向上应变的测量。在明确主应力方向的前提下,各向同性材料只需要测量3个主应力方向的弹性畸变,并根据Hook定律可以计算出三向应力,表示为[8]:

式中,σxx 、σyy 和σzz 分别为x、y、z正交方向的主应力;εxx 、εyy 和εzz 分别为3个主应力方向的晶格应变;

总体来说,中子衍射针对工程构件测试方面具有以下特点和优势:(1) 穿透力强,能够无损探测大多数金属厘米级纵深部位的衍射信息,并且满足反射和透射衍射几何;(2) 由入射和衍射狭缝限定的采样区域大,对粗晶材料也具有较好的织构、应力统计性;(3) 能够建立块体材料三维应变/应力统计信息,应力梯度分布信息;(4) 由于中子束准直性好,样品与光源和探测器之间距离充裕,可以集成温度、加载、磁场等原位设备,有助于材料微观力学和相变行为等微观机制相关的原位研究。

但正如实验室X射线、同步辐射高能X射线在物质内部探测方面存在局限一样,中子衍射不易获得材料近表面信息。需要指出的是,为准确计算应变,需要知道样品无应力时精确的晶面间距d0。通过采用粉末法、切片法、无规行走法或在工件无应力区进行测量等途径可以相对准确地确定d0 [33],但对于两相或多相材料,必须已知其中一相的d0,否则切片法或利用平衡条件计算d0的方法并不适用。

2 中子衍射的应用进展

中子衍射通过追踪单相、多相材料内特定晶面间距的变化,研究形变、相变过程中应力配分以及失效机制,为材料性能改良、工艺优化以及失效分析等提供理论基础与科学依据。同时,中子衍射的深穿透、体相分析优势使其可以获得工程构件加工制造、服役及失效分析中残余应力演变信息。

2.1 材料基础与前沿研究

(1) 材料微观机制研究

经过剧烈塑性变形加工后,多晶金属材料的原始晶粒可以被细化至超细晶或纳米晶尺度,显著提高材料的强度、硬度及疲劳性能。研究发现,在热-力耦合条件下疲劳载荷会诱发金属细化晶粒的异常长大,因而在温度、加载条件下超细晶金属的组织稳定性引起人们的关注。然而,温度和应力对于晶粒长大的贡献难以定量区分,其中所涉及的温度效应与应力作用机理、超细晶异常长大机制等仍未达成共识。Zhao等[39,40]通过室温/低温(-200℃)原位中子衍射实验、等温退火、拉伸及疲劳实验等方法对比研究(图2[39]),区分了高周疲劳过程中的温度效应和应力对于超细晶工业纯Ti晶粒长大的贡献及作用,揭示了该材料在不同温度及应力加载条件下的再结晶晶粒长大机理及织构演化机制。该研究结果对于优化超细晶钛合金材料的制备工艺,微观组织、性能改善方法具有指导意义。

图2

图2

ENGIN-X原位中子衍射测试疲劳实验样品示意图及结果[39]

Fig.2

Illustration and the results of the in-situ neutron diffraction measurements of the fatigue specimen in ENGIN-X[39]

(a) arrangement of the fatigue specimen in ENGIN-X for measurements along both longitudinal and transversal directions (2θ—diffraction angle)

(b) a comparison of two diffraction spectra obtained from both directions for the pre-fatigued MDF-1 showing the initial texture (MDF—multi-directional forging)

(c, d) comparisons of pre- and post-fatigued MDF-1 for longitudinal (c) and transversal (d) directions, respectively (Diffraction spectra were normalised against {100} for longitudinal and {0002} for transversal direction)

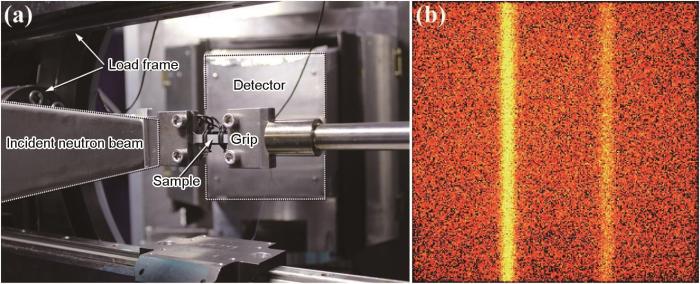

(2) 宏微观力学行为

材料构件在表面处理、成型、焊接以及服役过程中通常会受到力-热耦合作用,并产生高水平残余应力。通过多个方向不同{hkl}点阵应变的准确测量和微观力学模拟,能够为量化和评估材料宏微观性能提供重要依据。反应堆中子源为固定波长的衍射技术,通常配备一个探测器,因此需要调整探测器位置以采集不同衍射峰,时效性相对较差。而依托散裂中子源的TOF技术可以同时获得多个{hkl}的点阵畸变信息,因此更具优势。在模拟方面,研究人员发展了考虑晶体塑性变形行为的自洽(self-consistent,SC)模型以及晶体塑性有限元方法(crystal plasticity finite element method,CPFEM)进行微观行为研究。Zhang等[41,42]发展了热机械过程中宏微观残余应力演化的多尺度模拟方法,并针对金属基复合材料焊接接头的宏微观残余应力演化进行研究,预测的结果与中子衍射实验结果十分吻合。

(3) 变形机制研究

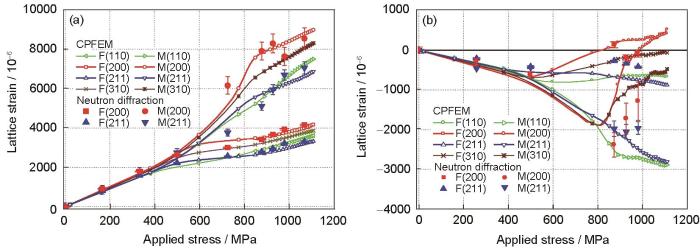

Woo等[48]利用原位中子衍射技术对DP980双相钢微观力学行为进行研究,跟踪铁素体和马氏体代表性晶格应变随宏观应力的变化。如图3[48]所示,通过双峰Gausssian拟合法对铁素体和马氏体重叠衍射峰进行分离,确定两相在形变过程中晶格应变的变化,并据此建立了晶体塑性有限元模型。图4[48]给出了轴向拉伸过程中的晶格应变随外加应力的变化曲线,模拟了两相轴向与横向的应力分配及晶体学取向行为,证明了铁素体晶体学取向严重影响剪切应变的位置,并描述了拉伸过程中铁素体靠近马氏体区域的微孔形核行为,进一步揭示其相间应变与晶粒间应变协调机制。由图4[48]可见,不同指数晶面的弹性模量不同,存在所谓的“硬取向晶粒”与“软取向晶粒”,当外加应力超过铁素体的屈服强度后,铁素体的弹性应变停止,同时渗碳体的弹性应变快速增加,结果还证实由于相间应力/应变协调,铁素体中出现显著加工硬化现象。

图3

图4

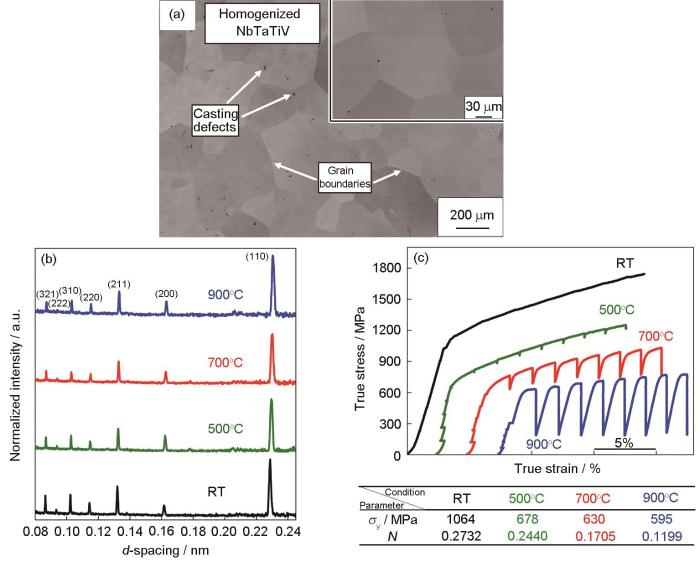

单相难熔HEA在高温下具有良好的屈服强度和抗软化能力,利用原位中子衍射实验能够获得宏微观力学参数,验证理论计算、仿真模拟实验结果。Lee等[49]通过原位中子衍射技术与理论计算方法探讨了NbTaTiV难熔HEA在室温和高温下的弹塑性变形行为,图5[49]给出了扫描电子显微镜(SEM)、常温和高温原位中子衍射测试结果。结果表明,NbTaTiV难熔HEA在室温下表现出弹性各向同性,然而随着温度的升高,各晶面衍射弹性常数(diffraction elastic constants,DEC)开始出现微小差异,表现出弹性各向异性。基于原位中子衍射实验确定的单晶弹性模量、宏观弹性模量、剪切模量、体积模量等力学参数与第一性原理、机器学习以及共振超声光谱分析结果基本一致。Pan等[52]开展梯度位错单元结构(gradient dislocation cell structure,GDS)样品的中子衍射原位拉伸实验,确定低拉伸应变(约5%)下堆垛层错的形成伴随(111)和(222)晶面的不同响应,然而在细晶样品中该现象发生在高应变(约30%)状态。结果表明,堆垛层错更易在GDS样品的初期阶段形成,为深入研究HEA强韧化机制提供了直接的证明。

图5

图5

通过SEM、中子衍射(ND)和原位高温ND实验中的真应变-应力曲线获得的均匀化NbTaTiV合金的微观结构、相特征和力学性能[49]

Fig.5

Microstructures, phase characteristics, and mechanical properties of the homogenized NbTaTiV alloy, studied by SEM, neutron diffraction (ND), and true strain-stress curves during in situ ND experiments at elevated temperatures[49]

(a) SEM-BSE image of the homogenization-treated NbTaTiV refractory high-entropy alloy (Inset shows the corresponding high magnified image)

(b) ND patterns with the peaks indexed for a bcc structure at room temperature (RT), 500oC, 700oC, and 900oC (d-spacing—interplanar spacing)

(c) true stress-strain curves recorded during the in situ compression experiment at RT, 500oC, 700oC, and 900oC with a strain rate of 1 × 10-4 s-1 (Table in Fig.5c show the yield strength (σy) and work-hardening exponent (N) of the present alloy gradually decreased from 1064 MPa (RT) to 595 MPa (900oC) and from 0.2732 (RT) to 0.1199 (900oC), respectively)

低温下HEA的变形机制十分复杂,传统的实验方法,如透射电子显微镜(TEM)受限于视场及实验环境,难以开展超低温下的HEA变形行为的研究,原位低温中子衍射实验有助于阐明HEA在不同变形阶段的变形机制。Naeem等[51]在低温环境下开展CrMnFeCoNi HEA的中子衍射实验,获得了室温、140 K以及15 K不同温度下HEA在加载过程中沿着加载方向不同晶面的衍射强度、晶格应变等重要的微观参数信息,深入研究了变形过程中取向的转变和应力分配的演化行为。如图6[51]所示,中子衍射结果表明,CrMnFeCoNi合金在降温过程中保持良好的结构稳定性,随着变形温度的降低,HEA强度和韧性同时呈现升高趋势,在动态回复作用下变形初始阶段应变硬化速率(strain-hardening rate,SHR)迅速下降,并且在15 K的超低温下具有最高的SHR,通过进一步分析晶格应变以及织构演化规律,为深入研究低温变形过程中变形机制,阐明低温下HEA的变形行为提供了理论和实验支持。

图6

图6

CrMnFeCoNi合金在低温下的晶体结构和变形行为[51]

Fig.6

Crystal structure and deformation behavior of CrMnFeCoNi alloy at low temperature[51]

(a) selected diffraction patterns at room temperature and at 15 K during deformation, showing a clean single-phase fcc structure (σu—ultimate tensile strength)

(b) true stress-strain curves at room temperature, 140 K, and 15 K (The trend of temperature fluctuations (right-hand axis) due to serrations at 15 K is also superimposed)

(c) two serrations are shown with temperature (plotted in reverse scale for better comparison) to illustrate details of serrated deformation

(d) plots of strain-hardening rate (SHR) at three temperatures (Δσ—change in true stress, Δε—change in true strain)

(e) SEM image of the fractured sample at 15 K showing the 45° wedge

(4) 取向相关应力配分机制

对于各向异性材料,晶粒取向分布演化及应力配分机制对材料的性能有重要影响[13,32]。Zhai等[53]利用中子衍射技术的织构-组分相关(texture-component dependent,TCD)测试方法开展了CuZn合金不同取向的晶间应力分配、织构演化等研究工作。结果显示,不同方向上晶格应变演化差异十分明显,在变形过程中承受拉伸应力最大的{

图7

2.2 工程构件残余应力分析

(1) 航空/航天关键构件

镍基高温合金以优良的组织稳定性、抗腐蚀性及力学性能在能源(气电、煤电、核电)、航空航天、石油化工等领域广泛应用。涡轮盘主要通过对镍基高温合金锻造而成,由于层错能低、回复困难,相比其他金属,在机加工、热处理过程中残余应力更易累积且调控难度大,同时多服役于高温高压、离心力、振动应力、热循环与高/低周疲劳等环境,导致构件尺寸精度、结构稳定性、超预期变形和疲劳开裂等问题突出。张哲维[64]在CMRR中子应力分析谱仪(residual stress neutron diffractometer,RSND)麒麟、CARR的残余应力谱仪(neutron residual stress diffractometer,RSD)上均开展了相关研究工作,对锻造态、固溶态和时效态粉末涡轮盘表面到内部的残余应力进行测量,获得了三向宏观残余应力面分布情况及演化规律,利用有限元模拟对空冷淬火应力场模拟结果进行了验证。

航空发动机叶片具有精细、复杂的空腔结构,从型芯到后处理制造全流程均会引入残余应力,并且长期服役于高温高压、交变载荷等复杂环境,导致叶片微组织损伤、叶型变化、力学性能衰减甚至疲劳断裂等。目前,国内单晶叶片残余应力检测处于起步阶段,常规有损类测试方法局限性大而不适合实际应用,原位检测难以实现,相应的控制措施更是无从下手。Wang等[65]利用原位中子衍射技术表征了航空发动机关键材料Inconel 625合金的DEC,为残余应力的仿真计算、晶体塑性模拟提供了重要的数据基础,有助于深入掌握和理解金属构件的宏观应力演化及其变形机制。Wu等[66]利用中子和X射线衍射技术研究了DZ125L合金在热机械疲劳(thermomechanical fatigue,TMF)变形后的内应力状态,对比分析了TMF过程中内应力分布、塑性变形及晶格错配的变化,发现γ基体在初始TMF循环下率先发生屈服和硬化行为,而γ'析出相相对滞后,并且随着应力的累积和显著集中产生不均匀的分布和变形。Pierret等[67]利用中子断层成像技术获得了镍基单晶高温合金叶片内部复杂的中空结构情况,为中子衍射测试时取样体积的精确定位提供依据,成功实现了叶片内部残余应变的准确测量。Seo等[68]利用中子衍射研究了固定振幅循环加载及过载条件下,不锈钢的疲劳裂纹扩展时裂纹尖端残余应力场演化,明确了残余应力对延缓疲劳裂纹扩展的作用。

(2) 深海耐压装备

钛合金具有低模量、高强度、耐蚀性好等优良性能,是航空发动机叶片/轴套/压气机盘、深海耐压结构件、生物医学支架等优选材料,并被誉为21世纪“海洋金属”。用于载人舱耐压球壳的钛合金厚板通常采用窄间隙焊接、电子束焊接等工艺组装,焊接难度高、工艺复杂。由于能量密度大、瞬时热量高、温度区间窄,在特定方向上残余应力变化剧烈,降低组织稳定性并引起局部氢聚集,对构件应力腐蚀敏感性、结构整体的服役安全造成严重的负面影响。由于强吸收、高非相干背底以及低散射能力,中子衍射在钛合金残余应力分析时衍射信号弱,测试深度和空间分辨均受到影响,通过微观组织分析、测量参数优化和数据精细处理可以获得较好的残余应力结果[69]。

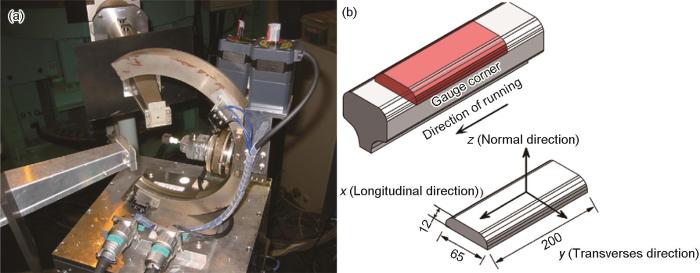

(3) 轨道交通

图8

3 基于中子衍射的高通量表征技术

材料的静态、动态行为和性能(宏观服役性能和功能属性)由其微结构单元特性所决定。代表性的微结构单元包括化学成分、组织结构、织构、界面以及缺陷等,具有多尺度(原子、纳观、微观、介观及宏观)、多维度(一维到三维)特征,并随时间和外场环境变化而演变,因而成为人们重点研究对象。传统的“尝试法”在新材料开发中周期长、成本高,使得新材料研发严重滞后产品设计的问题凸显。随着人们对材料机理认识的不断深入,先进实验方法以及计算机分析技术也逐渐成熟,为高通量合成制备、快速测试与分析处理奠定了基础。

先进材料的发展与创新不仅是现代制造业的核心要素,也体现着一个国家科技发展的整体水平,近年来,“材料基因工程”引起国内外的高度重视与大力支持[73]。2011年美国、欧盟相继启动以大数据作为支撑的“材料基因组计划”,通过融合高通量计算/高通量实验/专用数据库,快速优化材料组分/工艺/性能,推动材料研究从传统试错模式向低成本、快速响应的高通量研制新模式的转变。在材料基因工程支持下,美国通用电气公司(General Electric Company,GE)航空航天部门极大地缩短了René N6单晶、René 88DT粉末合金等材料的研制周期和成本,进一步证明了该项目的重要性和必要性[74]。我国在2016年正式启动“材料基因工程关键技术与支撑平台”重点专项,建立以高通量材料设计、制备、表征以及专用数据库为核心的示范平台,研发高通量计算方法与关键实验技术,在能源材料、生物医用材料、稀土功能材料、催化材料和特种合金等支撑高端制造业和高新技术发展的典型材料上开展示范应用,实现新材料研发周期与成本“双减半”目标[73,75]。

高通量表征技术最初以新材料的开发为目标,聚焦于微小样品的原位、快速分析并表现出高时空分辨的特征和需求。目前,高通量微区光学、磁学、热力学及电学等相关技术逐渐被开发应用,缺乏宏观尺度下的测试技术。由于“尺寸效应”的影响,从具有梯度结构的合金中获得的微观组织和微区性能往往与大块合金存在差异,常规的微区类实验技术方法不能完全适用,开发制备宏观块体材料的高通量实验技术是解决这一问题的重要途径[75]。中子衍射技术能够无损、定量探测材料深部三维应力/应变、晶体学织构、缺陷等信息,使其在加工制造以及服役状态工程构件的高通量表征中具有极大的开发潜力,可为部件的服役评价提供科学依据。例如,通过中子小角散射(small angle neutron scattering,SANS)与中子衍射技术的同步测试,能同时对材料中的相变动力学和析出动力学进行分析。Ioannidou等[76]联合这2种技术研究了微合金钢在热处理过程中VC析出相与奥氏体/铁素体相变的作用机制(图9[76])。

图9

4 总结与展望

长期以来,材料表征技术呈现从有损到无损、从静态到动态、从宏观到微观的发展趋势。中子衍射作为依托高通量中子源的先进实验技术,其功能性已经在复杂材料体系机理研究、多场耦合等科学问题与工程构件工艺优化、服役评价等研究中充分验证,以中子源、同步辐射先进光源为代表的大科学装置使得跨尺度、多维度物质分析成为可能。多年来,我国在中子源大科学装置以及各类谱仪的设计和使用方面积累了丰富经验,同时也逐年加大在这些领域的投入和支持,中子机时紧张的问题得到缓解,配套设施、资源配置也在不断丰富和完善。

“材料高通量实验”在未来材料研究中占据重要地位,庞大的数据量是实现这一目标的重要前提。常规实验技术在原子尺度、微纳尺度上搜集数据信息,由于面临诸多挑战,宏观尺度的高通量表征技术和方法很少被提及。国内研究学者已前瞻性地提出结合大科学装置发展原位、实时、高通量制备与表征技术的要求和基本思路,为中子和同步辐射等先进光源实验技术发展提供了新方向。对于中子衍射而言,其充裕的样品空间除了便于开展原位实验外,与其他测试技术(例如瞬发伽玛活化分析、中子照相等)集成,同步开展多参量测试是获取关键数据、实现高通量表征行之有效的办法。

随着高性能中子准直、聚焦及探测器件的升级和发展,中子衍射技术测试精度、分辨率及测试效率得以大幅提升,也使得诸如中子衍射应力-织构同步分析技术,中子衍射-中子照相、中子衍射-瞬发伽玛等先进的同步测量技术的实现成为可能,从而满足如航空发动机新材料研发、反应堆容器服役和延寿等领域对材料成分-组织结构-性能高通量一体化表征的迫切需求。如何高效、可靠地实现这些功能,必然依赖于相关实验数据分析、算法的开发和优化,这些工作势必会对中子衍射无损表征方法理论基础和实验技术的发展起到重要的推动作用。相比其他方法,中子衍射的实验效率仍然相对较低,为数不多的国内或国际研究机构或中心难以形成丰富的数据库,综合反应堆中子源、散裂中子源以及同步辐射等机构的原始数据和实验技术,有望建成一定规模的数据库,为高通量、跨尺度材料表征发挥大科学装置的优势与作用。

参考文献

Progress in materials genome engineering in China

[J].Materials genome engineering (MGE) is a frontier technology in the field of material science and engineering, which is well capable to revolutionize the research and development (R&D) mode of new materials, greatly improve the R&D efficiency, shorten the R&D time, and reduce the cost. This paper reviews the progress of MGE in China from the aspects of the fundamental theory and methods, key technology and equipment, the R&D of new materials and related engineering application, talents training, formation and promotion of new concept of material genetic engineering. The paper also looks forward to the future development of MGE in China.

中国材料基因工程研究进展

[J].材料基因工程是材料领域的颠覆性前沿技术,将对材料研发模式产生革命性的变革,全面加速材料从设计到工程化应用的进程,大幅度提升新材料的研发效率,缩短研发周期,降低研发成本,促进工程化应用。本文从基础理论与方法、关键技术与装备、新材料研发与工程化应用、人才培养以及材料基因工程新理念的形成和推广等方面,综述了中国材料基因工程的研究进展,并提出了未来发展方向建议。

Mesoscopic and multiscale modelling in materials

[J].The concept of multiscale modelling has emerged over the last few decades to describe procedures that seek to simulate continuum-scale behaviour using information gleaned from computational models of finer scales in the system, rather than resorting to empirical constitutive models. A large number of such methods have been developed, taking a range of approaches to bridging across multiple length and time scales. Here we introduce some of the key concepts of multiscale modelling and present a sampling of methods from across several categories of models, including techniques developed in recent years that integrate new fields such as machine learning and material design.

Multi-dimensional multi-scale and high-flux characterization techniques for advanced materials

[J].

先进材料多维多尺度高通量表征技术

[J].

Control and characterization of individual grains and grain boundaries in graphene grown by chemical vapour deposition

[J].The strong interest in graphene has motivated the scalable production of high-quality graphene and graphene devices. As the large-scale graphene films synthesized so far are typically polycrystalline, it is important to characterize and control grain boundaries, generally believed to degrade graphene quality. Here we study single-crystal graphene grains synthesized by ambient chemical vapour deposition on polycrystalline Cu, and show how individual boundaries between coalescing grains affect graphene's electronic properties. The graphene grains show no definite epitaxial relationship with the Cu substrate, and can cross Cu grain boundaries. The edges of these grains are found to be predominantly parallel to zigzag directions. We show that grain boundaries give a significant Raman 'D' peak, impede electrical transport, and induce prominent weak localization indicative of intervalley scattering in graphene. Finally, we demonstrate an approach using pre-patterned growth seeds to control graphene nucleation, opening a route towards scalable fabrication of single-crystal graphene devices without grain boundaries.© 2011 Macmillan Publishers Limited. All rights reserved

Residual stresses in additively manufactured AlSi10Mg: Raman spectroscopy and X-ray diffraction analysis

[J].

Measurement of plastic strain of polycrystalline material by electron backscatter diffraction

[J].

Three-dimensional X-ray diffraction technique for metals science

[J].

三维X射线衍射技术在金属材料研究中的应用

[J].

Residual stress measurements by means of neutron diffraction

[J].

High-energy synchrotron X-ray diffraction and its application to in situ structural phase-transition studies in complex sample environments

[J].

An in situ high-energy X-ray diffraction study of micromechanical behavior of multiple phases in advanced high-strength steels

[J].

Formation of deformation textures in face-centered-cubic materials studied by in-situ high-energy X-ray diffraction and self-consistent model

[J].

Research progress of high-throughput material synthesis and characterization

[J].

材料高通量制备与表征技术研究进展

[J].

Research progress on multi-dimensional and multi-scale high-throughput characterization for advanced materials

[J].Multi-dimensional and multi-scale high-throughput characterization can effectively improve the development efficiency and significantly accelerate the industrialization process of advanced materials, which also serves as a scientific evidence for the reliable in-service assessment and entire lifetime management of engineering materials and structures. Firstly introduces the research background and fundamental concept of the multi-dimensional and multi-scale high-throughput characterization technology. The high-throughput sample preparation, multi-dimensional and multi-scale correlation tomography, in-situ high-throughput characterization technology are then summarized systematically. In addition, both current technological applications and limitations of the multi-dimensional and multi-scale high-throughput characterization technology are discussed in details. Finally, the technological challenges and future developing directions to the multi-dimensional and multi-scale high-throughput characterization technology are given to pursue the correlation between these problems and service performance of advanced materials and structures particularly subjected to extremely complex loading and environment conditions. This paper attempts to provide a basic reference to establish the quantitative relationship between the microstructural features and macro in-service performance, revealing the damage mechanism and failure mode of engineering components and promoting the development and application of advanced materials.

先进材料多维多尺度高通量表征研究进展

[J].先进材料的多维多尺度高通量表征可显著提高新材料研发效率,加快新材料应用进程,为材料及结构的可靠性服役和全寿命管理提供科学依据。介绍材料多维多尺度高通量表征技术的背景与内涵,然后对高通量样品制备与表征、多维多尺度关联成像、高通量原位表征等技术的发展进行了系统介绍,讨论多维多尺度高通量表征技术的前沿应用和技术局限性,最后对其未来发展趋势及面临的挑战进行了解析,指出这些技术挑战直接关系到高通量表征技术在先进材料及结构服役行为研究中的应用,展望多维多尺度高通量表征的若干发展方向,从而为建立材料微结构和服役性能的映射关系、跨尺度揭示工程部件的伤损机理和失效模式、推进先进材料的研发与应用进程提供参考。

Residual stresses in turning: Part I: influence of process parameters

[J].

Critical review on the assessment of fatigue and fracture in composite materials and structures

[J].

Operando measurement of lattice strain in internal combustion engine components by neutron diffraction

[J].Engineering neutron diffraction can nondestructively and noninvasively probe stress, strain, temperature, and phase evolutions deep within bulk materials. In this work, we demonstrate operando lattice strain measurement of internal combustion engine components by neutron diffraction. A modified commercial generator engine was mounted in the VULCAN diffractometer at the Spallation Neutron Source, and the lattice strains in both the cylinder block and head were measured under static nonfiring conditions as well as steady state and cyclic transient operation. The dynamic temporal response of the lattice strain change during transient operation was resolved in two locations by asynchronous stroboscopic neutron diffraction. We demonstrated that operando neutron measurements can allow for understanding of how materials behave throughout operational engineering devices. This study opens a pathway for the industrial and academic communities to better understand the complexities of material behavior during the operation of internal combustion engines and other real-scale devices and systems and to leverage techniques developed here for future investigations of numerous new platforms and alloys.Copyright © 2020 the Author(s). Published by PNAS.

The D20 instrument at the ILL: A versatile high-intensity two-axis neutron diffractometer

[J].

High-resolution neutron powder diffractometer SPODI at research reactor FRM II

[J].

In-situ neutron diffraction studies of various metals on Engin-X at ISIS

[J].

KOWARI-OPAL's new stress diffractometer for the engineering community: Capabilities and first results

[J].

IBARAKI materials design diffractometer (iMATERIA)-Versatile neutron diffractometer at J-PARC

[J].

Neutron diffractometer RSND for residual stress analysis at CAEP

[J]

Current status and future prospect of neutron facilities at China advanced research reactor

[J].

中国先进研究堆中子科学平台发展现状及展望

[J].

Applications of the China spallation neutron source

[J].

中国散裂中子源的多学科应用

[J].

Novel engineering materials diffractometer fabricated at the China Spallation Neutron Source

[J].

Design and performance of the high-resolution stress and texture neutron diffractometer HETU

[J].

HETU: A new high-resolution stress and texture neutron diffractometer at China Mianyang Research Reactor

[J].

The use of time-of-flight neutron diffraction to study grain interaction stresses

[J].

A novel method for constructing the mean field of grain-orientation-dependent residual stress

[J].

Investigation of reference samples for residual strain measurements in a welded specimen by neutron and synchrotron X-ray diffraction

[J].

In situ neutron diffraction during tensile deformation of a ferrite-cementite steel

[J].

Interactions between the phase stress and the grain-orientation-dependent stress in duplex stainless steel during deformation

[J].

Phase-stress partition and stress-induced martensitic transformation in NbTi/NiTi nanocomposite

[J].

A transforming metal nanocomposite with large elastic strain, low modulus, and high strength

[J].Freestanding nanowires have ultrahigh elastic strain limits (4 to 7%) and yield strengths, but exploiting their intrinsic mechanical properties in bulk composites has proven to be difficult. We exploited the intrinsic mechanical properties of nanowires in a phase-transforming matrix based on the concept of elastic and transformation strain matching. By engineering the microstructure and residual stress to couple the true elasticity of Nb nanowires with the pseudoelasticity of a NiTi shape-memory alloy, we developed an in situ composite that possesses a large quasi-linear elastic strain of over 6%, a low Young's modulus of ~28 gigapascals, and a high yield strength of ~1.65 gigapascals. Our elastic strain-matching approach allows the exceptional mechanical properties of nanowires to be exploited in bulk materials.

Structural-disorder and its effect on mechanical properties in single-phase TaNbHfZr high-entropy alloy

[J].

High-cycle-fatigue induced continuous grain growth in ultrafine-grained titanium

[J].The cyclic deformation behaviour and microstructural stability of severe plastic deformation processed bulk nanostructured (ultrafine-grained, UFG) commercially pure cp-Ti were investigated by using in situ neutron diffraction combined with R = -1 high-cycle-fatigue (HCF) loading at room and cryogenic temperatures. The UFG microstructure was created by equal channel angular pressing (ECAP) and multi-direction forging (MDF). A considerable continuous grain growth was revealed by neutron diffraction for MDF cp-Ti fatigued at 25 degrees C, as opposed to that at -200 degrees C. The same HCF fatigue loading at 25 degrees C only caused very limited grain growth for ECAP cp-Ti. Transmission electron microscopy confirmed the grain growth. Further confirmation of the room-temperature HCF fatigue-induced grain growth was obtained by transmission Kikuchi diffraction based analysis. Novel insights into fatigue induced grain growth mechanism in UFG cp-Ti are thus provided: (i) the thermally activated process plays an important role in grain growth during the room-temperature HCF fatigue; (ii) Continuous dynamic recrystallisation is responsible for the grain growth and dislocation slip or twinning is not essential to trigger such a grain growth; (iii) the anisotropic grain growth behaviour in {0002} grain family can be reconciled by accepting that these grains accumulated highly stored energy during initial severe plastic deformation and the subsequent recrystallisation nucleation occurred at these highly deformed regions. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

Microstructure and texture evolution in a post-dynamic recrystallized titanium during annealing, monotonic and cyclic loading

[J].

Enhanced multiscale modeling of macroscopic and microscopic residual stresses evolution during multi-thermo-mechanical processes

[J].

Effects of welding speed on the multiscale residual stresses in friction stir welded metal matrix composites

[J].The effects of welding speed on the macroscopic and microscopic residual stresses (RSes) in friction stir welded 17 vol.% SiCp/2009Al-T4 composite plates were studied via neutron diffraction and an improved decoupled hierarchical multiscale modeling methods. Measurements showed that the macroscopic and total RSes had the largest variations in the longitudinal direction (LD). Increasing the welding speed led to higher values of measured LD macroscopic and total RSes in the matrix. The welding speed also significantly influenced the distributions and magnitudes of the microscopic RSes. The RSes were predicted via an improved hierarchical multiscale model, which includes a constant coefficient of friction based thermal model. The RSes in the composite plates before friction stir welding (FSW) were computed and then set as the initial states of the FSW process during modeling. This improved decoupled multiscale model provided improved predictions of the temperature and RSes compared with our previous model.

Stress and strain partitioning of ferrite and martensite during deformation

[J].

In-situ residual stress analysis during annealing treatments using neutron diffraction in combination with a novel furnace design

[J].

Phase-specific deformation behavior of a NiAl-Cr(Mo) lamellar composite under thermal and mechanical loads

[J].

Multiscale modeling of macroscopic and microscopic residual stresses in metal matrix composites using 3D realistic digital microstructure models

[J].

In situ neutron diffraction study of a new type of stress-induced confined martensitic transformation in Fe22Co20Ni19Cr20Mn12Al7 high-entropy alloy

[J].

Stress-strain relationship between ferrite and martensite in a dual-phase steel studied by in situ neutron diffraction and crystal plasticity theories

[J].

Temperature dependence of elastic and plastic deformation behavior of a refractory high-entropy alloy

[J].

Mechanical properties and impact energy release characteristics of Al0.5NbZrTi1.5Ta0.8Ce0.85 high-entropy alloy

[J].

Cooperative deformation in high-entropy alloys at ultralow temperatures

[J].

Gradient cell-structured high-entropy alloy with exceptional strength and ductility

[J].

Measuring texture-component-dependent stress of CuZn39Pb2 by neutron diffraction

[J].

Microscopic stresses in carbon nanotube reinforced aluminum matrix composites determined by in-situ neutron diffraction

[J].One of the most desired strengthening mechanisms in the carbon nanotube reinforced aluminum matrix composites (CNT/Al) composites is the load transfer strengthening mechanism (LTSM). However, a fundamental issue concerning the LTSM is that quantitative measurements of load partitioning in these composites during loading are very limited. In this study, in-situ neutron diffraction study on the tensile deformation of the 3 vol.% CNT/2009Al composite and the unreinforced 2009Al alloy was conducted. The {311} and {220} diffraction elastic constants (DECs) of the 2009Al alloy were determined. Using those DECs the average stress in the 2009Al matrix of the composite was calculated. Then the average stress in the CNTs was separated by using the stress equilibrium condition. Computational homogenization models were also applied to explain the stress evolution in each phase. Predicted results agree with experimental data. In the present case, the average stress in the CNTs reaches 1630 MPa at the yield strength of the composite based on linear regression of the measured data, which leads to an increment of yield strength by about 37 MPa. As the result of this work, an approach to quantify load partitioning in the CNTs is developed for the CNT/Al composites, which can be applied to optimize the mechanical properties of the composites.

Role of residual stresses induced by industrial fabrication on stress corrosion cracking susceptibility of austenitic stainless steel

[J].

On the exceptional stress corrosion cracking susceptibility of selective laser melted 316L stainless steel under the individual effect of surface residual stresses

[J].

Effect of cutting parameters in the surface residual stresses generated by turning in AISI 4340 steel

[J].

The role of residual stress and heat affected zone properties on fatigue crack propagation in friction stir welded 2024-T351 aluminium joints

[J].

Residual stress distributions and their influence on fatigue lifetimes

[J].

Recent progress of residual stress measurement methods: A review

[J].

Residual stress measurement of titanium casting alloy by neutron diffraction

[J].

Neutron diffraction residual stress measurements in a 316L stainless steel bead-on-plate weld specimen

[J].

Study on the evolution of three-dimensional residual stress field in turbine discs by using neutron/X-ray diffraction and finite element method

[D].

基于中子/X射线衍射与有限元法的涡轮盘模拟件三维残余应力场演变研究

[D].

Diffraction and single-crystal elastic constants of Inconel 625 at room and elevated temperatures determined by neutron diffraction

[J].

Neutron and X-Ray diffraction study of internal stress in thermomechanically fatigued single-crystal superalloy

[J].

Combining neutron diffraction and imaging for residual strain measurements in a single crystal turbine blade

[J].

Neutron diffraction residual stress analysis during fatigue crack growth retardation of stainless steel

[J].

Multiscale residual stress evaluation of engineering materials/components based on neutron and synchrotron radiation technology

[J].Multiscale residual stress exists throughout the manufacturing process of engineering components, from design and production to processing and servicing. This stress can impact the machining accuracy, structural load capacity, and fatigue lifespan of these components. Therefore, accurate measurement and regulation of residual stress are critical for ensuring the longevity and reliability of engineering components. However, precise characterization of residual stress is challenging owing to its multilevel and cross-scale distribution traits and dynamic evolution under various conditions, such as temperature and load. Compared with laboratory X-ray measurement methods, neutron diffraction (ND), synchrotron-based high-energy X-ray diffraction (HE-XRD), and synchrotron-based X-ray microbeam diffraction (μ-XRD) techniques offer increased penetration depth and better time and spatial resolutions. In addition, the ability to attach environmental devices enables nondestructive and accurate in situ characterization of three types of residual stresses: macroscopic residual stress, intergranular or interphase microscopic stress, and intragranular ultramicroscopic stress. ND is currently the only nondestructive method capable of accurately measuring three-dimensional (3D) stress at centimeter-level depths within engineering components. HE-XRD, due to its high flux, excellent collimation, and millimeter-level penetration depth for metals, can be utilized for in situ studies of intergranular and interphase stress evolution and partitioning during deformation. The μ-XRD employs a submicron focused beam and differential aperture technology to analyze depth information of a sample. By conducting point-by-point scanning, it can capture 3D distribution of microscopic stress inside a single grain. Furthermore, our group has developed a novel method and device for depth stress characterization based on differential aperture technology under synchrotron-based high-energy monochromatic X-ray transmission geometry, and can measure stress gradients with high precision from the surface to the interior of engineering materials at millimeter-level depths. This study presents the measurement principles, application ranges, and applications of the above-mentioned multiscale stress characterization technologies based on the neutron/synchrotron facilities as well as envisaging the future development of related technologies.

基于中子与同步辐射技术的工程材料/部件多尺度残余应力评价

[J].多尺度残余应力贯穿于工程部件设计、生产、加工和服役的全生命周期,对工程部件的长寿命可靠服役具有重要意义。残余应力具有多层次、跨尺度的分布特征,在温度、载荷等服役环境作用下发生动态演化,给精确表征带来了很大困难。相较于传统实验室X射线残余应力测量方法,中子衍射、同步辐射高能X射线衍射和同步辐射微束衍射技术在穿透深度、时间分辨率、空间分辨率、环境装置等方面具有显著优势,能够实现宏观残余应力、晶间/相间微观应力、晶内超微观应力3类残余应力的原位无损精确表征。本文详细介绍了上述基于中子/同步辐射大科学装置的多尺度应力表征技术的测量原理、应用范围和典型应用案例,并对相关技术的发展进行了展望。

Measurement of residual stresses in rails by neutron diffraction

[J]

Gradient residual strain measurement procedure in surface impacted railway steel axles by using neutron scattering

[J].

Triaxial residual strains in a railway rail measured by neutron diffraction

[J].

High-throughput experimental tools for the materials genome initiative

[J].

材料基因组计划中的高通量实验方法

[J].

Requirements of microstructure and risidual stress evaluation of aeronautical materials for neutron scattering and synchrotron radiation techniques

[J].

航空材料组织与残余应力评价对中子散射与同步辐射技术的需求

[J].

Progress in high-throughput materials synthesis and characterization

[J].Over the last 40 years, high throughput experimentation has been demonstrated to be an effective approach to generate huge amount of material data in a short period of time, and it is now considered a key element of Materials Genome Initiative (MGI) to fulfill its promise to deliver materials of emerging importance with much faster paces and lower costs. In this article, the briefly history for high throughput materials synthesis and characterization is recalled. A series of representative techniques are reviewed, their limitations are identified, and the challenges and future trends are analyzed. In perspective, a facility consisting of <em>in-situ</em> real time materials processing, characterization and analysis based on synchrotron light sources or spallation neutron sources, as well as the original position statistic reflecting mapping technology for non-uniform materials are likely to play important role in the future generation high throughput material experimentation.

材料的高通量制备与表征技术

[J].经过40 年的发展,材料高通量制备与表征技术已取得了较大的进展,并被证明可有效地加速材料研发-应用进程,因此被列为材料基因组计划的三大技术要素之一。本文简要回顾材料高通量实验技术的发展历程,阐述高通量实验在材料基因组技术中的地位与作用,系统介绍一系列有代表性的高通量制备与表征技术,并指出一些高通量实验方法的应用局限。对未来面临的挑战与发展趋势进行了分析展望,重点介绍基于同步辐射、散裂中子源等大科学装置以及基于材料非均匀性本质的原位统计映射表征解析等发展新一代材料原位实时高通量制备、表征与分析技术的新思路,以期为中国材料基因组技术的跨越式发展提供参考。

Phase-transformation and precipitation kinetics in vanadium micro-alloyed steels by in-situ, simultaneous neutron diffraction and SANS

[J].