Cavitation erosion behavior in seawater of electroless Ni-P coating and process optimization using Taguchi method

1

2019

... 空化是水环境中由局部压力波动引起的一种常见现象,它的特点是在非常小的区域内存在高压、高应变率的相互作用.空化腐蚀通常发生在高速流动的流体和局部压力突然变化的情况下,比如流体以相对较高的速率通过泵、阀等液压系统中的流体元件时,流体压力在机械元件的表面下降,如果局部压力低于饱和水汽压力就会产生空化泡.当这些气泡从低压部分运动到高压部分时,它们就会崩溃,气泡崩塌产生的激波和微射流则会对机械元件表面造成空化损伤[1~3].在非腐蚀性的环境中,这种高速率的冲击本质上是一个机械过程,类似于冲击载荷或高振幅低周疲劳的作用[2],这种冲击作用会在材料表面引发局部塑性变形、脆性断裂并使材料发生质量损失,导致工程构件的使用寿命显著降低[2,3].然而,在腐蚀性水溶液中(如海洋环境),这些构件会同时承受机械载荷和电化学腐蚀的作用,因此,对于在恶劣环境下使用的流体机械构件,必须同时考察其电化学和空化腐蚀性能. ...

The influence of semiconducting properties of passive films on the cavitation erosion resistance of a NbN nanoceramic coating

2

2021

... 空化是水环境中由局部压力波动引起的一种常见现象,它的特点是在非常小的区域内存在高压、高应变率的相互作用.空化腐蚀通常发生在高速流动的流体和局部压力突然变化的情况下,比如流体以相对较高的速率通过泵、阀等液压系统中的流体元件时,流体压力在机械元件的表面下降,如果局部压力低于饱和水汽压力就会产生空化泡.当这些气泡从低压部分运动到高压部分时,它们就会崩溃,气泡崩塌产生的激波和微射流则会对机械元件表面造成空化损伤[1~3].在非腐蚀性的环境中,这种高速率的冲击本质上是一个机械过程,类似于冲击载荷或高振幅低周疲劳的作用[2],这种冲击作用会在材料表面引发局部塑性变形、脆性断裂并使材料发生质量损失,导致工程构件的使用寿命显著降低[2,3].然而,在腐蚀性水溶液中(如海洋环境),这些构件会同时承受机械载荷和电化学腐蚀的作用,因此,对于在恶劣环境下使用的流体机械构件,必须同时考察其电化学和空化腐蚀性能. ...

... [2,3].然而,在腐蚀性水溶液中(如海洋环境),这些构件会同时承受机械载荷和电化学腐蚀的作用,因此,对于在恶劣环境下使用的流体机械构件,必须同时考察其电化学和空化腐蚀性能. ...

Cavitation erosion resistance of 316L austenitic steel processed by selective laser melting (SLM)

10

2019

... 空化是水环境中由局部压力波动引起的一种常见现象,它的特点是在非常小的区域内存在高压、高应变率的相互作用.空化腐蚀通常发生在高速流动的流体和局部压力突然变化的情况下,比如流体以相对较高的速率通过泵、阀等液压系统中的流体元件时,流体压力在机械元件的表面下降,如果局部压力低于饱和水汽压力就会产生空化泡.当这些气泡从低压部分运动到高压部分时,它们就会崩溃,气泡崩塌产生的激波和微射流则会对机械元件表面造成空化损伤[1~3].在非腐蚀性的环境中,这种高速率的冲击本质上是一个机械过程,类似于冲击载荷或高振幅低周疲劳的作用[2],这种冲击作用会在材料表面引发局部塑性变形、脆性断裂并使材料发生质量损失,导致工程构件的使用寿命显著降低[2,3].然而,在腐蚀性水溶液中(如海洋环境),这些构件会同时承受机械载荷和电化学腐蚀的作用,因此,对于在恶劣环境下使用的流体机械构件,必须同时考察其电化学和空化腐蚀性能. ...

... ,3].然而,在腐蚀性水溶液中(如海洋环境),这些构件会同时承受机械载荷和电化学腐蚀的作用,因此,对于在恶劣环境下使用的流体机械构件,必须同时考察其电化学和空化腐蚀性能. ...

... 由于316L不锈钢具有较高的应变硬化能力、良好的焊接性以及较强的耐腐蚀性能,因此其对空化腐蚀也具有较高的抵抗能力,可用于有空化泡存在的液体环境中[3].近年来,增材制造316L (AM-316L)不锈钢被应用于生产重量轻、体积小的液压元件[21,22],部分流体机械元件在高旋转速率和具有腐蚀性的介质中工作,因此材料的电化学和空化腐蚀性能显得尤为重要.关于SLM-316L和LMD-316L不锈钢的电化学腐蚀性能已有较多报道[15,16,23~25]:一些研究工作[6,16]表明,由于AM-316L不锈钢不可避免地存在各种缺陷,导致其耐腐蚀性能弱于锻造316L不锈钢;而有些研究工作[24,25]却表明AM-316L不锈钢的特殊微结构使得其比锻造316L不锈钢具有更好的耐点蚀性能和更低的稳态点蚀速率.Ziętala等[16]的研究结果表明,LMD-316L不锈钢胞结构壁面上形成了δ铁素体相,这种相结构不会出现在传统冶金方法制造的316L不锈钢中,他们指出δ铁素体相的形成是打印态材料力学性能和耐腐蚀性能提高的主要原因;通过改变工艺参数调控材料内部的初始位错密度[23]或使用后处理手段改变打印态材料内部的非平衡微观结构(如亚晶、小角度晶界比例和缺陷尺寸),可以显著影响材料的钝化膜厚度和腐蚀电位[6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... [3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... [3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... [3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

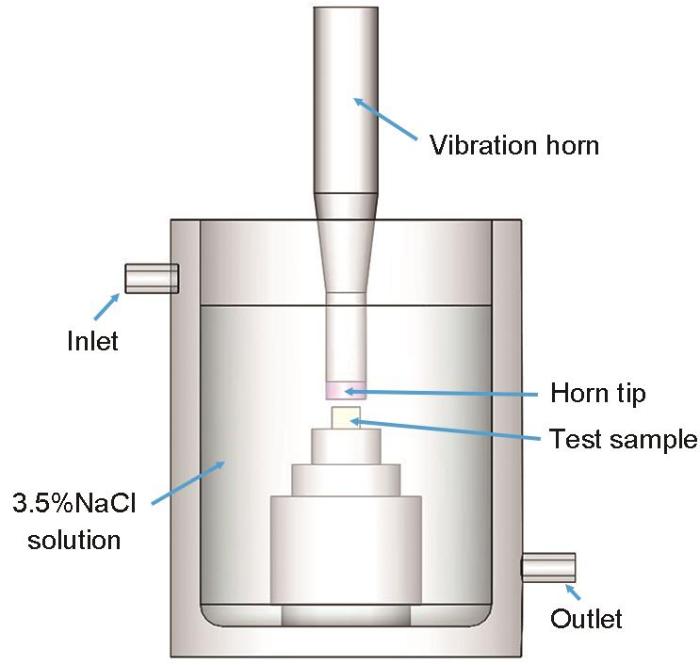

... 在进行电化学及空化腐蚀实验之前,对所有试样的待测面依次用耐水砂纸进行打磨至3000号,最后用1.5 μm的金刚石悬浮液抛光至镜面[9,27],然后放置在75%酒精溶液中超声清洗并烘干后备用.采用CHI660E电化学工作站在室温下对不同成形工艺下的试样进行耐腐蚀性能测试,用硅橡胶密封被测试试样,电化学测试溶液为3.5%NaCl (质量分数)溶液,阳极为被测试试样,阴极为Pt电极,参比电极为饱和甘汞电极.开路电位(OCP)测试时间为3600 s,当开路电位稳定后进行动电位极化测试,阴极初始电位比被测试样对应的腐蚀电位低0.6~0.7 V,扫描速率为0.001 V/s.采用超声振动系统对各工艺下制备的LMD-316L不锈钢试样进行空化腐蚀实验,设备工作原理如图2所示,采用的超声振动频率和振幅分别为20 kHz和6 μm,输出功率为500 W.超声波探头顶端与被测试样相对的材料为不锈钢,按照文献[3,21]推荐的值将试样与探头顶端之间的距离调整为0.5 mm.空化腐蚀实验在3.5%NaCl水溶液中进行,温度保持为25℃,每30 min更换一次NaCl水溶液.每个样品在空化实验结束后,利用75%酒精溶液进行超声清洗,烘干后储存. ...

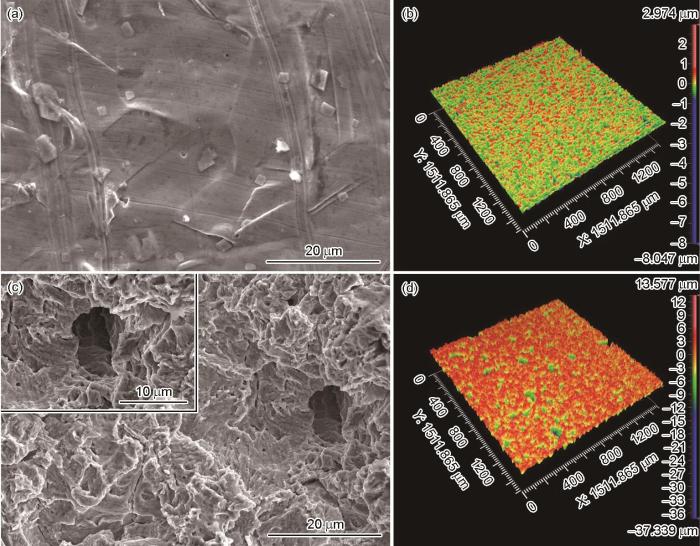

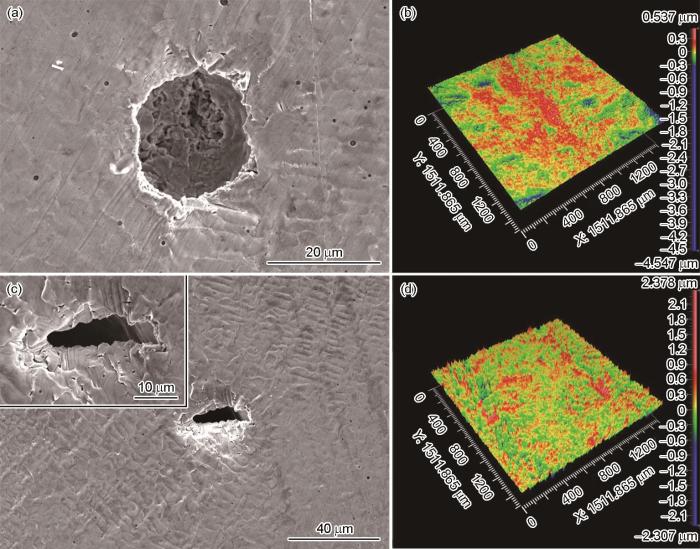

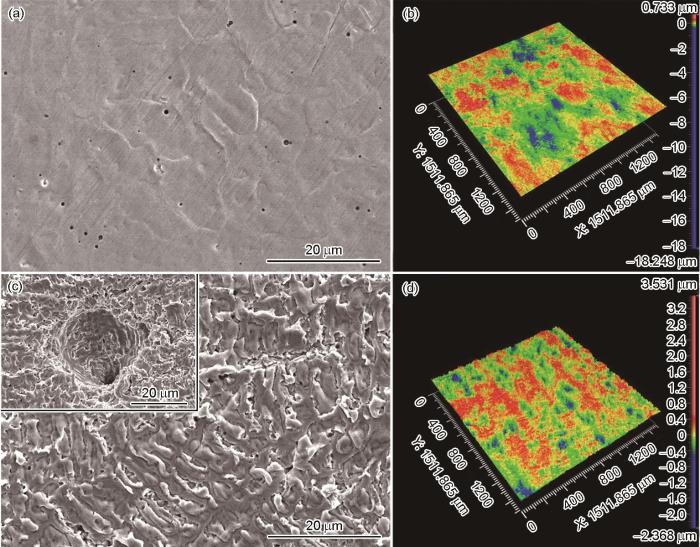

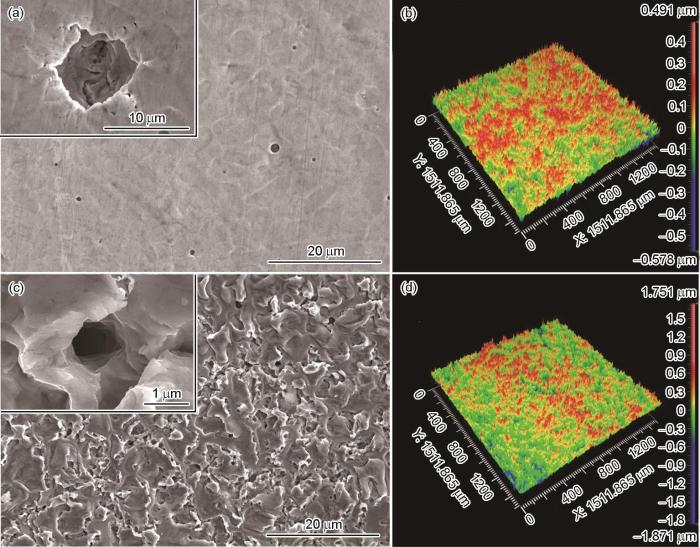

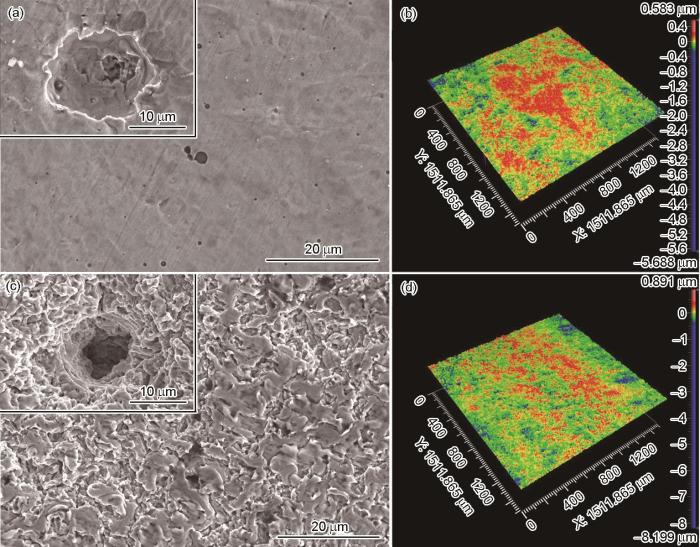

... 对不同工艺参数下LMD-316L及锻造316L不锈钢在超声振动系统中进行4 h的空化腐蚀实验,图12a~18a和图12c~18c分别为锻造316L不锈钢和No.1~No.6试样在暴露0.5和4 h空化实验后表面的SEM像.可以看出,所有试样的表面在经过空化腐蚀后均变得更加粗糙,在空化实验的早期,所有试样表面均形成了条带状凸起(图12a~18a),随着空化实验时间的延长,各试样表面粗糙度进一步增加,表面形貌出现了大量的韧窝(图12c~18c),这种韧窝形貌与文献[16,18]报道的拉伸断口中出现的韧窝非常相似,这表明所有被空化腐蚀的试样在空化泡的作用下发生了严重的材料损伤和塑性变形.观察试样表面还可以看出:试样表面的凸起优先发生在晶界和未熔缺陷位置,这是因为在塑性变形过程中位错倾向于沿着晶界堆积以抵抗塑性变形[29],在晶界处更容易发生空化损伤,这与空化腐蚀作用下的疲劳过程有关[21];而缺陷(如未熔缺陷或气孔缺陷等)的边缘在空化泡的作用下易引起应力集中,是产生裂纹继而发生裂纹扩展的高发区[50],对增材制造零件的力学性能是不利的[9,28,47,50],会导致材料在空化泡的冲击作用下发生撕裂而造成质量损失[3,21].Ding等[21]研究表明,SLM-316L不锈钢在空化腐蚀过程中材料的晶界会优先发生塑性变形,并认为沿晶界发生空化损伤的区域不仅会造成应力集中,还会导致空化泡在晶界附近溃灭,促使在晶界附近形成沟壑/凸起,这与本工作图12a~18a和图12c~18c观察到的结果是一致的.图12b~18b和图12d~18d分别为使用三维白光干涉表面形貌仪测量锻造316L不锈钢和No.1~No.6试样在暴露0.5和4 h的典型表面形貌,图中基本未变形的部分用绿色表示,而凹陷的区域和凸起的区域分别用蓝色和红色表示.可以看出,锻造316L不锈钢的变形较为均匀(图12b),经过4 h的空化腐蚀后试样表面出现了大量的凹坑和凸起(图12d),这是典型的侵蚀空化损伤,这与LMD-316L不锈钢的空化行为有显著区别(图13b~18b和图13d~18d):LMD-316L不锈钢的表面形貌非常不均匀,有的区域出现了密集的凸起,而有的区域出现了明显的凹陷,且这2种形貌分布较为分散(图13b~18b),经过4 h的空化腐蚀后,LMD-316L不锈钢并不像锻造316L不锈钢形成大量明显的凸起,其表面形貌分布特征与0.5 h的形貌类似(图13d~18d). ...

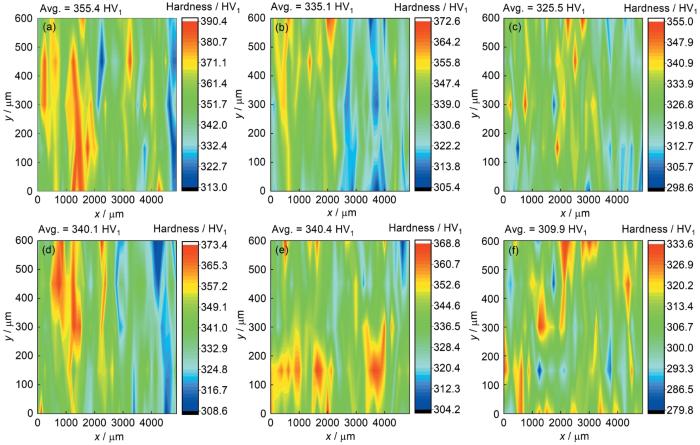

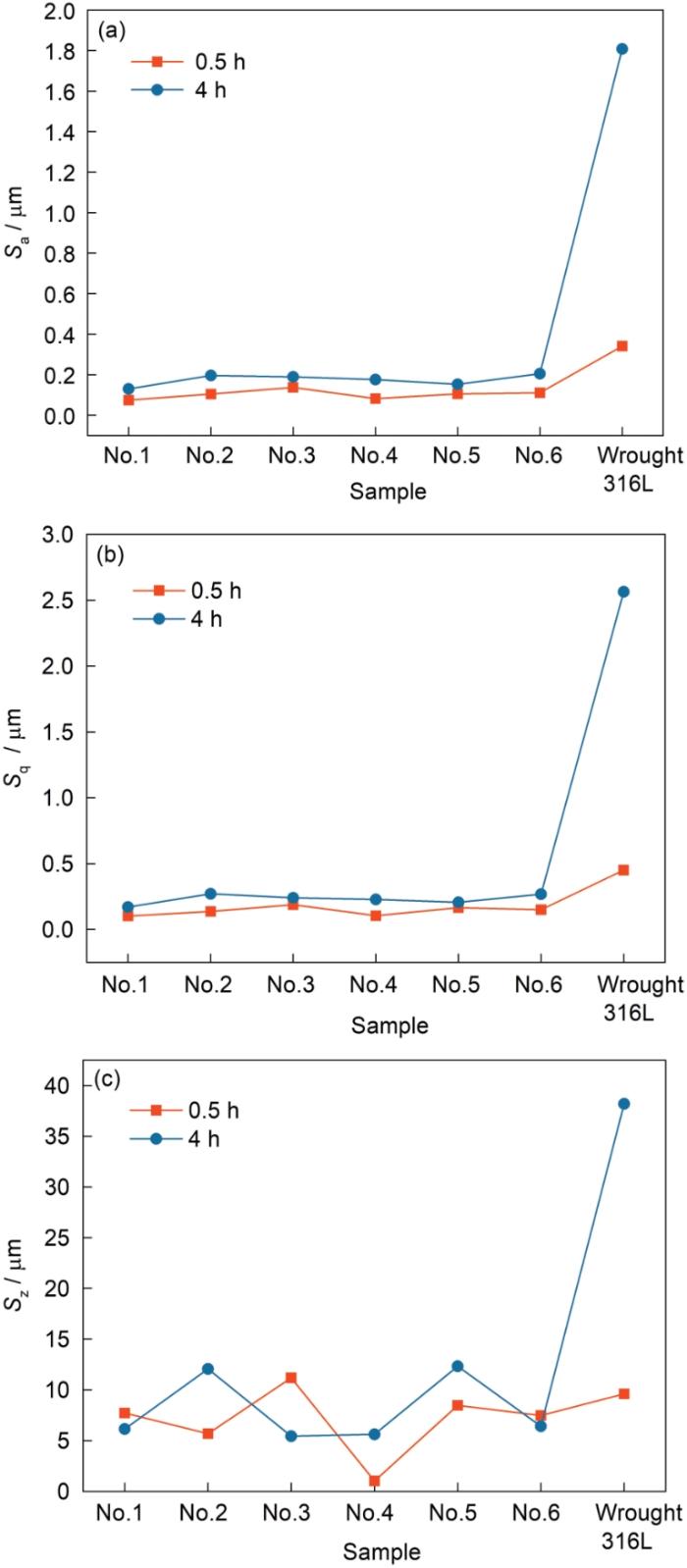

... 从空化腐蚀的机理方面来讲,超声振动在液体介质中形成的空化泡会产生反复的冲击波和微射流,这种具有高能量状态的冲击波/微射流作用到试样表面后会在材料的薄弱区域优先发生空化损伤,一些较轻微的冲击会在工艺诱导的缺陷和晶界位置处出现局部应力集中,导致位错沿晶界移动,随着空化实验时间的延长,会逐渐塑性变形并形成凹坑,而一些高能量的强烈冲击波则会导致材料的质量损失[3,21].材料在3.5%NaCl溶液中的空化腐蚀可以看成机械损伤、腐蚀损伤及机械腐蚀协同作用损伤3部分[51],即:T = E + C + S,其中,T为总质量损失率;E为纯空化腐蚀导致的质量损失率;C为纯腐蚀而导致的质量损失率,C = K · icorr· EW,K取8.954 × 10-3,EW为当量重量(其值为物质的摩尔质量除以它接受或失去电子的数目),对于不锈钢EW取25.12[51];S为2者的协同效应导致的质量损失率.Zheng等[51]的研究结果表明,当空化腐蚀时间不大于2 h时,纯腐蚀的作用可以忽略,而当空化腐蚀时间超过8 h时,材料会经受腐蚀和空化腐蚀的共同作用.鉴于本工作空化腐蚀总时长较短(4 h),因此,可以用材料的抗机械损伤作为评价LMD-316L不锈钢在3.5%NaCl溶液中的空化腐蚀演变规律.不同工艺参数下的纯机械损伤可以用显微硬度衡量,上述研究结果已表明LMD-316L不锈钢的耐腐蚀性能与其内部的二次枝晶臂间距直接相关(纯腐蚀损伤度量指标),而二次枝晶臂间距又直接影响材料的显微硬度(机械损伤度量指标).图3e和图9分别为锻造316L不锈钢和LMD-316L不锈钢No.1~No.6的硬度云图.可见,锻造316L不锈钢的硬度分布较为均匀,而且其显微硬度明显低于LMD-316L不锈钢;此外,相比锻造316L不锈钢,LMD-316L不锈钢的硬度分布更加不均匀,这主要是由增材制造材料的不均匀跨尺度微观组织和局部工艺缺陷导致的[27,52].LMD-316L不锈钢硬度不均匀分布的特点也导致其在空化腐蚀的进程中出现局部破坏严重,而有些区域只是轻微变形.然而,由于LMD-316L不锈钢的平均硬度显著高于锻造316L不锈钢,因此前者的抗空化腐蚀能力显著高于后者.为了更好地评价不同工艺制备的材料表面粗糙度随空化腐蚀时间的变化,利用表面形貌参数对表面粗糙度进行了量化,分别为:表面粗糙度(Sa)、表面均方根粗糙度(Sq)和表面微观不平度十点高度(Sz),这些参数的具体定义和计算方法参见文献[53].图19为利用这3个表面形貌参数表征被测试样形貌的结果(所有数据均为2次测量的平均值).可以看出,Sa和Sq的变化与材料硬度的变化具有一定的关联,即:随着激光功率的增加,材料的平均硬度降低,Sa和Sq有增加的趋势(图19a和b,No.1~3);重熔处理(No.4)、90°旋转扫描打印(No.5)和垂直方向打印(No.6)与No.1试样相比均会导致LMD-316L不锈钢的硬度降低(图9),因而Sa和Sq值略高于No.1 (图19a和b),产生这一结果的根本原因是材料的二次枝晶臂间距增大,材料的腐蚀电流密度增大,显微硬度降低,因而材料的纯腐蚀损伤和机械损伤均会增大,导致材料的机械损伤和腐蚀损伤加重.此外,4 h后材料表面的Sa和Sq均高于对应0.5 h的测量值.然而,不同工艺参数下的Sz没有明显的变化规律,这是因为Sz是一个极端参数,它定义为采样区内5个最高峰的绝对高度和5个最深凹坑/峰谷深度的平均值[53],其值取决于表面高度峰值和峰谷,而在空化腐蚀的进程中材料表面在空化泡的冲击作用下会发生质量损失[3,21,51],因而表面Sz存在较大的不确定性,总体看LMD-316L不锈钢的Sz小于相应空化时间下锻造316L不锈钢的Sz (图19c). ...

... [3,21,51],因而表面Sz存在较大的不确定性,总体看LMD-316L不锈钢的Sz小于相应空化时间下锻造316L不锈钢的Sz (图19c). ...

Tensile properties, strain rate sensitivity, and activation volume of additively manufactured 316L stainless steels

1

2019

... 316L作为一种低碳奥氏体不锈钢,是商业上少数可打印的钢铁材料之一,同时也是国际上热核实验反应堆中真空容器和制造液体火箭发动机喷油器的关键材料,在航空航天、生物医疗、核电工业等关键领域有广泛的应用[4~7].增材制造(AM)作为一种变革性的制造技术,它最大的优势在于可以直接成形形状复杂的构件.由于高能密度热源熔化粉末形成的熔池内冷却速率可达105~107 K/s[5,8,9],材料的微观组织与传统制备方法得到的微观结构存在显著的差异[5,10]:选区激光熔化沉积成形316L (SLM-316L)不锈钢中形成了一种新的跨尺度结构,它由百微米尺度的熔池、几十微米到百微米的晶粒、亚微米尺度的胞结构、几十纳米的氧化物颗粒等构成.然而,SLM和激光熔化沉积(LMD)的冷却速率相差约3个数量级,所形成的跨尺度层级结构在具体每一个微观结构尺度上也存在数量级的差异,如激光熔化沉积成形316L (LMD-316L)不锈钢的熔池尺寸、晶粒长度和胞/枝晶结构尺寸分别为几毫米、500 μm~2.5 mm和2~20 μm,而相应SLM-316L不锈钢的特征尺寸分别为约100 μm、数百微米和小于1 μm[8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting

2

2016

... 316L作为一种低碳奥氏体不锈钢,是商业上少数可打印的钢铁材料之一,同时也是国际上热核实验反应堆中真空容器和制造液体火箭发动机喷油器的关键材料,在航空航天、生物医疗、核电工业等关键领域有广泛的应用[4~7].增材制造(AM)作为一种变革性的制造技术,它最大的优势在于可以直接成形形状复杂的构件.由于高能密度热源熔化粉末形成的熔池内冷却速率可达105~107 K/s[5,8,9],材料的微观组织与传统制备方法得到的微观结构存在显著的差异[5,10]:选区激光熔化沉积成形316L (SLM-316L)不锈钢中形成了一种新的跨尺度结构,它由百微米尺度的熔池、几十微米到百微米的晶粒、亚微米尺度的胞结构、几十纳米的氧化物颗粒等构成.然而,SLM和激光熔化沉积(LMD)的冷却速率相差约3个数量级,所形成的跨尺度层级结构在具体每一个微观结构尺度上也存在数量级的差异,如激光熔化沉积成形316L (LMD-316L)不锈钢的熔池尺寸、晶粒长度和胞/枝晶结构尺寸分别为几毫米、500 μm~2.5 mm和2~20 μm,而相应SLM-316L不锈钢的特征尺寸分别为约100 μm、数百微米和小于1 μm[8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

... [5,10]:选区激光熔化沉积成形316L (SLM-316L)不锈钢中形成了一种新的跨尺度结构,它由百微米尺度的熔池、几十微米到百微米的晶粒、亚微米尺度的胞结构、几十纳米的氧化物颗粒等构成.然而,SLM和激光熔化沉积(LMD)的冷却速率相差约3个数量级,所形成的跨尺度层级结构在具体每一个微观结构尺度上也存在数量级的差异,如激光熔化沉积成形316L (LMD-316L)不锈钢的熔池尺寸、晶粒长度和胞/枝晶结构尺寸分别为几毫米、500 μm~2.5 mm和2~20 μm,而相应SLM-316L不锈钢的特征尺寸分别为约100 μm、数百微米和小于1 μm[8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

Heat treatment effect on the microstructure and corrosion behavior of 316L stainless steel fabricated by selective laser melting for proton exchange membrane fuel cells

2

2018

... 由于316L不锈钢具有较高的应变硬化能力、良好的焊接性以及较强的耐腐蚀性能,因此其对空化腐蚀也具有较高的抵抗能力,可用于有空化泡存在的液体环境中[3].近年来,增材制造316L (AM-316L)不锈钢被应用于生产重量轻、体积小的液压元件[21,22],部分流体机械元件在高旋转速率和具有腐蚀性的介质中工作,因此材料的电化学和空化腐蚀性能显得尤为重要.关于SLM-316L和LMD-316L不锈钢的电化学腐蚀性能已有较多报道[15,16,23~25]:一些研究工作[6,16]表明,由于AM-316L不锈钢不可避免地存在各种缺陷,导致其耐腐蚀性能弱于锻造316L不锈钢;而有些研究工作[24,25]却表明AM-316L不锈钢的特殊微结构使得其比锻造316L不锈钢具有更好的耐点蚀性能和更低的稳态点蚀速率.Ziętala等[16]的研究结果表明,LMD-316L不锈钢胞结构壁面上形成了δ铁素体相,这种相结构不会出现在传统冶金方法制造的316L不锈钢中,他们指出δ铁素体相的形成是打印态材料力学性能和耐腐蚀性能提高的主要原因;通过改变工艺参数调控材料内部的初始位错密度[23]或使用后处理手段改变打印态材料内部的非平衡微观结构(如亚晶、小角度晶界比例和缺陷尺寸),可以显著影响材料的钝化膜厚度和腐蚀电位[6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... [6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

State of the art of selective laser melted 316L stainless steel: Process, microstructure, and mechanical properties

2

2022

... 316L作为一种低碳奥氏体不锈钢,是商业上少数可打印的钢铁材料之一,同时也是国际上热核实验反应堆中真空容器和制造液体火箭发动机喷油器的关键材料,在航空航天、生物医疗、核电工业等关键领域有广泛的应用[4~7].增材制造(AM)作为一种变革性的制造技术,它最大的优势在于可以直接成形形状复杂的构件.由于高能密度热源熔化粉末形成的熔池内冷却速率可达105~107 K/s[5,8,9],材料的微观组织与传统制备方法得到的微观结构存在显著的差异[5,10]:选区激光熔化沉积成形316L (SLM-316L)不锈钢中形成了一种新的跨尺度结构,它由百微米尺度的熔池、几十微米到百微米的晶粒、亚微米尺度的胞结构、几十纳米的氧化物颗粒等构成.然而,SLM和激光熔化沉积(LMD)的冷却速率相差约3个数量级,所形成的跨尺度层级结构在具体每一个微观结构尺度上也存在数量级的差异,如激光熔化沉积成形316L (LMD-316L)不锈钢的熔池尺寸、晶粒长度和胞/枝晶结构尺寸分别为几毫米、500 μm~2.5 mm和2~20 μm,而相应SLM-316L不锈钢的特征尺寸分别为约100 μm、数百微米和小于1 μm[8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

... 微观结构的变化会导致材料力学性能的变化.图9为各工艺下的硬度分布云图,相应的硬度数据列于表2.随着激光功率的增加,LMD-316L不锈钢的平均显微硬度从355.4 HV1降低到325.5 HV1 (图9a~c和表2),相比No.1试样,重熔和90°旋转扫描均会降低试样的显微硬度(图9a、d、e和表2);相比水平打印的试样,垂直打印试样的显微硬度显著降低(图9a、f和表2),降幅约12.8%,这与文献[40]中报道的结果较为一致,即:沿水平方向打印的试样比沿垂直方向打印的试样强度高约10%.值得注意的是,虽然不同工艺参数下LMD-316L不锈钢的晶粒尺寸显著大于锻造316L不锈钢,但是其显微硬度明显高于锻造316L不锈钢(图3e、图9和表2).进一步分析发现:LMD-316L不锈钢硬度的变化与二次枝晶臂间距的变化具有明显的关联,即:枝晶臂间距增大会导致显微硬度的下降,然而显微硬度与晶粒尺寸的变化没有明显关系(图5、6和9),这预示着使用二次枝晶臂间距可能会更好地预测LMD-316L不锈钢的力学性能.虽然关于AM-316L材料屈服强度的预测目前还存在争议[7],但是现有研究[10,28,48]表明,使用晶粒内部的胞结构/二次枝晶臂间距能更好地预测AM-316L不锈钢力学性能的变化. ...

激光选区熔化成形316L不锈钢工艺、微观组织、力学性能的研究现状

2

2022

... 316L作为一种低碳奥氏体不锈钢,是商业上少数可打印的钢铁材料之一,同时也是国际上热核实验反应堆中真空容器和制造液体火箭发动机喷油器的关键材料,在航空航天、生物医疗、核电工业等关键领域有广泛的应用[4~7].增材制造(AM)作为一种变革性的制造技术,它最大的优势在于可以直接成形形状复杂的构件.由于高能密度热源熔化粉末形成的熔池内冷却速率可达105~107 K/s[5,8,9],材料的微观组织与传统制备方法得到的微观结构存在显著的差异[5,10]:选区激光熔化沉积成形316L (SLM-316L)不锈钢中形成了一种新的跨尺度结构,它由百微米尺度的熔池、几十微米到百微米的晶粒、亚微米尺度的胞结构、几十纳米的氧化物颗粒等构成.然而,SLM和激光熔化沉积(LMD)的冷却速率相差约3个数量级,所形成的跨尺度层级结构在具体每一个微观结构尺度上也存在数量级的差异,如激光熔化沉积成形316L (LMD-316L)不锈钢的熔池尺寸、晶粒长度和胞/枝晶结构尺寸分别为几毫米、500 μm~2.5 mm和2~20 μm,而相应SLM-316L不锈钢的特征尺寸分别为约100 μm、数百微米和小于1 μm[8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

... 微观结构的变化会导致材料力学性能的变化.图9为各工艺下的硬度分布云图,相应的硬度数据列于表2.随着激光功率的增加,LMD-316L不锈钢的平均显微硬度从355.4 HV1降低到325.5 HV1 (图9a~c和表2),相比No.1试样,重熔和90°旋转扫描均会降低试样的显微硬度(图9a、d、e和表2);相比水平打印的试样,垂直打印试样的显微硬度显著降低(图9a、f和表2),降幅约12.8%,这与文献[40]中报道的结果较为一致,即:沿水平方向打印的试样比沿垂直方向打印的试样强度高约10%.值得注意的是,虽然不同工艺参数下LMD-316L不锈钢的晶粒尺寸显著大于锻造316L不锈钢,但是其显微硬度明显高于锻造316L不锈钢(图3e、图9和表2).进一步分析发现:LMD-316L不锈钢硬度的变化与二次枝晶臂间距的变化具有明显的关联,即:枝晶臂间距增大会导致显微硬度的下降,然而显微硬度与晶粒尺寸的变化没有明显关系(图5、6和9),这预示着使用二次枝晶臂间距可能会更好地预测LMD-316L不锈钢的力学性能.虽然关于AM-316L材料屈服强度的预测目前还存在争议[7],但是现有研究[10,28,48]表明,使用晶粒内部的胞结构/二次枝晶臂间距能更好地预测AM-316L不锈钢力学性能的变化. ...

A comparison on metallurgical behaviors of 316L stainless steel by selective laser melting and laser cladding deposition

5

2017

... 316L作为一种低碳奥氏体不锈钢,是商业上少数可打印的钢铁材料之一,同时也是国际上热核实验反应堆中真空容器和制造液体火箭发动机喷油器的关键材料,在航空航天、生物医疗、核电工业等关键领域有广泛的应用[4~7].增材制造(AM)作为一种变革性的制造技术,它最大的优势在于可以直接成形形状复杂的构件.由于高能密度热源熔化粉末形成的熔池内冷却速率可达105~107 K/s[5,8,9],材料的微观组织与传统制备方法得到的微观结构存在显著的差异[5,10]:选区激光熔化沉积成形316L (SLM-316L)不锈钢中形成了一种新的跨尺度结构,它由百微米尺度的熔池、几十微米到百微米的晶粒、亚微米尺度的胞结构、几十纳米的氧化物颗粒等构成.然而,SLM和激光熔化沉积(LMD)的冷却速率相差约3个数量级,所形成的跨尺度层级结构在具体每一个微观结构尺度上也存在数量级的差异,如激光熔化沉积成形316L (LMD-316L)不锈钢的熔池尺寸、晶粒长度和胞/枝晶结构尺寸分别为几毫米、500 μm~2.5 mm和2~20 μm,而相应SLM-316L不锈钢的特征尺寸分别为约100 μm、数百微米和小于1 μm[8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

... [8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

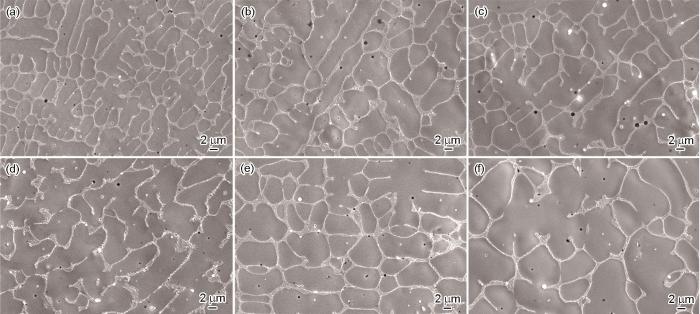

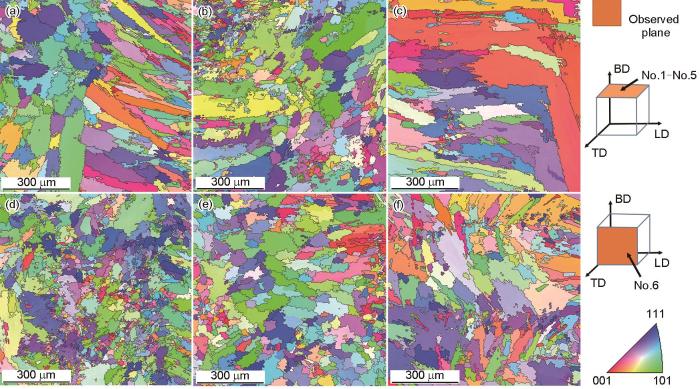

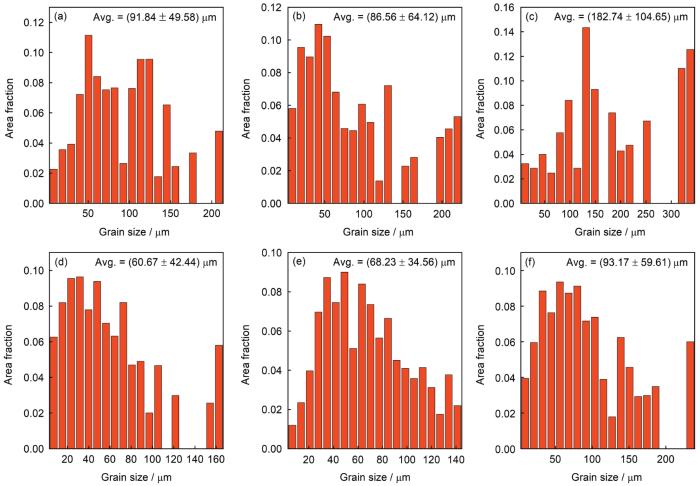

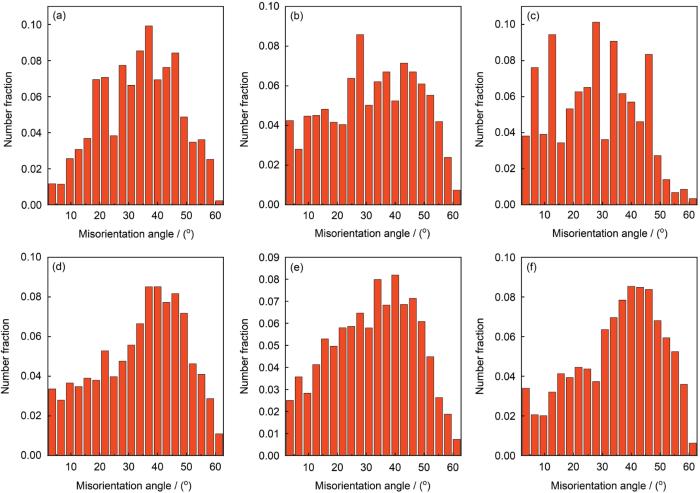

... 图5为不同工艺参数下制备的LMD-316L不锈钢显微组织的SEM像.可以看出,不同工艺参数下LMD-316L不锈钢的显微组织是柱状树枝晶和胞晶的混合组织,其中树枝晶占据主要比例,这与文献[42]中报道的结果是一致的.从图中还可看出,随着功率的增加(图5a~c,No.1~No.3),材料的二次枝晶臂间距呈增加的趋势,平均尺寸分别为(2.57 ± 0.43)、(3.38 ± 0.83)和(3.77 ± 0.71) μm;每2层重熔一次打印时,材料的二次枝晶臂间距变大,为(3.84 ± 0.74) μm (图5a和d);相比105°旋转扫描,90°旋转扫描打印所得材料的二次枝晶臂间距更加粗大,为(4.29 ± 0.56) μm (图5a和e);垂直打印的试样二次枝晶臂间距为(5.13 ± 0.79) μm,高于水平打印的试样(图5a和f).众所周知,冷却速率决定了材料最终微观结构尺寸,冷却速率越大,材料的二次枝晶臂间距越小[8,9],根据二次枝晶臂间距与冷却速率的关系[43],估算了样品No.1~No.6的冷却速率,分别为:8.99 × 103、2.98 × 103、1.93 × 103、1.79 × 103、1.15 × 103和5.64 × 102 K/s.因此,通过调控工艺参数或扫描策略控制熔池内的冷却速率,进而控制二次枝晶臂间距是可行的.图6为不同工艺参数下LMD-316L不锈钢的EBSD像,相应的晶粒尺寸分布及晶粒取向差分布分别见图7和8.可以看出,晶粒尺寸随着工艺参数的变化更加复杂,不同工艺参数下的材料均由曲折晶界组成的长条状晶粒和细小的晶粒组成,这是增材制造材料区别于传统方法制造材料所独有的特征[44,45].虽然1400 W下的平均晶粒尺寸相比1200 W的略小,但考虑到测量误差和晶粒尺寸分布,整体上看,晶粒仍然表现出粗化的趋势,随着功率从1200 W提高到1600 W,LMD-316L不锈钢的平均晶粒尺寸增大了2倍(图6和7a~c),以往的研究[8,46]也表明晶粒尺寸随着激光功率的增加而增大;重熔后表层材料经历了短时熔化再结晶,可观察到大量的细小晶粒(图6d),这可能是因为这些细小的形核晶粒没有足够的保温时间导致的[28];相邻层旋转角度从105°调整到90°后,平均晶粒尺寸从91.84 μm降至68.23 μm,Saboori等[36]研究也表明通过调整相邻层的旋转角度会改变LMD-316L不锈钢的微观结构尺寸,因此可以推断,本工作中相邻层间采用2种扫描角度时,熔道在后续的成形过程中热积累会有显著差别,进而影响最终凝固后材料的晶粒尺寸;垂直打印的试样表现出典型的外延生长晶粒结构特征[28,31],并随相邻层间扫描角度的变化而有一定角度的偏转,这主要是由晶粒的择优取向导致的,晶粒一般总是沿着最大温度梯度的方向生长[47].就晶粒尺寸分布、晶粒取向差分布和平均晶粒尺寸而言,水平和垂直打印的试样没有太大区别(图6a~8a和图6f~8f).与锻造316L不锈钢晶粒取向差分布以大量Σ3孪晶界为主不同,各工艺下的LMD-316L不锈钢晶粒取向差分布呈现正态分布的特征,且小角度晶界的比例显著高于锻造316L不锈钢(图3d和8). ...

... [8,46]也表明晶粒尺寸随着激光功率的增加而增大;重熔后表层材料经历了短时熔化再结晶,可观察到大量的细小晶粒(图6d),这可能是因为这些细小的形核晶粒没有足够的保温时间导致的[28];相邻层旋转角度从105°调整到90°后,平均晶粒尺寸从91.84 μm降至68.23 μm,Saboori等[36]研究也表明通过调整相邻层的旋转角度会改变LMD-316L不锈钢的微观结构尺寸,因此可以推断,本工作中相邻层间采用2种扫描角度时,熔道在后续的成形过程中热积累会有显著差别,进而影响最终凝固后材料的晶粒尺寸;垂直打印的试样表现出典型的外延生长晶粒结构特征[28,31],并随相邻层间扫描角度的变化而有一定角度的偏转,这主要是由晶粒的择优取向导致的,晶粒一般总是沿着最大温度梯度的方向生长[47].就晶粒尺寸分布、晶粒取向差分布和平均晶粒尺寸而言,水平和垂直打印的试样没有太大区别(图6a~8a和图6f~8f).与锻造316L不锈钢晶粒取向差分布以大量Σ3孪晶界为主不同,各工艺下的LMD-316L不锈钢晶粒取向差分布呈现正态分布的特征,且小角度晶界的比例显著高于锻造316L不锈钢(图3d和8). ...

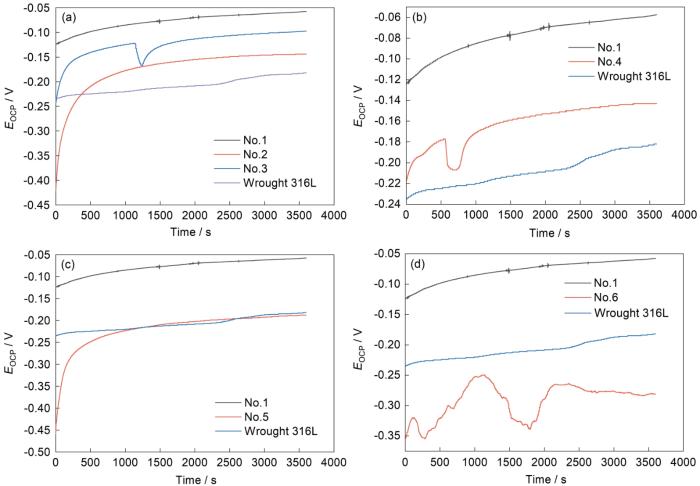

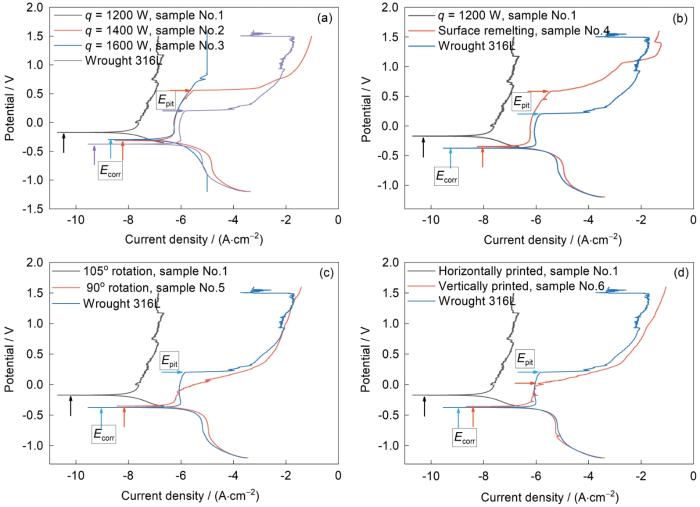

... 图10为不同工艺参数制备的LMD-316L和锻造316L不锈钢在NaCl溶液中的开路电位(EOCP)随时间的变化规律.可以看出,所有被测试样的开路电位均随着时间的推移而呈现先增加(由负值向正值变化)后逐渐稳定的趋势,这表明试样在NaCl溶液中自主形成了钝化膜[44],钝化膜的形成起到了进一步阻抗腐蚀的作用.与锻造316L不锈钢相比,LMD-316L不锈钢在开路电位曲线中显现出多个小的尖峰,个别试样出现了明显的峰谷,这表明LMD-316L不锈钢在EOCP达到稳定前存在击穿和再钝化的过程[44].观察3600 s对应的开路电位,可以发现No.1~No.4的EOCP明显高于锻造316L不锈钢,90°旋转扫描打印(No.5)的试样与锻造316L不锈钢的EOCP非常接近,而垂直打印的试样(No.6)的EOCP低于锻造316L不锈钢.图11为各工艺下的LMD-316L不锈钢动电位极化曲线测试结果,腐蚀电位(Ecorr)和点蚀电位(Epit)在图中也进行了标注,相应的电化学参数列于表3.可以看出:LMD-316L不锈钢的极化电阻(Rp)相比锻造316L不锈钢提高了2~98倍,而腐蚀电流密度(icorr)下降了至少1个数量级.就Ecorr而言,No.1~No.3均明显高于锻造316L,而No.4~No.6的Ecorr与锻造316L不锈钢相差不大.除了No.6外,材料的EOCP变化规律与Ecorr一致,No.6的EOCP与Ecorr变化规律不一致可能是开路电位在测试时间内不稳定造成的.进一步比较各工艺下材料的Epit,可以发现No.1和No.3没有发生明显的点蚀,No.2和No.4的Epit明显高于锻造316L不锈钢,但No.5和No.6的Epit明显低于锻造316L不锈钢,这表明LMD-316L不锈钢在某些工艺下易发生点蚀.Kazemipour等[24]的研究指出SLM-316L不锈钢具有比锻造316L不锈钢更强的耐点蚀性能且其亚稳态点蚀速率也更低,材料内部的工艺缺陷在早期并不影响合金的点蚀电位,本工作No.1~No.4的测试结果与Kazemipour等[24]的研究规律一致.然而,由于材料微观结构的显著变化(图5和6),No.5和No.6在保持较小的腐蚀速率下点蚀电位相比锻造316L不锈钢明显降低.总体来讲,在考虑材料的Ecorr和icorr条件下,LMD-316L不锈钢相比锻造316L不锈钢的腐蚀电位更高而腐蚀速率更小,其耐腐蚀性能大幅提高.最近有研究[16,23]表明AM-316L不锈钢的耐腐蚀性能与其材料的微观结构变化密切相关,其中具有高位错密度的亚稳态胞/枝晶结构对AM-316L不锈钢的耐腐蚀性能具有显著影响,研究[10,15]已表明打印态的316L不锈钢处于高应力状态,亚稳态的胞结构/枝晶壁面上存在大量的位错网络结构[13,23],提高扫描速率亦即降低输入到熔池内的能量密度可使材料的一次/二次枝晶臂间距减小[8,9,13,42],进而提高壁面上的位错密度[23,49].Nie等[25]指出LMD-316L不锈钢内大量的小角度晶界和较高的位错密度促使材料表面形成更致密且更厚的钝化膜,从而能够获得比锻造316L不锈钢更好的耐腐蚀性能.本工作的微观结构表征已证实提高激光功率、重熔处理、90°旋转扫描打印和垂直方向打印均会导致LMD-316L不锈钢的二次枝晶臂间距变大(图5),并进一步导致材料内部初始位错密度的降低[23,49],因而材料的极化电阻降低而腐蚀电流密度提高(图11和表3).这表明打印态LMD-316L不锈钢的耐腐蚀性能与其内部的亚结构尺寸(二次枝晶臂间距)可能直接相关,二次枝晶臂间距的增大会导致耐腐蚀性能的降低.然而,与锻造316L不锈钢相比,所有工艺下的LMD-316L不锈钢小角度晶界比例均高于锻造316L不锈钢(图3d和图8),且LMD-316L不锈钢的初始位错密度高于锻造316L不锈钢[25],这可能是本工作LMD-316L不锈钢耐腐蚀性能相比锻造316L不锈钢大幅提高的原因. ...

Effect of process parameters on defects, melt pool shape, microstructure, and tensile behavior of 316L stainless steel produced by selective laser melting

9

2021

... 316L作为一种低碳奥氏体不锈钢,是商业上少数可打印的钢铁材料之一,同时也是国际上热核实验反应堆中真空容器和制造液体火箭发动机喷油器的关键材料,在航空航天、生物医疗、核电工业等关键领域有广泛的应用[4~7].增材制造(AM)作为一种变革性的制造技术,它最大的优势在于可以直接成形形状复杂的构件.由于高能密度热源熔化粉末形成的熔池内冷却速率可达105~107 K/s[5,8,9],材料的微观组织与传统制备方法得到的微观结构存在显著的差异[5,10]:选区激光熔化沉积成形316L (SLM-316L)不锈钢中形成了一种新的跨尺度结构,它由百微米尺度的熔池、几十微米到百微米的晶粒、亚微米尺度的胞结构、几十纳米的氧化物颗粒等构成.然而,SLM和激光熔化沉积(LMD)的冷却速率相差约3个数量级,所形成的跨尺度层级结构在具体每一个微观结构尺度上也存在数量级的差异,如激光熔化沉积成形316L (LMD-316L)不锈钢的熔池尺寸、晶粒长度和胞/枝晶结构尺寸分别为几毫米、500 μm~2.5 mm和2~20 μm,而相应SLM-316L不锈钢的特征尺寸分别为约100 μm、数百微米和小于1 μm[8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

... [9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

... 在进行电化学及空化腐蚀实验之前,对所有试样的待测面依次用耐水砂纸进行打磨至3000号,最后用1.5 μm的金刚石悬浮液抛光至镜面[9,27],然后放置在75%酒精溶液中超声清洗并烘干后备用.采用CHI660E电化学工作站在室温下对不同成形工艺下的试样进行耐腐蚀性能测试,用硅橡胶密封被测试试样,电化学测试溶液为3.5%NaCl (质量分数)溶液,阳极为被测试试样,阴极为Pt电极,参比电极为饱和甘汞电极.开路电位(OCP)测试时间为3600 s,当开路电位稳定后进行动电位极化测试,阴极初始电位比被测试样对应的腐蚀电位低0.6~0.7 V,扫描速率为0.001 V/s.采用超声振动系统对各工艺下制备的LMD-316L不锈钢试样进行空化腐蚀实验,设备工作原理如图2所示,采用的超声振动频率和振幅分别为20 kHz和6 μm,输出功率为500 W.超声波探头顶端与被测试样相对的材料为不锈钢,按照文献[3,21]推荐的值将试样与探头顶端之间的距离调整为0.5 mm.空化腐蚀实验在3.5%NaCl水溶液中进行,温度保持为25℃,每30 min更换一次NaCl水溶液.每个样品在空化实验结束后,利用75%酒精溶液进行超声清洗,烘干后储存. ...

... 对于LMD-316L不锈钢,将抛光至镜面的试样放置在VHX-5000光学显微镜(OM)下进行观察,根据拍摄的抛光截面信息,利用金相法测量成形件的致密度,该方法根据灰度的不同来区分缺陷,利用金相处理软件Image-Pro Plus 6.0统计缺陷面积分数,致密度的具体计算过程参见文献[9].随后,用自制的酸性水溶液(2%HF + 8%HNO3 + 90%H2O,体积分数)在室温下对试样腐蚀约30 min,利用Ultra 55扫描电子显微镜(SEM)观察打印态材料的微观组织,为量化不同工艺参数下LMD-316L不锈钢微观结构尺寸,针对每个试样使用Image-Pro Plus 6.0软件测量至少20个位置的二次枝晶臂间距,取平均值作为该工艺的测量值.利用线切割对购置的商业锻造316L基板进行切割(切割块体尺寸为:10 mm × 10 mm × 5 mm),块体试样用于微观结构表征和腐蚀实验.块体锻造316L经过标准的研磨、抛光流程后,同样用自制的酸性水溶液腐蚀,先利用OM观察样品的腐蚀情况,无明显划痕且可观察到晶界后再利用SEM进行观察.用JSM-7900F SEM的电子背散射衍射(EBSD)系统对不同工艺参数下LMD-316L和锻造316L不锈钢的晶粒形貌和尺寸进行观察与统计,测试时所有被观察的样品均倾斜70°,加速电压为20 kV,扫描步长为2 μm.使用TSL-OIM分析软件处理EBSD数据,其中晶粒取向差介于2°~10°之间的晶界为小角度晶界(low angle grain boundaries,LAGBs),大于10°的晶界为大角度晶界(high angle grain boundaries,HAGBs)[10,28].对于空化腐蚀后的试样,首先利用SU8100场发射SEM对试样的空化损伤情况进行观察,然后利用ZYGO NexView三维白光干涉表面形貌仪对空化腐蚀后的表面粗糙度进行量化,该设备的垂直分辨率为0.1 nm.最后,为了阐明不同工艺参数下试样的空化腐蚀性能差异,利用Everone MH-6显微硬度计在打印态试样的中部位置按照125 μm的间距分别沿着x和y方向等间距地进行测量,其中x方向40个测试点,y方向5个测试点,载荷9.8 N,加载时间15 s,每个试样的硬度云图由200个硬度数据组成. ...

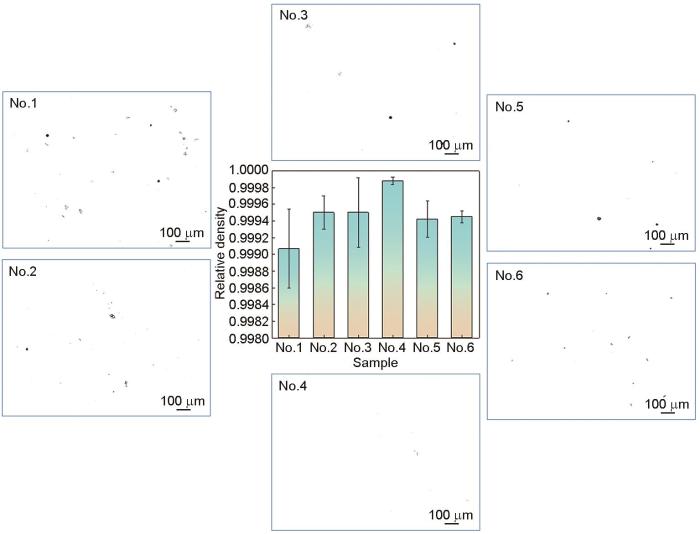

... 图4为不同工艺参数下LMD-316L不锈钢的致密度测量结果和相应的代表性缺陷OM像.可以看出,所有工艺制备的316L材料致密度均值都超过了99.9%,这与使用SLM方法制备的316L材料致密度相当,一般认为成形件致密度达到99%为高致密度零件[9,10,31].可以看出:① 提高激光功率,致密度有增加的趋势(图4,No.1、No.2、No.3),这是因为激光功率的大小直接决定熔池的峰值温度,激光功率越大,熔池内的峰值温度越高[32],因而粉末会熔化得更加充分,材料更加致密,这在SLM-316L不锈钢随激光功率变化的研究[9,33]中也得到了类似的规律;② 重熔可以使得LMD-316L不锈钢的致密度提高(图4,No.1和No.4),这是因为重熔可以有效地使孔洞缺陷有更多的几率从熔池中逃逸出来,而且重熔可以降低成形件表面粗糙度进而使粉末熔化得更加充分,促使缺陷含量降低[34,35];③ 相比105°旋转扫描策略,采用90°旋转扫描策略有助于提高成形件的致密度(图4,No.1和No.5).Saboori等[36]研究指出,通过调控相邻两层之间的旋转角度可以显著改变熔池内的冷却速率,使得最终材料的微观结构及力学性能有较大的差异.因此,可以推断通过调控相邻层之间的旋转角度可以改变成形件的热积累程度,进而影响最终材料的致密度、微观结构和力学性能;④ 垂直打印的样品致密度略高于水平打印的试样(图4,No.1和No.6),这与Ronneberg等[37] SLM-316L的研究结果一致,而Ding等[21]的研究结果却表明孔隙率在水平和垂直打印的SLM-316L不锈钢试样中基本无差别.缺陷作为应力集中源是材料发生过早断裂失效的重要原因,然而,文献中报道的关于打印方向对成形件延伸率影响的结果似乎是矛盾的:有研究[38]认为沿水平方向打印的316L材料延伸率高于相应沿着垂直方向打印的材料,而一些研究[16,39~41]则认为沿着垂直方向打印的试样延伸率更高.进一步分析可以发现这些研究工作中所用的实验设备、制备的试样尺寸和打印参数是不同的,这些因素均会导致成形件的致密度发生变化,下面将通过显微组织观察的手段分析不同工艺参数下材料的微观结构变化规律. ...

... [9,33]中也得到了类似的规律;② 重熔可以使得LMD-316L不锈钢的致密度提高(图4,No.1和No.4),这是因为重熔可以有效地使孔洞缺陷有更多的几率从熔池中逃逸出来,而且重熔可以降低成形件表面粗糙度进而使粉末熔化得更加充分,促使缺陷含量降低[34,35];③ 相比105°旋转扫描策略,采用90°旋转扫描策略有助于提高成形件的致密度(图4,No.1和No.5).Saboori等[36]研究指出,通过调控相邻两层之间的旋转角度可以显著改变熔池内的冷却速率,使得最终材料的微观结构及力学性能有较大的差异.因此,可以推断通过调控相邻层之间的旋转角度可以改变成形件的热积累程度,进而影响最终材料的致密度、微观结构和力学性能;④ 垂直打印的样品致密度略高于水平打印的试样(图4,No.1和No.6),这与Ronneberg等[37] SLM-316L的研究结果一致,而Ding等[21]的研究结果却表明孔隙率在水平和垂直打印的SLM-316L不锈钢试样中基本无差别.缺陷作为应力集中源是材料发生过早断裂失效的重要原因,然而,文献中报道的关于打印方向对成形件延伸率影响的结果似乎是矛盾的:有研究[38]认为沿水平方向打印的316L材料延伸率高于相应沿着垂直方向打印的材料,而一些研究[16,39~41]则认为沿着垂直方向打印的试样延伸率更高.进一步分析可以发现这些研究工作中所用的实验设备、制备的试样尺寸和打印参数是不同的,这些因素均会导致成形件的致密度发生变化,下面将通过显微组织观察的手段分析不同工艺参数下材料的微观结构变化规律. ...

... 图5为不同工艺参数下制备的LMD-316L不锈钢显微组织的SEM像.可以看出,不同工艺参数下LMD-316L不锈钢的显微组织是柱状树枝晶和胞晶的混合组织,其中树枝晶占据主要比例,这与文献[42]中报道的结果是一致的.从图中还可看出,随着功率的增加(图5a~c,No.1~No.3),材料的二次枝晶臂间距呈增加的趋势,平均尺寸分别为(2.57 ± 0.43)、(3.38 ± 0.83)和(3.77 ± 0.71) μm;每2层重熔一次打印时,材料的二次枝晶臂间距变大,为(3.84 ± 0.74) μm (图5a和d);相比105°旋转扫描,90°旋转扫描打印所得材料的二次枝晶臂间距更加粗大,为(4.29 ± 0.56) μm (图5a和e);垂直打印的试样二次枝晶臂间距为(5.13 ± 0.79) μm,高于水平打印的试样(图5a和f).众所周知,冷却速率决定了材料最终微观结构尺寸,冷却速率越大,材料的二次枝晶臂间距越小[8,9],根据二次枝晶臂间距与冷却速率的关系[43],估算了样品No.1~No.6的冷却速率,分别为:8.99 × 103、2.98 × 103、1.93 × 103、1.79 × 103、1.15 × 103和5.64 × 102 K/s.因此,通过调控工艺参数或扫描策略控制熔池内的冷却速率,进而控制二次枝晶臂间距是可行的.图6为不同工艺参数下LMD-316L不锈钢的EBSD像,相应的晶粒尺寸分布及晶粒取向差分布分别见图7和8.可以看出,晶粒尺寸随着工艺参数的变化更加复杂,不同工艺参数下的材料均由曲折晶界组成的长条状晶粒和细小的晶粒组成,这是增材制造材料区别于传统方法制造材料所独有的特征[44,45].虽然1400 W下的平均晶粒尺寸相比1200 W的略小,但考虑到测量误差和晶粒尺寸分布,整体上看,晶粒仍然表现出粗化的趋势,随着功率从1200 W提高到1600 W,LMD-316L不锈钢的平均晶粒尺寸增大了2倍(图6和7a~c),以往的研究[8,46]也表明晶粒尺寸随着激光功率的增加而增大;重熔后表层材料经历了短时熔化再结晶,可观察到大量的细小晶粒(图6d),这可能是因为这些细小的形核晶粒没有足够的保温时间导致的[28];相邻层旋转角度从105°调整到90°后,平均晶粒尺寸从91.84 μm降至68.23 μm,Saboori等[36]研究也表明通过调整相邻层的旋转角度会改变LMD-316L不锈钢的微观结构尺寸,因此可以推断,本工作中相邻层间采用2种扫描角度时,熔道在后续的成形过程中热积累会有显著差别,进而影响最终凝固后材料的晶粒尺寸;垂直打印的试样表现出典型的外延生长晶粒结构特征[28,31],并随相邻层间扫描角度的变化而有一定角度的偏转,这主要是由晶粒的择优取向导致的,晶粒一般总是沿着最大温度梯度的方向生长[47].就晶粒尺寸分布、晶粒取向差分布和平均晶粒尺寸而言,水平和垂直打印的试样没有太大区别(图6a~8a和图6f~8f).与锻造316L不锈钢晶粒取向差分布以大量Σ3孪晶界为主不同,各工艺下的LMD-316L不锈钢晶粒取向差分布呈现正态分布的特征,且小角度晶界的比例显著高于锻造316L不锈钢(图3d和8). ...

... 图10为不同工艺参数制备的LMD-316L和锻造316L不锈钢在NaCl溶液中的开路电位(EOCP)随时间的变化规律.可以看出,所有被测试样的开路电位均随着时间的推移而呈现先增加(由负值向正值变化)后逐渐稳定的趋势,这表明试样在NaCl溶液中自主形成了钝化膜[44],钝化膜的形成起到了进一步阻抗腐蚀的作用.与锻造316L不锈钢相比,LMD-316L不锈钢在开路电位曲线中显现出多个小的尖峰,个别试样出现了明显的峰谷,这表明LMD-316L不锈钢在EOCP达到稳定前存在击穿和再钝化的过程[44].观察3600 s对应的开路电位,可以发现No.1~No.4的EOCP明显高于锻造316L不锈钢,90°旋转扫描打印(No.5)的试样与锻造316L不锈钢的EOCP非常接近,而垂直打印的试样(No.6)的EOCP低于锻造316L不锈钢.图11为各工艺下的LMD-316L不锈钢动电位极化曲线测试结果,腐蚀电位(Ecorr)和点蚀电位(Epit)在图中也进行了标注,相应的电化学参数列于表3.可以看出:LMD-316L不锈钢的极化电阻(Rp)相比锻造316L不锈钢提高了2~98倍,而腐蚀电流密度(icorr)下降了至少1个数量级.就Ecorr而言,No.1~No.3均明显高于锻造316L,而No.4~No.6的Ecorr与锻造316L不锈钢相差不大.除了No.6外,材料的EOCP变化规律与Ecorr一致,No.6的EOCP与Ecorr变化规律不一致可能是开路电位在测试时间内不稳定造成的.进一步比较各工艺下材料的Epit,可以发现No.1和No.3没有发生明显的点蚀,No.2和No.4的Epit明显高于锻造316L不锈钢,但No.5和No.6的Epit明显低于锻造316L不锈钢,这表明LMD-316L不锈钢在某些工艺下易发生点蚀.Kazemipour等[24]的研究指出SLM-316L不锈钢具有比锻造316L不锈钢更强的耐点蚀性能且其亚稳态点蚀速率也更低,材料内部的工艺缺陷在早期并不影响合金的点蚀电位,本工作No.1~No.4的测试结果与Kazemipour等[24]的研究规律一致.然而,由于材料微观结构的显著变化(图5和6),No.5和No.6在保持较小的腐蚀速率下点蚀电位相比锻造316L不锈钢明显降低.总体来讲,在考虑材料的Ecorr和icorr条件下,LMD-316L不锈钢相比锻造316L不锈钢的腐蚀电位更高而腐蚀速率更小,其耐腐蚀性能大幅提高.最近有研究[16,23]表明AM-316L不锈钢的耐腐蚀性能与其材料的微观结构变化密切相关,其中具有高位错密度的亚稳态胞/枝晶结构对AM-316L不锈钢的耐腐蚀性能具有显著影响,研究[10,15]已表明打印态的316L不锈钢处于高应力状态,亚稳态的胞结构/枝晶壁面上存在大量的位错网络结构[13,23],提高扫描速率亦即降低输入到熔池内的能量密度可使材料的一次/二次枝晶臂间距减小[8,9,13,42],进而提高壁面上的位错密度[23,49].Nie等[25]指出LMD-316L不锈钢内大量的小角度晶界和较高的位错密度促使材料表面形成更致密且更厚的钝化膜,从而能够获得比锻造316L不锈钢更好的耐腐蚀性能.本工作的微观结构表征已证实提高激光功率、重熔处理、90°旋转扫描打印和垂直方向打印均会导致LMD-316L不锈钢的二次枝晶臂间距变大(图5),并进一步导致材料内部初始位错密度的降低[23,49],因而材料的极化电阻降低而腐蚀电流密度提高(图11和表3).这表明打印态LMD-316L不锈钢的耐腐蚀性能与其内部的亚结构尺寸(二次枝晶臂间距)可能直接相关,二次枝晶臂间距的增大会导致耐腐蚀性能的降低.然而,与锻造316L不锈钢相比,所有工艺下的LMD-316L不锈钢小角度晶界比例均高于锻造316L不锈钢(图3d和图8),且LMD-316L不锈钢的初始位错密度高于锻造316L不锈钢[25],这可能是本工作LMD-316L不锈钢耐腐蚀性能相比锻造316L不锈钢大幅提高的原因. ...

... 对不同工艺参数下LMD-316L及锻造316L不锈钢在超声振动系统中进行4 h的空化腐蚀实验,图12a~18a和图12c~18c分别为锻造316L不锈钢和No.1~No.6试样在暴露0.5和4 h空化实验后表面的SEM像.可以看出,所有试样的表面在经过空化腐蚀后均变得更加粗糙,在空化实验的早期,所有试样表面均形成了条带状凸起(图12a~18a),随着空化实验时间的延长,各试样表面粗糙度进一步增加,表面形貌出现了大量的韧窝(图12c~18c),这种韧窝形貌与文献[16,18]报道的拉伸断口中出现的韧窝非常相似,这表明所有被空化腐蚀的试样在空化泡的作用下发生了严重的材料损伤和塑性变形.观察试样表面还可以看出:试样表面的凸起优先发生在晶界和未熔缺陷位置,这是因为在塑性变形过程中位错倾向于沿着晶界堆积以抵抗塑性变形[29],在晶界处更容易发生空化损伤,这与空化腐蚀作用下的疲劳过程有关[21];而缺陷(如未熔缺陷或气孔缺陷等)的边缘在空化泡的作用下易引起应力集中,是产生裂纹继而发生裂纹扩展的高发区[50],对增材制造零件的力学性能是不利的[9,28,47,50],会导致材料在空化泡的冲击作用下发生撕裂而造成质量损失[3,21].Ding等[21]研究表明,SLM-316L不锈钢在空化腐蚀过程中材料的晶界会优先发生塑性变形,并认为沿晶界发生空化损伤的区域不仅会造成应力集中,还会导致空化泡在晶界附近溃灭,促使在晶界附近形成沟壑/凸起,这与本工作图12a~18a和图12c~18c观察到的结果是一致的.图12b~18b和图12d~18d分别为使用三维白光干涉表面形貌仪测量锻造316L不锈钢和No.1~No.6试样在暴露0.5和4 h的典型表面形貌,图中基本未变形的部分用绿色表示,而凹陷的区域和凸起的区域分别用蓝色和红色表示.可以看出,锻造316L不锈钢的变形较为均匀(图12b),经过4 h的空化腐蚀后试样表面出现了大量的凹坑和凸起(图12d),这是典型的侵蚀空化损伤,这与LMD-316L不锈钢的空化行为有显著区别(图13b~18b和图13d~18d):LMD-316L不锈钢的表面形貌非常不均匀,有的区域出现了密集的凸起,而有的区域出现了明显的凹陷,且这2种形貌分布较为分散(图13b~18b),经过4 h的空化腐蚀后,LMD-316L不锈钢并不像锻造316L不锈钢形成大量明显的凸起,其表面形貌分布特征与0.5 h的形貌类似(图13d~18d). ...

Additively manufactured hierarchical stainless steels with high strength and ductility

6

2018

... 316L作为一种低碳奥氏体不锈钢,是商业上少数可打印的钢铁材料之一,同时也是国际上热核实验反应堆中真空容器和制造液体火箭发动机喷油器的关键材料,在航空航天、生物医疗、核电工业等关键领域有广泛的应用[4~7].增材制造(AM)作为一种变革性的制造技术,它最大的优势在于可以直接成形形状复杂的构件.由于高能密度热源熔化粉末形成的熔池内冷却速率可达105~107 K/s[5,8,9],材料的微观组织与传统制备方法得到的微观结构存在显著的差异[5,10]:选区激光熔化沉积成形316L (SLM-316L)不锈钢中形成了一种新的跨尺度结构,它由百微米尺度的熔池、几十微米到百微米的晶粒、亚微米尺度的胞结构、几十纳米的氧化物颗粒等构成.然而,SLM和激光熔化沉积(LMD)的冷却速率相差约3个数量级,所形成的跨尺度层级结构在具体每一个微观结构尺度上也存在数量级的差异,如激光熔化沉积成形316L (LMD-316L)不锈钢的熔池尺寸、晶粒长度和胞/枝晶结构尺寸分别为几毫米、500 μm~2.5 mm和2~20 μm,而相应SLM-316L不锈钢的特征尺寸分别为约100 μm、数百微米和小于1 μm[8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

... ,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

... 对于LMD-316L不锈钢,将抛光至镜面的试样放置在VHX-5000光学显微镜(OM)下进行观察,根据拍摄的抛光截面信息,利用金相法测量成形件的致密度,该方法根据灰度的不同来区分缺陷,利用金相处理软件Image-Pro Plus 6.0统计缺陷面积分数,致密度的具体计算过程参见文献[9].随后,用自制的酸性水溶液(2%HF + 8%HNO3 + 90%H2O,体积分数)在室温下对试样腐蚀约30 min,利用Ultra 55扫描电子显微镜(SEM)观察打印态材料的微观组织,为量化不同工艺参数下LMD-316L不锈钢微观结构尺寸,针对每个试样使用Image-Pro Plus 6.0软件测量至少20个位置的二次枝晶臂间距,取平均值作为该工艺的测量值.利用线切割对购置的商业锻造316L基板进行切割(切割块体尺寸为:10 mm × 10 mm × 5 mm),块体试样用于微观结构表征和腐蚀实验.块体锻造316L经过标准的研磨、抛光流程后,同样用自制的酸性水溶液腐蚀,先利用OM观察样品的腐蚀情况,无明显划痕且可观察到晶界后再利用SEM进行观察.用JSM-7900F SEM的电子背散射衍射(EBSD)系统对不同工艺参数下LMD-316L和锻造316L不锈钢的晶粒形貌和尺寸进行观察与统计,测试时所有被观察的样品均倾斜70°,加速电压为20 kV,扫描步长为2 μm.使用TSL-OIM分析软件处理EBSD数据,其中晶粒取向差介于2°~10°之间的晶界为小角度晶界(low angle grain boundaries,LAGBs),大于10°的晶界为大角度晶界(high angle grain boundaries,HAGBs)[10,28].对于空化腐蚀后的试样,首先利用SU8100场发射SEM对试样的空化损伤情况进行观察,然后利用ZYGO NexView三维白光干涉表面形貌仪对空化腐蚀后的表面粗糙度进行量化,该设备的垂直分辨率为0.1 nm.最后,为了阐明不同工艺参数下试样的空化腐蚀性能差异,利用Everone MH-6显微硬度计在打印态试样的中部位置按照125 μm的间距分别沿着x和y方向等间距地进行测量,其中x方向40个测试点,y方向5个测试点,载荷9.8 N,加载时间15 s,每个试样的硬度云图由200个硬度数据组成. ...

... 图4为不同工艺参数下LMD-316L不锈钢的致密度测量结果和相应的代表性缺陷OM像.可以看出,所有工艺制备的316L材料致密度均值都超过了99.9%,这与使用SLM方法制备的316L材料致密度相当,一般认为成形件致密度达到99%为高致密度零件[9,10,31].可以看出:① 提高激光功率,致密度有增加的趋势(图4,No.1、No.2、No.3),这是因为激光功率的大小直接决定熔池的峰值温度,激光功率越大,熔池内的峰值温度越高[32],因而粉末会熔化得更加充分,材料更加致密,这在SLM-316L不锈钢随激光功率变化的研究[9,33]中也得到了类似的规律;② 重熔可以使得LMD-316L不锈钢的致密度提高(图4,No.1和No.4),这是因为重熔可以有效地使孔洞缺陷有更多的几率从熔池中逃逸出来,而且重熔可以降低成形件表面粗糙度进而使粉末熔化得更加充分,促使缺陷含量降低[34,35];③ 相比105°旋转扫描策略,采用90°旋转扫描策略有助于提高成形件的致密度(图4,No.1和No.5).Saboori等[36]研究指出,通过调控相邻两层之间的旋转角度可以显著改变熔池内的冷却速率,使得最终材料的微观结构及力学性能有较大的差异.因此,可以推断通过调控相邻层之间的旋转角度可以改变成形件的热积累程度,进而影响最终材料的致密度、微观结构和力学性能;④ 垂直打印的样品致密度略高于水平打印的试样(图4,No.1和No.6),这与Ronneberg等[37] SLM-316L的研究结果一致,而Ding等[21]的研究结果却表明孔隙率在水平和垂直打印的SLM-316L不锈钢试样中基本无差别.缺陷作为应力集中源是材料发生过早断裂失效的重要原因,然而,文献中报道的关于打印方向对成形件延伸率影响的结果似乎是矛盾的:有研究[38]认为沿水平方向打印的316L材料延伸率高于相应沿着垂直方向打印的材料,而一些研究[16,39~41]则认为沿着垂直方向打印的试样延伸率更高.进一步分析可以发现这些研究工作中所用的实验设备、制备的试样尺寸和打印参数是不同的,这些因素均会导致成形件的致密度发生变化,下面将通过显微组织观察的手段分析不同工艺参数下材料的微观结构变化规律. ...

... 微观结构的变化会导致材料力学性能的变化.图9为各工艺下的硬度分布云图,相应的硬度数据列于表2.随着激光功率的增加,LMD-316L不锈钢的平均显微硬度从355.4 HV1降低到325.5 HV1 (图9a~c和表2),相比No.1试样,重熔和90°旋转扫描均会降低试样的显微硬度(图9a、d、e和表2);相比水平打印的试样,垂直打印试样的显微硬度显著降低(图9a、f和表2),降幅约12.8%,这与文献[40]中报道的结果较为一致,即:沿水平方向打印的试样比沿垂直方向打印的试样强度高约10%.值得注意的是,虽然不同工艺参数下LMD-316L不锈钢的晶粒尺寸显著大于锻造316L不锈钢,但是其显微硬度明显高于锻造316L不锈钢(图3e、图9和表2).进一步分析发现:LMD-316L不锈钢硬度的变化与二次枝晶臂间距的变化具有明显的关联,即:枝晶臂间距增大会导致显微硬度的下降,然而显微硬度与晶粒尺寸的变化没有明显关系(图5、6和9),这预示着使用二次枝晶臂间距可能会更好地预测LMD-316L不锈钢的力学性能.虽然关于AM-316L材料屈服强度的预测目前还存在争议[7],但是现有研究[10,28,48]表明,使用晶粒内部的胞结构/二次枝晶臂间距能更好地预测AM-316L不锈钢力学性能的变化. ...

... 图10为不同工艺参数制备的LMD-316L和锻造316L不锈钢在NaCl溶液中的开路电位(EOCP)随时间的变化规律.可以看出,所有被测试样的开路电位均随着时间的推移而呈现先增加(由负值向正值变化)后逐渐稳定的趋势,这表明试样在NaCl溶液中自主形成了钝化膜[44],钝化膜的形成起到了进一步阻抗腐蚀的作用.与锻造316L不锈钢相比,LMD-316L不锈钢在开路电位曲线中显现出多个小的尖峰,个别试样出现了明显的峰谷,这表明LMD-316L不锈钢在EOCP达到稳定前存在击穿和再钝化的过程[44].观察3600 s对应的开路电位,可以发现No.1~No.4的EOCP明显高于锻造316L不锈钢,90°旋转扫描打印(No.5)的试样与锻造316L不锈钢的EOCP非常接近,而垂直打印的试样(No.6)的EOCP低于锻造316L不锈钢.图11为各工艺下的LMD-316L不锈钢动电位极化曲线测试结果,腐蚀电位(Ecorr)和点蚀电位(Epit)在图中也进行了标注,相应的电化学参数列于表3.可以看出:LMD-316L不锈钢的极化电阻(Rp)相比锻造316L不锈钢提高了2~98倍,而腐蚀电流密度(icorr)下降了至少1个数量级.就Ecorr而言,No.1~No.3均明显高于锻造316L,而No.4~No.6的Ecorr与锻造316L不锈钢相差不大.除了No.6外,材料的EOCP变化规律与Ecorr一致,No.6的EOCP与Ecorr变化规律不一致可能是开路电位在测试时间内不稳定造成的.进一步比较各工艺下材料的Epit,可以发现No.1和No.3没有发生明显的点蚀,No.2和No.4的Epit明显高于锻造316L不锈钢,但No.5和No.6的Epit明显低于锻造316L不锈钢,这表明LMD-316L不锈钢在某些工艺下易发生点蚀.Kazemipour等[24]的研究指出SLM-316L不锈钢具有比锻造316L不锈钢更强的耐点蚀性能且其亚稳态点蚀速率也更低,材料内部的工艺缺陷在早期并不影响合金的点蚀电位,本工作No.1~No.4的测试结果与Kazemipour等[24]的研究规律一致.然而,由于材料微观结构的显著变化(图5和6),No.5和No.6在保持较小的腐蚀速率下点蚀电位相比锻造316L不锈钢明显降低.总体来讲,在考虑材料的Ecorr和icorr条件下,LMD-316L不锈钢相比锻造316L不锈钢的腐蚀电位更高而腐蚀速率更小,其耐腐蚀性能大幅提高.最近有研究[16,23]表明AM-316L不锈钢的耐腐蚀性能与其材料的微观结构变化密切相关,其中具有高位错密度的亚稳态胞/枝晶结构对AM-316L不锈钢的耐腐蚀性能具有显著影响,研究[10,15]已表明打印态的316L不锈钢处于高应力状态,亚稳态的胞结构/枝晶壁面上存在大量的位错网络结构[13,23],提高扫描速率亦即降低输入到熔池内的能量密度可使材料的一次/二次枝晶臂间距减小[8,9,13,42],进而提高壁面上的位错密度[23,49].Nie等[25]指出LMD-316L不锈钢内大量的小角度晶界和较高的位错密度促使材料表面形成更致密且更厚的钝化膜,从而能够获得比锻造316L不锈钢更好的耐腐蚀性能.本工作的微观结构表征已证实提高激光功率、重熔处理、90°旋转扫描打印和垂直方向打印均会导致LMD-316L不锈钢的二次枝晶臂间距变大(图5),并进一步导致材料内部初始位错密度的降低[23,49],因而材料的极化电阻降低而腐蚀电流密度提高(图11和表3).这表明打印态LMD-316L不锈钢的耐腐蚀性能与其内部的亚结构尺寸(二次枝晶臂间距)可能直接相关,二次枝晶臂间距的增大会导致耐腐蚀性能的降低.然而,与锻造316L不锈钢相比,所有工艺下的LMD-316L不锈钢小角度晶界比例均高于锻造316L不锈钢(图3d和图8),且LMD-316L不锈钢的初始位错密度高于锻造316L不锈钢[25],这可能是本工作LMD-316L不锈钢耐腐蚀性能相比锻造316L不锈钢大幅提高的原因. ...

Microstructure and mechanical properties of AISI 316L produced by directed energy deposition-based additive manufacturing: A review

0

2020

Additive manufacturing of metals

1

2016

... 316L作为一种低碳奥氏体不锈钢,是商业上少数可打印的钢铁材料之一,同时也是国际上热核实验反应堆中真空容器和制造液体火箭发动机喷油器的关键材料,在航空航天、生物医疗、核电工业等关键领域有广泛的应用[4~7].增材制造(AM)作为一种变革性的制造技术,它最大的优势在于可以直接成形形状复杂的构件.由于高能密度热源熔化粉末形成的熔池内冷却速率可达105~107 K/s[5,8,9],材料的微观组织与传统制备方法得到的微观结构存在显著的差异[5,10]:选区激光熔化沉积成形316L (SLM-316L)不锈钢中形成了一种新的跨尺度结构,它由百微米尺度的熔池、几十微米到百微米的晶粒、亚微米尺度的胞结构、几十纳米的氧化物颗粒等构成.然而,SLM和激光熔化沉积(LMD)的冷却速率相差约3个数量级,所形成的跨尺度层级结构在具体每一个微观结构尺度上也存在数量级的差异,如激光熔化沉积成形316L (LMD-316L)不锈钢的熔池尺寸、晶粒长度和胞/枝晶结构尺寸分别为几毫米、500 μm~2.5 mm和2~20 μm,而相应SLM-316L不锈钢的特征尺寸分别为约100 μm、数百微米和小于1 μm[8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

Dislocation network in additive manufactured steel breaks strength-ductility trade-off

3

2018

... 316L作为一种低碳奥氏体不锈钢,是商业上少数可打印的钢铁材料之一,同时也是国际上热核实验反应堆中真空容器和制造液体火箭发动机喷油器的关键材料,在航空航天、生物医疗、核电工业等关键领域有广泛的应用[4~7].增材制造(AM)作为一种变革性的制造技术,它最大的优势在于可以直接成形形状复杂的构件.由于高能密度热源熔化粉末形成的熔池内冷却速率可达105~107 K/s[5,8,9],材料的微观组织与传统制备方法得到的微观结构存在显著的差异[5,10]:选区激光熔化沉积成形316L (SLM-316L)不锈钢中形成了一种新的跨尺度结构,它由百微米尺度的熔池、几十微米到百微米的晶粒、亚微米尺度的胞结构、几十纳米的氧化物颗粒等构成.然而,SLM和激光熔化沉积(LMD)的冷却速率相差约3个数量级,所形成的跨尺度层级结构在具体每一个微观结构尺度上也存在数量级的差异,如激光熔化沉积成形316L (LMD-316L)不锈钢的熔池尺寸、晶粒长度和胞/枝晶结构尺寸分别为几毫米、500 μm~2.5 mm和2~20 μm,而相应SLM-316L不锈钢的特征尺寸分别为约100 μm、数百微米和小于1 μm[8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

... 图10为不同工艺参数制备的LMD-316L和锻造316L不锈钢在NaCl溶液中的开路电位(EOCP)随时间的变化规律.可以看出,所有被测试样的开路电位均随着时间的推移而呈现先增加(由负值向正值变化)后逐渐稳定的趋势,这表明试样在NaCl溶液中自主形成了钝化膜[44],钝化膜的形成起到了进一步阻抗腐蚀的作用.与锻造316L不锈钢相比,LMD-316L不锈钢在开路电位曲线中显现出多个小的尖峰,个别试样出现了明显的峰谷,这表明LMD-316L不锈钢在EOCP达到稳定前存在击穿和再钝化的过程[44].观察3600 s对应的开路电位,可以发现No.1~No.4的EOCP明显高于锻造316L不锈钢,90°旋转扫描打印(No.5)的试样与锻造316L不锈钢的EOCP非常接近,而垂直打印的试样(No.6)的EOCP低于锻造316L不锈钢.图11为各工艺下的LMD-316L不锈钢动电位极化曲线测试结果,腐蚀电位(Ecorr)和点蚀电位(Epit)在图中也进行了标注,相应的电化学参数列于表3.可以看出:LMD-316L不锈钢的极化电阻(Rp)相比锻造316L不锈钢提高了2~98倍,而腐蚀电流密度(icorr)下降了至少1个数量级.就Ecorr而言,No.1~No.3均明显高于锻造316L,而No.4~No.6的Ecorr与锻造316L不锈钢相差不大.除了No.6外,材料的EOCP变化规律与Ecorr一致,No.6的EOCP与Ecorr变化规律不一致可能是开路电位在测试时间内不稳定造成的.进一步比较各工艺下材料的Epit,可以发现No.1和No.3没有发生明显的点蚀,No.2和No.4的Epit明显高于锻造316L不锈钢,但No.5和No.6的Epit明显低于锻造316L不锈钢,这表明LMD-316L不锈钢在某些工艺下易发生点蚀.Kazemipour等[24]的研究指出SLM-316L不锈钢具有比锻造316L不锈钢更强的耐点蚀性能且其亚稳态点蚀速率也更低,材料内部的工艺缺陷在早期并不影响合金的点蚀电位,本工作No.1~No.4的测试结果与Kazemipour等[24]的研究规律一致.然而,由于材料微观结构的显著变化(图5和6),No.5和No.6在保持较小的腐蚀速率下点蚀电位相比锻造316L不锈钢明显降低.总体来讲,在考虑材料的Ecorr和icorr条件下,LMD-316L不锈钢相比锻造316L不锈钢的腐蚀电位更高而腐蚀速率更小,其耐腐蚀性能大幅提高.最近有研究[16,23]表明AM-316L不锈钢的耐腐蚀性能与其材料的微观结构变化密切相关,其中具有高位错密度的亚稳态胞/枝晶结构对AM-316L不锈钢的耐腐蚀性能具有显著影响,研究[10,15]已表明打印态的316L不锈钢处于高应力状态,亚稳态的胞结构/枝晶壁面上存在大量的位错网络结构[13,23],提高扫描速率亦即降低输入到熔池内的能量密度可使材料的一次/二次枝晶臂间距减小[8,9,13,42],进而提高壁面上的位错密度[23,49].Nie等[25]指出LMD-316L不锈钢内大量的小角度晶界和较高的位错密度促使材料表面形成更致密且更厚的钝化膜,从而能够获得比锻造316L不锈钢更好的耐腐蚀性能.本工作的微观结构表征已证实提高激光功率、重熔处理、90°旋转扫描打印和垂直方向打印均会导致LMD-316L不锈钢的二次枝晶臂间距变大(图5),并进一步导致材料内部初始位错密度的降低[23,49],因而材料的极化电阻降低而腐蚀电流密度提高(图11和表3).这表明打印态LMD-316L不锈钢的耐腐蚀性能与其内部的亚结构尺寸(二次枝晶臂间距)可能直接相关,二次枝晶臂间距的增大会导致耐腐蚀性能的降低.然而,与锻造316L不锈钢相比,所有工艺下的LMD-316L不锈钢小角度晶界比例均高于锻造316L不锈钢(图3d和图8),且LMD-316L不锈钢的初始位错密度高于锻造316L不锈钢[25],这可能是本工作LMD-316L不锈钢耐腐蚀性能相比锻造316L不锈钢大幅提高的原因. ...

... ,13,42],进而提高壁面上的位错密度[23,49].Nie等[25]指出LMD-316L不锈钢内大量的小角度晶界和较高的位错密度促使材料表面形成更致密且更厚的钝化膜,从而能够获得比锻造316L不锈钢更好的耐腐蚀性能.本工作的微观结构表征已证实提高激光功率、重熔处理、90°旋转扫描打印和垂直方向打印均会导致LMD-316L不锈钢的二次枝晶臂间距变大(图5),并进一步导致材料内部初始位错密度的降低[23,49],因而材料的极化电阻降低而腐蚀电流密度提高(图11和表3).这表明打印态LMD-316L不锈钢的耐腐蚀性能与其内部的亚结构尺寸(二次枝晶臂间距)可能直接相关,二次枝晶臂间距的增大会导致耐腐蚀性能的降低.然而,与锻造316L不锈钢相比,所有工艺下的LMD-316L不锈钢小角度晶界比例均高于锻造316L不锈钢(图3d和图8),且LMD-316L不锈钢的初始位错密度高于锻造316L不锈钢[25],这可能是本工作LMD-316L不锈钢耐腐蚀性能相比锻造316L不锈钢大幅提高的原因. ...

High strength and ductility of additively manufactured 316L stainless steel explained

1

2018

... 为了更好地了解LMD-316L不锈钢耐腐蚀性能及空化腐蚀性能随工艺参数的变化,对锻造316L不锈钢的微观结构、耐腐蚀性能及空化腐蚀性进行了表征与测试,并将其结果与打印态LMD-316L不锈钢进行对比.图3为锻造316L不锈钢的微观组织特征.可以看出,其晶粒为典型的等轴晶结构(图3a和b),平均晶粒尺寸为(19.26 ± 8.76) μm (图3c),大角度晶界的比例为97.3%,其中约有40%的晶界取向差在58.2°~61.3°之间.研究[14]表明,对于低层错能的316L不锈钢,60°的取向差界面是Σ3孪晶界,位错与这些连贯的孪晶界面相互作用,在提高材料强度的同时还可以保持较好的韧性,这是因为这些连续的孪晶界不仅可以作为位错的源/汇,还可以阻止位错从孪晶的一侧运动到另一侧,此外,它可以作为滑移面,在滑移面上可发生位错的滑移和堆积.因此,沿着孪晶界面的位错滑移可以有效地释放位错与孪晶交互产生的应力集中[29].图3e为锻造316L不锈钢的显微硬度测试结果.可以看出,整个测试区域的显微硬度分布较为均匀,为179.6~217.3 HV1,平均显微硬度为(196.4 ± 5.7) HV1,略低于文献[30]中报道的商业锻造316L硬度(214.8 ± 10.2) HV. ...

Mechanical properties and corrosion behavior of selective laser melted 316L stainless steel after different heat treatment processes

5

2019

... 316L作为一种低碳奥氏体不锈钢,是商业上少数可打印的钢铁材料之一,同时也是国际上热核实验反应堆中真空容器和制造液体火箭发动机喷油器的关键材料,在航空航天、生物医疗、核电工业等关键领域有广泛的应用[4~7].增材制造(AM)作为一种变革性的制造技术,它最大的优势在于可以直接成形形状复杂的构件.由于高能密度热源熔化粉末形成的熔池内冷却速率可达105~107 K/s[5,8,9],材料的微观组织与传统制备方法得到的微观结构存在显著的差异[5,10]:选区激光熔化沉积成形316L (SLM-316L)不锈钢中形成了一种新的跨尺度结构,它由百微米尺度的熔池、几十微米到百微米的晶粒、亚微米尺度的胞结构、几十纳米的氧化物颗粒等构成.然而,SLM和激光熔化沉积(LMD)的冷却速率相差约3个数量级,所形成的跨尺度层级结构在具体每一个微观结构尺度上也存在数量级的差异,如激光熔化沉积成形316L (LMD-316L)不锈钢的熔池尺寸、晶粒长度和胞/枝晶结构尺寸分别为几毫米、500 μm~2.5 mm和2~20 μm,而相应SLM-316L不锈钢的特征尺寸分别为约100 μm、数百微米和小于1 μm[8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

... 由于316L不锈钢具有较高的应变硬化能力、良好的焊接性以及较强的耐腐蚀性能,因此其对空化腐蚀也具有较高的抵抗能力,可用于有空化泡存在的液体环境中[3].近年来,增材制造316L (AM-316L)不锈钢被应用于生产重量轻、体积小的液压元件[21,22],部分流体机械元件在高旋转速率和具有腐蚀性的介质中工作,因此材料的电化学和空化腐蚀性能显得尤为重要.关于SLM-316L和LMD-316L不锈钢的电化学腐蚀性能已有较多报道[15,16,23~25]:一些研究工作[6,16]表明,由于AM-316L不锈钢不可避免地存在各种缺陷,导致其耐腐蚀性能弱于锻造316L不锈钢;而有些研究工作[24,25]却表明AM-316L不锈钢的特殊微结构使得其比锻造316L不锈钢具有更好的耐点蚀性能和更低的稳态点蚀速率.Ziętala等[16]的研究结果表明,LMD-316L不锈钢胞结构壁面上形成了δ铁素体相,这种相结构不会出现在传统冶金方法制造的316L不锈钢中,他们指出δ铁素体相的形成是打印态材料力学性能和耐腐蚀性能提高的主要原因;通过改变工艺参数调控材料内部的初始位错密度[23]或使用后处理手段改变打印态材料内部的非平衡微观结构(如亚晶、小角度晶界比例和缺陷尺寸),可以显著影响材料的钝化膜厚度和腐蚀电位[6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... ,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... [15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... 图10为不同工艺参数制备的LMD-316L和锻造316L不锈钢在NaCl溶液中的开路电位(EOCP)随时间的变化规律.可以看出,所有被测试样的开路电位均随着时间的推移而呈现先增加(由负值向正值变化)后逐渐稳定的趋势,这表明试样在NaCl溶液中自主形成了钝化膜[44],钝化膜的形成起到了进一步阻抗腐蚀的作用.与锻造316L不锈钢相比,LMD-316L不锈钢在开路电位曲线中显现出多个小的尖峰,个别试样出现了明显的峰谷,这表明LMD-316L不锈钢在EOCP达到稳定前存在击穿和再钝化的过程[44].观察3600 s对应的开路电位,可以发现No.1~No.4的EOCP明显高于锻造316L不锈钢,90°旋转扫描打印(No.5)的试样与锻造316L不锈钢的EOCP非常接近,而垂直打印的试样(No.6)的EOCP低于锻造316L不锈钢.图11为各工艺下的LMD-316L不锈钢动电位极化曲线测试结果,腐蚀电位(Ecorr)和点蚀电位(Epit)在图中也进行了标注,相应的电化学参数列于表3.可以看出:LMD-316L不锈钢的极化电阻(Rp)相比锻造316L不锈钢提高了2~98倍,而腐蚀电流密度(icorr)下降了至少1个数量级.就Ecorr而言,No.1~No.3均明显高于锻造316L,而No.4~No.6的Ecorr与锻造316L不锈钢相差不大.除了No.6外,材料的EOCP变化规律与Ecorr一致,No.6的EOCP与Ecorr变化规律不一致可能是开路电位在测试时间内不稳定造成的.进一步比较各工艺下材料的Epit,可以发现No.1和No.3没有发生明显的点蚀,No.2和No.4的Epit明显高于锻造316L不锈钢,但No.5和No.6的Epit明显低于锻造316L不锈钢,这表明LMD-316L不锈钢在某些工艺下易发生点蚀.Kazemipour等[24]的研究指出SLM-316L不锈钢具有比锻造316L不锈钢更强的耐点蚀性能且其亚稳态点蚀速率也更低,材料内部的工艺缺陷在早期并不影响合金的点蚀电位,本工作No.1~No.4的测试结果与Kazemipour等[24]的研究规律一致.然而,由于材料微观结构的显著变化(图5和6),No.5和No.6在保持较小的腐蚀速率下点蚀电位相比锻造316L不锈钢明显降低.总体来讲,在考虑材料的Ecorr和icorr条件下,LMD-316L不锈钢相比锻造316L不锈钢的腐蚀电位更高而腐蚀速率更小,其耐腐蚀性能大幅提高.最近有研究[16,23]表明AM-316L不锈钢的耐腐蚀性能与其材料的微观结构变化密切相关,其中具有高位错密度的亚稳态胞/枝晶结构对AM-316L不锈钢的耐腐蚀性能具有显著影响,研究[10,15]已表明打印态的316L不锈钢处于高应力状态,亚稳态的胞结构/枝晶壁面上存在大量的位错网络结构[13,23],提高扫描速率亦即降低输入到熔池内的能量密度可使材料的一次/二次枝晶臂间距减小[8,9,13,42],进而提高壁面上的位错密度[23,49].Nie等[25]指出LMD-316L不锈钢内大量的小角度晶界和较高的位错密度促使材料表面形成更致密且更厚的钝化膜,从而能够获得比锻造316L不锈钢更好的耐腐蚀性能.本工作的微观结构表征已证实提高激光功率、重熔处理、90°旋转扫描打印和垂直方向打印均会导致LMD-316L不锈钢的二次枝晶臂间距变大(图5),并进一步导致材料内部初始位错密度的降低[23,49],因而材料的极化电阻降低而腐蚀电流密度提高(图11和表3).这表明打印态LMD-316L不锈钢的耐腐蚀性能与其内部的亚结构尺寸(二次枝晶臂间距)可能直接相关,二次枝晶臂间距的增大会导致耐腐蚀性能的降低.然而,与锻造316L不锈钢相比,所有工艺下的LMD-316L不锈钢小角度晶界比例均高于锻造316L不锈钢(图3d和图8),且LMD-316L不锈钢的初始位错密度高于锻造316L不锈钢[25],这可能是本工作LMD-316L不锈钢耐腐蚀性能相比锻造316L不锈钢大幅提高的原因. ...

The microstructure, mechanical properties and corrosion resistance of 316L stainless steel fabricated using laser engineered net shaping

8

2016

... 316L作为一种低碳奥氏体不锈钢,是商业上少数可打印的钢铁材料之一,同时也是国际上热核实验反应堆中真空容器和制造液体火箭发动机喷油器的关键材料,在航空航天、生物医疗、核电工业等关键领域有广泛的应用[4~7].增材制造(AM)作为一种变革性的制造技术,它最大的优势在于可以直接成形形状复杂的构件.由于高能密度热源熔化粉末形成的熔池内冷却速率可达105~107 K/s[5,8,9],材料的微观组织与传统制备方法得到的微观结构存在显著的差异[5,10]:选区激光熔化沉积成形316L (SLM-316L)不锈钢中形成了一种新的跨尺度结构,它由百微米尺度的熔池、几十微米到百微米的晶粒、亚微米尺度的胞结构、几十纳米的氧化物颗粒等构成.然而,SLM和激光熔化沉积(LMD)的冷却速率相差约3个数量级,所形成的跨尺度层级结构在具体每一个微观结构尺度上也存在数量级的差异,如激光熔化沉积成形316L (LMD-316L)不锈钢的熔池尺寸、晶粒长度和胞/枝晶结构尺寸分别为几毫米、500 μm~2.5 mm和2~20 μm,而相应SLM-316L不锈钢的特征尺寸分别为约100 μm、数百微米和小于1 μm[8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

... 由于316L不锈钢具有较高的应变硬化能力、良好的焊接性以及较强的耐腐蚀性能,因此其对空化腐蚀也具有较高的抵抗能力,可用于有空化泡存在的液体环境中[3].近年来,增材制造316L (AM-316L)不锈钢被应用于生产重量轻、体积小的液压元件[21,22],部分流体机械元件在高旋转速率和具有腐蚀性的介质中工作,因此材料的电化学和空化腐蚀性能显得尤为重要.关于SLM-316L和LMD-316L不锈钢的电化学腐蚀性能已有较多报道[15,16,23~25]:一些研究工作[6,16]表明,由于AM-316L不锈钢不可避免地存在各种缺陷,导致其耐腐蚀性能弱于锻造316L不锈钢;而有些研究工作[24,25]却表明AM-316L不锈钢的特殊微结构使得其比锻造316L不锈钢具有更好的耐点蚀性能和更低的稳态点蚀速率.Ziętala等[16]的研究结果表明,LMD-316L不锈钢胞结构壁面上形成了δ铁素体相,这种相结构不会出现在传统冶金方法制造的316L不锈钢中,他们指出δ铁素体相的形成是打印态材料力学性能和耐腐蚀性能提高的主要原因;通过改变工艺参数调控材料内部的初始位错密度[23]或使用后处理手段改变打印态材料内部的非平衡微观结构(如亚晶、小角度晶界比例和缺陷尺寸),可以显著影响材料的钝化膜厚度和腐蚀电位[6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... ,16]表明,由于AM-316L不锈钢不可避免地存在各种缺陷,导致其耐腐蚀性能弱于锻造316L不锈钢;而有些研究工作[24,25]却表明AM-316L不锈钢的特殊微结构使得其比锻造316L不锈钢具有更好的耐点蚀性能和更低的稳态点蚀速率.Ziętala等[16]的研究结果表明,LMD-316L不锈钢胞结构壁面上形成了δ铁素体相,这种相结构不会出现在传统冶金方法制造的316L不锈钢中,他们指出δ铁素体相的形成是打印态材料力学性能和耐腐蚀性能提高的主要原因;通过改变工艺参数调控材料内部的初始位错密度[23]或使用后处理手段改变打印态材料内部的非平衡微观结构(如亚晶、小角度晶界比例和缺陷尺寸),可以显著影响材料的钝化膜厚度和腐蚀电位[6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... [16]的研究结果表明,LMD-316L不锈钢胞结构壁面上形成了δ铁素体相,这种相结构不会出现在传统冶金方法制造的316L不锈钢中,他们指出δ铁素体相的形成是打印态材料力学性能和耐腐蚀性能提高的主要原因;通过改变工艺参数调控材料内部的初始位错密度[23]或使用后处理手段改变打印态材料内部的非平衡微观结构(如亚晶、小角度晶界比例和缺陷尺寸),可以显著影响材料的钝化膜厚度和腐蚀电位[6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... ,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... 图4为不同工艺参数下LMD-316L不锈钢的致密度测量结果和相应的代表性缺陷OM像.可以看出,所有工艺制备的316L材料致密度均值都超过了99.9%,这与使用SLM方法制备的316L材料致密度相当,一般认为成形件致密度达到99%为高致密度零件[9,10,31].可以看出:① 提高激光功率,致密度有增加的趋势(图4,No.1、No.2、No.3),这是因为激光功率的大小直接决定熔池的峰值温度,激光功率越大,熔池内的峰值温度越高[32],因而粉末会熔化得更加充分,材料更加致密,这在SLM-316L不锈钢随激光功率变化的研究[9,33]中也得到了类似的规律;② 重熔可以使得LMD-316L不锈钢的致密度提高(图4,No.1和No.4),这是因为重熔可以有效地使孔洞缺陷有更多的几率从熔池中逃逸出来,而且重熔可以降低成形件表面粗糙度进而使粉末熔化得更加充分,促使缺陷含量降低[34,35];③ 相比105°旋转扫描策略,采用90°旋转扫描策略有助于提高成形件的致密度(图4,No.1和No.5).Saboori等[36]研究指出,通过调控相邻两层之间的旋转角度可以显著改变熔池内的冷却速率,使得最终材料的微观结构及力学性能有较大的差异.因此,可以推断通过调控相邻层之间的旋转角度可以改变成形件的热积累程度,进而影响最终材料的致密度、微观结构和力学性能;④ 垂直打印的样品致密度略高于水平打印的试样(图4,No.1和No.6),这与Ronneberg等[37] SLM-316L的研究结果一致,而Ding等[21]的研究结果却表明孔隙率在水平和垂直打印的SLM-316L不锈钢试样中基本无差别.缺陷作为应力集中源是材料发生过早断裂失效的重要原因,然而,文献中报道的关于打印方向对成形件延伸率影响的结果似乎是矛盾的:有研究[38]认为沿水平方向打印的316L材料延伸率高于相应沿着垂直方向打印的材料,而一些研究[16,39~41]则认为沿着垂直方向打印的试样延伸率更高.进一步分析可以发现这些研究工作中所用的实验设备、制备的试样尺寸和打印参数是不同的,这些因素均会导致成形件的致密度发生变化,下面将通过显微组织观察的手段分析不同工艺参数下材料的微观结构变化规律. ...

... 图10为不同工艺参数制备的LMD-316L和锻造316L不锈钢在NaCl溶液中的开路电位(EOCP)随时间的变化规律.可以看出,所有被测试样的开路电位均随着时间的推移而呈现先增加(由负值向正值变化)后逐渐稳定的趋势,这表明试样在NaCl溶液中自主形成了钝化膜[44],钝化膜的形成起到了进一步阻抗腐蚀的作用.与锻造316L不锈钢相比,LMD-316L不锈钢在开路电位曲线中显现出多个小的尖峰,个别试样出现了明显的峰谷,这表明LMD-316L不锈钢在EOCP达到稳定前存在击穿和再钝化的过程[44].观察3600 s对应的开路电位,可以发现No.1~No.4的EOCP明显高于锻造316L不锈钢,90°旋转扫描打印(No.5)的试样与锻造316L不锈钢的EOCP非常接近,而垂直打印的试样(No.6)的EOCP低于锻造316L不锈钢.图11为各工艺下的LMD-316L不锈钢动电位极化曲线测试结果,腐蚀电位(Ecorr)和点蚀电位(Epit)在图中也进行了标注,相应的电化学参数列于表3.可以看出:LMD-316L不锈钢的极化电阻(Rp)相比锻造316L不锈钢提高了2~98倍,而腐蚀电流密度(icorr)下降了至少1个数量级.就Ecorr而言,No.1~No.3均明显高于锻造316L,而No.4~No.6的Ecorr与锻造316L不锈钢相差不大.除了No.6外,材料的EOCP变化规律与Ecorr一致,No.6的EOCP与Ecorr变化规律不一致可能是开路电位在测试时间内不稳定造成的.进一步比较各工艺下材料的Epit,可以发现No.1和No.3没有发生明显的点蚀,No.2和No.4的Epit明显高于锻造316L不锈钢,但No.5和No.6的Epit明显低于锻造316L不锈钢,这表明LMD-316L不锈钢在某些工艺下易发生点蚀.Kazemipour等[24]的研究指出SLM-316L不锈钢具有比锻造316L不锈钢更强的耐点蚀性能且其亚稳态点蚀速率也更低,材料内部的工艺缺陷在早期并不影响合金的点蚀电位,本工作No.1~No.4的测试结果与Kazemipour等[24]的研究规律一致.然而,由于材料微观结构的显著变化(图5和6),No.5和No.6在保持较小的腐蚀速率下点蚀电位相比锻造316L不锈钢明显降低.总体来讲,在考虑材料的Ecorr和icorr条件下,LMD-316L不锈钢相比锻造316L不锈钢的腐蚀电位更高而腐蚀速率更小,其耐腐蚀性能大幅提高.最近有研究[16,23]表明AM-316L不锈钢的耐腐蚀性能与其材料的微观结构变化密切相关,其中具有高位错密度的亚稳态胞/枝晶结构对AM-316L不锈钢的耐腐蚀性能具有显著影响,研究[10,15]已表明打印态的316L不锈钢处于高应力状态,亚稳态的胞结构/枝晶壁面上存在大量的位错网络结构[13,23],提高扫描速率亦即降低输入到熔池内的能量密度可使材料的一次/二次枝晶臂间距减小[8,9,13,42],进而提高壁面上的位错密度[23,49].Nie等[25]指出LMD-316L不锈钢内大量的小角度晶界和较高的位错密度促使材料表面形成更致密且更厚的钝化膜,从而能够获得比锻造316L不锈钢更好的耐腐蚀性能.本工作的微观结构表征已证实提高激光功率、重熔处理、90°旋转扫描打印和垂直方向打印均会导致LMD-316L不锈钢的二次枝晶臂间距变大(图5),并进一步导致材料内部初始位错密度的降低[23,49],因而材料的极化电阻降低而腐蚀电流密度提高(图11和表3).这表明打印态LMD-316L不锈钢的耐腐蚀性能与其内部的亚结构尺寸(二次枝晶臂间距)可能直接相关,二次枝晶臂间距的增大会导致耐腐蚀性能的降低.然而,与锻造316L不锈钢相比,所有工艺下的LMD-316L不锈钢小角度晶界比例均高于锻造316L不锈钢(图3d和图8),且LMD-316L不锈钢的初始位错密度高于锻造316L不锈钢[25],这可能是本工作LMD-316L不锈钢耐腐蚀性能相比锻造316L不锈钢大幅提高的原因. ...

... 对不同工艺参数下LMD-316L及锻造316L不锈钢在超声振动系统中进行4 h的空化腐蚀实验,图12a~18a和图12c~18c分别为锻造316L不锈钢和No.1~No.6试样在暴露0.5和4 h空化实验后表面的SEM像.可以看出,所有试样的表面在经过空化腐蚀后均变得更加粗糙,在空化实验的早期,所有试样表面均形成了条带状凸起(图12a~18a),随着空化实验时间的延长,各试样表面粗糙度进一步增加,表面形貌出现了大量的韧窝(图12c~18c),这种韧窝形貌与文献[16,18]报道的拉伸断口中出现的韧窝非常相似,这表明所有被空化腐蚀的试样在空化泡的作用下发生了严重的材料损伤和塑性变形.观察试样表面还可以看出:试样表面的凸起优先发生在晶界和未熔缺陷位置,这是因为在塑性变形过程中位错倾向于沿着晶界堆积以抵抗塑性变形[29],在晶界处更容易发生空化损伤,这与空化腐蚀作用下的疲劳过程有关[21];而缺陷(如未熔缺陷或气孔缺陷等)的边缘在空化泡的作用下易引起应力集中,是产生裂纹继而发生裂纹扩展的高发区[50],对增材制造零件的力学性能是不利的[9,28,47,50],会导致材料在空化泡的冲击作用下发生撕裂而造成质量损失[3,21].Ding等[21]研究表明,SLM-316L不锈钢在空化腐蚀过程中材料的晶界会优先发生塑性变形,并认为沿晶界发生空化损伤的区域不仅会造成应力集中,还会导致空化泡在晶界附近溃灭,促使在晶界附近形成沟壑/凸起,这与本工作图12a~18a和图12c~18c观察到的结果是一致的.图12b~18b和图12d~18d分别为使用三维白光干涉表面形貌仪测量锻造316L不锈钢和No.1~No.6试样在暴露0.5和4 h的典型表面形貌,图中基本未变形的部分用绿色表示,而凹陷的区域和凸起的区域分别用蓝色和红色表示.可以看出,锻造316L不锈钢的变形较为均匀(图12b),经过4 h的空化腐蚀后试样表面出现了大量的凹坑和凸起(图12d),这是典型的侵蚀空化损伤,这与LMD-316L不锈钢的空化行为有显著区别(图13b~18b和图13d~18d):LMD-316L不锈钢的表面形貌非常不均匀,有的区域出现了密集的凸起,而有的区域出现了明显的凹陷,且这2种形貌分布较为分散(图13b~18b),经过4 h的空化腐蚀后,LMD-316L不锈钢并不像锻造316L不锈钢形成大量明显的凸起,其表面形貌分布特征与0.5 h的形貌类似(图13d~18d). ...

Revealing relationships between heterogeneous microstructure and strengthening mechanism of austenitic stainless steels fabricated by directed energy deposition (DED)

1

2021

... 316L作为一种低碳奥氏体不锈钢,是商业上少数可打印的钢铁材料之一,同时也是国际上热核实验反应堆中真空容器和制造液体火箭发动机喷油器的关键材料,在航空航天、生物医疗、核电工业等关键领域有广泛的应用[4~7].增材制造(AM)作为一种变革性的制造技术,它最大的优势在于可以直接成形形状复杂的构件.由于高能密度热源熔化粉末形成的熔池内冷却速率可达105~107 K/s[5,8,9],材料的微观组织与传统制备方法得到的微观结构存在显著的差异[5,10]:选区激光熔化沉积成形316L (SLM-316L)不锈钢中形成了一种新的跨尺度结构,它由百微米尺度的熔池、几十微米到百微米的晶粒、亚微米尺度的胞结构、几十纳米的氧化物颗粒等构成.然而,SLM和激光熔化沉积(LMD)的冷却速率相差约3个数量级,所形成的跨尺度层级结构在具体每一个微观结构尺度上也存在数量级的差异,如激光熔化沉积成形316L (LMD-316L)不锈钢的熔池尺寸、晶粒长度和胞/枝晶结构尺寸分别为几毫米、500 μm~2.5 mm和2~20 μm,而相应SLM-316L不锈钢的特征尺寸分别为约100 μm、数百微米和小于1 μm[8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

Study on microstructure, mechanical properties and machinability of efficiently additive manufactured AISI 316L stainless steel by high-power direct laser deposition

3

2017

... 316L作为一种低碳奥氏体不锈钢,是商业上少数可打印的钢铁材料之一,同时也是国际上热核实验反应堆中真空容器和制造液体火箭发动机喷油器的关键材料,在航空航天、生物医疗、核电工业等关键领域有广泛的应用[4~7].增材制造(AM)作为一种变革性的制造技术,它最大的优势在于可以直接成形形状复杂的构件.由于高能密度热源熔化粉末形成的熔池内冷却速率可达105~107 K/s[5,8,9],材料的微观组织与传统制备方法得到的微观结构存在显著的差异[5,10]:选区激光熔化沉积成形316L (SLM-316L)不锈钢中形成了一种新的跨尺度结构,它由百微米尺度的熔池、几十微米到百微米的晶粒、亚微米尺度的胞结构、几十纳米的氧化物颗粒等构成.然而,SLM和激光熔化沉积(LMD)的冷却速率相差约3个数量级,所形成的跨尺度层级结构在具体每一个微观结构尺度上也存在数量级的差异,如激光熔化沉积成形316L (LMD-316L)不锈钢的熔池尺寸、晶粒长度和胞/枝晶结构尺寸分别为几毫米、500 μm~2.5 mm和2~20 μm,而相应SLM-316L不锈钢的特征尺寸分别为约100 μm、数百微米和小于1 μm[8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

... 由于316L不锈钢具有较高的应变硬化能力、良好的焊接性以及较强的耐腐蚀性能,因此其对空化腐蚀也具有较高的抵抗能力,可用于有空化泡存在的液体环境中[3].近年来,增材制造316L (AM-316L)不锈钢被应用于生产重量轻、体积小的液压元件[21,22],部分流体机械元件在高旋转速率和具有腐蚀性的介质中工作,因此材料的电化学和空化腐蚀性能显得尤为重要.关于SLM-316L和LMD-316L不锈钢的电化学腐蚀性能已有较多报道[15,16,23~25]:一些研究工作[6,16]表明,由于AM-316L不锈钢不可避免地存在各种缺陷,导致其耐腐蚀性能弱于锻造316L不锈钢;而有些研究工作[24,25]却表明AM-316L不锈钢的特殊微结构使得其比锻造316L不锈钢具有更好的耐点蚀性能和更低的稳态点蚀速率.Ziętala等[16]的研究结果表明,LMD-316L不锈钢胞结构壁面上形成了δ铁素体相,这种相结构不会出现在传统冶金方法制造的316L不锈钢中,他们指出δ铁素体相的形成是打印态材料力学性能和耐腐蚀性能提高的主要原因;通过改变工艺参数调控材料内部的初始位错密度[23]或使用后处理手段改变打印态材料内部的非平衡微观结构(如亚晶、小角度晶界比例和缺陷尺寸),可以显著影响材料的钝化膜厚度和腐蚀电位[6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... 对不同工艺参数下LMD-316L及锻造316L不锈钢在超声振动系统中进行4 h的空化腐蚀实验,图12a~18a和图12c~18c分别为锻造316L不锈钢和No.1~No.6试样在暴露0.5和4 h空化实验后表面的SEM像.可以看出,所有试样的表面在经过空化腐蚀后均变得更加粗糙,在空化实验的早期,所有试样表面均形成了条带状凸起(图12a~18a),随着空化实验时间的延长,各试样表面粗糙度进一步增加,表面形貌出现了大量的韧窝(图12c~18c),这种韧窝形貌与文献[16,18]报道的拉伸断口中出现的韧窝非常相似,这表明所有被空化腐蚀的试样在空化泡的作用下发生了严重的材料损伤和塑性变形.观察试样表面还可以看出:试样表面的凸起优先发生在晶界和未熔缺陷位置,这是因为在塑性变形过程中位错倾向于沿着晶界堆积以抵抗塑性变形[29],在晶界处更容易发生空化损伤,这与空化腐蚀作用下的疲劳过程有关[21];而缺陷(如未熔缺陷或气孔缺陷等)的边缘在空化泡的作用下易引起应力集中,是产生裂纹继而发生裂纹扩展的高发区[50],对增材制造零件的力学性能是不利的[9,28,47,50],会导致材料在空化泡的冲击作用下发生撕裂而造成质量损失[3,21].Ding等[21]研究表明,SLM-316L不锈钢在空化腐蚀过程中材料的晶界会优先发生塑性变形,并认为沿晶界发生空化损伤的区域不仅会造成应力集中,还会导致空化泡在晶界附近溃灭,促使在晶界附近形成沟壑/凸起,这与本工作图12a~18a和图12c~18c观察到的结果是一致的.图12b~18b和图12d~18d分别为使用三维白光干涉表面形貌仪测量锻造316L不锈钢和No.1~No.6试样在暴露0.5和4 h的典型表面形貌,图中基本未变形的部分用绿色表示,而凹陷的区域和凸起的区域分别用蓝色和红色表示.可以看出,锻造316L不锈钢的变形较为均匀(图12b),经过4 h的空化腐蚀后试样表面出现了大量的凹坑和凸起(图12d),这是典型的侵蚀空化损伤,这与LMD-316L不锈钢的空化行为有显著区别(图13b~18b和图13d~18d):LMD-316L不锈钢的表面形貌非常不均匀,有的区域出现了密集的凸起,而有的区域出现了明显的凹陷,且这2种形貌分布较为分散(图13b~18b),经过4 h的空化腐蚀后,LMD-316L不锈钢并不像锻造316L不锈钢形成大量明显的凸起,其表面形貌分布特征与0.5 h的形貌类似(图13d~18d). ...

Process-structure-property relationships for 316L stainless steel fabricated by additive manufacturing and its implication for component engineering

0

2017

Directed energy deposition of AISI 316L stainless steel powder: Effect of process parameters

2

2021

... 316L作为一种低碳奥氏体不锈钢,是商业上少数可打印的钢铁材料之一,同时也是国际上热核实验反应堆中真空容器和制造液体火箭发动机喷油器的关键材料,在航空航天、生物医疗、核电工业等关键领域有广泛的应用[4~7].增材制造(AM)作为一种变革性的制造技术,它最大的优势在于可以直接成形形状复杂的构件.由于高能密度热源熔化粉末形成的熔池内冷却速率可达105~107 K/s[5,8,9],材料的微观组织与传统制备方法得到的微观结构存在显著的差异[5,10]:选区激光熔化沉积成形316L (SLM-316L)不锈钢中形成了一种新的跨尺度结构,它由百微米尺度的熔池、几十微米到百微米的晶粒、亚微米尺度的胞结构、几十纳米的氧化物颗粒等构成.然而,SLM和激光熔化沉积(LMD)的冷却速率相差约3个数量级,所形成的跨尺度层级结构在具体每一个微观结构尺度上也存在数量级的差异,如激光熔化沉积成形316L (LMD-316L)不锈钢的熔池尺寸、晶粒长度和胞/枝晶结构尺寸分别为几毫米、500 μm~2.5 mm和2~20 μm,而相应SLM-316L不锈钢的特征尺寸分别为约100 μm、数百微米和小于1 μm[8~12].这导致SLM与LMD制备的316L材料宏观力学性能也存在较大的区别:大量的文献[9,10,13~15]报道了通过调控工艺参数可以制备高强高韧的SLM-316L不锈钢,然而,除了少数文献[16,17]外,大多数文献的研究结果都表明LMD-316L不锈钢的力学性能通常表现为强度大幅提高,而延伸率明显降低[18~20].因此,尽管SLM与LMD在技术原理上有诸多相似之处,其制备的材料微观结构差异也可能导致不同的力学性能响应. ...

... 由于316L不锈钢具有较高的应变硬化能力、良好的焊接性以及较强的耐腐蚀性能,因此其对空化腐蚀也具有较高的抵抗能力,可用于有空化泡存在的液体环境中[3].近年来,增材制造316L (AM-316L)不锈钢被应用于生产重量轻、体积小的液压元件[21,22],部分流体机械元件在高旋转速率和具有腐蚀性的介质中工作,因此材料的电化学和空化腐蚀性能显得尤为重要.关于SLM-316L和LMD-316L不锈钢的电化学腐蚀性能已有较多报道[15,16,23~25]:一些研究工作[6,16]表明,由于AM-316L不锈钢不可避免地存在各种缺陷,导致其耐腐蚀性能弱于锻造316L不锈钢;而有些研究工作[24,25]却表明AM-316L不锈钢的特殊微结构使得其比锻造316L不锈钢具有更好的耐点蚀性能和更低的稳态点蚀速率.Ziętala等[16]的研究结果表明,LMD-316L不锈钢胞结构壁面上形成了δ铁素体相,这种相结构不会出现在传统冶金方法制造的316L不锈钢中,他们指出δ铁素体相的形成是打印态材料力学性能和耐腐蚀性能提高的主要原因;通过改变工艺参数调控材料内部的初始位错密度[23]或使用后处理手段改变打印态材料内部的非平衡微观结构(如亚晶、小角度晶界比例和缺陷尺寸),可以显著影响材料的钝化膜厚度和腐蚀电位[6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

Cavitation erosion resistance of 316L stainless steel fabricated using selective laser melting

10

2021

... 由于316L不锈钢具有较高的应变硬化能力、良好的焊接性以及较强的耐腐蚀性能,因此其对空化腐蚀也具有较高的抵抗能力,可用于有空化泡存在的液体环境中[3].近年来,增材制造316L (AM-316L)不锈钢被应用于生产重量轻、体积小的液压元件[21,22],部分流体机械元件在高旋转速率和具有腐蚀性的介质中工作,因此材料的电化学和空化腐蚀性能显得尤为重要.关于SLM-316L和LMD-316L不锈钢的电化学腐蚀性能已有较多报道[15,16,23~25]:一些研究工作[6,16]表明,由于AM-316L不锈钢不可避免地存在各种缺陷,导致其耐腐蚀性能弱于锻造316L不锈钢;而有些研究工作[24,25]却表明AM-316L不锈钢的特殊微结构使得其比锻造316L不锈钢具有更好的耐点蚀性能和更低的稳态点蚀速率.Ziętala等[16]的研究结果表明,LMD-316L不锈钢胞结构壁面上形成了δ铁素体相,这种相结构不会出现在传统冶金方法制造的316L不锈钢中,他们指出δ铁素体相的形成是打印态材料力学性能和耐腐蚀性能提高的主要原因;通过改变工艺参数调控材料内部的初始位错密度[23]或使用后处理手段改变打印态材料内部的非平衡微观结构(如亚晶、小角度晶界比例和缺陷尺寸),可以显著影响材料的钝化膜厚度和腐蚀电位[6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... ,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... [21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... 在进行电化学及空化腐蚀实验之前,对所有试样的待测面依次用耐水砂纸进行打磨至3000号,最后用1.5 μm的金刚石悬浮液抛光至镜面[9,27],然后放置在75%酒精溶液中超声清洗并烘干后备用.采用CHI660E电化学工作站在室温下对不同成形工艺下的试样进行耐腐蚀性能测试,用硅橡胶密封被测试试样,电化学测试溶液为3.5%NaCl (质量分数)溶液,阳极为被测试试样,阴极为Pt电极,参比电极为饱和甘汞电极.开路电位(OCP)测试时间为3600 s,当开路电位稳定后进行动电位极化测试,阴极初始电位比被测试样对应的腐蚀电位低0.6~0.7 V,扫描速率为0.001 V/s.采用超声振动系统对各工艺下制备的LMD-316L不锈钢试样进行空化腐蚀实验,设备工作原理如图2所示,采用的超声振动频率和振幅分别为20 kHz和6 μm,输出功率为500 W.超声波探头顶端与被测试样相对的材料为不锈钢,按照文献[3,21]推荐的值将试样与探头顶端之间的距离调整为0.5 mm.空化腐蚀实验在3.5%NaCl水溶液中进行,温度保持为25℃,每30 min更换一次NaCl水溶液.每个样品在空化实验结束后,利用75%酒精溶液进行超声清洗,烘干后储存. ...

... 图4为不同工艺参数下LMD-316L不锈钢的致密度测量结果和相应的代表性缺陷OM像.可以看出,所有工艺制备的316L材料致密度均值都超过了99.9%,这与使用SLM方法制备的316L材料致密度相当,一般认为成形件致密度达到99%为高致密度零件[9,10,31].可以看出:① 提高激光功率,致密度有增加的趋势(图4,No.1、No.2、No.3),这是因为激光功率的大小直接决定熔池的峰值温度,激光功率越大,熔池内的峰值温度越高[32],因而粉末会熔化得更加充分,材料更加致密,这在SLM-316L不锈钢随激光功率变化的研究[9,33]中也得到了类似的规律;② 重熔可以使得LMD-316L不锈钢的致密度提高(图4,No.1和No.4),这是因为重熔可以有效地使孔洞缺陷有更多的几率从熔池中逃逸出来,而且重熔可以降低成形件表面粗糙度进而使粉末熔化得更加充分,促使缺陷含量降低[34,35];③ 相比105°旋转扫描策略,采用90°旋转扫描策略有助于提高成形件的致密度(图4,No.1和No.5).Saboori等[36]研究指出,通过调控相邻两层之间的旋转角度可以显著改变熔池内的冷却速率,使得最终材料的微观结构及力学性能有较大的差异.因此,可以推断通过调控相邻层之间的旋转角度可以改变成形件的热积累程度,进而影响最终材料的致密度、微观结构和力学性能;④ 垂直打印的样品致密度略高于水平打印的试样(图4,No.1和No.6),这与Ronneberg等[37] SLM-316L的研究结果一致,而Ding等[21]的研究结果却表明孔隙率在水平和垂直打印的SLM-316L不锈钢试样中基本无差别.缺陷作为应力集中源是材料发生过早断裂失效的重要原因,然而,文献中报道的关于打印方向对成形件延伸率影响的结果似乎是矛盾的:有研究[38]认为沿水平方向打印的316L材料延伸率高于相应沿着垂直方向打印的材料,而一些研究[16,39~41]则认为沿着垂直方向打印的试样延伸率更高.进一步分析可以发现这些研究工作中所用的实验设备、制备的试样尺寸和打印参数是不同的,这些因素均会导致成形件的致密度发生变化,下面将通过显微组织观察的手段分析不同工艺参数下材料的微观结构变化规律. ...

... 对不同工艺参数下LMD-316L及锻造316L不锈钢在超声振动系统中进行4 h的空化腐蚀实验,图12a~18a和图12c~18c分别为锻造316L不锈钢和No.1~No.6试样在暴露0.5和4 h空化实验后表面的SEM像.可以看出,所有试样的表面在经过空化腐蚀后均变得更加粗糙,在空化实验的早期,所有试样表面均形成了条带状凸起(图12a~18a),随着空化实验时间的延长,各试样表面粗糙度进一步增加,表面形貌出现了大量的韧窝(图12c~18c),这种韧窝形貌与文献[16,18]报道的拉伸断口中出现的韧窝非常相似,这表明所有被空化腐蚀的试样在空化泡的作用下发生了严重的材料损伤和塑性变形.观察试样表面还可以看出:试样表面的凸起优先发生在晶界和未熔缺陷位置,这是因为在塑性变形过程中位错倾向于沿着晶界堆积以抵抗塑性变形[29],在晶界处更容易发生空化损伤,这与空化腐蚀作用下的疲劳过程有关[21];而缺陷(如未熔缺陷或气孔缺陷等)的边缘在空化泡的作用下易引起应力集中,是产生裂纹继而发生裂纹扩展的高发区[50],对增材制造零件的力学性能是不利的[9,28,47,50],会导致材料在空化泡的冲击作用下发生撕裂而造成质量损失[3,21].Ding等[21]研究表明,SLM-316L不锈钢在空化腐蚀过程中材料的晶界会优先发生塑性变形,并认为沿晶界发生空化损伤的区域不仅会造成应力集中,还会导致空化泡在晶界附近溃灭,促使在晶界附近形成沟壑/凸起,这与本工作图12a~18a和图12c~18c观察到的结果是一致的.图12b~18b和图12d~18d分别为使用三维白光干涉表面形貌仪测量锻造316L不锈钢和No.1~No.6试样在暴露0.5和4 h的典型表面形貌,图中基本未变形的部分用绿色表示,而凹陷的区域和凸起的区域分别用蓝色和红色表示.可以看出,锻造316L不锈钢的变形较为均匀(图12b),经过4 h的空化腐蚀后试样表面出现了大量的凹坑和凸起(图12d),这是典型的侵蚀空化损伤,这与LMD-316L不锈钢的空化行为有显著区别(图13b~18b和图13d~18d):LMD-316L不锈钢的表面形貌非常不均匀,有的区域出现了密集的凸起,而有的区域出现了明显的凹陷,且这2种形貌分布较为分散(图13b~18b),经过4 h的空化腐蚀后,LMD-316L不锈钢并不像锻造316L不锈钢形成大量明显的凸起,其表面形貌分布特征与0.5 h的形貌类似(图13d~18d). ...

... ,21].Ding等[21]研究表明,SLM-316L不锈钢在空化腐蚀过程中材料的晶界会优先发生塑性变形,并认为沿晶界发生空化损伤的区域不仅会造成应力集中,还会导致空化泡在晶界附近溃灭,促使在晶界附近形成沟壑/凸起,这与本工作图12a~18a和图12c~18c观察到的结果是一致的.图12b~18b和图12d~18d分别为使用三维白光干涉表面形貌仪测量锻造316L不锈钢和No.1~No.6试样在暴露0.5和4 h的典型表面形貌,图中基本未变形的部分用绿色表示,而凹陷的区域和凸起的区域分别用蓝色和红色表示.可以看出,锻造316L不锈钢的变形较为均匀(图12b),经过4 h的空化腐蚀后试样表面出现了大量的凹坑和凸起(图12d),这是典型的侵蚀空化损伤,这与LMD-316L不锈钢的空化行为有显著区别(图13b~18b和图13d~18d):LMD-316L不锈钢的表面形貌非常不均匀,有的区域出现了密集的凸起,而有的区域出现了明显的凹陷,且这2种形貌分布较为分散(图13b~18b),经过4 h的空化腐蚀后,LMD-316L不锈钢并不像锻造316L不锈钢形成大量明显的凸起,其表面形貌分布特征与0.5 h的形貌类似(图13d~18d). ...

... [21]研究表明,SLM-316L不锈钢在空化腐蚀过程中材料的晶界会优先发生塑性变形,并认为沿晶界发生空化损伤的区域不仅会造成应力集中,还会导致空化泡在晶界附近溃灭,促使在晶界附近形成沟壑/凸起,这与本工作图12a~18a和图12c~18c观察到的结果是一致的.图12b~18b和图12d~18d分别为使用三维白光干涉表面形貌仪测量锻造316L不锈钢和No.1~No.6试样在暴露0.5和4 h的典型表面形貌,图中基本未变形的部分用绿色表示,而凹陷的区域和凸起的区域分别用蓝色和红色表示.可以看出,锻造316L不锈钢的变形较为均匀(图12b),经过4 h的空化腐蚀后试样表面出现了大量的凹坑和凸起(图12d),这是典型的侵蚀空化损伤,这与LMD-316L不锈钢的空化行为有显著区别(图13b~18b和图13d~18d):LMD-316L不锈钢的表面形貌非常不均匀,有的区域出现了密集的凸起,而有的区域出现了明显的凹陷,且这2种形貌分布较为分散(图13b~18b),经过4 h的空化腐蚀后,LMD-316L不锈钢并不像锻造316L不锈钢形成大量明显的凸起,其表面形貌分布特征与0.5 h的形貌类似(图13d~18d). ...

... 从空化腐蚀的机理方面来讲,超声振动在液体介质中形成的空化泡会产生反复的冲击波和微射流,这种具有高能量状态的冲击波/微射流作用到试样表面后会在材料的薄弱区域优先发生空化损伤,一些较轻微的冲击会在工艺诱导的缺陷和晶界位置处出现局部应力集中,导致位错沿晶界移动,随着空化实验时间的延长,会逐渐塑性变形并形成凹坑,而一些高能量的强烈冲击波则会导致材料的质量损失[3,21].材料在3.5%NaCl溶液中的空化腐蚀可以看成机械损伤、腐蚀损伤及机械腐蚀协同作用损伤3部分[51],即:T = E + C + S,其中,T为总质量损失率;E为纯空化腐蚀导致的质量损失率;C为纯腐蚀而导致的质量损失率,C = K · icorr· EW,K取8.954 × 10-3,EW为当量重量(其值为物质的摩尔质量除以它接受或失去电子的数目),对于不锈钢EW取25.12[51];S为2者的协同效应导致的质量损失率.Zheng等[51]的研究结果表明,当空化腐蚀时间不大于2 h时,纯腐蚀的作用可以忽略,而当空化腐蚀时间超过8 h时,材料会经受腐蚀和空化腐蚀的共同作用.鉴于本工作空化腐蚀总时长较短(4 h),因此,可以用材料的抗机械损伤作为评价LMD-316L不锈钢在3.5%NaCl溶液中的空化腐蚀演变规律.不同工艺参数下的纯机械损伤可以用显微硬度衡量,上述研究结果已表明LMD-316L不锈钢的耐腐蚀性能与其内部的二次枝晶臂间距直接相关(纯腐蚀损伤度量指标),而二次枝晶臂间距又直接影响材料的显微硬度(机械损伤度量指标).图3e和图9分别为锻造316L不锈钢和LMD-316L不锈钢No.1~No.6的硬度云图.可见,锻造316L不锈钢的硬度分布较为均匀,而且其显微硬度明显低于LMD-316L不锈钢;此外,相比锻造316L不锈钢,LMD-316L不锈钢的硬度分布更加不均匀,这主要是由增材制造材料的不均匀跨尺度微观组织和局部工艺缺陷导致的[27,52].LMD-316L不锈钢硬度不均匀分布的特点也导致其在空化腐蚀的进程中出现局部破坏严重,而有些区域只是轻微变形.然而,由于LMD-316L不锈钢的平均硬度显著高于锻造316L不锈钢,因此前者的抗空化腐蚀能力显著高于后者.为了更好地评价不同工艺制备的材料表面粗糙度随空化腐蚀时间的变化,利用表面形貌参数对表面粗糙度进行了量化,分别为:表面粗糙度(Sa)、表面均方根粗糙度(Sq)和表面微观不平度十点高度(Sz),这些参数的具体定义和计算方法参见文献[53].图19为利用这3个表面形貌参数表征被测试样形貌的结果(所有数据均为2次测量的平均值).可以看出,Sa和Sq的变化与材料硬度的变化具有一定的关联,即:随着激光功率的增加,材料的平均硬度降低,Sa和Sq有增加的趋势(图19a和b,No.1~3);重熔处理(No.4)、90°旋转扫描打印(No.5)和垂直方向打印(No.6)与No.1试样相比均会导致LMD-316L不锈钢的硬度降低(图9),因而Sa和Sq值略高于No.1 (图19a和b),产生这一结果的根本原因是材料的二次枝晶臂间距增大,材料的腐蚀电流密度增大,显微硬度降低,因而材料的纯腐蚀损伤和机械损伤均会增大,导致材料的机械损伤和腐蚀损伤加重.此外,4 h后材料表面的Sa和Sq均高于对应0.5 h的测量值.然而,不同工艺参数下的Sz没有明显的变化规律,这是因为Sz是一个极端参数,它定义为采样区内5个最高峰的绝对高度和5个最深凹坑/峰谷深度的平均值[53],其值取决于表面高度峰值和峰谷,而在空化腐蚀的进程中材料表面在空化泡的冲击作用下会发生质量损失[3,21,51],因而表面Sz存在较大的不确定性,总体看LMD-316L不锈钢的Sz小于相应空化时间下锻造316L不锈钢的Sz (图19c). ...

... ,21,51],因而表面Sz存在较大的不确定性,总体看LMD-316L不锈钢的Sz小于相应空化时间下锻造316L不锈钢的Sz (图19c). ...

Influence of surface pores on selective laser melted parts under lubricated contacts: A case study of a hydraulic spool valve

1

2019

... 由于316L不锈钢具有较高的应变硬化能力、良好的焊接性以及较强的耐腐蚀性能,因此其对空化腐蚀也具有较高的抵抗能力,可用于有空化泡存在的液体环境中[3].近年来,增材制造316L (AM-316L)不锈钢被应用于生产重量轻、体积小的液压元件[21,22],部分流体机械元件在高旋转速率和具有腐蚀性的介质中工作,因此材料的电化学和空化腐蚀性能显得尤为重要.关于SLM-316L和LMD-316L不锈钢的电化学腐蚀性能已有较多报道[15,16,23~25]:一些研究工作[6,16]表明,由于AM-316L不锈钢不可避免地存在各种缺陷,导致其耐腐蚀性能弱于锻造316L不锈钢;而有些研究工作[24,25]却表明AM-316L不锈钢的特殊微结构使得其比锻造316L不锈钢具有更好的耐点蚀性能和更低的稳态点蚀速率.Ziętala等[16]的研究结果表明,LMD-316L不锈钢胞结构壁面上形成了δ铁素体相,这种相结构不会出现在传统冶金方法制造的316L不锈钢中,他们指出δ铁素体相的形成是打印态材料力学性能和耐腐蚀性能提高的主要原因;通过改变工艺参数调控材料内部的初始位错密度[23]或使用后处理手段改变打印态材料内部的非平衡微观结构(如亚晶、小角度晶界比例和缺陷尺寸),可以显著影响材料的钝化膜厚度和腐蚀电位[6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

Dislocation microstructure and its influence on corrosion behavior in laser additively manufactured 316L stainless steel

7

2021

... 由于316L不锈钢具有较高的应变硬化能力、良好的焊接性以及较强的耐腐蚀性能,因此其对空化腐蚀也具有较高的抵抗能力,可用于有空化泡存在的液体环境中[3].近年来,增材制造316L (AM-316L)不锈钢被应用于生产重量轻、体积小的液压元件[21,22],部分流体机械元件在高旋转速率和具有腐蚀性的介质中工作,因此材料的电化学和空化腐蚀性能显得尤为重要.关于SLM-316L和LMD-316L不锈钢的电化学腐蚀性能已有较多报道[15,16,23~25]:一些研究工作[6,16]表明,由于AM-316L不锈钢不可避免地存在各种缺陷,导致其耐腐蚀性能弱于锻造316L不锈钢;而有些研究工作[24,25]却表明AM-316L不锈钢的特殊微结构使得其比锻造316L不锈钢具有更好的耐点蚀性能和更低的稳态点蚀速率.Ziętala等[16]的研究结果表明,LMD-316L不锈钢胞结构壁面上形成了δ铁素体相,这种相结构不会出现在传统冶金方法制造的316L不锈钢中,他们指出δ铁素体相的形成是打印态材料力学性能和耐腐蚀性能提高的主要原因;通过改变工艺参数调控材料内部的初始位错密度[23]或使用后处理手段改变打印态材料内部的非平衡微观结构(如亚晶、小角度晶界比例和缺陷尺寸),可以显著影响材料的钝化膜厚度和腐蚀电位[6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... [23]或使用后处理手段改变打印态材料内部的非平衡微观结构(如亚晶、小角度晶界比例和缺陷尺寸),可以显著影响材料的钝化膜厚度和腐蚀电位[6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... ,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... 图10为不同工艺参数制备的LMD-316L和锻造316L不锈钢在NaCl溶液中的开路电位(EOCP)随时间的变化规律.可以看出,所有被测试样的开路电位均随着时间的推移而呈现先增加(由负值向正值变化)后逐渐稳定的趋势,这表明试样在NaCl溶液中自主形成了钝化膜[44],钝化膜的形成起到了进一步阻抗腐蚀的作用.与锻造316L不锈钢相比,LMD-316L不锈钢在开路电位曲线中显现出多个小的尖峰,个别试样出现了明显的峰谷,这表明LMD-316L不锈钢在EOCP达到稳定前存在击穿和再钝化的过程[44].观察3600 s对应的开路电位,可以发现No.1~No.4的EOCP明显高于锻造316L不锈钢,90°旋转扫描打印(No.5)的试样与锻造316L不锈钢的EOCP非常接近,而垂直打印的试样(No.6)的EOCP低于锻造316L不锈钢.图11为各工艺下的LMD-316L不锈钢动电位极化曲线测试结果,腐蚀电位(Ecorr)和点蚀电位(Epit)在图中也进行了标注,相应的电化学参数列于表3.可以看出:LMD-316L不锈钢的极化电阻(Rp)相比锻造316L不锈钢提高了2~98倍,而腐蚀电流密度(icorr)下降了至少1个数量级.就Ecorr而言,No.1~No.3均明显高于锻造316L,而No.4~No.6的Ecorr与锻造316L不锈钢相差不大.除了No.6外,材料的EOCP变化规律与Ecorr一致,No.6的EOCP与Ecorr变化规律不一致可能是开路电位在测试时间内不稳定造成的.进一步比较各工艺下材料的Epit,可以发现No.1和No.3没有发生明显的点蚀,No.2和No.4的Epit明显高于锻造316L不锈钢,但No.5和No.6的Epit明显低于锻造316L不锈钢,这表明LMD-316L不锈钢在某些工艺下易发生点蚀.Kazemipour等[24]的研究指出SLM-316L不锈钢具有比锻造316L不锈钢更强的耐点蚀性能且其亚稳态点蚀速率也更低,材料内部的工艺缺陷在早期并不影响合金的点蚀电位,本工作No.1~No.4的测试结果与Kazemipour等[24]的研究规律一致.然而,由于材料微观结构的显著变化(图5和6),No.5和No.6在保持较小的腐蚀速率下点蚀电位相比锻造316L不锈钢明显降低.总体来讲,在考虑材料的Ecorr和icorr条件下,LMD-316L不锈钢相比锻造316L不锈钢的腐蚀电位更高而腐蚀速率更小,其耐腐蚀性能大幅提高.最近有研究[16,23]表明AM-316L不锈钢的耐腐蚀性能与其材料的微观结构变化密切相关,其中具有高位错密度的亚稳态胞/枝晶结构对AM-316L不锈钢的耐腐蚀性能具有显著影响,研究[10,15]已表明打印态的316L不锈钢处于高应力状态,亚稳态的胞结构/枝晶壁面上存在大量的位错网络结构[13,23],提高扫描速率亦即降低输入到熔池内的能量密度可使材料的一次/二次枝晶臂间距减小[8,9,13,42],进而提高壁面上的位错密度[23,49].Nie等[25]指出LMD-316L不锈钢内大量的小角度晶界和较高的位错密度促使材料表面形成更致密且更厚的钝化膜,从而能够获得比锻造316L不锈钢更好的耐腐蚀性能.本工作的微观结构表征已证实提高激光功率、重熔处理、90°旋转扫描打印和垂直方向打印均会导致LMD-316L不锈钢的二次枝晶臂间距变大(图5),并进一步导致材料内部初始位错密度的降低[23,49],因而材料的极化电阻降低而腐蚀电流密度提高(图11和表3).这表明打印态LMD-316L不锈钢的耐腐蚀性能与其内部的亚结构尺寸(二次枝晶臂间距)可能直接相关,二次枝晶臂间距的增大会导致耐腐蚀性能的降低.然而,与锻造316L不锈钢相比,所有工艺下的LMD-316L不锈钢小角度晶界比例均高于锻造316L不锈钢(图3d和图8),且LMD-316L不锈钢的初始位错密度高于锻造316L不锈钢[25],这可能是本工作LMD-316L不锈钢耐腐蚀性能相比锻造316L不锈钢大幅提高的原因. ...

... ,23],提高扫描速率亦即降低输入到熔池内的能量密度可使材料的一次/二次枝晶臂间距减小[8,9,13,42],进而提高壁面上的位错密度[23,49].Nie等[25]指出LMD-316L不锈钢内大量的小角度晶界和较高的位错密度促使材料表面形成更致密且更厚的钝化膜,从而能够获得比锻造316L不锈钢更好的耐腐蚀性能.本工作的微观结构表征已证实提高激光功率、重熔处理、90°旋转扫描打印和垂直方向打印均会导致LMD-316L不锈钢的二次枝晶臂间距变大(图5),并进一步导致材料内部初始位错密度的降低[23,49],因而材料的极化电阻降低而腐蚀电流密度提高(图11和表3).这表明打印态LMD-316L不锈钢的耐腐蚀性能与其内部的亚结构尺寸(二次枝晶臂间距)可能直接相关,二次枝晶臂间距的增大会导致耐腐蚀性能的降低.然而,与锻造316L不锈钢相比,所有工艺下的LMD-316L不锈钢小角度晶界比例均高于锻造316L不锈钢(图3d和图8),且LMD-316L不锈钢的初始位错密度高于锻造316L不锈钢[25],这可能是本工作LMD-316L不锈钢耐腐蚀性能相比锻造316L不锈钢大幅提高的原因. ...

... [23,49].Nie等[25]指出LMD-316L不锈钢内大量的小角度晶界和较高的位错密度促使材料表面形成更致密且更厚的钝化膜,从而能够获得比锻造316L不锈钢更好的耐腐蚀性能.本工作的微观结构表征已证实提高激光功率、重熔处理、90°旋转扫描打印和垂直方向打印均会导致LMD-316L不锈钢的二次枝晶臂间距变大(图5),并进一步导致材料内部初始位错密度的降低[23,49],因而材料的极化电阻降低而腐蚀电流密度提高(图11和表3).这表明打印态LMD-316L不锈钢的耐腐蚀性能与其内部的亚结构尺寸(二次枝晶臂间距)可能直接相关,二次枝晶臂间距的增大会导致耐腐蚀性能的降低.然而,与锻造316L不锈钢相比,所有工艺下的LMD-316L不锈钢小角度晶界比例均高于锻造316L不锈钢(图3d和图8),且LMD-316L不锈钢的初始位错密度高于锻造316L不锈钢[25],这可能是本工作LMD-316L不锈钢耐腐蚀性能相比锻造316L不锈钢大幅提高的原因. ...

... [23,49],因而材料的极化电阻降低而腐蚀电流密度提高(图11和表3).这表明打印态LMD-316L不锈钢的耐腐蚀性能与其内部的亚结构尺寸(二次枝晶臂间距)可能直接相关,二次枝晶臂间距的增大会导致耐腐蚀性能的降低.然而,与锻造316L不锈钢相比,所有工艺下的LMD-316L不锈钢小角度晶界比例均高于锻造316L不锈钢(图3d和图8),且LMD-316L不锈钢的初始位错密度高于锻造316L不锈钢[25],这可能是本工作LMD-316L不锈钢耐腐蚀性能相比锻造316L不锈钢大幅提高的原因. ...

Microstructure and corrosion characteristics of selective laser-melted 316L stainless steel: The impact of process-induced porosities

3

2019

... 由于316L不锈钢具有较高的应变硬化能力、良好的焊接性以及较强的耐腐蚀性能,因此其对空化腐蚀也具有较高的抵抗能力,可用于有空化泡存在的液体环境中[3].近年来,增材制造316L (AM-316L)不锈钢被应用于生产重量轻、体积小的液压元件[21,22],部分流体机械元件在高旋转速率和具有腐蚀性的介质中工作,因此材料的电化学和空化腐蚀性能显得尤为重要.关于SLM-316L和LMD-316L不锈钢的电化学腐蚀性能已有较多报道[15,16,23~25]:一些研究工作[6,16]表明,由于AM-316L不锈钢不可避免地存在各种缺陷,导致其耐腐蚀性能弱于锻造316L不锈钢;而有些研究工作[24,25]却表明AM-316L不锈钢的特殊微结构使得其比锻造316L不锈钢具有更好的耐点蚀性能和更低的稳态点蚀速率.Ziętala等[16]的研究结果表明,LMD-316L不锈钢胞结构壁面上形成了δ铁素体相,这种相结构不会出现在传统冶金方法制造的316L不锈钢中,他们指出δ铁素体相的形成是打印态材料力学性能和耐腐蚀性能提高的主要原因;通过改变工艺参数调控材料内部的初始位错密度[23]或使用后处理手段改变打印态材料内部的非平衡微观结构(如亚晶、小角度晶界比例和缺陷尺寸),可以显著影响材料的钝化膜厚度和腐蚀电位[6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... 图10为不同工艺参数制备的LMD-316L和锻造316L不锈钢在NaCl溶液中的开路电位(EOCP)随时间的变化规律.可以看出,所有被测试样的开路电位均随着时间的推移而呈现先增加(由负值向正值变化)后逐渐稳定的趋势,这表明试样在NaCl溶液中自主形成了钝化膜[44],钝化膜的形成起到了进一步阻抗腐蚀的作用.与锻造316L不锈钢相比,LMD-316L不锈钢在开路电位曲线中显现出多个小的尖峰,个别试样出现了明显的峰谷,这表明LMD-316L不锈钢在EOCP达到稳定前存在击穿和再钝化的过程[44].观察3600 s对应的开路电位,可以发现No.1~No.4的EOCP明显高于锻造316L不锈钢,90°旋转扫描打印(No.5)的试样与锻造316L不锈钢的EOCP非常接近,而垂直打印的试样(No.6)的EOCP低于锻造316L不锈钢.图11为各工艺下的LMD-316L不锈钢动电位极化曲线测试结果,腐蚀电位(Ecorr)和点蚀电位(Epit)在图中也进行了标注,相应的电化学参数列于表3.可以看出:LMD-316L不锈钢的极化电阻(Rp)相比锻造316L不锈钢提高了2~98倍,而腐蚀电流密度(icorr)下降了至少1个数量级.就Ecorr而言,No.1~No.3均明显高于锻造316L,而No.4~No.6的Ecorr与锻造316L不锈钢相差不大.除了No.6外,材料的EOCP变化规律与Ecorr一致,No.6的EOCP与Ecorr变化规律不一致可能是开路电位在测试时间内不稳定造成的.进一步比较各工艺下材料的Epit,可以发现No.1和No.3没有发生明显的点蚀,No.2和No.4的Epit明显高于锻造316L不锈钢,但No.5和No.6的Epit明显低于锻造316L不锈钢,这表明LMD-316L不锈钢在某些工艺下易发生点蚀.Kazemipour等[24]的研究指出SLM-316L不锈钢具有比锻造316L不锈钢更强的耐点蚀性能且其亚稳态点蚀速率也更低,材料内部的工艺缺陷在早期并不影响合金的点蚀电位,本工作No.1~No.4的测试结果与Kazemipour等[24]的研究规律一致.然而,由于材料微观结构的显著变化(图5和6),No.5和No.6在保持较小的腐蚀速率下点蚀电位相比锻造316L不锈钢明显降低.总体来讲,在考虑材料的Ecorr和icorr条件下,LMD-316L不锈钢相比锻造316L不锈钢的腐蚀电位更高而腐蚀速率更小,其耐腐蚀性能大幅提高.最近有研究[16,23]表明AM-316L不锈钢的耐腐蚀性能与其材料的微观结构变化密切相关,其中具有高位错密度的亚稳态胞/枝晶结构对AM-316L不锈钢的耐腐蚀性能具有显著影响,研究[10,15]已表明打印态的316L不锈钢处于高应力状态,亚稳态的胞结构/枝晶壁面上存在大量的位错网络结构[13,23],提高扫描速率亦即降低输入到熔池内的能量密度可使材料的一次/二次枝晶臂间距减小[8,9,13,42],进而提高壁面上的位错密度[23,49].Nie等[25]指出LMD-316L不锈钢内大量的小角度晶界和较高的位错密度促使材料表面形成更致密且更厚的钝化膜,从而能够获得比锻造316L不锈钢更好的耐腐蚀性能.本工作的微观结构表征已证实提高激光功率、重熔处理、90°旋转扫描打印和垂直方向打印均会导致LMD-316L不锈钢的二次枝晶臂间距变大(图5),并进一步导致材料内部初始位错密度的降低[23,49],因而材料的极化电阻降低而腐蚀电流密度提高(图11和表3).这表明打印态LMD-316L不锈钢的耐腐蚀性能与其内部的亚结构尺寸(二次枝晶臂间距)可能直接相关,二次枝晶臂间距的增大会导致耐腐蚀性能的降低.然而,与锻造316L不锈钢相比,所有工艺下的LMD-316L不锈钢小角度晶界比例均高于锻造316L不锈钢(图3d和图8),且LMD-316L不锈钢的初始位错密度高于锻造316L不锈钢[25],这可能是本工作LMD-316L不锈钢耐腐蚀性能相比锻造316L不锈钢大幅提高的原因. ...

... [24]的研究规律一致.然而,由于材料微观结构的显著变化(图5和6),No.5和No.6在保持较小的腐蚀速率下点蚀电位相比锻造316L不锈钢明显降低.总体来讲,在考虑材料的Ecorr和icorr条件下,LMD-316L不锈钢相比锻造316L不锈钢的腐蚀电位更高而腐蚀速率更小,其耐腐蚀性能大幅提高.最近有研究[16,23]表明AM-316L不锈钢的耐腐蚀性能与其材料的微观结构变化密切相关,其中具有高位错密度的亚稳态胞/枝晶结构对AM-316L不锈钢的耐腐蚀性能具有显著影响,研究[10,15]已表明打印态的316L不锈钢处于高应力状态,亚稳态的胞结构/枝晶壁面上存在大量的位错网络结构[13,23],提高扫描速率亦即降低输入到熔池内的能量密度可使材料的一次/二次枝晶臂间距减小[8,9,13,42],进而提高壁面上的位错密度[23,49].Nie等[25]指出LMD-316L不锈钢内大量的小角度晶界和较高的位错密度促使材料表面形成更致密且更厚的钝化膜,从而能够获得比锻造316L不锈钢更好的耐腐蚀性能.本工作的微观结构表征已证实提高激光功率、重熔处理、90°旋转扫描打印和垂直方向打印均会导致LMD-316L不锈钢的二次枝晶臂间距变大(图5),并进一步导致材料内部初始位错密度的降低[23,49],因而材料的极化电阻降低而腐蚀电流密度提高(图11和表3).这表明打印态LMD-316L不锈钢的耐腐蚀性能与其内部的亚结构尺寸(二次枝晶臂间距)可能直接相关,二次枝晶臂间距的增大会导致耐腐蚀性能的降低.然而,与锻造316L不锈钢相比,所有工艺下的LMD-316L不锈钢小角度晶界比例均高于锻造316L不锈钢(图3d和图8),且LMD-316L不锈钢的初始位错密度高于锻造316L不锈钢[25],这可能是本工作LMD-316L不锈钢耐腐蚀性能相比锻造316L不锈钢大幅提高的原因. ...

Corrosion mechanism of additively manufactured 316?L stainless steel in 3.5?wt.% NaCl solution

5

2021

... 由于316L不锈钢具有较高的应变硬化能力、良好的焊接性以及较强的耐腐蚀性能,因此其对空化腐蚀也具有较高的抵抗能力,可用于有空化泡存在的液体环境中[3].近年来,增材制造316L (AM-316L)不锈钢被应用于生产重量轻、体积小的液压元件[21,22],部分流体机械元件在高旋转速率和具有腐蚀性的介质中工作,因此材料的电化学和空化腐蚀性能显得尤为重要.关于SLM-316L和LMD-316L不锈钢的电化学腐蚀性能已有较多报道[15,16,23~25]:一些研究工作[6,16]表明,由于AM-316L不锈钢不可避免地存在各种缺陷,导致其耐腐蚀性能弱于锻造316L不锈钢;而有些研究工作[24,25]却表明AM-316L不锈钢的特殊微结构使得其比锻造316L不锈钢具有更好的耐点蚀性能和更低的稳态点蚀速率.Ziętala等[16]的研究结果表明,LMD-316L不锈钢胞结构壁面上形成了δ铁素体相,这种相结构不会出现在传统冶金方法制造的316L不锈钢中,他们指出δ铁素体相的形成是打印态材料力学性能和耐腐蚀性能提高的主要原因;通过改变工艺参数调控材料内部的初始位错密度[23]或使用后处理手段改变打印态材料内部的非平衡微观结构(如亚晶、小角度晶界比例和缺陷尺寸),可以显著影响材料的钝化膜厚度和腐蚀电位[6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... ,25]却表明AM-316L不锈钢的特殊微结构使得其比锻造316L不锈钢具有更好的耐点蚀性能和更低的稳态点蚀速率.Ziętala等[16]的研究结果表明,LMD-316L不锈钢胞结构壁面上形成了δ铁素体相,这种相结构不会出现在传统冶金方法制造的316L不锈钢中,他们指出δ铁素体相的形成是打印态材料力学性能和耐腐蚀性能提高的主要原因;通过改变工艺参数调控材料内部的初始位错密度[23]或使用后处理手段改变打印态材料内部的非平衡微观结构(如亚晶、小角度晶界比例和缺陷尺寸),可以显著影响材料的钝化膜厚度和腐蚀电位[6,15].这些研究结果充分表明,AM-316L不锈钢的耐腐蚀性能是与工艺参数高度相关的,可以通过与工艺相关的微观结构调控获得优于锻件的耐腐蚀性能.然而,现有的关于AM-316L不锈钢空化腐蚀性能的研究还较少,主要集中在SLM-316L不锈钢[3,21]:材料的空化损伤破坏主要有2个典型的过程,首先是材料表面逐渐积累塑性变形,此时不发生显著的质量损失,空化腐蚀处于孕育期阶段;其次是在空化泡的反复作用下,材料表面的应力集中区发生疲劳损伤和裂纹扩展,导致材料发生以疲劳为主的表面损伤,此时空化腐蚀处于侵蚀阶段.Hardes等[3]指出SLM-316L不锈钢的晶粒尺寸比相应铸件和热轧件更加细小且位错密度更高,因而材料的硬度和屈服强度提高,导致孕育期空化侵蚀阶段材料的表面完整性相对较好.然而SLM-316L不锈钢内部存在各种冶金缺陷,这些位置处会发生明显的空化质量损失.在空化侵蚀的进程中,材料表面沿着激光扫描轨迹的位置会优先形成凸起,它的存在增加了后续空化泡冲击材料表面的可能性,对材料的抗空化侵蚀性能不利.Ding等[21]的研究进一步指出孔洞缺陷的比例和晶粒的形貌(柱状晶和棋盘胞状晶粒结构)对SLM-316L不锈钢的空化侵蚀能力有较大影响,材料内部的缺陷比例越高,其抗空化腐蚀的能力越低;当微观结构以棋盘胞状晶为主时,材料的抗空化腐蚀能力较低.值得注意的是,韧性材料和脆性材料在孕育期和侵蚀期的变形行为是不同的[3].鉴于LMD-316L不锈钢的延伸率通常比SLM-316L不锈钢的低[18~20],材料的空化腐蚀行为可能与SLM-316L不锈钢有所不同,但现有的AM-316L不锈钢研究主要集中在电化学腐蚀性能[15,16,23~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...

... ~25],且空化腐蚀性能的研究主要集中在韧性较好的SLM-316L不锈钢,系统研究工艺参数(如激光功率、扫描策略、打印方向、重熔处理等)相关的微观结构变化对LMD-316L不锈钢电化学腐蚀和空化腐蚀性能的影响则较为不足. ...