含(3%~12%)Mn (质量分数,下同)的中锰钢由于其优异的力学性能与相对较低的合金成本受到广泛关注,中锰钢组织通常由马氏体、奥氏体与铁素体构成[1~3]。其优异的性能主要是由于在变形中可以发生残余奥氏体向马氏体的相转变从而贡献额外的加工硬化的同时提高钢的强度与塑性。因此,中锰钢的拉伸力学性能与残余奥氏体的数量和机械稳定性密切相关,通常在一个宽泛的范围内变化,如文献[4]中报道的中锰钢屈服强度为300~1000 MPa、抗拉强度为800~1600 MPa、延伸率在15%~70%之间。但值得注意的是,虽然中锰钢可以同时获得比低合金钢高很多的抗拉强度和延伸率,但屈服强度的提升却并不显著,通常低于1000 MPa[4~11]。这是因为该钢需要经两相区临界退火获得残余奥氏体,此时通常会发生位错回复甚至再结晶、晶粒粗化和析出相粗化等,导致屈服强度下降。因此,有学者尝试用析出强化来提升中锰钢屈服强度。如,Zhu等[5]前期在0.3C-9Mn-2.4Al钢中添加0.25%V,发现可提高屈服强度约200 MPa并仍然保持40%高延伸率;Park等[6]在0.2C-8Mn-3Al钢中加入0.2%V,也发现屈服强度提高了170~250 MPa而塑性没有恶化。而从单相α-Fe基体中析出的共格的bcc-Cu析出相平均直径一般为2~6 nm[7~9]。通过对比时效前后的力学性能,Hu等[10]发现富Cu相的析出可使铁素体屈服强度提高267 MPa;Isheim等[11]在奥氏体单相钢中添加6%Cu,经时效处理后显微硬度由约150 HV提高至180 HV。本工作尝试将Cu和V的析出强化共同引入到中锰钢中,以期大幅提高材料的屈服强度,并进一步改善材料的综合力学性能。

1 实验方法

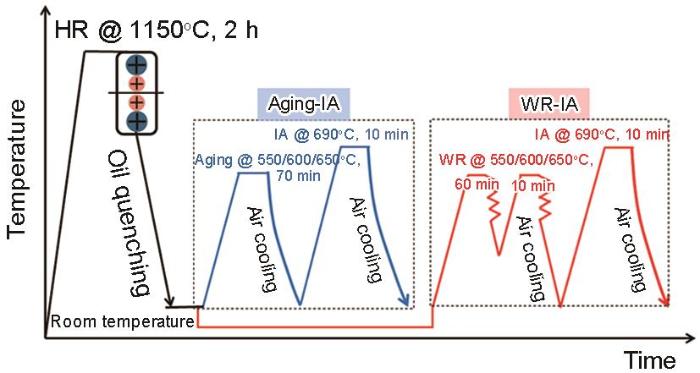

实验用钢的化学成分为0.3C-3Mn-1.1Al-2Cu-0.33V-0.52Mo (记为3Mn钢),根据该成分通过ThermoCalc软件计算得出升温时开始形成奥氏体的热力学平衡温度(A1)和全部转化为奥氏体的热力学平衡温度(A3)分别为606和800℃。采用50 kg真空感应炉熔炼,铸锭热锻为60 mm厚锻坯,加热至1150℃均匀化2 h,经8道次热轧至3.5 mm厚获得热轧板,终轧温度控制在850℃左右且每道次下压量小于33%,轧后油淬(工艺记为HR)。一部分热轧板在550、600和650℃不同温度时效70 min后全部经690℃临界退火10 min,空冷(记为热轧时效退火样品,工艺记为Aging-IA);另一部分热轧板加热至相同温度后保温60 min,在四辊轧机轧制两道次后回炉保温10 min后再轧两道次轧至2 mm厚(记为温轧样品,工艺记为WR),然后也同样再经690℃临界退火10 min,空冷(记为温轧退火样品,工艺记为WR-IA)。样品制备工艺示意图如图1所示。根据采用温度的不同,各工艺制备的样品编号记为:热轧时效退火样品:HR550-690、HR600-690和HR650-690,温轧样品:WR550、WR600和WR650,温轧退火样品:WR550-690、WR600-690和WR650-690。

图1

图1

实验所采用的2种制备工艺流程示意图

Fig.1

Schematic illustration of two manufacturing processes employed in this study (HR, WR, and IA represent hot rolling, warm rolling, and intercritical annealing processes, respectively)

沿轧制方向加工出标距为25mm的板状拉伸试样,以10-3 s-1应变速率进行室温单向拉伸实验以检测拉伸性能。通过JSM-6701F型场发射扫描电子显微镜(SEM)和电子背散射衍射(EBSD)系统、JEM-2200FS透射电子显微镜(TEM)和能谱仪(EDS)、D8 DISCOVER A25 X射线衍射仪(XRD)等手段对样品组织进行表征。其中,SEM样品经过标准磨抛后在5% (体积分数)硝酸酒精中侵蚀;XRD和EBSD样品经过标准磨抛后在20% (体积分数)高氯酸酒精溶液中25 V电压下进行电解抛光;TEM样品经过机械减薄和冲压后制备成直径3 mm、厚度50 μm的圆片,然后在-20℃的5% (体积分数)高氯酸酒精溶液中进行双喷减薄。残余奥氏体含量通过XRD测得的γ(200)、α(200)、γ(220)、α(211)、γ(311)衍射峰的综合积分强度进行计算。

式中,

式中,αγ 为残余奥氏体的平均晶格常数;WC、WMn、WAl和WCu分别为实验用钢奥氏体的C、Mn、Al和Cu的质量分数,通过TEM-EDS检测得到。

2 实验结果

2.1 力学性能

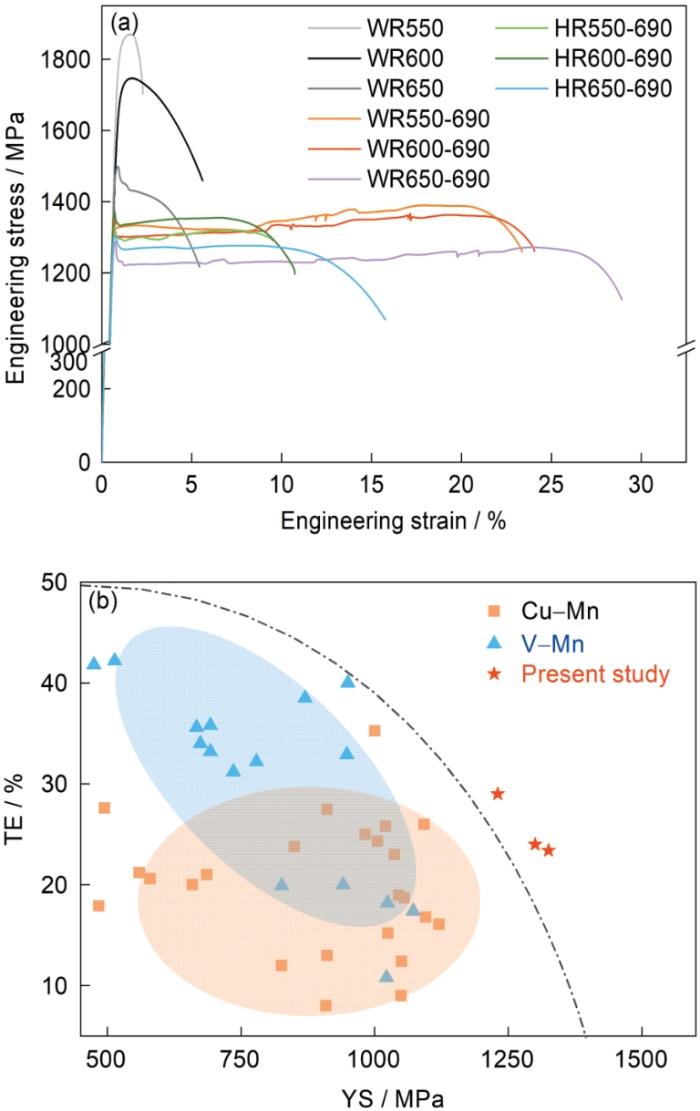

实验用3Mn钢的拉伸工程应力-应变曲线如图2a所示,其强度和延伸率列于表1。温轧样品屈服强度高但塑性差,且强度随温轧温度升高而降低;经过临界退火后可实现强度与塑性的良好结合。温轧退火试样与热轧时效退火试样的屈服强度接近,但温轧退火试样延伸率要比热轧时效退火试样高15%左右。图2b总结了文献[5,6,10,16~23]中已报道的Cu-Mn、V-Mn等Cu/V单一强化中锰钢的屈服强度和延伸率,其屈服强度不超过1100 MPa,延伸率保持在10%~40%。而本工作中的实验用钢通过温轧退火工艺可将屈服强度提升到1250~1350 MPa,提高了150~200 MPa,还同时维持了25%~30%的高延伸率,明显优于所报道的Cu/V单一合金化的中锰钢。

图2

图2

经不同工艺制备的实验用3Mn钢拉伸性能

Fig.2

Tensile properties of the 3Mn steel after different manufacturing processes

(a) engineering stress-strain curves of WR, WR-IA, and Aging-IA specimens

(b) comparison on the tensile properties of the studied steel and Cu or V alloyed medium Mn steels reported[5,6,10,16-23] (TE—total elongation, YS—yield strength)

表1 经不同工艺制备的实验用3Mn钢力学性能总结

Table 1

| Specimen | YS / MPa | UTS / MPa | TE / % |

|---|---|---|---|

| WR550 | 1800 ± 9.2 | 1870 ± 7.8 | 2.28 ± 0.21 |

| WR600 | 1650 ± 11.3 | 1745 ± 8.7 | 5.61 ± 0.32 |

| WR650 | 1455 ± 4.3 | 1520 ± 3.7 | 5.43 ± 0.41 |

| WR550-690 | 1325 ± 13.2 | 1390 ± 10.3 | 23.37 ± 0.72 |

| WR600-690 | 1300 ± 12.7 | 1365 ± 9.8 | 24.05 ± 0.47 |

| WR650-690 | 1230 ± 15.1 | 1290 ± 12.8 | 28.92 ± 0.94 |

| HR550-690 | 1290 ± 10.4 | 1330 ± 5.6 | 9.51 ± 0.41 |

| HR600-690 | 1330 ± 8.8 | 1370 ± 8.7 | 10.73 ± 0.38 |

| HR650-690 | 1265 ± 7.8 | 1305 ± 5.5 | 15.75 ± 0.49 |

2.2 微观组织

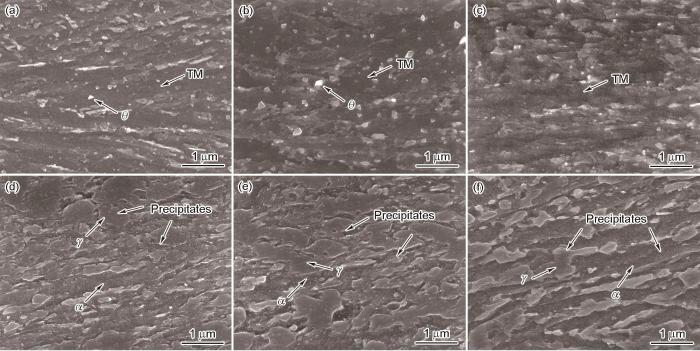

图3

图3

温轧及温轧退火样品组织的二次电子像

Fig.3

Secondary electronic images of the microstructures of WR and WR-IA specimens (TM, α, θ, and γ represent tempered martensite, ferrite, cementite, and austenite, respectively)

(a) WR550 (b) WR600 (c) WR650 (d) WR550-690 (e) WR600-690 (f) WR650-690

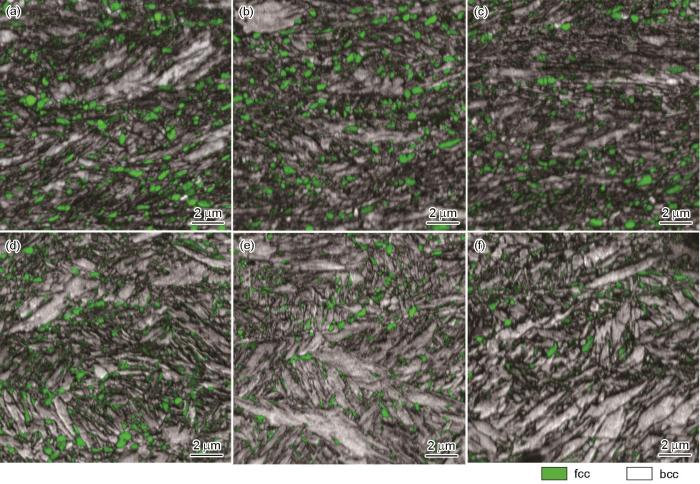

图4a~c和4d~f分别为温轧退火试样和热轧时效退火试样显微组织的EBSD结果。可以看出,后者的残余奥氏体含量明显要更低,且临界退火后残余奥氏体晶粒呈等轴状。统计结果显示,2种样品中残余奥氏体晶粒尺寸均在100~400 nm范围,平均尺寸在260 nm左右,温轧工艺采用与否对其影响甚微。

图4

图4

温轧退火以及热轧时效退火组织的EBSD质量图与相分布叠加图

Fig.4

EBSD band contrast images overlapped with phase distribution on the microstructures of WR-IA and Aging-IA specimens

(a) WR550-690 (b) WR600-690 (c) WR650-690 (d) HR550-690 (e) HR600-690 (f) HR650-690

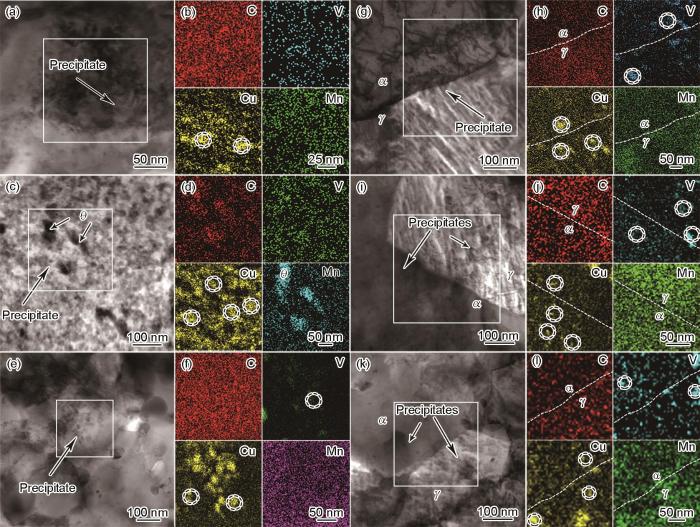

各样品的析出相TEM表征结果如图5所示。随温轧温度升高,温轧样品回火马氏体中富Cu相逐渐变大,数量密度则先升高后降低。对图5中STEM-EDS检测结果中的富Cu相和VC粒子的尺寸与数量进行统计,将实测的粒子平均尺寸R与体积分数f代入

图5

图5

温轧及温轧退火试样显微组织的TEM表征结果

Fig.5

TEM images (a, c, e, g, i, k) and corresponding EDS mappings of elements on the rectangle areas (b, d, f, h, j, l) of the microstructures of WR and WR-IA specimens (The areas marked by dashed circles in Figs.5b, d, f, h, j, and l represent Cu-rich or V-rich precipitates)

(a, b) WR550 (c, d) WR600 (e, f) WR650 (g, h) WR550-690 (i, j) WR600-690 (k, l) WR650-690

表2 温轧及温轧退火试样中富Cu和VC纳米析出相的尺寸、密度与体积分数

Table 2

Specimen | Precipitate | Diameter nm | Number density m-3 | Volume fraction % |

|---|---|---|---|---|

| WR550 | Cu-rich | 8.8 ± 1.9 | 4.51 × 1023 | 0.34 |

| WR600 | Cu-rich | 13.6 ± 2.8 | 5.85 × 1023 | 0.77 |

| WR650 | Cu-rich | 15.7 ± 1.7 | 3.35 × 1023 | 0.68 |

| VC | 11.9 ± 3.5 | 2.15 × 1023 | 0.19 | |

| WR550-690 | Cu-rich | 19.2 ± 2.9 | 7.89 × 1022 | 0.29 |

| VC | 19.3 ± 6.5 | 6.64×1022 | 0.25 | |

| WR600-690 | Cu-rich | 27.1 ± 3.5 | 1.27 × 1023 | 0.69 |

| VC | 21.1 ± 6.1 | 5.89 × 1022 | 0.29 | |

| WR650-690 | Cu-rich | 34.5 ± 3.8 | 1.44 × 1022 | 0.31 |

| VC | 20.2 ± 3.6 | 8.57 × 1022 | 0.37 |

3 分析讨论

3.1 热轧时效退火与温轧退火工艺对力学性能的影响

式中,

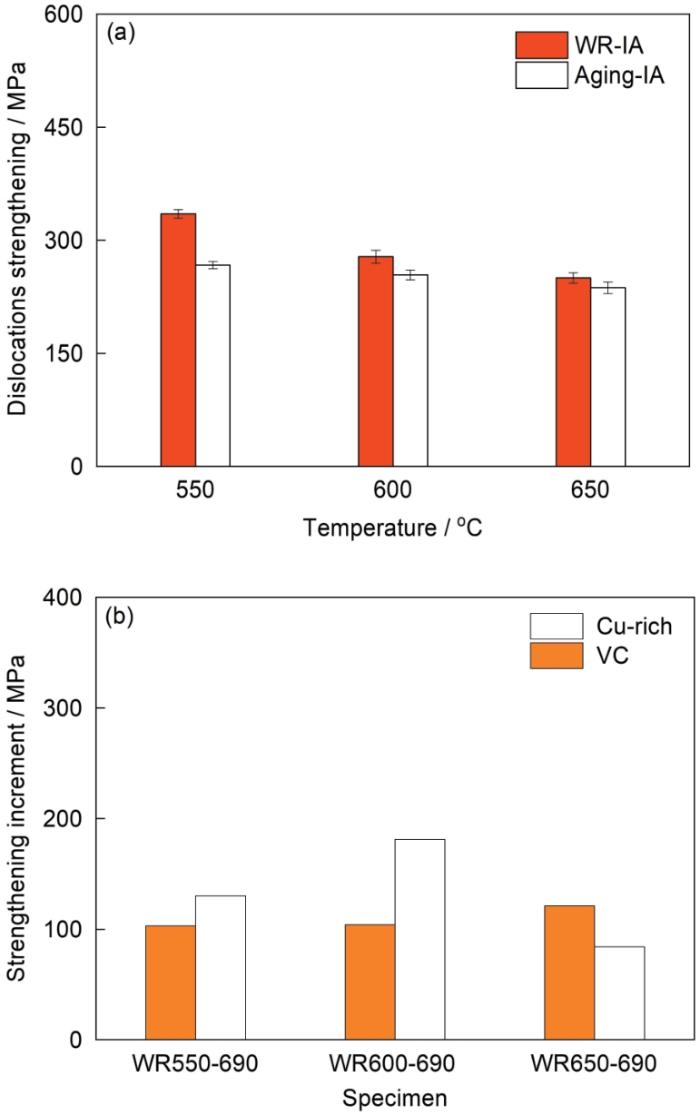

通过位错密度计算强化增量[28]的结果见图6a。在550℃温轧和时效时,温轧退火样品和热轧时效退火样品的位错强化增量相差约50 MPa,其他温度下两类样品的位错强化均很接近,这也导致了最终热轧时效退火与温轧退火样品的屈服强度相差也在50 MPa内,见图2a。但温轧退火工艺可在保持高屈服强度的同时,通过提高残余奥氏体分数来改善塑性。另外,该样品在变形过程没有显著的加工硬化,而是通过形成Lüders局部形变带的扩展来贡献塑性,这种由细小等轴铁素体和奥氏体晶粒组成的显微组织在中锰钢中常常出现[29~31]。通常认为[31~33]这是由再结晶导致初始位错密度很低,而在变形时这一类型相界可以向奥氏体内发射不全位错,导致位错的快速增殖进而形成不连续屈服,而奥氏体仅在Lüders带内转变,加工硬化贡献小,仅提供塑性而没有提高强度。

图6

图6

实验用钢在不同工艺下所计算得到的位错与析出强化增量

Fig.6

Calculated dislocation and precipitation streng-thening increments for the studied steel manu-factured by the different processes

(a) calculated dislocation strengthening incre-ments by Eq.(3) varied with warm rolling/aging temperatures

(b) calculated precipitation strengthening incre-ments of VC and Cu-rich precipitates in WR-IA specimens

3.2 温轧温度对临界退火后样品的残余奥氏体和力学性能的影响

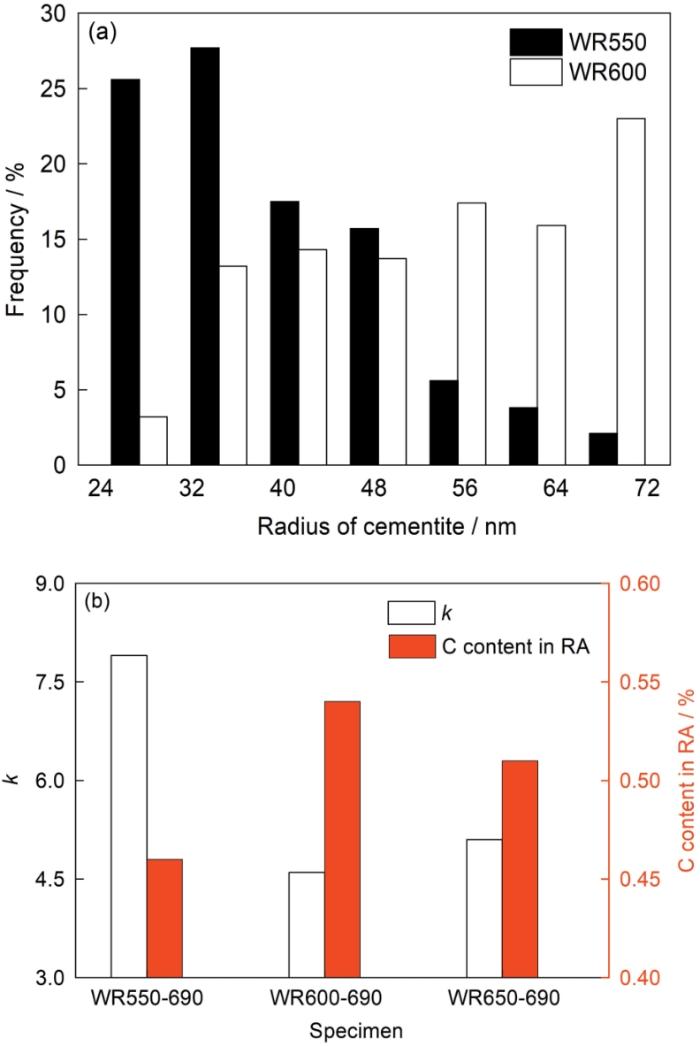

温轧温度对温轧退火样品最终的残余奥氏体体积分数的影响见表3。可见,WR550-690样品残余奥氏体最多,而WR600-690残余奥氏体最少。虽然WR550与WR600温轧试样均含有弥散分布的渗碳体,但后者由于温轧温度更高,根据对图3a和b中渗碳体尺寸与数量的统计可知,WR650中的渗碳体更粗大且数量较少(图7a),减少了临界区退火过程中逆转变奥氏体的形核位点,而且使得渗碳体更难完全固溶[34,35],这导致WR600-690样品残余奥氏体体积分数明显低于WR550-690。当温轧温度为650℃时(高于A1),渗碳体在退火时固溶且开始形成奥氏体,温轧后还保留了约8.3%的残余奥氏体,这些晶粒可作为退火过程中逆相变的形核核心而进一步长大[36],进而在退火后也获得了较高体积分数的残余奥氏体。

表3 不同样品在变形前后的奥氏体体积分数

Table 3

| Specimen | Before deformation | After deformation | Transformed percentage |

|---|---|---|---|

| WR550 | 1.3 ± 0.12 | None | None |

| WR600 | 2.1 ± 0.09 | ||

| WR650 | 8.3 ± 0.41 | ||

| WR550-690 | 31.4 ± 0.71 | 5.2 ± 0.46 | 83.4 |

| WR600-690 | 22.3 ± 0.56 | 7.1 ± 0.28 | 68.1 |

| WR650-690 | 28.3 ± 0.89 | 6.4 ± 0.25 | 77.3 |

| HR550-690 | 21.1 ± 0.31 | 7.4 ± 0.36 | 64.9 |

| HR600-690 | 15.7 ± 0.43 | 7.5 ± 0.43 | 52.2 |

| HR650-690 | 18.1 ± 0.49 | 6.8 ± 0.49 | 62.4 |

图7

图7

温轧样品中渗碳体粒子的尺寸分布及温轧退火样品中奥氏体C含量与机械稳定性

Fig.7

Size distributions of cementite particles in WR specimens (a) and mechanical stability and C contents (mass fraction) of austenite grains in WR-IA specimens (b) (k—index of austenitic mechanical stability, RA—retained austenite)

在临界退火后,WR550-690与WR600-690 2者屈服强度和延伸率均类似,而WR650-690屈服强度略低但塑性好。这是由于低温轧制导致WR550-690样品位错密度最高,因此位错强化也最高(图6a),而WR600-690样品虽然位错密度较低,但其含有更高数量密度的富Cu相(表2),根据Ashby-Orowan方程[37,38]对析出强化增量计算得知,其析出强化更高(图6b),所以最终导致2者屈服强度持平;而WR650-690中位错密度低且析出相的尺寸大、数量少,因此屈服强度较前述样品低了约100 MPa,但是其残余奥氏体分数约30%,接近WR550-690的最大残余奥氏体分数而显著高于WR600-690,而其机械稳定性显著高于WR550-690的残余奥氏体,因此WR650-690样品中的残余奥氏体同时具有较高分数与较高稳定性,这导致WR650-690的塑性最优。

另外,本工作的Cu-V双合金化3Mn钢的屈服强度和综合力学性能显著优于已报道[5,6,10,16~23]的Cu/V单一合金化中锰钢(图2b)。这主要是由于先通过温轧引入高密度位错和弥散析出的富Cu析出相,然后再进行临界退火形成22%~31%奥氏体来保证塑性,同时在退火时析出VC来弥补退火时由于回复再结晶导致的软化,最终实现屈服强度1250~1350 MPa,延伸率25%~30%。而之前的研究多采用一步退火工艺,即逆转变形成奥氏体和纳米粒子析出过程均在临界退火时进行。在这样的一步退火工艺条件下,固然低温或短时间退火可获得弥散细小析出相而得到高屈服强度(900~1100 MPa),但此时奥氏体分数较少而塑性较差[6,17~19,22];而高温或长时间退火虽然可形成更多的残余奥氏体来改善塑性,但析出相会显著粗化而导致屈服强度下降(500~900 MPa)[5,6,16,19,21,23]。

4 结论

(1) 温轧退火样品的塑性显著高于热轧时效退火样品,但2者屈服强度类似,这是由于温轧时引入高密度位错,促进了临界退火时的奥氏体逆转变进而获得更多残余奥氏体,因此改善了塑性。

(2) 550和600℃温轧样品在临界退火后2者屈服强度和延伸率均类似,而650℃温轧样品退火后屈服强度相较前2者降低约100 MPa但塑性提高约5%,达到1230 MPa屈服度和约30%的延伸率,这主要是由于650℃温轧产生的位错密度低且析出相尺寸大、数量少,降低了屈服强度,同时其残余奥氏体体积分数提高至约30%且有较高稳定性,使得塑性最优。

(3) 温轧退火工艺所获得的屈服强度要较文献报道的Cu/V单一合金化中锰钢高150~200 MPa,同时还具备25%~30%的高延伸率,这是由于采用了Cu-V双合金化和在热轧后采用了两段热处理工艺所致。首先在温轧阶段引入富Cu析出相以强化,而在临界退火时又可通过VC析出弥补了由于回复再结晶、富Cu相固溶所导致的软化,最终实现高屈服强度;同时临界退火后获得了体积分数为25%~30%、机械稳定性合适的残余奥氏体,通过TRIP效应保证了高塑性。

参考文献

Microstructure and performance control technology of the 3rd generation auto sheet steels

[J].

第3代汽车钢的组织与性能调控技术

[J].

Effect of warm rolling process on microstructures and tensile properties of 10 Mn steel

[J].

M3 microstructure control theory and technology of the third-generation automotive steels with high strength and high ductility

[J].

高强度高塑性第三代汽车钢的M3组织调控理论与技术

[J].高强度、高塑性是汽车钢的重要发展方向,本文综述了高强度高塑性第三代汽车钢的“多相(multiphase)、亚稳(metastable)和多尺度(multiscale)” M<sup>3</sup>组织性能调控理论和技术,以及面临的新挑战。M<sup>3</sup>组织与性能调控理论为高强度高塑性钢提供了理论支持,亚稳奥氏体的相变诱发塑性(TRIP)效应能够提高加工硬化率并推迟颈缩的发生,从而提高了钢的强度与塑性,同时产生了剪切边裂纹敏感性提高,氢致延迟断裂性能下降,循环载荷下亚稳奥氏体的转变行为复杂等新的问题和挑战。当前,含亚稳奥氏体高强度高塑性钢的质量一致性和应用基础研究缺乏,而汽车钢作为量大面广的产品,需要从它的成分设计和组织调控-冲裁切割-成形制造-连接涂装-服役评价等全链条环节中开展组织演变和性能评估,充分考虑产品的技术适用性和成本,进而为组织调控理论和技术的完善提供依据。

Medium Mn transformation-induced plasticity steels: Recent progress and challenges

[J].

Influence of Nb and V on microstructure and mechanical properties of hot-rolled medium Mn steels

[J].

Improved strength of a medium-Mn steel by V addition without sacrificing ductility

[J].

High-resolution electron microscopy studies of the structure of Cu precipitates in α-Fe

[J].

Precipitation and phase transformation of copper particles in low alloy ferritic and martensitic steels

[J].

Microstructure and mechanical properties of HSLA steel containing 1.4%Cu

[J].The Cu bearing high strength low alloy (HSLA) steels exhibit high-strength, high toughness and good weldability, which have been widely used in shipbuilding, offshore structures etc. Due to the extremely poor impact energy when attained peak strength, the Cu bearing HSLA steels are usually used at overaged state, which have a good combination of impact energy and strength. In order to clarify the effect of Cu on mechanical properties especially on the impact energy for HSLA steels at peak ageing state, two HSLA steels without Cu (0Cu) and with 1.4%Cu (1.4Cu), were prepared by vacuum induction melting in this study. The influence of Cu on the microstructure of HSLA steel was investigated by OM, SEM and EBSD. Meanwhile, the Cu-riched clusters were characterized by APT and the mechanical properties were measured by tensile test and impact test. The results show that the Cu is completely solid-solutioned into the matrix after quenching, and there are a great number of Cu-riched clusters precipitated in the matrix and boundaries after tempering. Cu element has no obvious effect on the prior austenite grain size, microstructure and effective grain size of tempered HSLA steel, but has significant influence on the strength and impact energy for tempered HSLA steel. After tempered at 450 ℃, the 1.4Cu steel attained the maximum yield strength (1053 MPa), higher than that of 0Cu steel. It is worth noting that the impact energy of 1.4Cu steel tempered at 450 ℃ is only 24 J at room temperature and the impact fracture is a quasi-cleavage brittle fracture mode dominated by river patterns. However, 0Cu steel exhibits a completely ductile fracture mode dominated by dimples at room temperature and the impact energy is 127 J. The APT results show that both 0Cu and 1.4Cu tempered steels have the segregation of C, Cr, Ni, Mn elements at the lath boundary. Compared with 0Cu steel, there precipitate a great number of Cu-riched clusters at the lath boundary for 1.4Cu steel, which will result in the stress concentration and then promote the crack initiation at the lath boundary. In addition, the Cu-rich clusters precipitated at the lath boundary could prevent the Mo segregated at the lath boundary, which will decrease the bonding energy and then promote the crack propagation along the lath boundary. Besides, the negative effect of strengthening due to the Cu-riched clusters at matrix will also accelerate the crack propagation in the matrix, which will decrease the impact energy of 1.4Cu steel. Therefore, the impact energy of 1.4Cu steel is much lower than that of 0Cu steel at room temperature.

含1.4%Cu的HSLA钢的组织和力学性能

[J].以不含Cu (0Cu)和含1.4%Cu (1.4Cu)的HSLA钢为研究对象,利用OM、SEM、EBSD等技术手段研究了Cu对HSLA合金钢显微组织的影响,利用APT表征了纳米富Cu团簇的析出特征,并通过拉伸和冲击实验测定了合金钢的力学性能。结果表明,淬火态Cu固溶在基体中,经回火后则以富Cu团簇的形式在基体和界面处析出。Cu对回火态HSLA合金钢的原始奥氏体晶粒尺寸、显微组织及有效晶粒尺寸均无明显影响,但对其强度和冲击功影响较大。1.4Cu钢经过450 ℃回火处理后获得最佳强化效果,其屈服强度比0Cu钢提升了143 MPa,此时1.4Cu钢的室温冲击功仅为24 J,断口以河流花样为主,其断裂方式为准解理脆性断裂;而0Cu钢的室温冲击功高达127 J,其断裂方式为韧窝的韧性断裂。APT实验结果表明,2种回火态合金钢的板条界面处均存在C、Cr、Ni、Mn元素的富集。与0Cu钢相比,1.4Cu钢的板条界面处存在大量富Cu团簇,从而导致较大的应力集中,有利于裂纹的萌生,并且板条界面处析出的富Cu团簇会排斥Mo元素,抑制了Mo元素在板条界处的偏聚,相对降低了板条界面处的结合强度,有利于裂纹沿板条界扩展。此外,富Cu团簇在强化基体的同时,也会降低基体的韧性,加快裂纹在基体内的扩展。因而,1.4Cu钢在获得最佳强化效果时其冲击性能较差。

Nanoscale precipitation and ultrafine retained austenite induced high strength-ductility combination in a newly designed low carbon Cu-bearing medium-Mn steel

[J].

Copper-precipitation hardening in a non-ferromagnetic face-centered cubic austenitic steel

[J].

Stability of retained austenite in TRIP-assisted steels

[J].

Ductility and strain-induced transformation in a high-strength transformation-induced plasticity-aided dual-phase steel

[J].

In-situ observations of lattice parameter fluctuations in austenite and transformation to bainite

[J].

Thermal stability of austenite retained in bainitic steels

[J].

Non-uniform distribution and strengthening effect of Cu precipitates enclosed in austenite during intercritical annealing in a medium Mn steel

[J].

Influence of retained austenite and Cu precipitates on the mechanical properties of a cold-rolled and intercritically annealed medium Mn steel

[J].

Aging characteristics and strengthening behavior of a low-carbon medium-Mn Cu-bearing steel

[J].

Combined contribution of Cu-rich precipitates and retained austenite on mechanical properties of a novel low-carbon medium-Mn steel plate

[J].Simultaneous improvement in yield strength, ductility and impact toughness has always been a challenge for structural steels. In the attempt to achieve this goal, we proposed a Cu-precipitation-strengthened low-carbon medium-Mn steel in the present study. Upon aging at 600 degrees C for 1h, a considerable amount of Cu-rich precipitates with average radius of 6.3nm was uniformly distributed in the tempered martensitic matrix. An ultra-high yield strength, therefore, was attained by the strong interaction of Cu-rich precipitates with dislocations. In addition to the precipitation strengthening effect, the introduction of Cu also dramatically promoted the dissolution of cementite particles and formation of retained austenite at triple junctions or other high-angle grain boundaries. Compositional analysis of cementite and retained austenite was conducted by atom probe tomography. Austenite formation removed Mn segregation from the grain boundaries, consumed brittle cementite particles, and hence eliminated intergranular fracture, leading to a remarkable improvement in toughness. Moreover, a volume fraction of 23.2% retained austenite with appropriate mechanical stability also enabled the steel to be more ductile. The optimal mechanical properties, yield strength of 1005MPa, tensile strength of 1070MPa, total elongation of 24.3% and room temperature impact energy of 73J were obtained, through the cumulative contribution of Cu-rich precipitates and retained austenite.

Breaking the strength-ductility paradox in advanced nanostructured Fe-based alloys through combined Cu and Mn additions

[J].

A novel Cu-Ni added medium Mn steel: Precipitation of Cu-rich particles and austenite reversed transformation occurring simultaneously during ART annealing

[J].

1.0 GPa low carbon medium Mn heavy steel plate with excellent ductility

[J].

Structure and properties of vanadium microalloyed medium manganese steel

[J].

钒微合金化中锰钢组织与性能研究

[J].

Effect of cold deformation extent and ART annealing duration on the microstructure and mechanical properties of a medium manganese steel

[J].

III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray Debye-Scherrer spectrum

[J].

The effect of dislocation contrast on X-ray line broadening: A new approach to line profile analysis

[J].

The mechanism of plastic deformation of crystals. Part I.—Theoretical

[J].

The effects of the initial martensite microstructure on the microstructure and tensile properties of intercritically annealed Fe-9Mn-0.05C steel

[J].

Effect of grain refinement on thermal stability of metastable austenitic steel

[J].

Two-step intercritical annealing to eliminate Lüders band in a strong and ductile medium Mn steel

[J].

Macroscopic to nanoscopic in situ investigation on yielding mechanisms in ultrafine grained medium Mn steels: Role of the austenite-ferrite interface

[J].

Effect of intercritical annealing on the Lüders strains of medium Mn transformation-induced plasticity steels

[J].

A novel two-step intercritical annealing process to improve mechanical properties of medium Mn steel

[J].

Experimental and numerical analysis of influence of carbide on austenitisation kinetics in 5Mn TRIP steel

[J].

Effect of pre-existed austenite on austenite reversion and mechanical behavior of an Fe-0.2C-8Mn-2Al medium Mn steel

[J].