Mg及镁合金作为一类重要的轻质金属结构材料,具有低密度、高比刚度和比强度,以及优异的生物相容性、生物降解性和阻尼特性,因而在交通运输、生物医用、电子产品和军工等诸多领域具有广泛的应用前景[1~5]。然而,Mg及镁合金的绝对刚度和强度以及抗高温蠕变能力均明显低于钢铁、铝合金、钛合金等其他常用的金属结构材料[6~9],这在一定程度上限制了Mg及镁合金作为结构材料的应用。通过在Mg基体中引入增强相制备镁基复合材料为强化Mg及镁合金提供了一种可行的途径。研究[10~17]表明,镁基复合材料的力学性能在很大程度上依赖于其微观组织,例如增强相的含量、空间构型、排布、取向等特征。因此,在镁基复合材料中探索新型组织结构的设计与构筑,并揭示材料的组织结构与其室温及高温力学性能之间的关系,对于指导优化镁基复合材料的结构以提升其性能具有重要意义。

与人造材料相比,自然界中生物材料的组织结构在长期进化过程中得以持续优化,从而具备优异的力学性能,因此有望为人造材料的组织结构优化设计提供有益的启示[18~21]。鱼鳞作为一种典型的天然生物材料,兼具轻、柔、强、韧等多种优点,能够在不显著降低鱼类灵活性的前提下为其提供良好的防护功能。鱼鳞主要由2部分构成,分别为矿化程度较高的骨质外层和由羟基磷灰石矿化的胶原纤维组成的内层,其中坚硬的外层主要提供硬度和强度,能够防止穿透以及损伤开裂,而强而韧的内层能够通过变形高效吸收能量,增强鱼鳞的韧性并抑制裂纹扩展,从而提高损伤容限[22~24]。研究[23~26]表明,鱼鳞内层中的胶原纤维通常以层状形式相互堆叠,各层内纤维取向一致,而在相邻层之间则表现出特定的取向特征,这种结构赋予鱼鳞内层良好的强韧性匹配,使其能够减弱应力集中并缓和冲击,有效减轻外载荷造成的损伤。真鲷和腔棘鱼的鱼鳞是鱼鳞独特结构和优异性能的典型代表[25~28],这2种鱼的体长均可达1 m以上,却可以生活在鲨鱼出没的水域,其鱼鳞可以抵抗来自鲨鱼的撕咬。真鲷和腔棘鱼的鱼鳞这种高效的抗损伤能力分别主要与其内层的正交层合板和双螺旋层合板结构有关。其中,真鲷鱼鳞的正交层合板结构是由正交取向的胶原纤维层堆叠而成,即相邻层内的胶原纤维呈相互垂直排列;而腔棘鱼鱼鳞具有双螺旋层合板结构,又称为双Bouligand结构,其相互垂直的胶原纤维层以特定的角度在相邻层之间发生扭转,形成周期性的双螺旋排列,与鱼鳞中较为常见的单螺旋(即单Bouligand)结构不同[29~31],其发生扭转的结构单元由相互垂直的2层胶原纤维组成。鱼鳞的正交层合板和双螺旋层合板结构均有利于耗散外载荷施加的机械能,增加裂纹面积的同时诱导裂纹沿结构发生偏转,从而有效增大裂纹扩展阻力,特别是双Bouligand结构能够通过减弱层内损伤并优化层间应力分布,获得优异的断裂韧性,并且在冲击载荷条件下表现出良好的层间耦合能力和应力传递效率,因此能够显著提升材料抵抗损伤的能力[25~28]。

鉴于鱼鳞的独特结构和优异性能,研究者们越来越多地通过在人造材料中构筑与鱼鳞相似的结构来探索优化材料的性能,这种类鱼鳞仿生结构设计已被应用于树脂、陶瓷等多种材料体系[32~36]。其中,本团队[35~37]近期利用低熔点金属熔渗高熔点金属编织骨架的方法,首次在Cu-W和Mg-Ti 2种金属材料体系中成功构筑了仿鱼鳞结构,从而实现了材料力学性能的提升。在前期基础上,本工作进一步选用容易获取、成本较低且强度高于Ti的316L不锈钢纤维作为镁基复合材料的增强相,设计并构筑2种不同的类鱼鳞仿生结构类型,探索优化镁基复合材料的力学性能,并揭示其仿生结构与力学性能之间的关系,以期为新型镁基仿生复合材料设计提供指导。

1 实验方法

1.1 复合材料制备

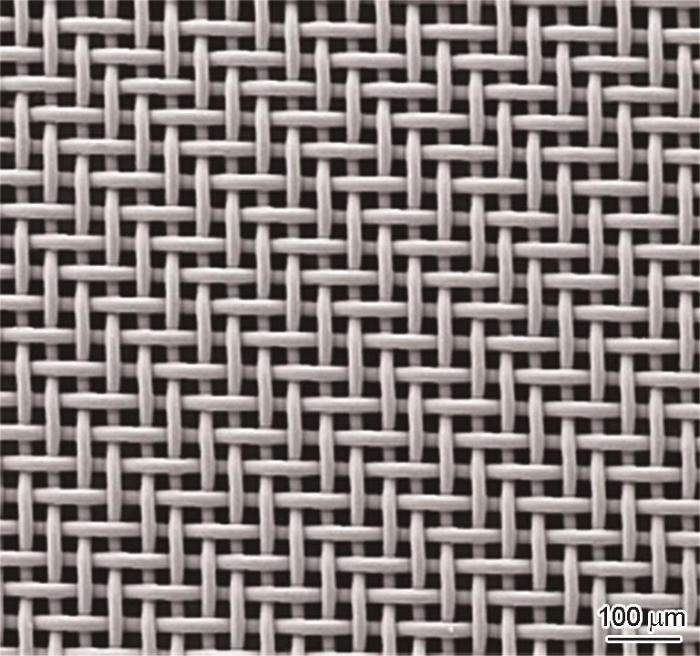

选用具有正交编织结构的商用316L不锈钢网作为增强相,这些不锈钢网由连续的316L不锈钢纤维相互垂直交织而成,不锈钢纤维直径为28 μm,相邻纤维间距为50 μm,如图1所示。利用剪刀将不锈钢网裁剪成直径约75 mm的圆形网片,采用浓度为10% (质量分数)的HF水溶液超声清洗网片5 min以去除表面油污及氧化层,再用无水乙醇清洗后晾干。然后将上述圆形网片分别按照正交及螺旋形式进行堆叠,得到正交层合板和双螺旋层合板结构。其中,正交层合板结构中各层的纤维取向完全一致,而双螺旋层合板结构中相邻层之间的纤维自下而上沿逆时针方向依次扭转7.5°。研究[28,35,36]表明,较小的层间扭转角度(一般小于10°)有利于提高双螺旋层合板结构的损伤容限,本工作中扭转角度选定为7.5°,这样可以确保在实验室制备的小样品中(厚度约为1 mm)形成2个完整的螺旋周期(单个周期为90°),即包含24层不锈钢网。沿层厚方向以35 MPa压力、保压2 h的工艺对堆叠好的不锈钢网进行致密化处理,得到具有正交层合板和双螺旋层合板结构的不锈钢纤维编织骨架。作为对比,选用直径为15 μm、长度为3 mm的316L不锈钢短切纤维作为增强相,将纤维装填入截面尺寸为30 mm × 30 mm的方形模具中,采用35 MPa压力、保压2 h的工艺进行致密化处理,得到纤维在二维面内随机取向的增强体骨架。

图1

选用纯Mg (纯度99.95%)作为复合材料的基体,在SRYL-2300/9型石墨电阻炉中对纤维骨架进行无压熔渗,为了防止熔渗过程中不锈钢编织骨架发生变形,熔渗前在其上、下两面绑定具有更粗直径(1 mm)的刚性不锈钢网格。将纯Mg块置于骨架上方并放入炉内,在流动的Ar气中以10°/min的速率加热至850℃(即比Mg的熔点高约200℃),保温10 min,然后随炉冷却,制备得到具有类鱼鳞结构的镁基仿生复合材料及对比样。

1.2 微观结构表征

采用D8 Advance型X射线衍射仪(XRD)以CuKαX射线对复合材料进行物相分析。采用Supra-35型场发射扫描电子显微镜(SEM)在20 kV加速电压下进行显微组织结构观察,并使用配备的Model 7426型光谱仪进行X射线能谱(EDS)分析。采用Xradia Versa XRM-500型三维X射线显微镜(XRT)在80 kV加速电压下表征复合材料的三维微观结构[38],样品围绕X射线源和探测器所在平面的法线轴旋转360°,等间隔采集二维投影,获得1600张二维投影图像,然后利用滤波反投影算法进行三维重建,重建后的三维图像的空间分辨率约为每像素1.6 μm,利用Avizo Fire软件对XRT图像进行三维处理和分析。

1.3 拉伸性能测试

拉伸性能测试的样品均由电火花线切割加工得到,测试前对样品表面进行机械磨抛。室温拉伸样品标距段的尺寸为13.5 mm × 6 mm × 0.8 mm,样品的长度方向与其所包含的最外层不锈钢网片中相互垂直的两束纤维中的任意一束平行。分别使用Instron 8871和MTS E45.105型万能试验机在室温和200℃对样品进行单轴拉伸测试。对于200℃拉伸实验,为了避免试样的夹持端因Mg基体蠕变而发生明显变形,将拉伸试样嵌入2个由高温合金制成的凹槽型夹具之间,200℃拉伸样品标距段的尺寸为18 mm × 4 mm × 1.5 mm。室温与200℃拉伸测试均在空气中进行,拉伸应变速率均为10-3 s-1,样品的应变利用Instron 2620-601型引伸计监测。使用Supra-35型场发射SEM在20 kV加速电压下观察样品的断后形貌。

2 实验结果

2.1 组成与微观结构

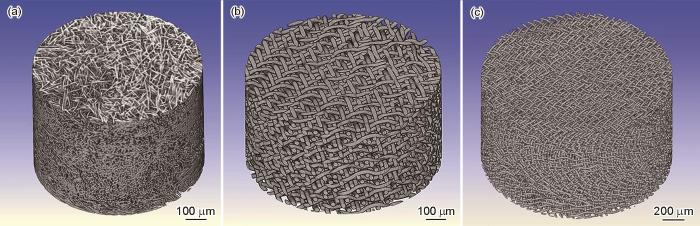

图2为具有不同微观结构的镁基复合材料中不锈钢纤维在三维空间的堆叠形式与空间排列结构。其中,对比样中的不锈钢短切纤维择优沿二维平面方向排布,而在面内则表现出随机取向特征(图2a)。相比而言,具有类鱼鳞结构的镁基仿生复合材料以相互垂直交织的不锈钢纤维层作为增强相。其中,对于类似真鲷鱼鳞的正交层合板结构,相邻层中的不锈钢纤维取向完全一致(图2b),而对于类似腔棘鱼鱼鳞的双螺旋层合板结构(即双Bouligand结构),相邻层中的不锈钢纤维自下而上沿逆时针方向依次扭转7.5°,形成螺旋式的周期性取向变化(图2c)。以上2种结构具有与天然鱼鳞相似的纤维空间排列形式。然而,天然鱼鳞中的每个结构单元层均由相互垂直排列的2层定向纤维构成[25,27],而仿生正交和双螺旋层合板结构中,每个单元内相互垂直的纤维则形成相互交织的网状结构,该结构有利于防止不同取向纤维之间的分离[27,35,36],从而提高层间结合强度。

图2

图2

具有不同微观结构的镁基复合材料中不锈钢纤维在三维空间的堆叠形式与空间排列的结构示意图

Fig.2

Schematics of the spatial arrangement of stainless steel fibers in three-dimensional space in the Mg-based composites with random stacking (a), orthogonal plywood (b), and double-Bouligand (c) architectures

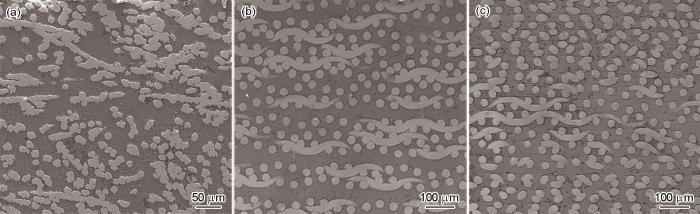

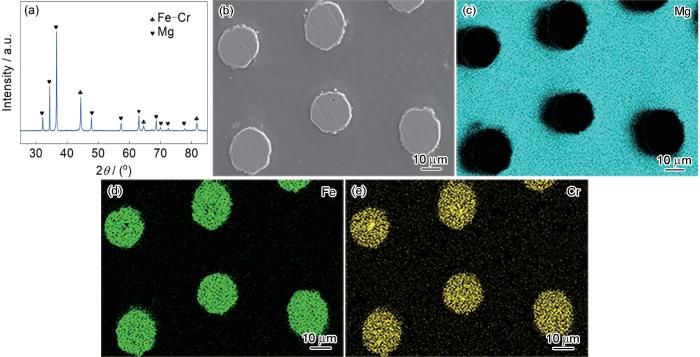

利用Mg熔体无压熔渗上述3种不锈钢纤维骨架,即可制备得到具有不同微观结构的不锈钢纤维增强镁基复合材料。图3为3种复合材料沿厚度方向截面二维微观形貌的SEM像。可以看出,3种复合材料中的不锈钢纤维在二维截面上呈现明显不同的分布特征,这与其差异显著的三维空间排列相对应。3种复合材料的三维微观结构,特别是材料中不锈钢增强纤维的空间排列,可由XRT像清晰显示,如图4所示。可见,3种复合材料中不锈钢纤维的空间排列特征均与所设计的排布形式(图2)相符,即分别表现为二维面内随机取向结构(图4a)以及与鱼鳞相似的正交层合板(图4b)和双螺旋层合板结构(图4c)。这说明通过构筑不锈钢纤维骨架结合无压熔渗的方法,可以制备得到具有不同微观结构的不锈钢纤维增强镁基仿生复合材料,并且材料中不锈钢纤维的空间排列可以通过改变不锈钢网的堆叠形式进行有效控制。经XRT测定,3种复合材料中不锈钢纤维的体积分数分别约为40%、32%和30%。在SEM和XRT分辨率下均未发现复合材料中存在明显的孔洞或裂纹等缺陷,说明Mg熔体在无压熔渗过程中能够充分填充不锈钢纤维骨架中的孔隙,形成致密的复合材料,这是由于金属熔体与固态金属之间润湿性良好[39~41],并且不锈钢纤维骨架中的开孔具有较好的连通性。

图3

图3

具有不同微观结构的不锈钢纤维增强镁基复合材料沿厚度方向截面二维微观形貌的SEM像

Fig.3

SEM images of the through-thickness cross-sections of the Mg-based composites with random stacking (a), orthogonal plywood (b), and double-Bouligand (c) architectures (Light gray: stainless steel fiber; dark gray: Mg matrix)

图4

图4

具有不同微观结构的镁基复合材料中不锈钢纤维在三维空间排布的XRT体积渲染图

Fig.4

XRT volume renderings of the spatial arrangement of the stainless steel fibers in the Mg-based composites with random stacking (a), orthogonal plywood (b), and double-Bouligand (c) architectures

图5

图5

不锈钢纤维增强镁基复合材料的XRD谱、SEM像及对应区域的EDS元素面分布图(以正交层合板结构为例)

Fig.5

XRD spectrum (a), SEM image (b), and corresponding area distributions of elements Mg (c), Fe (d), and Cr (e) measured by EDS of the Mg-based composites by taking the orthogonal plywood architecture as an example

2.2 力学性能

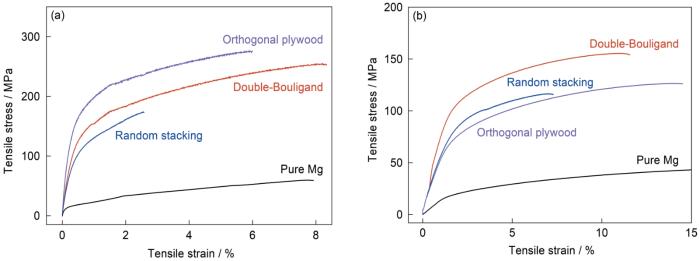

图6为具有不同微观结构的3种不锈钢纤维增强镁基复合材料在室温以及200℃的典型拉伸工程应力-应变曲线。作为对比,图中同时显示了与复合材料经历相同处理工艺的纯Mg的拉伸数据。在室温条件下(图6a),以不锈钢纤维增强的镁基复合材料均表现出显著高于纯Mg的屈服强度、抗拉强度和加工硬化率,表明不锈钢纤维起到了有效的强化作用。相比于二维平面随机取向结构,具有类鱼鳞结构的复合材料表现出更加稳定的塑性变形和加工硬化行为,从而具备更高的拉伸强度和塑性,其拉伸应变量可达5%以上。其中,正交层合板结构的强度更高,而双螺旋层合板结构的塑性更高。在200℃下(图6b),由于Mg基体发生蠕变,复合材料的强度和加工硬化率相比于室温都有所降低,但仍然显著高于纯Mg。与二维平面随机取向结构相比,具有仿生结构的复合材料表现出更优异的塑性变形能力,其拉伸塑性均可达到10%以上。特别是相比于正交层合板结构,双螺旋层合板结构在200℃下塑性变形前期的加工硬化率更大,能够在高温下表现出更显著的强化作用,而在室温下表现出更高的拉伸塑性,这与钛纤维增强镁基仿生复合材料中的情况相似[36]。此外,在室温和200℃下,具有不同微观结构的不锈钢纤维增强镁基复合材料均表现出具有连续加工硬化特征的均匀塑性变形行为,其加工硬化率均显著高于纯Mg,并且在断裂前没有发生明显的颈缩现象。

图6

图6

具有不同微观结构的不锈钢纤维增强镁基复合材料和纯Mg在室温以及200℃的典型拉伸工程应力-应变曲线

Fig.6

Representative tensile engineering stress-strain curves of the Mg-based composites with different architectures at room temperature (a) and 200oC (b) compared to pure Mg

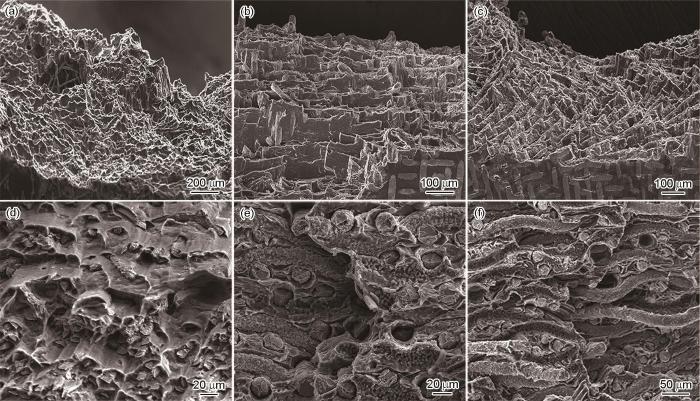

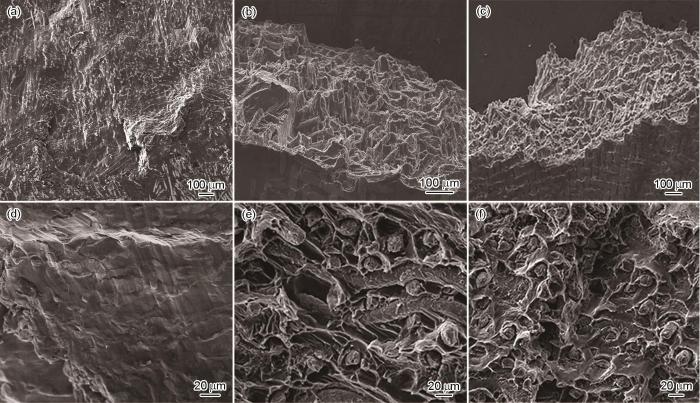

图7为具有不同微观结构的不锈钢纤维增强镁基复合材料在室温拉伸断裂后的微观形貌。可见,3种复合材料的断面均表现为断裂的纤维嵌入Mg基体中或从Mg基体中拔出后留下的凹坑特征,并且纤维的取向均与其微观结构相对应。具体而言,对于二维平面随机取向结构,不锈钢纤维在二维平面内无特定的择优取向(图7a和d);对于正交层合板结构,其纤维相互垂直排列,断面表现出分层特征,与拉伸方向平行的纤维发生断裂,而与拉伸方向垂直的纤维沿纤维间的Mg基体发生分离(图7b和e);而对于双螺旋层合板结构,断面具有螺旋状分层形貌,并且同时表现出纤维拉断与分离(图7c和f)。此外,3种复合材料断面上明显的纤维露头和凹坑特征说明纤维断裂后从Mg基体中拔出,这有利于进一步消耗能量,促进整体发生塑性变形。3种复合材料在200℃拉伸断裂后的微观形貌如图8所示。与室温相比,在200℃拉伸断裂后的试样断面上Mg基体的塑性变形特征更明显,这与高温下Mg基体发生蠕变有关。对于二维平面随机取向结构,短纤维之间沿Mg基体相互滑动,因此纤维露头和拔出均不明显(图8a和d);而对于仿生结构,断面上纤维周围的韧窝相比于室温情况更深更大(图8b和e),特别是对于双螺旋层合板结构,其断面上裸露的纤维界面明显减少(图8c和f),说明更多纤维倾向于发生断裂而不是沿界面中的Mg基体分离。

图7

图7

具有不同微观结构的不锈钢纤维增强镁基复合材料在室温拉伸断裂后的微观形貌

Fig.7

Low (a-c) and high (d-f) magnified fracture morphologies of the Mg-based composites with random stacking (a, d), orthogonal plywood (b, e), and double-Bouligand (c, f) architectures after tensile testing at room temperature

图8

图8

具有不同微观结构的不锈钢纤维增强镁基复合材料在200℃拉伸断裂后的微观形貌

Fig.8

Low (a-c) and high (d-f) magnified fracture morphologies of the Mg-based composites with random stacking (a, d), orthogonal plywood (b, e), and double-Bouligand (c, f) architectures after tensile testing at 200oC

3 分析讨论

自然界中的生物材料经过长期进化形成了复杂而巧妙的组织结构,赋予其优异的力学性能,而这种组织结构在金属结构材料中往往难以实现,特别是熔炼、轧制等传统材料制备加工工艺很难在多级尺度上对金属材料的组织结构进行有效控制。本工作利用低熔点金属熔渗高熔点金属纤维的编织骨架,为在金属基复合材料中构筑复杂的仿生结构提供了有效的方法,并且其所制备的金属基仿生复合材料中增强相的空间构型和取向等特征可以较方便地进行设计和调控。利用熔体浸渗工艺制备类鱼鳞结构镁基仿生复合材料需要注意以下3点:(1) 增强相与基体之间具有良好的润湿性,以保证熔体完全填充骨架;(2) 增强相的熔点明显高于基体,以保证有足够的温度窗口可供熔渗操作;(3) 在熔渗温度范围,基体与增强相之间不发生明显的化学反应或溶解。相比于本团队前期制备的钛纤维增强镁基仿生复合材料[36],本工作选用的316L不锈钢纤维尽管密度有所增加,但成本更低而强度更高。

对比纯Mg与镁基复合材料的力学性能可以发现,不锈钢纤维增强相的引入能够显著提高复合材料在室温与高温下的强度和加工硬化率,并且具有不同微观结构的复合材料均表现出连续的加工硬化特征,而在断裂前没有发生明显的颈缩现象,这说明复合材料整体塑性变形较为均匀,并未产生明显局域化。此外,复合材料断面上的纤维露头与凹坑特征表明不锈钢纤维断裂后从Mg基体中拔出,该过程有利于避免纤维断裂引起材料明显弱化,通过促进整体塑性变形进一步消耗能量[42],而不锈钢纤维的微观粗糙表面则有助于增大纤维拔出的阻力[43],阻碍界面滑移,从而有助于保证不锈钢纤维的强化效果。此外,不锈钢纤维增强镁基复合材料的力学性能与其微观结构密切相关。与二维平面随机取向结构相比,类鱼鳞正交层合板和双螺旋层合板结构尽管具有相对较低的不锈钢纤维增强相含量,但均表现出更高的拉伸强度和塑性,表明类鱼鳞仿生结构具有明显优势。

由于不锈钢纤维的强度远高于Mg基体并且具有一定的塑性变形能力,因此在外界载荷作用下,复合材料中的Mg基体首先发生塑性变形并伴随着加工硬化,随后沿拉伸方向的不锈钢纤维发生塑性变形直至纤维断裂,断后的纤维在Mg基体中拔出,从而在断面上留下明显的纤维露头与凹坑特征。然而,当不锈钢纤维的取向逐渐偏离拉伸方向时,纤维与基体之间逐渐倾向于发生沿两相界面分离,使得纤维的强化效率降低。在室温条件下,对于二维平面随机取向结构,由于不锈钢纤维在二维平面内无特定择优取向,因此纤维变形-断裂-拔出与两相界面分离均发生。对于正交层合板结构,平行于拉伸方向的纤维发生变形断裂并从基体中拔出,因而强化作用显著,而垂直于拉伸方向的纤维则倾向于沿两相界面相互分离。对于双螺旋层合板结构,不锈钢纤维按一定的角度扭转,尽管强度低于正交层合板结构,但不同取向的纤维之间能够协调变形,并且通过诱导裂纹沿纤维取向发生扭转,有利于减弱变形和损伤的局域化程度,提高材料的损伤容限,因而表现出更高的塑性,并且不锈钢纤维连续逐层断裂,呈现出螺旋状分层断口形貌。相比于室温,在200℃下,由于Mg基体发生蠕变,双螺旋层合板结构中的不锈钢纤维更易于在基体中向着拉伸方向偏转[44],更倾向于发生断裂而非与基体分离,因而相比于正交层合板结构表现出更高的强化效率。

此外,由于不锈钢的Young's模量(约193 GPa)与硬度均高于纯Mg (约45 GPa),而热膨胀系数(1.66 × 10-5℃-1)低于纯Mg (2.86 × 10-5℃-1)[45],因此不锈钢纤维在实现材料强化的同时,也有望提高材料的弹性模量和耐磨性,并降低其热膨胀系数。通过Archimedes排水法测得具有二维平面随机取向、正交层合板和双螺旋层合板结构的镁基复合材料的密度分别为3.60、3.11和3.42 g/cm3,相比于Mg基体均明显增大,可能对其实际应用带来不利影响。本工作旨在探索不同的增强相种类与仿生结构类型,并且揭示仿生结构与力学性能之间的关系,这能够为优化设计镁基复合材料的结构以提高其性能提供参考和指导。

4 结论

(1) 利用编织纤维增强骨架结合Mg熔体无压熔渗的方法,成功制备得到具有类似天然鱼鳞的正交层合板和双螺旋层合板结构的不锈钢纤维增强镁基仿生复合材料,并且能够对复合材料中增强纤维的空间排列与取向等结构特征进行有效的设计和调控。

(2) 在室温和200℃下,不锈钢纤维增强镁基复合材料表现出显著高于纯Mg的屈服强度、抗拉强度和加工硬化率,并且均发生具有连续加工硬化特征的均匀塑性变形,相较于二维平面随机取向结构,类鱼鳞正交层合板和双螺旋层合板结构尽管具有相对较低的不锈钢增强纤维含量,但均表现出更高的拉伸强度和塑性,其中双螺旋层合板结构在室温下塑性更高,而在高温下强度更高。

(3) 类鱼鳞正交层合板和双螺旋层合板结构能够通过纤维从基体中拔出促进变形和消耗能量,特别是双螺旋层合板结构中不同取向的纤维之间能够协调变形,并能够诱导裂纹沿纤维取向发生偏转,有利于减弱变形和损伤的局域化程度。

参考文献

Development and application of plastic processing technologies of magnesium alloys

[J].China has the most abundant magnesium resources in the world. Magnesium and its alloys have the advantages of low density, high specific strength, good damping property, and exceptional electromagnetic-shielding and energy-storage characteristics. They are one of the most promising lightweight materials. The enhanced applications of magnesium alloys can save energy and reduce emissions and are significant to the new Chinese energy strategy. However, magnesium alloys have a hexagonal close-packed structure and exhibit relatively low ductility. A bottleneck in expanding the application of magnesium alloys is improving the ductility of magnesium alloys. For more than ten years, efforts have been made to improve the ductility and plastic deformation ability. Progress has been made in plastic-processing technologies of magnesium alloys. The novel alloy design theory “solid solution strengthening and ductilizing” and advanced preparation technologies such as “melt self-purification through varying temperature” have been established. Series of new magnesium alloys with good ductility and corresponding alloy grades have been developed, where the impurity content of iron can be reduced to below 10 × 10-6; the elongation was more than 60% for ultrahigh plasticity magnesium alloys and is above 10% for the ultrahigh-strength magnesium alloys (UTS > 550 MPa). New plastic-processing technologies, such as asymmetric extrusion, asymmetric rolling, asymmetric modification, cyclical multipass upsetting and squeezing, expansion control large ratio forging, and extrusion and forging composite forming, have been developed. These newly developed magnesium alloys and processing technologies weaken the basal texture in wrought magnesium alloys, improving the formability of sheets, tubes, profiles, and forgings and their product quality and reducing their product cost. These technologies have been successfully applied in the processing of magnesium sheets, pipe profiles, and forgings.

镁合金塑性加工技术发展及应用

[J].我国是世界上镁资源最为丰富的国家,镁及镁合金具有质轻、比强度高、阻尼减振、电磁屏蔽性能优良、储能特性好等优点,是最有潜力的轻量化材料之一,其推广应用对节能减排和能源转型战略具有重要意义。但镁合金具有密排六方晶体结构,塑性变形能力较差。如何改善镁合金的塑性变形能力是扩大镁合金应用的瓶颈问题之一。本文综述了10多年来,世界各国在改善镁合金塑性、提升镁合金塑性变形能力等方面所做的大量工作,及在镁合金塑性加工技术等方面取得的重要进展。发展了“固溶强化增塑”新型镁合金设计理论和“熔体变温自纯化”等关键制备技术,形成了一批高塑性变形镁合金材料和牌号,其中杂质Fe含量可降到10 × 10<sup>-6</sup>以下,超高塑性镁合金延伸率可达到60%以上,超高强度(抗拉强度大于550 MPa)镁合金延伸率可以达到10%以上;开发了非对称挤压、非对称轧制、非对称改性、往复循环多道次镦挤开坯技术、扩收控制大比率锻造技术、挤锻复合成形技术等一批镁合金新型塑性加工技术。这些合金和技术使变形镁合金基面织构显著弱化,明显提高了变形镁合金板材、管型材和锻件的塑性成形能力和制品质量,产品成本大幅度降低,在板材、管型材和锻件制备加工中实现了成功应用。

Magnesium: Properties-applications-Potential

[J].

Technological advances in fabrication of magnesium matrix composites

[J].

镁基复合材料的制备技术进展

[J].

Microstructure evolution of Mg-10Gd-3Y-1.2Zn-0.4Zr alloy during heat-treatment at 773 K

[J].

Cast magnesium alloys for elevated temperature applications

[J].

Fabrication of Mg-based composites reinforced by SiC whisker scaffolds with three-dimensional interpenetrating-phase architecture and their mechanical properties

[J].Mg and Mg alloys, as important lightweight metal materials, have attracted great attention due to their excellent properties, such as low density, high specific strength, and good damping properties; however, their extensive applications are strictly limited by their low strength. The strength of Mg and Mg alloys can be effectively increased by introducing reinforcement phases into their matrices, i.e., via fabricating Mg-based composites. Nevertheless, the mechanical properties of Mg-based composites demonstrate a strong dependence on their microstructures. Here, new Mg-based composites reinforced by SiC whisker scaffolds with three-dimensional interpenetrating-phase architecture were fabricated through pressureless infiltration of the melt of pure Mg or AZ91D Mg alloy into the porous scaffolds of SiC whiskers. These whiskers were preferentially stacked in-plane within lamellae in the composites using gravity-assisted sedimentation and subsequent densification during the fabrication process. The microstructures and mechanical properties of the composites, particularly their fracture toughness, were characterized and analyzed. The wettability between the SiC whisker scaffolds and the melt was improved by introducing surface reactions between them which was accomplished by a pre-oxidation treatment of the scaffolds before infiltration. The pre-oxidation temperature was adjusted to ensure an adequate filling of the scaffolds without voids while avoiding the formation of excessive reaction products. The resulting composites exhibited a high flexural strength with a certain extent of fracture toughness as evidenced by stable crack propagation with rising R-curve behavior. In comparison to pure Mg, the composites infiltrated with AZ91D Mg alloy as the matrix contained a larger amount of coarsened precipitates, resulting in apparent brittleness despite increased strength.

三维互穿结构SiC晶须骨架增强镁基复合材料制备及其力学性能

[J].选用SiC晶须骨架作为增强相,利用重力辅助沉降、压缩致密化、骨架烧结及无压熔渗的方法制备了具有微观三维互穿结构的SiC晶须骨架增强镁基复合材料,并对其微观组织结构与力学性能(特别是断裂韧性)进行了表征与分析。通过对SiC晶须骨架进行预氧化处理,提高了增强相与基体之间的润湿性,并通过调节预氧化温度控制析出相含量和孔洞等缺陷,优化了复合材料的弯曲强度与断裂韧性,获得了稳定的裂纹扩展行为(上升的R曲线)。相比于以纯Mg为基体的复合材料,以AZ91D镁合金为基体的复合材料中析出相含量高且发生粗化,使得材料强度提高的同时断裂韧性降低。

Magnesium strengthened by SiC nanoparticles

[J].

What is going on in magnesium alloys?

[J].China has been developed into one of the most active regions in terms of both fundamental and applied research on magnesium (Mg) and its alloys in the world from a solid base laid by its prominent metallurgist and materials scientists over the past decades. Nowadays, a large number of young-generation researchers have been inspired by their predecessors and become the key participants in the fields of Mg alloys, which consequently led to the establishment of China Youth Scholar Society for Magnesium Alloys Research in 2015. Since then, the first two China Youth Scholars Symposiums on Mg Alloys Research had been held at Harbin (2015) and Chongqing (2016) China, respectively. A number of crucial research interests related to fundamental and applied Mg research were discussed at the conferences and summarized in this short perspective, aiming to boost far-reaching initiatives for development of new Mg-based materials to satisfy the requirements for a broad range of industrial employments. Herein, four main aspects are included as follows: i) Plastic deformation mechanism and strengthening strategy, ii) Design and development of new Mg-based materials, iii) Key service properties, and iv) New processing technologies.

Strengthening and toughening of Mg-based bulk metallic glass via in-situ formed B2-type AgMg phase

[J].

Enhancing mechanical properties of Mg-Sn alloys by combining addition of Ca and Zn

[J].

Hierarchical magnesium nano-composites for enhanced mechanical response

[J].

Enhanced properties of Mg-based nano-composites reinforced with Al2O3 nano-particles

[J].

High temperature compressive deformation behavior of an extruded Mg-8Gd-3Y-0.5Zr (wt. %) alloy

[J].

Microstructure, mechanical properties and fracture behavior of as-extruded Zn-Mg binary alloys

[J].

Processing, microstructure, and mechanical behavior of cast magnesium metal matrix composites

[J].

Particle reinforced aluminium and magnesium matrix composites

[J].

Rigid biological systems as models for synthetic composites

[J].Advances that have been made in understanding the mechanisms underlying the mechanical behavior of a number of biological materials (namely mollusk shells and sponge spicules) are discussed here. Attempts at biomimicry of the structure of a nacreous layer of a mollusk shell have shown reasonable success. However, they have revealed additional issues that must be addressed if new synthetic composite materials that are based on natural systems are to be constructed. Some of the important advantages and limitations of copying from nature are also described here.

Tough, bio-inspired hybrid materials

[J].The notion of mimicking natural structures in the synthesis of new structural materials has generated enormous interest but has yielded few practical advances. Natural composites achieve strength and toughness through complex hierarchical designs that are extremely difficult to replicate synthetically. We emulate nature's toughening mechanisms by combining two ordinary compounds, aluminum oxide and polymethyl methacrylate, into ice-templated structures whose toughness can be more than 300 times (in energy terms) that of their constituents. The final product is a bulk hybrid ceramic-based material whose high yield strength and fracture toughness [ approximately 200 megapascals (MPa) and approximately 30 MPa.m(1/2)] represent specific properties comparable to those of aluminum alloys. These model materials can be used to identify the key microstructural features that should guide the synthesis of bio-inspired ceramic-based composites with unique strength and toughness.

Nature-inspired nacre-like composites combining human tooth-matching elasticity and hardness with exceptional damage tolerance

[J].

Functional gradients and heterogeneities in biological materials: Design principles, functions, and bioinspired applications

[J].

Teleost fish scales amongst the toughest collagenous materials

[J].Fish scales from modern teleost fish are high-performance materials made of cross-plies of collagen type I fibrils reinforced with hydroxyapatite. Recent studies on this material have demonstrated the remarkable performance of this material in tension and against sharp puncture. Although it is known that teleost fish scales are extremely tough, actual measurements of fracture toughness have so far not been reported because it is simply not possible to propagate a crack in this material using standard fracture testing configurations. Here we present a new fracture test setup where the scale is clamped between two pairs of miniature steel plates. The plates transmit the load uniformly, prevent warping of the scale and ensure a controlled crack propagation. We report a toughness of 15 to 18kJm(-2) (depending on the direction of crack propagation), which confirms teleost fish scales as one of the toughest biological material known. We also tested the individual bony layers, which we found was about four times less tough than the collagen layer because of its higher mineralization. The mechanical response of the scales also depends on the cohesion between fibrils and plies. Delamination tests show that the interface between the collagen fibrils is three orders of magnitude weaker than the scale, which explains the massive delamination and defibrillation observed experimentally. Finally, simple fracture mechanics models showed that process zone toughening is the principal source of toughening for the scales, followed by bridging by delaminated fibrils. These findings can guide the design of cross-ply composites and engineering textiles for high-end applications. This study also hints on the fracture mechanics and performance of collagenous materials with similar microstructures: fish skin, lamellar bone or tendons. Copyright © 2014 Elsevier Ltd. All rights reserved.

Mechanical adaptability of the Bouligand-type structure in natural dermal armour

[J].Arapaima gigas, a fresh water fish found in the Amazon Basin, resist predation by piranhas through the strength and toughness of their scales, which act as natural dermal armour. Arapaima scales consist of a hard, mineralized outer shell surrounding a more ductile core. This core region is composed of aligned mineralized collagen fibrils arranged in distinct lamellae. Here we show how the Bouligand-type (twisted plywood) arrangement of collagen fibril lamellae has a key role in developing their unique protective properties, by using in situ synchrotron small-angle X-ray scattering during mechanical tensile tests to observe deformation mechanisms in the fibrils. Specifically, the Bouligand-type structure allows the lamellae to reorient in response to the loading environment; remarkably, most lamellae reorient towards the tensile axis and deform in tension through stretching/sliding mechanisms, whereas other lamellae sympathetically rotate away from the tensile axis and compress, thereby enhancing the scale's ductility and toughness to prevent fracture.

Twisting cracks in Bouligand structures

[J].The Bouligand structure, which is found in many biological materials, is a hierarchical architecture that features uniaxial fiber layers assembled periodically into a helicoidal pattern. Many studies have highlighted the high damage-resistant performance of natural and biomimetic Bouligand structures. One particular species that utilizes the Bouligand structure to achieve outstanding mechanical performance is the smashing Mantis Shrimp, Odontodactylus Scyllarus (or stomatopod). The mantis shrimp generates high speed, high acceleration blows using its raptorial appendage to defeat highly armored preys. The load-bearing part of this appendage, the dactyl club, contains an interior region [16] that consists of a Bouligand structure. This region is capable of developing a significant amount of nested twisting microcracks without exhibiting catastrophic failure. The development and propagation of these microcracks are a source of energy dissipation and stress relaxation that ultimately contributes to the remarkable damage tolerance properties of the dactyl club. We develop a theoretical model to provide additional insights into the local stress intensity factors at the crack front of twisting cracks formed within the Bouligand structure. Our results reveal that changes in the local fracture mode at the crack front leads to a reduction of the local strain energy release rate, hence, increasing the necessary applied energy release rate to propagate the crack, which is quantified by the local toughening factor. Ancillary 3D simulations of the asymptotic crack front field were carried out using a J-integral to validate the theoretical values of the energy release rate and the local stress intensity factors.Copyright © 2017 Elsevier Ltd. All rights reserved.

Microstructure, mechanical, and biomimetic properties of fish scales from Pagrus major

[J].

Crack twisting and toughening strategies in Bouligand architectures

[J].

Novel defense mechanisms in the armor of the scales of the “living fossil” Coelacanth fish

[J].

Hyperelastic phase-field fracture mechanics modeling of the toughening induced by Bouligand structures in natural materials

[J].

Analysis and simulation of fracture behavior in naturally occurring Bouligand structures

[J].

Fracture modes and hybrid toughening mechanisms in oscillated/twisted plywood structure

[J].Twisted or oscillated plywood structure can be often found in biological composites such as claws of lobsters, bone of mammals, dactyl club of mantis shrimps, and exoskeleton of beetles, which exhibits a combination of high stiffness, high fracture toughness and low density. However, there lacks a quantitative understanding of the relationship between the fracture toughness of the composite and its internal geometry. In this article, we propose that a combination of crack tilting and crack bridging determines the effective fracture toughness of the fiber-reinforced composite with the plywood structure. During the fracturing process, a crack plane initially propagates in the matrix-fiber interface following the twisted fiber alignment. Such crack tilting mechanism can significantly enlarge the area of cracking surface and thus enhance the effective fracture toughness of the composite. With the propagation of the tilted crack plane, the local energy release rate becomes too small to maintain the growth of the tilted crack plane, leading the crack to grow into the matrix, crossing the fibers. Because of the high strength of the fiber, a few fibers can maintain unbroken behind the crack tip, corresponding to crack bridging mechanism. Based on our quantitative analysis, it is found that the effective fracture toughness of the composite can be maximized for a certain pitch angle of the oscillated/twisted plywood structure, which agrees well with experiments. STATEMENTS OF SIGNIFICANCE: Fiber-reinforced composites can be widely found in nature and engineering applications. Recently, it has been discovered that many fiber-reinforced composites in biology have twisted or oscillated plywood structure with high fracture toughness, high mechanical stiffness and low density. Detailed experiments have indicated that an optimal pitch angle may exist for the plywood structure to maximize the fracture toughness of the composites. However, there lacks a quantitative model of revealing such pitch angle-dependent fracture toughness. In this work, we propose a hybrid toughening mechanism and predict the optimal pitch angle in twisted/oscillated plywood structure for maximizing the fracture toughness. Our predictions agree reasonably well with experimental results. As such, the theory may help the design of better fiber-reinforced composites.Copyright © 2019 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Structure and mechanical adaptability of a modern elasmoid fish scale from the common carp

[J].

Biomimetic twisted plywood structural materials

[J].

Multiscale toughening mechanisms in biological materials and bioinspired designs

[J].

Bio-inspired impact-resistant composites

[J].Through evolutionary processes, biological composites have been optimized to fulfil specific functions. This optimization is exemplified in the mineralized dactyl club of the smashing predator stomatopod (specifically, Odontodactylus scyllarus). This crustacean's club has been designed to withstand the thousands of high-velocity blows that it delivers to its prey. The endocuticle of this multiregional structure is characterized by a helicoidal arrangement of mineralized fiber layers, an architecture which results in impact resistance and energy absorbance. Here, we apply the helicoidal design strategy observed in the stomatopod club to the fabrication of high-performance carbon fiber-epoxy composites. Through experimental and computational methods, a helicoidal architecture is shown to reduce through-thickness damage propagation in a composite panel during an impact event and result in an increase in toughness. These findings have implications in the design of composite parts for aerospace, automotive and armor applications. Copyright © 2014 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Bioinspired tungsten-copper composites with Bouligand-type architectures mimicking fish scales

[J].The microscopic Bouligand-type architectures of fish scales demonstrate a notable efficiency in enhancing the damage tolerance of materials; nevertheless, it is challenging to reproduce in metals. Here bioinspired tungsten-copper composites with different Bouligand-type architectures mimicking fish scales were fabricated by infiltrating a copper melt into woven contextures of tungsten fibers. These composites exhibit a synergetic enhancement in both strength and ductility at room temperature along with an improved resistance to high-temperature oxidization. The strengths were interpreted by adapting the classical laminate theory to incorporate the characteristics of Bouligand-type architectures. In particular, under load the tungsten fibers can reorient adaptively within the copper matrix by their straightening, stretching, interfacial sliding with the matrix, and the cooperative kinking deformation of fiber grids, representing a successful implementation of the optimizing mechanisms of the Bouligand-type architectures to enhance strength and toughness. This study may serve to promote the development of new high-performance tungsten-copper composites for applications, e.g., as electrical contacts or heat sinks, and offer a viable approach for constructing bioinspired architectures in metallic materials.

Bioinspired fish-scale-like magnesium composites strengthened by contextures of continuous titanium fibers: Lessons from Nature

[J].

On the damage tolerance of 3-D printed Mg-Ti interpenetrating-phase composites with bioinspired architectures

[J].Bioinspired architectures are effective in enhancing the mechanical properties of materials, yet are difficult to construct in metallic systems. The structure-property relationships of bioinspired metallic composites also remain unclear. Here, Mg-Ti composites were fabricated by pressureless infiltrating pure Mg melt into three-dimensional (3-D) printed Ti-6Al-4V scaffolds. The result was composite materials where the constituents are continuous, mutually interpenetrated in 3-D space and exhibit specific spatial arrangements with bioinspired brick-and-mortar, Bouligand, and crossed-lamellar architectures. These architectures promote effective stress transfer, delocalize damage and arrest cracking, thereby bestowing improved strength and ductility than composites with discrete reinforcements. Additionally, they activate a series of extrinsic toughening mechanisms, including crack deflection/twist and uncracked-ligament bridging, which enable crack-tip shielding from the applied stress and lead to "Γ"-shaped rising fracture resistance R-curves. Quantitative relationships were established for the stiffness and strengths of the composites by adapting classical laminate theory to incorporate their architectural characteristics.© 2022. This is a U.S. government work and not under copyright protection in the U.S.; foreign copyright protection may apply.

Application of high resolution transmission X-ray tomography in material science

[J].The continuing development of X-ray light sources, optical devices and image analysis technologies enables us to nondestructively analyze internal structures of materials by using 3D imaging with a spatial resolution of micron, even dozens of nanometers. Innovations in materials science and technology will benefit from the new achievements of the X-ray tomography with higher resolution. This article devotes to review the origination and development of the X-ray tomography techniques for 3D imaging and introduce the principles and specifications of three imaging methods, including absorption imaging, phase contrast imaging and holographic imaging. The differences between synchrotron-based and laboratory-based X-ray tomography are also discussed. To explore new opportunities of the high resolution X-ray tomography in the development of material science and technology, particular emphasis is laid on the applications for traditional materials with a 3D view, such as the characterizations of holes, cracks, corrosion, composites, and in situ testing etc..

高分辨透射X射线三维成像在材料科学中的应用

[J].随着X射线光源、光学器件及图像分析技术的不断发展,微米甚至数十纳米空间分辨X射线三维数字化成像成为可能. 在此基础上,提供了高分辨无损探测材料内部结构的技术和方法,预计高分辨X射线三维成像新技术将会进一步促进材料科学技术的发展.本文将简述X射线三维成像的产生背景和发展过程,介绍吸收衬度成像、相位衬度成像和全息成像的原理与特点,着重分析高分辨透射X射线三维成像在材料孔洞、裂纹与腐蚀、复合材料以及原位测试等方向的应用及其特点,比较同步辐射与实验室X射线高分辨透射三维成像技术的不同,以探讨高分辨透射X射线三维成像在材料科学研究中进一步应用的可能性.

Manufacture studies and impact behaviour of light metal matrix composites reinforced by steel wires

[J].

Compressive properties and damping capacities of magnesium reinforced with continuous steel wire

[J].

Microstructure and mechanical properties of magnesium matrix composites interpenetrated by different reinforcement

[J].

Processing and mechanical properties of Al2O3 fiber-reinforced NiAl composites

[J].

Crack bridging in fiber reinforced cementitious composites with slip-hardening interfaces

[J].

Adaptive structural reorientation: Developing extraordinary mechanical properties by constrained flexibility in natural materials

[J].Seeking strategies to enhance the overall combinations of mechanical properties is of great significance for engineering materials, but still remains a key challenge because many of these properties are often mutually exclusive. Here we reveal from the perspective of materials science and mechanics that adaptive structural reorientation during deformation, which is an operating mechanism in a wide variety of composite biological materials, functions more than being a form of passive response to allow for flexibility, but offers an effective means to simultaneously enhance rigidity, robustness, mechanical stability and damage tolerance. As such, the conflicts between different mechanical properties can be "defeated" in these composites merely by adjusting their structural orientation. The constitutive relationships are established based on the theoretical analysis to clarify the effects of structural orientation and reorientation on mechanical properties, with some of the findings validated and visualized by computational simulations. Our study is intended to give insight into the ingenious designs in natural materials that underlie their exceptional mechanical efficiency, which may provide inspiration for the development of new man-made materials with enhanced mechanical performance. STATEMENT OF SIGNIFICANCE: It is challenging to attain certain combinations of mechanical properties in man-made materials because many of these properties - for example, strength with toughness and stability with flexibility - are often mutually exclusive. Here we describe an effective solution utilized by natural materials, including wood, bone, fish scales and insect cuticle, to "defeat" such conflicts and elucidate the underlying mechanisms from the perspective of materials science and mechanics. We show that, by adaptation of their structural orientation on loading, composite biological materials are capable of developing enhanced rigidity, strength, mechanical stability and damage tolerance from constrained flexibility during deformation - combinations of attributes that are generally unobtainable in man-made systems. The design principles extracted from these biological materials present an unusual yet potent new approach to guide the development of new synthetic composites with enhanced combinations of mechanical properties.Copyright © 2019 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Development of ductile magnesium composite materials using titanium as reinforcement

[J].