颗粒增强金属基复合材料(MMC)表现出比传统金属材料更高的比强度、比模量和高温性能[1]。合适的陶瓷颗粒增强体可以同时提高金属材料强度和塑性。Huo等[2]通过放电等离子烧结(SPS)技术成功制备了(TiC + Ti5Si3)/Ti复合材料,其最大屈服强度可达829 MPa,比纯Ti提高178%。Jiao等[3]报道了具有层状结构的多层石墨烯增强的Cu-Al-Mn复合材料表现出优越的拉伸性能,其抗拉强度和断裂应变分别高达913.3 MPa和13.4% (分别是原始Cu-Al-Mn合金的2.5倍和4.1倍)。MMC不仅可以减轻材料重量,还可以提高材料服役温度,能够满足航空航天关键零部件,如压气机叶片、筒式接收器、热保护部件等复杂服役环境的要求。其中钛基复合材料已成功应用于航空发动机压气机叶片[4,5]。

TiAl合金因其低密度、高比强度且耐高温蠕变的特点,在高温环境下具有广阔的应用前景,尤其在航空航天领域应用广泛[6,7]。在650~750℃,γ-TiAl合金已成功取代镍基高温合金应用于GEnx涡轮发动机的低压涡轮叶片[8]。但是,航空航天工业的快速发展对发动机提出了更高的服役需求,可以在800~900℃下使用的高温结构材料越来越重要[9]。因此,提高服役温度和高温力学性能是TiAl合金的一个研究热点。通过原位自生和外加法向TiAl合金中引入陶瓷增强相是提高其高温性能的有效途径之一,原位自生法解决了增强体与TiAl基体界面反应的问题,可以实现增强体体积分数、尺寸、分布以及形态控制,进而大幅度提升其增强效果[10~12]。Fang等[10]报道了一种具有多尺度增强相的Ti-47Al-2Cr-2Nb (原子分数,%,下同)复合材料,其抗拉强度在850℃达到541 MPa,断裂应变保持在8.9%。Guo等[12]利用感应凝壳熔炼技术成功制备了纳米Y2O3增强的Ti-48Al-2Cr-2Nb合金,高温下抗拉强度和断裂应变同时提高,其在850℃抗拉强度和断裂应变分别为587 MPa和23%。本团队前期工作[13~15]已采用SPS技术成功制备出微纳米Ti2AlC颗粒增强全片层TiAl复合材料,微纳米Ti2AlC颗粒在α2和γ板条界面原位析出,显著提高了复合材料的室温抗压强度、室温摩擦磨损性能、高温抗压强度和抗氧化性能。与传统微米级大颗粒增强相比,微纳米颗粒由于在高温下阻碍位错运动,促进变形孪晶形核,因此可以同时提高金属材料高温下的强度和塑性,有望大幅度提高高温结构材料服役温度。微纳米Ti2AlC颗粒增强TiAl复合材料展现出极大的应用潜力,有望进一步突破TiAl合金性能极限,扩展其高温应用范围。然而,关于宏观片层组织对微纳米Ti2AlC颗粒增强TiAl复合材料高温性能的影响,尤其是有关高温拉伸性能的研究尚未见报道,微纳米颗粒在复合材料高温拉伸变形中的作用机制仍不清晰,尚需进一步研究。基于上述问题,本工作通过控制烧结温度(1250~1350℃),分别获得近片层、细小全片层和粗大全片层组织,同时在片层间引入微纳米Ti2AlC颗粒增强相,研究不同组织Ti2AlC/TiAl复合材料在800和850℃时的拉伸断裂行为,系统分析了微纳米颗粒在高温拉伸变形中的作用机制,进一步为微纳米颗粒增强TiAl复合材料的设计、制备和应用提供参考依据。

1 实验方法

采用Ti-48Al-2Nb-2Cr预合金粉末(粒径53~150 μm),利用机械球磨法将不同含量(0.1%、0.3%、0.5% 和1.0%,质量分数)的氧化石墨烯(GO)与TiAl粉混合,QM3SP4球磨机转速为300 r/min,球磨时间为360 min。然后将混合均匀的混合粉末装填入内径30 mm、外径70 mm的石墨模具中,利用LABOX-650F SPS设备在1250~1350℃、烧结压力45 MPa条件下烧结,其中升温速率100℃/min,并在目标温度保温5 min,烧结过程中采用IR-AH高温红外测温仪进行温度测量,红外光束距离样品中心约5 mm,故样品实际温度应高于测量温度。在烧结过程中,GO随着烧结温度升高逐渐分解并以C原子形式扩散进入TiAl基体。由于C在γ相中的固溶度极低,烧结温度达到γ单相区时,在γ等轴晶的边界处形成初生Ti2AlC颗粒。然而,由于C在α相中的固溶度高于γ相,因此在保温阶段,残余C进一步在基体中溶解。在随后的快速冷却过程中,显微组织演变为α→α + γ→片层(α2 + γ),同时从α2/γ相界面原位析出微纳米Ti2AlC颗粒。烧结结束后,通过程序控温以100℃/min冷却速率降温至800℃,随后停止加热程序,利用循环水快速冷却至室温。最终获得直径30 mm、高度15 mm的烧结体。采用同样的方法在1300℃对Ti-48Al-2Nb-2Cr合金进行烧结,作为对照试样。

高温拉伸实验在MTS 370.10试验机上进行,实验温度分别为800和850℃,应变速率为0.0001 s-1。利用线切割机在烧结试样中心部位切取拉伸试样,试样具体尺寸为:宽度6 mm,厚度2 mm,总长28 mm,试样有效标距为15 mm。高温拉伸实验结束后,立即取下试样进行淬火,以保留高温组织便于观察。每个温度下每个样品分别进行2次拉伸测试,测试前用砂纸对样品进行机械研磨至1000号。

在室温下,利用激发波长为532 nm的LabRAM HR Evolution激光Raman光谱仪研究烧结后复合材料中是否有GO残留,激光扫描范围为200~3000 cm-1。采用MPS30金相显微镜(OM)、SU8010扫描电子显微镜(SEM)和F200C透射电子显微镜(TEM)对Ti-48Al-2Nb-2C合金和复合材料的烧结组织、增强相、高温拉伸断口和断裂侧面组织进行观察。在进行组织观察前,先利用金相砂纸机械研磨试样至2000号,然后对试样进行机械抛光处理,随后在Kroll试剂(5%HF + 5%HNO3 + 90%H2O,体积分数)中腐蚀样品,腐蚀时间为6~10 s。利用Nano Measurer 1.2软件对烧结组织的片层团和片层间距进行了统计,统计数量均在100以上。

2 实验结果与讨论

2.1 初始组织

图1

图1

1300℃烧结TiAl合金及不同温度烧结添加0.5%氧化石墨烯(GO)的Ti2AlC颗粒增强TiAl复合材料微观组织的OM像

Fig.1

OM images of TiAl alloy sintered at 1300oC (a) and Ti2AlC reinforced TiAl composites with 0.5%GO addition sintered at 1250oC (b), 1300oC (c), and 1350oC (d) (GO—graphene oxide)

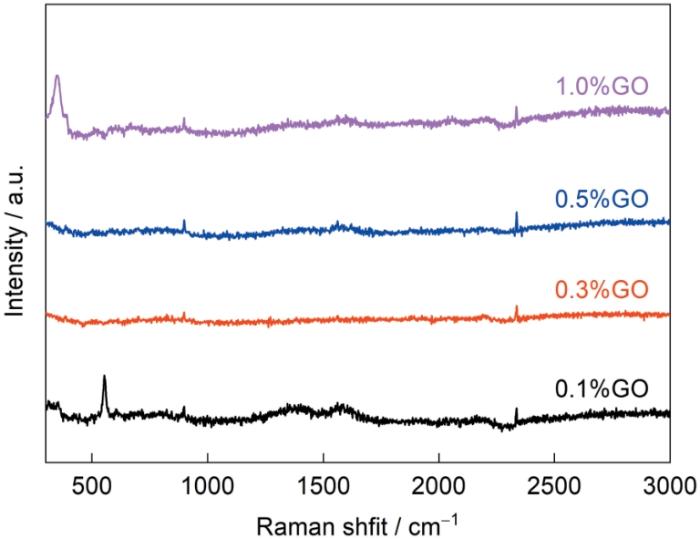

图2为1300℃烧结TiAl合金及不同温度烧结添加0.5%GO的Ti2AlC颗粒增强TiAl复合材料微观组织的SEM像。1300℃烧结TiAl合金为α2相和γ相全片层组织,如图2a所示。Ti2AlC颗粒增强TiAl复合材料中有大量白色微纳米颗粒析出,这是GO与TiAl合金基体通过原位反应生成的碳化物,形成的碳化物均匀弥散分布于α2相和γ相之间,如图2b~d所示。C原子在TiAl合金中的溶解度较低(< 0.1%,原子分数),当基体中C原子达到极限固溶度时,相应的碳化物会通过原位反应析出,C与TiAl合金通常反应生成TiC和Ti2AlC等碳化物,当温度低于1000℃时碳化物主要以TiC为主,当温度高于1200℃时碳化物则主要以Ti2AlC为主[15,17~19]。SEM观察表明复合材料中析出相尺寸、形貌和分布特点单一,应该为单一的碳化物。对添加不同含量GO的复合材料1300℃烧结样品进一步进行了Raman光谱测试,结果如图3所示。可以看出,没有出现相应的GO和其他碳化物峰,因此,可以推测GO与TiAl合金完全反应生成100%Ti2AlC。烧结过程中形成的碳化物将有效抑制晶粒长大,产生细晶强化效果,提高合金的力学性能。

图2

图2

1300℃烧结TiAl合金及不同温度烧结添加0.5%GO的Ti2AlC颗粒增强TiAl复合材料微观组织的SEM像

Fig.2

SEM images of TiAl alloy sintered at 1300oC (a) and Ti2AlC reinforced TiAl composites with 0.5%GO addition sintered at 1250oC (b), 1300oC (c), and 1350oC (d)

图3

图3

1300℃烧结添加不同含量GO的Ti2AlC颗粒增强TiAl复合材料的Raman光谱

Fig.3

Raman spectra for Ti2AlC reinforced TiAl composites with different GO additions sintered at 1300oC

为了进一步研究GO与TiAl合金在烧结过程中原位生成的微纳米析出相,选取1300℃烧结添加0.5%GO的复合材料进行了TEM表征,结果如图4所示。图4a为明场(BF)模式下1300℃烧结添加0.5%GO复合材料的TEM像。图4b和b1分别为图4a中标记区域的高分辨透射电镜(HRTEM)像和相应的快速Fourier变化(FFT)花样,标定结果表明微纳米颗粒为Ti2AlC相,与前期研究结果[15]一致。此外,通过进一步分析发现,在片层间原位析出的Ti2AlC相与γ-TiAl界面的取向关系服从[2

图4

图4

1300℃烧结添加0.5%GO的Ti2AlC颗粒增强TiAl复合材料的TEM表征

Fig.4

TEM characterizations of Ti2AlC reinforced TiAl composites with 0.5%GO addition sintered at 1300oC

(a) bright field TEM image

(b, b1) HRTEM image marked in Fig.4a (b) and corresponding fast Fourier transform (FFT) pattern of square area in Fig.4b (b1)

(c, c1) HRTEM image marked in Fig.4a (c) and corresponding FFT pattern of square area in Fig.4c (c1) (T—twin)

根据图1和2,分别对1300℃烧结TiAl合金及在不同温度烧结添加0.5%GO的Ti2AlC颗粒增强TiAl复合材料的平均片层团尺寸和片层间距进行了统计,结果如图5所示。可以看出,烧结温度低于1350℃时,随着微纳米尺度Ti2AlC颗粒的弥散析出,平均片层团尺寸显著减小,如1300℃烧结的TiAl合金和添加0.5%GO的Ti2AlC颗粒增强TiAl复合材料的平均片层团尺寸分别为345.15和182.95 μm,这主要是因为烧结过程中Ti2AlC颗粒的析出阻碍了晶界迁移和晶粒长大。除此之外,随着烧结温度的升高,添加0.5%GO的Ti2AlC/TiAl复合材料的平均片层团尺寸显著增大,表明较高的烧结温度为晶界迁移提供了更多的能量,导致晶粒快速长大[21]。而Ti2AlC增强相和烧结温度并未对添加0.5%GO的Ti2AlC/TiAl复合材料片层间距产生明显影响,这是因为片层间距主要与烧结结束后的冷却速率有关[14]。

图5

图5

1300℃烧结TiAl合金及不同温度烧结添加0.5%GO的Ti2AlC颗粒增强TiAl复合材料的片层团尺寸及片层间距的统计结果

Fig.5

Statistical results of lamellar colony size and lamellar space for TiAl alloy sintered at 1300oC and Ti2AlC reinforced TiAl composites with 0.5%GO addition sintered at different temperatures

2.2 高温拉伸性能

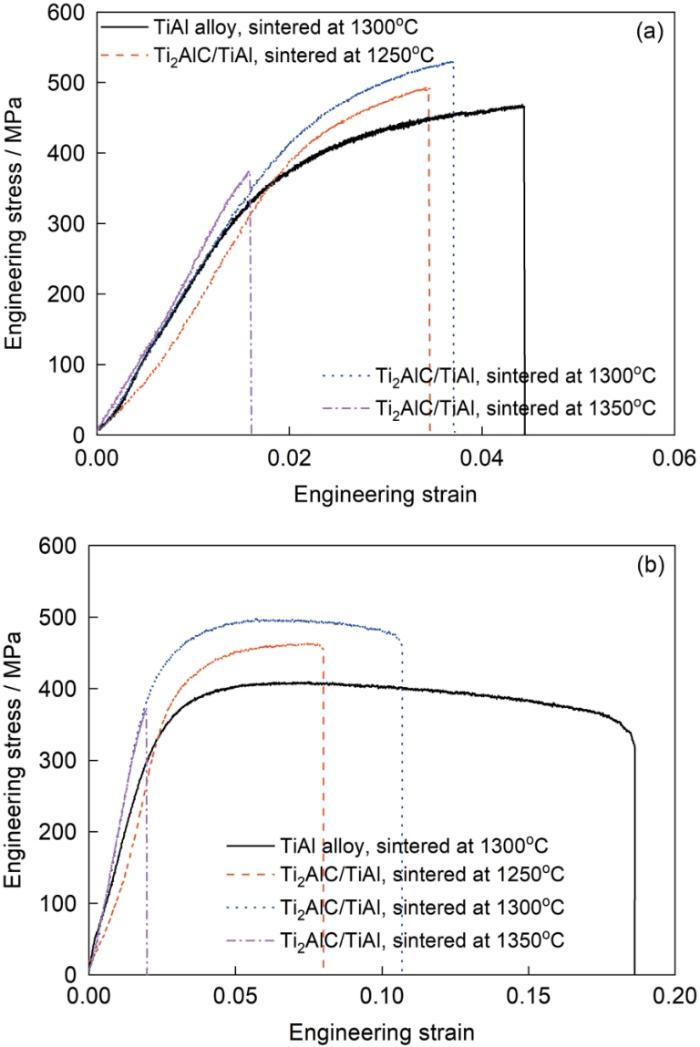

图6所示为在800和850℃、应变速率为0.0001 s-1条件下,1300℃烧结TiAl合金及不同温度烧结添加0.5%GO的Ti2AlC颗粒增强TiAl复合材料的高温拉伸工程应力-应变曲线,表1为相应的力学性能。相比于1300℃烧结的TiAl合金,1250和1300℃烧结添加0.5%GO的Ti2AlC/TiAl复合材料由于具有近片层和细小全片层组织表现出优异的强度和塑性,1300℃烧结添加0.5%GO的Ti2AlC/TiAl复合材料在800和850℃拉伸的抗拉强度(UTS)分别为530和496 MPa,相比1300℃烧结的TiAl合金的467和404 MPa分别提高了13.5%和22.8%。另外,具有细小全片层组织的复合材料展现出更优异的高温力学性能,如1300℃烧结添加0.5%GO的Ti2AlC/TiAl复合材料较1250℃烧结添加0.5%GO的复合材料(近片层组织)在相同变形条件下具有更为优异的强度和塑性。复合材料较高的抗拉强度主要归因于微纳米Ti2AlC相引起的细晶强化和第二相强化[10]。值得注意的是,1350℃烧结添加0.5%GO的Ti2AlC/TiAl复合材料在800和850℃拉伸时均未达到屈服就发生断裂,这种现象是由于过高的烧结温度导致片层团的粗化,粗大的片层团在拉伸变形中更易产生应力集中而萌生裂纹,从而恶化了复合材料力学性能。随着拉伸温度的升高,TiAl合金和添加0.5%GO的Ti2AlC/TiAl复合材料的抗拉强度降低,断裂应变增加。当拉伸温度从800℃升高850℃,1300℃烧结TiAl合金的抗拉强度从467 MPa下降到404 MPa,断裂应变从4.5%增加至18.6%。显著增加的断裂应变意味着1300℃烧结TiAl合金的韧性-脆性转变温度低于850℃。然而,同样在800和850℃下进行拉伸时,1300℃烧结添加0.5%GO的Ti2AlC/TiAl复合材料的抗拉强度从530 MPa下降到496 MPa,断裂应变从3.7%增加至10.7%,抗拉强度降低了6.4%,而断裂应变增加了189%,在850℃变形条件下展现出优异的强度和塑性。结果表明Ti2AlC颗粒增强TiAl复合材料可以提高使用温度50℃。

图6

图6

1300℃烧结TiAl合金及不同温度烧结添加0.5%GO的Ti2AlC颗粒增强TiAl复合材料的高温拉伸工程应力-应变曲线

Fig.6

800oC (a) and 850oC (b) tensile engineering stress-strain curves of TiAl alloy sintered at 1300oC and Ti2AlC reinforced TiAl composites with 0.5%GO addition sintered at different temperatures under strain rate of 0.0001 s-1

表1 1300℃烧结TiAl合金及不同温度烧结添加0.5%GO的Ti2AlC颗粒增强TiAl复合材料高温拉伸性能

Table 1

| Alloy | Ts oC | T oC | UTS MPa | εf % |

|---|---|---|---|---|

| TiAl alloy | 1300 | 800 | 467 | 4.5 |

| 850 | 404 | 18.6 | ||

| Ti2AlC/TiAl | 1250 | 800 | 492 | 3.5 |

| 850 | 462 | 8.1 | ||

| Ti2AlC/TiAl | 1300 | 800 | 530 | 3.7 |

| 850 | 496 | 10.7 | ||

| Ti2AlC/TiAl | 1350 | 800 | 373 | 1.6 |

| 850 | 371 | 2.1 |

2.3 断裂组织与强韧化机制

图7所示为1300℃烧结TiAl合金和添加0.5%GO的Ti2AlC颗粒增强TiAl复合材料在800、850℃下高温拉伸断口形貌的SEM像。在800℃下拉伸变形时,2种材料的高温拉伸断裂面都包含粗糙的解理断裂面,由穿晶断裂与沿晶断裂混合组成,如图7a和b所示。在变形过程中,由于各片层团取向不一,在片层团界面处更易发生应力集中,故裂纹主要在片层团界面处萌生,并沿着片层团界面扩展导致材料断裂失效[22~24]。在850℃下拉伸变形时,1300℃烧结的TiAl合金仍然呈现解理断裂的特征,裂纹数量增多,如图7c所示。值得注意的是,在1300℃烧结添加0.5%GO的Ti2AlC/TiAl复合材料拉伸断裂面中,除了典型的解理断裂面,还可以观察到由韧性断裂产生的韧窝(直径2~10 μm),如图7d所示。类似现象在纳米Y2O3增强的TiAl合金变形过程中被发现,研究[12]表明韧窝的形成主要与纳米级的析出相有关。

图7

图7

1300℃烧结TiAl合金及添加0.5%GO的Ti2AlC颗粒增强TiAl复合材料高温拉伸断口形貌的SEM像

Fig.7

SEM fracture images of TiAl alloy (a, c) and Ti2AlC reinforced TiAl composites with 0.5%GO addition (b, d) sintered at 1300oC after tensile tests at 800oC (a, b) and 850oC (c, d) under strain rate of 0.0001 s-1

为了进一步研究微纳米Ti2AlC颗粒对高温断裂行为的影响,分别对1300℃烧结TiAl合金和添加0.5%GO的Ti2AlC颗粒增强TiAl复合材料高温拉伸断口附近的变形组织进行观察,结果分别如图8和9所示。可以看出,2种材料断口的共同特征是,在断口附近裂纹沿片层团晶界和片层团内部的α2 + γ片层扩展,这是引起最终断裂的主要解理裂纹。研究[25,26]表明,在全片层结构的TiAl合金中,由于γ-TiAl板条的不连续粗化,使得片层团内部板条界面结合强度下降,α2/γ界面和片层团晶界更易成为潜在的裂纹萌生部位。如图8所示,1300℃烧结的TiAl合金,其变形产生的裂纹倾向于在α2 + γ板条的界面中萌生和扩展,这是由α2 + γ板条相对较低的结合强度导致。此外,高温下由于晶界强度的降低而引起的晶界滑动是影响断裂行为的另一个关键因素。变形过程中处于硬变形取向的片层团会使晶界滑动难以进行,从而导致晶界处,特别是三叉晶界处形成应力集中而成为裂纹源[27]。因此,沿片层团晶界和α2/γ片层界面的裂纹扩展而形成的解理断裂是1300℃烧结的TiAl合金高温断裂的主要模式。

图8

图8

1300℃烧结的TiAl合金高温拉伸断口附近变形组织的SEM像

Fig.8

Low (a, b) and locally high (a1, b1) magnified SEM images of TiAl alloy sintered at 1300oC after tensile tests at 800oC(a, a1) and 850oC (b, b1)

图9

图9

1300℃烧结添加0.5%GO的Ti2AlC颗粒增强TiAl复合材料高温拉伸断口附近变形组织的SEM像

Fig.9

Low (a, b) and locally high (a1, b1) magnified SEM images of Ti2AlC reinforced TiAl with 0.5%GO addition composite sintered at 1300oC after tensile tests at 800oC (a, a1) and 850oC (b, b1)

如图9a和a1所示,对于1300℃烧结添加0.5%GO的Ti2AlC/TiAl复合材料,在800℃下拉伸变形时,大部分α2 + γ片层间的微纳米Ti2AlC颗粒的周围没有明显的微裂纹,说明微纳米Ti2AlC颗粒与基体的结合强度较好。特别地,在图9a1中可以观察到沿片层扩展的主裂纹转变为穿片层扩展的分裂纹,这是由于微纳米Ti2AlC颗粒在拉伸变形过程中阻碍了裂纹扩展,造成应力集中,微纳米Ti2AlC颗粒与TiAl合金界面处产生新的裂纹,裂纹进一步发生偏转。值得注意的是,大量的孔洞分布在α2 + γ片层间,这是由于结合强度的降低和高温下塑性变形的增加导致部分微纳米Ti2AlC颗粒从基体中剥落。一般来说,微裂纹和孔洞更倾向于在破碎和剥离的微纳米Ti2AlC颗粒周围成核。随着变形的发展,在α2 + γ片层间形成的孔洞扩大并逐渐连接,最终形成韧窝,与图7观察到的结果一致。然而,微纳米Ti2AlC颗粒周围的裂纹和孔洞并不容易单独形成,第二相仍然可以抑制先前存在的裂纹的扩展,如图9b1所示。与1300℃烧结的TiAl合金相比,解理裂纹引起的断裂仍然是1300℃烧结添加0.5%GO的Ti2AlC/TiAl复合材料失效的主要原因。不同的是,微纳米Ti2AlC颗粒对位错运动和裂纹扩展起到了很强的阻碍作用,从而提高了复合材料的强度和塑性。复合材料中细小的片层组织更有利于晶界滑动,减少裂纹的形成,从而使复合材料在具有高强度的同时也表现出优异的断裂应变。特别是微纳米Ti2AlC颗粒与基体具有良好的半共格关系,在发生高温变形时,仅发生少量颗粒断裂。当拉伸温度为850℃时,1300℃烧结添加0.5%GO的Ti2AlC/TiAl复合材料表现出脆性和韧性的混合断裂特点。微纳米Ti2AlC颗粒增强TiAl复合材料的高温性能存在多种机制,主要包括微纳米Ti2AlC颗粒钉扎晶界抑制晶界迁移和晶粒长大细化片层团引起细晶强化。此外,微纳米Ti2AlC颗粒引起的应力集中使基体中形成大量的纳米孪晶会进一步强化基体。在高温拉伸变形过程中,微纳米Ti2AlC颗粒还能阻碍位错运动和裂纹扩展,从而显著提高复合材料的高温力学性能。

3 结论

(1) Ti2AlC/TiAl复合材料的微观结构可以通过烧结工艺进行调控,随着烧结温度的升高,可分别获得近片层、细小全片层、粗大全片层组织的微纳米Ti2AlC颗粒增强TiAl复合材料。

(2) 具有细小全片层组织的Ti2AlC/TiAl复合材料的高温强度和塑性协同提升,1300℃烧结添加0.5%GO的复合材料在850℃拉伸的抗拉强度和断裂应变分别为496 MPa和10.7%,较全片层组织的1300℃烧结的TiAl合金使用温度提升50℃。

(3) Ti2AlC/TiAl复合材料的高温强度和塑性协同提升,归因于微纳米Ti2AlC颗粒引起的细晶强化和纳米孪晶强化,以及在变形过程中阻碍位错运动和裂纹扩展。

参考文献

Effect of hot extrusion and heat treatment on the microstructure and tensile properties of network structured TiBw/TC18 composites

[J].To improve the comprehensive performance of Ti matrix composites for defense applications such as aviation and aerospace, as-sintered TiBw/TC18 composites with different reinforcement contents were hot extruded and heat-treated. The composites were characterized and analyzed by OM, SEM, and TEM. The mechanical properties of the composites were measured using an electronic universal testing machine. By extruding in the β single-phase region, the β grain size of TiBw/TC18 was reduced from 70 μm to about 40 μm. After the subsequent triple-annealing or solution aging heat treatment, α phase with different sizes was precipitated and distributed in the β phase. The elongation of the as-extruded composites significantly showed improvement, but the strength decreased by about 17%. After applying the triple-annealing heat treatment, the tensile strength and elongation of 2.0%TiBw/TC18 (volume fraction) reached 1200 MPa and 21.7%, which are higher by 5.5% and 189%, respectively, than those in the sintered state. Moreover, after applying the solution aging heat treatment, the as-extruded 2.0%TiBw/TC18 exhibited tensile strength and elongation of 1389 MPa and 9.9%, which are higher by 22.2% and 32%, respectively, than those exhibited by as-sintered 2.0%TiBw/TC18. Consequently, the hot extrusion can effectively reduce the grain size of as-sintered TiBw/TC18, and the tensile properties of the extruded TiBw/TC18 can be modified to meet the requirements of different service conditions through different subsequent heat treatments.

热挤压与热处理对网状TiBw/TC18复合材料组织及性能的影响

[J].

Superior strength-ductility synergy of (TiC + Ti5Si3)/Ti composites with nacre-inspired architecture

[J].

Novel laminated multi-layer graphene/Cu-Al-Mn composites with ultrahigh damping capacity and superior tensile mechanical properties

[J].

Microstructure and mechanical properties of SiC nanowires reinforced titanium matrix composites

[J].

Multiscale architecture and superior high-temperature performance of discontinuously reinforced titanium matrix composites

[J].

Optimization of electromagnetic energy in cold crucible used for directional solidification of TiAl alloy

[J].

Continuous-cooling-transformation (CCT) behaviors and fine-grained nearly lamellar (FGNL) microstructure formation in a cast Ti-48Al-4Nb-2Cr Alloy

[J].

Balancing the strength and ductility of Ti2AlC/TiAl composite with a bioinspired micro-nano laminated architecture

[J].

Research progress of particulates reinforced TiAl based composites

[J].

颗粒增强TiAl基复合材料的研究进展

[J].

The effects of the formation of a multi-scale reinforcing phase on the microstructure evolution and mechanical properties of a Ti2AlC/TiAl alloy

[J].

Interfacial reaction and thermal stability of the SiCf/TiAl composites

[J].

SiCf/TiAl复合材料界面反应及热稳定性

[J].采用真空吸铸法制备了SiC<sub>f</sub>/TiAl复合材料,利用SEM和TEM对制备态复合材料界面反应层进行元素扩散分析和产物确定。结果表明,制备态复合材料的界面反应产物主要由靠近碳层的等轴细晶TiC和靠近钛合金涂层的等轴粗晶TiC组成。对复合材料进行800℃热暴露实验,结果显示,界面反应层随热暴露时间的延长而增长,且在长大过程中出现了分层现象。根据热暴露后反应层厚度随时间的变化规律,绘制出800℃界面反应的动力学曲线,并推测出界面生长速率。热暴露200 h后的界面反应产物共有4层,从纤维一侧到基体一侧分别是细晶TiC层、粗晶TiC层、(Ti, Zr)<sub>5</sub>Si<sub>4</sub>层和Ti<sub>3</sub>Sn + Ti<sub>2</sub>AlC层。分别对制备态和热暴露态的SiC<sub>f</sub>/TiAl复合材料界面反应产物的形成机理进行了分析,得出热暴露过程中界面分层出现的主要原因是Ti<sub>2</sub>AlC新相的生成消耗了部分TiC相。

High temperature tensile properties and fracture behavior of Y2O3-bearing Ti-48Al-2Cr-2Nb alloy

[J].

Achieving superior high-temperature strength and oxidation resistance of TiAl nanocomposite through in situ semicoherent MAX phase precipitation

[J].

Microstructure and mechanical properties of micro-nano Ti2AlC-reinforced TiAl composites

[J].

Improvement in oxidation resistance of TiAl alloys by in-situ precipitation of Ti2AlC at the interface of α2 and γ lamellae

[J].

Modification of microstructure and properties of Ti-47Al-2Cr-4Nb-0.3W alloys fabricated by SPS with trace multilayer graphene addition

[J].

Formation of TiC/Ti2AlC and α2 + γ in in-situ TiAl composites with different solidification paths

[J].

Microstructure, mechanical and tribological properties of TiAl-based composites reinforced with high volume fraction of nearly network Ti2AlC particulates

[J].TiAl-based composites reinforced with different high volume fractions of nearly network Ti2AlC phase have been successfully prepared by mechanical alloying and hot-pressing method. Their microstructure, mechanical and tribological properties have been investigated. Ti2AlC network becomes continuous but the network wall grows thicker with increasing the Ti2AlC content. The continuity and wall size of the network Ti2AlC phase exert a significant influence on the mechanical properties. The bending strength of the composites first increases and then decreases with the Ti2AlC content. The compressive strength of the composite decreases slightly compared to the TiAl alloy, but the hardness is enhanced. Due to the high hardness and load-carrying capacity of the network structure, these composites have the better wear resistance. And this enhancement is more notable at low applied loads and high Ti2AlC content. The mechanisms simulating the role of network Ti2AlC phase on the wear behavior and the wear process of TiAl/Ti2AlC composites at different applied loads have been proposed.

Understanding the role of carbon atoms on microstructure and phase transformation of high Nb containing TiAl alloys

[J].

Strengthening materials by engineering coherent internal boundaries at the nanoscale

[J].Strengthening materials traditionally involves the controlled creation of internal defects and boundaries so as to obstruct dislocation motion. Such strategies invariably compromise ductility, the ability of the material to deform, stretch, or change shape permanently without breaking. Here, we outline an approach to optimize strength and ductility by identifying three essential structural characteristics for boundaries: coherency with surrounding matrix, thermal and mechanical stability, and smallest feature size finer than 100 nanometers. We assess current understanding of strengthening and propose a methodology for engineering coherent, nanoscale internal boundaries, specifically those involving nanoscale twin boundaries. Additionally, we discuss perspectives on strengthening and preserving ductility, along with potential applications for improving failure tolerance, electrical conductivity, and resistance to electromigration.

Influence of nano-Y2O3 addition on microstructure and tensile properties of high-Al TiAl alloys

[J].

Anisotropy of microstructure and tensile properties of Ti-48Al-2Cr-2Nb fabricated by electron beam melting

[J].

Electron beam melting of Ti-48Al-2Cr-2Nb alloy: Microstructure and mechanical properties investigation

[J].

Microstructure characteristics and failure mechanisms of Ti-48Al-2Nb-2Cr titanium aluminide intermetallic alloy fabricated by directed energy deposition technique

[J].

Effects of Tantalum on the microstructure and properties of Ti-48Al-2Cr-2Nb alloy fabricated via laser additive manufacturing

[J].

Microstructure evolution and tensile properties of conventional cast TiAl-based alloy with trace Ni addition

[J].

Twin-wire directed energy deposition-arc of Ti-48Al-2Cr-2Nb alloy: Feasibility, microstructure, and tensile property investigation

[J].