Mg及其合金具有密度低、比强度和比刚度高、弹性模量大、抗震性能好、生物相容性好和储氢容量大等优秀的物理化学性能,被广泛应用于航空航天和交通运输等领域[1~4]。然而,由于镁合金具有hcp结构和较少的滑移系,导致其强度和塑性较差,阻碍了镁合金在结构部件上的应用[5]。研究[6~11]表明,预制{10

然而,在上述研究中,采用的AZ31镁合金板材多具有常见的基面织构特征且预变形多是以平面压缩的方式完成。事实上,这种平面压缩预变形的方法对实验设备有较高要求,且在预变形的过程中容易使板材产生翘曲进而导致材料失稳[7,9]。文献调研表明,目前对于非基面织构镁合金板材的预变形工艺及后续塑性变形行为研究还未见报道。Tu等[12]通过等径角轧制-连续弯曲-退火(equal channel angular rolling and continuous bending process with subsequent annealing,ECAR-CB-A)工艺,成功将双峰分离非基面织构引入AZ31镁合金板材,将其Erichsen值显著提升至7.4 mm,大幅度提升了板材的室温成形性能。另外,Zhang等[13]的研究表明,对这种双峰分离非基面织构AZ31镁合金板材进行道次压下量5%的深冷轧制变形,可以在不明显提升板材位错密度的同时,成功引入面积分数为8.4%的{10

鉴于此,本工作通过对双峰分离非基面织构AZ31镁合金板材施加小压下量的深冷轧制预变形,随后对其进行室温单轴拉伸实验,配合光学显微(OM)和电子背散射衍射(EBSD)表征,以阐明预变形对双峰分离非基面织构AZ31镁合金板材力学行为的影响及其与微观组织演化间的内在关联。

1 实验方法

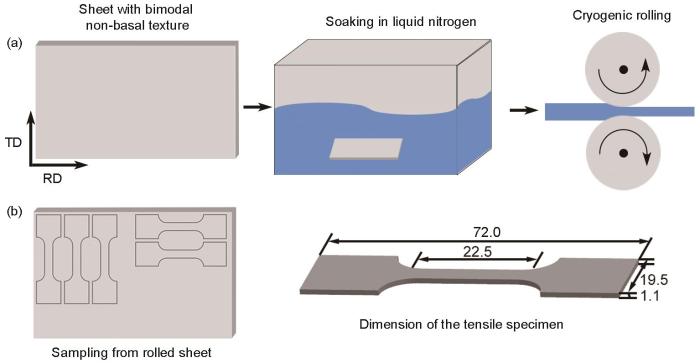

采用ECAR-CB-A工艺制备具有双峰分离非基面织构的AZ31镁合金板材,相关工艺流程及工艺参数详见文献[12]。随后对板材进行电火花加工(electro-discharge machining,EDM)以得到尺寸为80 mm (RD) × 40 mm (TD) × 1.1 mm (法向,normal direction,ND)的矩形试样。在深冷轧制变形前,将矩形试样放置在充满液氮的容器中10 min以使其温度均匀,取出后立即进行轧制实验,道次减薄率为5%,轧辊转速为400 mm/s,轧机辊径为170 mm,相关过程如图1a所示。对深冷轧制后的试样再次进行EDM加工,分别沿RD和TD制得狗骨头状的拉伸试样(分别命名为RD试样和TD试样),试样尺寸如图1b所示,然后在SANS试验机上以0.001 s-1的恒定应变率进行室温单轴拉伸实验。为保证力学性能测试的准确性,上述实验各重复3次。另外,将RD试样分别拉伸至变形程度3%和6%,将TD试样分别拉伸至变形程度6%和12%,以观察相应条件下的微观组织演化。

图1

图1

实验流程及拉伸试样取样方式和相应尺寸示意图

Fig.1

Schematics of experiment procedure (a), and the sampling method and the corresponding dimension of manufactured tensile sample (b) (TD—transverse direction, RD—rolling direction. unit: mm)

采用DMI5000M型OM设备和装有HKL-Nordlys MAX探测器(EBSD探头)的NOVA 400场发射扫描电子显微镜(SEM)表征初始板材和变形板材的微观组织演化。上述关于OM和EBSD试样的制备方法详见文献[13]。另外在本工作中,EBSD试样的扫描步长为0.8 μm,观察面为RD × TD面,EBSD后处理软件为Channel 5。

2 实验结果

2.1 初始微观组织和织构

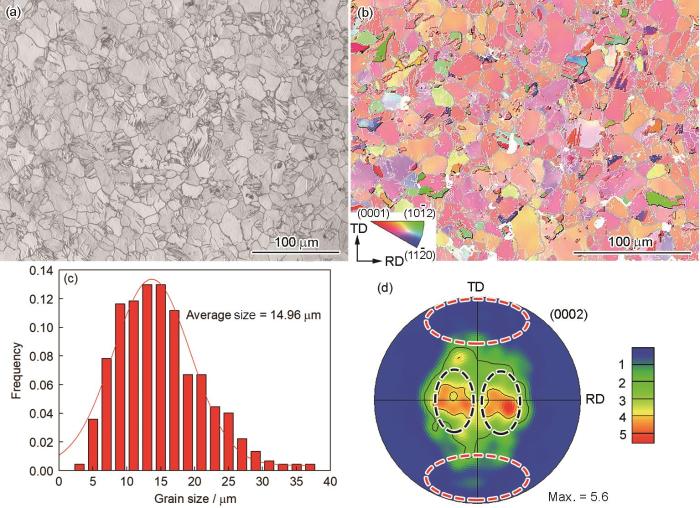

图2为深冷轧制预变形试样的微观组织和织构。由OM像(图2a)和反极图(IPF) (图2b)可以看出,该试样具有典型的等轴晶结构特征,且部分晶粒中出现了相互平行或交叉的{10

图2

图2

深冷轧制5%后AZ31镁合金板材的初始微观组织和织构

Fig.2

Initial microstructure and texture of AZ31 Mg alloy sheet after 5% cryogenic rolling

(a) OM image (b) inverse pole figure (IPF) (c) statistic analysis of grain size

(d) (0002) pole figure (PF) (The black dotted ellipses represent the non-basal bimodal texture with the basal poles tilting about ±24° away from normal direction (ND) to RD, and the red dotted ellipses represent the TD texture components)

2.2 单轴拉伸力学行为

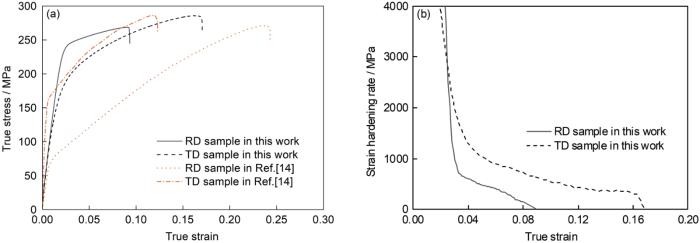

图3a为深冷轧制预变形双峰分离非基面织构试样分别沿RD和TD拉伸的真应力-真应变曲线,为了对比,将未经深冷轧制预变形的双峰分离非基面织构试样的力学曲线[14]也显示在图中。可以看出,经过5%深冷轧制预变形后,RD试样的初始屈服强度(225 MPa)明显高于TD试样(140 MPa)。未预变形试样沿RD和TD拉伸的初始屈服强度分别为72和150 MPa[14]。可见,相较于未预变形试样,本工作中预变形试样沿RD拉伸的初始屈服强度有明显提升(212.5%),而沿TD拉伸的初始屈服强度则有轻微下降(6.7%)。就断裂延伸率(fracture elongation,FE)而言,深冷轧制预变形RD试样的FE (9.3%)显著低于TD试样的FE (17.1%),而未预变形试样则刚好相反(未预变形RD和TD试样的FE分别为21.6%和12.4%[14])。相较于未预变形试样,本工作中预变形试样在RD上的FE有明显下降(56.9%),而在TD上的FE则有明显提高(37.9%)。基于真应力-真应变曲线计算得到的加工硬化率曲线如图3b所示。可见,预变形试样沿RD拉伸过程中表现为两阶段硬化,而沿TD拉伸过程中表现为三阶段硬化。这表明,RD和TD试样在室温单轴拉伸过程中的变形机制存在显著差异。

图3

图3

RD和TD试样的真应力-真应变曲线和加工硬化曲线

Fig.3

True stress-strain curves (a) and strain hardening rate curves (b) of RD and TD samples

2.3 单轴拉伸过程中的微观组织和织构演化

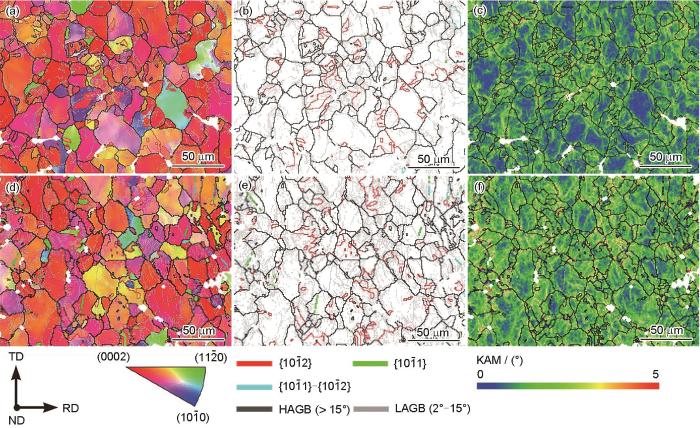

图4和5分别为RD和TD试样在室温单轴拉伸不同变形程度下的EBSD分析,包括IPF、晶界(GB)图和局部取向差(kernel average misorientation,KAM)图。在GB图中,考虑识别镁合金中常见的孪晶类型,即{10

图4

图4

RD试样单轴拉伸3%和6%条件下的EBSD分析

Fig.4

EBSD analyses of RD samples deformed to the deformation 3% (a-c) and 6% (d-f) (HAGB—high angle grain boundary, LAGB—low angle grain boundary) (a, d) IPFs (b, e) grain boundary (GB) maps (c, f) kernel average misorientation (KAM) maps

图5

图5

TD试样单轴拉伸6%和12%条件下的EBSD分析

Fig.5

EBSD analyses of TD samples deformed to the deformation 6% (a-c) and 12% (d-f) (a, d) IPFs (b, e) GB maps (c, f) KAM maps

从图4a、b和图5a、b可以看出,RD和TD试样分别在经历3%和6%拉伸变形后,晶粒中出现了大量的LAGB,同时出现的孪晶主要为{10

3 分析讨论

3.1 初始屈服强度的差异

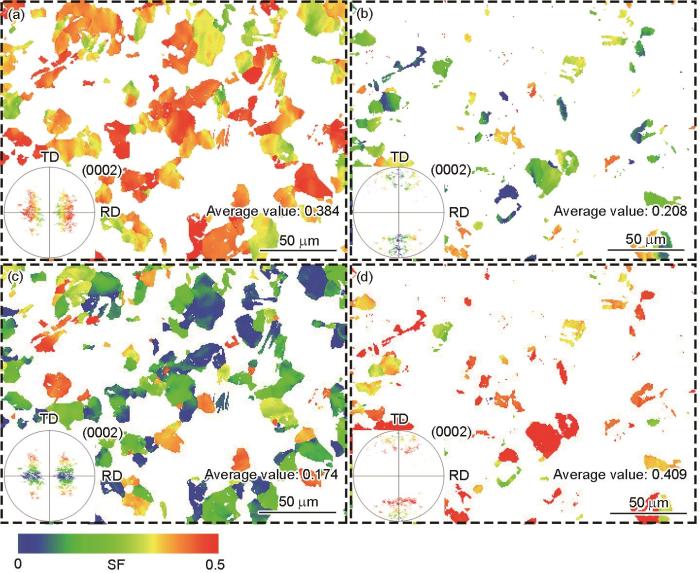

另外,RD试样的初始屈服强度(225 MPa)明显高于TD试样的初始屈服强度(140 MPa)。研究[23,24]表明,初始织构会显著影响镁合金板材室温塑性变形过程中的变形机制激活,从而在变形过程发生不同的组织演化和织构演化,最终影响镁合金板材的室温塑性变形行为。在本工作中,经过深冷轧制预变形的板材,其主要织构特征包括基极由ND向RD倾斜约24°的双峰分离非基面织构组分(图2d中黑色线框)和TD织构(晶粒c轴//TD)组分(图2d中红色线框)。同时,Chen等[17]和Song等[25]的研究表明,由于具有最低的临界分切应力(critical revolved shear stress,CRSS),基面<a>滑移将在镁合金板材室温塑性变形的初始阶段即大量激活,进而决定初始屈服应力的大小。因此,本工作将具有上述2种织构组分特征的晶粒(亦包括预变形引入的{10

图6

图6

预变形板材沿RD和TD单轴拉伸条件下相应织构组分晶粒的Schmid因子(SF)分布

Fig.6

Schmid factor (SF) distributions of basal <a> slip in chosen grains with non-basal bimodal (a, c) and TD (b, d) texture characteristics (The inserted (0002) pole figures show the corresponding texture characteristics of selected regions) (a, b) loading along RD (c, d) loading along TD

值得注意的是,相较于未预变形试样,本工作中预变形试样沿TD拉伸的初始屈服强度有轻微下降(6.7%)。这主要是由于TD试样中TD织构组分所对应晶粒的平均基面<a>滑移SF较大(0.409),基面<a>滑移易于在室温单轴拉伸过程中激活,基本抵消了预变形引入的大量{10

3.2 断裂延伸率的差异

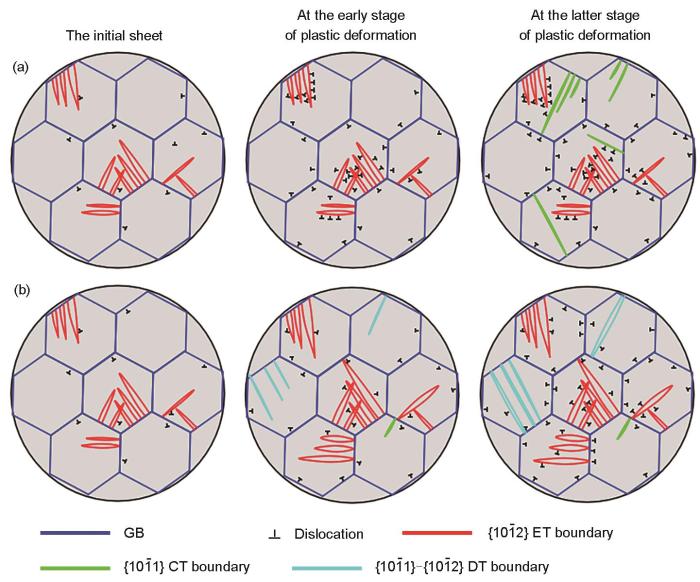

图7

图7

RD和TD试样室温单轴拉伸过程中的变形机制示意图

Fig.7

Schematics of involved deformation mechanisms of RD (a) and TD (b) samples during uniaxial tension deformation at room temperature (ET—extension twin, CT—compression twin, DT—double twin)

针对TD试样而言,双峰分离非基面织构组分所对应的晶粒在单轴拉伸条件下的平均基面<a>滑移SF仅为0.174。可见,基面<a>滑移在塑性变形初始阶段起在相关晶粒中的激活水平将低于RD试样,这亦会降低深冷预变形引入的{10

4 结论

(1) 深冷轧制预变形试样沿RD单轴拉伸条件下的初始屈服强度和断裂延伸率分别为225 MPa和9.3%,较未预变形试样的初始屈服强度和断裂延伸率分别提升212.5%和降低56.9%。深冷轧制预变形试样沿TD单轴拉伸条件下的初始屈服强度和断裂延伸率分别为140 MPa和17.1%,较未预变形试样的初始屈服强度和断裂延伸率分别降低6.7%和提升37.9%。

(2) 单道次5%减薄率的深冷轧制变形可以在双峰分离非基面AZ31镁合金板材中引入面积分数为8.9%的{10

(3) RD试样室温单轴拉伸过程中的变形机制可归纳为:基面<a>滑移在双峰分离非基面织构组分所对应的晶粒中大量激活→{10

参考文献

The texture and its optimization in magnesium alloy

[J].he crystallographic orientations are generally non-random in wrought Mg alloy, which will lead to their macroscopic physical properties to be anisotropic. Understanding the texture evolution in processing of Mg alloy billets and its effect on mechanical properties is therefore an important project for all scientists and engineers in material area. This paper is concerned with the description of texture, with the mechanisms of texture evolution and with the interrelationships between texture and mechanical properties in Mg alloy. It is a full review of understanding of the basic mechanism on texture evolution, of texture altering by alloying or processing, and of the mechanism of texture weakening. Moreover, it provides theories necessary and available techniques to develop high-performance Mg wrought with optimized texture in the field.

In vitro biocompatibility and degradation assessment of tantalum oxide coated Mg alloy as biodegradable implants

[J].

Effect of Y and Gd content on the microstructure and mechanical properties of Mg-Y-RE alloys

[J].

Corrosion behavior of Mg-Gd-Zn based alloys in aqueous NaCl solution

[J].

Latest research advances on magnesium and magnesium alloys worldwide

[J].

Enhancing the age-hardening response of rolled AZ80 alloy by pre-twinning deformation

[J].

Improving the room-temperature formability of a magnesium alloy sheet by texture control

[J].

Strengthening and toughening of magnesium alloy by {10

Improving the room temperature stretch formability of a Mg alloy thin sheet by pre-twinning

[J].

Effect of pre-deformation on microstructure characteristics, texture evolution and deformation mechanism of AZ31 magnesium alloy

[J].

Texture tailoring and bendability improvement of rolled AZ31 alloy using {10

Effect of rolling speeds on texture modification and mechanical properties of the AZ31 sheet by a combination of equal channel angular rolling and continuous bending at high temperature

[J].

Influence of bimodal non-basal texture on microstructure characteristics, texture evolution and deformation mechanisms of AZ31 magnesium alloy sheet rolled at liquid-nitrogen temperature

[J].

Dependence of microstructure evolution and mechanical properties on loading direction for AZ31 magnesium alloy sheet with non-basal texture during in-plane uniaxial tension

[J].

Dynamic recrystallization of titanium: Effect of pre-activated twinning at cryogenic temperature

[J].

Refinement of lamellar structures in Ti-Al alloy

[J].

Effect of texture types on microstructure evolution and mechanical properties of AZ31 magnesium alloy undergoing uniaxial tension deformation at room temperature

[J].

Enhancement of tensile ductility of magnesium alloy produced by torsion extrusion

[J].

Enhanced ductility in strongly textured magnesium produced by equal channel angular processing

[J].

Crack behavior in Mg/Al alloy thin sheet during hot compound extrusion

[J].A novel and effective method to co-extrude metallic alloys is described which named Direct Extrusion and Bending-Shear Deformation. The compound extrusion plates have cracked at 290 degrees C and 3 mm/s. According to this phenomenon, a model was built to investigate the crack generation and development between the 6061 Al and AZ31 Mg alloy during the compound extrusion process by DEFORM-3D. The cracking behavior of the Mg/Al composite rod with a soft Mg AZ31 core and a hard Al 6061 sleeve were systematically studied to disclose the influence of microstructure on crack in the different regions. The simulation results show that the distribution of strain and velocity has significant differences due to the influence of dies structure and material properties at different locations in the same region. The experimental results show that in the same conditions, there are differences in recrystallization and texture weakening of AZ31 Mg alloys and 6061 Al alloy, which are important factors for the formation of crack. Both the Mg layer and the Al layer have a homogeneous microstructure in the region d. (C) 2019 Published by Elsevier B.V. on behalf of Chongqing University.

Microstructural evolution and mechanical behavior of Mg/Al laminated composite sheet by novel corrugated rolling and flat rolling

[J].

Enhanced plasticity at cryogenic temperature in a magnesium alloy

[J].

Influence of texture on Hall-Petch relationships in an Mg alloy

[J].

What is going on in magnesium alloys?

[J].China has been developed into one of the most active regions in terms of both fundamental and applied research on magnesium (Mg) and its alloys in the world from a solid base laid by its prominent metallurgist and materials scientists over the past decades. Nowadays, a large number of young-generation researchers have been inspired by their predecessors and become the key participants in the fields of Mg alloys, which consequently led to the establishment of China Youth Scholar Society for Magnesium Alloys Research in 2015. Since then, the first two China Youth Scholars Symposiums on Mg Alloys Research had been held at Harbin (2015) and Chongqing (2016) China, respectively. A number of crucial research interests related to fundamental and applied Mg research were discussed at the conferences and summarized in this short perspective, aiming to boost far-reaching initiatives for development of new Mg-based materials to satisfy the requirements for a broad range of industrial employments. Herein, four main aspects are included as follows: i) Plastic deformation mechanism and strengthening strategy, ii) Design and development of new Mg-based materials, iii) Key service properties, and iv) New processing technologies.

Influence of basal slip activity in twin lamellae on mechanical behavior of Mg alloys

[J].

Deformation mechanisms in magnesium single crystals compressed in the direction parallel to hexagonal axis

[J].

Plasticity of magnesium crystals

[J].

Twin-like domains and fracture in deformed magnesium

[J].