镍基高温合金具有优良的室温和高温力学性能、良好的抗氧化腐蚀性能和组织稳定性等诸多优点,广泛应用于制造航空航天发动机及地面燃气轮机的涡轮叶片等关键热端部件[1~5]。研究[6~10]表明,镍基高温合金优异的高温力学性能主要得益于其独特的共格组织,即方形或球形的L12-γ′有序相(cP4-Cu3Au结构)纳米粒子在fcc-γ固溶体基体上共格析出。此外,为获得优异的综合性能,镍基高温合金的合金化元素多达十几种,这些合金元素通常分为3类,分别为与基体Ni相似的类Ni元素(

复杂的合金成分和高温服役条件容易导致合金中一些其他相的析出。例如,当添加过量的Mo、W、Ta、Nb和Re等难熔元素时,会使得高温合金在服役过程中产生γ /γ′共格组织失稳,并析出脆性拓扑密排(TCP)相,如σ-Cr46Fe54相(D8b结构)、μ-(Ni, Co)7(W, Mo)6相(D85结构)和η-Ni3Ti相(D024结构)等,导致其高温蠕变性能恶化[24~27]。因此,当多组元共同合金化时,需要对各元素含量进行精确调控,目前已经发展出多种指导成分设计的方法,如PHACOMP[28,29] (基于电子空位理论的相计算方法)、New PHACOMP[30,31] (基于d-电子理论的计算方法)和ADP[32,33] (基于微观组织和性能数据库的数学回归模型开发的合金设计软件)等。在本课题组早期的研究[34,35]中,利用团簇式成分设计方法探索了镍基高温合金的成分规律,得出了镍基高温合金理想团簇成分式[

1 实验方法

实验用金属Ni、Al、Cr和Ti的纯度为99.99%,Mo、Ta、Nb和W的纯度为99.95%。系列合金的成分,包括团簇成分式和质量分数列于表1。在高纯Ar气保护下通过非自耗真空电弧炉熔炼制备母合金铸锭(每个约30 g),每个合金铸锭至少反复熔炼5次以确保成分的均匀性,整个制备过程质量损失不超过0.1%。进而将合金样品真空封装在石英硅管中,在1300℃固溶15 h,然后在900℃下分别进行50、100、200和500 h的时效处理,每步热处理后均进行水淬冷却。

表1 系列合金的团簇式和成分,900℃、500 h时效后γ′粒子尺寸(r)、γ′体积分数(f)和合金显微硬度(H),及900℃、50 h时效后γ和γ′的点阵常数(aγ 、aγ′)、γ/γ′点阵错配度(δ)

Table 1

| Alloy | Cluster formula | Composition mass fraction, % | r nm | f % | H HV | aγ, aγ' nm | δ % |

|---|---|---|---|---|---|---|---|

| S1-CM | [Al-(Ni12)]- (Al1(Ti, Nb, Ta)0.5(Cr1.0Mo0.5)) | Ni77.23Al5.92Ta3.31Ti0.88Nb1.70- Cr5.70Mo5.26 | 329 ± 46 | 73.9 ± 3.5 | 356 ± 5 | aγ = 0.3605 ± 0.0002 aγ' = 0.3596 ± 0.0003 | -0.25 ± 0.06 |

| S2-CW | [Al-(Ni12)]- (Al1(Ti, Nb, Ta)0.5(Cr1.0W0.5)) | Ni73.68Al5.65Ta3.16Ti0.83Nb1.62- Cr5.44W9.62 | 323 ± 52 | 74.7 ± 3.9 | 374 ± 7 | aγ = 0.3603 ± 0.0002 aγ' = 0.3591 ± 0.0002 | -0.33 ± 0.05 |

| S3-CMW | [Al-(Ni12)]- (Al1(Ti, Nb, Ta)0.5(Cr0.7Mo0.4W0.4)) | Ni73.35Al5.62Ta3.14Ti0.83Nb1.61- Cr3.79Mo4.00W7.66 | 288 ± 54 | 76.1 ± 3.7 | 397 ± 7 | aγ = 0.3623 ± 0.0004 aγ' = 0.3606 ± 0.0003 | -0.47 ± 0.07 |

采用D8 Focus X射线衍射仪(XRD,CuKα,波长λ = 0.15406 nm)分析合金的相结构,并利用Origin软件中的pseudo-Voigt函数对(200)衍射峰进行分峰拟合,以计算γ /γ′两共格相的点阵常数和错配度。利用BX51光学显微镜(OM)和Supra 55扫描电子显微镜(SEM)观察合金的微观组织,金相化学腐蚀液成分为5 g FeCl3·6H2O + 25 mL HCl + 25 mL C2H5OH,采用的电解腐蚀液为42 mL H3PO4 + 34 mL H2SO4 + 24 mL H2O,电压5 V、腐蚀时间5~7 s,并采用Image ProPlus图像分析软件统计分析γ′析出相的粒子尺寸和体积分数(f),其中,γ′粒子尺寸采用等效球形粒子半径(r)表示,计算采用等面积法,即r =

2 实验结果

2.1 热力学计算

图1给出了利用Pandat软件计算的系列合金组成相随温度的演化情况。可以看出,添加Cr1.0Mo0.5的S1-CM合金的熔点约为1366℃,且凝固初期只有fcc-γ相;当温度降低到1296℃左右时,有序的L12-γ′相开始从fcc-γ基体中析出,且在此温度以下,γ′相可以和基体γ以共格的关系稳定存在;当温度低于594℃时,出现了摩尔分数小于0.7%的富Cr、Mo的P-Cr18Mo42Ni40相。当用W元素替换Mo元素添加Cr1.0W0.5元素时,S2-CW合金的熔点温度提高至1389℃,γ′相的回溶温度为1301℃,且当温度低于510℃时,出现了摩尔分数小于2%的富Cr的Ni2Cr相。而当添加近等摩尔比例的Cr0.7Mo0.4W0.4时,S3-CMW合金的熔点温度为1381℃,γ′相的回溶温度为1313℃,且当温度低于637℃时,出现了摩尔分数小于0.6%的P相;温度介于542~571℃时,析出了摩尔分数小于0.3%的富Cr、Mo、W的μ-(Ni, Cr)7(Mo,W)6相;而当温度低于546℃时出现了摩尔分数小于0.1%的γ″-Ni3Nb相。

图1

图1

由Pandat软件计算的系列合金的平衡相图

Fig.1

Equilibrium phase diagrams of the designed alloys calculated by Pandat software (Inset shows the typical peak-separation fitting of (200) plane in S1-CM alloy)

(a) S1-CM (b) S2-CW (c) S3-CMW

2.2 微观组织表征

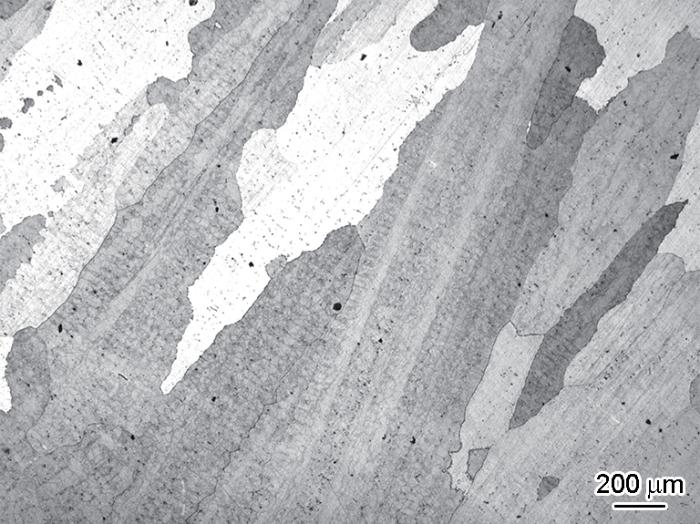

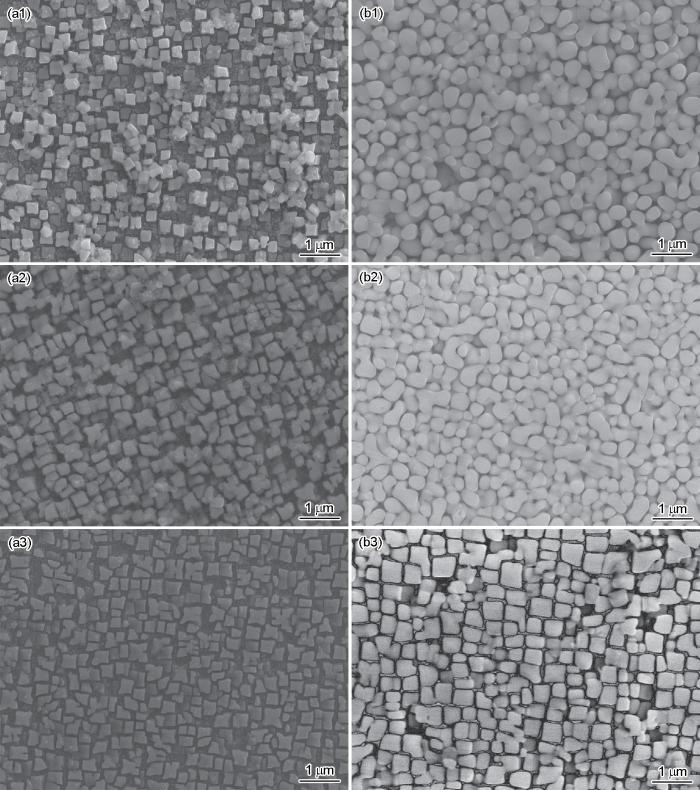

图2给出了S3-CMW合金在900℃、50 h时效处理后显微组织的OM像。可以看出,样品合金由粗大的柱状晶粒组成,晶粒尺寸为200~600 μm。图3给出了系列合金在900℃、50 h时效处理后的XRD谱。可以看出,系列合金均由fcc-γ基体和L12-γ′析出相(由(110)特征衍射峰确定)组成。观察其微观组织(图4)发现,所有合金均表现出典型的γ /γ′两相共格形貌,即方形或球形的γ′纳米粒子均匀地分布在fcc-γ基体上。需要指出,3种合金在固溶处理后γ′粒子均表现为方形,而时效50 h后,S1-CM合金和S2-CW合金中γ′粒子均转变为椭球形,S3-CMW合金中γ′粒子的形貌则仍保持为方形,且排列也变得较为规整。具体地,当添加Cr1.0Μο0.5时,S1-CM合金中γ′粒子r = (194 ± 25) nm,f约为75% (图4b1);当添加Cr1.0W0.5时,S2-CW合金中γ′粒子r = (197 ± 28) nm,f约为76% (图4b2);而当同时添加近等摩尔比例的Cr0.7Mo0.4W0.4时,S3-CMW合金中γ′粒子r = (216 ± 32) nm,f约为75% (图4b3)。可以看出,这3种合金中γ′粒子的体积分数相当,但S3-CMW合金中γ′粒子的尺寸稍大些。

图2

图2

S3-CMW合金在900℃时效50 h后的OM像

Fig.2

OM image of the S3-CMW alloy after aging at 900oC for 50 h

图3

图3

系列合金900℃、50 h时效后的XRD谱

Fig.3

XRD spectra of designed series of alloys after aging at 900oC for 50 h (Inset shows the corresponding local plots)

图4

图4

系列合金在1300℃、15 h固溶并在900℃、50 h时效后的SEM像

Fig.4

SEM images of designed alloys of S1-CM (a1, b1), S2-CW (a2, b2), and S3-CMW (a3, b3) after solid-solutionized at 1300oC for 15 h (a1-a3) and aged at 900oC for 50 h (b1-b3)

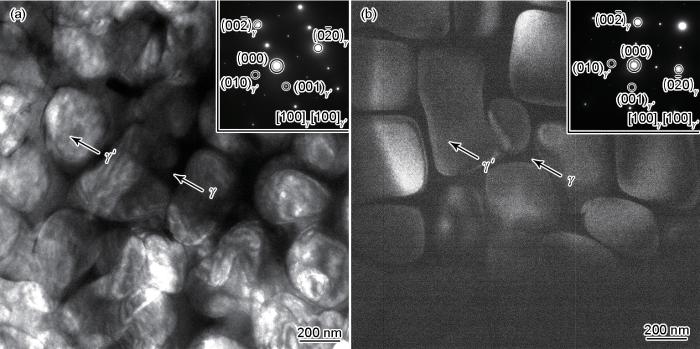

图5

图5

S1-CM和S3-CMW合金时效50 h后的TEM暗场像及选区电子衍射(SAED)花样

Fig.5

TEM dark-field images and selected area electron diffraction (SAED) patterns (insets) of 50 h-aged S1-CM (a) and S3-CMW (b) alloys

2.3 长期时效过程中的微观组织演化

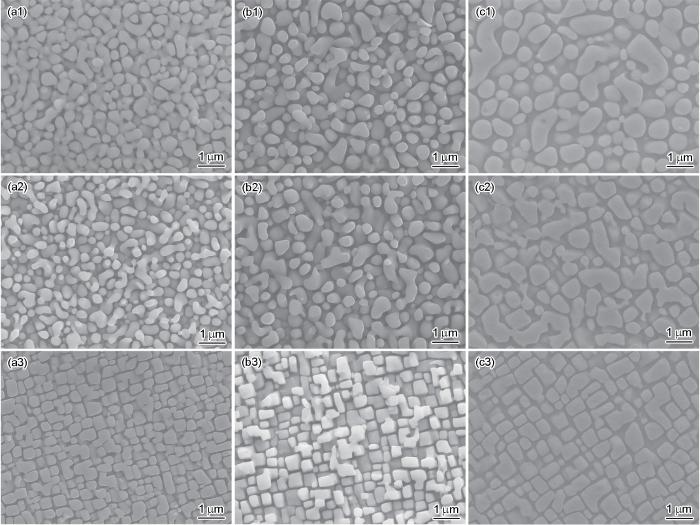

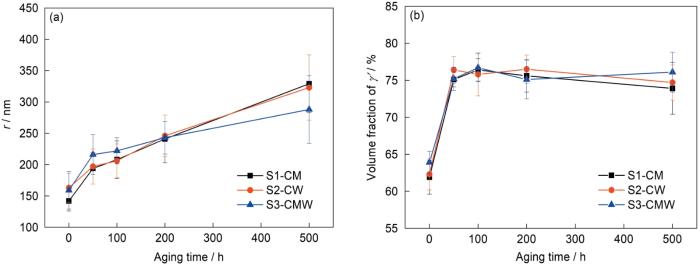

将系列合金在900℃分别时效100、200和500 h,观察合金在该温度下长期时效过程中γ /γ′共格组织的演化规律,结果如图6所示。可以看出,随着时效时间的延长,系列合金中γ′粒子的形状均未发生明显改变,但粒子发生不同程度的粗化,如S1-CM合金时效100 h后,γ′粒子r = (208 ± 30) nm,延长时效时间至200和500 h时,粒子尺寸增加到r = (241 ± 38) nm和r = (329 ± 46) nm;且在此过程中γ′粒子的形貌一直保持为椭球形,如图6a1~c1所示。W元素替换Mo元素的S2-CW合金在时效过程中γ′粒子的尺寸和形貌一直与S1-CM合金相当,在时效500 h后的γ′粒子尺寸为r = (323 ± 52) nm (图6c2)。而当Cr、Mo、W以近等摩尔比例添加时,S3-CMW合金在时效500 h之后拥有最小尺寸的γ′粒子(r = (288 ± 54) nm),且其形貌仍保持为方形(图6c3)。图7a给出了系列合金在时效过程中γ′粒子的尺寸随时效时间的变化。可以看出,γ′粒子尺寸随着时效时间的延长均不断增大,且S3-CMW合金中γ′粒子粗化速率较其他2个合金慢。此外,对每个时效状态下γ′粒子的体积分数进行统计分析,其随时效时间的变化趋势如图7b所示。结果表明,系列合金在短期时效50 h之前γ′粒子的体积分数随时效时间显著增加,当时效时间超过50 h之后体积分数基本保持不变,如S1-CM合金时效50 h后,f约为75%,时效500 h后f约为74%,这与经典Ostwald粗化理论[43,44]是一致的,即高温合金中与基体共格的γ′粒子在时效过程中的粗化一般是通过γ′粒子的聚集完成,而γ′粒子的体积分数在这个过程中基本保持不变。系列合金在900℃时效500 h后γ′粒子尺寸和体积分数也列于表1中。

图6

图6

系列合金在900℃长期时效过程中γ /γ′共格组织演变

Fig.6

Microstructure evolutions of the alloys S1-CM (a1-c1), S2-CW (a2-c2), and S3-CMW (a3-c3) aged at 900oC for 100 h (a1-a3), 200 h (b1-b3), and 500 h (c1-c3)

图7

图7

系列合金在900℃时效时γ′粒子尺寸和体积分数随时效时间的演变

Fig.7

Variations of particle size (a) and volume fraction (b) of γ′ precipitates with the aging time at 900oC in the designed alloys

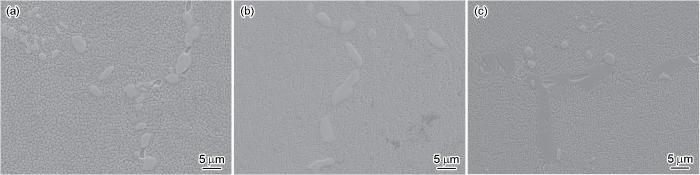

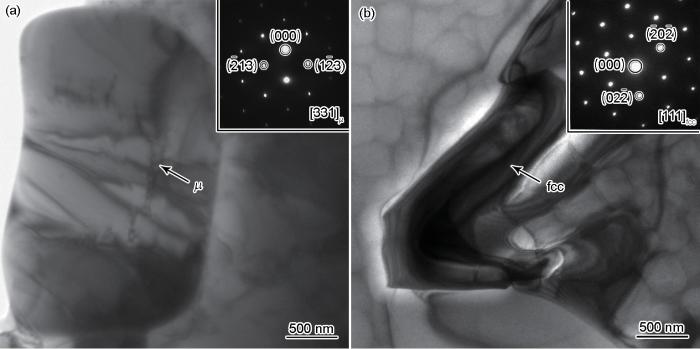

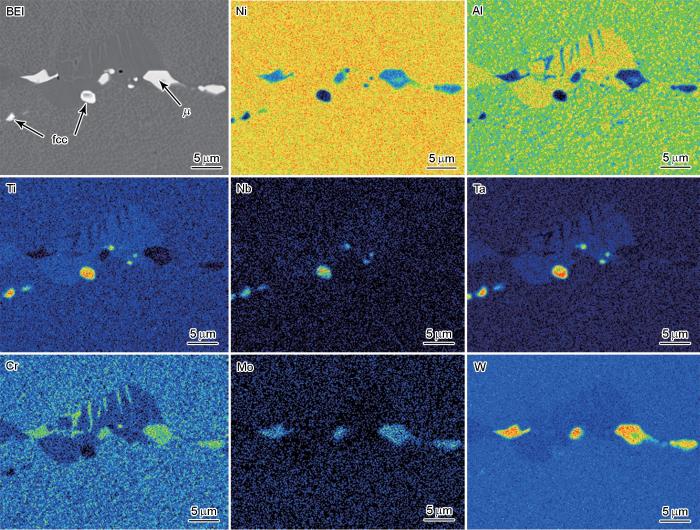

在900℃长期时效500 h后,除了晶内γ′粒子的粗化外,在晶界处的微观组织也发生了明显变化,如图8所示。这3种合金在晶界附近均出现了连续粗化的γ′析出相,且在粗化γ′析出相上析出了微米级的椭球状、棒状及不规则形状的第二相粒子(图8)。对S3-CMW合金进行TEM表征(图9),表明晶界处粗大的γ′粒子上析出的微米级第二相粒子为2种析出相。如图9a所示,通过标定的SAED花样可知,不规则块状析出粒子的晶体结构为六方结构,点阵常数a = 0.513 nm,c = 2.563 nm。EPMA结果(图10)进一步表明不规则块状的析出粒子明显富集Cr、Mo、W元素;测得该相的平均成分为Ni38.86Al1.49Cr14.63-Mo29.77W13.34Ti0.21Nb1.33Ta0.37 (原子分数,%),其中(Ni, Cr)与(Mo, W, Ti, Nb, Ta)的比例为53∶45,接近于7∶6,表明它是具有六方结构的μ-(Ni, Cr)7(Mo, W, Ti, Nb, Ta)6相。此外,在该相周围也出现了少量椭球形或棒状相,通过标定的SAED花样可知(图9b),其晶体结构为fcc结构,点阵常数a = 1.121 nm。EPMA结果(图10)表明该相平均成分为Ni11.95Al0.35Cr1.08Mo4.37W4.02-Ti21.34Nb35.85Ta21.04 (原子分数,%),因此该相为含有Ni、Cr、Mo、W、Ti、Nb和Ta等多种元素的fcc结构析出相。

图8

图8

系列合金900℃时效500 h后晶界处微观组织的SEM像

Fig.8

SEM images of microstructures on the grain boundaries in 500 h-aged alloys at 900oC

(a) S1-CM (b) S2-CW (c) S3-CMW

图9

图9

S3-CMW合金900℃时效500 h后晶界处析出相的TEM明场像及其对应的SAED花样

Fig.9

TEM bright-field images and the corresponding SAED patterns (insets) of precipitated phases on grain boundaries in 500 h-aged S3-CMW alloy at 900oC

(a) μ phase (b) fcc phase

图10

图10

S3-CMW合金在900℃时效500 h后晶界处的背散射电子像及元素分布图

Fig.10

Back scattered electrons image (BEI) and corresponding elemental distribution maps on grain boundaries in 500 h-aged S3-CMW alloy at 900oC

2.4 力学性能

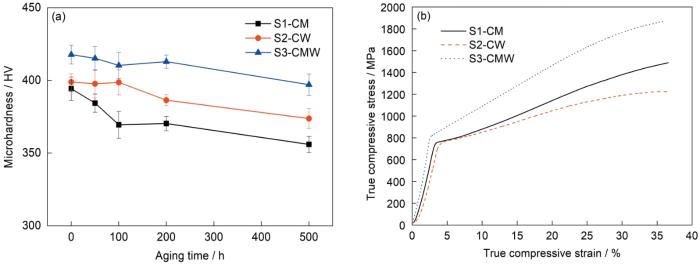

图11a给出了系列合金的显微硬度随时效时间的变化。可以看出,系列合金在固溶状态下都表现出较高的显微硬度(394~418HV),这主要是由于系列合金在固溶后γ′粒子已经从fcc-γ基体上大量析出(f约为60%),且具有较小的γ′粒子尺寸(142~163 nm);之后随着时效时间的延长,γ′粒子逐渐粗化合金硬度略有降低。其中,S3-CMW合金不论是在固溶态还是其他时效状态下都保持着较其他2个合金更高的硬度,如时效500 h后S3-CMW合金的硬度为(397 ± 7) HV,而S1-CM合金的硬度为(356 ± 5) HV,S2-CW合金的硬度为(374 ± 7) HV,这是因为S3-CMW合金中γ′粒子的体积分数(f约为76%)虽与其他2个合金相差不大,但γ′粒子具有最小粒子尺寸(r约为288 nm)。这也表明S3-CMW合金中γ /γ′共格组织具有最高的组织稳定性。

图11

图11

系列合金在900℃时效时显微硬度随时效时间的变化,及时效200 h的系列合金在室温下压缩的真应力-应变曲线

Fig.11

Variations of microhardness of the 900oC-aged alloys with the aging time (a) and compressive true stress-strain curves of 200 h-aged alloys measured at room temperature (b)

3 分析讨论

表1列出了系列合金时效50 h后γ /γ′两共格相的点阵常数(aγ 、aγ′)和δ。可以看出,添加Cr1.0Mo0.5的S1-CM合金中γ /γ′两相的δ约为-0.25%;添加Cr1.0W0.5的S2-CW合金中γ /γ′两相的δ约为-0.33%,这2个合金的γ /γ′两相点阵错配度相对较小且相差不大,因此S1-CM合金和S2-CW合金均形成椭球形的γ′粒子。而当以近等摩尔比例添加Cr0.7Mo0.4W0.4时,S3-CMW合金则拥有更负的错配度(δ 约为-0.47%)和方形的γ′粒子,这主要是因为Mo (0.140 nm)和W (0.141 nm)的原子半径大于Cr (0.128 nm)的原子半径。此外,由于γ′纳米粒子的体积分数在时效过程中几乎保持不变,因此可以用经典Ostwald粗化理论[43,44]来研究γ′纳米粒子的粗化行为。γ′粒子随时效时间的粗化过程可用下式进行描述[46]:

其中,r(t)是时效时间为t时γ′粒子尺寸;r(t0)是固溶状态下的γ′粒子尺寸;K是粗化速率。图12给出了r3(t)随t的变化曲线。对这些点进行线性拟合可知,S1-CM合金和S2-CW合金中γ′粒子的K分别为17.89和16.35 nm3/s;而S3-CMW合金γ′粒子的K则有所减小,为K = 10.02 nm3/s。长期时效过程中,γ′粒子的粗化通常涉及2个微观动力学步骤:扩散和界面反应[47],因此,γ与γ′两相之间的点阵错配度和元素的扩散速率均是影响影响粒子粗化行为的重要因素。一般地,较大的点阵错配度和较快的元素扩散速率均导致γ′粒子的快速粗化。图12显示,S1-CM合金和S2-CW合金的γ′粒子粗化速率均大于S3-CMW合金,这主要是因为与Mo、W原子相比,较轻的Cr原子拥有更快的扩散速率,且S3-CMW合金中同时含有Cr、Mo、W 3种元素,元素之间亦存在着强相互作用的拖拽效应[41],因此S3-CMW合金虽具有最大的点阵错配度,但其γ′粒子粗化速率最慢。此外,S3-CMW合金在长期时效后晶界处析出的第二相粒子也较少,展现出最佳的γ /γ′共格组织稳定性。

图12

图12

系列合金在900℃时效过程中γ′粒子尺寸r3随时效时间t的变化

Fig.12

Variations of the average particle size r3 with the aging time at 900oC in the series of alloys (K—coarsening rate constant, R2—coefficient of determination)

4 结论

(1) 在团簇成分式[Al-Ni12](Al1(Ti, Nb, Ta)0.5(Cr, Mo, W)1.5)的基础上设计了系列镍基高温合金:S1-CM、S2-CW和S3-CMW,研究了Cr、Mo、W元素含量对γ /γ′共格组织在900℃长期时效过程中热稳定性的影响。结果表明,900℃时效50 h后,系列合金的微观组织均表现为高体积分数(f > 70%)的L12-γ′有序相均匀分布在fcc-γ基体中,且两相之间保持着稳定的共格关系。其中,添加Cr1.0Mo0.5的S1-CM合金和添加Cr1.0W0.5的S2-CW合金时效后的γ′粒子形貌均表现为椭球形,以近等摩尔比例添加Cr0.7Mo0.4W0.4的S3-CMW合金则表现为方形,这取决于后者拥有更负的错配度(后者δ = -0.47%,前者δ = -0.25%~-0.33%)。

(2) 在900℃长期时效过程中,各合金中的γ′粒子形貌均没有发生变化,且都具有较慢的粗化速率(K = 10~18 nm3/s)。尤其S3-CMW合金γ′粒子在时效50和500 h后的尺寸分别约为216和288 nm,具有最慢的粗化速率(K = 10.02 nm3/s),这主要是因为S3-CMW合金虽具有较负的点阵错配度(δ约为-0.47%),但较重的Mo和W元素所占比例较大,且Cr、Mo、W 3种元素又存在多元素的拖拽效应,致使元素的扩散较慢。此外,除了晶内γ′粒子的粗化,系列合金在晶界处的γ′粒子也出现了不同程度的粗化,同时在晶界处粗化的γ′粒子上又析出了不规则形状的第二相粒子μ-(Ni, Cr)7(Mo, W, Ti, Nb, Ta)6相以及椭球状或棒状的含Ni、Cr、Mo、W、Ti、Nb和Ta等多种元素的fcc结构相。其中,具有方形γ′粒子的S3-CMW合金中第二相粒子析出最少,展现出最佳的γ /γ′共格组织稳定性,且该合金在时效过程中具有最高的硬度(397~418 HV)和室温压缩屈服强度(818 MPa),并且硬度不随时效时间发生明显变化。

参考文献

Low cycle fatigue of a polycrystalline Ni-based superalloy: Deformation substructure analysis

[J].

Effects of grain size on the high-cycle fatigue behavior of IN792 superalloy

[J].

High temperature creep properties of directionally solidified CM-247LC Ni-based superalloy

[J].

Research process on microstructural stability and mechanical behavior of advanced Ni-based single crystal superalloys

[J].<p>Ni-based single crystal superalloys have been widely used to produce turbine blades for advanced aero-engines because of the super temperature-related microstructural stability and comprehensive mechanical properties. However, due to effects of the high temperature and complicated stresses in service, the microstructures of superalloys might gradually evolve and fail in different modes. The present paper reviews the progress of microstructural stability and mechanical behavior including the γ’ phase rafting, TCP phase precipitation, high temperature creep, low cycle fatigue and thermomechanical fatigue of single crystal superalloys. The addition of Ru improves the creep life of superalloys, but also indirectly promotes the occurrence of “topological inversion”. On the other hand, with the increase of aging temperature and time, the contents of refractory elements in <i>m</i> phase rise significantly. With the increase of applied tension stress, more <i>m</i> phase precipitate from the γ matrix, whereas inverse tendency is shown under compression stress. Numerous planar defects are formed during precipitation of <i>m</i><i> </i>phase, and these defects promote the nucleation of P and R phases. During high temperature and low stress creep, an important dislocation a<010> superdislocation is observed, which moves in the γ’ phase slowly by a combination of slide and climb. Under very high temperature, incubation with accelerating creep rate occurs before the primary stage, which relates to the extending process of the γ width. At last, the stacking fault energy is significantly reduced after Ru additions, and thus a series of complex deformation mechanisms occur during low cycle fatigue, e.g. stacking faults penetrating γ/γ’ interface, trailing a/6<112> Shockley dislocations shearing into the γ’ phase. During thermomechanical fatigue, the life of superalloys is influenced by the site of crack initiation, microstructural evolution and oxidation resistance.</p>

先进镍基单晶高温合金组织稳定性及力学行为的研究进展

[J].

Effects of W on microstructural stability of the third generation Ni-based single crystal superalloys

[J].Ni-based single crystal superalloys are widely used in the manufacture of aero engine turbine blades because of the excellent mechanical properties at high temperature. With the development of single crystal superalloys, the content of refractory elements is constantly increased (especially Re) to improve the high temperature capability, which in turn leads to the decrease in microstructural stability of alloys, such as the TCP phase precipitation. It is important to find one element which not only can maintain high temperature performance but also does not evidently promote TCP phase precipitation and is very cheap in price to replace Re partially. W is one of the most important solution strengthening elements in superalloys, its diffusion rate in Ni matrix is close to Re and far below the other alloying elements, meanwhile, the advantage of low price make it to be the most suitable substitute of Re. However, there is little work about the effect of W on microstructural stability in Re contained third generation superalloys. In this work, the effects of W on the elemental segregation, elemental partitioning ratio of γ /γ′, microstructure evolution and TCP phase precipitation during thermal exposure at 950, 1000 and 1050 ℃ have been investigated in a third generation Ni-based single crystal superalloys with varied contents of W (6%~8%, mass fraction). The results show that the addition of W has no obvious effect on segregation of the alloying elements of as-cast alloys as well as the morphology, size and volume fraction of γ′ phase after heat treatment. During the thermal exposure at 950 ℃, the connection and deformation of γ′ phase are accelerated, but its coarsening rate is decreased with increasing W content. The TCP phases precipitated in three alloys during thermal exposure are mainly μ phase and σ phase. The area fraction of TCP phases is increased slightly with the W addition during thermal exposure, which is the largest at 1000 ℃, less at 950 ℃ and the least at 1050 ℃.

W对第三代镍基单晶高温合金组织稳定性的影响

[J].

Optimal precipitate shapes in nickel-base γ-γ ′ alloys

[J].

A review of composition evolution in Ni-based single crystal superalloys

[J].Due to the outstanding creep performance, nickel-based single crystal superalloys (Ni-SXs) are extensively applied in modern aero-engine and industrial gas turbine. Apart from the special single crystal structure which is disadvantageous to extension of creep cracks, Ni-SXs derive the creep strength from intrinsic two-phase microstructure (γphase and γ’ phase). Main microstructural parameters including volume fraction of γ’ phase and the lattice misfit, and the formation and distribution of precipitated phase are determined by the compositions of alloys. Besides, the creep properties are greatly influenced by these microstructural parameters and precipitated phase. This review has summarized the relationships between different alloying elements and microstructures and indicated their influence on creep properties of Ni-SXs. In addition, with the improvements of experimental methods and characterization technique, some recent discoveries have provided additional evidence to support or challenge the pervious creep theories of superalloys. In view of these new discoveries, this review has provided some perspectives which can be referenced in future compositional design of Ni-SXs.

Creep deformation of a sixth generation Ni-base single crystal superalloy at 800oC

[J].

High-temperature and low-stress creep anisotropy of single-crystal superalloys

[J].

Nickel-based single-crystal superalloys (Ni, Co)-Al-(Ta, Ti)-(Cr, Mo, W) designed by cluster-plus-glue-atom model and their 1000 h long-term ageing behavior at 900oC

[J].

基于团簇模型设计的镍基单晶高温合金(Ni, Co)-Al-(Ta, Ti)-(Cr, Mo, W)及其在900℃下1000 h的长期时效行为

[J].

Influence of small rhenium additions on the lattice spacing of nickel solid solution

[J].

Reasons for the enhanced phase stability of Ru-containing nickel-based superalloys

[J].

Influence of element Re on lattice misfits and stress rupture properties of single crystal nickel-based superalloys

[J].

Lattice misfits in four binary Ni-Base γ /γ′ alloys at ambient and elevated temperatures

[J].

Influence of molybdenum on the creep properties of nickel-base superalloy single crystals

[J].

Effect of initial gamma prime size on the elevated temperature creep properties of single crystal nickel base superalloys

[J].

Dislocations and high-temperature plastic deformation of superalloy single crystals

[J].

Effect of Mo addition on microstructural characteristics in a Re-containing single crystal superalloy

[J].The effect of Mo addition on microstructural characteristics of a nickel-base single crystal superalloy containing 4 wt% Re was investigated. The γ/γ′ partitioning ratios determined by energy dispersive spectrometer attached to a transmission electron microscope showed that the addition of Mo enhanced the partitioning of Re, W and Cr in the γ matrix while decreased the concentration of Ta in the matrix. Synchrotron radiation diffraction was adopted to measure the γ/γ′ lattice misfit at room temperature. The results indicated that Mo addition changed the γ/γ′ lattice misfit towards larger negative as well as increased the tetragonal distortion of the γ lattice. Additionally, Mo addition led to microstructural instability and altered the precipitation behavior of topologically close-packed phases during 1100 °C exposure. Instead of precipitating directly from the matrix, the μ phase was observed to be converted from the σ phase which precipitated preferentially as a metastable intermediate in the alloy with high Mo content.

The effect of lattice misfit on the dislocation motion in superalloys during high-temperature low-stress creep

[J].

The importance of sign and magnitude of γ/γ′ lattice misfit in superalloys—With special reference to the new γ′-hardened cobalt-base superalloys

[J].

Oxidation resistant Ru containing Ni base single crystal superalloys

[J].Oxidation resistant fourth and fifth generation Ni base superalloys were developed. The fourth generation superalloys TMS-138A were modified by increasing the content of Al and Cr and deceasing Mo. Designed alloys were cast as single crystal and examined in cyclic and isothermal exposures at 1100°C and creep rupture test. Under high temperature/low stress condition, 0·5 wt-% of Al addition was effective to improve the oxidation resistance but degrade creep property. Cr addition and Mo and W reduction were effective to improve the oxidation resistance and display creep property almost equal to the original TMS-138A. The fourth generation superalloy TMS-138 and fifth generation superalloy TMS-173 were also modified. By adding Cr and removing Mo and W, their oxidation resistances were dramatically improved. Thus it was found that it is possible to improve the oxidation resistance of Ru containing SC superalloys with keeping the high temperature strength by the increase in Cr and decrease in Mo and W.

Development of an oxidation-resistant high-strength sixth-generation single-crystal superalloy TMS-238

[A].

The influence of high temperature annealing and creep on the microstructure and chemical element distribution in the γ, γ ′ and TCP phases in single crystal Ni-base superalloy

[J].

Structural evolution of topologically closed packed phase in a Ni-based single crystal superalloy

[J].

The nucleation and growth of η phase in nickel-based superalloy during long-term thermal exposure

[J].

Crystal chemistry and Calphad modeling of the σ phase

[J].

An electronic approach to alloy design and its application to Ni-based single-crystal superalloys

[J].

Recent progress in molecular orbital approach to alloy design

[J].

New PHACOMP and its applications to alloy design

[A].

Alloy design of Ni-based single crystal superalloys for the combination of strength and surface stability at elevated temperatures

[J].

Design of Ni-base superalloys

[A].

Alloy design for high strength nickel-base single crystal alloys

[A].

High-temperature structural stabilities of Ni-based single-crystal superalloys Ni-Co-Cr-Mo-W-Al-Ti-Ta with varying Co contents

[J].

Composition rules of Ni-base single crystal superalloys and its influence on creep properties via a cluster formula approach

[J].The present work investigated the composition evolution of the TMS series of Ni-base single crystal (SC) superalloys in light of the cluster formula approach systematically. The cluster formula of SC superalloys could be expressed with [Formula: see text], in which all the alloying elements were classified into three groups, Al series ([Formula: see text]), Cr series ([Formula: see text]), and Ni series ([Formula: see text]). It was found that the total atom number (Z) of the cluster formula units for TMS series of superalloys varies from Z ~ 17 to Z ~ 15.5, and then to Z ~ 16 with the alloy development from the 1st to the 6th generation, in which the superalloys with prominent creep resistance possess an ideal cluster formula of [Formula: see text] with Z = 16. Similar tendency of composition evolution also appears in the PWA and CMSX series of SC superalloys. Typical TMS series of superalloys with prominent creep properties generally exhibit a moderate lattice misfit of γ/γ' which could render alloys with appropriate particle size of cuboidal γ' precipitates to acquire a maximum strength increment by precipitation strengthening mechanism. More importantly, the relationship between the lattice misfit (δ) of γ/γ' and the creep rupture lifetime (t) of superalloys was then established, showing a linear correlation in the form of lgt-lg|δ| at both conditions of 900 °C/392 MPa and 1100 °C/137 MPa. Combined with the lattice misfit, the cluster formula approach would provide a new way to modify or optimize the compositions of Ni-base superalloys for further improvement of creep property.

Accelerated exploration of multi-principal element alloys with solid solution phases

[J].Senkov, O. N.; Miller, J. D.; Miracle, D. B.; Woodward, C. Air Force Res Lab, Mat & Mfg Directorate, Wright Patterson AFB, OH 45433 USA.

High-entropy alloy: Challenges and prospects

[J].

A critical review of high entropy alloys and related concepts

[J].

Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes

[J].

Microstructures and properties of high-entropy alloys

[J].

Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys

[J].Alloy design based on single-principal-element systems has approached its limit for performance enhancements. A substantial increase in strength up to gigapascal levels typically causes the premature failure of materials with reduced ductility. Here, we report a strategy to break this trade-off by controllably introducing high-density ductile multicomponent intermetallic nanoparticles (MCINPs) in complex alloy systems. Distinct from the intermetallic-induced embrittlement under conventional wisdom, such MCINP-strengthened alloys exhibit superior strengths of 1.5 gigapascals and ductility as high as 50% in tension at ambient temperature. The plastic instability, a major concern for high-strength materials, can be completely eliminated by generating a distinctive multistage work-hardening behavior, resulting from pronounced dislocation activities and deformation-induced microbands. This MCINP strategy offers a paradigm to develop next-generation materials for structural applications.Copyright © 2018 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Microstructural stability of low-cost Ni-base superalloys with a high volume fraction of cuboidal γ' nanoprecipitates

[J].

Ostwald ripening in multicomponent alloys

[J].

Diffusion-defining atomic-scale spinodal decomposition within nanoprecipitates

[J].Stoichiometric precipitates owe their fixed composition to an ordered crystal structure. Deviations from that nominal value, however, are encountered at times. Here we investigate composition, structure and diffusion phenomena of ordered precipitates that form during heat treatment in an industrially cast Al-Mg-Sc-Zr alloy system. Experimental investigations based on aberration-corrected scanning transmission electron microscopy and analytical tomography reveal the temporal evolution of precipitate ordering and formation of non-equilibrium structures with unprecedented spatial resolution, supported by thermodynamic calculations and diffusion simulations. This detailed view reveals atomic-scale spinodal decomposition to majorly define the ongoing diffusion process. It is illustrated that even small deviations in composition and ordering can have a considerable impact on a system's evolution, due to the interplay of Gibbs energies, atomic jump activation energies and phase ordering, which may play an important role for multicomponent alloys.

Microstructures and properties of a novel γ ′-strengthened multi-component CoNi-based wrought superalloy designed by CALPHAD method

[J].

Recent progress in high-temperature resistant aluminum-based alloys: Microstructural design and precipitation strategy

[J].Many load-bearing industrial settings require light-weight structural materials with adequate strength. Although commercial aluminum (Al) alloys are suitable for room-temperature applications, their strength at elevated temperatures (300-500oC) is largely reduced by coarsening of the strengthening precipitates. However, high-temperature alternatives such as titanium alloys are much heavier and more expensive than Al alloys. Creating microstructures that remain stable over 300oC is an important goal of the aluminum-manufacturing community. This article focuses on the recent development of high-temperature resistant Al-based alloys. Especially, it discusses the unique microstructural features, selection criteria of the strengthening phase, alloying effects, and microstructural stabilization of aluminum. The strategies summarized in this review are expected to realize the new microstructural architectures of light-weight alloys, which are currently limited to low-temperature service.

耐热铝基合金研究进展: 微观组织设计与析出策略

[J].工业选材在满足强度要求以保证结构安全之余,通常也需要尽可能兼顾轻量化以使机械结构更加轻盈。当仅仅考虑室温服役性能时,大量的商用铝合金材料因其优异的室温力学性能可供备选,并通常能很好地契合“轻质-高强”这一目标。然而,对于需要在300~500℃中温区间服役的构件,铝合金的上述优势则荡然无存。其主要原因在于传统高强铝合金赖以强化的析出相在200℃以上便将发生快速失稳粗化,导致材料丧失强化效果并快速软化失效。而若以更耐热的钛合金、高温合金等作为替代,则随之带来的结构增重与成本提高又令设计者甚觉“重材轻用”。目前,在>300℃温度区间难以实现安全服役仍是轻质铝基材料开发的难点所在,而其关键的解决方案在于如何寻求微观组织的高温稳定化。本文从耐热铝合金中特异性的微观组织特点出发,综述近期业界在耐热铝基合金开发过程中关于强化相选择、合金化策略以及微观组织热稳定化的进展与内在构建机理,以期能够提供一些耐热轻质合金材料微观组织设计过程的普适性基本理论依据。

Role of Re and Co on microstructures and γ' coarsening in single crystal superalloys

[J].