焊接是铁素体耐热钢投入服役应用前不可或缺的主要过程[6],同时作为连接上游钢厂和下游用户的重要纽带,在火力发电厂承压设备制造、安装和检修中占据重要地位。焊接是一个局部急速升温和迅速冷却的非平衡相变过程,热影响区(heat-affected zone,HAZ)由于经历了特殊的焊接热循环[7],从而导致各部分易产生非均匀的混杂结构[8,9]。尤其在粗晶热影响区(coarse-grained heat-affected zone,CGHAZ)中可能会产生残留δ-Fe、残留奥氏体、贝氏体或马氏体等多种组织[10],甚至出现再热裂纹[11];后续服役时,细晶热影响区(fine-grained heat-affected zone,FGHAZ)中IV型蠕变裂纹也时有发生[12,13],这严重影响了焊接件的室温组织并导致其性能恶化,进而对电站安全稳定运行产生严重威胁。因此,对铁素体耐热钢焊接过程中CGHAZ和FGHAZ的固态相变及微观组织进行全面深入的研究至关重要。

值得注意的是,焊接过程是在高温条件下进行的非可视化操作[14],研究该过程中HAZ的相变行为和组织演变是一项非常困难且富有挑战性的工作。Wang等[15]的研究主要致力于对耐热钢焊接之后室温下HAZ微观组织和晶体结构的表征。Quidort和Brechet[16]建立动力学模型描述奥氏体向铁素体/贝氏体/马氏体转变时的形核和生长过程。Ueshima等[17]通过数学模拟计算的方式研究相变过程中两相界面位置溶质的重新分布问题。依据上述传统研究方法得到的实验结果都是基于非原位的观察和模拟分析,并不能准确反映实际焊接热循环过程中HAZ动态相变和组织演变的实时状况。随着材料表征技术和测试方法的快速发展,一些高端检测技术渐次应用于钢铁材料研究,并不断刷新对相变本质的认识。Mayr等[18]和Yu等[19]曾借助同步辐射光源等大科学装置,通过采用高能X射线衍射(high-energy X-ray diffraction,HEXRD)对耐热钢和防爆钢焊接HAZ的相变过程进行实时记录,得到各相(δ-Fe、γ-Fe、α-Fe)随时间变化的体积分数。但是由于HEXRD只能针对相变过程中材料的晶体学参数进行实时采集分析,并不能直观呈现出微观组织演变图像及进行相变动力学分析。同时,在HEXRD实验过程中为了获得充足的衍射信号,通常会减小焊接热循环的升降温速率,这与实际焊接条件相比也有较大出入。因此,亟需寻找一种更为有效的手段进行深入研究。

高温激光扫描共聚焦显微镜(high-temperature confocal scanning laser microscope,CSLM)作为研究高温下钢铁等材料相变和微观组织变化的强有力工具,不仅能够对钢铁材料在高温下的微观组织演变过程进行实时跟踪观察,而且能够对相变动力学进行定量分析[20,21]。此外,借助CSLM这一先进的表征手段得到的实验现象明显、结果直观,对焊接过程的实时、原位以及高清晰观察与分析具有重要帮助[22,23]。Zou等[24]通过CSLM原位观测了不同冷却速率下铁素体的生长过程,阐明了冷却过程中铁素体在夹杂物表面和原奥氏体晶界表面的竞争形核关系,并据此构建了针状铁素体择优形核原理图。因此,利用CSLM原位观察的特点,研究铁素体耐热钢HAZ在高温下的组织演变行为和相变动力学过程,可以使其达到可视化和定量化的程度。

本工作采用CSLM原位观察技术对P11、P22、P91 3种典型铁素体耐热钢焊接过程中CGHAZ和FGHAZ的相变行为进行研究,通过重现HAZ的焊接热循环过程,实现了相变和微观组织演变的原位观察及量化分析,阐明了贝氏体/马氏体板条的生长机制及其相变动力学,补充了铁素体耐热钢HAZ高温下微观组织演变实时观察的图像信息,从而为先进耐热钢材料的发展以及焊接工艺的优化提供重要的理论指导和促进作用,并有利于后续蠕变开裂机理的进一步研究。

1 实验方法

表1 P11、P22和P91铁素体耐热钢的化学成分

Table 1

| Steel | C | Mn | P | S | Si | Cr | Mo | V | N | Nb | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P11 | 0.130 | 0.540 | 0.0170 | 0.0030 | 0.590 | 1.120 | 0.572 | 0.003 | 0.0049 | 0.003 | 0.590 | Bal. |

| P22 | 0.141 | 0.557 | 0.0049 | 0.0015 | 0.092 | 2.395 | 0.967 | 0.014 | 0.0049 | 0.020 | 0.157 | Bal. |

| P91 | 0.100 | 0.450 | 0.0170 | 0.0050 | 0.300 | 8.150 | 0.950 | 0.210 | 0.0440 | 0.060 | 0.170 | Bal. |

表2 P11、P22和P91铁素体耐热钢的热处理工艺

Table 2

| Steel | Normalizing | Tempering |

|---|---|---|

| P11 | 930oC, 52 min | 760oC, 91 min |

| P22 | 930oC, 48 min | 750oC, 84 min |

| P91 | 1060oC, 30 min | 760oC, 60 min |

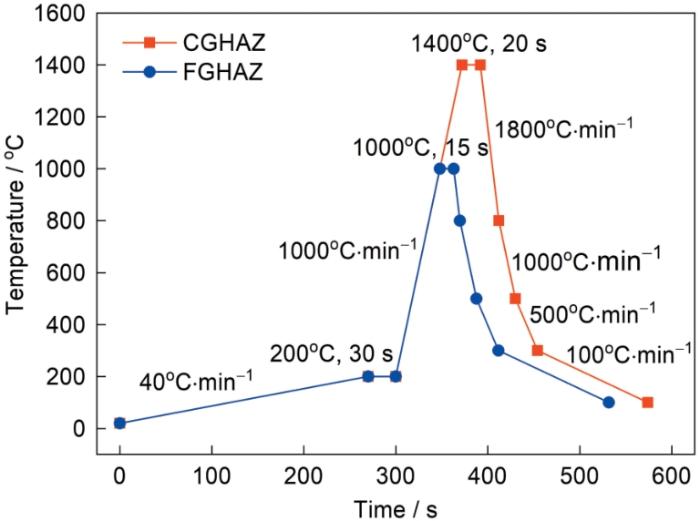

通过线切割机械加工在P11、P22、P91 3种NT态铁素体耐热钢上取得直径5 mm、厚4 mm的圆柱样品,用于在VL2000DX-SVF18SP 型CSLM上进行原位观察实验。实验前首先用砂纸将样品上下表面及圆周打磨至完全露出金属光泽,然后依次使用240、800、1200和1500号的砂纸对样品上下表面进行研磨,保证这2个表面水平平行,随后依次使用粒径为2.5和0.25 μm的水溶金刚石研磨膏在金丝绒抛光布上对待观察表面进行机械抛光。实验时将制备好的样品放入直径6.5 mm、厚4 mm的Al2O3陶瓷坩埚中,并将其置于Pt试样托架上,密封加热炉体后用高纯Ar气(99.99%)清洗3次,同时实验全程充Ar气保护防止样品氧化。实验采用的焊接热循环工艺曲线如图1所示。具体如下:(1) 以40℃/min的速率升温至200℃,保温30 s;(2) 以1000℃/min的速率分别升温至1000和1400℃,并分别保温15和20 s;(3) 以1800℃/min的速率降温至800℃;(4) 以1000℃/min的速率降温至500℃;(5) 以500℃/min的速率降温至300℃;(6) 以100℃/min的速率降至室温。该曲线专门用于重现热输入为18 kJ/cm手工电弧焊条件下CGHAZ和FGHAZ的焊接热循环过程。此外,在冷却过程中,CSLM的电荷耦合器件(CCD)相机会以15 frame/s的速率捕获实时图像,并通过系统将实验全程的原位观察结果记录在视频文件中。随后借助ImageJ图像分析处理软件对板条尺寸进行测量,同时使用截线法(ASTM E112)统计晶粒尺寸。

图1

图1

高温激光扫描共聚焦显微镜(CSLM)的热循环曲线

Fig.1

Thermal cycles employed for in situ observation under CSLM (CSLM—high-temperature confocal scanning laser microscope, CGHAZ—coarse-grained heat-affected zone, FGHAZ—fine-grained heat-affected zone)

将上述原位观察后的样品经过常规的机械研磨、抛光后,再利用电解抛光消除其表面的应力层以得到无变形损伤的平整表面。本工作采用的电解抛光液为5%高氯酸酒精溶液(体积分数),抛光温度为20℃,抛光电压为35 V,抛光时间为36 s。随后将电解抛光后的样品固定在搭载了C-Nano电子背散射衍射(EBSD)信号收集器的MIRA3型场发射扫描电子显微镜(SEM)上进行晶体学信息采集,实验中将样品倾斜70°,扫描步长为0.3 μm,加速电压为20 kV,并使用HKL CHANNEL5软件进行后续数据处理。

2 实验结果

2.1 P11铁素体耐热钢HAZ相变过程的原位观察

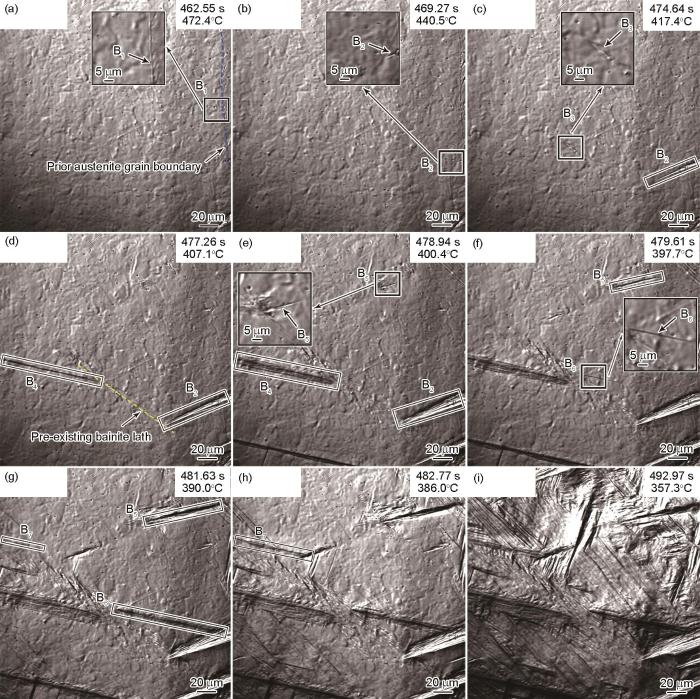

图2为P11铁素体耐热钢CGHAZ冷却过程中贝氏体板条生长演变行为的实时图像。从图2a的局部放大插图可见,当温度从峰值1400℃逐步降低至472.4℃时,样品表面出现明显的浮凸,由此可以判断此时开始发生贝氏体相变[25,26],大量平行的贝氏体板条(B1)首先在原奥氏体晶界上同时形核生长。随后,当温度降低至440.5℃时,第2个贝氏体板条(B2)在夹杂物上开始形核生长,如图2b中的局部放大插图所示。随着温度继续降低至417.4℃时,第3个贝氏体板条(B3)在晶粒内部开始形核生长,如图2c中的局部放大插图所示。通过观察图2a~c中的局部放大插图可以看出,冷却过程中贝氏体板条依次从原奥氏体晶界、夹杂物、晶粒内部这3个不同位置形核生长。

图2

图2

P11铁素体耐热钢粗晶热影响区(CGHAZ)冷却过程中贝氏体板条长大过程的CSLM像

Fig.2

CSLM images of the growth of bainite laths in the CGHAZ of P11 ferritic heat-resistant steel (a-i) (B1-B7 represent growing bainite laths, the same in Figs.3-5; Insets show partial enlarged bainite laths)

此外,通过CSLM原位观察还记录了另外4个典型贝氏体板条(B4~B7)的生长特征,如图2d~i所示。首先,在407.1℃时单个贝氏体板条B4在原奥氏体晶粒内部与其他已存在的贝氏体板条(图2d中的黄色虚线)相遇碰撞后停止生长,随后一簇并行排列的贝氏体板条与B4平行逐层生长,板条宽度由1.0 μm增加到7.2 μm,如图2d和e所示。样品内部朝不同方向生长的贝氏体板条会造成表面凸起形态不同[27],与晶粒内部平整区域相比,局部凸起明显处畸变较为严重,这就促使该区域更容易形核。贝氏体板条B5在晶粒内部畸变区域形核并迅速延伸生长,随着冷却时间的增加,可以清楚地看到一些新形成的贝氏体板条总是依附在先前的贝氏体板条上同向平行生长,导致板条纵向生长的同时横向宽度也明显增加,形成宽为5.1 μm的贝氏体板条束,如图2所示。而贝氏体板条B6依附在先前的贝氏体板条尖端形核,并与其成30°的夹角生长,如图2e~gf和g所示。贝氏体板条B7在晶粒内部平整区域形核并迅速延伸生长,观察发现随后的贝氏体板条总是优先选择依附在先前的贝氏体板条旁形核生长,如图2g和h所示。随着温度的降低,贝氏体相变不断进行,在357.3℃时贝氏体板条覆盖了整个原奥氏体晶粒,奥氏体完全转变为贝氏体,呈现出典型的羽毛状上贝氏体形态,如图2i所示。

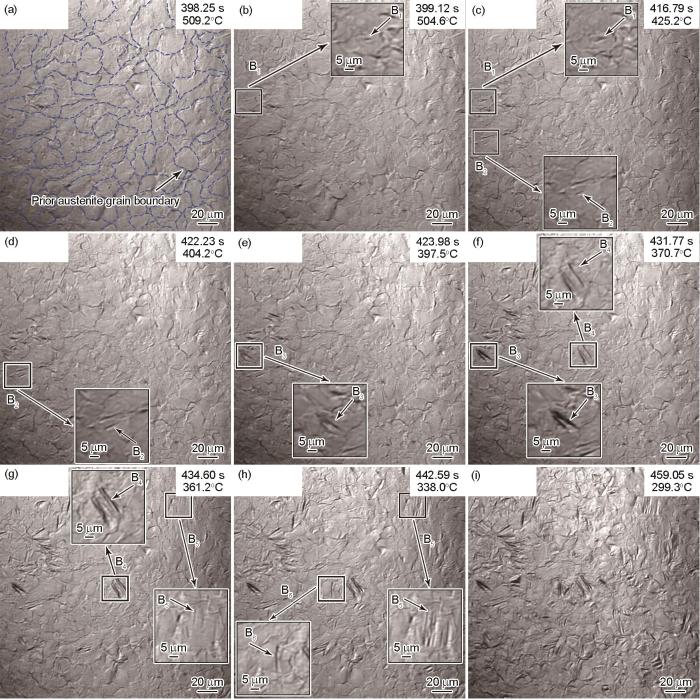

图3为P11铁素体耐热钢FGHAZ从峰值温度(1000℃)连续冷却至室温过程中CSLM原位观察的典型结果。如图3a所示,将原奥氏体晶界用蓝色虚线勾画出来,测量计算出原奥氏体的平均晶粒尺寸为19.0 μm。根据冷却过程中样品表面发生贝氏体转变时产生的明显浮凸可以判断,在504.6℃时开始发生贝氏体相变,第1个贝氏体板条(B1)在原奥氏体晶界处形核,如图3b中的局部放大插图所示。随后第2个贝氏体板条(B2)在原奥氏体晶粒内部形核生长,如图3c和d中的局部放大插图所示。这与上述CGHAZ中所揭示的研究结果基本一致,即贝氏体板条先后分别在原奥氏体晶界和晶粒内部形核生长。随着温度的降低和冷却时间的增加,观察发现FGHAZ中的贝氏体板条(B3~B6)不断在原奥氏体晶粒内部形核生长,并且开始出现贝氏体板条相互依附平行生长的现象,形成较为宽大的贝氏体板条束,如图3e~h中的局部放大插图所示,这一贝氏体相变的典型特征与CGHAZ中保持一致。最终当温度降至299.3℃以下时,发现样品表面不再发生变化,表明贝氏体相变结束,可以清楚看到其中一部分奥氏体晶粒被贝氏体板条覆盖,呈现出细小的羽毛状特征,而另一部分并未出现明显变化,初步推断在高温阶段已转变为块状铁素体,如图3i所示。

图3

图3

P11铁素体耐热钢细晶热影响区(FGHAZ)冷却过程中贝氏体板条长大过程的CSLM像

Fig.3

CSLM images of the growth of bainite laths in the FGHAZ of P11 ferritic heat-resistant steel (a-i) (Insets show partial enlarged bainite laths)

2.2 P22铁素体耐热钢HAZ相变过程的原位观察

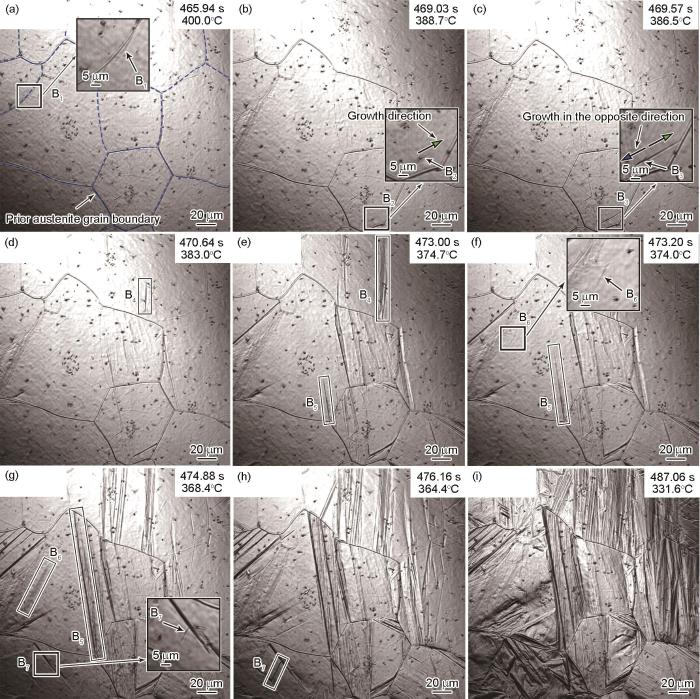

图4为P22铁素体耐热钢CGHAZ冷却过程中奥氏体到贝氏体相变的原位观察结果。如图4a中的局部放大插图所示,在400.0℃时,第1个贝氏体板条(B1)首先在蓝色虚线描绘的原奥氏体晶界上形核,并与晶界成一定角度沿直线生长到晶粒内部。当温度降低至388.7和386.5℃时,第2个贝氏体板条(B2)和第3个贝氏体板条(B3)开始在同一个夹杂物上形核并朝相反方向生长,分别如图4b和c中的绿色和蓝色箭头所示。随后,一簇平行的贝氏体板条(B4)在晶粒内部的畸变区域形核并迅速延伸生长,如图4d和e所示。此外,可以清楚地看到另一个贝氏体板条(B5)在原奥氏体的三叉晶界交汇处形核,同时板条贯穿整个晶粒内部完成生长,紧接着大量贝氏体板条依附在B5上形核,并沿着与B5成7°~10°夹角的方向平行生长成为贝氏体板条束,如图4e~g所示。随着温度继续降低至374.0℃时,贝氏体板条最后的形核位置出现在晶粒内部无畸变的平整区域,如图4f中的局部放大插图所示,第6个贝氏体板条(B6)开始在原奥氏体晶粒内部形核生长,后来的贝氏体板条则依附于B6侧边逐层生长,形成较为宽大的贝氏体板条束,如图4g所示。随着温度的不断降低,贝氏体转变继续进行。观察发现还有一些贝氏体板条(B7)会选择依附在先前的贝氏体板条旁边快速生长,在遇到其他贝氏体板条的阻碍后停止生长,形成交叉互锁的结构,如图4g和h所示。在331.6℃时贝氏体板条覆盖了整个原奥氏体晶粒,呈现出典型的羽毛状上贝氏体形态,如图4i所示。

图4

图4

P22铁素体耐热钢CGHAZ冷却过程中贝氏体板条长大过程的CSLM像

Fig.4

CSLM images of the growth of bainite laths in the CGHAZ of P22 ferritic heat-resistant steel (a-i) (Insets show partial enlarged bainite laths)

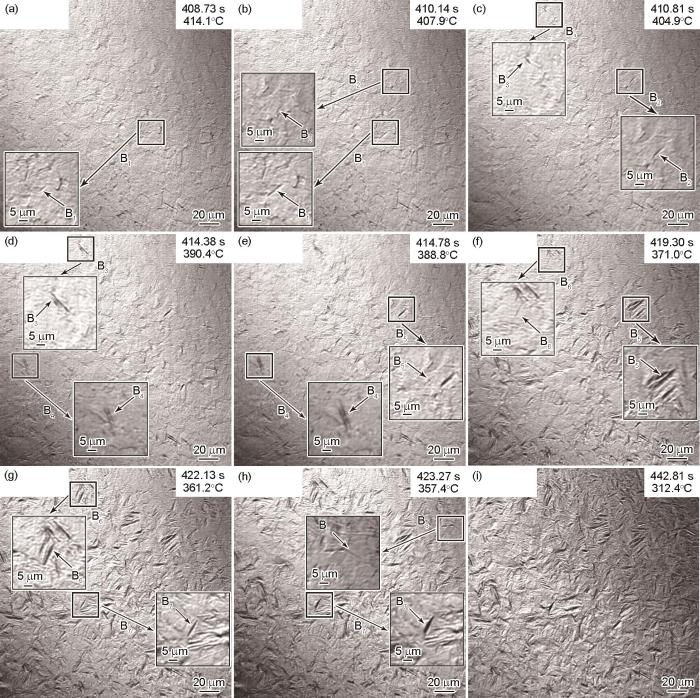

图5为P22铁素体耐热钢FGHAZ冷却过程中CSLM原位观察的典型结果。当温度从1000℃连续冷却至414.1℃时,样品表面开始出现明显的浮凸,第1个贝氏体板条(B1)在原奥氏体晶粒内发生固态相变,如图5a和b中的局部放大插图所示。随着温度的降低,观察到大量细小的贝氏体板条(B2~B8)不断在原奥氏体晶粒内部形核生长,同时贝氏体板条之间呈现相互依附且平行生长的典型特征,形成较为宽大的贝氏体板条束,如图5b~h所示,这一现象与P11铁素体耐热钢FGHAZ中观察到的贝氏体相变过程完全一致。随着冷却时间的不断增加,最终当温度降低至312.4℃以下时,样品表面不再出现持续的浮凸现象,表明贝氏体相变结束,可以清楚地看到奥氏体晶粒完全被贝氏体板条覆盖,呈现出细小的羽毛状特征,如图5i所示。

图5

图5

P22铁素体耐热钢FGHAZ冷却过程中贝氏体板条长大过程的CSLM像

Fig.5

CSLM images of the growth of bainite laths in the FGHAZ of P22 ferritic heat-resistant steel (a-i) (Insets show partial enlarged bainite laths)

2.3 P91铁素体耐热钢HAZ相变过程的原位观察

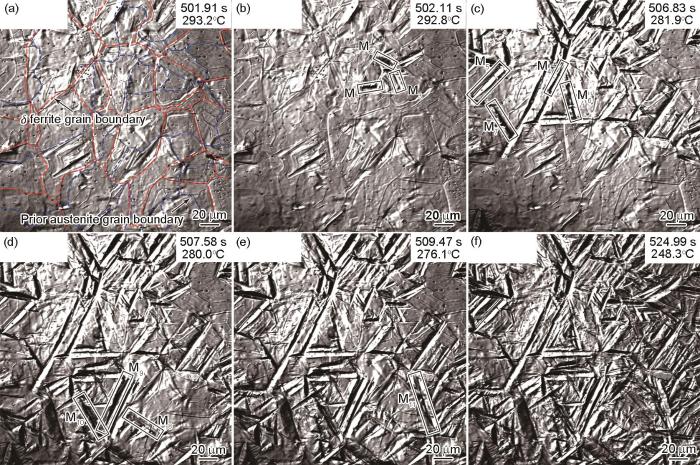

图6为通过CSLM原位观察捕获的P91铁素体耐热钢CGHAZ从峰值温度连续冷却至室温过程中低温阶段奥氏体到马氏体相变的典型图像。如图6a所示,将经历高温相变后的δ铁素体晶界和奥氏体晶界分别用红色和蓝色虚线勾画出来,测量计算出δ铁素体和奥氏体的平均晶粒尺寸分别62.5和39.5 μm。292.8℃时在样品表面可以清楚地观察到相转变时产生明显的浮凸效应,如图6b所示,根据相变温度并结合浮凸剧烈程度推断该现象是由奥氏体向马氏体切变所引起。随着温度的降低,如图6c~e所示,大量马氏体板条(M4~M11)通过切变在晶粒内部迅速生长。随着马氏体相变的进行,马氏体板条在奥氏体晶粒内部呈放射状生长,并在248.3℃时转变结束,奥氏体全部由马氏体板条覆盖,如图6f所示。

图6

图6

P91铁素体耐热钢CGHAZ冷却过程中马氏体板条长大过程的CSLM像

Fig.6

CSLM images of the growth of martensite laths in the CGHAZ of P91 ferritic heat-resistant steel (a-f) (M1-M11 represent growing martensite laths, the same below)

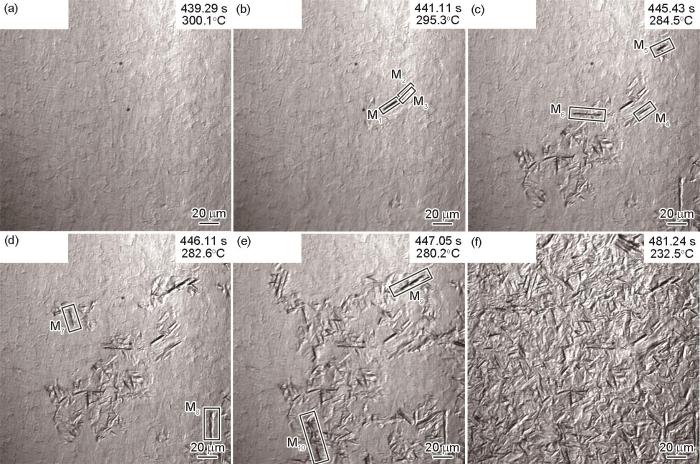

图7为P91铁素体耐热钢FGHAZ在焊接热循环冷却过程中的原位观察结果。如图7a所示,在300.1℃时,平整的样品表面未观察到浮凸,奥氏体晶粒边界不明显,通过在室温下的非原位观察测得原奥氏体的平均晶粒尺寸为9.4 μm。当温度降低至295.3℃时,开始发生马氏体相变,3个马氏体板条(M1~M3)同时在奥氏体晶粒内部切变生长,如图3b所示。随着温度的降低,马氏体板条(M4~M10)以放射状快速在奥氏体晶粒内部切变生长,并且相较于图6中P91铁素体耐热钢CGHAZ的原位观察结果,由于FGHAZ中原奥氏体晶粒尺寸的限制,成簇的马氏体板条束尺寸显著减小,板条长度由40.9 μm减小到15.8 μm,如图7c~e所示。最终在232.5℃时,马氏体相变结束,样品表面不再出现浮凸变化,可以清楚看到细小的马氏体板条完全覆盖了整个奥氏体晶粒,如图7f所示。

图7

图7

P91铁素体耐热钢FGHAZ冷却过程中马氏体板条长大过程的CSLM像

Fig.7

CSLM images of the growth of martensite laths in the FGHAZ of P91 ferritic heat-resistant steel (a-f)

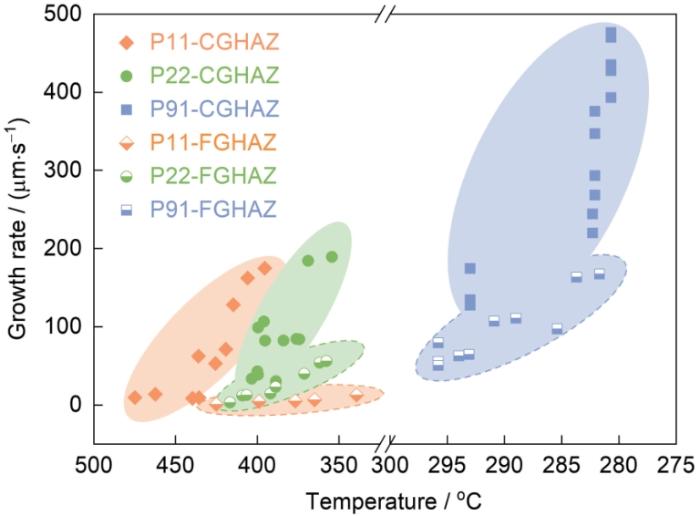

2.4 铁素体耐热钢HAZ贝氏体/马氏体板条的生长速率

通过CSLM对上述P11、P22、P91 3种铁素体耐热钢CGHAZ和FGHAZ在连续冷却过程中的相变行为进行原位观察,并使用ImageJ图像分析处理软件定量分析贝氏体/马氏体板条长度随冷却时间的变化规律,计算得到板条生长速率与温度的关系,如图8所示。系统分析HAZ的相变动力学,发现P11-CGHAZ、P22-CGHAZ、P91-CGHAZ中贝氏体/马氏体板条的生长速率在较大的范围内变化,分别为8.4~174.9、30.3~189.3和127.5~476.4 μm/s,并且随着温度的降低,板条生长速率呈现急剧增大的趋势。同时还发现相较于CGHAZ而言,FGHAZ中贝氏体/马氏体板条的生长速率较小,P11-FGHAZ、P22-FGHAZ、P91-FGHAZ中板条的生长速率分别为0.2~12.6、3.2~56.1和50.4~191.3 μm/s,但随着温度的降低,贝氏体/马氏体板条的生长速率不断加快,这与CGHAZ中生长速率的变化规律一致。此外,对比P11、P22、P91 3种不同铁素体耐热钢在CGHAZ或FGHAZ相同焊接热循环条件下板条的生长速率,发现随着铁素体耐热钢中合金元素含量的增加,在发生相变时马氏体板条的生长速率明显高于贝氏体板条。

图8

图8

贝氏体/马氏体板条生长速率与温度的关系

Fig.8

Relationships between growth rate and temperature for bainite laths and martensite laths

3 分析讨论

3.1 HAZ的组织演变特征

由上述图2~5的原位观察结果可知,在P11和P22铁素体耐热钢HAZ的连续冷却过程中,发生贝氏体相变时板条的可能形核位置按照由易到难的顺序依次为原奥氏体晶界、夹杂物、晶粒内部畸变区域、先前的贝氏体板条和晶粒内部自由表面(free surface)。通常情况下,能量势垒的高低会影响贝氏体板条开始形核的先后顺序,能量势垒越低,贝氏体板条形核越容易。根据Bhadeshia等[28]提出的贝氏体相变理论,Chang等[29]和Singh等[30]的研究结果表明贝氏体板条首先会在原奥氏体晶界处形核并延伸生长。Ricks等[31]依据经典形核理论研究夹杂物作为相变的形核位点时发现,在相同驱动力的作用下,夹杂物表面形核的能量势垒要高于奥氏体晶界。同时还发现,相比于较小尺寸的夹杂物,相变更易于在较大尺寸的夹杂物上发生。此外,从样品表面产生的明显浮凸判断,贝氏体板条是以切变方式进行转变的[25],由于位移性转变可以通过引入产生局部应力场的形核位点来有效地诱导贝氏体形核[32,33],因此晶粒内部畸变区域和先前的贝氏体板条成为辅助降低能量势垒的有力因素。徐祖耀等[34]还指出,在奥氏体基体的自由表面上均匀形核的能量势垒最高。正因如此,晶粒内部无畸变的自由表面成为贝氏体板条最后的形核位置。综上所述,贝氏体板条形核位置的能量势垒按照由低到高的顺序依次排列为:晶界、夹杂物等缺陷以及晶粒内部的自由表面。在本工作中,通过CSLM原位观察提供了贝氏体板条形核位置先后顺序的直接证据,与先前研究人员[35,36]揭示的理论研究结果一致。

此外,不同种类铁素体耐热钢在连续冷却过程中贝氏体板条的生长方式呈现出相似的特征。首先在最初阶段,大量平行的贝氏体板条沿着与晶界成一定角度的方向直线生长,并且在晶粒内部形成较为宽大的板条束。这表明当晶粒中没有贝氏体板条形核生长时,依附于原奥氏体晶界生长是贝氏体板条束的优先选择方式,这一发现与Mao等[37]基于等温热处理过程对低碳贝氏体焊缝金属中发生贝氏体相变行为的阐述一致。其次,观察发现,晶粒内部新形成的贝氏体板条在形貌变化上主要呈现出2种典型特征:一种是选择依附在先前的贝氏体板条旁边,并与之平行生长;另一种是选择在先前的贝氏体板条尖端或者侧面,并与之成一定角度延伸生长。这些生长特征表明,相较于原奥氏体晶界,依附于现存已有的贝氏体板条成为后续贝氏体板条生长的优选方式,这主要归因于已有的贝氏体板条可以提供大量形核生长的机会[38]。最后,贝氏体生长还以板条的碰撞为特征,即随着温度的降低,相变的不断进行,贝氏体板条一旦遇到原奥氏体晶界或其他贝氏体的阻碍后就会停止生长[39,40],最终同一晶粒内部不同生长方向的贝氏体板条会形成交叉互锁的结构。

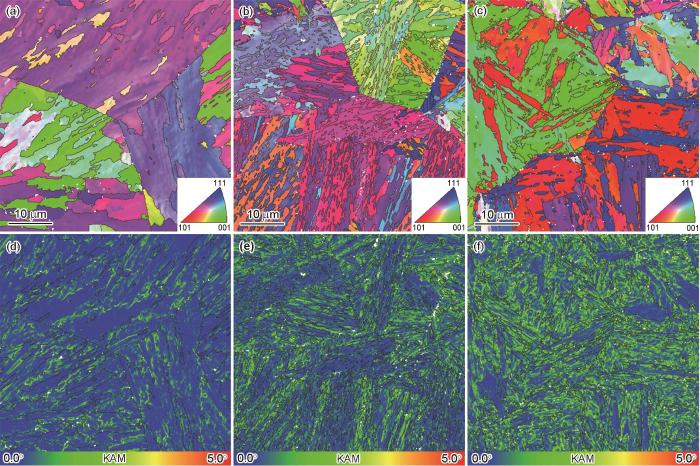

为进一步理解3种典型铁素体耐热钢HAZ的微观组织演变特征,对CSLM原位观察后的样品进行EBSD表征分析,详细结果如图9所示。从图9a~c的反极图(invers pole figure,IPF)可以看出,贝氏体/马氏体的微观组织呈现出等级层次分明的特征,主要包括块(packet)、束(block)以及板条(lath)[42,43]。原奥氏体晶粒内部分成多个朝不同方向生长的贝氏体/马氏体块,单个贝氏体/马氏体块中又包含了几个取向不同的贝氏体/马氏体束,而贝氏体/马氏体束则由取向近乎相同的板条组成,这些板条相互之间以2°~10°的取向差平行分布。此外,一些贝氏体/马氏体板条即使相隔很远,但是它们的晶体取向相同,这可能属于Kurdjumov-Sachs (K-S)取向关系中的相同变体对[44]。同时,如图9d~f所示,通过局部平均取向差(kernel average misorientation,KAM)的分布可以定量评估材料的局部应变分布[45,46],其中蓝色表示低应变区,红色表示高应变区。可以看出应变集中分布在板条边界处和部分板条内部,这表明当HAZ中发生贝氏体或马氏体相变时由于原子位移以切变方式进行,会导致点阵畸变,板条内具有较高的局部应变能。经过计算可知P11、P22和P91铁素体耐热钢CGHAZ中KAM的平均值分别为0.55°、0.78°和0.96°。因此相较于贝氏体相变,马氏体相变时晶粒内部的应变集中更强,变形程度更大,这一变化规律与CSLM原位观察过程中样品表面浮凸程度相符。

图9

图9

P11、P22和P91铁素体耐热钢CGHAZ的反极图(IPF)和局部平均取向差(KAM)图

Fig.9

Invers pole figures (IPFs) (a-c) and kernel average misorientation (KAM) maps (d-f) of the CGHAZ in P11 (a, d), P22 (b, e), and P91 (c, f) ferritic heat-resistant steels

3.2 HAZ的相变动力学

从相变动力学角度分析,通过图8对相变过程中大量典型板条生长速率的统计量化可知,铁素体耐热钢HAZ中贝氏体/马氏体板条的生长速率随着温度的降低而不断增大;并且同一种铁素体耐热钢CGHAZ中板条的生长速率明显高于FGHAZ;此外,随着铁素体耐热钢中合金元素含量的增加,板条的生长速率也会显著升高。

式中,Bs和Ms分别为贝氏体相变和马氏体相变的起始温度,℃;ωM 为铁素体耐热钢中元素M (M = C、Cr、Mo、Mn、Ni)的质量分数,%。根据

表3 P11铁素体耐热钢中贝氏体板条的过冷度和生长速率的计算值

Table 3

| Bainite lath (i) | ΔT / oC | V / (μm·s-1) |

|---|---|---|

| 1 | 123.7 | 9.4 |

| 2 | 136.2 | 13.6 |

| 3 | 158.9 | 8.4 |

| 4 | 162.6 | 62.5 |

| 5 | 162.9 | 9.3 |

| 6 | 172.9 | 52.9 |

| 7 | 179.3 | 71.2 |

| 8 | 183.8 | 128.2 |

| 9 | 192.6 | 162.4 |

| 10 | 203.1 | 174.9 |

结果表明随着温度的降低,ΔT会增加,板条生长速率整体呈现上升趋势,其中部分贝氏体板条的生长速率与ΔT的变化规律略有差异,这可能与不规则的原子排列、晶格畸变、缺陷等因素有关[51,52]。Endo等[53]研究了Y1Ba2Cu3O7 - x 超导体中ΔT与生长速率的关系,发现生长速率随着ΔT的增加呈现增加趋势。此外,研究人员[54]普遍认为冷却速率越大,实际相变温度越低,从而导致ΔT越大。Mao等[37]研究了不同冷却速率(0.2、1和5℃/s)对低碳贝氏体焊缝金属中贝氏体板条生长速率的影响,结果表明上述冷却速率条件下的实际贝氏体转变温度分别为425.4、404.3和262.2℃,相应的贝氏体板条平均生长速率分别为2.25、183和1979 μm/s。假设该研究中的理论贝氏体转变温度恒定不变,0.2和1℃/s的冷却速率差异将导致ΔT的差值为21.1℃,而0.2和5℃/s的冷却速率差异将导致ΔT的差值增大到41.1℃,该研究结果表明,不同冷却速率导致贝氏体板条生长速率的巨大差异源自于ΔT所带来的影响。因此,ΔT增加,相变驱动力增大,这会促进贝氏体板条生长速率的增加。

另一方面,Celada-Casero等[55]通过Thermo-Calc热力学计算软件(TCFE9数据库)对原奥氏体晶粒尺寸(Dγ )与临界相变驱动力(ΔGc)的关系进行评估,研究发现,当Dγ = 185 μm时,微观组织转变的ΔGc = 1570 J/mol,而当Dγ = 6 μm时,微观组织转变的ΔGc = 1800 J/mol,这意味着当原奥氏体晶粒从185 μm细化为6 μm时,需要额外提供230 J/mol的驱动力。同时,Hu等[56]和Xu等[57]研究也指出,粗大的奥氏体晶粒导致更快的转变速率,这是因为在较小的奥氏体晶粒内发生相变时板条碰撞更为频繁,从而会限制板条的生长。由此可知,原奥氏体的晶粒尺寸会显著影响贝氏体/马氏体的相变驱动力。在本工作中,通过量化分析可知FGHAZ中的原奥氏体晶粒尺寸显然远小于CGHAZ,如表4所示,因此FGHAZ在后续相变时驱动力较小,导致FGHAZ中板条的生长速率远小于CGHAZ。

表4 P11、P22和P91铁素体耐热钢CGHAZ和FGHAZ的原奥氏体晶粒尺寸

Table 4

| Steel | CGHAZ | FGHAZ |

|---|---|---|

| P11 | 89.5 | 19.0 |

| P22 | 61.2 | 11.2 |

| P91 | 39.5 | 9.4 |

众所周知,Cr、Mo、Mn等合金元素能够提高钢的淬透性,与此同时这些合金元素对钢的微观组织及相变动力学也有深刻的影响。Liu等[58]及Kong和Xie[59]研究在连续冷却过程中合金元素对贝氏体转变的影响时指出,随着钢中Mo元素含量(质量分数)从0.16%增加到1.0%,Bs不断降低,板条生长速率则显著升高。此外,Hu等[60]也报道了相同的研究结果,这意味着增加合金元素含量可以提高贝氏体/马氏体板条的生长速率。在本工作中,随着P11、P22、P91铁素体耐热钢中主要合金元素(Cr和Mo)含量不断增加,显著提高了过冷奥氏体的稳定性,保留了更多的过冷奥氏体用于后续的贝氏体/马氏体转变,而且由此降低了相转变温度,增大了过冷度,导致后续相变驱动力增加,提高了板条的生长速率。因此,P11、P22、P91 3种铁素体耐热钢在CGHAZ或FGHAZ焊接热循环条件下板条生长速率的变化主要归因于钢中合金元素含量的不同而导致过冷度的差异,进而导致相变驱动力的不同。

4 结论

(1) 通过CSLM原位观察提供了铁素体耐热钢HAZ相变行为的直接证据。在P11和P22铁素体耐热钢的CGHAZ和FGHAZ中发生了贝氏体相变,贝氏体板条优先选择在原奥氏体晶界处形核生长,然后依次在夹杂物、晶粒内部畸变区域、先前的贝氏体板条、晶粒内部自由表面形核生长;而在P91铁素体耐热钢HAZ中则发生了马氏体相变。

(2) 揭示了铁素体耐热钢HAZ相变过程中的微观组织演变特征。贝氏体相变时,初生的贝氏体板条束通常会优先选择依附于原奥氏体晶界生长,而后续次生的贝氏体板条则依附于先前的贝氏体板条生长。马氏体相变时,大量马氏体板条在原奥氏体晶粒内部通过切变呈放射状迅速生长。此外,几乎所有的贝氏体/马氏体板条都通过与晶界或其他板条相遇碰撞而停止生长,形成交叉互锁的结构,并产生较高的局部应变能。

(3) 随着温度的降低,3种铁素体耐热钢HAZ中板条的生长速率都不断增大,并且同种铁素体耐热钢CGHAZ中板条的生长速率明显高于FGHAZ。此外,随着耐热钢中合金元素含量的增加,导致相变驱动力增加,板条的生长速率也会显著增大。分析上述HAZ相变动力学认为,板条生长速率的变化本质主要与过冷度、原奥氏体晶粒尺寸有关,过冷度及原奥氏体晶粒尺寸越大,板条生长速率就越快。

参考文献

Systematical innovation of heat resistant materials used for 630-700oC advanced ultra-supercritical (A-USC) fossil fired boilers

[J].

630~700℃超超临界燃煤电站耐热管及其制造技术进展

[J].迄今,600 ℃超超临界是世界最先进商用燃煤电站技术。630~700 ℃超超临界燃煤电站研发将奠定我国火电技术的国际领先地位,对实现国家节能减排目标具有重要战略意义。耐热材料是制约火电机组蒸汽温度进一步提升的技术瓶颈,本文简述了国内外630~700 ℃超超临界电站耐热材料研制现状,指出了我国急需研发的关键耐热材料。阐述了作者团队在多年实践中总结的电站耐热材料“全流程选择性冶金过程设计和选择性强韧化设计”观点,重点介绍了在该设计观点指导下,我国成功研发了用于630~650 ℃的马氏体耐热钢G115<sup>?</sup>,用于650~700 ℃的固溶强化型镍基耐热合金C-HRA-2<sup>?</sup>、C-HRA-3<sup>?</sup>,以及用于700~750 ℃的析出强化型镍基耐热合金C-HRA-1<sup>?</sup>,系统构建了我国630~700 ℃超超临界燃煤锅炉耐热材料体系,并已成功制造了上述新型耐热材料锅炉管。

Research progress of a novel martensitic heat-resistant steel G115

[J].Improving the steam temperature and the pressure of the boiler applied in the thermal power could enhance the coal-fired efficiency and reduce the emission of harmful gases. Due to the dual impact of dwindling fossil resources and an exacerbated global greenhouse effect, it is critical to develop new heat-resistant boiler materials for ultra super-critical (USC) units at temperatures of 650oC and higher. With great thermal conductivity, good fatigue resistance, and low cost, martensitic heat-resistant steel G115, based on P92 steel applied in 600oC USC units, is a promising steel to be applied to this among all candidate materials. This paper introduces the main chemical composition and the microstructure feature of G115 steel, and the research progress in the areas of microstructure stability, creep performance, fatigue resistance, steam oxidation resistance, and industrial pipe production are summarized, with a focus on the role of Cu-rich phase in G115 steel. Finally, some key points on G115 steel are proposed to provide ideas for future research.

新一代马氏体耐热钢G115的研究进展

[J].提高火电机组中耐热锅炉的蒸汽温度和压力参数可以有效提升燃煤效率,减少有害气体排放。受煤炭资源紧缺和温室效应的双重影响,发展650℃及更高温度超超临界(ultra super-critical,USC)机组中的耐热锅炉材料已迫在眉睫。我国在600℃ USC机组用耐热材料P92钢基础上研发的马氏体耐热钢G115有望成为优选材料之一。本文介绍了G115钢的成分特点、形貌特征,综述了其在组织稳定性、蠕变性能、抗疲劳性能、抗蒸汽氧化性能以及工业管材制备等方面的研究进展,重点归纳了G115钢中富Cu相的作用,展望了未来研究重点,以期为更深入研究G115钢提供可行思路。

Localization of boiler steel technology in China used for ultra super critical power plants

[J].

超超临界火电机组用锅炉钢技术国产化问题

[J].

The state-of-the-art of steel technology used for Chinese power plants and its future

[J].

中国电站用钢技术现状和未来发展

[J].

Type IV cracking susceptibility in weld joints of different grades of Cr-Mo ferritic steel

[J].

Microstructure evolution and mechanical properties of dissimilar material diffusion-bonded joint for high Cr ferrite heat-resistant steel and austenitic heat-resistant steel

[J].High Cr ferrite heat-resistant steel has excellent geometric structure stability, low radiation swelling rate, and good corrosion resistance of liquid metal. TP347H austenitic heat-resistant steel is based on the traditional 18-8 austenitic steel with the addition of a certain amount of Nb and a small amount of N to precipitate MX-type carbonitride, which results in superior high-temperature properties. Steam with high temperature and pressure flowing through supercritical thermal power units may exhibit heterogeneous connections between high Cr ferrite and austenitic heat-resistant steel components in the supercritical thermal power units. In this study, the vacuum diffusion-bonding of dissimilar materials between high Cr ferritic and TP347H austenitic heat-resistant steel was performed, the effects of diffusion-bonding time and post weld heat treatment (PWHT) process on the microstructural evolution and mechanical properties of the diffusion-affected zone was examined. The results indicated that with the extension of diffusion-bonding time, the interfacial bonding rate gradually increased. The interaction due to the difference in deformation storage energy and dislocation slips resulted in dynamic recrystallization, and the fine grains formed at the diffusion-bonding interface evolved into a serrated interface. Fine and dispersed MX and M23C6 phases were precipitated in the austenite grain boundaries and at the grain boundaries of the diffusion-bonding zone. After PWHT, the grains in the diffusion-bonding zone were further refined, dislocations were stable, dislocation density reduced, small-angle grain boundaries increased, and element diffusion was more sufficient. Tensile tests at different temperatures showed that the fractured sites were all in the matrix, which indicates that high-quality diffusion-bonding joints of dissimilar materials were achieved.

高Cr铁素体耐热钢与奥氏体耐热钢的异种材料扩散连接接头组织演变及力学性能

[J].

An integrated study on the evolution of inclusions in EH36 shipbuilding steel with Mg addition: From casting to welding

[J].

On the heterogeneous microstructure development in the welded joint of 12MnNiVR pressure vessel steel subjected to high heat input electrogas welding

[J].Microstructure features of 12MnNiVR pressure vessel steel welded joint deposited by the high heat input electrogas welding have been systematically investigated. It is revealed that the welded joint is featured by a heterogeneous juxtaposition. The coarse grained heat-affected zone (CGHAZ) primarily consists of lath bainites and minor granular bainites. The fine grained heat-affected zone (FGHAZ) is dominated by polygonal ferrites, pearlites, and fine cementite particles. Moreover, electron backscatter diffraction results further demonstrate that the CGHAZ is populated by coarse prior austenite grains (PAGs) with high frequency (61.3%) of low angle grain boundaries (LAGBs). On the other hand, the FGHAZ is filled with fine PAGs with a lower frequency (19.6%) of LAGBs. Such microstructural differences may likely contribute to differed mechanical properties for samples tested at designed positions.

TiO2-assisted microstructural variations in the weld metal of EH36 shipbuilding steel subject to high heat input submerged arc welding

[J].

Microstructural analysis of the as-welded heat-affected zone of a grade 91 steel heavy section weldment

[J].

Ghost microstructure evolution and identification in the coarse grain heat affected zone of 2.25Cr-1Mo-V-Ti steel using tint etching

[J].

Long term creep behaviour of welded joints of P91 steel at 650oC

[J].

Microstructure and creep fracture behavior in HR3C/T92 dissimilar steel welds

[J].

Fine-tuning weld metal compositions via flux optimization in submerged arc welding: an overview

[J].

埋弧焊中焊剂对焊缝金属成分调控的研究进展

[J].

Characterization of as-welded microstructure of heat-affected zone in modified 9Cr-1Mo-V-Nb steel weldment

[J].

A model of isothermal and non isothermal transformation kinetics of bainite in 0.5%C steels

[J].

Analysis of solute distribution in dendrites of carbon steel with δ/γ transformation during solidification

[J].

Formation of delta ferrite in 9 wt pct Cr steel investigated by in-situ X-ray diffraction using synchrotron radiation

[J].

In-situ observations of martensitic transformation in blast-resistant steel

[J].

High-temperature confocal laser scanning microscopy studies of ferrite formation in inclusion-engineered steels: A review

[J].

In situ observation and growth kinetics of bainite laths in the coarse-grained heat-affected zone of 2.25Cr-1Mo heat-resistant steel during simulated welding

[J].

Dissolution kinetics of arbitrarily-shaped alumina in oxide melt: An integration of phase-field modelling and real-time observation study

[J].

Ferrite formation dynamics and microstructure due to inclusion engineering in low-alloy steels by Ti2O3 and TiN addition

[J].

In situ observation of the nucleation and growth of ferrite laths in the heat-affected zone of EH36-Mg shipbuilding steel subjected to different heat inputs

[J].

Diffusional and displacive transformation behaviour in low carbon-low alloy steels studied by a hybrid in situ observation system

[J].

High resolution observations of displacements caused by bainitic transformation

[J].

Bainite in steels

[J].

Microstructure of lower bainite formed at large undercoolings below bainite start temperature

[J].

Effect of prior austenite grain size on the morphology of nano-bainitic steels

[J].

The nature of acicular ferrite in HSLA steel weld metals

[J].

Discontinuous lath martensite transformation and its relationship with annealing twin of parent austenite and cooling rate in low carbon RAFM steel

[J].

Formation of bainite below the MS temperature: Kinetics and crystallography

[J].

Effects of holding temperature on bainite transformation in Cr-Mo steel

[J].

Ferrite nucleation at ceramic/austenite interfaces

[J].

In situ observation of kinetic processes of lath bainite nucleation and growth by laser scanning confocal microscope in reheated weld metals

[J].

Morphology and crystallography of microstructures in Mg-deoxidized offshore engineering steels after simulated welding thermal cycles

[J].

In situ study on interrupted growth behavior and crystallography of bainite

[J].

Effect of austenite grain size on the transformation kinetics of upper and lower bainite in a low-alloy steel

[J].

In-situ investigation of phase transformation behaviors of 300M steel in continuous cooling process

[J].

Influence of refined hierarchical martensitic microstructures on yield strength and impact toughness of ultra-high strength stainless steel

[J].The hierarchical martensitic features in ultra-high strength stainless steel (UHSSS), including the prior austenite grains, martensite packets, blocks and laths with the descending size, were refined to various extents by employing different thermomechanical processes and then carefully characterized. Their relation to yield strength and impact toughness was analyzed. We conclude that the refinement of martensitic structures could lead to the significant increase of yield strength, which follows the Hall-Petch relation with the effect grain size defined by high angle boundaries (HABs). Impact toughness of UHSSS depends on the frequency and capability for retained austenite (RA) grains at both HABs and martensite lath boundaries to trap the propagating cracks via strain-induced transformation, in which the film-like RA grains at lath boundaries appear to make the greater contribution.

Crystallography of upper bainite in Fe-Ni-C alloys

[J].

Correlation between the microstructural development of bainitic ferrite and the characteristics of martensite-austenite constituent

[J].

A review of strain analysis using electron backscatter diffraction

[J].Since the automation of the electron backscatter diffraction (EBSD) technique, EBSD systems have become commonplace in microscopy facilities within materials science and geology research laboratories around the world. The acceptance of the technique is primarily due to the capability of EBSD to aid the research scientist in understanding the crystallographic aspects of microstructure. There has been considerable interest in using EBSD to quantify strain at the submicron scale. To apply EBSD to the characterization of strain, it is important to understand what is practically possible and the underlying assumptions and limitations. This work reviews the current state of technology in terms of strain analysis using EBSD. First, the effects of both elastic and plastic strain on individual EBSD patterns will be considered. Second, the use of EBSD maps for characterizing plastic strain will be explored. Both the potential of the technique and its limitations will be discussed along with the sensitivity of various calculation and mapping parameters.

Kernel average misorientation confidence index correlation from FIB sliced Ni-Fe-Cr alloy surface

[J].

Prediction of bainite start temperature in alloy steels with different grain sizes

[J].

Continuous cooling transformation behaviour and bainite formation kinetics of new bainitic steel

[J].

The temperature of formation of martensite and bainite in low-alloy steels

[J].

Empirical formulae for the calculation of some transformation temperatures

[J].

In situ measured growth rates of bainite plates in an Fe-C-Mn-Si superbainitic steel

[J].

Austenite to bainite phase transformation in the heat-affected zone of a high strength low alloy steel

[J].

Relationship between growth rate and undercooling in Pt-added Y1Ba2Cu3O7 - x

[J].

Effect of cooling rate on grain refinement of cast aluminium alloys

[J].

The role of the austenite grain size in the martensitic transformation in low carbon steels

[J].

Acceleration of the super bainite transformation through a coarse austenite grain size

[J].

A new approach to quantitative analysis of bainitic transformation in a superbainite steel

[J].

In-situ observation of bainite transformation in CGHAZ of 420 MPa grade offshore engineering steel with different Mo contents

[J].

Effect of molybdenum on continuous cooling bainite transformation of low-carbon microalloyed steel

[J].

Effect of Mo content on microstructure and property of low-carbon bainitic steels

[J].