在镁合金塑性变形过程中,动态再结晶、孪晶形核、位错密度是影响其强度及塑性的主要原因。第一,铸态AZ80镁合金在变形过程中存在控制晶粒均匀度的临界应变,当应变超过临界应变时,可获得均匀的动态再结晶晶粒,从而提高镁合金的强度及塑性[5]。AZ31、AZ61镁合金经等温多向锻造随锻造道次增加,晶粒逐渐细化、组织均匀性增强,其强度和塑性有很大提高[6,7]。AZ80镁合金等温多道次变形保温时间小于300 s时晶粒迅速长大,当保温时间大于300 s时晶粒生长速率则趋于稳定,随道次间隔保温时间延长其流变应力峰值越高,使其强度得到提升[8,9]。第二,AZ80镁合金室温多道次压缩过程中织构演变主要受{10

本工作对AZ80镁合金分别采用恒温(400℃)多道次压缩变形和阶梯降温(400、350、300℃)多道次压缩变形工艺,模拟不同路径下锻造工艺对AZ80镁合金微观组织演化的影响,旨在为实际生产提供参考。

1 实验方法

实验所用材料为商用AZ80镁合金(Al 7.9%,Zn 0.4%,Mn 0.2%,Mg余量,质量分数)铸态毛坯圆柱试件,经过360℃、16 h均质化处理后机加工成直径8 mm、长15 mm圆柱形试样,试样轴线平行于浇铸方向。采用Gleeble 3500热模拟试验机进行热压缩变形,变形速率均为

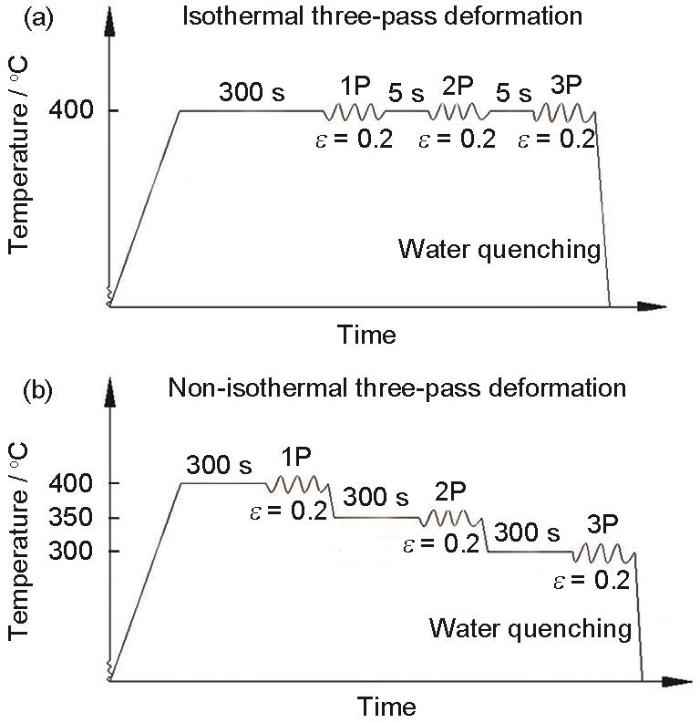

图1

图1

恒温三次变形工艺及阶梯降温三次变形工艺流程图

Fig.1

Process maps of three-step deforming process with constant-temperature (a) and three-step deforming process with step-cooling (b) (P—pass, ε—strain)

2 实验结果

2.1 晶粒形貌与尺寸演化

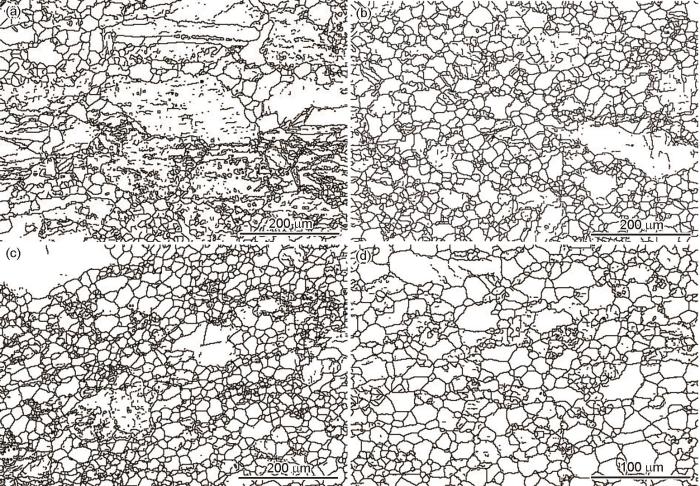

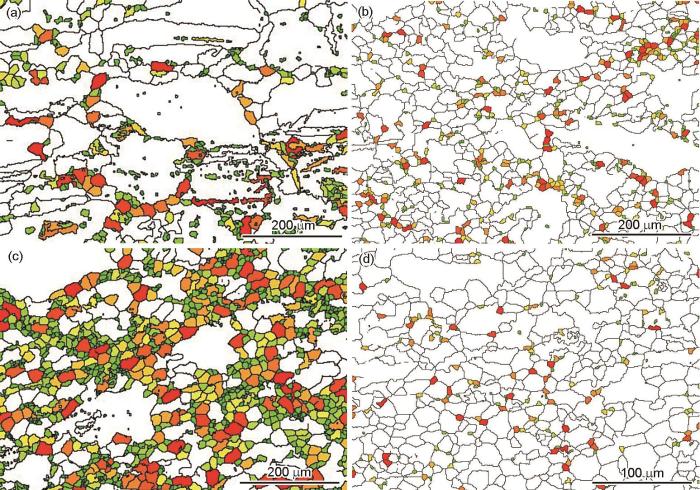

图2

图2

恒温、阶梯降温2类变形工艺的微观组织演变

Fig.2

Microstructure evolutions of constant-temperature deformation process at ε = 0.2 (a), ε = 0.4 (b), and ε = 0.6 (c); and step-cooling deformation process at ε = 0.6 (d)

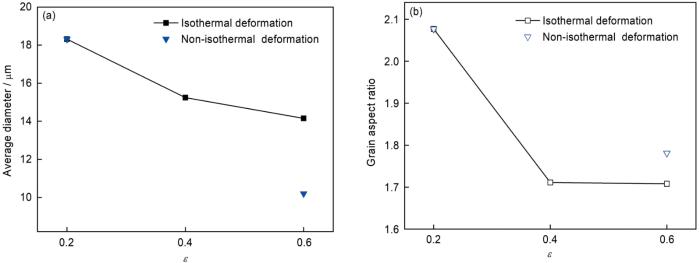

图3为恒温、阶梯降温2类变形工艺下平均晶粒尺寸和平均晶粒纵横比的定量描述(重点分析变形量ε = 0.2和0.6变形工艺)。从图3a可知,恒温多次变形平均晶粒尺寸从18.315 μm (ε = 0.2)下降到14.152 μm (ε = 0.6),而阶梯降温多次变形平均晶粒尺寸则从18.315 μm (ε = 0.2)下降到10.197 μm (ε = 0.6);从图3b可知,恒温多次变形平均晶粒纵横比从2.077 (ε = 0.2)下降到1.708 (ε = 0.6),阶梯降温多次变形平均晶粒纵横比从2.077 (ε = 0.2)下降到1.781 (ε = 0.6)。即恒温多次变形时,随变形程度增加,晶粒尺寸更加细小、晶粒形状更趋于等轴状(这与图2a~c吻合)。而阶梯降温三次变形(ε = 0.6)则比恒温三次变形(ε = 0.6)晶粒尺寸更加细小,因此本工作中300℃是AZ80镁合金晶粒细化的适宜变形温度。

图3

图3

恒温、阶梯降温2类变形工艺的平均晶粒尺寸与平均晶粒纵横比变化

Fig.3

Average grain sizes (a) and average grain shape aspect ratios (b) of constant-temperature and step-cooling deformation processes

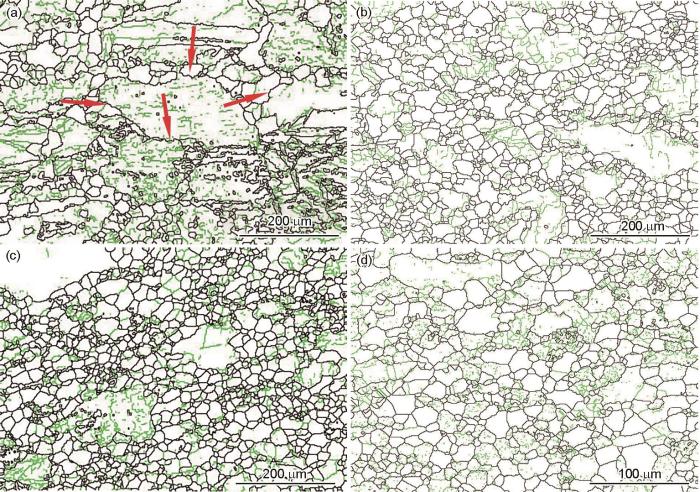

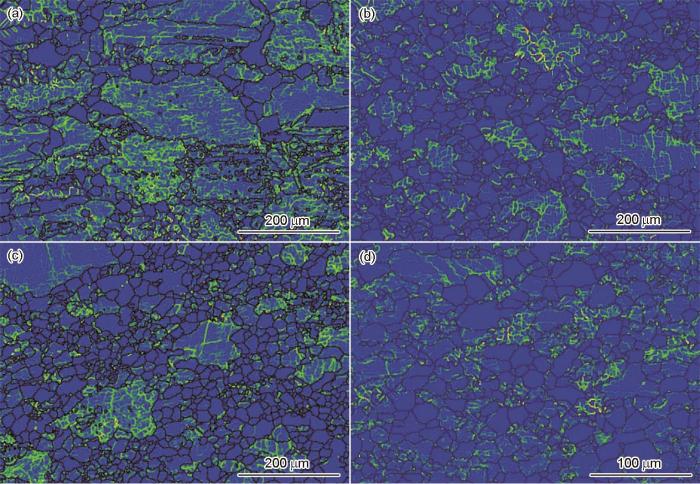

图4为恒温、阶梯降温2类变形工艺下的晶界分布图。如图4a所示,恒温变形时存在大量“弓弯”晶界(如红色箭头所示),由于压缩变形导致材料内部产生应变,进而导致晶界滑移,“弓弯”晶界成为动态再结晶的潜在形核中心[20,21]。恒温一次变形(ε = 0.2) (图4a)时,晶界和亚晶界分布不均匀,随着变形程度(ε = 0.2、0.4、0.6)增加,原始晶粒中亚晶界从晶粒内部向晶界迁移并逐渐减少,这是因为亚晶界的可动性,随着压缩变形进行亚晶界逐渐被大晶界所吞噬[22]。相比恒温三次变形(ε = 0.6) (图4c),阶梯降温三次变形(ε = 0.6) (图4d)中亚晶界数量较多并且分布不均匀,这是由于外加应力作用的结果[22]。

图4

图4

恒温、阶梯降温2类变形工艺的晶界分布

Fig.4

Grain boundaries distributions of constant-temperature deformation process at ε = 0.2 (a), ε = 0.4 (b), and ε = 0.6 (c); and step-cooling deformation process at ε = 0.6 (d) (The green lines represent subgrain boundaries, and the grain boundaries indicated by the red arrows are the bow-bend grain boundaries)

图5为恒温、阶梯降温2类变形工艺的晶粒尺寸图。可以观察到典型的“项链”结构,这通常被认为是动态再结晶的重要特征,表明恒温、阶梯降温2类变形工艺均发生了动态再结晶。

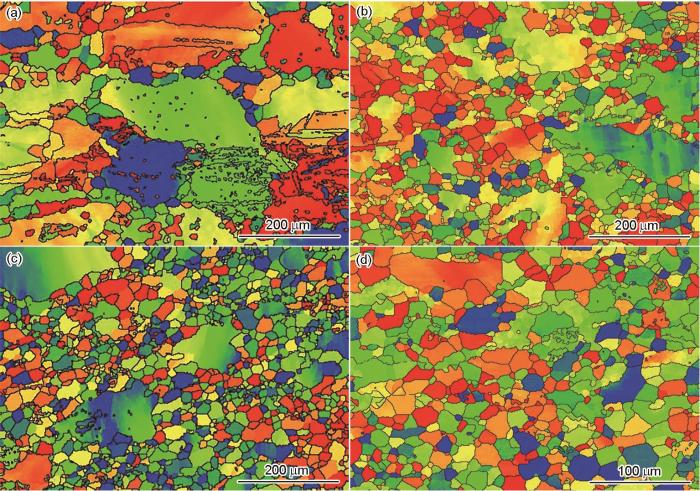

图5

图5

恒温、阶梯降温2类变形工艺的晶粒尺寸图

Fig.5

Grain size diagrams of constant-temperature deformation process at ε = 0.2 (a), ε = 0.4 (b), and ε = 0.6 (c); and step-cooling deformation process at ε = 0.6 (d) (The colored small grains are dynamically recrystallized grains, the red grains are basal orientation, and the other colored grains are non-basal orientation)

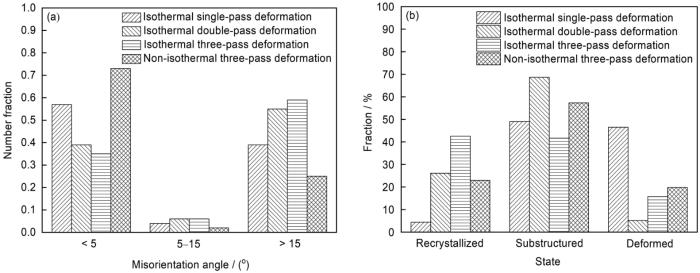

图6为恒温、阶梯降温2类变形工艺的大角度晶界(θ > 10°)、小角度晶界(θ ≤ 10°)占比图与动态再结晶占比图。如图6a所示,5°~15°范围内晶界占比最大只有6%,其占比较少,因此,本工作将重点讨论晶界取向差< 5°、> 15° 2类,不再讨论5°~15°部分。由图6a可知,恒温一次变形时小角度晶界和大角度晶界占比分别为57%和39%;恒温二次变形时2者占比分别为39%和55%;恒温三次变形时2者占比分别为35%和59%。即恒温多次变形时,随着变形程度增加,小角度晶界逐渐减少而大角度晶界逐渐增加。与恒温三次变形相比,阶梯降温三次变形时,小角度晶界和大角度晶界占比分别为73%和25%,即小角度晶界增加而大角度晶界减小。

图6

图6

恒温、阶梯降温变形2类工艺晶界占比图与动态再结晶占比图

Fig.6

Grain boundary ratios (a) and dynamic recrystallization ratios (b) of constant-temperature and step-cooling deformation processes

图7为恒温、阶梯降温2类变形工艺的取向差图。在图中“Correlated”表示相邻晶粒取向差分布,“Uncorrelated”表示不相邻晶粒取向差分布,“Rondom”表示随机或理论取向差分布。由图7a可知,恒温一次变形后,相邻晶粒取向差呈“双峰”分布,分别在2°和86°左右出现峰值。如图7b~d可知,分别在2°、30°和86°左右出现了峰值,但取向差在2°左右的峰值仍然比较高,这是由于压缩变形所致,同时取向差在30°左右出现峰值,这是由于六方结构的六次对称轴限制,2个理想(0001)晶粒间最大取向差是30°,转角为<0001>[24]。由图7a~d知,2种工艺均在86°左右出现峰值,表明恒温、阶梯降温2类变形工艺均存在{10

图7

图7

恒温、阶梯降温变形工艺下的取向差统计图

Fig.7

Misorientation distributions of constant-temperature deformation process at ε = 0.2 (a), ε = 0.4 (b), and ε = 0.6 (c); and step-cooling deformation process at ε = 0.6 (d)

2.2 位错密度演化

为了定量研究不同变形工艺下位错密度演化,利用EBSD取向数据的局部取向差计算几何必需位错密度(ρGND)演化规律,采用核平均取向差(KAM)方法[17]:

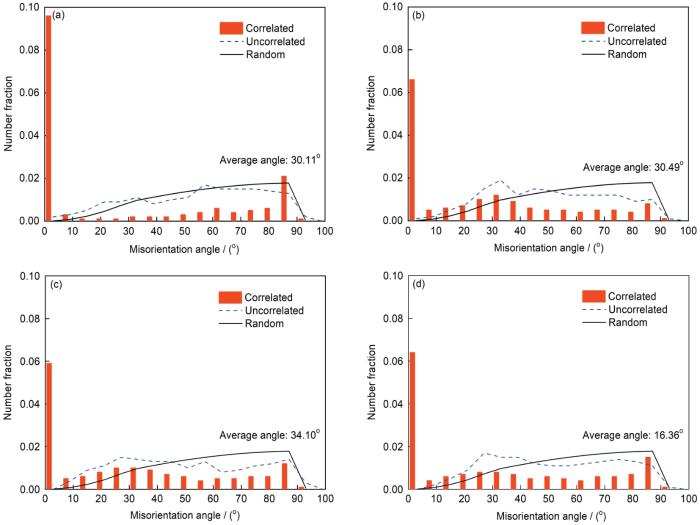

图8

图8

恒温、阶梯降温2类变形工艺的几何必需位错密度分布图

Fig.8

Geometrically necessary dislocation (GND) density distribution maps of constant-temperature deformation process at ε = 0.2 (a), ε = 0.4 (b), and ε = 0.6 (c); and step-cooling deformation process at ε = 0.6 (d) (The green is the dislocation concentration area, and the blue is the dislocation-free area)

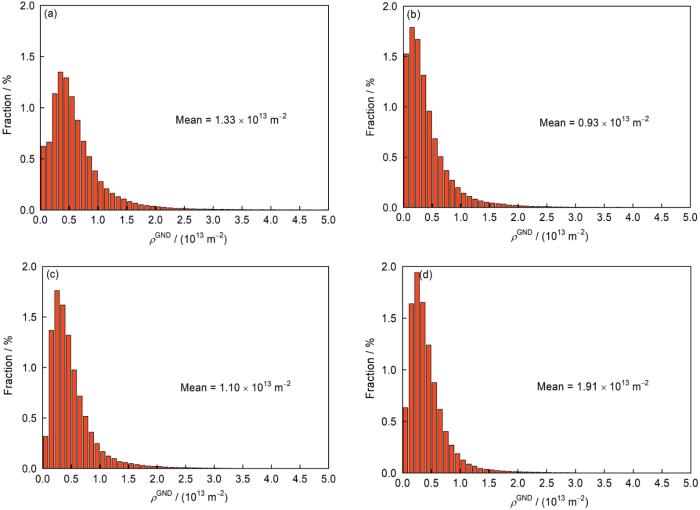

图9

图9

恒温、阶梯降温变形工艺的几何必需位错密度(ρGND)统计图

Fig.9

Geometrical necessary dislocation density (ρGND) statistical maps of constant-temperature deformation process at ε = 0.2 (a), ε = 0.4 (b), and ε = 0.6 (c); and step-cooling deformation process at ε = 0.6 (d)

2.3 Schmid因子变化

图10

图10

恒温、阶梯降温变形工艺的Schmid因子分布图

Fig.10

Schmid factor distribution maps of constant-temperature deformation process at ε = 0.2 (a), ε = 0.4 (b), and ε = 0.6 (c); and step-cooling deformation process at ε = 0.6 (d) (The blue is hard orientation, the red is soft orientation, and other colors are between hard orientation and soft orientation)

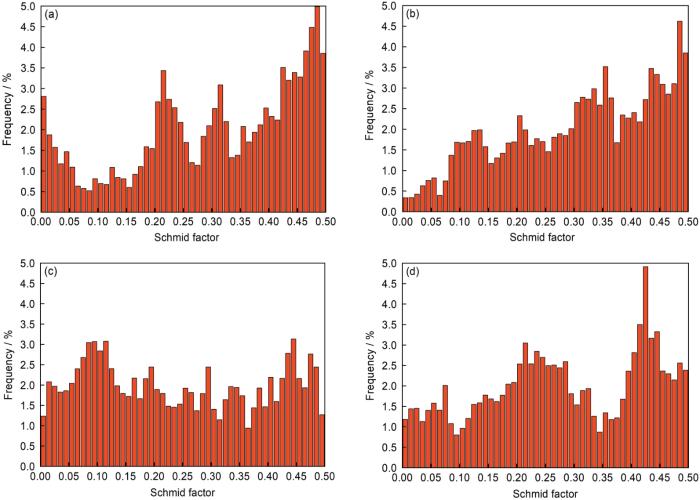

图11

图11

恒温、阶梯降温变形工艺的Schmid因子分布直方图

Fig.11

Schmid factor statistical maps of constant-temperature deformation process at ε = 0.2 (a), ε = 0.4 (b), and ε = 0.6 (c); and step-cooling deformation process at ε = 0.6 (d)

如图11所示,当Schmid因子从0到0.5变化时,晶体由硬取向向软取向转变。恒温一次变形(ε = 0.2)、恒温二次变形(ε = 0.4)的Schmid因子分布并不均匀,主要集中在0.2~0.5之间,以软取向为主导,而恒温三次变形(ε = 0.6)的Schmid因子变得更均匀,大部分集中在0.1左右,以硬取向为主导,即经过恒温多次变形后材料中出现明显“加工硬化”现象(图11c)。由图11d知,阶梯降温三次变形(ε = 0.6)Schmid因子主要集中在“中间部分”(0.2~0.3之间) (与图10情况一致),表明阶梯降温三次变形并未出现很强烈的“加工硬化”现象,而是介于软化与加工硬化之间,故阶梯降温三次变形(ε = 0.6)比恒温三次变形(ε = 0.6)更有利于塑性变形。

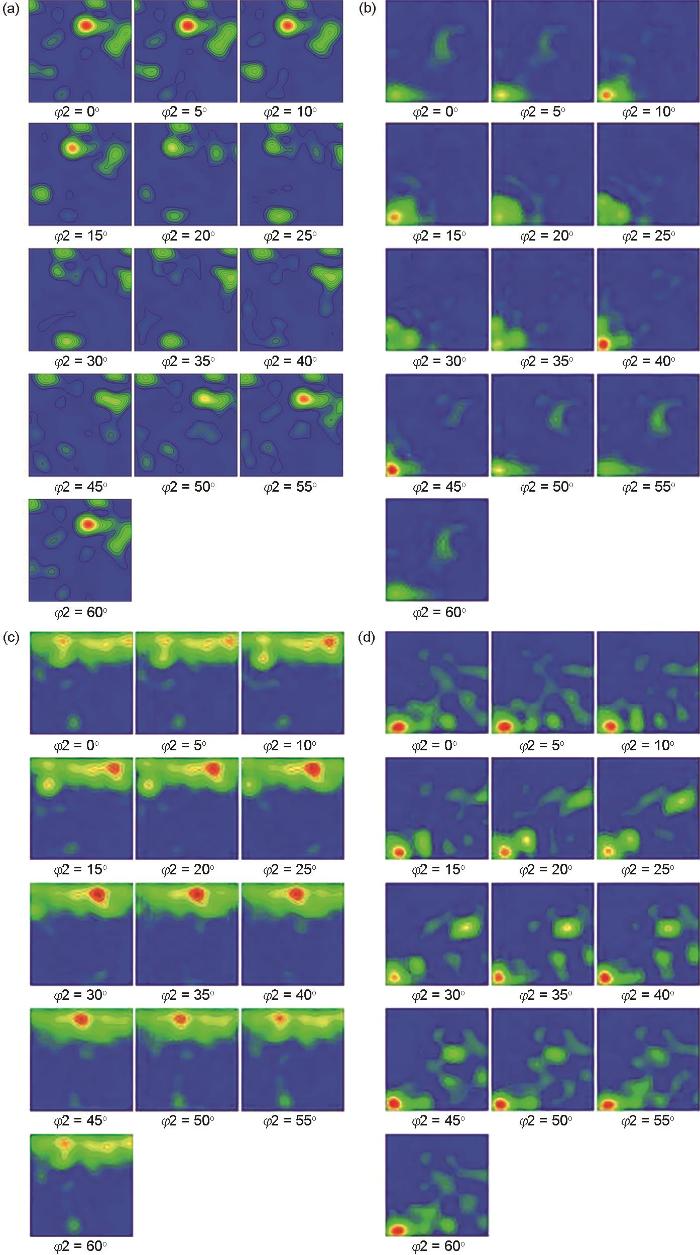

2.4 变形过程中织构演化

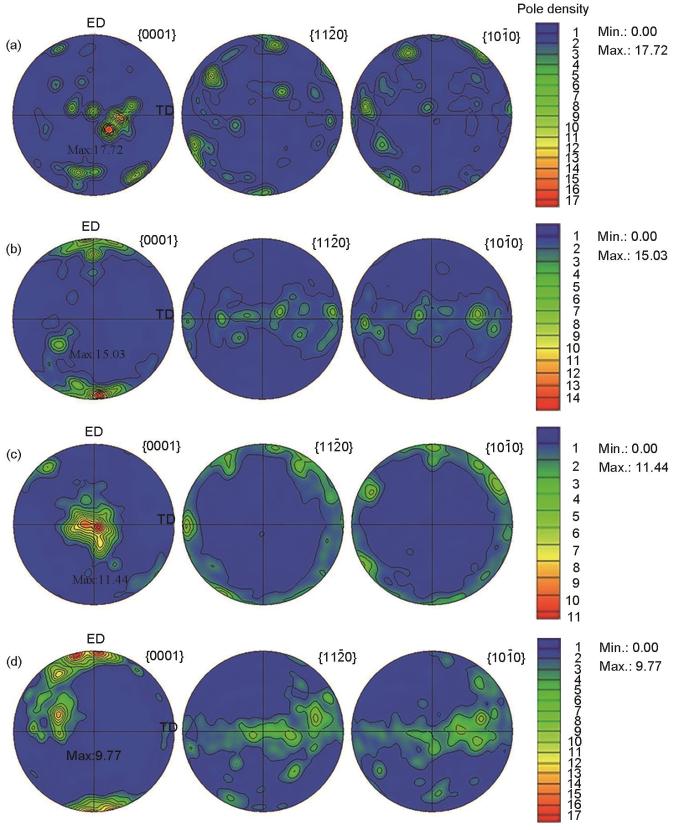

图12给出了恒温、阶梯降温2类变形工艺的织构演化过程。恒温一次变形(ε = 0.2)极密度最大为17.72 (图12a),恒温二次变形(ε = 0.4)极密度最大为15.03 (图12b),恒温三次变形(ε = 0.6)极密度最大为11.44 (图12c)。即恒温三次变形时,随变形程度(ε = 0.2、0.4、0.6)增加极密度逐渐减小,这是由于随着变形程度增加,再结晶程度不断增加而导致基面织构弱化。而阶梯降温三次变形(ε = 0.6)时,基面(0001)织构极密度最大为9.77 (图12d),相比于恒温三次变形,阶梯降温三次变形(ε = 0.6)极密度变得更小,这是因为拉伸孪晶增加(图7),织构得到弱化使塑性提升,这与文献[11]吻合。

图12

图12

恒温、阶梯降温2类变形工艺的极图

Fig.12

Pole figures of constant-temperature deformation process at ε = 0.2 (a), ε = 0.4 (b), and ε = 0.6 (c); and step-cooling deformation process at ε = 0.6 (d) (ED—extrusion direction, TD—transverse direction)

图13

图13

恒温、阶梯降温2类变形工艺的取向分布函数(ODF)图

Fig.13

Orientation distribution function (ODF) maps of constant-temperature deformation process at ε = 0.2 (a), ε = 0.4 (b), and ε = 0.6 (c); and step-cooling deformation process at ε = 0.6 (d) (The red area is strong texture, the blue area is weak texture, and the texture intensity of the green area is between them; φ2—Euler angle)

3 分析讨论

3.1 多道次压缩变形镁合金织构演变

由图12和13可知,恒温三次变形时,随变形程度(ε = 0.2、0.4、0.6)增加,不仅极密度逐渐减小,而且织构类型也发生转变:基面织构→柱面织构→基面织构(见2.4节),但阶梯降温三次变形(ε = 0.6)主要是柱面织构,其主要原因是:(1) 动态再结晶的影响(图6)。经过不同路径压缩变形均伴随着动态再结晶的发生,而这会弱化基面织构。(2) 晶粒细化的影响。晶粒细化导致晶粒转动和晶界迁移更加容易,随着晶粒不断转动,使晶粒的取向发生变化(图2)。(3) GND密度的影响(图9)。阶梯降温三次变形(ε = 0.6)较恒温三次变形(ε = 0.6)的GND密度急剧增大,GND密度的升高阻碍孪晶生长和晶粒间旋转移动[19,26],使晶粒取向不易发生变化,因此阶梯降温三次变形主要为柱面织构。(4) 孪晶的影响(图7)。孪晶可以改变晶粒取向,阶梯降温三次变形(ε = 0.6)比恒温三次变形(ε = 0.6)产生更多86°{10

3.2 晶界演化对孪晶的影响

孪晶能促使织构转变,而孪晶的形成主要受晶粒取向差、小角度晶界数量、GND密度3方面的影响。

(1) 晶粒取向差对孪晶形成的影响。晶粒取向差对孪晶影响主要表现在“是否能够增强晶界迁移能力(晶界迁移与晶界结构密切相关)”进而有利于孪晶形成。本工作中,恒温三次变形(ε = 0.6)、阶梯降温三次变形(ε = 0.6)局部晶粒取向差平均值分别为34.10°和16.36°,根据小角度晶界迁移阻力

因此,阶梯降温三次变形(ε = 0.6)比恒温三次变形(ε = 0.6)出现更多孪晶主要原因是:(1) 低晶粒取向差使晶界迁移能力增强,从而促进孪晶形成;(2)小角度晶界增多使亚结构区增大,从而为孪晶形成提供能量;(3) GND密度增加使孪晶生长受阻,从而为孪晶形成提供空间。这样,阶梯降温三次变形(ε = 0.6)在3者共同作用下促使孪晶增多,从而改善了镁合金塑性。

3.3 塑性调控机理

根据2.4节变形过程中Schmid因子变化,恒温三次变形(ε = 0.6) Schmid因子表现为“硬化现象”(在0.1左右),而阶梯降温三次变形(ε = 0.6) Schmid因子介于“软化与硬化之间(0.2~0.3)”,即阶梯降温三次变形比恒温三次变形更有利于塑性变形,其主要原因是:(1) 恒温三次变形、阶梯降温三次变形的平均晶粒尺寸分别为14.152和10.197 μm,阶梯降温三次变形的晶粒更细小,即单位体积内晶粒更多,因此压缩变形时相同变形程度可分散到更多晶粒产生较均匀形变而不会引起裂纹过早形核与扩展。(2) 由于阶梯降温三次变形通过“晶粒取向差减小、小角度晶界增加、GND密度增加”3者共同作用,产生更多86°{10

综上,“晶粒尺寸、孪晶、织构3者综合作用”对AZ80塑性的调控明显优于“单一动态再结晶”对其塑性调控。

4 结论

(1) 恒温三次变形更有利于动态再结晶。恒温多道次变形随变形程度(ε = 0.2、0.4、0.6)增加,小角度晶界逐渐减少,大角度晶界逐渐增加;而阶梯降温多次变形随变形程度(ε = 0.2、0.4、0.6)增加,小角度晶界逐渐增多,大角度晶界减少,因此恒温三次变形(ε = 0.6)更有利于动态再结晶,而阶梯降温三次变形(ε = 0.6)则不利于动态再结晶。

(2) 阶梯降温三次变形(ε = 0.6)工艺更有利于塑性变形。主要原因是阶梯降温三次变形(ε = 0.6) 比恒温三次变形(ε = 0.6)晶粒尺寸更细小且产生更多孪晶,阶梯降温三次变形(ε = 0.6)主要为非基面织构(柱面织构),而恒温三次变形(ε = 0.2、0.4、0.6)过程中织构类型发生转变(基面织构→柱面织构→基面织构)。

(3) 晶粒取向差减小、小角度晶界增多、几何必需位错密度增加是导致阶梯降温三次变形(ε = 0.6)出现更多86°{10

参考文献

Review on research and development of magnesium alloys

[J].

Study on the dynamic recrystallization softening behavior of AZ80 magnesium alloy

[J].Magnesium alloys are considered as one of the lightest structural metallic materials with excellent properties such as high specific strength, superior damping characteristics and electromagnetic shielding performance. In order to improve the mechanical properties of magnesium alloys, the hot rolling, hot extrusion and other hot forming processes are often introduced to produce the high performance parts. Both of the two softening mechanisms, dynamic recovery and dynamic recrystallization (DRX), occur during the hot deformation. As an important softening mechanism in hot processing, DRX is beneficial to obtaining fine grains structure, eliminating defects and improving mechanical properties for magnesium alloys. In this work, isothermal compression tests of AZ80 magnesium alloy were conducted on Gleeble thermo-mechanical simulator in the temperature range of 200 to 400 ℃ and strain rate range of 0.001 to 1 s-1. In view of the dynamic hardening and softening mechanisms, the softening behavior of AZ80 magnesium alloy, dominated by dynamic recrystallization, was depicted. Dynamic recrystallization volume fraction was introduced to reveal the power dissipation during the microstructural evolution which was indicated by the strain rate sensitivity value based on the dynamic material model. To quantify the dynamic recrystallization softening behavior by the strain rate sensitivity (SRS) value, the SRS value distribution maps were constructed depending on various temperatures and strain rates. Therefore, the critical conditions and evolution process were studied in terms of temperatures and strain rates, while features of the SRS value distribution maps at different strains were deeply investigated. It can be concluded that the value of dynamic recrystallization critical condition decreases and dynamic recrystallization volume fraction increases when the temperature increases and strain rate decreases during the deformation. The strain rate sensitivity was positive correlated with the dynamic recrystallization volume fraction. It has been verified effectively by the analysis of microstructure that the region in which the strain rate sensitivity value is above 0.21 corresponds to the higher dynamic recrystallization volume fraction and lower strain rate.

AZ80镁合金动态再结晶软化行为研究

[J].

First-principles data for solid-solution strengthening of magnesium: From geometry and chemistry to properties

[J].

The post-deformation recrystallization behaviour of magnesium alloy Mg-3Al-1Zn

[J].

Grain refinement in as-cast AZ80 Mg alloy under large strain deformation

[J].

Microstructures and mechanical properties of AZ61 magnesium alloy after isothermal multidirectional forging with increasing strain rate

[J].

Microstructure and mechanical properties of SPD-processed an as-cast AZ91D+Y magnesium alloy by equal channel angular extrusion and multi-axial forging

[J].

Effects of holding time and Zener-Hollomon parameters on deformation behavior of cast Mg-8Gd-3Y alloy during double-pass hot compression

[J].Double-pass hot compression tests were carried out over a wide range of holding time (0-180 s) and Zener-Hollomon parameter (1.6E15-1.3E20) to study the deformation behavior of cast Mg-8Gd-3Y alloy. The flow curves show obvious work hardening and strain softening stages, leading to the peak stress of double-pass hot compression. Holding time and Zener-Hollomon parameter can significantly affect the second pass peak stress. It is found that increasing the holding time can cause a higher peak stress in the second pass deformation. The second pass stress reaches the peak stress of 71 MPa at Zener-Hollomom parameter of 1.6E15. When the parameter rises to 1.3E20, the second pass peak goes up to 237 MPa. In addition, the second pass peak stress is significantly higher than the unloading stress, which is opposite to the flow behavior of aluminum alloys. Residual stored deformation energy caused by the first pass deformation could be consumed by metadynamic recrystallization. Therefore, more strain energy is required for subsequent dynamic recrystallization, resulting in hardening behavior. A hardening fraction is defined to describe the deformation behavior quantitatively, which shows a positive correlation with the metadynamic recrystallization fraction. The metadynamic recrystallization leads to grain growth at the inter pass holding stage, diminishing dynamic recrystallization nucleation positions in the second pass deformation.

Grain growth model of ultra-fine grain AZ80 magnesium alloy multi-directionally forged during the isothermal heating process

[J].

Microstructure and texture evolution of AZ31 Mg alloy processed by multi-pass compressing under room temperature

[J].

AZ31镁合金室温多道次压缩过程微观组织和织构演变的研究

[J].对AZ31镁合金在室温进行多道次压缩变形,利用EBSD技术研究其微观组织和织构演变,分析孪晶在细化晶粒和调控织构方面发挥的作用。结果表明:多道次压缩过程中的组织和织构演变主要受{101ˉ2}拉伸孪生影响,道次应变量越大,织构变化越明显,每道次压缩后,利于拉伸孪生的晶粒取向发生孪生转到压缩轴附近,从而弱化初始基面织构,而退孪晶的发生则不利于细化晶粒和弱化织构。在多道次压缩过程中,孪生Schmid准则支配着变形中的{101ˉ2}孪晶变体的选择,从而控制织构的演变。残留的基体、预变形产生的孪晶与后续变形中产生的孪晶片层相互交叉,分割细化晶粒;道次变形量会影响多向变形过程每道次孪晶的激活量和孪晶片层的形貌,从而影响晶粒的细化程度。

Effect of texture on deformation mechanism of AZ31 Magnesium alloy warm compression

[J].

织构对AZ31镁合金温热压缩变形机制影响

[J].

Strain path dependent evolutions of microstructure and texture in AZ80 magnesium alloy during hot deformation

[J].

Fabrication of high-strength AZ80 alloys via multidirectional forging in air with no need of ageing treatment

[J].

Twinning in magnesium alloy AZ31B under different strain paths at moderately elevated temperatures

[J].

Deformation behaviors and cyclic strength assessment of AZ31B magnesium alloy based on steady ratcheting effect

[J].

Constitutive modeling for the dynamic recrystallization evolution of AZ80 magnesium alloy based on stress-strain data

[J].

Mechanical properties of copper/bronze laminates: Role of interfaces

[J].

Effects of cooperative grain boundary sliding and migration on the particle cracking of fine-grained magnesium alloys

[J].

Nucleation and propagation of {10

Microstructural aspects of grain boundary bulge in a dynamically recrystallized Mg-Al-Zn alloy

[J].

High-temperature tensile deformation behavior and microstructure evolution of Ti55 titanium alloy

[J]

Experimental observations of stress-driven grain boundary migration

[J].In crystalline materials, plastic deformation occurs by the motion of dislocations, and the regions between individual crystallites, called grain boundaries, act as obstacles to dislocation motion. Grain boundaries are widely envisaged to be mechanically static structures, but this report outlines an experimental investigation of stress-driven grain boundary migration manifested as grain growth in nanocrystalline aluminum thin films. Specimens fabricated with specially designed stress and strain concentrators are used to uncover the relative importance of these parameters on grain growth. In contrast to traditional descriptions of grain boundaries as stationary obstacles to dislocation-based plasticity, the results of this study indicate that shear stresses drive grain boundaries to move in a manner consistent with recent molecular dynamics simulations and theoretical predictions of coupled grain boundary migration.

Microstructure evolution during high cycle fatigue in Mg-6Zn-1Mn alloy

[J].

Texture investigation on the deformation mechanisms in magnesium alloy AZ31 deformed at high temperatures

[J].Deformation mechanisms of a magnesium alloys AZ31 deformed at high temperature in the presence of dynamic recrystallization and super-plasticity are investigated by texture analysis using X-ray diffraction and electron back scattering diffraction techniques. Results indicate that deformation by plastic slip inside grains still plays an important role due to the facts that preferred orientations are found in recrystallized grains and that some strongly elongated deformed grains are present in samples. Difference in texture can be detected in the new grains of samples with different initial textures and different slip mechanisms are ascribed to the elongated deformed grains in different samples. The improved plasticity due to increasing temperature in deformed grains with same orientation is discussed. Orientation mapping reveals a misorientation distribution of large amount of small angle grain boundaries and an orientation relationship of 30°<0001> among basal oriented grains which is due to the 6-fold crystallographic symmetry of hexagonal close-packed structure of magnesium.

镁合金AZ31高温形变机制的织构分析

[J].