第四代核能系统代表了先进核能的发展趋势,具备安全性好、核燃料利用率高、经济竞争力强、有效防止核扩散等特点。钠冷快堆是第四代核能系统中技术发展最为成熟的堆型,国际上已建造了20余座,积累了400堆年以上的运行经验[1~4]。堆本体设备(包括堆容器和堆内构件)是承载液态钠介质的重要屏障,长期处于高温、腐蚀、辐照等苛刻工况,同时要求在40年设计寿期内不可更换,因此,堆本体设备的安全可靠性是反应堆安全运行的基础。国际上普遍采用具有优良的冷热加工性能的奥氏体不锈钢进行钠冷快堆堆本体设备的制造,各国均研发出相应牌号的材料,例如法国的X2CrNiMo17-12-2、俄罗斯的08Х16Н11М3、日本的316FR、美国的Type 316、印度的316LN等[2,3]。中国CFR600钠冷示范快堆工程已经启动,根据结构设计和服役工况对材料性能的设计要求,堆本体设备采用自主研制的控碳控氮型316KD奥氏体不锈钢。

奥氏体不锈钢的力学性能与微观组织密切相关,而微观组织主要取决于化学成分。研究人员建立了奥氏体不锈钢中相组成与Cr / Ni当量比的定量关系,进而发展出预测微观组织的方法,经典方法包括Schaeffler组织图、Delong组织图、Espy组织图等[5~7]。虽然预测结果表明316KD奥氏体不锈钢为单相奥氏体组织,但是工业化规模铸锭中会出现因成分偏析造成的高温δ-铁素体,并且随着铸锭尺寸的增加,δ-铁素体的含量显著增加,180 mm厚铸坯心部的δ-铁素体含量可接近8%[8,9]。本课题组前期研究[8]表明,铸坯沿厚度方向的Cr、Ni宏观偏析,使得铸坯心部具有较高的Cr/Ni当量比,δ-铁素体的形成倾向增强;与此同时,铸坯心部较低的冷却速率,延长了固液相区停留时间,导致δ-铁素体形成数量的增加。工业生产过程中发现,δ-铁素体的存在会影响热加工过程中奥氏体晶粒度的控制,出现晶粒尺寸不均匀的现象。已有奥氏体不锈钢热加工行为的研究主要着眼于本构关系方程和热加工图的建立,重点关注了奥氏体的动态再结晶行为[10~15],关于δ-铁素体对热变形行为的影响研究比较少。奥氏体和铁素体共存的双相不锈钢的高温变形行为研究[16~20]发现,铁素体和奥氏体的动态软化机制不同,铁素体以动态回复为主,而奥氏体以动态再结晶为主。Dehghan-Manshadi和Hodgson[19]对2250双相不锈钢和AISI 304奥氏体不锈钢热扭转变形行为的研究发现,相同变形条件下,AISI 304奥氏体不锈钢的动态再结晶体积分数和晶粒尺寸均高于2250双相不锈钢中的奥氏体,但关于铁素体对奥氏体动态再结晶行为的影响机制尚不清楚。

基于此,本工作以180 mm厚316KD奥氏体不锈钢铸坯为研究对象,开展均质化处理工艺研究,以实现消除铸坯中的δ-铁素体。在此基础上,采用热压缩方法,对比研究了含有δ-铁素体和不含δ-铁素体铸坯的热变形行为,从而厘清δ-铁素体对热变形行为和动态再结晶的影响机制,并为热加工工艺的制定提供理论依据。

1 实验方法

实验材料取自工业规模的180 mm厚316KD奥氏体不锈钢铸坯,其化学成分为Fe-0.039C-0.075N-12.4Ni-17.6Cr-2.55Mo-1.46Mn-0.38Si-0.001S-0.013P(质量分数,%)。在铸坯心部位置切取试样,分别在1323、1423和1473 K进行不同时间的保温处理,以考察均质化处理制度对δ-铁素体转变行为的影响。

将铸态和均质化处理态样品加工成直径8 mm、高度12 mm的圆柱体试样,在Gleeble-3800热力模拟试验机上进行热压缩实验。首先以10 K/s的速率加热到1503 K保温5 min,以消除铸态样品中的析出相;然后以10 K/s的速率冷却至1423 K,保温5 min后进行压缩变形,应变速率为0.1 s-1,变形量分别为20%、30%和60%,对应的真应变为0.22、0.36和0.92,变形结束后水淬至室温。将热压缩变形后的试样沿压缩轴心方向切开,进行显微组织分析。采用体积分数为60%的硝酸水溶液进行电化学腐刻,电压1.2 V,腐蚀时间10 s,随后在GX51光学显微镜(OM)上观察显微组织。基于面积分数的统计结果来衡量δ-铁素体含量,采用Image Pro Plus软件进行统计,每个试样随机选取5个视场进行统计,取平均值。采用体积分数为10%的高氯酸酒精溶液进行电解抛光,电压为15 V,在配有Symmetry探头的Merlin Compact场发射扫描电镜(SEM)上进行电子背散射衍射(EBSD)分析。透射电镜(TEM)样品经电解双喷减薄后,在Tecnai G2 F30 TEM上进行显微组织观察。

2 实验结果与分析

2.1 均质化处理对 δ-铁素体转变行为的影响

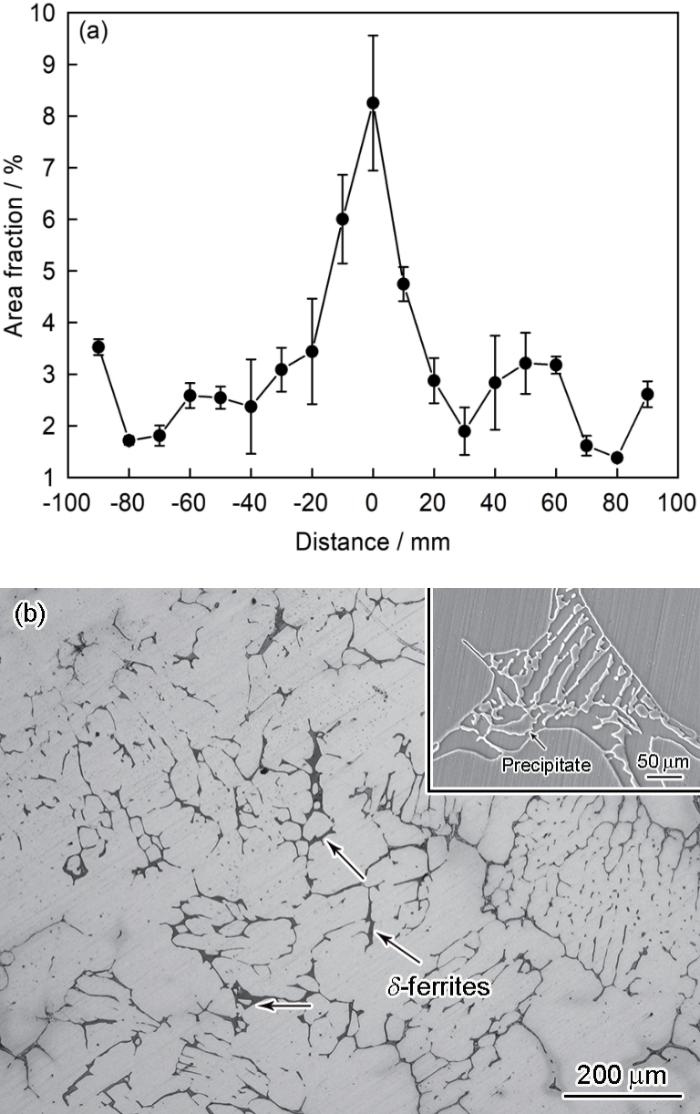

图1

图1

180 mm厚316KD奥氏体不锈钢铸坯中δ-铁素体含量沿厚度方向的分布曲线和心部位置微观组织

Fig.1

Changes in the area fraction of δ-ferrite across the thickness (a) and OM image of as-cast samples at the center position (b) of 180 mm thick 316KD austenitic stainless steel billet (Inset in Fig.1b shows the SEM image of precipitate in δ-ferrite)

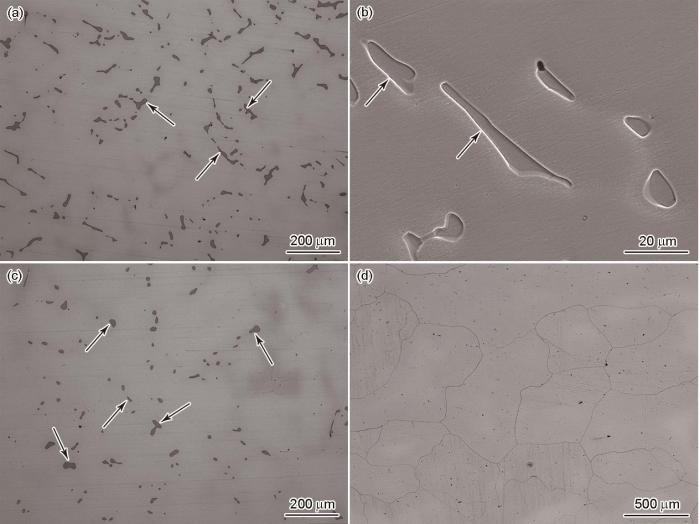

图2为铸坯心部样品中的δ-铁素体含量随均质化处理温度和保温时间的变化曲线。经1323 K均质化处理后,δ-铁素体含量随保温时间的延长而略有降低,保温处理14 h后,δ-铁素体含量约4%。当均质化温度高于1423 K后,δ-铁素体含量随保温时间的延长而迅速降低。1423 K保温处理14 h后,仅存在少量的δ-铁素体,含量约0.6%;而1473 K保温处理14 h可实现δ-铁素体的基本消除,含量仅约0.03%。1473 K均质化处理2、4和14 h后的微观组织如图3所示。1473 K均质化处理2 h后,原来的骨架状形态基本消失,取而代之的是断续分布的棒状δ-铁素体(图3a)。与此同时,均质化处理使得δ-铁素体内部的析出相发生回溶(图3b)。均质化处理4 h后,δ-铁素体开始球化,球状/短棒状δ-铁素体弥散分布在奥氏体中(图3c)。均质化处理14 h后,δ-铁素体可完全消除,但是奥氏体晶粒显著长大,晶粒尺寸可达500 μm (图3d)。

图2

图2

铸坯心部样品的δ-铁素体含量与均质化处理温度和保温时间的关系曲线

Fig.2

Area fraction curves of δ-ferrite as a function of homogenization temperature and time of as-cast samples at the center position of 180 mm thick slab

图3

图3

铸坯心部样品经1473 K均质化处理2、4和14 h后的微观组织

Fig.3

OM (a, c, d) and SEM (b) images of as-cast samples at the center position of 180 mm thick slab after homogenization treatment at 1473 K for 2 h (a, b), 4 h (c), and 14 h (d) (The black arrows indicate the δ-ferrite)

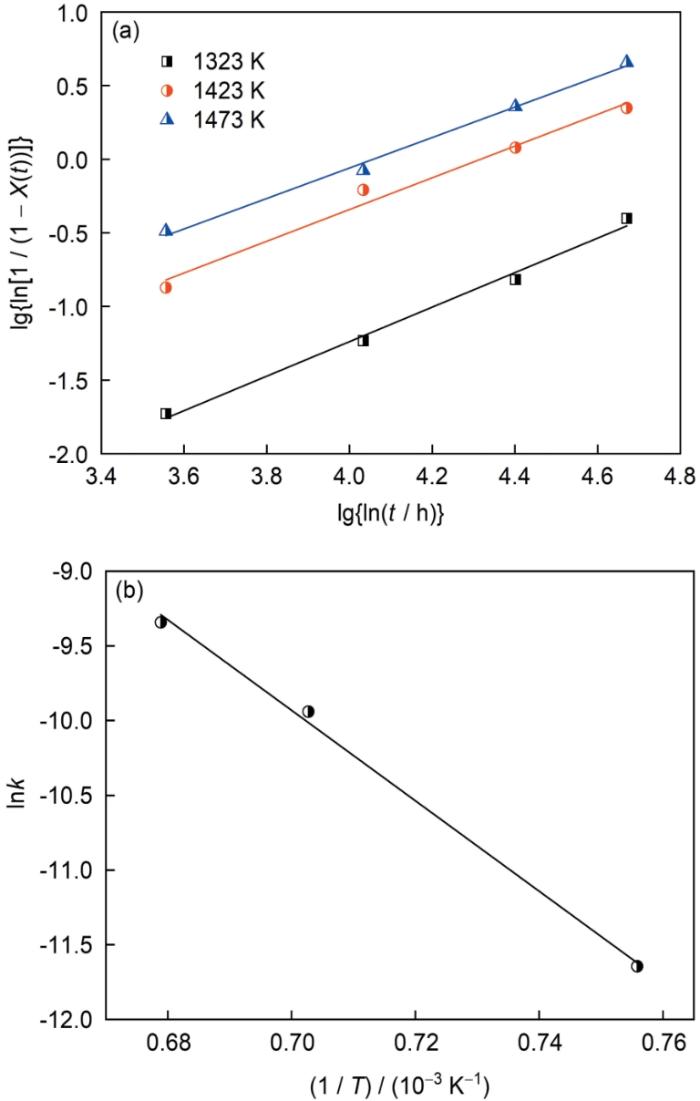

式中,t为时间;n为时间指数;k为反应速率常数;X(t)为δ-铁素体面积分数随时间的相对变化,可表示为:

式中,A0、At 分别为均质化处理前及均质化处理t时间后δ-铁素体面积分数。不同均质化温度下lg{ln[1 / (1 - X(t))]}与lg{lnt}的拟合结果如图4a所示,拟合曲线的线性相关系数均接近1 (分别为0.993、0.984和0.995),呈现良好的线性关系,由此说明JMAK方程可准确反应出δ-铁素体含量随均质化处理时间的变化规律。通过线性拟合亦可得出k和n值,如表1所示。研究[22]表明,n的大小与相转变行为有关,对于棒状/圆柱形的相来说,n = 1表明相转变行为受控于合金元素的扩散。本工作中,1323、1423和1473 K下拟合曲线的n值均接近于1,分别为1.173、1.079和1.035,表明1323~1473 K范围内δ-铁素体含量随均质化处理时间的转变行为相同,主要取决于合金元素的扩散。此外,k与温度密切相关,随着均质化温度的提高,k值逐渐增大,1473 K下的k值比1323 K提高了1个数量级,这说明转变速率显著加快(表1)。k可表述为:

图4

图4

lg{ln[1 / (1 - X(t))]}与lg{lnt}以及lnk与1 / T之间的拟合关系曲线

Fig.4

lg{ln[1 / (1 - X(t))]} as a function of lg{lnt} (a) and lnk as a function of 1 / T (b) (T—homogenization temperature, X—area fraction of δ-ferrite, t—time, k—reaction rate constant)

表1 δ-铁素体等温转变动力学方程中时间指数(n)和反应速率常数(k)的计算值

Table 1

| T / K | n | k | r |

|---|---|---|---|

| 1323 | 1.173 | 8.77 × 10-6 | 0.993 |

| 1423 | 1.079 | 4.82 × 10-5 | 0.984 |

| 1473 | 1.035 | 8.76 × 10-5 | 0.995 |

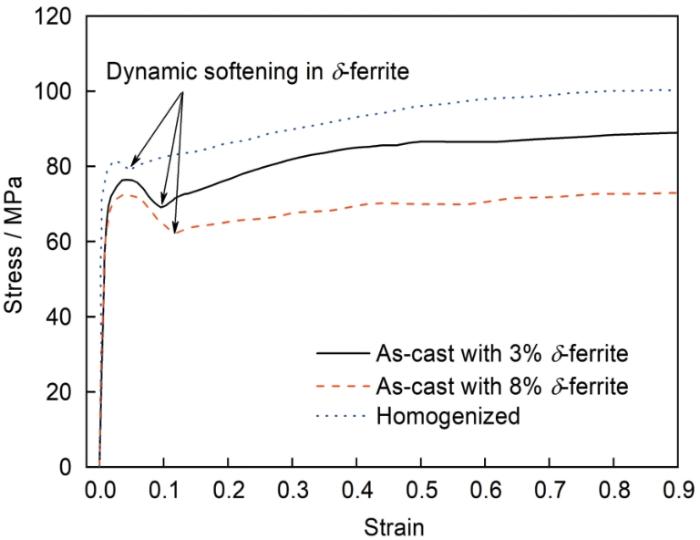

2.2 δ-铁素体对热变形行为和动态再结晶的影响

基于上述研究结果,选用1473 K均质化处理14 h后的样品进行热压缩实验,并与铸坯表面位置和心部位置的样品进行了比较,铸坯心部位置样品的δ-铁素体含量约为8%,铸坯表面位置样品的δ-铁素体含量约3%。图5为铸态样品和均质化处理态样品在1423 K压缩变形时的真应力-真应变曲线。可见,3种样品流变应力随应变的变化规律基本相同。对于铸态样品来说,变形初始阶段,流变应力随应变的增加而快速增加,表现出明显的加工硬化;应变达到临界值后,流变应力出现一定程度的下降,呈现出明显的软化(图5箭头所示);随后流变应力略有增加,并趋于稳态。同一应变下,均质化处理态样品的流变应力显著高于铸态样品,并且铸态样品的流变应力随δ-铁素体含量的增加而逐渐降低。以稳态应力为例,均质化处理态样品的稳态应力约100 MPa,比含3%δ-铁素体的铸态样品(约87 MPa)提高了15%,比含8%δ-铁素体的铸态样品(约72 MPa)提高了38%。此外,随δ-铁素体的含量减少,铸态样品变形初期的软化程度逐渐减弱,无δ-铁素体的均质化处理态样品仅表现出微弱软化。

图5

图5

铸态和均质化处理态样品经1423 K、0.1 s-1压缩变形时的真应力-真应变曲线

Fig.5

True stress-true strain curves of as-cast and homogenized samples after deformation at 1423 K and 0.1 s-1

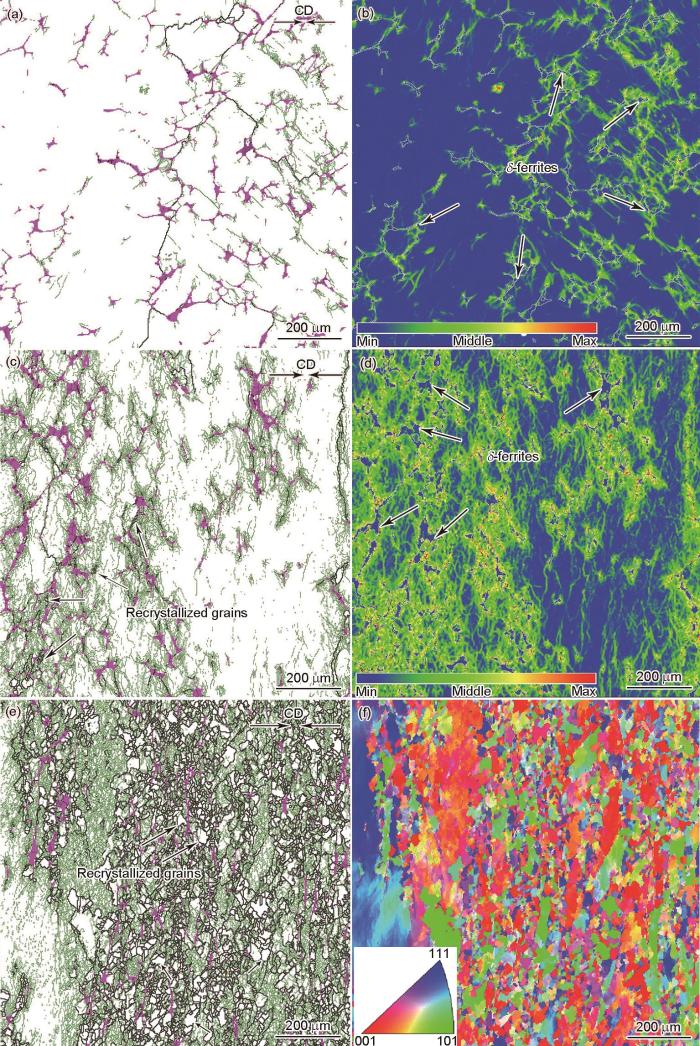

图6为铸态样品经不同应变压缩变形后的晶界特征分布和局域取向差图。应变为0.22时,相比于奥氏体相(白色),在δ-铁素体/奥氏体界面附近观察到小角度晶界优先形成,未观察到动态再结晶的发生(图6a)。局域取向差可定量表征变形后微观区域内的应变分布特征,不同的颜色代表了不同程度的应变集中,如图6b所示。可见,样品呈现出显著的应变分布不均匀现象,δ-铁素体(粉色)和δ-铁素体/奥氏体界面处的局域取向差较大,最大的局域取向差出现在δ-铁素体/奥氏体界面处。应变为0.36时,靠近δ-铁素体/奥氏体界面的奥氏体内形成的小角度晶界数量显著增加,同时原始奥氏体晶界、δ-铁素体/奥氏体界面处可观察到少量的细小晶粒(图6c箭头所示),晶界类型为大角度晶界,说明发生了少量的动态再结晶。δ-铁素体/奥氏体界面偏奥氏体一侧以及原始奥氏体晶界处的局域取向差较高,而δ-铁素体内部的局域取向差显著减小(图6d)。由此可见,随应变的增加,δ-铁素体内部的应变集中基本消失。应变增至0.92后,动态再结晶比例显著提升,未发生再结晶区域内存在较多的小角度晶界(图6e)。EBSD取向分布亦证实,再结晶晶粒的取向分布随机,而未发生再结晶区域的取向相同(图6f)。此外,δ-铁素体的形态随应变的增加而改变,最终沿垂直于压缩方向呈条带状分布(图6e)。

图6

图6

铸态样品经不同变形量压缩后的EBSD晶界特征、局域取向差分布和晶粒取向图

Fig.6

Grain boundary maps (a, c, e), corresponding local misorientation maps (b, d), and inverse pole figure (IPF) (f) of as-cast samples with the strains of 0.22 (a, b), 0.36 (c, d), and 0.92 (e, f) (In Figs.6a, c, and e, the black and green lines indicate the high angle grain boundaries (misorientation angle > 15°) and low angle grain boundaries (misorientation angle 2°-15°), respectively; pink color represents the δ-ferrite; the same in figures below. CD—compression direction)

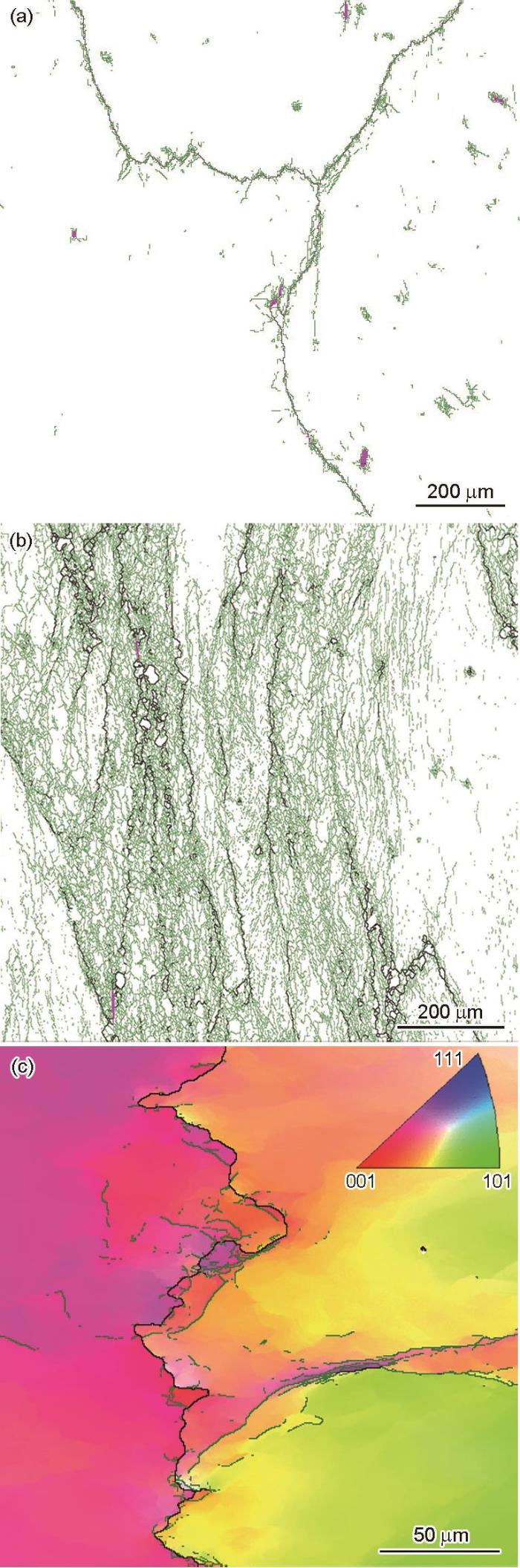

图7

图7

均质化处理态样品经不同变形量压缩后的EBSD晶界特征分布

Fig.7

Grain boundary maps (a, b) and IPF (c) of homogenized samples with the strains of 0.36 (a, c) and 0.92 (b)

热变形过程中,流变应力的变化是加工硬化和动态软化相互竞争的结果。变形初始阶段,位错增殖和缠结导致加工硬化,造成流变应力快速增加。随着应变累积,位错密度显著增大,动态回复和动态再结晶发生,动态回复作用下晶内的位错相互作用而形成亚晶,达到临界应变后,动态再结晶优先在原始奥氏体晶界处发生(图7b)。由于动态回复和动态再结晶引起的软化效果逐渐抵消加工硬化作用,使得流变应力增速变缓(图5)。由图7c的原始奥氏体晶界特征分布可见,晶界前沿呈不均匀的“锯齿”状,为典型的晶界弓出形核特征,晶界两侧的位错密度差促使晶界迁移,从而发生动态再结晶形核。因此,均质化处理态样品的动态再结晶机制是以原始奥氏体晶界弓出形核的不连续动态再结晶[24]。均质化处理在消除δ-铁素体的同时,会促进奥氏体晶粒的显著长大,大大减少了动态再结晶的潜在形核位置,即使应变为0.92时,动态再结晶程度也不高(图7b)。与此同时,动态再结晶的软化效果不能完全抵消加工硬化作用,造成流变应力随应变增加而略有增加的现象(图5)。这与文献[12,15]报道的316LN奥氏体不锈钢真应力-真应变曲线呈现逐渐软化至稳态的规律不同,这是由于较小的原始晶粒尺寸促进了动态再结晶的发生,动态软化作用更加显著。

2种样品热变形行为的对比分析发现,δ-铁素体的存在促进了铸态样品中动态再结晶的发生,并且δ-铁素体和奥氏体在变形过程中的演变规律不同。变形初期,铸态样品的δ-铁素体内部、δ-铁素体/奥氏体界面处出现明显的应变集中(图6b),表明δ-铁素体内部、δ-铁素体/奥氏体界面处的塑性变形先于奥氏体相,这是由于δ-铁素体的高温变形抗力低于奥氏体[25]。由于软相(δ-铁素体)的存在,铸态样品的流变应力明显低于均质化处理态样品(图5)。随着变形的进行,δ-铁素体内部、δ-铁素体/奥氏体界面处塞积的高密度位错进行运动,铁素体的层错能较高[26],位错的攀移和交滑移比较容易进行而发生动态回复,造成δ-铁素体内部的应变集中基本消失(图6d)。δ-铁素体内部动态回复引起的软化可能是铸态样品真应力-真应变曲线出现流变应力显著下降的主要原因(图5箭头所示)。在均质化处理态样品中仍可观察到随机分布的少量δ-铁素体(图7a和b),变形初期的微弱软化特征可能是由于少量δ-铁素体的动态回复所致。

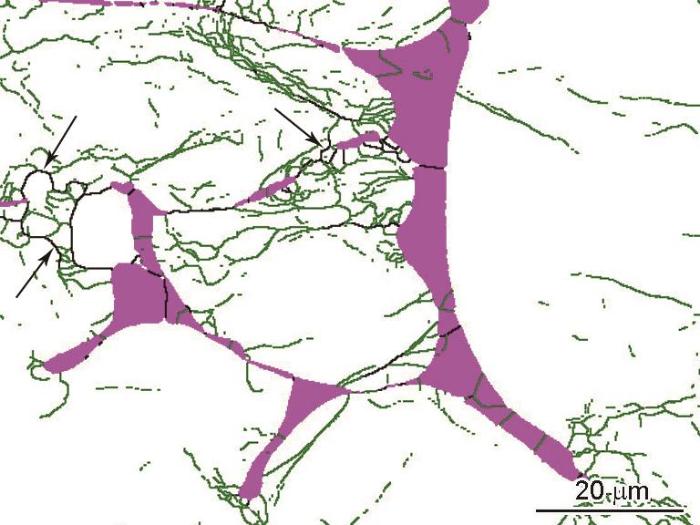

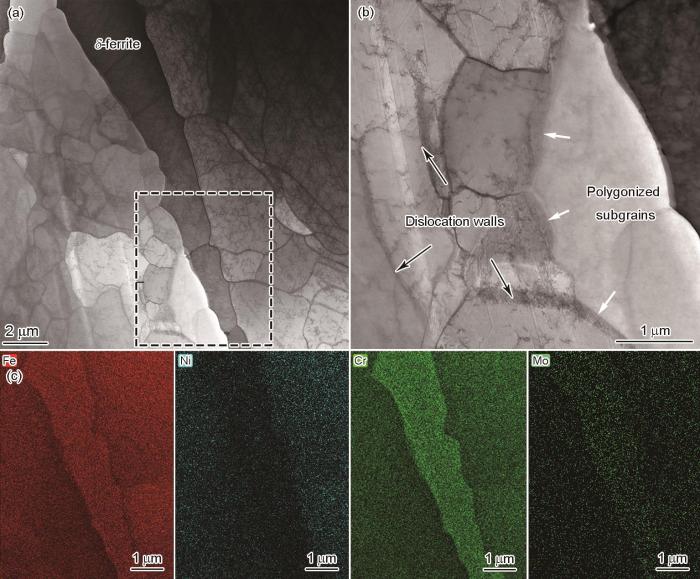

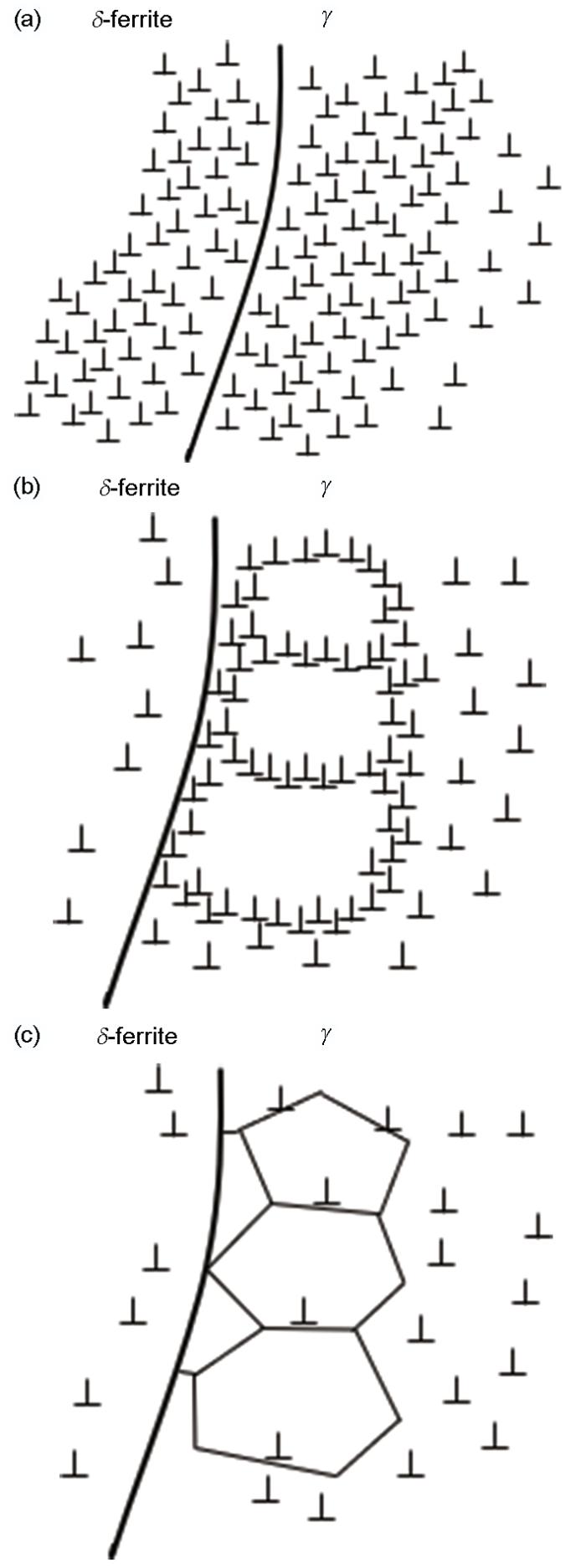

与δ-铁素体不同,靠近δ-铁素体/奥氏体界面的奥氏体应变集中程度随应变增加而加剧。应变为0.36时,δ-铁素体/奥氏体界面附近的晶界特征分布如图8所示。δ-铁素体内部发生了明显的动态回复,仅存在少量的小角度晶界。然而,奥氏体中存在较多的小角度晶界,也可观察到少量的等轴状亚晶,这是动态回复所致。值得注意的是,奥氏体中可观察到小角度晶界向大角度晶界的转换(图8箭头所示)。为进一步确定动态再结晶机制,对δ-铁素体/奥氏体界面附近的微观组织进行TEM观察,如图9所示。元素分布图表明,δ-铁素体为富Cr、富Mo、贫Ni的区域(图9c)。δ-铁素体内部形成了细小晶粒,尺寸< 2 μm,结合图8的EBSD晶界特征,为亚晶晶粒结构。δ-铁素体晶粒内部未观察到高密度的位错缠结,由此证明δ-铁素体发生了明显的动态回复,这与局域取向差分析结果吻合(图6d)。靠近δ-铁素体/奥氏体界面的奥氏体内部形成了近似等轴状的位错胞/亚晶,平均尺寸约2 μm (图9a),部分位错胞/亚晶界仍由位错墙构成(图9b黑色箭头所示);同时观察到多边形化的亚晶,内部的位错密度较低(图9b白色箭头所示)。综上所述,δ-铁素体/奥氏体界面附近奥氏体的连续动态再结晶机制如图10所示:变形过程中δ-铁素体/奥氏体界面处塞积了高密度位错(图10a),位错相互作用而形成位错墙/位错胞(图10b),位错墙/位错胞附近的位错不断重排和湮灭逐渐演变为亚晶界,亚晶界不断吸附周围位错而转变为大角度晶界(图10c),从而发生连续动态再结晶。随着应变累积,连续动态再结晶持续进行,进而形成细小的再结晶晶粒(图6e和f)。此外,铸态样品中存在原始奥氏体晶界,变形过程中同时发生以原始奥氏体晶界弓出形核的不连续动态再结晶。奥氏体不锈钢的热变形行为研究[27~29]表明,连续动态再结晶通常发生在较低温度(< 1273 K),而且需要较大的变形量,而在本工作的热变形条件下,奥氏体的动态再结晶机制为不连续动态再结晶。均质化处理态样品中发生的不连续动态再结晶与文献[12~15]报道一致;而铸态样品中存在的δ-铁素体,促进了δ-铁素体/奥氏体界面附近奥氏体的连续动态再结晶。

图8

图8

铸态样品经应变为0.36压缩变形后的EBSD晶界特征分布

Fig.8

Grain boundary map of as-cast samples with the strain of 0.36 (The black arrows indicate the newly formed high angle grain boundaries)

图9

图9

铸态样品经应变为0.36压缩变形后的TEM像及元素分布图

Fig.9

TEM bright field images (a, b) and corresponding elemental mapping (c) from the selected rectangular area indicated in Fig.9a of as-cast samples with the strain of 0.36 (Fig.9b shows the high magnification image at the lower left corner of the selected rectangular area in Fig.9a)

图10

图10

δ-铁素体/奥氏体界面处奥氏体的动态再结晶过程示意图

Fig.10

Schematics about the continuous dynamic recrystallization processes in austenite near the δ-ferrite/austenite interface

(a) dislocation pile-up at interface

(b) formation of dislocation walls/cells

(c) formation of recrystallized grain

3 结论

(1) 1323~1473 K范围内的均质化处理中,δ-铁素体向奥氏体的转变行为与合金元素的扩散有关,转变速率主要受控于Cr在奥氏体中的扩散。1473 K均质化处理14 h可基本消除δ-铁素体,同时伴随着奥氏体晶粒的显著长大。

(2) 1423 K压缩变形过程中,δ-铁素体内部、δ-铁素体/奥氏体界面处的塑性变形先于奥氏体相,较软δ-铁素体的存在,造成铸态样品的流变应力明显低于均质化处理态样品。随着变形的进行,δ-铁素体易发生动态回复,动态回复引起的软化导致流变应力显著下降。

(3) 均质化处理态样品的动态再结晶机制是以原始奥氏体晶界弓出形核的不连续动态再结晶。均质化处理引起的奥氏体晶粒显著长大,大大减少了动态再结晶的潜在形核位置。

(4) δ-铁素体的存在促进了δ-铁素体/奥氏体界面附近奥氏体的动态再结晶,其机制为连续动态再结晶。铸态样品中同时发生以原始奥氏体晶界弓出形核的不连续动态再结晶。2种动态再结晶机制的耦合作用使得铸态样品的动态再结晶程度显著高于均质化处理态样品,并造成晶粒尺寸不均匀现象。

参考文献

A review of inherent safety characteristics of metal alloy sodium-cooled fast reactor fuel against postulated accidents

[J].

Review on sodium corrosion evolution of nuclear-grade 316 stainless steel for sodium-cooled fast reactor applications

[J].

A summary of sodium-cooled fast reactor development

[J].

Type 316 austenitic steels for reactor vessel and internals in sodium fast reactors and their creep rupture properties

[J].

钠冷快堆堆容器堆内构件用316型不锈钢及其持久断裂性能

[J].

Constitution diagram for stainless steel weld metal

[J].

Ferrite in austenitic stainless steel weld metal

[J].

Weldability of nitrogen-strengthened stainless steels

[J].

δ-Ferrite formation and its effect on the mechanical properties of heavy-section AISI 316 stainless steel casting

[J].

Role of δ-ferrite in fatigue crack growth of AISI 316 austenitic stainless steel

[J].

Precipitation and hot deformation behavior of austenitic heat-resistant steels: A review

[J].The austenitic heat resistant-steels have been considered as important candidate materials for advanced supercritical boilers, nuclear reactors, super heaters and chemical reactors, due to their favorable combination of high strength, corrosion resistance, perfect mechanical properties, workability and low cost. Since the precipitation behavior of the steels during long-term service at elevated temperature would lead to the deterioration of mechanical properties, it is essential to clarify the evolution of secondary phases in the microstructure of the steels. Here, a summary of recent progress in the precipitation behavior and the coarsening mechanism of various precipitates during aging in austenitic steels is made. Various secondary phases are formed under service conditions, like MX carbonitrides, M23C6 carbides, Z phase, sigma phase and Laves phase. It is found that the coarsening rate of M23C6 carbides is much higher than that of MX carbonitrides. In order to understand the thermal deformation mechanism, a constitutive equation can be established, and thus obtained processing maps are beneficial to optimizing thermal processing parameters, leading to improved thermal processing properties of steels.

Processing maps and microstructural evolution of the type 347H austenitic heat-resistant stainless steel

[J].

Research on flow stress during hot deformation process and processing map for 316LN austenitic stainless steel

[J].

Hot working and recrystallization of as-cast 316L

[J].

Hot deformation and recrystallization of austenitic stainless steel: Part I. Dynamic recrystallization

[J].

Study on the dynamic recrystallization model and mechanism of nuclear grade 316LN austenitic stainless steel

[J].

Hot deformation behavior of 2205 duplex stainless steel

[J].<p>During hot deformation of the duplex stainless steels consisting of $\delta$--ferrite and $\gamma$--austenite, their microstructure evolution and mechanical response are more complicated as compared with those of single--phase ferritic or austenitic stainless steels, especially for study of the mechanical behavior. In the present research, the hot deformation behavior of a 2205 duplex stainless steel has been investigated through uniaxial compression test using Gleeble--3800 thermal--mechanical simulator within the temperature range of 1223---1523 K and the strain rate range of 0.01---10 s$^{-1}$, the corresponding flow curves and their characters and microstructures have been determined and analyzed. Elongated austenite distributes in ferrite matrix, and the volume fraction of ferrite increases with rising temperature. Dynamic recrystallization of austenite is enhanced by increasing temperature and decreasing strain rate. Based on the constitutive equation for hot deformation, the apparent activation energy (<em>Q</em>) and the apparent stress exponent (<em>n</em>) of the steel are obtained to be about 451 kJ/mol and 4.026, respectively. There is a particular shape of flow curves, <em>i.e</em>. a yield point elongation-like effect, which is characterized by a non-strengthening plateau during the initial stages of plastic deformation. This yield point elongation-like effect increases with decreasing Zener-Hollomon parameter, <em>Z</em>. When used a simplified stress function, a deviation of linear relationship between ln <em>Z</em> and peak stress (<em>σ</em><sub>p</sub>) occurred at the critical value (ln <em>Z</em><sub>c</sub>=38.18). Relationships between peak stress and temperature and strain rate can be more simply described as <em>σ</em><sub>p</sub>=20.6ln <em>ε</em>+1118002/<em>T</em>-266.8(ln <em>Z</em>>38.18), and <em>σ</em><sub>p</sub>=9.1ln ε+493874/<em>T</em>-701.9(ln <em>Z</em>≦38.18).</p>

2205双相不锈钢的高温变形行为

[J].

Softening behavior of 18.7Cr-1.0Ni-5.8Mn-0.2N low nickel-type duplex stainless steel during hot compression deformation under large strain

[J].It is difficult to form the precipitated phase of duplex stainless steel (DSS) with low nickel content, and a low Cr content of 18.7% (mass fraction) during hot working. However, the stability of the austenite phase changes by substituting Mn for Ni, which can increase the difference between the softening mechanisms of the two phases under high temperature and deformation conditions. Under a temperature and strain rate of 1123-1423 K and 0.1-10 s-1, respectively, the large thermal compression deformation behavior (70%) of 18.7Cr-1.0Ni-5.8Mn-0.2N DSS was investigated. The thermal deformation microstructures were analyzed by OM, SEM, and EBSD. The results show that the dynamic recrystallization (DRX) of the ferrite phase mainly occurred at a lower deformation temperature of 1123 K, and that the degree of grain refinement increased, and the degree of grain inhomogeneity decreased with an increase in strain rate. The strain rate was observed to have a large impact on the ferrite phase DRX, while the austenite phase DRX was more sensitive to deformation temperature. The ferrite phase underwent continuous dynamic recrystallization (CDRX) with the transition from low-angle to high-angle grain boundaries under deformation at 1223 K and 10 s-1, while the austenite phase was dominated by discontinuous dynamic recrystallization (DDRX) deformed at 1323 K and 0.1 s-1. DDRX can be easily induced by increasing the temperature at a low strain rate, while CDRX can be induced at a higher strain rate. The crystal orientation of the austenite phase is mainly characterized by the recrystallization texture of the (001) and (111) planes at higher temperatures and lower strain rates. In the ferrite phase, there is a competitive relationship between the recrystallization texture of the (001) and (111) planes. The critical stress (strain) was obtained by data fitting and its relationship with the peak stress (strain) was determined. As the strain increased, the flow instability domain of hot compression decreased, and the stability zone gradually moved toward higher temperature and strain rate. Furthermore, the optimum hot working conditions, 1323-1423 K and 0.01-6.05 s-1, were obtained.

18.7Cr-1.0Ni-5.8Mn-0.2N节Ni型双相不锈钢的大变形热压缩软化行为

[J].

Microstructure evolution of lean duplex stainless steel 2101 during hot deformation

[J].

节约型双相不锈钢2101高温变形过程中微观组织演化

[J].采用电子背散射衍射技术(EBSD)和TEM研究了节约型双相不锈钢2101在温度为1000℃和应变速率为5 s<sup>-1</sup>的高温变形过程中的微观组织演化. 结果表明, 铁素体和奥氏体都发生以小角度晶界不断向大角度晶界转变为特征的连续动态再结晶(CDRX).固溶退火后双相不锈钢奥氏体内出现大量退火孪晶. 随变形量增加, 奥氏体中具有Σ3位向关系的晶界逐渐消失. 高温变形过程中双相微观组织演化机制的耦合作用共同决定了流变曲线特征.

Effect of δ-ferrite co-existence on hot deformation and recrystallization of austenite

[J].

Microstructural evolution during hot deformation of duplex stainless steel

[J].The microstructure evolution during hot deformation of a 23Cr–5Ni–3Mo duplex stainless steel was investigated in torsion. The presence of a soft δ ferrite phase in the vicinity of austenite caused strain partitioning, with accommodation of more strain in the δ ferrite. Furthermore, owing to the limited number of austenite/austenite grain boundaries, the kinetics of dynamic recrystallisation (DRX) in austenite was very slow. The first DRX grains in the austenite phase formed at a strain beyond the peak and proceeded to <15% of the microstructure at the rupture strain of the sample. On the other hand, the microstructure evolution in δ ferrite started by formation of low angle grain boundaries at low strains and the density of these boundaries increased with increasing strain. There was clear evidence of continuous dynamic recrystallisation in this phase at strains beyond the peak. However, in the δ ferrite phase at high strains, most grains consisted of δ/ δ and δ/ γ boundaries.

Comparing the Johnson-Mehl-Avrami-Kolmogorov equations for isothermal and linear heating conditions

[J].

Theory of diffusion-limited precipitation

[J].

Interdiffusion of Cr, Mo, and W in iron

[J].

Necklace formation during dynamic recrystallization: Mechanisms and impact on flow behavior

[J].

δ /γ Interface bondary sliding as a mechanism for strain accommodation during hot deformation in a duplex stainless steel

[J].

Effect of silicon on the microstructure and mechanical properties of reduced activation ferritic/martensitic steel

[J].

Microstructural evolution of a 304-type austenitic stainless steel during rolling at temperatures of 773-1273 K

[J].

Hot-workability of super-304H exhibiting continuous to discontinuous dynamic recrystallization transition

[J].

Dependency of recrystallization mechanism to the initial grain size

[J].

A model of continuous dynamic recrystallization

[J].