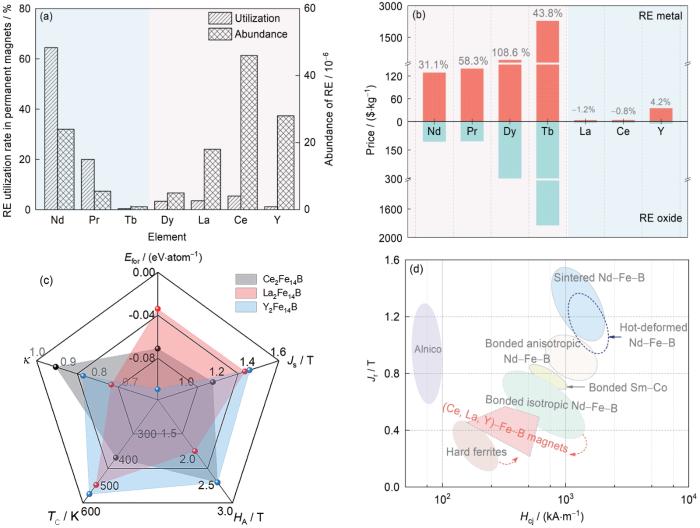

随着绿色低碳经济的持续发展,Nd-Fe-B永磁材料因其优异的室温磁性能在风力发电、智能制造、新能源汽车、节能家电等新兴领域的应用规模快速增长,在永磁市场的占有量超过了60%,已成为支撑和推动社会发展的关键功能材料之一[1,2]。Nd-Fe-B作为消耗稀土(rare earth,RE)最多的永磁材料,市场需求与日俱增,必然导致Pr、Nd、Dy和Tb等制造Nd-Fe-B的关键稀土元素消耗巨大。可以预见,这些关键稀土元素必将面临供应短缺和价格不断上涨的局面。稀土元素在地壳中常以共伴生矿物形式存在,其中Ce、La、Y元素占70%以上,Nd、Pr约占20%,而Dy、Tb的占比不足3%。与这些价格昂贵的关键稀土元素相比,Ce、La和Y元素在地壳中的含量非常丰富,它们也因此被统称为高丰度稀土[3]。一方面,在永磁体制造过程中,Pr、Nd、Tb和Dy等关键稀土的使用率要远远高于这些高丰度稀土,稀土丰度和其实际使用率的不平衡导致了高丰度稀土被大量堆积,稀土资源面临着利用极不平衡的产业难题,如图1a[4~6]所示。另一方面,根据近期稀土现货产品报价[7],无论是金属还是相应的金属氧化物,Pr、Nd、Tb和Dy的价格均是高丰度稀土的几十甚至几百倍,如图1b[7]所示。另外,金属Pr、Nd、Tb和Dy的价格在2022年涨幅明显,Nd的平均涨幅超过了30%,而Dy的平均涨幅更是超过了100%。相比之下,高丰度稀土的市场价格波动较小且十分低廉。随着稀土永磁下游终端需求的快速增加,如何进一步降低Nd-Fe-B永磁材料的成本和扩大高丰度稀土在永磁材料中的应用成为了目前产业发展的重要方向。

图1

图1

稀土元素的地壳丰度、价格和各自在Nd-Fe-B磁体中的使用率[4~7],高丰度稀土RE2Fe14B化合物的相关性能参数[3,9]以及各类永磁材料的性能对比[11]

Fig.1

Relative abundance and utilization rate of rare earth (RE) element[4-6] (a), RE metals and the corresponding RE oxides price[7] (b), comparison of RE2Fe14B (RE = Ce, La, and Y) compounds in intrinsic magnetic properties, magnetic hardness parameter and formation energy, the data are extracted from an online database[3,9] (c), and comparison of the properties of different types of permanent magnets[11] (d) (Efor—formation energy, к— magnetic hardness parameter, Js—saturation magnetic polarization, TC—Curie temperature, HA—anisotropy field, Jr—remanence, Hcj—intrinsic coercivity)

Nd-Fe-B的永磁特性来源于Nd2Fe14B (2∶14∶1)化合物的内禀磁性能,而高丰度稀土Ce、La和Y同样可与Fe、B形成RE2Fe14B化合物,但它们的内禀性能各不相同[8],相关性能参数如图1c[3,9]所示。Ce2Fe14B具有相对更高的磁晶各向异性场,但其饱和磁极化强度和Curie温度较低,相对而言,Y2Fe14B和La2Fe14B在饱和磁极化强度和Curie温度方面要比Ce2Fe14B更有优势。研究[10]表明,通过合理的工艺优化和特殊微观结构的构建,高丰度稀土基磁体具有成为硬磁材料的潜力,并具有重要的使用价值。Coey[3]定义单轴各向异性材料的磁硬度系数к来评估材料是否具备成为永磁体的能力,Ce2Fe14B、La2Fe14B和Y2Fe14B的к值介于0.7~1之间,表明它们可以制备成具有一定磁能积的永磁体。根据各类永磁材料的性能对比,如图1d[11]所示,在永磁铁氧体和黏结Nd-Fe-B之间存在着明显的性能空白区域,尽管Ce2Fe14B、La2Fe14B和Y2Fe14B化合物的内禀磁性能劣于Nd2Fe14B,但基于高丰度稀土Ce、La、Y制备的低成本永磁材料仍具有填补这一性能区间的巨大潜力[12]。因此,发展高丰度稀土永磁材料并实现其规模化应用,不仅是解决当前稀土资源利用不平衡的有效手段,而且能满足中低端领域对永磁体的多样化需求,具有重大的经济效益和社会效益。

近年来,La和Ce已被用于部分替代Nd-Fe-B中昂贵的Nd、Pr元素,旨在提高混合稀土磁体的性价比,相关的技术和工作也已逐步实现产业化。但高丰度稀土的替代量一般不超过50%,否则会产生强烈的磁稀释作用,磁体性能下降明显,这制约了高丰度稀土在永磁材料中的规模化应用。从长远角度看,低成本、高性价比的全高丰度稀土永磁材料的研究与开发势在必行。目前有关高丰度稀土基RE-Fe-B永磁的研究大部分集中在Ce-Fe-B合金,而针对Ce、La、Y构建的多组元RE-Fe-B合金和磁体的研究相对较少,且获得的磁性能都比较低,无法得到实际应用。本文主要综述了国内外关于高丰度稀土永磁的研究进展,并结合作者团队的相关研究,重点介绍RE-Fe-B纳米晶快淬合金的相结构、冶金行为和成分设计以及致密化磁体的制备、显微结构及其硬磁性能,并对高丰度稀土永磁性能强化的未来发展进行了展望,以期为新一代高性价比稀土永磁材料的开发提供参考。

1 RE-Fe-B (RE = La, Ce, Y)三元合金的基本特性

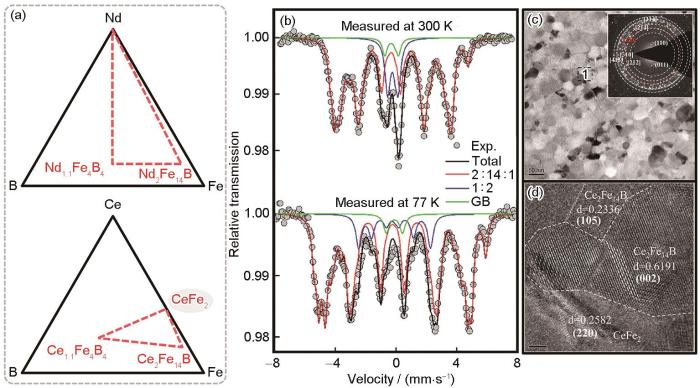

稀土永磁合金的磁性能与稀土元素的成相规律密切相关。早期对于三元Nd-Fe-B相图的研究[13]表明,Nd2Fe14B硬磁相是在约1180℃下经包晶反应L + γ-Fe→Nd2Fe14B产生的。通过不同RE-Fe-B相图间的对比发现,即使是稀土含量相近的合金中,也可能存在不同的平衡相组成,这说明不同稀土元素具有各自的成相规律。相较于Nd、Pr元素,Ce、La、Y与重稀土的4f电子结构不同,在合金中的成相倾向也不同,这显著影响2∶14∶1化合物的内禀磁性和合金的显微组织。最初人们普遍认为Ce2Fe14B化合物中Ce是单一的+3价,原子磁矩为零[14]。得益于表征技术的进步,研究人员最终确认,Ce呈+3.44的混合价态,即+3价4f1与+4价4f2 2种电子态共存,区别于Nd2Fe14B中Nd的+3价[15]。由于+4价无外层4f电子,电子自旋磁矩等于零,因而Ce2Fe14B相的饱和磁极化强度较低。不同于三元Nd-Fe-B的相组分,Ce-Fe-B的相组分中出现了CeFe2 (1∶2)相,如图2a所示。对于富稀土成分的Ce-Fe-B而言,1∶2相是自发产生的且形成时会消耗过量的稀土,导致合金中2∶14∶1相和富稀土晶界相减少[16]。如图2b[17]所示,Ce16Fe78B6快淬合金在300和77 K时的Mössbauer谱结果均显示合金中84%Fe原子在2∶14∶1相中,13%Fe在1∶2相中,而仅有3%Fe存在于晶界或晶界相中。1∶2相的Curie温度约为235 K,在室温下为顺磁性,对应于300 K时Mössbauer谱中的蓝色双线谱[18]。而与Nd-Fe-B中的低熔点富Nd相不同,1∶2相的熔点约为1198 K,润湿能力较弱,通常呈聚集或块状形式分布于三角晶界处。如图2c和d[17]所示,Ce16Fe78B6合金中的结晶相主要由2∶14∶1相和1∶2相组成,且晶粒之间多为直接接触,无明显的富稀土晶间相存在,这种显微结构对合金的磁性能尤其是矫顽力是不利的。根据Ce-Fe-B合金成分和制备工艺的不同,合金中析出相也会有所不同。Zhang等[19]对Ce2Fe14B非晶合金在加热过程中的相析出行为进行了分析,发现合金中的相组成主要为先析出的软磁相α-Fe和后析出的2∶14∶1相。但在Ce14.16Fe79.82B6.02速凝合金中会同时存在2∶14∶1、1∶2、α-Fe和Fe2B等相,并且微观组织极不均匀[20]。贫稀土成分的Ce10Fe84B6快淬合金则主要由Ce2Fe17和CeFe7相组成,仅形成了少量的2∶14∶1相,因而合金的硬磁性能恶化严重[21]。Herbst等[22]对Ce-Fe-B相图中一系列成分进行了比较,发现成分为Ce17Fe78B6的快淬合金具有比其他成分更为优异的磁性能。在此成分的基础上,Tan等[23]进一步优化了Ce17Fe78B6合金制备时的快淬速率和腔体压力等工艺参数,获得了最佳的综合磁性能,其中矫顽力为429.9 kA/m,剩磁为0.49 T,最大磁能积为32.6 kJ/m3。

图2

图2

Nd-Fe-B和Ce-Fe-B相组分示意图,快淬Ce16Fe78B6合金在300和77 K时57Fe的Mössbauer谱以及合金在室温下的微观结构[17]

Fig.2

Schematic drawing of the Nd-Fe-B and Ce-Fe-B phase components (a), 57Fe Mössbauer spectra of the melt-spun Ce16Fe78B6 alloy measured at 300 and 77 K[17] (b), TEM image and corresponding selected area diffraction (SAED) pattern (inset) for the melt-spun Ce16Fe78B6 alloy (c), and the HRTEM image for selected area 1 in Fig.2c[17] (d) (GB—grain boundary phase; d—interplanar distance, nm)

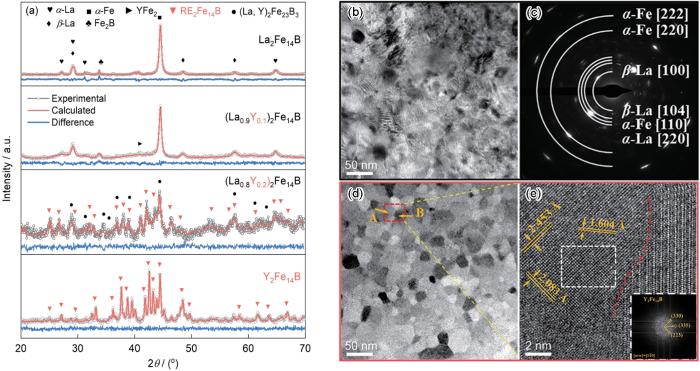

相较于备受关注的Ce-Fe-B合金,目前对于La-Fe-B和Y-Fe-B合金的研究较为缺乏。早期普遍认为La-Fe-B合金中的La2Fe14B相是不易形成的,并且很难像其他稀土元素的2∶14∶1相一样,可以在较宽的温度区间内稳定存在[24]。Hadjipanayis等[25]对La16Fe78B6铸锭和非晶合金进行长时间热处理,发现尽管2者中均可以形成La2Fe14B相,但900℃退火后合金中的大部分La2Fe14B相会分解为α-Fe相和La-B相。这一现象与之前Stadelmaier等[26]的研究结果一致,即La2Fe14B相在高于860℃后就会不稳定。然而,最近Wei等[27]对La2Fe14B化合物的热力学稳定性进行了系统分析,推断La2Fe14B相是一种可以存在于795~926℃的高温稳定化合物,并且La2Fe14B相是由Fe + La + Fe2B→La2Fe14B生成;而在低于795℃时La2Fe14B相会发生分解:La2Fe14B→Fe + La + LaFe4B4。作者团队[28]发现La2Fe14B快淬合金在较低快淬速率下未能形成2∶14∶1相,而主要由α-La、β-La、α-Fe和Fe2B相组成,如图3a[28]所示。La2Fe14B合金的显微组织中也未能发现明显的晶粒和晶界相,整体结构较为混乱,很难从形貌上区分不同相。进一步的选区电子衍射(SAED)结果同样证实了La2Fe14B合金是由α-La、β-La、α-Fe相组成的多晶结构,如图3b和c[28]。对非晶La2Fe14B合金在不同温度下进行热处理时发现,α-Fe相和β-La相逐渐从基体中析出,并且800℃热处理后的La2Fe14B合金中液态的La相和α-Fe相共存,而整个热处理过程中并未观察到La2Fe14B相[29]。这些结果表明,通过熔体快淬和非晶热处理工艺在La-Fe-B合金中均不易获得稳定的2∶14∶1相,这严重限制了La在稀土永磁材料中的应用。关于La2Fe14B成相困难的原因,有学者[30]认为La的大原子半径和离子半径是导致其失稳的主要原因,其晶格常数a和c分别为0.883和1.236 nm,是所有RE2Fe14B中最大的。也有一些学者[31]认为La2Fe14B难以成相可能与La-Fe-B合金较强的非晶形成能力密切相关。作者团队[29]研究发现,La2Fe14B合金在快淬速率高于20 m/s时,合金中的主要相成分即为非晶相,这似乎也说明La-Fe-B合金更容易非晶化。综上所述,目前在La2Fe14B相的稳定形成方面仍有不同的观点,后续仍需对La-Fe-B系合金中La2Fe14B相的凝固特性、相变、相组成和热稳定性作进一步研究。为了在镧基合金中形成稳定的2∶14∶1相,作者团队[28]提出了利用其他稀土元素部分替代La的解决思路,结果发现20% (原子分数)以上的Ce或Y替代La能够稳定三元La2Fe14B合金中的2∶14∶1相。如图3a[28]所示,在(La0.8Y0.2)2Fe14B快淬合金中α-La、β-La、Fe2B、α-Fe和YFe2相均已消失,硬磁相RE2Fe14B成为合金中的主要组成相之一。Li等[32]关于(Nd1 - x La x )2Fe14B快淬合金相结构的研究,同样证实了一定量的Nd可以促进2∶14∶1相的稳定形成。

图3

图3

(La1 - x Y x )2Fe14B快淬合金的XRD谱与微观结构[28,35]

Fig.3

XRD spectra for the as-spun (La1 - x Y x )2Fe14B alloys[28] (a), bright field TEM image (b) and corresponding SAED (c) for the as-spun La2Fe14B alloy[28], and bright field TEM image (d) and HRTEM image and corresponding fast Fourier transformation (inset) (e) for the as-spun Y2Fe14B alloy[35]

对于三元Y-Fe-B合金而言,Y2Fe14B相是由液相与Y2Fe17相在1185℃下通过包晶反应L + Y2Fe17→Y2Fe14B生成的[33]。由于Y原子的4f电子缺失,Y2Fe14B相在较宽的温度区间内具有正的各向异性场温度系数,可有效减缓磁体在高温环境下因内禀性能恶化而导致的矫顽力大幅降低[34]。Liu等[35]发现Y2Fe14B合金在快淬速率为36 m/s时具有最佳磁性能,合金的矫顽力为149 kA/m,饱和磁极化强度为1.43 T,剩磁为0.88 T,最大磁能积为54.1 kJ/m3。此时Y2Fe14B合金主要由Y2Fe14B相组成,晶粒均匀分布且不存在晶界相或其他杂相,如图3d和e[35]所示。对Y2Fe14B非晶合金在加热过程中的相析出行为进行分析发现,α-Fe相会先从非晶基体中析出,随后析出Y2Fe14B相和少量的Fe-B相。Sun等[36]发现Y16Fe78B6合金中同样会自发形成1∶2相,但YFe2是软磁相,在富相成分的Y-Fe-B合金中形成了包含YFe2和Y2Fe14B的双相纳米复合结构。而进一步的研究表明,采用非晶晶化热处理的Y16Fe78B6合金中存在着更为强烈的Y2Fe14B/YFe2双相交换耦合作用,产生了剩磁增强效应;而YFe2相又以弥散形式分布于硬磁晶粒周围,一定程度上起到了磁耦合的作用,也提高了合金的矫顽力,因而表现出比直接快淬合金更优异的磁性能。另外,Y在RE-Fe-B快淬合金中不仅可以提高合金的非晶形成能力,改善合金的显微组织,而且能够在较大的温度范围增强双相纳米复合合金的交换耦合作用,有效提高合金的剩磁和最大磁能积[37]。因此,尽管Y-Fe-B合金的综合磁性能不如Ce-Fe-B合金,但Y在开发满足高温环境应用需求的永磁合金或磁体方面拥有着巨大优势。表1[19,29,35]总结了Ce2Fe14B、La2Fe14B和Y2Fe14B非晶合金在加热过程中的相析出规律,这些关于Ce-Fe-B、La-Fe-B和Y-Fe-B合金在快淬和热处理过程中的相析出行为、微观结构和磁性能等基本特性的研究,为全高丰度稀土永磁的开发和调控性能奠定实验基础。

表1 Ce2Fe14B、La2Fe14B和Y2Fe14B非晶合金热处理过程中的相析出行为[19,29,35]

Table 1

| Alloy | Phase | Reaction formula | T / oC | Ref. |

|---|---|---|---|---|

Ce2Fe14B | α-Fe | Amorphous → α-Fe | 513.8 | [19] |

| Ce2Fe14B | Amorphous → Ce2Fe14B | 610.9 | ||

| α-Fe + Ce2Fe14B + Fe x B | Amorphous → α-Fe + Ce2Fe14B + Fe x B | 689.9 | ||

| L + γ-Fe + Fe2B | Ce2Fe14B→L + γ-Fe + Fe2B | 966.9 | ||

| L′ | Ce2Fe14B→L′ | 1047.1 | ||

| γ-Fe + Fe2B | L″→γ-Fe + Fe2B | 1056.5 | ||

| L′′′ | γ-Fe + Fe2B→L′′′ | 1167.7 | ||

Y2Fe14B | α-Fe | Amorphous → α-Fe | 329.2 | [29] |

| Y2Fe14B | Amorphous → Y2Fe14B | 622.2 | ||

| Fe3B + Y2Fe14B | Amorphous → Ce2Fe14B + Fe3B | 748.3 | ||

La2Fe14B | α-Fe + β-La | Amorphous → α-Fe + β-La | 404.1 | [35] |

| β-La + α-Fe + Fe2B | Amorphous → β-La + α-La + Fe2B | 487.1 | ||

| L | α-Fe + β-La → L | 764.7 | ||

| L′ | γ-Fe + Fe2B → L′ | 1168.5 |

2 全高丰度稀土(Ce/La/Y)-Fe-B永磁合金的开发

尽管Ce2Fe14B、La2Fe14B和Y2Fe14B化合物的内禀磁性能低于Nd2Fe14B,且相互间的内禀磁性能存在一定的差异,但最近的研究表明,通过混合Ce、La和Y稀土元素进行多元合金成分开发,利用元素间的相互作用可有效提升全高丰度稀土RE-Fe-B永磁的综合磁性能。此外,3种元素在磁体内的非均质分布和微量元素替代所诱导产生的特殊显微组织同样有利于改善永磁材料的硬磁性能。

2.1 (Ce, La, Y)-Fe-B合金成分设计

目前基于全高丰度稀土永磁的研究大部分集中在三元Ce-Fe-B合金,对其他含有Ce、La、Y中的2种或3种元素的多组元RE-Fe-B合金的研究相对较少。成分被认为是决定材料性能的首要因素,因此在开发全高丰度稀土永磁材料时,通过对Ce、La、Y进行合理的成分设计是其获得优异磁性能的关键因素之一。在三元Ce-Fe-B合金基础上,将La部分替代Ce可以使2∶14∶1相的晶格膨胀,促进Ce的价态转变为具有4f磁矩的+3价态,在稳定2∶14∶1相的同时提高合金的饱和磁极化强度[38]。Soeda等[39]发现(La1 - x Ce x )2Fe14B相的各向异性常数在x约为0.7时最大,这为后续优化四元(Ce, La)-Fe-B合金硬磁性能提供了理论基础。基于此,作者团队[38,40]通过实验发现在(Ce1 - x La x )2Fe14B快淬合金中添加少量的La会导致矫顽力的异常增加。10% (原子分数)的La替代Ce使得(Ce0.9La0.1)2Fe14B合金的矫顽力达到整个成分系列的极大值(256 kA/m),明显高于Ce2Fe14B合金的199 kA/m。矫顽力的内在决定因素是各向异性场[41],La2Fe14B的各向异性场要小于Ce2Fe14B,理论上La加入到Ce2Fe14B合金中应当会降低矫顽力,而上述实验结果与此推论并不一致。由此也说明含多元稀土的2∶14∶1相的内禀磁性能并非简单的线性关系。Y2Fe14B化合物的饱和磁极化强度远高于Ce2Fe14B,Y替代部分的Ce可以显著增加(Ce1 - x Y x )2Fe14B合金的剩磁,同时提高了合金的最大磁能积。另外,Y2Fe14B的各向异性场对温度的依赖性较弱,Y的加入也会改善合金的剩磁热稳定系数α和矫顽力热稳定系数β。而在(Y1 - x La x )2Fe14B快淬合金中,引入少量的La可大大提高合金的热稳定性,(Y0.8La0.2)2Fe14B合金在300~500 K范围内β值为-0.08%/K,优于目前报道的钕基和铈基RE-Fe-B合金[28]。在这些四元合金成分的结果上,Liao等[42]利用La和Y复合替代Ce,不仅显著提高了Ce-Fe-B合金的室温磁性能,也极大改善了磁性能的高温热稳定性。例如,五元[(Ce0.7La0.3)0.8Y0.2]2Fe14B快淬合金的综合磁性能为207 kA/m、0.74 T和57.5 kJ/m3,且300~400 K温度范围内的α和β分别为-0.245%/K和-0.253%/K。表2[17,19,21~23,28,29,35,36,38,40,42~48]总结了目前文献中报道的高丰度稀土基RE-Fe-B快淬合金的硬磁性能。可以看出,无论是单相成分还是富稀土成分的合金,含有Ce、La、Y中的2种或3种元素的多组元RE-Fe-B快淬合金的综合磁性能普遍要优于三元合金。但需要指出的是,多元稀土元素混合进行成分设计时,多元合金体系的成相规律较复杂,不同稀土配比的高丰度稀土永磁中2∶14∶1相内禀磁性能的演变规律还有待进一步研究。

表2 基于高丰度稀土Ce、La、Y的RE-Fe-B快淬合金的硬磁性能[17,19,21~23,28,29,35,36,38,40,42~48]

Table 2

| Type of alloy | Composition | Hcj kA·m-1 | Jr T | Js T | (BH)max kJ·m-3 | TC K | 300-400 K | Ref. | |

|---|---|---|---|---|---|---|---|---|---|

| α / (%·K-1) | β / (%·K-1) | ||||||||

| Ternary | Ce2Fe14B | 211 | 0.42 | 1.08 | 17.0 | 424 | - | - | [19] |

| Ce2Fe14B | 207 | 0.57 | 1.07 | 28.6 | 420 | -0.623 | -0.536 | [40] | |

| Ce10Fe84B6 | 135 | 0.60 | 1.19 | 11.3 | - | - | - | [21] | |

| Ce12Fe82B6 | 167 | 0.59 | - | 21.0 | - | - | - | [43] | |

| Ce16Fe77B6 | 367 | 0.47 | 0.90 | 33.3 | - | - | - | [17] | |

| Ce17Fe77B6 | 344 | 0.43 | 0.77 | 28.5 | 420 | - | - | [44] | |

| Ce16Fe78B6 | 350 | 0.49 | 0.93 | 33.8 | 420 | -0.54 | -0.74 | [44] | |

| Ce17Fe78B6 | 494 | 0.49 | - | 33.0 | - | - | - | [22] | |

| Ce17Fe78B6 | 438 | 0.46 | - | 34.2 | 424 | -0.500 | -0.663 | [23] | |

| Ce17Fe78B6 | 352 | 0.43 | - | 29.0 | 425 | -0.56 | -0.75 | [45] | |

| La2Fe14B | 14 | 0.11 | - | - | - | - | - | [29] | |

| Y2Fe14B | 149 | 0.88 | 1.43 | 54.1 | 553 | -0.154 | -0.03 | [35] | |

| Y2.5Fe14B | 230 | 0.75 | 1.27 | 51.7 | 542 | - | - | [35] | |

| Y3Fe14B | 281 | 0.72 | 1.18 | 42.2 | 546 | - | - | [35] | |

| Y16Fe78B6 | 240 | 0.61 | - | 21.0 | - | - | - | [36] | |

| Quaternary | (Ce0.9La0.1)2Fe14B | 251 | 0.65 | 1.12 | 46.2 | 434 | -0.402 | -0.442 | [40] |

| (Ce0.8La0.2)2Fe14B | 235 | 0.68 | 1.15 | 47.9 | 443 | -0.356 | -0.328 | ||

| (Ce0.7La0.3)2Fe14B | 214 | 0.69 | 1.16 | 49.1 | 456 | -0.292 | -0.299 | ||

| (Ce0.7La0.3)2Fe14B | 183 | 0.67 | - | 37.0 | - | - | - | ||

| (Ce0.6La0.4)2Fe14B | 203 | 0.72 | 1.19 | 47.0 | 468 | -0.259 | -0.286 | ||

| (Ce0.5La0.5)2Fe14B | 197 | 0.68 | 1.14 | 40.8 | 476 | -0.220 | -0.261 | ||

| (Ce0.4La0.6)2Fe14B | 163 | 0.66 | 1.12 | 34.4 | 487 | -0.207 | -0.225 | ||

| (Ce0.3La0.7)2Fe14B | 134 | 0.59 | 1.04 | 21.3 | 493 | -0.179 | -0.208 | ||

| (Ce0.2La0.8)2Fe14B | 32 | 0.37 | 0.87 | 2.5 | 508 | - | - | ||

| (Ce0.1La0.9)2Fe14B | 9 | 0.30 | 1.17 | 1.5 | - | - | - | ||

| (Ce0.7La0.3)2.5Fe14B | 345 | 0.60 | 1.04 | 50.1 | - | - | - | [38] | |

| (Ce0.7La0.3)3Fe14B | 439 | 0.69 | 1.12 | 61.1 | - | - | - | ||

| (Ce0.7La0.3)3Fe14B | 362 | 0.56 | 1.00 | 46.2 | - | - | - | ||

| (Ce0.7La0.3)3.5Fe14B | 406 | 0.53 | 0.97 | 41.5 | - | - | - | ||

| (Ce0.7La0.3)4Fe14B | 436 | 0.50 | 0.89 | 38.5 | - | - | - | ||

| (Ce0.9La0.1)17Fe78B6 | 520 | 0.52 | 0.94 | 41.8 | 427 | -0.463 | -0.631 | ||

| (Ce0.8La0.2)17Fe78B6 | 453 | 0.55 | 0.96 | 43.2 | 432 | -0.437 | -0.582 | ||

| (Ce0.7La0.3)17Fe78B6 | 332 | 0.58 | 1.05 | 46.9 | 442 | - | - | ||

| (Y0.9La0.1)2Fe14B | 140 | 0.86 | 1.41 | 52.1 | 552 | -0.146 | 0.05 | [28] | |

| (Y0.8La0.2)2Fe14B | 138 | 0.83 | 1.40 | 46.2 | 550 | -0.140 | 0.04 | ||

| (Y0.7La0.3)2Fe14B | 133 | 0.81 | 1.39 | 43.5 | 547 | -0.145 | 0.03 | ||

| (Y0.6La0.4)2Fe14B | 122 | 0.79 | 1.38 | 39.4 | 543 | -0.152 | -0.02 | ||

| (Y0.5La0.5)2Fe14B | 108 | 0.74 | 1.37 | 30.4 | 540 | -0.160 | -0.07 | ||

| (Y0.4La0.6)2Fe14B | 92 | 0.71 | 1.36 | 26.2 | 536 | - | - | ||

| (Y0.3La0.7)2Fe14B | 86 | 0.65 | 1.31 | 20.8 | 532 | - | - | ||

| (Y0.2La0.8)2Fe14B | 60 | 0.56 | 1.12 | 5.1 | 528 | - | - | ||

| (Y0.1La0.9)2Fe14B | 27 | 0.51 | 1.26 | 3.4 | - | - | - | ||

| Quaternary | (Y0.9Ce0.1)2Fe14B | 156 | 0.85 | 1.40 | 56.1 | 543 | -0.153 | 0.009 | [46] |

| (Y0.8Ce0.2)2Fe14B | 163 | 0.82 | 1.37 | 52.0 | 529 | -0.164 | -0.012 | ||

| (Y0.7Ce0.3)2Fe14B | 170 | 0.78 | 1.33 | 51.1 | 519 | -0.189 | -0.079 | ||

| (Y0.6Ce0.4)2Fe14B | 187 | 0.76 | 1.29 | 48.4 | 507 | -0.209 | -0.153 | ||

| (Y0.5Ce0.5)2Fe14B | 211 | 0.75 | 1.25 | 49.8 | 493 | -0.218 | -0.182 | ||

| (Y0.4Ce0.6)2Fe14B | 202 | 0.71 | 1.21 | 40.2 | 481 | -0.276 | -0.305 | ||

| (Y0.3Ce0.7)2Fe14B | 207 | 0.68 | 1.16 | 40.3 | 465 | -0.285 | -0.342 | ||

| (Y0.2Ce0.8)2Fe14B | 217 | 0.64 | 1.13 | 39.5 | 449 | -0.319 | -0.391 | ||

| (Y0.1Ce0.9)2Fe14B | 209 | 0.62 | 1.10 | 25.5 | 435 | -0.410 | -0.488 | ||

| (Y0.5Ce0.5)17Fe78B6 | 323 | - | - | 40.0 | 519 | - | - | [47] | |

| Quinary | [(Ce0.7La0.3)0.9Y0.1]2Fe14B | 212 | 0.71 | 1.19 | 51.7 | 464 | -0.277 | -0.288 | |

| [(Ce0.7La0.3)0.8Y0.2]2Fe14B | 207 | 0.74 | 1.23 | 57.3 | 475 | -0.246 | -0.256 | [48] | |

| [(Ce0.7La0.3)0.7Y0.3]2Fe14B | 204 | 0.75 | 1.25 | 54.9 | 487 | -0.236 | -0.182 | ||

| [(Ce0.7La0.3)0.6Y0.4]2Fe14B | 186 | 0.76 | 1.28 | 51.4 | 494 | -0.213 | -0.163 | ||

| [(Ce0.7La0.3)0.5Y0.5]2Fe14B | 167 | 0.77 | 1.34 | 48.0 | 506 | -0.199 | -0.051 | ||

| [(Ce0.7La0.3)0.8Y0.2]17Fe78B6 | 354 | 0.70 | 1.07 | 56.5 | 481 | - | -0.246 | [42] | |

| [(Ce0.8La0.2)0.7Y0.3]17Fe78B6 | 400 | 0.63 | - | 58.9 | 488 | -0.255 | -0.241 | ||

| [(Ce0.8La0.2)0.5Y0.5]17Fe78B6 | 332 | 0.66 | - | 60.0 | 515 | -0.197 | -0.102 | ||

2.2 (Ce, La, Y)-Fe-B合金中稀土元素的交互作用

许多研究已经证实,高丰度稀土Ce、La、Y在Nd-Fe-B永磁中存在化学非均质分布,其在2∶14∶1相和晶界相中的分布特性对磁体的磁性能有着重要影响。含高丰度稀土永磁中的化学非均质现象最早发现于双主相烧结(Nd, Ce/La)-Fe-B磁体中,Ce和La的化学性质和原子半径差异导致它们在晶内与晶界迁移趋势有所不同,进而产生成分上的不均匀分布[49,50]。Jin等[51]将Ce/La含量不同的2种磁粉混合并烧结,发现磁体中同时存在富Ce/La和贫Ce/La的2种硬磁晶粒,且La和Ce元素在晶粒间的分布也是不均匀的。当Ce/La富集于晶粒内部时,Nd富集于该晶粒的壳层;而在贫La/Ce的晶粒边界处会形成明显的富La/Ce壳层。与Ce/La取代量相同的单主相磁体(SMP)比较,这种双主相工艺制备的磁体具有更优异的硬磁性能,甚至在(La+Ce)含量增加至18% (质量分数)时,双主相磁体(MMP)仍具有比La+Ce含量仅9% (质量分数)的单相磁体更高的剩磁和矫顽力。这种化学非均质性极大地增强了单个晶粒内部的短程交换作用,产生了剩磁增强效应,同时晶粒间也会存在长程静磁耦合,能抑制反磁化畴的长大,因而同步提高了磁体的剩磁和矫顽力[52]。Liu等[53]通过第一性原理计算出Y和La在Nd2Fe14B中的取代能分别为0.41和-0.38 eV/atom,理论上证明Y倾向于进入2∶14∶1相而La偏向于富集在晶界相中。而Fan等[54]在含高丰度稀土的钕基烧结磁体中观察到了Y主要富集于2∶14∶1相中,Ce和La倾向于分布在晶界相中。同时,Ce元素的晶界偏析行为也帮助(Nd, Ce)-Fe-B磁体中形成了比(Nd, Y)-Fe-B磁体更厚且分布更连续的晶界层,增强了硬磁晶粒间的磁隔离效果,从而获得了比含Y磁体更高的矫顽力。

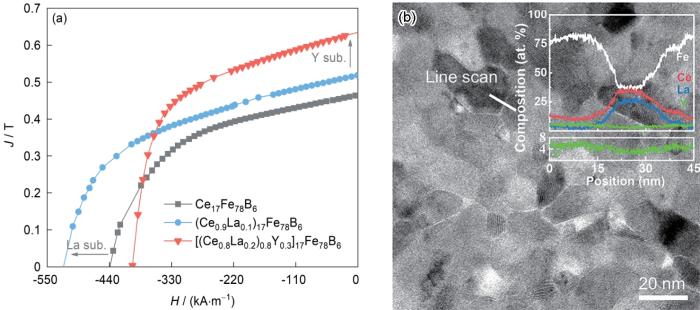

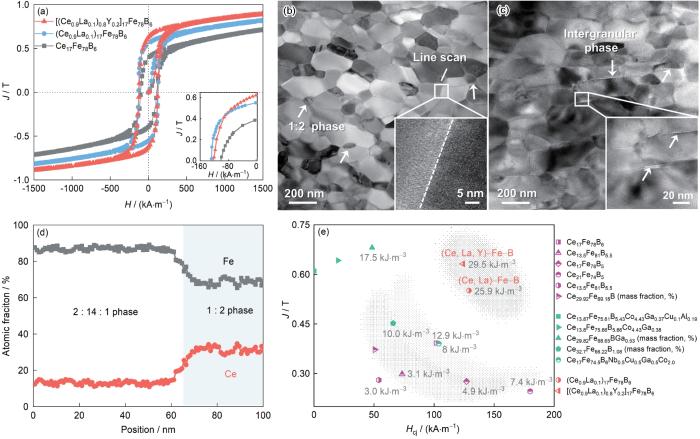

通过将La、Ce、Y元素混合使用,作者团队[42]设计出了一系列性能优异的多组元(Ce, La, Y)17Fe78B6纳米晶合金。图4a[42]对比了Ce17Fe78B6、(Ce0.9La0.1)17Fe78B6和[(Ce0.8La0.2)0.7Y0.3]17Fe78B6快淬合金在室温下的退磁曲线。(Ce0.9La0.1)17Fe78B6合金的矫顽力为520 kA/m,明显高于Ce17Fe78B6合金的438 kA/m,矫顽力提升的原因除了前述提到的(Ce, La)2Fe14B异常增加的各向异性场外,La的加入也有助于晶粒周围形成连续分布的薄层晶界相,削弱晶粒间的交换耦合作用以提高合金的矫顽力。在(Ce, La)-Fe-B合金的基础上,虽然加入Y会降低(Ce, La, Y)17Fe78B6合金的矫顽力,但能明显提高合金的剩磁。而与同样原子配比的(Ce, La, Y)2-Fe14B对比,(Ce, La, Y)17Fe78B6合金具有更高的Curie温度,出现这一现象的原因主要是由于在富稀土成分下,La和Ce的晶界偏析导致晶粒中2者含量减少,而Y强烈的晶内迁移特性会使其在晶粒中的含量略高于名义成分,导致更多的Y保留在主相晶粒中,从而提高了Curie温度,相关的元素分布如图4b[42]所示。

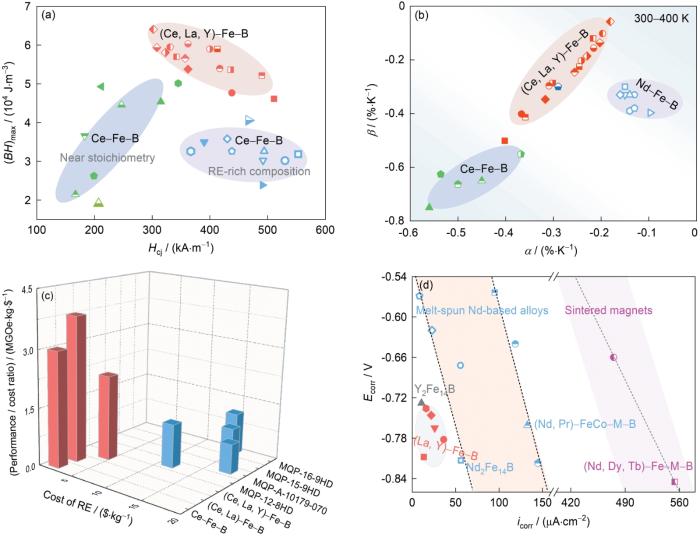

图4

图5给出了(Ce, La, Y)17Fe78B6合金与其他RE-Fe-B合金在磁性能[17,21~23,37,38,40,42~46,55~64]、性价比以及腐蚀性能[28,65~70]方面的对比。目前报道的铈基快淬合金主要分为两大类。第一类为单相合金或者名义成分接近于2∶14∶1的合金,它们通常具有较低的矫顽力,但合金的剩磁和最大磁能积较高。第二类为富稀土成分的合金,多具有优异的矫顽力,但其剩磁和最大磁能积一般较低。在Ce-Fe-B合金中,即使调整初始合金成分仍然无法同步提升矫顽力和剩磁,2者间一直存在此消彼长的关系,最终导致矫顽力和最大磁能积无法同时达到最优,相关合金的磁性能[17,21~23,37,38,40,42~46,55~64]总结如图5a所示。然而,在五元(Ce, La, Y)-Fe-B快淬合金中,Ce、La、Y元素间的相互作用可以有效提高RE-Fe-B合金的磁性能,并且元素在晶粒和晶界内的非均质分布所形成的特殊显微组织也对磁性能有利,从而使(Ce, La, Y)-Fe-B在没有采取其他强化措施的情况下,同时表现出更高的矫顽力和最大磁能积,意味着更为优异的室温磁性能。目前已报道的(Ce, La, Y)-Fe-B快淬合金的最大磁能积可达64 kJ/m3 [42]。同时,(Ce, La, Y)-Fe-B合金也具有较优异的高温热稳定性[17,37,38,40,42~46,55~64],如图5b所示。(Ce, La, Y)-Fe-B合金的α值在(-0.4~-0.1)%/K范围内,介于Ce-Fe-B和Nd-Fe-B快淬合金之间;而相应的β值均要高于Ce-Fe-B合金,并且部分(Ce, La, Y)-Fe-B合金甚至要高于Nd-Fe-B合金。此外,在Y含量较高的(Ce, La, Y)-Fe-B合金中能够同时获得更高的剩磁热稳定系数和矫顽力热稳定系数,表明具有更优异的热稳定性。

图5

图5

(Ce, La, Y)17Fe78B6合金与其他RE-Fe-B合金在磁性能[17,21~23,37,38,40,42~46,55~64]、性价比以及腐蚀性能[28,65~70]方面的对比

Fig.5

Comparisons of Hcj and (BH)max (a), and values of α and β (b) of the as-spun (Ce, La, Y)17Fe78B6 alloys with reported Ce or Nd-based RE-Fe-B alloys[17,21-23,37,38,40,42-46,55-64]; comparison of the cost performance for as-spun (Ce, La, Y)17Fe78B6 alloys with commercial isotropic magnetic powders (c) and comparison of corrosion resistance (d) of RE-based permanent magnets[28,65-70] (Ecorr—self corrosion potential, icorr—self corrosion current density)

除了磁性能方面的优势外,(Ce, La, Y)-Fe-B合金也同时兼具了高性价比和较好的耐腐蚀性能。性能/成本比可以通过最大磁能积(单位MGOe)除以1 kg磁粉的稀土成本(单位$/kg)来计算,用于评价磁体的性价比。如图5c所示,高丰度稀土基合金的性能/成本比比市售的不同牌号各向同性Nd-Fe-B磁粉(MQP)高得多,是其2~3倍,这意味着多组元(Ce, La, Y)-Fe-B合金具有比常见的商用Nd-Fe-B磁粉更优异的性价比。烧结磁体的耐腐蚀性能通常较差,主要是由于富稀土晶界相的电极电位要低于主相晶粒,腐蚀会优先发生于晶界处并延伸至硬磁晶粒,导致晶粒脱离,进而引起磁性能的严重下降。而快淬RE-Fe-B合金的组织均匀且晶粒细小,自腐蚀电流和自腐蚀电压均要远远优于烧结磁体,普遍具有更优异的耐腐蚀性能[28,65~70],如图5d所示。此外,La和Y的标准电极电位要高于Nd的,因此高丰度快淬合金的腐蚀电流密度大都要低于钕基快淬合金,一般要小于50 μA/cm2,表明其具有良好的耐腐蚀性能。

2.3 高丰度稀土RE-Fe-B合金磁性能的进一步优化

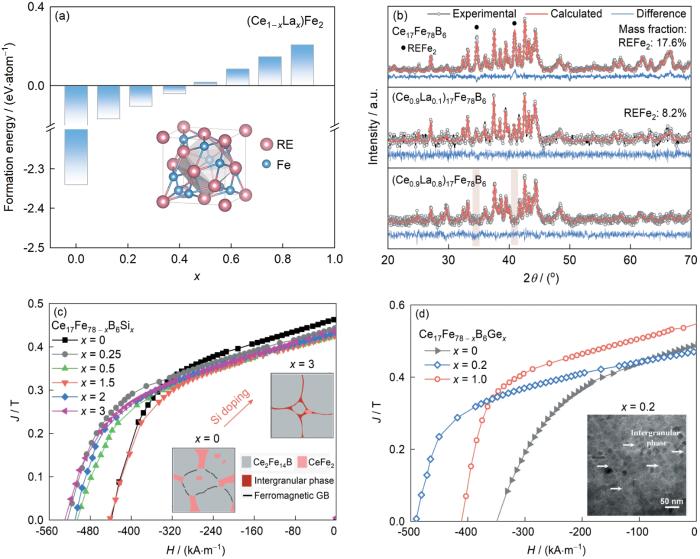

在开发高性能的高性价比稀土永磁合金过程中,进一步改善高丰度稀土RE-Fe-B合金的室温磁性能和热稳定性是十分有必要的。对于铈基合金而言,由于只有Ce3+具有4f磁矩,因此驱使Ce转变为+3价,是提高磁性能的一种可行的策略。通过形成伪三元化合物改变单胞体积,可以影响Ce的价态。例如,前述提到的(Ce, La)-Fe-B合金,La替代Ce能增大晶胞体积,使Ce从混合价态向+3价转变。Jin等[15]发现在[(Pr, Nd)1 - x (La, Ce) x ]2.14Fe14B (x = 0~0.5)合金中,当x > 0.3时,合金的饱和磁化强度Ms会出现异常升高,这一变化的主要原因是合金中Ce价态转向+3价,提高了2∶14∶1相的总体磁矩,进而使得合金的Ms增加。然而,有研究[71]发现Co替代Fe会减小晶胞体积,但同样可以提高合金的磁性能,主要是因为Ce和Co具有强烈的电子亲和性,Co会优先占据4c晶位,Co在Ce周边聚集导致Ce位体积增大,Ce倾向于转变为+3价,进而提高2∶14∶1相的内禀性能。Jiang等[45]在Ce16Fe78B6快淬合金中掺杂非稀土元素Ga,结果表明合金的磁性能和热稳定性均得到改善,而带来这一有利变化的原因,除了与显微组织的改善有关外,合金中Ce3+含量的增加也是磁性能提高的一个重要因素。在富相成分的铈基合金中,通过抑制1∶2相可有效提升磁性能。如图6a所示,第一原理计算的结果表明,La部分取代Ce可以使(Ce, La)Fe2相的形成能变正,说明La的加入会降低1∶2相的稳定性,造成1∶2相失稳进而达到抑制效果。Liao等[42]利用0.1% (原子分数)的La取代Ce后,Ce17Fe78B6快淬合金中的1∶2相的含量由17.6% (质量分数)大幅减少至8.2%;而当La的取代量增加至0.2% (原子分数)时,合金中1∶2相可以被完全抑制,如图6b[42]所示。除了利用稀土元素外,Zhang等[55]发现Si同样可以抑制Ce-Fe-B合金中1∶2相的形成,在显著提高合金矫顽力的同时改善其热稳定性。如图6c[55]所示,Ce17Fe75Si3B6合金的矫顽力为530 kA/m,比未掺杂的合金提高了92 kA/m。矫顽力改善的主要原因是Si在消除1∶2相的同时也促进了2∶14∶1相周围形成连续的薄层晶界相。此外,相关的研究[72]也发现,非稀土元素Ti也具有抑制1∶2相形成的作用,但其影响机制还需要进一步厘清。

图6

图6

(Ce1 - x La x )Fe2相的形成能、(Ce1 - x La x )17Fe78B6快淬合金的XRD精修图谱[42]以及Ce17Fe78 - x B6Si x[55]和Ce16Fe78 - x B6Ge x 快淬合金的退磁曲线[74]

Fig.6

Calculated formation energiesfor (Ce1 - x La x )Fe2 phase (Inset shows the schematic illustration of the cubic CeFe2 crystal) (a), XRD refinement spectra for (Ce1 - x La x )17Fe78B6 alloys[42] (b), demagnetization curves for the as-spun Ce17Fe78 - x B6Si x (Insets in Fig.6c show the microstructure evolutions of Ce17Fe78 - x B6Si x alloys)[55] (c) and Ce16Fe78 - x B6Ge x alloys (Inset shows the HRTEM image of Ce16Fe77.8B6Ge0.2 alloy)[74] (d)

尽管1∶2相的润湿性远不如富稀土晶界相,但在烧结磁体中1∶2相的存在可能会发挥一定的积极作用。Zhang等[73]研究了1∶2相对双主相烧结Nd-Ce-Fe-B磁体组织和磁性能的影响,结果表明1∶2相的存在有利于优化磁体微观结构,从而提高矫顽力。这主要是因为在烧结温度高于1∶2相熔点时,它可以增加磁体中的液相含量,提高2∶14∶1相的润湿性,并促进形成连续光滑的晶界相,削弱了相邻晶粒之间的磁耦作用。通过对1∶2相进行合理的改性,调控其在铈基合金中的含量和分布特性,1∶2相同样可以用于改善合金的磁性能。作者团队的研究[74]表明,当0.2% (原子分数)的Ge掺杂到Ce16Fe78B6合金中时,在增加1∶2相含量的同时也提高了其分布的均匀性和连续性,合金的矫顽力也因此提高了147 kA/m,增幅约为42.1%,如图6d[74]所示。Ge掺杂提高合金矫顽力的作用机制主要有2个:一方面,Ge会进入1∶2相中并大幅降低其形成能,使1∶2相在富Ce合金中更易形成,因而提高了合金中1∶2相的含量;另一个方面,Ge会降低1∶2相的熔点,在一定程度上改善了1∶2相的润湿能力,减少了1∶2相在三角晶界区域的富集,使1∶2相较均匀地分布在晶粒间。另外,一些低熔点的元素如Al[75]、Cu[76]以及前述提到的Ga同样可以起到优化1∶2相分布的作用,使硬磁晶粒能够被有效地隔绝,在改善铈基合金的矫顽力方面表现出良好的效果。

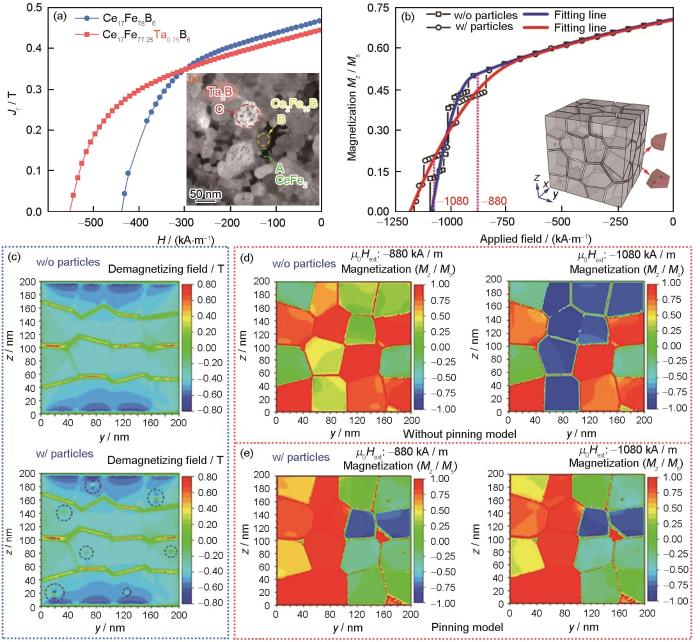

此外,掺杂微量的难熔元素如Nb[77]、Zr[58]、Hf[78]和Ta[56]同样可以改善高丰度稀土基RE-Fe-B合金的磁性能。一方面,这些难溶元素通常会在2∶14∶1相中析出非磁性沉淀相如Zr2B、HfB和TaB2等,作为钉扎中心以阻止畴壁传播;另一方面,这些沉淀相也能够抑制晶粒的生长,有助于形成细小均匀的显微结构,以减小相邻反向磁化晶粒带来的散逸磁场,从而提高硬磁性能。以Ta元素为例,Zhang等[56]在Ce17Fe78B6快淬合金中掺杂0.75% (原子分数)的Ta后,发现硬磁晶粒内会形成许多弥散分布的TaB2颗粒;合金的矫顽力也由未掺杂时的439 kA/m大幅提高至553 kA/m,矫顽力机制则由形核转为钉扎,如图7a[56]所示。而微磁学模拟的结果进一步表明,磁体模型的硬磁晶粒内析出非磁性颗粒时,这些析出相周围的退磁场会明显升高,导致反磁化核在这些区域提前形成。而磁体在不同外磁场下的截面磁化强度分布表明,与不含非磁性析出相的磁体模型相比,当晶粒内有析出相时,该磁体的磁化矢量在外磁场增加时仍基本保持不变,如图7b~d[56]所示。以上结果说明,通过掺杂难熔元素诱导晶粒内部形成的非磁性纳米析出相颗粒能够有效钉扎畴壁,提高磁体的矫顽力。

图7

图7

Ce17Fe78 - x B6Ta x (x = 0、0.75) 快淬合金的退磁曲线及其对应的微磁学模拟结果[56] (w/o和w/分别表示不含非磁性析出相的磁体模型和含有非磁性析出相的磁体模型)

Fig.7

Demagnetization curves for the as-spun Ce17Fe78 - x B6Ta x (x = 0, 0.75) alloys (Inset shows the bright-field TEM image of Ce17Fe77.25B6Ta0.75 alloy) (a), simulation demagnetization curves of the model magnets (Inset shows Ce-Fe-B magnet model with non-magnetic particles) (b), demagnetizing field distributions for both models in the saturation state (c), and magnetization reversal behaviors both models at different reversed magnetic fields (d, e)[56] (w/o and w/ represent the magnet model without non-magnetic particles and the magnet model with non-magnetic particles, respectively; μ0Hext—external applied field, Mz —magnetization in z direction, Ms—saturation magnetization)

掺杂非稀土元素虽然有助于提高合金的矫顽力,但通常伴随着剩磁和饱和磁极化强度的下降,导致合金的最大磁能积增加有限甚至会有所下降,并且微量元素掺杂的效果也会因合金成分的不同而不同。例如,前述提到Si会改善Ce-Fe-B合金的磁性能,但它在(Ce, La)-Fe-B合金中反而不利于2∶14∶1相的形成。此外,目前对微合金化调控高丰度稀土永磁合金磁性能的研究多集中于单个元素的掺杂,而一些研究结果表明,多元素间的协同作用可能会进一步改善组织并提升磁性能。江庆政[79]发现通过Nb、Cu、Ga和Co等元素复合掺杂后,可以在不降低铈基合金剩磁和最大磁能积的同时较大幅度地提高矫顽力。在后续研究中,非稀土元素在多元合金中的作用机制还需深入研究,以期获得更广泛的应用,而通过复合添加微量元素改善高丰度稀土RE-Fe-B合金磁性能的研究也亟待被更多的实验结果所验证。

除了采取上述微合金化的方法外,利用现有工艺手段的优化和融合也是改善高丰度稀土永磁合金磁性能的一种可行的思路。Zha等[80]采用熔体快淬与电子束曝光技术相结合的制备工艺,在1 s内完成了非晶Ce-Fe-B合金的晶化过程,高效的结晶效率使合金的晶粒细小且晶界相分布均匀,Ce12.2Fe81.6B6.2合金的最大磁能积高达51.7 kJ/m3,比采用常规快速热处理方法制备的合金提高了约4倍。Cui等[81]则利用提高烧结Nd-Fe-B性能的晶界扩散技术,在铈基快淬合金表面溅射沉积Nd70Cu30或Nd80Ag20扩散层,经适当的热处理后,扩散合金中形成了Ce2Fe14B/(Ce, Nd)2Fe14B的核壳结构,合金矫顽力的提高幅度超过了400 kA/m,增幅约250%。

3 全高丰度稀土(Ce/La/Y)-Fe-B磁体的制备

通常RE-Fe-B大块磁体都是采用粉末冶金工艺制备,将微米晶或纳米晶磁粉经无压或热压烧结等工艺使磁粉致密化,以获得可以实际应用的磁体。相比于高丰度稀土基RE-Fe-B合金,目前有关高丰度稀土基致密化磁体的研究相对较少;而在大多数应用场景中,大块磁体最终的使用价值往往取决于其磁性能。与全致密Nd-Fe-B磁体的制备工艺相似,高丰度稀土基RE-Fe-B磁体的致密化工艺主要包括烧结、热压/热变形和黏结。但由于高丰度稀土基RE-Fe-B的冶金行为与Nd-Fe-B存在差异,且内禀磁性能低,目前仍难以获得具有一定性能的大块磁体。本节将对基于Ce、La、Y的RE-Fe-B致密化磁体的相关研究进行总结,并重点阐述不同制备工艺下RE-Fe-B致密化磁体的显微组织与磁性能。

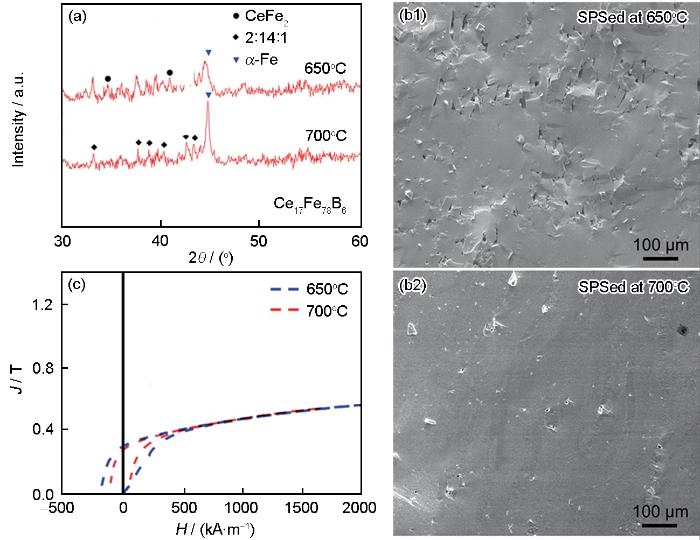

3.1 铈基RE-Fe-B烧结磁体

如前所述,当烧结温度高于1∶2相熔点时,它可以作为润湿硬磁晶粒的液相,这意味着通过烧结工艺应当是可以制备出类似于烧结Nd-Fe-B那样的各向异性铈基磁体。然而,Chen等[82]发现采用烧结工艺制备的Ce-Fe-B磁体中硬磁晶粒形状不规则,晶界相明显团聚且分布极不均匀。Ce17Fe77B6烧结磁体的矫顽力仅为9 kA/m,而即使增加Ce含量,Ce-Fe-B烧结磁体的磁性能也并没有明显提高。理论上,不规则的硬磁晶粒和表面缺陷都会增加反磁化畴形核的可能性,从而降低磁体的矫顽力。近年来,放电等离子烧结(SPS)技术作为一种快速烧结新工艺也被运用于大块磁体制备中。张振扬[83]采用SPS技术制备了各向同性的纳米晶Ce17Fe78B6磁体,发现烧结温度由650℃升高至700℃时,磁体中的α-Fe相显著增加,而CeFe2相消失,如图8a[83]所示。进一步的组织分析表明,提高烧结温度有助于促进磁粉的进一步变形,同时熔化的富Ce相在压力作用下会填充孔洞或间隙处,大幅增加了磁体的致密度。如图8b1和b2[83]所示,700℃的烧结温度下,磁体基本实现了完全致密化,但高温也导致了硬磁晶粒粗化,使得磁体的矫顽力、剩磁和最大磁能积由650℃时的214 kA/m、0.3 T和12 kJ/m3分别降低至128 kA/m、0.28 T和9 kJ/m3,磁体性能下降明显,如图8c[83]所示。为了改善Ce-Fe-B烧结磁体的性能,Jiang等[84]首先利用微合金化提高快淬合金的磁性能,然后将优化得到的Ce17Fe74.5B6-Nb0.5Cu0.5Ga0.5Co2.0合金制备成各向同性的SPS烧结磁体,其矫顽力、剩磁和最大磁能积分别为227 kA/m、0.37 T和16 kJ/m3,略高于同工艺下制备的Ce17Fe78B6磁体。相似地,Lu等[85]通过La部分取代Ce以改善(La, Ce)3Fe14B快淬合金的磁性能,并在此基础上制备了成分为(Ce0.7La0.3)3Fe14B的SPS烧结磁体。该磁体的矫顽力、剩磁和最大磁能积分别为259 kA/m、0.43 T和19 kJ/m3,优于已报道的Ce-Fe-B烧结磁体[82]。但就目前而言,在不添加Pr、Nd、Tb、Dy等关键稀土元素的情况下,无论是微米晶或纳米晶高丰度稀土基RE-Fe-B烧结磁体的性能仍普遍太低。

图8

3.2 (Ce/La/Y)-Fe-B热变形磁体

为了获得高性能的全致密大块磁体,磁体内部必须实现晶粒取向一致,即制备成各向异性磁体。对于快淬合金而言,热变形过程中纳米晶粒在压力作用下通过物质输运和晶界滑移产生沿垂直压力方向的平板状结构使磁体具有高的各向异性[86]。但高丰度稀土基RE-Fe-B磁体的热变形过程与Nd-Fe-B相比存在明显的差异,例如,Ce-Fe-B热变形磁体中由于缺乏低熔点的富稀土相,晶粒很难通过扩散蠕变而获得c轴取向,不仅磁体的剩磁不能得到很好的改善,矫顽力也会因晶粒粗化而导致大幅下降。Hou等[87]通过不断提高Ce-Fe-B磁体中的Ce含量,发现原先零星状分布的1∶2相随Ce含量的增加而逐渐在硬磁晶粒周围呈弥散分布。这种分布特性的改变有助于提高热变形磁体的矫顽力,但1∶2相不利于c轴取向的形成。即使热变形温度提高至1∶2相熔点以上,Ce-Fe-B磁体中仍未出现具有取向特征的(105)和(006)衍射峰,说明在纯Ce-Fe-B热变形磁体中很难通过形成织构获得各向异性。Wang等[88]在Ce29.82Fe69.18B1合金中添加了适量的Ga以改善磁粉的热流变性能,结果表明Ga可以进一步优化磁体微观组织,在硬磁晶粒周围形成的薄层富Ce-Ga相使磁体获得了较好的板状结构,热变形磁体的剩磁由0.37 T大幅增加至0.68 T,但因磁体晶粒尺寸过大,Ce29.82Fe68.65Ga0.53B1磁体的矫顽力和最大磁能积并不理想,仅为48 kA/m和18 kJ/m3。

为了解决Ce-Fe-B基磁体热变形过程中取向困难的问题,作者团队[89]最近通过混合使用Ce、La和Y元素,以成分为(Ce0.9La0.1)17Fe78B6和[(Ce0.9La0.1)0.8Y0.2]17-Fe78B6快淬合金为前驱体,制备得到了各向异性的纳米晶热变形磁体。图9a[89]为Ce17Fe78B6、(Ce0.9La0.1)17Fe78-B6和[(Ce0.9La0.1)0.8Y0.2]17Fe78B6热变形磁体平行于压力方向测得的磁滞回线。可以看到,后2者的退磁曲线具有更好的方形度,说明磁体中形成了较好织构组织。Ce17Fe78B6磁体c轴方向上测得的剩磁仅为0.39 T,而(Ce0.9La0.1)17Fe78B6和[(Ce0.9La0.1)0.8Y0.2]17Fe78B6磁体的剩磁分别为0.55和0.63 T,剩磁得到明显改善的最直接原因是磁体各向异性的增强。如图9b和d[89]所示,Ce-Fe-B磁体中的硬磁晶粒仍然保持等轴晶状态,多个晶粒间夹杂着晶粒粗大的1∶2相,并且各晶粒之间是直接接触,缺乏明显的晶界相。反之多组元(Ce, La)-Fe-B和(Ce, La, Y)-Fe-B磁体中存在排列整齐的板条状硬磁晶粒,且晶粒之间围绕着连续的薄层富稀土晶界相,如图9c[89]所示。这些富稀土晶界相不仅可以改善热变形过程中磁晶粒的择优取向过程,使得晶粒获得c轴取向,大幅增强磁体的剩磁,而且能够消弱硬磁晶粒之间的磁交换耦合作用,使热变形磁体具有更高的矫顽力。(Ce0.9La0.1)17Fe78B6和[(Ce0.9La0.1)0.8Y0.2]17Fe78B6的矫顽力分别为129和124 kA/m,高于Ce17Fe78B6磁体的102 kA/m。如图9e所示,与不同成分的Ce-Fe-B基热变形磁体的性能[16,87~93]进行比较,可以发现,虽然富稀土成分的Ce-Fe-B基热变形磁体具有比(Ce, La)-Fe-B和(Ce, La, Y)-Fe-B磁体更高的矫顽力,但由于磁体取向程度很差,它们的剩磁和最大磁能积普遍较低。而(Ce, La)-Fe-B和(Ce, La, Y)-Fe-B热变形磁体表现出更为优越的磁性能,并且良好的矫顽力和剩磁协同也使(Ce, La, Y)-Fe-B热变形磁体的最大磁能积达到了29.5 kJ/m3,这也是全高丰度稀土基致密化磁体迄今为止报道的最高值。但与目前市售的高端铁氧体相比,(Ce, La, Y)-Fe-B热变形磁体的硬磁性能仍需要进一步提高。

图9

图9

Ce-Fe-B、(Ce, La)-Fe-B和(Ce, La, Y)-Fe-B热变形磁体的磁滞回线、微观结构[89]以及与其他铈基热变形磁体[16,87~93]的性能对比

Fig.9

Hysteresis loops measured parallel (//) to the pressing direction of hot-deformed Ce17Fe78B6, (Ce0.9La0.1)Fe78B6, and [(Ce0.9La0.1)0.8Y0.2)]17Fe78B6 magnets (Inset shows the demagnetization curves of the hot-deformed magnets) (a), bright field TEM images of hot-deformed Ce17Fe78B6 (b) and [(Ce0.9La0.1)0.8Y0.2)]17Fe78B6 magnets (Insets show the HRTEM images of the hot-deformed magnets) (c), EDS line-scan profiles for hot-deformed Ce17Fe78B6 magnet (d)[89], and comparison of Hcj and Jr for hot-deformed (Ce, La)-Fe-B and (Ce, La, Y)-Fe-B magnets with available reported hot-deformed Ce-Fe-B magnets[16,87-93] (e)

晶界扩散工艺是改善高丰度稀土永磁性能的一种有效手段,一些含关键稀土元素的扩散剂,如Pr-Cu[94]、Nd-Cu[16,95]和Pr-Cu-Al[96]等,已经被应用于高丰度稀土基磁体中,通过提高磁体的塑性变形能力,增强其c轴取向,以最终实现磁体性能的显著提升。例如,Lu等[85]将5% (质量分数)的Nd70Cu30扩散剂混入到(Ce0.7La0.3)3Fe14B快淬磁粉中,扩散后的磁体矫顽力和最大磁能积分别为446 kA/m和37 kJ/m3,较未添加Nd70Cu30的磁体,2者的提升幅度均超过了70%。相似地,Tang等[16]将Nd70Cu30合金粉的使用量提高到10% (质量分数),将Ce13.87Fe75.61Co4.43Ga0.37Cu0.1-Al0.19B5.43热变形磁体的矫顽力和剩磁由扩散前的637 A/m和0.61 T大幅增加至398 kA/m和0.96 T。虽然使用晶界扩散技术可以改善高丰度稀土永磁体的性能,但目前这些含关键稀土元素的扩散剂使用量普遍过高,不仅导致磁体的成本激增,同时也加剧了对关键稀土的过度依赖。

3.3 (Ce, La, Y)-Fe-B黏结磁体

与烧结和热加工磁体相比,黏结磁体的制备工艺相对简单且能制备出形状复杂的磁体,因此被广泛用于传感器、小型电机等精密器件领域[97]。目前报道的各类黏结磁体主要是以Nd-Fe-B为主,也常通过混入包括Ba/Sr铁氧体[98]、Sm-Co[99]、Sm-Fe-N[100,101]、MnBi[102]等磁粉来改善黏结磁体的温度稳定性和耐腐蚀性能,以提高磁体的实际服役性能。如前所述,多组元(Ce, La, Y)-Fe-B永磁合金具有较好的综合磁性能,并且表现出比Nd-Fe-B磁粉更为优异的性价比和耐腐蚀性能。基于这些突出的先决条件,开发基于高丰度稀土的黏结磁体将会极大地丰富高丰度稀土永磁材料的应用场景。

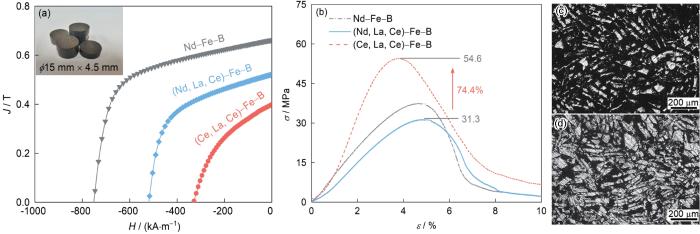

Huang等[103]将多组元[(Ce0.7La0.3)0.8Y0.2]17Fe78B6的快淬磁粉与4.69% (质量分数)热固性黏合剂混合,经冷压和固化后得到了全高丰度稀土黏结磁体,并将其与商用Nd26.4Fe67.6Co5B和Nd6Pr2La6.7Ce13.4Fe69.3Zr1.5B1.1磁粉制备的Nd-Fe-B和(Nd, La, Ce)-Fe-B黏结磁体在磁性能、耐腐蚀性能和力学性能等方面进行了详细比较。在室温磁性能方面,(Ce, La, Y)-Fe-B黏结磁体的剩磁、矫顽力和最大磁能积分别为0.40 T、330 kA/m和 21.7 kJ/m3,低于(Nd,Ce,La)-Fe-B的0.52 T、519 kA/m和43.8 kJ/m3以及Nd-Fe-B的0.66 T、751 kA/m和75.3 kJ/m3,如图10a[103]所示。但(Ce, La, Y)-Fe-B黏结磁体的磁性能,尤其是矫顽力和最大磁能积随温度升高时的下降速率要比上述2种含Nd黏结磁体慢。在300~400 K的温度范围内,与含Nd黏结磁体相比,(Ce, La, Y)-Fe-B磁体具有更高的β值(-0.181%/K),且其α值也仅为-0.241%/K,这说明(Ce, La, Y)-Fe-B黏结磁体拥有更为优异的高温热稳定性。(Ce, La, Y)-Fe-B黏结磁体性能/成本比约为7.97 kJ·m-3·kg·$-1,是Nd-Fe-B和(Nd, La, Ce)-Fe-B黏结磁体的3~6倍,展现出了极佳的性价比优势。此外,(Ce, La, Y)-Fe-B黏结磁体还具有比含Nd的黏结磁体更好的耐腐蚀性能和力学性能。(Ce, La, Y)-Fe-B黏结磁体良好的耐腐蚀性能主要是因为La、Y具有比Nd、Ce更高的标准电极电位,降低磁体发生电化学腐蚀的趋势[104]。而(Ce, La, Y)-Fe-B黏结磁体高的抗压强度主要得益于磁粉压制变形过程中所形成的致密规整的磁体结构。如图10c和d[103]中的显微结构所示,与Nd-Fe-B黏结磁体相比,脆性较小的(Ce, La, Y)-Fe-B磁粉颗粒堆垛排列得更加紧密,磁粉填充更为饱满,极大地提高了磁体的致密度,从而使得(Ce, La, Y)-Fe-B黏结磁体的抗压强度达到了54.6 MPa,远高于Nd-Fe-B和(Nd, Ce, La)-Fe-B黏结磁体,如图10b[103]所示。

图10

图10

Nd26.4Fe67.6Co5B, Nd6Pr2La6.7Ce13.4Fe69.3Zr1.5B1.1和[(Ce0.7La0.3)0.8Y0.2]17Fe78B6黏结磁体的退磁曲线、压缩应力/应变曲线以及金相显微组织[103]

Fig.10

Demagnetizations curves (a) and stress-strain (σ-ε) curves (b) of Nd26.4Fe67.6Co5B, Nd6Pr2La6.7Ce13.4Fe69.3Zr1.5B1.1 and [(Ce0.7La0.3)0.8Y0.2]17Fe78B6 bonded magnets (Inset shows the macroscopic image of bonded [(Ce0.7La0.3)0.8Y0.2]17Fe78B6 magnet), and metallographic microstructures of Nd26.4Fe67.6Co5B (c) and [(Ce0.7La0.3)0.8Y0.2]17Fe78B6 bonded (d) magnets[103]

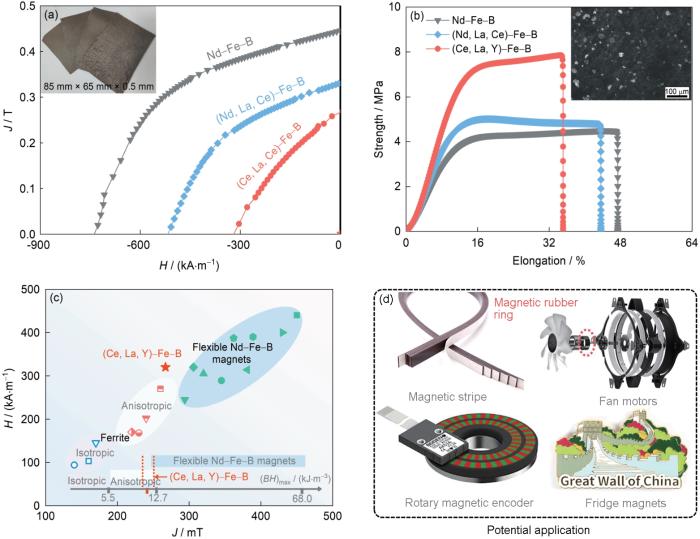

橡胶磁体作为黏结磁体的重要组成部分,具有优异的延展性和可绕曲性,已经在汽车电子磁性元器件中得到了很好的应用。最近,在基于上述(Ce, La, Y)-Fe-B黏结磁体的工作基础上,作者团队[105]利用[(Ce0.7La0.3)0.8Y0.2]17Fe78B6的快淬磁粉进一步开发出了全高丰度稀土橡胶磁体。(Ce, La, Y)-Fe-B橡胶磁体的矫顽力、剩磁和最大磁能积分别为320 kA/m、0.27 T和10.1 kJ/m3,虽然室温磁性能要低于钕基橡胶磁体,但它在耐腐蚀、力学性能、抗老化等服役性能方面要更具优势。例如,如图11b[105]所示,(Ce, La, Y)-Fe-B橡胶磁体的抗拉强度为7.86 MPa,比Nd-Fe-B和(Nd, La, Ce)-Fe-B橡胶磁体的抗拉强度分别提高了74.2%和56.8%。而(Ce, La, Y)-Fe-B橡胶磁体较好的服役性能与其橡胶基体中均匀分布的小粒径磁粉密切相关。这是因为在磁粉与橡胶基体混炼时会相互摩擦,而脆性比钕基磁粉更大的(Ce, La, Y)-Fe-B磁粉更易破碎成小粒径粉末而被橡胶基体有效地包封,有效减弱了磁粉的氧化;而粉末细化也有助于增强磁粉颗粒的弥散强化效果,显著提高橡胶磁体的拉伸性能[106]。如图11c和d[105]所示,与商用的橡胶铁氧体相比,(Ce, La, Y)-Fe-B磁体具有更高的剩磁和矫顽力,即更好的硬磁性能,并且它的最大磁能积介于各向异性橡胶铁氧体和Nd-Fe-B橡胶磁体之间。未来通过进一步的性能优化,(Ce, La, Y)-Fe-B橡胶磁体有望替代商用橡胶铁氧体,在柔性黏结磁条、磁环、磁贴以及永磁微特电机或磁编码器环形磁体方面得以应用。

图11

图11

[(Ce0.7La0.3)0.8Y0.2]17Fe78B6橡胶磁体的退磁曲线、拉伸曲线、性能对比及其潜在的应用领域[105]

Fig.11

Demagnetizations curves (Inset shows the optical image of [(Ce0.7La0.3)0.8Y0.2]17Fe78B6 rubber magnet) (a) and tensile curves (Inset shows the metallographic microstructure of [(Ce0.7La0.3)0.8Y0.2]17Fe78B6 rubber magnet) (b) of Nd26.4Fe67.6Co5B, Nd6Pr2La6.7Ce13.4Fe69.3Zr1.5B1.1, and [(Ce0.7La0.3)0.8Y0.2]17Fe78B6 rubber magnets, comparison of magnetic properties of (Ce, La, Y)-Fe-B rubber magnets with commercial rubber ferrite and Nd-Fe-B rubber magnet (c), and potential applications of the (Ce, La, Y)-Fe-B rubber magnets (d) [105]

4 结论和展望

高丰度稀土Ce、La和Y巨大的资源储量、低廉的价格和适中的内禀磁性能,使其在开发新一代高性价比稀土永磁方面显示出巨大的优势。利用Ce或La部分替代Nd、Pr等关键稀土元素的混合稀土永磁材料已经得到了工业化生产,但关于全高丰度Ce、La、Y基RE-Fe-B永磁材料的相关研究仍然非常有限。目前多组元(Ce, La, Y)-Fe-B快淬合金的最大磁能积已经超过了65 kJ/m3,并且(Ce, La, Y)-Fe-B磁体在力学性能、抗老化和耐腐蚀等服役性能方面也要优于商用钕基磁体或永磁铁氧体,但高丰度稀土基磁体的硬磁性能仍不如高端的永磁铁氧体。因此,如何通过合金化学成分设计和磁体加工技术改进,实现对高丰度稀土永磁相结构的稳定设计和界面结构的精准调控,更好地构筑材料的显微组织单元,从而实现磁性能的全面提升,是今后工作中需要关注的重点。但需要指出的是,基于Ce、La和Y的多元稀土永磁材料的冶金行为及成相规律尚不明确,并且多元素间交互作用对2∶14∶1相成相规律及内禀磁性的影响规律的研究还有待进一步深入。另外,现阶段有关高丰度稀土永磁的耐腐蚀性能、力学性能以及热减磁等服役性能方面的基础性研究相对缺乏,磁体的相关服役行为和机制尚不明确。厘清这些基本的科学问题对于进一步优化全高丰度稀土永磁的综合性能具有重要的指导意义。为了实现全高丰度稀土永磁的性能提升,可以从以下几个方面考虑。(1) 对于铈基高丰度稀土永磁而言,应当充分发挥Ce3+的积极作用,以提高2∶14∶1相的内禀性能;而通过抑制1∶2相或者优化1∶2相的分布,可实现对外禀结构的设计优化,最终改善铈基磁体的综合磁性能。(2) 高丰度稀土元素在冶金结构上具有天然的偏聚特性,通过充分利用Ce、La、Y间的交互作用和非均质分布特性调控磁体的显微组织和磁结构,实现多元高丰度稀土永磁性能的进一步优化。(3) 各向异性纳米晶磁体仍然面临着晶粒取向困难和矫顽力下降明显这2个亟待解决的难题,而微量元素的改性作用和晶界扩散工艺对晶界微观结构和成分的控制,可以显著改善高丰度稀土永磁的矫顽力。(4) 发展适用于高丰度稀土永磁的高效扩散源,改善基体与扩散源的适配性以提高扩散效力,获得高性能磁体,助推高丰度稀土永磁材料的高端应用。(5) 通过构建稀土永磁材料数据库,利用机器学习、高通量实验以及理论计算等一系列技术融合,缩短高丰度稀土永磁的成分筛选和性能调控周期,以实现对磁体的成分结构和制备工艺的高效优化。

与商用烧结Nd-Fe-B磁体相比,现阶段高丰度稀土永磁体的制备工艺远未成熟,加速实现高丰度稀土永磁从实验室研发到技术产品的市场化应用,离不开产学研用方面的高效协同创新。一方面,要促进企业、科研院所和高等学校在涉及高丰度永磁性能改进技术、磁体制备工艺和产业化推广方面的深度交叉融合,在保持磁体技术研发和产品生产同步性的同时,也能更好地满足市场对永磁产品的多样化需求,提高企业产品利润。另一方面,高丰度稀土永磁在磁吸附、磁选、声学器件甚至性能要求更为严苛的工业电机等领域均具有广阔的市场前景,开发满足应用需求的高丰度稀土永磁系列产品并推动它们在实际器件上的应用和产业化,将会倒推相关基础研究和制造技术的进步。随着我国经济结构向节能化方向发展,全高丰度稀土永磁的研制和产业化不仅有望提升其应用器件在终端市场的渗透率,对巩固我国在稀土永磁领域的产业优势也具有重要意义。

参考文献

Understanding the role of element grain boundary diffusion mechanism in Nd-Fe-B magnets

[J].

Several issues on the development of grain boundary diffusion process for Nd-Fe-B permanent magnets

[J].

钕铁硼永磁晶界扩散技术和理论发展的几个问题

[J].钕铁硼永磁在新能源、信息通讯和智能制造等领域有着广泛的应用。电动汽车驱动电机、风电系统发电机等对钕铁硼磁体的高温性能和矫顽力提出了更高的要求。重稀土Tb和Dy可以显著提高钕铁硼磁体的各向异性场,但降低了剩磁,增加了成本。21世纪初出现的晶界扩散技术是稀土永磁制造领域的一项重大进展。它通过将重稀土元素或稀土合金以晶界扩散的方式渗透入磁体,在有效提高磁体矫顽力的同时,大幅降低重稀土含量,提高性价比。晶界扩散技术发展至今,引起业内的广泛关注并已实现工业化,但在技术和理论层面上仍存在一些关键问题。本文基于国内外最新进展和作者团队的研究工作,总结了晶界扩散工艺目前亟需解决的问题及可能的解决措施。对厚磁体的晶界扩散技术、晶界扩散中各向异性行为的利用、低成本扩散剂的选择、晶界扩散与现存工艺的结合、晶界扩散对其他服役性能的影响以及晶界扩散的相关理论发展等问题进行了阐述,并对晶界扩散的未来发展趋势进行了展望。

Perspective and prospects for rare earth permanent magnets

[J].

Current status and challenges in corrosion and protection strategies for sintered NdFeB magnets

[J].The susceptibility of sintered NdFeB to corrosion in harsh environments limits their wide variety of applications. Improved resistance to corrosion of NdFeB magnets and advancement of surface coatings are critical directions in permanent magnet material fields. Significant work has been undertaken on the development of long-life NdFeB magnets. However, comprehensive research of NdFeB corrosion, from process technology to fundamental theory, is lacking, mainly owing to the hysteresis in the study of the elementary works of corrosion and protection related to magnetism, and improving the quality and diversified market demands. This analysis covers recent research that has led to advances in anti-corrosion material technology for NdFeB magnets, including corrosion factors, contemporary methodologies from technology to fundamentals, the basic framework for surface protection and key techniques in the industry application. Finally, prospects and existing challenges in the field of corrosion and protection are reviewed, attempting to identify future developments and directions.

烧结NdFeB永磁材料腐蚀与防护的研究现状及挑战

[J].烧结NdFeB永磁材料的腐蚀敏感性限制了其在复杂工况下的应用,提高磁体的抗腐蚀能力和开发优异的防护涂层是领域发展的重点方向。尽管针对长寿命NdFeB磁体的探索已经做了大量工作,但是从技术工艺到基础理论,系统地研究NdFeB磁体的腐蚀问题仍然比较少,这一方面是由于材料腐蚀与防护的基础研究滞后于磁性能方面的研究工作,另一方面还与市场对材料品质要求的不断提高及多样化需求有较大关系。本文综述了耐蚀烧结NdFeB永磁材料的最新研究成果,包括影响腐蚀的因素、提高磁体耐蚀性能的基础理论及方法、表面防护战略的基本框架及工程应用中的关键技术;最后,展望了未来前景并分析了面临的挑战,期望为今后的发展指明方向。

Development of non-rare earth grain boundary modification techniques for Nd-Fe-B permanent magnets

[J].The magnetic performance of Nd-Fe-B magnets depends on their grain boundary structure. Intergranular addition and grain boundary diffusion (GBD) process are effective approaches for enhancing coercivity with low material cost. This review summarizes the development of grain boundary modification techniques with emphasis on our recent work using cost-effective non-rare earth (non-RE) sources for GBD. Up to now, heavy rare earth (HRE) based compounds, metals and light rare earth (LRE) based alloys have been successfully employed as the diffusion sources for coercivity enhancement. Inspired from the previous investigations on the intergranular addition of non-RE compounds and alloys for Nd-Fe-B magnets, in 2015, we firstly proposed a novel GBD process based on diffusion source of MgO. After that, various non-RE diffusion sources have been developed. The fundamentals of non-RE additives and non-RE diffusion sources for hard magnetic properties enhancement of Nd-Fe-B magnets are summarized here based on both the experimental and computational results. In particular, the properties-microstructure relationships of non-RE GBD modified magnets are discussed. The non-RE alloys or compounds modify the composition and structure of the grain boundary by diffusing into the intergranular regions, resulting in enhanced coercivity and corrosion resistance. Recently, we used Al-Cr coatings for both coercivity enhancement and surface protection, which shortens the production process and makes non-RE diffusion sources more competitive. The opportunity and future directions for non-RE GBD are also discussed in this review.

Current progress and future challenges in rare-earth-free permanent magnets

[J].

Pricing of rare earth metals

[EB/OL]. https://www.metal.com/Rare-Earth-Metals,

Magnetocrystalline anisotropy of R2Fe14B tetragonal compounds

[J].A systematic study of magnetocrystalline anisotropy of R2Fe14B tetragonal compounds with various rare-earth elements (R) has been carried out at room temperature by the pulse method. The anisotropy fields of Y2Fe14B and Nd2Fe14B compounds are 3.1 and 12 MA/m, respectively. The maximum anisotropy field of 28 MA/m was observed in Tb2Fe14B compounds. The change in lattice parameters, saturation magnetization, and the Curie temperature with the rare-earth elements of R2Fe14B compounds is also described.

Review of additive manufacturing of permanent magnets for electrical machines: A prospective on wind turbine

[J].

Research status and prospect of high abundant rare earth of permanent magnetic materials

[J].

高丰度稀土永磁材料的研究现状与展望

[J].

Permanent magnets and hard magnetic materials

[J].

Magnetization and magnetic anisotropy of RE2Fe14B measured on single crystals

[J].The temperature dependence of the saturation magnetization and the magnetocrystalline anisotropy field have been measured on single-crystal samples of the R2Fe14B compounds for R=Y, Ce, Pr, Nd, Sm, Gd, Tb, Dy, Ho, Er, and Tm from 4.2 K to the magnetic ordering temperatures. A spin reorientation transition of the Nd2Fe14B type has been found in Ho2Fe14B at 57.6 K in zero field. Another type of spin reorientation caused by anisotropy compensation between the Fe and the R sublattices exists in Er2Fe14B and Tm2Fe14B. The temperature dependence of the angle of the easy direction of magnetization from the c axis has been measured for R=Nd, Ho, Er, and Tm. The relation between the magnetocrystalline anisotropy and the sublattice magnetization is investigated by employing a simplified two-sublattice molecular field model.

Manipulating Ce valence in RE2Fe14B tetragonal compounds by La-Ce Co-doping: Resultant crystallographic and magnetic anomaly

[J].Abundant and low-cost Ce has attracted considerable interest as a prospective alternative for those critically relied Nd/Pr/Dy/Tb in the 2: 14: 1-type permanent magnets. The (Nd, Ce)(2)Fe14B compound with inferior intrinsic magnetic properties to Nd2Fe14B, however, cannot provide an equivalent magnetic performance. Since Ce valence is sensitive to local steric environment, manipulating it towards the favorable trivalent state provides a way to enhance the magnetic properties. Here we report that such a desirable Ce valence can be induced by La-Ce co-doping into (Pr, Nd)(1-x)(La, Ce) x(2.14)Fe14B (0 < x < 0.5) compounds via strip casting. As verified by X-ray photoelectron spectroscopy results, Ce valence shifts towards the magnetically favorable Ce3+ state in the composition range of x > 0.3, owing to the codoping of large radius La3+ into 2: 14: 1 phase lattice. As a result, both crystallographic and magnetic anomalies are observed in the same vicinity of x = 0.3, above which lattice parameters a and c, and saturation magnetization M-s increase simultaneously. Over the whole doping range, 2: 14: 1 tetragonal structure forms and keeps stable even at 1250 K. This finding may shed light on obtaining a favorable Ce valence via La-Ce co-doping, thus maintaining the intrinsic magnetic properties of 2: 14: 1-type permanent magnets.

Coercivity enhancement of hot-deformed Ce-Fe-B magnets by grain boundary infiltration of Nd-Cu eutectic alloy

[J].

Structure, magnetic properties and Mössbauer study of melt-spun nanocrystalline Ce-rich ternary Ce-Fe-B alloy

[J].

57Fe Mössbauer spectrometry: A powerful technique to analyze the magnetic and phase characteristics in RE-Fe-B permanent magnets

[J].

Phase precipitation behavior of melt-spun ternary Ce2Fe14B alloy during rapid quenching and heat treatment

[J].

Phase constitution and microstructure of Ce-Fe-B strip-casting alloy

[J].

Microstructure and magnetic properties of Ce10+ x Fe84- x B6 nanocrystalline ribbons versus preparation conditions

[J].

Magnetic hardening of Ce2Fe14B

[J].

A cost-effective approach to optimizing microstructure and magnetic properties in Ce17Fe78B6 alloys

[J].

Permanent magnet materials based on the rare earth-iron-boron tetragonal compounds

[J].

Formation of Fe14La2B phase in as-cast and melt-spun samples

[J].The formation of the tetragonal Fe14La2B phase has been examined in both as-cast and melt-spun Fe-La-B alloys using thermal and magnetic techniques together with x-ray diffraction analysis. It is found that this phase exists in both types of alloys and that it is produced by annealing at relatively low temperatures. The Fe14La2B phase is unstable and is transformed to mostly α-Fe plus La-B upon annealing at higher temperatures.

Cobalt-free and samarium-free permanent magnet materials based on an iron-rare earth boride

[J].

Vertical section phase diagrams of La-Fe-B ternary system

[J].

Understanding the phase structure, magnetic properties and anti-corrosion behavior of melt-spun (La,Y)2Fe14B alloys

[J].

Phase precipitation behavior of rapidly quenched ternary La-Fe-B alloy and the effects of Nd substitution

[J].

Preparation and microstructure of La-containing R-Fe-B permanent magnets

[J].The unfavorable effect of La on the magnetic properties of R-Fe-B permanent magnets is shown to be related closely to remarkable changes in microstructure due to excessive oxidation of La-containing R-rich phases in the alloys. Ce and Al are found to be effective in promoting the sintering process of La-containing alloys, resulting in improvements in both microstructure and magnetic properties. Al segregates into the fcc R-rich phase and improves the wetting ability of its liquid at high temperatures. It is suggested that the influence of Al on coercivities of R-Fe-B magnets is connected with a depression of magnetic interactions between hard magnetic grains.

Study on the phase equlibria of La-Fe-B system and crystal structure and magnetic properties of compound

[D].

La-Fe-B体系相平衡及化合物晶体结构、性能研究

[D].

Effects of lanthanum substitution on microstructures and intrinsic magnetic properties of Nd-Fe-B alloy

[J].

Magnetic properties of Y-Fe-B system alloys

[J].

Research progress and prospect of high abundance rare earth permanent magnet materials

[J].

高丰度稀土永磁材料的研究进展与展望

[J].

Fundamental properties of melt-spun stoichiometric Y2Fe14B alloy and the advantages of Nd substitution

[J].

Hard magnetic properties of melt-spun nanocomposite Y16Fe78B6 ribbons

[J].

Reducing Dy content by Y substitution in nanocomposite ndfeb alloys with enhanced magnetic properties and thermal stability

[J].

Maximizing the hard magnetic properties of melt-spun Ce-La-Fe-B alloys

[J].To balance the utilization of rare earth (RE) resource and develop Ce-based permanent magnets with high performance/cost ratio, the role of La substitution in the melt-spun (Ce1-xLax)(y)Fe14B (x = 0-0.4, and 0.5; y = 2-4) alloys has been investigated. It has been confirmed that the hard magnetic properties of Ce-based magnets can be effectively enhanced by partial substitution of La. The maximum (BH)(max) of (Ce,La)-Fe-B alloys can be obtained at a Ce:La atomic ratio of 7:3. The lattice parameters and Curie temperature of the hard magnetic (Ce/La)(2)Fe14B phase increase linearly with increasing La content. Three different alloy systems with y = 2, 2.5 and 3 show similar behavior of magnetic properties dependences on La. In the RE-rich compositions, La substitution for Ce can effectively inhibit the precipitation of the CeFe2 phase. A solid solution, Ce(La) phase with a space group of Fm-3m, appears in the (Ce0.7La0.3)(y)Fe14B alloys with y >= 3.5. A good combination of magnetic properties with H-cj = 345 kA/m, J(5T) = 1.03 T, J(r) = 0.60T, and (BH)(max)= 6.3 MGOe is obtained in (Ce0.7La0.3)(2.5)Fe14B alloy. In addition, 30 at.% La substitution for Ce can significantly refine the grains, resulting in the enhancement of exchange coupling interaction. The present finding is beneficial for designing new and low-cost magnetic materials.

Hard magnetic properties of rapidly quenched (La, Ce)-Fe-B ribbons

[J].

Clarifying the basic phase structure and magnetic behavior of directly quenched (Ce, La)2Fe14B alloys with various Ce/La ratios

[J].To improve the performance/cost ratio of NdFeB based permanent magnets, Ce or/and La substitutions for Nd have been suggested. To better understand the effects of these substitutions, the fundamental behavior of (Ce,La)-Fe-B alloys has to be clearly understood. Here, we reported a systematic investigation on the phase structure, microstructure, and magnetic properties of melt-spun (Ce,La)(2)Fe14B alloys. The results confirm that partial substitution of Ce by La can effectively enhance the hard magnetism and thermal stability of (Ce1-xLax)(2)Fe14B alloys, while over 80% La substitution leads to the decomposition of 2:14:1 phase. The lattice parameters a, c and the Curie temperature T-c of 2:14:1 phase increase linearly with the increasing La content. La substitution can effectively refine the grain, resulting in the enhancement of inter-grain exchange coupling. The (Ce0.7La0.3)(2)Fe14B alloy with a mean grain size of 25 nm exhibits high remanence, maximum energy product and intrinsic coercivity up to 0.69 T, 6.2 MGOe and 217 kA/m, respectively. The present work provides a good understanding on the melt-spun (Ce,La)-Fe-B system for further developing low cost rare earth permanent magnets.

Grain boundary diffusion sources and their coating methods for Nd-Fe-B permanent magnets

[J].Nd-Fe-B magnets containing no heavy rare earth (HRE) elements exhibit insufficient coercivity to withstand the demagnetization field at elevated temperatures. The grain boundary diffusion (GBD) process provides the best route to fabricate high-coercive Nd-Fe-B magnets with low consumption of expensive HRE resources. Here we give a special review on the grain boundary diffusion sources and their coating methods. Up to now, various types of grain boundary sources have been developed, starting from the earliest Tb or Dy metal. The HRE-M eutectic alloys were firstly proposed for reducing the cost of the diffusion source. After that, the diffusion sources based on light rare earth and even non rare earth elements have also been proposed, leading to new understanding of GBD. Now, the diffusion sources including inorganic compounds, metals, and alloys have been employed in the industry. At the same time, to coat the diffusion source on the magnets before diffusion treatment, various methods have been developed. Different from the previous review articles for GBD, this review gives an introduction of typical types of diffusion sources and their fabrication approaches. The effects of diffusion source on the microstructure and magnetic properties are summarized briefly. In particular, the principles and applicability of different coating approaches were discussed in detail. It is believed that this review can provide a technical guidance for the industry for designing the diffusion process and products meeting specific requirements.

Development of cost-effective nanocrystalline multi-component (Ce, La, Y)-Fe-B permanent magnetic alloys containing no critical rare earth elements of Dy, Tb, Pr and Nd

[J].

Magnetic properties and microstructure of melt-spun Ce-Fe-B magnets

[J].

Phase constituents, magnetic properties, intergranular exchange interactions and transition temperatures of Ge-doped CeFeB alloys

[J].

Effect of Ga addition on the valence state of Ce and magnetic properties of melt-spun Ce17Fe78 - x B6Ga x (x = 0-1.0) ribbons

[J].

Exceptional elevated temperature behavior of nanocrystalline stoichiometric Y2Fe14B alloys with La or Ce substitutions

[J].

Enhanced hard-magnetic properties and thermal stability of nanocrystalline Ce-rich Ce-Fe-B alloys by combining La substitution and Si addition

[J].

Performance improvement and element segregation behavior in Y substituted nanocrystalline (La, Ce)-Fe-B permanent magnetic alloys without critical RE elements

[J].

Enhancement in hard magnetic properties of nanocrystalline (Ce, Y)-Fe-Si-B alloys due to microstructure evolution caused by chemical heterogeneity

[J].

Influences of element segregation on the magnetic properties in nanocrystalline Nd-Ce-Fe-B alloys

[J].

Chemically inhomogeneous RE-Fe-B permanent magnets with high figure of merit: Solution to global rare earth criticality

[J].The global rare earth (RE) criticality, especially for those closely- relied Nd/Pr/Dy/Tb in the 2: 14: 1-typed permanent magnets (PMs), has triggered tremendous attempts to develop new alternatives. Prospective candidates La/Ce with high abundance, however, cannot provide an equivalent performance due to inferior magnetic properties of (La/Ce)(2)Fe14B to Nd2Fe14B. Here we report high figure-of-merit La/Ce-rich RE-Fe-B PMs, where La/Ce are inhomogeneously distributed among the 2: 14: 1 phase. The resultant exchange coupling within an individual grain and magnetostatic interactions across grains ensure much superior performance to the La/Ce homogeneously distributed magnet. Maximum energy product (BH)(max) of 42.2 MGOe is achieved even with 36 wt. % La-Ce incorporation. The cost performance, (BH)(max)/cost, has been raised by 27.1% compared to a 48.9 MGOe La/Ce-free commercial magnet. The construction of chemical heterogeneity offers recipes to develop commercial-grade PMs using the less risky La/Ce, and also provides a promising solution to the REs availability constraints.

Structure and performance of La/Ce-rich multi-main-phase RE-Fe-B permanent magnets

[D].

富La/Ce多主相稀土永磁材料的结构和性能研究

[D].

The partitioning of La and Y in Nd-Fe-B magnets: A first-principles study

[J].

Whole process metallurgical behavior of the high-abundance rare-earth elements LRE (La, Ce and Y) and the magnetic performance of Nd0.75LRE0.25-Fe-B sintered magnets

[J].

Suppressing the CeFe2 phase formation and improving the coercivity and thermal stability of Ce-Fe-B alloys by Si substitution

[J].Low anisotropy field and low Curie temperature of Ce2Fe14B phase seriously restrict the application of Ce-Fe-B alloys. Most of the previous work suggest that REFe2 phase inevitably forms in the compositions with high Ce content. In this work, Si substitution for Fe is found to not only suppress the formation of CeFe2 phase, but also significantly improve the coercivity H-c and thermal stability of Ce17Fe78-xSixB6 (x = 0-3.0) alloys. All Si-doped alloys exhibit higher H-c and better thermal stability than Ce17Fe78B6 alloy. With increasing Si doping, a relatively high H-c = 525 kA/m is obtained in the Ce17Fe77.75Si0.25B6 alloy. An abnormal increase of H-c as well as almost unchanged J(r) and (BH)(max) is observed in Ce17Fe78-xSixB6 (x > 1.5) alloys. The refined XRD results indicate that the volume fraction of CeFe2 phase can be dramatically reduced via a moderate content of Si doping. Hard magnetic grains are isolated by forming a structure with thin and continuous intermediate layer, consequently preventing the domain wall propagation. The Curie temperature of the main phase monotonically increases from 424 K for x = 0-445 K for x = 3.0, resulting in improved thermal stability. The highest H-c of 530 kA/m, the lowest temperature coefficients (vertical bar beta vertical bar = 0.551%/degrees C and vertical bar alpha vertical bar = 0.368%/degrees C), and an acceptable J(r) = 0.44 T are obtained in Ce17Fe78-xSixB6 (x = 3.0) alloy. The nucleation and pinning are both responsible for the coercivity mechanism of Ce17Fe75Si3B6 alloy, which should be the reason for its high coercivity.

Improving the hard magnetic properties by intragrain pinning for Ta doped nanocrystalline Ce-Fe-B alloys

[J].To develop Ce based permanent magnets with high performance/cost ratio, Ta doping is was employed to enhance the magnetic performance of Ce-Fe-B alloys. For melt spun Ce17Fe78-xTaxB6 (x = 0-1) alloys, the coercivity Hc increases from 439 to 553 kA/m with increasing x value from 0 to 0.75. Microstructure characterizations indicate that Ta doping is helpful for grain refinement. A second phase of TaB2 is observed in Ce17Fe77.25Ta0.75B6 alloy, which acts as the pinning center of the magnetic domains, resulting in the change of coercivity mechanism from nucleation type to nucleation + pinning type. The micromagnetic simulation confirms that non-magnetic particles within hard magnetic phase can increase the demagnetization field around them and it is crucial for preventing the further magnetization reverse by pinning effect. Take the advantage of Ta doping for enhancing the coercivity, Ce content of Ce-Fe-B alloy can be further cut down to increase the remanence Jr due to the reduced volume fraction of CeFe2 phase and increased Fe/Ce ratio. As a result, a good combination of magnetic properties with Hc = 514 kA/m, Jr = 0.49 T, and the maximum energy product (BH)max = 36 kJ/m3 have been obtained in Ce15Fe79.25Ta0.75B6 alloy. It is expected that the present work can serve as a useful reference for designing new permanent magnetic materials with low-cost.

Variations of phase constitution and magnetic properties with Ce content in Ce-Fe-B permanent magnets

[J].

Study on magnetic properties of Ce17Fe78 - x Zr x B6 (x = 0-2.0) alloys

[J].

Crystal structure and magnetic properties of Ce2Fe14 - x Co x B alloys

[J].

Experimental and computational study on the phase formation and magnetic properties of Ce-La-Fe-B alloys

[J].

Enhanced formation of 2:14:1 phase in La-based rare earth-iron-boron permanent magnetic alloys by Nd substitution

[J].

A study on the role of Nb in melt-spun nanocrystalline Nd-Fe-B magnets

[J].

Magnetic properties of (misch metal, Nd)-Fe-B melt-spun magnets

[J].

Substitution of Nd with other rare earth elements in melt spun Nd2Fe14B magnets

[J].

Magnetic microstructures and corrosion behaviors of Nd-Fe-B-Ti-C alloy by Ga doping

[J].

Corrosion behavior of Nd9.4Pr0.6Febal.Co6B6Ga0.5Ti x C x (x = 0, 1.5, 3, 6) nanocomposites annealed melt-spun ribbons

[J].

Simultaneously improved corrosion resistance and magnetic properties of α-Fe/Nd2Fe14B type nanocomposite magnets by interfacial modification

[J].

Crucial role of the REFe2 intergranular phase on corrosion resistance of Nd-La-Ce-Fe-B sintered magnets

[J].

Corrosion resistance of Nd-Fe-B sintered magnets with intergranular addition of Cu60Zn40 powders

[J].

Effects of Cu nanopowders addition on magnetic properties and corrosion resistance of sintered Nd-Fe-B magnets

[J].

Mixed valency and site-preference chemistry for cerium and its compounds: A predictive density-functional theory study

[J].

Improvement of magnetic properties for Ti doped Ce-Fe-B alloys: Effectively inhibiting CeFe2 phase formation

[J].

Effects of REFe2 on microstructure and magnetic properties of Nd-Ce-Fe-B sintered magnets

[J].

Suppressing laves phase and overcoming magnetic properties tradeoff in nanostructured (Ce, La, Y)-Fe-B alloys via Ge substitution

[J].

Permanent magnetic properties of rapidly quenched Ce17Fe78 - x B6 Mx (M = Cu, Al, Ga; x = 0-1.0) alloys

[J].

Ce17Fe78 - x B6 Mx (M = Cu, Al, Ga; x=0~1.0)快淬合金永磁性能

[J].

Cu-mediated grain boundary engineering in Nd-Ce-Fe-B nanostructured permanent magnets

[J].

Enhancing the coercivity of Nd-Cu-diffused Nd-Fe-B permanent magnets by Nb-assisted grain boundary pinning

[J].

Striking effect of Hf addition on magnetic properties and thermal stability of Nd13Fe81 - x B6-Hf x (x = 0-1.0) alloys

[J].

Fabrication, microstructure and propertry regulation of nanocrystalline Ce-Fe-B based magnets

[D].

纳米晶Ce-Fe-B基磁体的制备、结构和性能调控

[D].

A novel strategy for the fabrication of high-performance nanostructured Ce-Fe-B magnetic materials via electron-beam exposure

[J].

Enhanced coercivity and grain boundary chemistry in diffusion-processed Ce13Fe79B8 ribbons

[J].

Coercivity enhancement of Ce-Fe-B sintered magnets by low-melting point intergranular additive

[J].

The fundamental properties of rapidly quenched Ce/La-Fe-B alloys and the preparation of Nd-Fe-B based permanent magnets

[D].

快淬铈/镧-铁-硼合金的基本特性及钕-铁-硼基永磁体的制备

[D].

Microstructure characterization and magnetic characteristics of Ce-Fe-B based spark plasma sintered magnets

[J].

Enhanced magnetic properties of spark plasma sintered (La/Ce)-Fe-B magnets

[J].

Preparation of hot worked dual-main phase Nd-Ce-Fe-B magnets and properties modification by grain boundary diffusion

[J].

Effects of Ce content on microstructure evolution and magnetic properties for hot deformed Ce-Fe-B magnets

[J].

Effects of Ga addition on the formability of main phase and microstructure of hot-deformed Ce-Fe-B magnets

[J].

Textured (Ce, La, Y)-Fe-B permanent magnets by hot deformation

[J].

Microstructure, magnetic anisotropy, plastic deformation, and magnetic properties: The role of Pr-Cu in hot deformed CeFeB magnets

[J].

Coercivity enhancement in Ce-Fe-B based magnets by core-shell grain structuring

[J].

Fabrication of anisotropic NdCeFeB hybrid magnets by hot-deformation: Microstructures and magnetic properties

[J].

Microstructure and magnetic properties of multi-main-phase Ce-Fe-B spark plasma sintered magnets by dual alloy method

[J].

Coercivity enhancement of hot-deformed (Ce, Nd, Pr)-Fe-B magnets by grain boundary diffusion of Pr-Cu alloy

[J].

Effect of Nb doping on microstructure and magnetic properties of hot-deformed Nd-Fe-B magnets with Nd-Cu eutectic diffusion

[J].To restrict grain growth in coarse grain regions caused by the diffusion of Nd-Cu eutectic alloys, the Nb element was introduced into the precursor alloy to regulate the microstructure of melt-spun powder and die-upset magnets. The magnetic properties and thermal stability of die-upset magnets were appreciably improved through the addition of Nb. For the Nb-doped diffusion die-upset magnet, the grains inside the ribbons were refined and the coarse non-oriented surface crystallite got suppressed on the interface of ribbons during the hot-deformation process to form the anisotropic magnet. Moreover, Nd gathers at the intergranular phases, which is considered to enforce domain wall pinning force. The Nb-modified microstructure is advantageous to thermal stability and coercivity enhancement. High-resolution transmission electron microscopy images revealed that the Nb element gathered on the grain boundary and triple grain boundary to form c-Nb and h-NbFeB to hinder the grain growth during the hot-deformation process, which led to direct enhancement in the coercivity. Furthermore, the c-Nb and h-NbFeB are nonmagnetic phases that strengthened the magnetic isolation. However, the h-NbFeB precipitated from the hard magnetic phase and formed crystal defects which led to remanence deterioration.

Production of anisotropic hot deformed Nd-Fe-B magnets with the addition of Pr-Cu-Al alloy based on nanocomposite ribbon

[J].

Recent progress in the development of high-performance bonded magnets using rare earth-Fe compounds

[J].

Microstructure and magnetic properties of MnBi alloys with high coercivity and significant anisotropy prepared by surfactant assisted ball milling

[J].MnBi alloys with high content of low temperature phase (LTP) MnBi and excellent magnetic properties were prepared by surfactant assistant ball milling (SABM), using annealed ribbons as precursors. Effects of the SABM processes on the phase constituent, microstructure, and magnetic properties were investigated in detail. It is found that the reduction of saturation magnetization is mainly attribute to the decomposition of LTP MnBi into Mn phase, Bi phase and MnO phase, with increasing the ball milling time. Meanwhile, due to the fine grain size and increased magnetic isolation effects between LTP MnBi grains, the coercivity increases monotonously with prolonging the ball milling time to 10 h for Mn55Bi45 powders. Through compression molding under the magnetic field, based on the SABM powders, the optimum anisotropic bonded magnet displays the maximum energy product (BH)(max) of 9.06 MGOe at room temperature, and a value of 7.05 MGOe at 380 K can be still achieved. In addition, the magnetic hardening mechanism of bonded magnets can be well explained by the strong pinning model. Strongly favorable magnetic properties make bonded MnBi magnets an attractive candidate material for small permanent magnets used for temperature applications up to 380 K.

Preparation and magnetic properties of anisotropic Nd2Fe14B/Sm2Co17 hybrid-bonded magnets

[J].

Preparation of anisotropic bonded NdFeB/SmFeN hybrid magnets by mixing two different size powders

[J].

Prediction method of flux loss in anisotropic NdFeB/SmFeN hybrid magnets

[J].

High-temperature magnetic properties of anisotropic MnBi/NdFeB hybrid bonded magnets

[J].

Development of bonded (La, Ce, Y)-Fe-B permanent magnets with higher performance/cost ratio than Nd-Fe-B and (Nd, La, Ce)-Fe-B magnets

[J].

Towards peculiar corrosion behavior of multi-main-phase Nd-Ce-Y-Fe-B permanent material with heterogeneous microstructure

[J].

Development of flexible rare earth-Fe-B rubber magnets toward efficient utilization of Ce, La, and Y elements

[J].