随着人工智能、大数据、云计算、物联网等新一代信息技术的快速发展,现代制造业正朝向智能化发展[1~5]。智能制造又可分为3种基本范式,即:数字化制造(第一代智能制造)、数字化网络化制造(“互联网+”制造或第二代智能制造)、数字化网络化智能化制造(新一代智能制造)[6]。数字化是智能制造的基础,其内涵贯穿于智能制造的3个基本范式[7]。随着信息技术的发展,数字化制造已经成为提升制造业生产效率和质量控制能力的重要途径,各国纷纷提出了相关的制造业发展战略。如德国在2013年提出工业4.0,旨在推动制造业向数字化和智能化转型。日本于2016年提出“社会5.0”概念,强调最大限度应用信息通讯技术(information and communication technology,ICT),实现网络空间与现实空间的融合。美国通用电气公司(General Electric Company,GE)于2012年提出“工业互联网”的概念,指出利用“智能设备”采集“智能数据”,利用“智能系统”进行数据挖掘和可视化呈现,形成“智能决策”,进而指导生产,优化制造工艺[8~11]。2017年我国国务院发布《关于深化“互联网+先进制造业”发展工业互联网的指导意见》,提出了制造业数字化转型的实现路径和方法论[12]。

3D打印,又称增材制造(additive manufacturing,AM),因其特殊的逐层沉积成形原理,能够快速、一体化成形具有复杂结构零部件的特点,被视为制造业领域的一项变革性技术[13~15]。自20世纪90年代诞生以来,3D打印技术得到了快速发展,并被广泛应用于航空航天、轨道交通、能源电力、电子信息、生物医学等领域[16~22]。金属3D打印,如激光粉末床熔融(laser powder bed fusion,L-PBF),是3D打印中一项重要技术,其成形金属零件具有晶粒细化、组织均匀、致密度高的特点,并具有生产周期短、原料利用率高、表面质量好、成形精度高等优势[23~25]。金属3D打印是一个多物理场耦合过程,涉及到高能束流与粉末和熔体的交互作用、能量的吸收与转化、热量/质量传输及熔体表面动量传输等复杂冶金过程。该过程工艺参数和边界条件的时变扰动强,涉及到粉末参数、激光参数等百余项变量,并且需要控制包括零件内、外部质量在内的几十种目标变量,是一个典型的具有多物理场强耦合作用、过程强时变扰动、内禀关系非线性以及多变量与多目标等特点的复杂过程。传统实验及物理建模难以解决3D打印全过程建模、综合优化和智能调控的问题,金属3D打印质量一致性与性能稳定性低成为金属增材制造智能化发展的重大瓶颈。

实现金属3D打印过程的数字化,有望解决3D打印全过程建模、综合优化与智能调控的问题,为实现增材制造的智能化控制提供了重要方法与手段。为总结3D打印数字化制造的相关进展,为未来研究提供参考,促进增材制造智能化的发展,本文从数字化制造角度综述了近年来金属3D打印技术的发展现状,首先分析了3D打印的技术特点和数字化制造的基本内涵,分3方面对金属3D打印数字化研究现状进行了分析和讨论,即3D打印过程数据的在线监测、过程仿真与可视化以及物理-信息系统的交互,并展望了金属3D打印数字化研究的应用前景,为推动3D打印智能化发展提供参考。

1 金属3D打印过程特征及研究现状

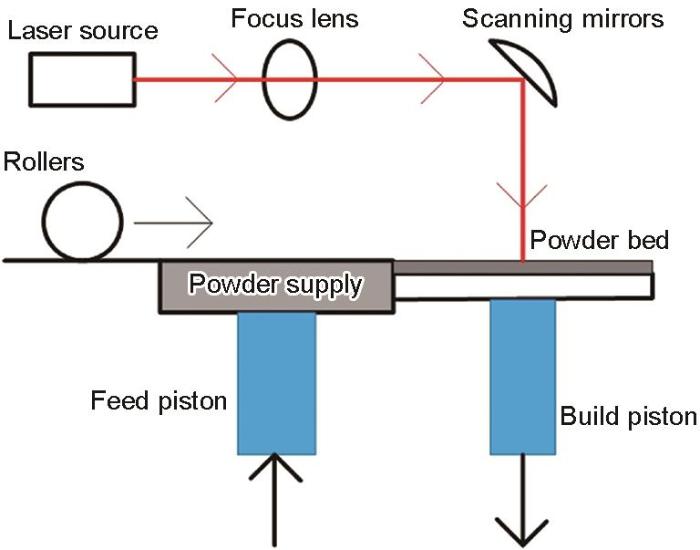

金属3D打印是以金属粉末、丝材等为原材料,通过逐层沉积进行构件成形的先进制造技术。与传统的金属减材工艺相比,增材制造能够一体化快速成形具有复杂结构的零部件,且成形周期更短,近年来成为金属材料加工领域的研究热点[26,27],已被广泛应用于航空、汽车、医疗等行业,特别是在高端复杂结构件的定制化制造上发挥了重要作用。目前粉末床熔融(powder bed fusion,PBF)和直接能量沉积(direct energy deposition,DED)是应用较为广泛的典型金属增材制造工艺。粉末床熔融利用高能束(如激光、电子束)照射粉末床(图1[13]),将金属粉末快速熔化并迅速冷却凝固,通过逐层熔化-沉积,形成致密的金属零件[28,29]。PBF过程冷却速率高、温度梯度大,伴随着急冷急热的热循环过程,可形成细小胞状晶/枝晶组织,具有比传统铸造更高的强度[30]。相较于传统铸造、锻造、机加工等工艺,PBF具有生产周期短、材料利用率高、适合小批量个性化定制以及力学性能优异等优点,目前已被广泛应用于航空航天、能源电力、医疗器械、轨道交通、模具等多个领域[31~33]。

图1

直接能量沉积是在传统激光熔覆与多层堆焊的基础上发展起来的一种金属增材制造技术。与PBF工艺不同,DED采用自动喷嘴(同轴或非同轴)送粉/送丝的方式将粉末/丝材通过保护气送至激光辐照产生的熔池中。在DED成形过程中,多轴机械手和高能量激光束热源在计算机控制下,根据用户定义的零件二维截面有选择地熔化粉末或丝材,形成熔池,并通过层层堆积的方式最终获得所需零件[34~36]。与PBF过程形成的微米级熔池不同,DED过程中形成的熔池可达到毫米级别[37]。此外,DED具有高度灵活性、使用范围广泛(可用于涂层制备、修复再制造、大型构件制造等)以及适用材料范围广泛(钛合金、钢铁、镍基高温合金和钴基高温合金等)等特点[38]。

金属3D打印技术因其能够快速成形具有复杂结构零件的特点,成为了制造业领域发展最快的技术之一。然而,目前金属3D打印也面临着诸多挑战。首先,金属3D打印过程中的材料基础问题有待进一步研究。金属3D打印,如激光粉末床熔融,是一个快速非平衡凝固过程,移动微熔池内部冶金行为、非稳态热循环下金属固态相变行为等难以直接观测,存在温度场、应力场、溶质场、应变场等多场耦合,成形构件内部特有的冶金缺陷与凝固组织基本特征及其形成机理尚未完全阐明,缺陷控制与组织、性能调控缺乏有效手段。其次,金属3D打印逐层沉积过程伴随着复杂的高能束流-粉末/丝材-熔体相互作用,影响过程稳定性的变量多,如高能束流参数、粉末/丝材参数、环境参数、扫描参数等,参数的时变扰动可导致铺粉不均匀、表面球化、翘曲等严重质量问题,甚至造成卡刀等事故,导致打印失败,降低成品率[39~42]。随着信息技术的快速发展,结合大数据、人工智能等技术,通过金属3D打印过程在线监控、数字仿真,实现打印过程数字化与智能化控制,是解决目前金属3D打印面临的质量一致性与性能稳定性差这一关键问题的有效手段,是未来金属3D打印发展的重要趋势之一。

2 数字化制造基本内涵

传统工业制造过程主要依赖人工操作和自动化机械设备,制造过程相对独立,灵活性及产品定制化能力较低。随着信息技术的快速发展,现代工业制造正朝向智能化发展。20世纪初,自动控制技术的发展推动了工业生产的自动化进程,传统机械设备被电气和电子设备取代,实现了部分生产过程的自动化,减少了人工干预,提高了生产效率,降低了劳动成本,提高了产品质量[43]。20世纪中期,计算机的广泛应用使生产过程中产生的大量数据得以被收集、存储、处理和分析,并实现了对生产过程的监控,为管理层提供了决策支持[44]。2010年代初,传感器、机器人、物联网等技术的引入,实现了将传统的模拟信号、物理信号和文档资料等转换为数字形式进行处理和管理,通过将生产过程中产生的数据进行数字化,实现了数据的高效存储、传输和分析,使各个设备和环节之间实现实时的数据交流和协作,进一步提升了生产效率和质量控制能力[45]。2010年代中期,人工智能和大数据分析技术的进步,为工业制造提供了更先进的数据管理与分析手段,可使设备具备自主优化和智能决策的能力,以适应环境和任务的随时变化,提高生产灵活性和智能化[46]。2020年代初,5G通信技术的商用推动了实时数据传输和协作能力的大幅提升,生产过程各工序以及各企业之间可通过云计算和边缘计算等技术实现更紧密的实时连接和协作[47]。工业制造实现网络化,可将生产资源有效整合在一起,实现更高的生产协同性、资源共享性和灵活性。

综合工业制造发展历史,自动化、信息化、智能化是工业制造不同阶段的重要概念和技术发展路径,共同推动着制造业的转型和升级。而数字化是智能制造的基础,数字化制造利用计算机网络、传感器、数据库、物联网和虚拟现实等技术,使各个生产环节数字化,并实时共享数据,实现对制造过程和产品质量等的实时监测、实时仿真与自动化控制,提高生产效率和产品质量。数字化制造主要包含以下内容。

(1) 数据在线获取。数字化制造的核心是将数据作为仿真建模的基础和决策的依据,通过在线收集、分析和利用数据,将制造过程中的各个环节(如产品设计、生产操作、管理等)转化为数字形式,并应用技术手段进行处理和分析,提高制造效率和产品质量。要实现这一目标,需要通过传感器、物联网和数据分析等技术,在线获取生产过程中的数据,包括原料物性、设备状态、工艺参数、产品质量等,并利用这些数据进行故障预测和工艺的实时优化,支持智能决策。

(2) 过程实时数字仿真。过程仿真是指通过大数据分析和机器学习算法,对生产数据进行挖掘和分析,建立能够映射生产过程和预测生产结果的动态数字模型,实现在虚拟环境中进行产品设计和工艺优化,以预测产品性能,减少实际制造中的试错成本。基于机器学习算法的数字模型可实现实时、自主决策,对偏离设定范围的生产状态进行在线修正,提高生产过程的稳定性和可靠性。

(3) 物理-信息系统交互。物理-信息系统交互是指利用自动化和机器人技术,实现生产过程的自动操作和智能决策。数字化制造强调基于数据和分析的决策制定,通过收集、整合和分析海量的生产数据,优化生产流程,提高资源和能源利用效率,实现数据驱动的智能决策,降低人为错误的风险。

数字化制造在各个领域都有着极大的应用潜力,可以应用于机械制造、电子制造、汽车制造、航空航天等领域,帮助企业实现智能化、自动化和定制化生产。可以应用于医疗设备的制造和个性化医疗产品的定制,如辅助3D打印工艺设计,降低制造假肢、矫形器具和牙齿矫正器等个性化产品的生产周期和成本。还可以应用于能源领域,帮助优化电网管理、太阳能和风能设备的制造,并支持智能家居和智慧城市的发展。

3 金属3D打印数字化制造研究现状

3D打印过程具有明显的数字化制造特点,其采用3D数字模型作为输入,并将数字模型转化为2D切片,通过控制高能束流(激光、电子束等)扫描路径,直接制造具有复杂结构的零部件。此外,在3D打印过程中,可以随时更改3D数字模型,快速适应模型变化,支持个性化定制。实现3D打印过程的数字化,首先需要在线获取打印过程的数据,主要依赖不同的在线监测系统(如铺粉过程、粉床温度等监测系统);其次,实现包括粉末熔化-凝固-相变微观过程以及构件成形宏观过程等的数字化模拟,能够将监测的数据实时传输到数字化模型中,实现物理过程的动态模拟;此外,通过在线监测系统获取的数据和数字模型逆向指导3D打印工艺优化和产品设计,同时保证数据流在各个部分的协同实时传输,实现物理-信息系统的交互。下文根据这3个方面对3D打印数字化研究现状进行综述,分析各要素目前存在的问题,并对未来发展方向提出建议。

3.1 数据在线监测

对于金属3D打印过程(主要指粉末床熔融技术),当前主要监测内容包括铺粉过程监测、粉末床温度场监测、成形过程缺陷监测等,主要使用到的传感器种类及其优缺点如表1所示。对于不同的监测对象,所采用的传感器种类也不同,根据信号类别,可分为声(声发射传感器)、光(高速X射线)、热(高温计)传感器等。

表1 金属3D打印过程在线监测常用传感器

Table 1

| Type | Object | Advantage | Disadvantage |

|---|---|---|---|

| Profilometer | Profiling of powder bed | Easy installation | High cost |

| Infrared camera | Thermal radiation of molten pool | Intuitive results with rich information retrieval | High resolution, high equipment cost |

| Pyrometer | Thermal radiation of molten pool | High accuracy and rapid response | High cost |

| High-speed camera | Molten pool morphology, thermal images, and geometric dimensions | Lower cost and extended measurement range | Optical filters required |

| Acoustic emission | Defects | High sensitivity, nondestructive monitoring, and low cost | Lower accuracy in high-noise conditions |

| Synchrotron X-ray | Dynamic behavior of molten pool | Real-time observation | High cost, complex equipment, limited commercial viability |

| Spectrometer | Spattering | Wide measurement range | High cost |

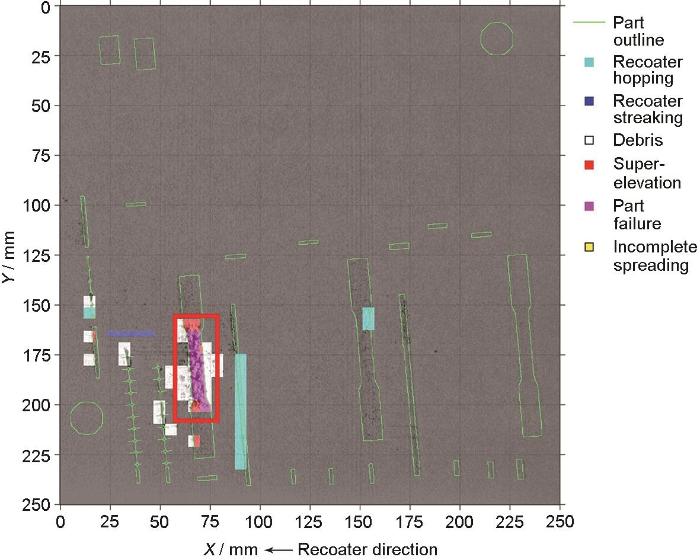

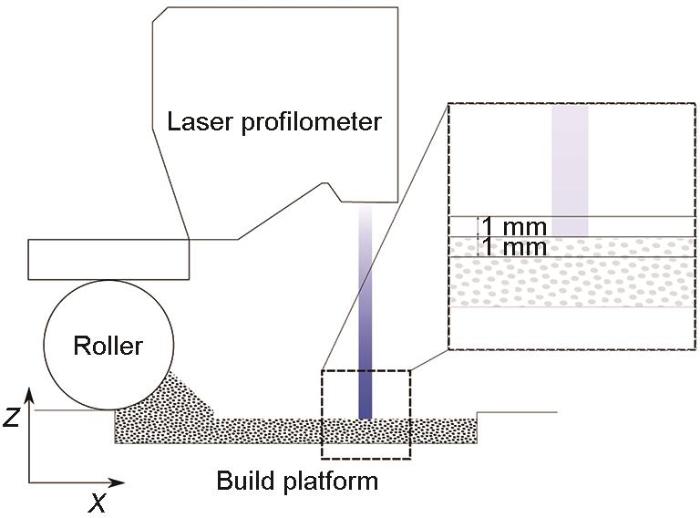

3.1.1 铺粉监测

图2

图3

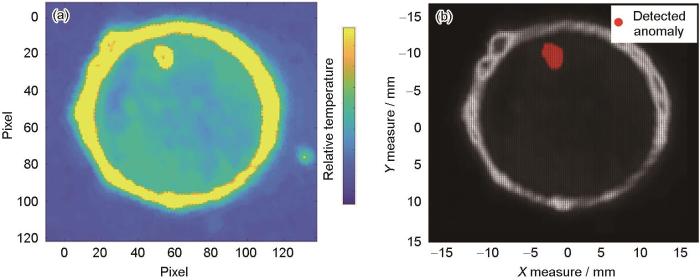

3.1.2 温度监测

图4

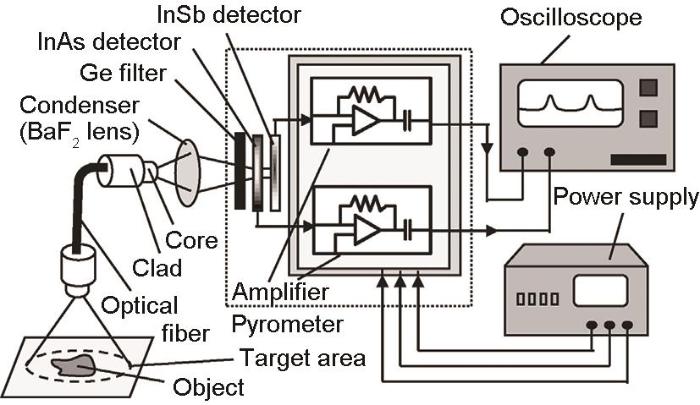

Furumoto等[51]使用比色测温仪测量了L-PBF成形过程激光与粉末作用区域表面辐射强度,如图5[51]所示。并采用已知熔点的Al2O3、不锈钢(1510℃)和SiC (2000℃)对辐射强度进行温度校正,获得校准曲线,通过该校准曲线可将辐射强度转化为温度数据,实现对激光作用区域温度的测量。此外,Furumoto等[51]还使用高速相机监测粉末床表面,直接观测粉末的熔化-凝固过程,结合温度测量发现,当输入能量密度为2.5和10.1 J/mm2时,L-PBF成形过程中激光和粉末床作用区域的温度分别为1520和1810℃。该工作将温度测量和金属粉末的熔化和凝固原位观察结合起来,证明了通过控制熔池温度调控凝固组织的可行性,但该方法测量温度区域较大,分辨率较低,难以获得熔池尺度的温度分布。

图5

Craeghs等[52]采用同轴安装的CMOS相机在线测量熔池几何尺寸和温度。通过CMOS相机可得到熔池的灰度值图片,通过对比实验观测到的熔池形貌,调控灰度阈值获得熔池几何尺寸。该方法能够有效实现对熔池几何尺寸的监测,但其对图像信号的处理时间较长,且采集到的图像信息会受到成形过程的干扰,有待进一步改进。

3.1.3 缺陷监测

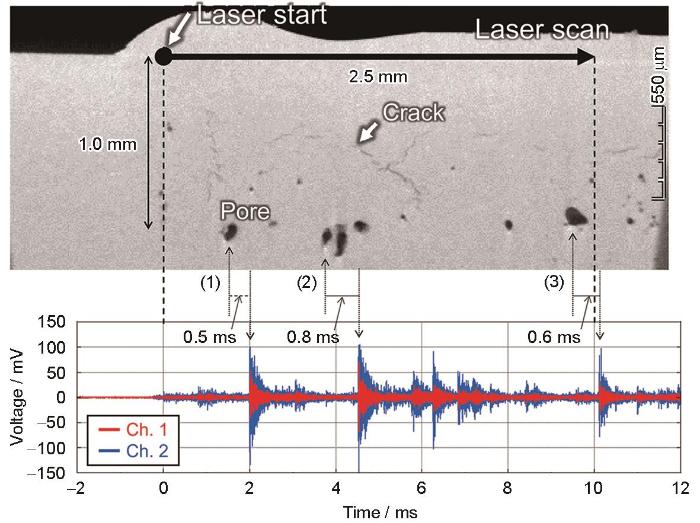

对成形件内部缺陷的直接监测可在3D打印过程中及时发现缺陷,为通过参数调整抑制缺陷创造条件,对构建增材制造缺陷监测与参数智能优化系统具有重要意义。传统成形样品中缺陷监测一般为离线检测,如激光成形后,将样品切开,采用光镜或电镜分析其内部缺陷,或者采用电子计算机断层扫描(CT)技术扫描内部缺陷,但通常CT扫描难以观测到微米级以下的气孔或裂纹,且检测周期较长、成本高。传统方法难以实现3D打印过程缺陷的实时、在线监测。Ito等[53]提出了一种基于声发射传感器(acoustic emission,AE)的增材制造缺陷在线监测系统。其原理为:从声发射源发出的弹性波传到材料的表面,使表面发生机械振动,AE传感器将该振动转化为电信号,通过收集和分析电信号,发现结构中的缺陷。Ito等[53]使用安装到基板上的AE传感器对单道次激光成形过程中的缺陷进行实时监测,结果如图6[53]所示。当采用高激光能量密度时,样品中出现了孔隙和微裂纹,同时AE传感器检测到了与这些孔隙和微裂纹相对应的波形振荡。根据定位,缺陷产生位置和AE波形振荡位置之间仅相差几毫秒,表明该装置具有较高的缺陷检测精度,为实现成形缺陷的在线监控提供了思路。

图6

图7

3.1.4 成分监测

金属3D打印通常采用高能束激光或电子束为热源,在扫描成形过程中,粉末受热熔化,熔池中心温度可达2000℃以上,低熔点元素如Al、Mg等挥发严重,导致成形件成分偏离设计,影响构件性能。因此实现3D打印过程中元素成分在线监测,对调控试样性能、提高成形构件质量稳定性具有重要意义。传统试样中元素分布监测一般采用离线检测的方式,如电感耦合等离子体(ICP)分析仪、能谱仪(EDS)等,但这些方法难以应用于3D打印过程中元素的在线监测,而光谱仪为实现成分在线监测提供了可行性。Song等[55]采用激光诱导等离子光谱仪(LIBS)测量了直接能量沉积过程中的光谱信号。研究发现熔池中的Al元素含量与谱线强度比呈线性关系,使用支持向量机回归(SVR)、偏最小二乘回归(PLSR)及人工神经网络(ANN)算法对Al含量进行了回归计算,并将拟合结果和EDS实际测量结果进行了对比。研究发现SVR算法对Al含量的拟合效果最好,和EDS测量结果之间误差仅为0.3%,能够实现对元素成分的在线监测。

3.1.5 组织监测

金属3D打印过程中,如激光粉末床熔融,移动熔池快速凝固,热流沿着成形方向,在超高温度梯度以及热循环作用下,晶粒沿熔池底部发生外延生长,形成沿成形方向的柱状晶,成形组织具有明显各向异性。对金属3D打印过程进行微观组织监测,有助于阐明移动熔池内局部晶粒形核与生长动力学特性以及熔池局部凝固组织演化规律,实现对凝固组织中晶粒尺寸、取向的有效调控,进而实现对零部件性能的有效调控。目前对金属3D打印过程中微观组织在线监测尚存在巨大挑战,当前的研究多通过实时监测成形过程中的熔池特征,来实现对微观组织的间接监测。如Farshidianfar等[56]确定了冷却速率是影响凝固微观组织的关键参数,利用红外摄像机监测熔池的温度分布,通过在同一位置的不同时间捕捉图像来计算熔池的冷却速率。在成形过程中通过比例-积分-微分 (proportion integration differentiation,PID)控制器调整激光的扫描速率,以控制熔池的冷却速率,通过该种方式获得了具有特定性质的微观组织,并在单道次和多道次的成形实验中验证了该系统的可靠性。Huang等[57]将Farshidianfar等[56]监测得到的温度数据和模拟得到的数据结合,引入了温度梯度G,结合G和冷却速率R预测了316L不锈钢和Inconel 625的微观组织。研究发现G / R和熔池的凝固模式相关,G × R控制微观组织的尺寸,较高的G × R会得到更细的亚结构,该结论在实际成形实验中得到了验证。

综上所述,目前文献中对金属3D打印成形过程监测的研究已有较多报道,包括对铺粉质量、粉末床与成形构件表面温度、熔池形貌、构件内部缺陷、成分的在线监测以及微观组织的预测调控均有研究,其中铺粉质量、粉末床温度和构件表面温度测量已较为成熟,且已安装在部分商业设备上。由于熔池尺寸较小(宽度约100 μm)、激光扫描速率快(约1 m/s),熔池内部温度场的测量需要极高分辨率(微米级)及高频的辐射信号探测设备,如高频红外摄像仪等,但通常需要大量的信号后处理工作(比如校正辐射强度与温度的关系),且设备成本大幅提高。此外激光与粉末相互作用会产生大量金属蒸气、等离子体以及颗粒飞溅等,干扰信号监测,影响熔池温度测量的准确性。由于熔池温度分布直接决定凝固组织及缺陷形成,因此有必要开发新的低成本、高分辨率、高准确性的熔池温度监测系统。此外,成形构件内部缺陷、成分及组织监测尚处于实验室测试阶段,其可行性及准确性仍有待进一步研究。

3.2 过程数字化仿真

金属3D打印是一个典型的多物理场耦合过程,包含温度场、应力场、溶质场、应变场等,此外工艺参数与边界条件具有时变扰动的特点,涉及到材料参数、高能束特征参数、成形工艺参数以及环境参数等百余项参数,上述参数决定了成形件的成分均匀性、组织均匀性以及尺寸与性能的稳定性,仅通过实验方法难以获得各参数对目标性能的影响规律。数值模拟(numerical simulation)是一种利用数学模型(传热、传质以及动量传输模型等)和数值计算方法(如有限差分、有限元等)来近似求解连续物理过程的方法。数值模拟仿真可以实现复杂物理过程的可视化,有助于阐明复杂的物理机制,如熔池在不同参数下的Marangoni流动、温度场与溶质分布等。目前常见的增材制造建模仿真模型如表2[58]所示。可以看出,通过数值模拟,可以实现增材制造过程热量、质量以及动量传输、凝固组织以及残余应力与变形等物理化学现象的可视化,具体包括L-PBF成形过程中粉末飞溅[59],熔池温度场和流场分布[60,61],增材制造快速凝固微观组织(局部温度梯度、组织凝固生长速率、熔池几何形状、晶粒外延形核、竞争生长等)[62~64],残余应力[65,66],以及缺陷[67]等。然而,数值模拟需要采用一定的方法(如有限差分法、有限元法等)求解复杂的物理方程,需要大量的计算和存储资源。在模拟构件尺寸较大或计算精度要求较高时,数值模拟需要进行大规模的计算,占用大量的计算机存储空间和计算时间(几小时甚至几天),难以实现增材制造过程的实时仿真。尽管有学者[68~70]研究了复杂物理过程的快速模拟,但通常采用简化计算过程,或者增大网格尺寸、忽略相关边界条件等,在提高运算速率的同时,牺牲了模拟的准确度,难以适用于增材制造的数字化仿真。

表2 金属增材制造常用数值模拟总结[58]

Table 2

| Purpose | Model | Feature | Application |

|---|---|---|---|

| Calculation of heat, mass, and momentum transfer | Part scale heat conduction model | Fourier heat conduction equation is solved either analytically in 1D or 2D or numerically in 3D | Temperature fields; fusion zone geometry; cooling rates |

| Part scale heat transfer and fluid flow | Solves 3D transient conservation equations of mass, momentum, and energy | Temperature and velocity fields; fusion zone geometry; cooling rates; solidification parameters; lack of fusion | |

| Part scale volume of fluid and level set methods | Tracks the free surface of the molten pool; computationally intensive; accumulates errors and the calculated deposit shape and size often do not agree well with experiments | 3D deposit geometry; temperature and velocity fields; cooling rates; solidification parameters | |

Powder-scale models | Involves free surface boundary conditions treating thermodynamics, surface tension, phase transitions, and wetting; small timescale and length scale, computationally intensive | Temperature and velocity fields; track geometry; lack of fusion; spatter; surface roughness | |

| Microstructure, nucleation, and grain growth prediction | TTT-based, CCT-based, and JMA-based models | Based on phase transformation kinetics during cooling; widely used for simulating phase transformations in steels and common alloys; high computational efficiency | Solid-state phase transformation kinetics |

| Monte Carlo method | A probabilistic approach of grain orientation change; provides grain size distribution with time; high computational efficiency | Grain growth; solidification structure; texture | |

| Cellular automata | Simulates growth of grain and subgrain structure during solidification; medium accuracy and computational efficiency | Solidification structure; grain growth; texture | |

Phase field model | Simulates microstructural features and properties by calculating an order parameter based on free energy that represents the state of the entire microstructure; computationally intensive | Nucleation; grain growth; evolution of phases; precipitate formation; solid-state phase transformation | |

Calculation of residual stresses and distortion | FEA-based thermomechanical models | Calculation of residual stresses and distortion FEA-based thermomechanical models solves 3D constitutive equations considering elastic, plastic, and thermal behavior; many software packages exist, and these are easy to implement and can handle intricate geometries; adaptive grid and inherent strain method are often used to increase calculation speed | Evolution of residual stress; strains; distortion; delamination; warping |

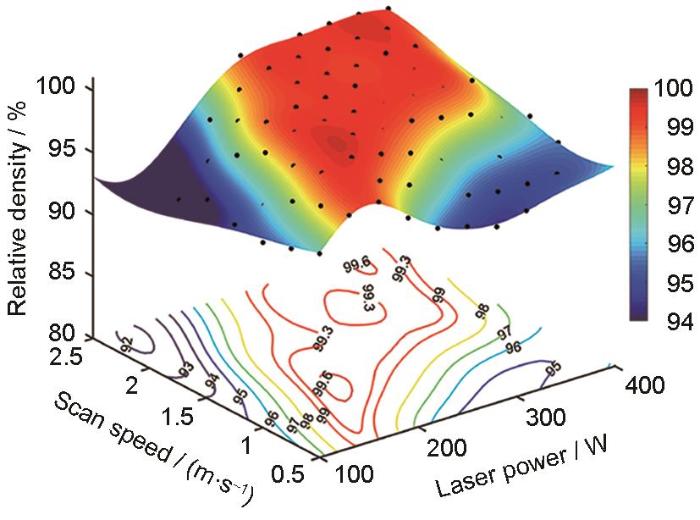

数字模拟(digital simulation)是一种使用数字信号和离散数据进行模拟和计算的过程。相对于数值模拟,数字模拟通过集成大量的实时数据和传感器信息,能够在实时或近实时的基础上监测和模拟物理实体(如3D打印过程)的状态和性能,并通过不断地更新和反馈实时数据,与实际成形过程保持同步,使得监测、分析和决策更加及时和动态,从而提供更精确的仿真结果。数字模拟对于具有复杂结构、多变量交互和非线性等特点的系统(如3D打印过程)尤为有效。通过对不同条件和场景的仿真分析,数字模型能够衡量不同决策和干预措施对打印过程的影响,帮助优化工艺参数、制定决策,实现智能化调控。机器学习是实现数字模拟的核心技术,机器学习通过从数据中学习规律,自动调整模型参数和拟合函数,实现对数据的分析和预测。此外,机器学习适用于高维数据的处理,可从大量参数中提取关键特征量,有助于处理复杂、非线性的映射关系。金属3D打印过程物理机制极为复杂,影响成形质量工艺变量多,包括高能束流参数(光斑、能量密度分布等)、成形工艺参数(功率、扫描速率、扫描间距等)、环境参数(O含量、气体流量等),以及材料参数(粉末流动性、松装密度、振实密度等)等。成形零件中常见的质量问题包括:翘曲、凸起、变形、球化、气孔、飞溅、裂纹等。3D打印是一个典型的多变量、多目标、具有非线性映射关系的复杂过程,采用传统实验试错方法难以快速、准确地建立过程参数与成形质量之间的关系,而采用基于机器学习的数字模拟,可以通过对成形过程中产生大量数据的分析,在不依赖成形过程内在物理机理的情况下,构建成形过程参数与目标特征量(如力学性能[71~73]和缺陷[54,74~76])之间的映射关系,实现对成形质量低成本、高效率的预测。目前已有部分相关报道,主要包括采用机器学习方法建立3D打印样品的缺陷和性能模型。

3.2.1 缺陷模型

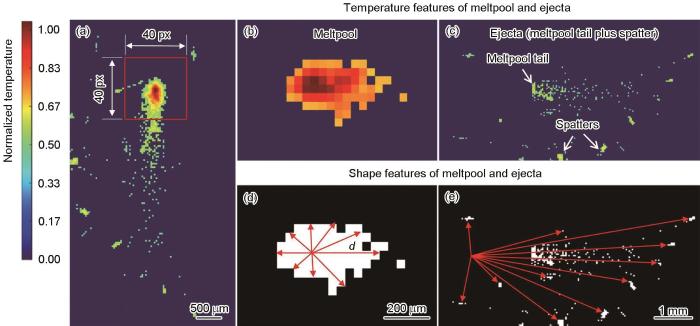

Smoqi等[77]使用旁轴安装的双波长高温计监测L-PBF成形过程中熔池的辐射数据,对采集的熔池辐射图像进行预处理,得到熔池的尺寸、温度分布和飞溅特征(如图8[77]所示),研究人员分别使用神经卷积网络(CNN)和K-近邻算法(KNN)、支持向量机(SVM)等模型对数据进行处理。其中CNN直接从图8a[77]中的原始图像中识别出缺陷的类型,而监督学习模型则使用图8b~e[77]中处理后的数据,将这些特征数据和样品孔隙建立映射关系,实现对成形样品孔隙率和孔隙类型的预测。经过对比,2种模型对孔隙率和孔隙类型的预测精度均超过了95%,而使用特征数据进行预测的监督学习算法更加简单,计算量和计算延迟都更低,更加适合于L-PBF成形过程的实时预测。

图8

图8

高温计监测L-PBF成形过程中熔池的辐射数据[77]

Fig.8

Original radiation data (a), images of the molten pool and spatters used for temperature feature extraction (b, c), and binarized images of the molten pool and spatters used for shape feature extraction (d, e)[77] (Red arrows refer to the Euclidean distances (d) measured from the center of the meltpool to edge pixels and ejecta pixels)

除孔隙外,裂纹也是3D打印过程中普遍存在的一种缺陷。Mondal等[78]采用机器学习建立了L-PBF成形铝合金的开裂模型。首先采用数值模拟计算了不同L-PBF成形参数下的温度场,进而根据前人提出的瞬态三维导热和流体流动模型[60],计算了不同成形参数和不同材料下的凝固应力、裂纹敏感性指数、温度梯度/凝固生长速率比以及冷却速率等,结合实验数据采用决策树、支持向量机和逻辑回归等方法建立增材制造过程裂纹预测模型。该研究建立了具有物理意义的机器学习模型,为L-PBF过程中裂纹等缺陷的实时预测提供了数字模型,但该工作中采用传统数值模拟方法建立温度场,从而为机器学习提供温度数值,难以用于缺陷的实时仿真。

图9

Dastjerdi等[80]采用遗传算法,结合传统有限元模拟,建立了激光扫描参数与打印零件翘曲变形的数字模型。首先基于实验数据,采用有限元模拟计算了不同工艺参数下的翘曲变形,之后使用反向传播神经网络(back-propagation neural network)建立了成形参数(扫描策略、扫描速率、激光功率、温度、层厚等)和翘曲变形之间的映射关系,输入参数和仿真结果对机器学习模型进行了训练和测试,最后使用遗传算法对目标函数进行了优化,获得了用于优化烧结层翘曲现象预测的机器学习模型,同时揭示了成形参数对烧结层翘曲现象的影响规律。该工作建立了增材制造过程参数与翘曲变形的数字模型,但采用有限元模拟获得不同参数下的变形量,难以应用于数字化制造过程。在实际增材制造过程中,可以采用在线监控方法监测零件变形量,通过数字模型和实时交互系统,对物理过程进行参数优化,从而降低变形量,提高产品合格率。

3.2.2 性能模型

Kusano等[71]使用多元线性回归方法建立了适用于L-PBF成形Ti6Al4V合金拉伸性能的预测模型。研究人员通过SEM图像处理,得到不同工艺条件下钛合金中α和β相晶粒的尺寸分布、晶粒纵横比等多个组织特征,并以此作为模型输入变量,将钛合金的屈服强度、极限抗拉强度、伸长率等作为目标变量,建立了晶粒尺寸与强度的定量关系,验证了Hall-Petch关系。同时该模型还量化了各微观组织结构特征对不同力学指标贡献的大小,提高了对增材制造金属材料变形机理的认识。Yu等[81]用多种机器学习算法建立了L-PBF成形碳纳米管强化铝基复合材料微观组织与硬度和致密度之间的关系。对不同L-PBF工艺参数下成形样品的性能进行了测试,并对样品进行了微观组织表征,对比了多种机器算法,最终发现决策树回归算法预测性能效果最好,硬度和相对密度的预测误差分别为3.61%和1.42%,表明机器学习模型具有较高的准确度。上述工作建立了组织结构与力学性能的数字模型,为实时仿真提供了模型,但上述工作均采用线下组织分析结果作为模型输入,难以满足数字化制造对实时性的要求。上述模型可作为数字化系统中预先建立的数字模型,通过在线监控获得组织信息后,可对零件性能进行预测,进而优化工艺参数,获得目标性能。

综上所述,金属3D打印过程数字化仿真的研究工作主要集中在线下采用机器学习建立工艺参数与缺陷和性能之间的数字模型,该数字模型是实现实时仿真的关键,但与数字化制造要求的实时仿真还存在较大差距,主要体现在机器学习模型算法仍需要进一步优化,以提高计算效率,满足实时性要求。通过算法优化后的数字模型,结合在线监控监测的数据,有望实现目标值的实时预测与实时调控。此外,目前数字模拟的目标主要为打印样品的缺陷和力学性能,对于3D打印过程的数字模拟,如熔池温度场和流场、激光与粉末相互作用,以及宏观/微观组织演化等复杂过程的模拟,还主要依赖传统的数值模拟方法,如有限元、有限差分法等,上述过程的数字模型仍有待开发。根据预先建立的数字模型,结合在线监控系统监测的过程时变扰动和边界参数,实现金属3D打印全流程的可视化,及时预测成形过程质量问题并实现参数智能调控,是实现3D打印数字化制造的关键环节,仍需要大量工作。

3.3 物理-信息系统交互

3.3.1 闭环控制系统

利用信息系统中的数字模型分析在线监测系统收集的数据,对3D打印物理过程进行在线调控,实现打印过程闭环控制,是金属3D打印数字化优势的主要体现。通过3D打印过程数字化模型实现工艺参数的快速优化和合金成分的逆向设计是金属3D打印的重要研究方向。Gan等[82]开发了一种结合物理模型、实验测量和数据挖掘的新型数据驱动方法,用于3D打印镍基高温合金微观组织和显微硬度的设计。研究团队利用计算热流体动力学(CtFD)模拟,获取熔池冷却速率、流场等关键参数,将模拟数据和实验数据输入自组织映射模型(SOM),建立了金属3D打印过程工艺-组织-性能的关系模型,实现了打印样品性能的预测与逆向设计。Silbernagel等[83]开发了一种结合深度卷积嵌入式聚类(DCEC)技术的机器学习方法,用于优化L-PBF成形工艺参数。研究人员对采集到的样品表面光学图像进行分析,通过无监督学习对图像数据进行聚类,实现对最优工艺参数的寻优。结果表明机器学习对样品表面质量获得的聚类和评分与实验结果相符。该研究通过建立表面质量与工艺参数的数字模型,实现了3D打印工艺参数的优化。

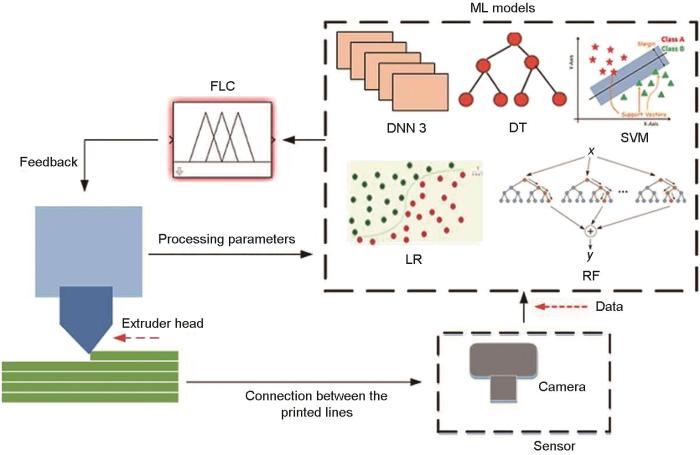

基于实时监测数据和数字化模型,建立闭环控制系统,对金属3D打印过程进行在线控制,是提高成形构件质量一致性和性能稳定性的重要方式,相关研究成为近年来3D打印的重要研究方向。Wang等[84]设计了一种实时高频(2 kHz)监测L-PBF成形过程中熔池热辐射的系统,结合PID控制及时调整成形过程中的激光功率,确保熔池尺寸的稳定性,进而保证成形质量一致性。研究人员对比了恒定功率打印和采用该系统打印的样品,发现经由控制系统调控后样品的尺寸误差明显低于恒定激光功率的情况,实现了对L-PBF样品成形质量的闭环控制。不同于Wang等[84]对单个参数(如功率)进行调控的研究,Tamir等[85]将机器学习模型和模糊逻辑控制系统结合,实现了对熔融沉积(FDM)成形过程的多参数闭环控制。研究人员采用机器学习建立了送料速率、层高、间距、打印速率和扫描线连接状态之间的映射关系,将其与模糊逻辑控制系统和在线监测系统结合,搭建了能够对多个参数进行在线调控的闭环控制系统(图10[85])。该研究的关键在于将实时监测数据与机器学习模型预测结果进行对比分析,通过模糊逻辑系统实现对打印过程参数的调整,从而实现整个打印过程中多个参数的自调节和优化。

图10

3.3.2 数据存储、传输与处理

金属3D打印过程在线采集的数据包括成形仓内环境(温度、O含量、压力等)、熔池信息(辐射强度、形貌)、铺粉质量、成形质量等。通过传感器将采集到的数据利用网络或者其他通信手段实时传输到信息系统,存储在云端或本地数据库中,如采用物联网(Internet of Things,IoT)技术,通过物理3D打印设备和在线监测传感器的互联,将3D打印设备、打印产品和工艺连接到云平台,实时监测和收集数据,并采用数据分析和大数据技术,通过对大规模数据的收集、处理和分析,可以发现打印过程中的趋势和异常,以实现远程工艺参数优化,提高生产效率。该过程中可产生海量数据,为了传输实时监控数据,需要采用高传输速率的网络连接,甚至采用专用的通信通道或者网络进行数据传输(5G、光纤通道协议等),以确保带宽满足实时监控的要求。虽然可以采用部署高速网络连接来提高通信效率,但仿真模型和机器学习模型计算需要一定时间,也使得数据传输存在延迟。当延迟发生时,信号分析(例如基于时域和频域的分析)可能无法实时地反映物理实体的当前状态,需要通过构建延迟域来对当前的延迟进行补偿,以此来降低延迟对实时控制的影响。

此外,对于海量数据存储,需要采用支持大规模数据存储并具有高可靠性和可扩展性的存储系统,如分布式文件系统(Hadoop Distributed File System)[86]、Google File System (GFS)[87]或对象存储(如Amazon S3、OpenStack Swift和Ceph)等[88~90]存储技术。此外,为了减小数据存储和传输的需求,可以采用数据压缩技术,例如使用压缩算法对数据进行压缩和解压缩。同时,针对增材制造实时监控中可能产生的冗余和噪声数据,可以使用数据滤波算法对数据进行处理,去除冗余和噪声,以减小存储和传输的数据量。对于关键的数据(如3D打印过程工艺参数和质量数据),还需要进行数据备份和灾难恢复策略的规划,如数据备份、冗余存储和分布式存储,以确保数据的安全性和可恢复性。

在信息系统接收到实时数据后,需要对数据进行处理和分析,基于预先建立的算法或模型,从数据中提取有用的信息,如3D打印过程产生的裂纹、形变等,对成形质量进行实时评估。根据评估结果,信息系统进一步迭代,更新数字模型,为后续目标变量的预测和优化提供基础。信息系统通过可视化界面可呈现不同工艺过程下的打印质量演变过程。通过虚拟和增强现实(virtual reality (VR)和augmented reality (AR))技术,在数字环境中模拟和可视化3D打印过程,进行设计评估和工艺优化。操作者通过可视化界面与物理系统进行交互,主动调整工艺参数或制定决策,实现物理-信息系统的交互,或者利用机器学习、深度学习和算法优化等技术,使3D打印系统能够自动学习、预测和优化生产过程,提高效率和质量。通过上述步骤,增材制造物理实体的实时数据和状态与信息系统实时交互,可以更好地监测增材制造过程,并实现增材制造过程故障诊断、预测分析、优化控制和决策制定。值得注意的是,上述海量数据实时传输与存储以及可视化系统存在价格昂贵的问题,如何降低软硬件成本,实现低成本、高效的物理-信息交互系统是未来需要突破的技术难题。

4 总结与展望

数字化制造为3D打印技术的智能化提供了有效途径,通过在线获取制造数据、建立数字仿真模型、实现物理-信息系统交互,有望实现对金属3D打印全过程的在线监测和智能控制,实现在虚拟环境中进行工艺试错和优化,即事先优化,显著缩短产品研发周期,降低制造成本,提高产品质量一致性及性能稳定性,推动3D打印技术的进一步发展和应用。

目前,3D打印的数字化技术尚处于研究初期,已有的研究主要集中在3D打印过程实时监控和数据在线获取系统的开发,包括声、光、热等多种类型的传感器已应用于3D打印过程的在线监测,能够较为准确地获取目标特征的实时信息,比如粉末床温度场、构件几何尺寸、铺粉质量等在线监测已经较为成熟。但是,对于关键数据的获取,比如熔池温度场的精确测量仍面临较大挑战,且成形构件的内部质量如裂纹、孔隙等的在线监测仍缺乏有效手段。

3D打印过程数值模拟取得一些进展,可实现从宏观构件到微观组织及缺陷的多尺度模拟,然而数值模拟通常需要长达几个小时甚至几天的时间,难以满足数字化制造对动态建模的要求。机器学习等数据分析、建模技术的发展,为实现3D打印过程实时仿真提供了新的途径。应用机器学习建立3D打印过程数字模型结合在线监控和数据采集,是实现3D打印全过程数字化的有效途径,是未来发展的重要方向。

建立3D打印过程物理-信息交互系统面临着较多的技术难题,需要重点突破在线监测系统、仿真模型、物理实体、反馈系统等各个部分间海量数据的实时互联,海量数据存储、数据低延迟传输、冗余与噪声处理、多种技术和系统(如计算机辅助设计(CAD)、计算机辅助制造(CAM)、IoT、人工智能(AI)等)的整合、数据备份与恢复等一系列难题。

此外,开展金属3D打印过程机理研究,阐明孔隙、裂纹、尺寸偏差等缺陷的形成机理和规律,是建立数字模型,实现智能控制的理论基础。虽然已有较多这方面的研究报道,但仍然很不充分,尤其需要研究方法和手段的创新。

参考文献

Intelligent manufacturing—Main direction of "made in China 2025"

[J].

智能制造——"中国制造2025"的主攻方向

[J].

Employment 5.0: The work of the future and the future of work

[J].

Human-cyber-physical systems (HCPSs) in the context of new-generation intelligent manufacturing

[J].

Outlook on human-centric manufacturing towards Industry 5.0

[J].

Smart manufacturing and intelligent manufacturing: A comparative review

[J].

Toward new-generation intelligent manufacturing

[J].

Brief analysis on three basic paradigms of intelligent manufacturing

[J].

智能制造的三个基本范式: 从数字化制造, “互联网+”制造到新一代智能制造

[J].

The smart factory as a key construct of industry 4.0: A systematic literature review

[J].

New IT driven service-oriented smart manufacturing: Framework and characteristics

[J].

Digital twin-driven product design, manufacturing and service with big data

[J].

Digital twin workshop: A new paradigm for future workshop

[J].

数字孪生车间——一种未来车间运行新模式

[J].

On thinking of constructing an industrial internet security protection system

[J].

构筑工业互联网安全防护体系 为推动先进制造业发展保驾护航

[J].

Laser powder bed fusion: A state-of-the-art review of the technology, materials, properties & defects, and numerical modelling

[J].

Additive manufacturing: Scientific and technological challenges, market uptake and opportunities

[J].

Additive manufacturing of metallic components—Process, structure and properties

[J].

Tailoring selective laser melting process for titanium drug-delivering implants with releasing micro-channels

[J].

Twinning induced plasticity in austenitic stainless steel 316L made by additive manufacturing

[J].

The present and future of additive manufacturing in the aerospace sector: A review of important aspects

[J].

The status, challenges, and future of additive manufacturing in engineering

[J].

3D printing of interdigitated Li-ion microbattery architectures

[J].

Additive manufacturing: Technology, applications and research needs

[J].

Biomedical production of implants by additive electro-chemical and physical processes

[J].

Recent progress and scientific challenges in multi-material additive manufacturing via laser-based powder bed fusion

[J].

Chapter seven—Additive manufacturing of biomaterials

[J].

Laser additive manufacturing on metal matrix composites: A review

[J].Important progresses in the study of laser additive manufacturing on metal matrix composites (MMCs) have been made. Recent efforts and advances in additive manufacturing on 5 types of MMCs are presented and reviewed. The main focus is on the material design, the combination of reinforcement and the metal matrix, the synthesis principle during the manufacturing process, and the resulted microstructures as well as properties. Thereafter, the trend of development in future is forecasted, including: Formation mechanism and reinforcement principle of strengthening phase; Material and process design to actively achieve expected performance; Innovative structure design based on the special properties of laser AM MMCs; Simulation, monitoring and optimization in the process of laser AM MMCs.

Additive manufacturing of metal-based functionally graded materials: Overview, recent advancements and challenges

[J].

Reactive metal additive manufacturing: Surface near ZrN-metallic glass composite formation and mechanical properties

[J].

Microstructure and mechanical properties of Cu-11Al-5Ni-4Fe wt% manufactured by LPBF

[J].Cu-11Al-5Ni-4Fe wt% alloy is processed by additive manufacturing using the laser powder bed fusion (LPBF) technique in two building orientations (90° and 0° to the building platform) to determine which laser parameters are more critical to obtain better mechanical properties. The resulting printed material is characterized microstructurally and mechanically by XRD, optical microscope, and under compressive stress. The results indicate that the alloy achieved good densification and mechanical properties similar to an as-cast counterpart. The as-built microstructure comprises acicular martensite and other thermodynamic equilibrium phases, while exothermic and endothermic curves show a poor response to temperature induce phase transformation at ~350 °C. The mechanical results show that it is possible to reach a compressive strength of 1300 MPa, up to 20% strain, and better mechanical properties in those samples fabricated in a vertical direction (90°) than the horizontal. The volumetric energy density also affects the samples’ maximum strength and superficial roughness.

Influence of TiB2 volume fraction on SiCp/AlSi10Mg composites by LPBF: Microstructure, mechanical, and physical properties

[J].

Effect of solution heat treatment on microstructure, mechanical and electrochemical properties of hastelloy X fabricated by laser powder bed fusion

[J].

Spall damage in laser-powder-bed-fusion manufactured Ti-6Al-4V: Mechanisms and microstructure effects

[J].

Outstanding strength-ductility synergy in Inconel 718 superalloy via laser powder bed fusion and thermomechanical treatment

[J].

Laser powder bed fusion of dissimilar metal materials: A review

[J].The laser powder bed fusion (LPBF) technique is used to manufacture complex and customised components by exploiting the unique advantages of two types of metal materials to meet specific performance requirements. A comprehensive overview of LPBF-processed dissimilar metal materials, a combination of different single metals or alloys, is developed. The microstructure in the fusion zone and the corresponding mechanical properties of LPBF-processed dissimilar metal materials are summarised. The influence of processing factors on the mechanism of defect formation, wetting properties and element diffusion behaviour at the interface between different materials and their typical cases are scientifically investigated in detail. Particular attention is paid to energy input, Marangoni convection and interfacial bonding behaviour. The underlying science of the metallurgical structure and properties of the LPBF-processed dissimilar metal materials is revealed. The build quality and efficiency could be further improved by designing machine structures and predicting the process–property relationship. This review provides a significant guide for expanding the industrial application of LPBF-processed dissimilar metal materials.

Effect of powder recycling on the organization and mechanical properties of GH4169 alloy by laser metal deposition

[J].The purpose of this research is to prepare GH4 169 alloy specimens by laser metal deposition, by investigating the changes in powder morphology, powder particle size, and elemental content during the cycling process. As well as the pore defects and microstructure of deposited samples prepared from recycled powder, we analyzed the changes in powder properties during the cycling process and the effects of using recycled powder on the organization and properties of LMD-deposited specimens. It was shown that the average particle size of the powder increased with the increase in the size of powder recycling, from 59.861 µm in the original powder to 64.144 µm after four cycles, with the phenomenon of powder burnout and satellite ball. The elemental content of the powder changed with the increase in the number of cycles, among which the elemental content of Nb increased significantly from 4.31 wt% of the original powder to 7.97 wt% after four cycles, the proportion of Laves phase in the deposited samples increased, the porosity and pore size increased, the tensile strength of the specimen decreased from 1046 MPa of the original powder to 936 MPa, the tensile strength decreased by 10.5%, and the elongation was increased to 27% from 11% of the original powder. Powder recycling can lead to powder aging and reduce the mechanical properties of the laser metal deposited formed parts.

Optimization of microstructure and properties in U75V steel rail cladding layers manufactured by laser melting deposition and laser shock peening

[J].

Microstructure evolution and wear resistance of the eutectic high-entropy alloy Al0.3CoCrFeNiNb0.5 produced by laser metal deposition

[J].Eutectic high-entropy alloys (EHEAs) are characterized by a fine lamellar microstructure. This allows for homogeneous functional surface properties. Furthermore, the risk of coarse precipitate formation during coating processes from the liquid state is avoided. However, the influence of the size and the texture of the local microstructure domain on functional properties is still unknown. The present work is devoted to the microstructural evolution of the EHEA Al0.3CoCrFeNiNb0.5. Inert gas atomized powder was processed by laser metal deposition (LMD) and spark plasma sintering (SPS). Both specimens were heat treated near their liquidus temperatures. The different production routes have a decisive influence on the orientation of the lamellar structure. The SPS bulk material has a statistically distributed orientation of the lamellae defined by the microstructure of the powder. However, the remelting of the powder during the LMD process causes a directional vertical solidification of the lamellar structure. Based on these differences, positive effects on their functional properties were detected for directionally solidified LMD coatings. As a result of the heat treatment, the influence of the lamellar orientation on their tribological properties is reduced, whereas the influence of the lamellar size on their property profile can be derived.

An overview of the process mechanisms in the laser powder directed energy deposition

[J].Laser Powder Directed Energy Deposition (LP-DED) is a very powerful Additive Manufacturing process for different applications, such as repair operations and the production of functionally graded material. However, the application is still limited, and one of the main reasons is related to the lack of knowledge of the process mechanisms. Since the mechanisms involved in the process, which are mutually related to each other, directly influence the properties of the produced part, their knowledge is crucial. This paper presents a review of the LP-DED mechanisms and the relationship between the input process parameters and related outcomes. The main mechanisms of the LP-DED process, which are identified as (i) laser irradiation and material addition, (ii) melt pool generation, and (iii) subsequent solidification, are discussed in terms of input parameters, with a focus on their effects on the deposition effectiveness, and interrelation among the mechanisms of the deposition process. The results highlight the complexity of the mechanisms involved in the LP-DED process and guide engineers in navigating the challenges of the deposition process, with a specific focus on the critical parameters that should be investigated when new materials are developed, or process optimization is carried out.

Latest developments to manufacture metal matrix composites and functionally graded materials through AM: A state-of-the-art review

[J].Multi-material structure fabrication has the potential to address some critical challenges in today’s industrial paradigm. While conventional manufacturing processes cannot deliver multi-material structures in a single operation, additive manufacturing (AM) has come up as an appealing alternative. In particular, laser-directed energy deposition (L-DED) is preferred for multi-material AM. The most relevant applications envisioned for multi-material L-DED are alloy design, metal matrix composites (MMC), and functionally graded materials (FGM). Nonetheless, there are still some issues that need to be faced before multi-material L-DED is ready for industrial use. Driven by this need, in this literature review, the suitability of L-DED for multi-material component fabrication is first demonstrated. Then, the main defects associated with multi-material L-DED and current opportunities and challenges in the field are reported. In view of the industrial relevance of high-performance coatings as tools to mitigate wear, emphasis is placed on the development of MMCs and FGMs. The identified challenges include—but are not limited to—tightly controlling the composition of the multi-material powder mixture injected into the melt pool; understanding the influence of the thermal history of the process on microstructural aspects, including the interactions between constituents; and studying the in-service behaviours of MMCs and FGMs with regard to their durability and failure modes.

Additive manufacturing methods and modelling approaches: A critical review

[J].

A review of model inaccuracy and parameter uncertainty in laser powder bed fusion models and simulations

[J].

A review of machine learning applications in additive manufacturing

[A].

Types of spatter and their features and formation mechanisms in laser powder bed fusion additive manufacturing process

[J].

Industry 4.0: A review on industrial automation and robotic

[J].

The readiness of ERP systems for the factory of the future

[J].

IOT and industry 4.0: the industrial new revolution

[A].

Big data and AI for process innovation in the Industry 4.0 era

[J].The fourth industrial revolution or what can be referred to as Industry 4 [...]

Smart manufacturing and tactile internet based on 5G in Industry 4.0: Challenges, applications and new trends

[J].For many applications deployed in manufacturing networks, communication latency has been a significant barrier. Despite the constant development of improved communication protocols and standards during Industry 4.0, the latency problem persists, lowering quality of services (QoS) and quality of experience (QoE). Tactile internet (TI), with its high availability, security, and ultra-low latency, will add a new dimension to human-machine interaction (HMI) by enabling haptic and tactile sensations. The tactile internet (TI) is a cutting-edge technology that uses 5G and beyond (B5G) communications to enable real-time interaction of haptic data over the internet between tactile ends. This emerging TI technology is regarded as the next evolutionary step for the Internet of Things (IoT) and is expected to bring about massive changes towards Society 5.0 and to address complex issues in current society. To that end, the 5G mobile communication systems will support the TI at the wireless edge. As a result, TI can be used as a backbone for delay mitigation in conjunction with 5G networks, allowing for ultra-reliable low latency applications like Smart Manufacturing, virtual reality, and augmented reality. Consequently, the purpose of this paper is to present the current state of 5G and TI, as well as the challenges and future trends for 5G networks beyond 2021, as well as a conceptual framework for integrating 5G and TI into existing industrial case studies, with a focus on the design aspects and layers of TI, such as the master, network, and slave layers. Finally, the key publications focused on the key enabling technologies of TI are summarized and the beyond 5G era towards Society 5.0 based on cyber-physical systems is discussed.

Anomaly detection and classification in a laser powder bed additive manufacturing process using a trained computer vision algorithm

[J].

In-situ monitoring of powder bed fusion of polymers using laser profilometry

[J].

In situ defect detection in selective laser melting via full-field infrared thermography

[J].

Investigation of laser consolidation process for metal powder by two-color pyrometer and high-speed video camera

[J].

Feedback control of layerwise laser melting using optical sensors

[J].

Detection and location of microdefects during selective laser melting by wireless acoustic emission measurement

[J].

Machine learning-aided real-time detection of keyhole pore generation in laser powder bed fusion

[J].Porosity defects are currently a major factor that hinders the widespread adoption of laser-based metal additive manufacturing technologies. One common porosity occurs when an unstable vapor depression zone (keyhole) forms because of excess laser energy input. With simultaneous high-speed synchrotron x-ray imaging and thermal imaging, coupled with multiphysics simulations, we discovered two types of keyhole oscillation in laser powder bed fusion of Ti-6Al-4V. Amplifying this understanding with machine learning, we developed an approach for detecting the stochastic keyhole porosity generation events with submillisecond temporal resolution and near-perfect prediction rate. The highly accurate data labeling enabled by operando x-ray imaging allowed us to demonstrate a facile and practical way to adopt our approach in commercial systems.

Real-time composition monitoring using support vector regression of laser-induced plasma for laser additive manufacturing

[J].

Real-time control of microstructure in laser additive manufacturing

[J].

Rapid prediction of real-time thermal characteristics, solidification parameters and microstructure in laser directed energy deposition (powder-fed additive manufacturing)

[J].

Metallurgy, mechanistic models and machine learning in metal printing

[J].

Experimental and computational study on thermal and fluid behaviours of powder layer during selective laser melting additive manufacturing

[J].

Heat and fluid flow in additive manufacturing—Part I: Modeling of powder bed fusion

[J].

Heat and fluid flow in additive manufacturing—Part II: Powder bed fusion of stainless steel, and titanium, nickel and aluminum base alloys

[J].

Three-dimensional modeling of grain structure evolution during welding of an aluminum alloy

[J].

Numerical methods for microstructural evolutions in laser additive manufacturing

[J].

Numerical investigation of effects of nucleation mechanisms on grain structure in metal additive manufacturing

[J].

Printability of 316 stainless steel

[J].A printability database can help in the selection of a printing process-alloy combination to reduce, and in some cases avoid, common defects in printed parts. The extensive testing of parts is not a viable option for determining printability because printing processes are inherently slow and expensive. Here we evaluate printability of stainless steel 316 by evaluating its susceptibilities to residual stresses, distortion, composition change and lack of fusion defects for laser (DED-L) and arc (DED-GMA) based directed energy deposition and laser powder bed fusion (PBF-L) processes using well-tested mechanistic models. Among these three processes, DED-GMA makes printed parts of 316 stainless steels most susceptible to residual stresses and distortion. High depth of penetration during DED-GMA makes components least susceptible to lack of fusion defects. Loss of volatile alloying elements from the tiny pools in PBF-L makes deposits the most vulnerable to composition change.

Coupled thermo-mechanical process simulation method for selective laser melting considering phase transformation steels

[J].

Phase-field simulation of lack-of-fusion defect and grain growth during laser powder bed fusion of Inconel 718

[J].

A semi-analytical thermal modelling approach for selective laser melting

[J].

A computationally efficient thermo-mechanical model for wire arc additive manufacturing

[J].

A computationally efficient thermal model for selective laser melting

[J].

Tensile properties prediction by multiple linear regression analysis for selective laser melted and post heat-treated Ti-6Al-4V with microstructural quantification

[J].

Prediction of selective laser melting part quality using hybrid Bayesian network

[J].

Deep learning-based tensile strength prediction in fused deposition modeling

[J].

Predicting mechanical properties from co-axial melt pool monitoring signals in laser powder bed fusion

[J].

Predicting defects in laser powder bed fusion using in-situ thermal imaging data and machine learning

[J].

Machine learning-enabled prediction of density and defects in additively manufactured Inconel 718 alloy

[J].

Monitoring and prediction of porosity in laser powder bed fusion using physics-informed meltpool signatures and machine learning

[J].

Crack free metal printing using physics informed machine learning

[J].

Machine-learning assisted laser powder bed fusion process optimization for AlSi10Mg: New microstructure description indices and fracture mechanisms

[J].

Optimization of process parameters for reducing warpage in selected laser sintering of polymer parts

[J].

Machine-learning-assisted microstructure-property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

[J].In this study, the cellular microstructural features in a subgrain size of carbon nanotube (CNT)-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion (LPBF) (a size range between 0.5–1 μm) were quantitatively extracted and calculated from scanning electron microscopy images by applying a cell segmentation method and various image analysis techniques. Over 80 geometric features for each cellular cell were extracted and statistically analyzed using machine learning techniques to explore the structure–property linkages of carbon nanotube reinforced AlSi10Mg nanocomposites. Predictive models for hardness and relative mass density were established using these subgrain cellular microstructural features. Data dimension reduction using principal component analysis was conducted to reduce the feature number to 3. The results showed that even AlSi10Mg nanocomposite specimens produced using different laser parameters exhibited similar Al–Si eutectic microstructures, displaying a large difference in their mechanical properties including hardness and relative mass density due to cellular structure variance. For hardness prediction, the Extra Tress regression models showed a relative error of 2.47% for prediction accuracies. For the relative mass density prediction, the Decision Tress regression models showed a relative error of 1.42% for prediction accuracies. The results demonstrate that the developed models deliver satisfactory performance for hardness and relative mass density prediction of AlSi10Mg nanocomposites. The framework established in this study can be applied to the LPBF process optimization and mechanical properties manipulation of AlSi10Mg-based alloys and other additive manufacturing newly designed alloys or composites.

Data-driven microstructure and microhardness design in additive manufacturing using a self-organizing map

[J].

Using machine learning to aid in the parameter optimisation process for metal-based additive manufacturing

[J].Metal-based additive manufacturing is a relatively new technology used to fabricate metal objects within an entirely digital workflow. However, only a small number of different metals are proven for this process. This is partly due to the need to find a new set of parameters which can be used to successfully build an object for every new alloy investigated. There are dozens of variables which contribute to a successful set of parameters and process parameter optimisation is currently a manual process which relies on human judgement.

Real-time process monitoring and closed-loop control on laser power via a customized laser powder bed fusion platform

[J].

Machine-learning-based monitoring and optimization of processing parameters in 3D printing

[J].

Small files problem resolution via hierarchical clustering algorithm

[J].

An improved technique for increasing availability in big data replication

[J].

Connecting workflow-oriented science gateways to multi-cloud systems

[A].

The Implementation of supporting uniform data distribution with software-dened storage service on heterogeneous cloud storage

[A].

Is cloud storage ready? A comprehensive study of IP-based storage systems

[A].