镍基单晶高温合金消除了在高温应力下薄弱的晶界,并且含有60% (体积分数)以上的L12型共格有序的γ'-Ni3(Al, Ti)沉淀强化相,因此具有优异的抗氧化、抗蠕变和耐疲劳等高温性能,是制造先进航空发动机涡轮叶片等热端部件的关键材料[1,2]。当前,此类单晶零部件主要采用螺旋选晶法或籽晶法的定向凝固铸造工艺制备[3],即在固-液凝固界面建立特定的温度梯度从而控制传热单向性,并利用晶粒竞争生长筛选保留[001]取向晶粒。特别地,温度梯度是该工艺的关键参数,提高温度梯度有助于减少杂晶、条纹晶、雀斑和偏析等冶金缺陷[4,5]。但是现有水冷或液Sn冷却技术的温度梯度仅达到30~100 K/cm,并且受加热和冷却方式限制,短期内难以有质的提升[6]。此外,为提高叶片承温能力和冷却效率,在其内部设计了细直孔、蛇形孔、双层壁等复杂冷却流道[7],因此需要制备出与之对应的精密陶瓷型芯,这对整个定向凝固工艺提出了很高的挑战。因此,探索镍基单晶合金制备的新方法具有重要科学和工程应用价值。

近十几年来迅速发展的选区激光熔化(selective laser melting,SLM)增材制造技术具有一定的潜力制备单晶组织和复杂结构。该技术类似于焊接,利用激光束逐点、逐道和逐层熔化微细金属粉末,并通过“道-道”和“层-层”搭接累加的方式成形,这种“变三维为二维”的加工方式使复杂结构成形简单化[8]。在制备单晶组织方面,由于激光与粉末的作用是一个高瞬态(10-5 s)、局域化(约100 μm)的微区快熔快凝过程,其熔池内部温度梯度和凝固速率可分别达103~105 K/cm和0.1~1 m/s[9],是定向凝固铸造的1~3个数量级。此外,激光能量具有典型的定向作用,熔池内部热流可自顶部向基底传递[10],并且fcc结构中,<001>取向的晶粒受晶间短程作用力的抑制最弱[11],生长竞争优势最大,最终<001>取向晶粒可在自上而下的单向热流作用下择优生长成定向组织。因此,SLM技术可为晶体的定向生长提供有利的热力学条件。

目前,高能束增材制备单晶组织主要集中于激光熔融沉积(laser melting deposition,LMD)和电子束粉床熔融(electron beam powder bed fusion,EB-PBF)。在LMD方面,激光光斑直径较大(1~3 mm),熔池尺寸大且形貌稳定,能够促进固-液凝固界面的稳定推进[12],例如Gäumann等[13]建立了晶体生长形态判据,并发现提高熔池温度梯度与凝固速率的比值能有效抑制杂晶形核;卢楠楠[14]使用间歇沉积策略制备出4 mm高的CMSX-10第三代单晶组织;慈世伟[15]发现降低激光功率、脉冲宽度和送粉量能够促进DD32第二代单晶的晶粒外延生长;刘小欣等[16]发现SRR99第一代单晶合金的多道搭接界面不会产生新的杂晶。在EB-PBF方面,其较高的能量吸收率和较低的热应力有利于少/无裂纹单晶组织形成[17],例如Körner等[18]制备出约80 mm高的CMSX-4第二代单晶组织;Li等[19]制备出14 mm × 14 mm × 95 mm的大尺寸IN738合金定向组织。上述研究证实了高能束增材制备单晶组织具有一定的可行性,而关于SLM的报道则较少。相比LMD和EB-PBF,SLM的激光束更细(约100 μm),较小的熔池能够提供更高的温度梯度和成形精度,在成形薄壁、尖角、曲面等复杂精密结构方面更具优势,但其熔池稳定性较低且熔道数量更多,特别是相邻熔道搭接区域的晶体生长难以调控,使SLM在制备大尺寸单晶组织时面临更大挑战。

本工作在4种工艺参数下成形了不同扫描间距(0.06、0.09、0.12和0.15 mm)的多道搭接试样,分析了工艺参数对熔道顶面形貌、熔池几何特征、晶体取向和微观组织的影响,揭示了裂纹、杂晶和取向偏差等缺陷的形成机理和抑制方法,可为SLM制备单晶涡轮叶片等复杂构件提供理论支撑和技术参考。

1 实验方法

1.1 实验材料

表1 镍基单晶高温合金DD491和DD6的名义化学成分 (mass fraction / %)

Table 1

| Alloy | Co | Cr + W + Mo + Ta | Re | Ru | Al | Hf | Ni |

|---|---|---|---|---|---|---|---|

| DD491 | 12.0 | 19.0 | 5.4 | 3.0 | 5.8 | 0.1 | Bal. |

| DD6 | 9.0 | 21.8 | 2.0 | - | 5.6 | 0.1 | Bal. |

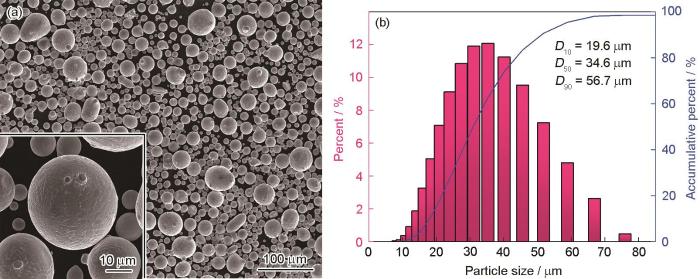

图1

图1

镍基单晶高温合金DD491粉末的微观形貌和粒径分布

Fig.1

SEM image (a) and particle size distribution (b) of the DD491 Ni-based single-crystal superalloy powder (Inset in Fig.1a shows the high magnified image. D10, D50, and D90—sizes below which 10%, 50%, and 90% of the particles are con-tained, respectively)

依据晶体外延定向生长的特性,基底选用定向凝固并经固溶-时效处理的第二代镍基单晶高温合金DD6棒材,其内部晶粒与[001]取向偏离角小于5°,名义化学成分如表1所示。实验前,使用电火花沿平行于(001)晶面切取尺寸为14 mm × 8 mm × 5 mm的4个块体试样,其(001)晶面即为成形面,随后将该表面经SiC砂纸研磨、喷砂以及酒精清洗备用。

1.2 设备与工艺

表2 选区激光熔化(SLM)成形单道和多道搭接试样的工艺参数

Table 2

| Processes | P / W | v / (mm·s-1) | h / mm |

|---|---|---|---|

| S1: low power, low speed | 260 | 500 | 0.06, 0.09, 0.12, 0.15 |

| S2: low power, medium speed | 260 | 600 | 0.06, 0.09, 0.12, 0.15 |

| S3: high power, medium speed | 310 | 600 | 0.06, 0.09, 0.12, 0.15 |

| S4: high power, high speed | 310 | 700 | 0.06, 0.09, 0.12, 0.15 |

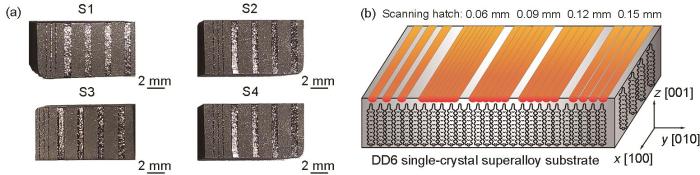

图2为4种工艺参数下成形的单道和多道搭接试样及其示意图。首先在4块DD6合金基底的(001)晶面上铺设约40 μm厚的DD491合金粉末,随后在每一块基底上成形出3条单道和4条多道搭接试样,其中多道h分别设置为0.06、0.09、0.12和0.15 mm,扫描宽度为1 mm,扫描方式为沿x轴往复扫描。

图2

图2

不同工艺参数下SLM成形的单道、多道搭接试样实物图和示意图

Fig.2

Samples (a) and schematic (b) of SLM-fabricated single-track and multi-track overlapping samples under different processes

1.3 表征设备与方法

采用Nova NanoSEM 450型SEM观察合金粉末形貌、熔道x-y (顶面)面形貌和y-z (侧面)面熔池的微观组织特征,该电镜搭载X-Max50型能谱仪(EDS)。在观察y-z面熔池微观组织前,需要制备金相试样,即将该侧面经SiC砂纸研磨,再使用金刚石喷雾抛光,随后在2 g CuSO4 + 10 mL HCl + 1 mL H2SO4 + 8 mL H2O金相腐蚀液中浸蚀90 s后清洗吹干即可。采用GeminiSEM300型电镜特殊功能电子背散射衍射(EBSD)分析y-z面熔池的晶体取向,扫描步长为0.5 μm,并使用AztecCrystal软件处理采集的数据。在EBSD测试前,使用电解抛光去除表面残余应力,即将机械磨抛后的试样浸入A2电解液(5% HClO4 + 95% C2H6O,体积分数)中,在30 V电解电压下工作10 s后,清洗吹干即可。熔池的几何特征尺寸使用ImageJ软件进行分析。

2 实验结果

2.1 单道形貌

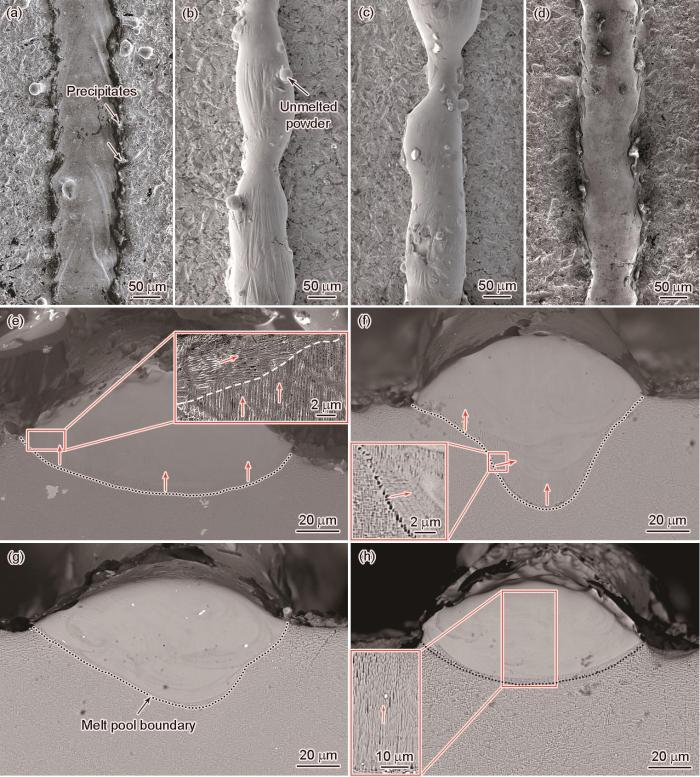

图3为4种参数下单道试样的x-y面和y-z面形貌的SEM像。从顶面(图3a~d)可以看出,S1和S4工艺下的熔道较为平整、规则,宽度均匀,沿熔道两侧边界有较多析出物;S2与S3工艺下的熔道扭曲、粗糙,宽度不均匀,并且表面有裂纹和较多未熔粉末颗粒等冶金缺陷。从侧面(图3e~h)可以看出,S1和S4工艺下的熔池呈现双弧状,底部曲率半径大,并且晶粒能够延续单晶基底的[001]取向生长(图3e和h插图),仅在熔池两侧出现少量[010]方向杂晶(图3e插图),这主要由于平缓的熔池底部增强了自上而下凝固传热的方向性;S2工艺下的熔池形状不规则,熔深较大,这是低功率、中速率下熔池中心能量密度远高于两侧造成的,这种熔池的传热方向较为紊乱,不利于晶粒的[001]定向生长(图3f插图);S3工艺下的熔池形状与S2工艺下的类似,在右侧边界出现了转折点,这是由于高功率、中速率的参数使熔体内部存在较大温差,进而形成了强烈Marangoni对流,导致熔体流动场紊乱。综上,S1和S4工艺下的熔道稳定平滑、熔池扁平规则,能够为晶粒的[001]定向生长提供稳定的几何形态、热力学和动力学条件。

图3

图3

4种工艺参数下的单道试样x-y面和y-z面形貌的SEM像

Fig.3

SEM images of single-track samples in the x-y (a-d) and y-z (e-h) planes under S1 (a, e), S2 (b, f), S3 (c, g), and S4 (d, h) processes (White dotted line in Fig.4e indicates boundary of grains in two different orientations, red arrows indicates growth directions)

2.2 多道形貌

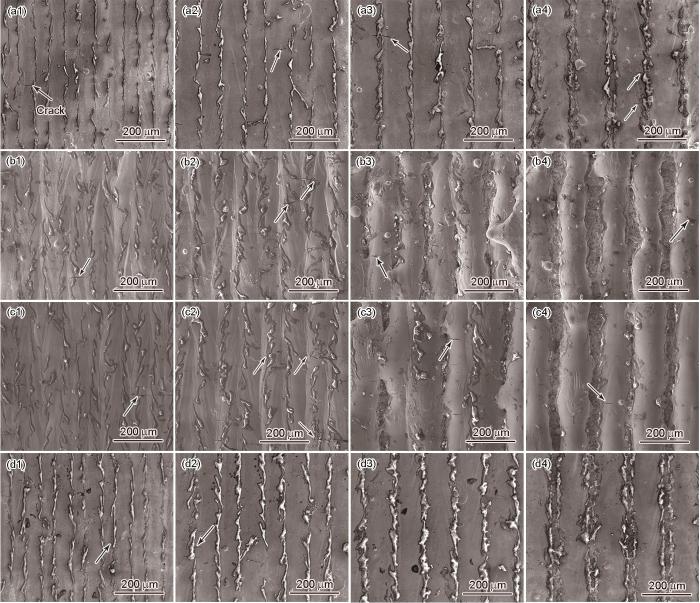

图4为不同扫描间距下多道搭接试样x-y面形貌的SEM像。可以看出,随着h的增大,熔道的搭接率和数量逐渐减少,特别是在S2和S3工艺下,当h > 0.12 mm时,相邻熔道几乎难以相互重叠;对于S1和S4工艺下的试样,无论h大小,熔道表面都较为平整规则、起伏较小,链条状析出物沿熔道边界有序分布,这得益于该2组参数下单道熔池的扁平化特征。需要注意的是,在每个试样中都能够观察到微裂纹(长度 < 100 μm),其扩展方向与激光扫描方向垂直,这说明裂纹的产生与工艺参数关联不大。此外,析出物的尺寸随着h的增大而逐渐变大,这是由于熔道数量减少并且相邻熔道距离变远,使得热积累程度降低,从而促进了析出物的形成。综上,S1和S4工艺下的多道搭接试样表面质量最优,但微裂纹和熔道边界的析出物难以避免;虽然较小的h有助于抑制析出物的产生,但是会大大降低成形效率,应综合考虑选择最优工艺窗口。

图4

图4

不同扫描间距的多道搭接试样x-y面形貌的SEM像

Fig.4

SEM images of S1 (a1-a4), S2 (b1-b4), S3 (c1-c4), and S4 (d1-d4) multi-track overlapping samples in the x-y plane under 0.06 mm (a1-d1), 0.09 mm (a2-d2), 0.12 mm (a3-d3), and 0.15 mm (a4-d4) scanning hatches (Arrows show cracks)

图5

图5

多道搭接试样凝固热裂纹、固态裂纹微观形貌的SEM像和元素分布

Fig.5

SEM images of solidification hot cracks (a, b), solid cracks (c, d), and EDS elemental distribution maps of rectangle area in Fig.5d (e) in the multi-track overlapping samples

(a) S1, h = 0.09 mm (b) S3, h = 0.12 mm (c) S1, h = 0.15 mm (d) S1, h = 0.06 mm

综上所述,激光增材制备高Al含量镍基高温合金的开裂问题难以避免,未来可通过改变扫描策略、调整工艺参数、基底预热等手段来降低热应力、大角度晶界和析出物含量,进而使其控制在较低范围内。

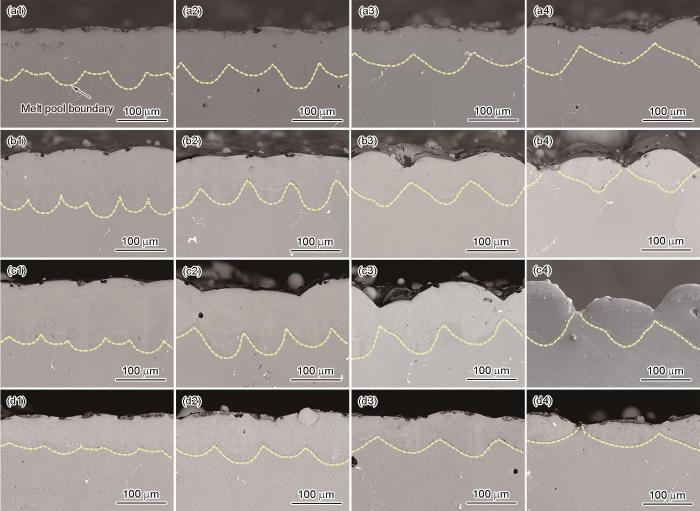

图6为不同h下多道搭接试样y-z面熔池形貌的SEM像。可以看出,熔池底部边界均呈现波浪状,并且随着h的增大,熔池搭接率逐渐减小,特别是在h = 0.15 mm时,相邻熔道几乎难以重叠。此外,S1和S4工艺下的熔池顶部较为平坦、高低起伏小,而S2和S3工艺下相邻熔道的尺寸特征变化较大,难以获得稳定的多道试样。

图6

图6

不同扫描间距的多道搭接试样y-z面形貌的SEM像

Fig.6

SEM images of S1 (a1-a4), S2 (b1-b4), S3 (c1-c4), and S4 (d1-d4) multi-track overlapping samples in the y-z plane under 0.06 mm (a1-d1), 0.09 mm (a2-d2), 0.12 mm (a3-d3), and 0.15 mm (a4-d4) scanning hatches (Dotted lines indicate melt pool boundaries)

为了进一步量化分析工艺参数对多道搭接质量的影响规律,建立如图7a所示的熔池几何模型。其中Di 为第i条熔道的深度;

图7

图7

多道搭接熔池示意图和熔池几何特征与工艺参数的关系

Fig.7

Schematic of multi-track overlapping melt pool (a); relationships between process parameters and standard deviation (SD) (b), average melt pool depth (

2.3 晶体取向

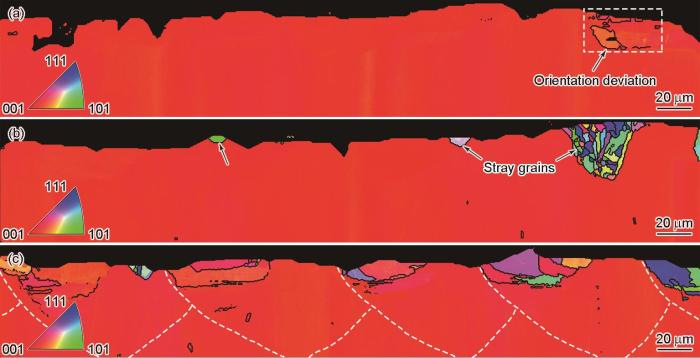

图8为S1工艺下不同扫描间距多道搭接试样的y-z面晶体取向图,红色区域表示晶粒沿<001>取向生长。可以看出,所有熔池底部都能够延续单晶基底的[001]生长方向,这与自上而下的凝固传热单向性密切相关。然而,顶部的局部区域随机出现了取向偏差(> 15°)的杂晶缺陷,并且随着h的增大,此类缺陷出现频率、大小和数量也随之增多。特别是当h = 0.12 mm时,较大面积的杂晶周期性地分布于熔池两侧。

图8

图8

S1工艺下不同扫描间距多道搭接试样的y-z面晶体取向图

Fig.8

Crystal orientation maps of S1 multi-track overlapping samples in the y-z plane under scanning hatches of 0.06 mm (a), 0.09 mm (b), and 0.12 mm (c) (Dotted lines in Fig.8c indicate melt pool boundaries)

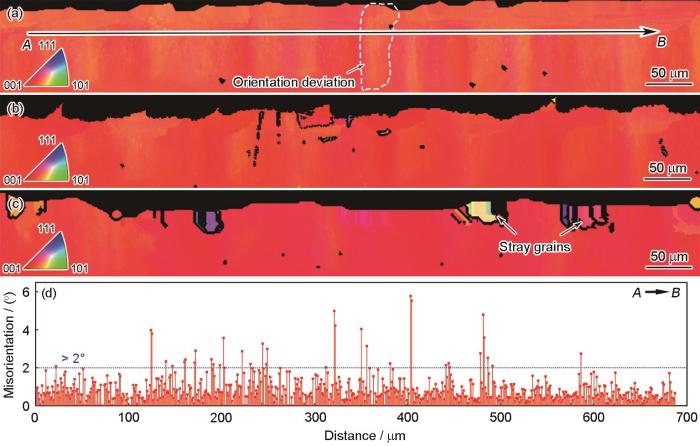

图9为S4工艺下不同扫描间距多道搭接试样的y-z面晶体取向图。可以看出,与图8相似,随着h的增大,顶部杂晶也逐渐增多。此外,当h = 0.06和0.09 mm时,出现了红色与橙色周期性的渐变,即晶体取向与<001>之间存在小角度偏差,其中橙色主要出现在搭接区,并且自上而下贯穿了整个熔池。图9d统计了图9a中从A到B点的相邻像素点取向偏差,可以发现,在任一位置都存在小角度偏差,说明在高功率和小搭接间距下,大量的热积累和Marangoni对流容易促使重熔区晶粒取向发生偏转。总而言之,虽然在单层制造中大部分取向偏差小于2°,但是在多层堆积过程中可能会逐步演化为大角度晶界甚至杂晶,因此应该尽可能消除此类缺陷。

图9

图9

S4工艺下不同扫描间距多道搭接试样的y-z面晶体取向图和取向偏差

Fig.9

Crystal orientation maps of S4 multi-track overlapping samples in the y-z plane under scanning hatches of 0.06 mm (a), 0.09 mm (b), and 0.12 mm (c); distribution of grain misorientation angle from point A to B in Fig.9a (d)

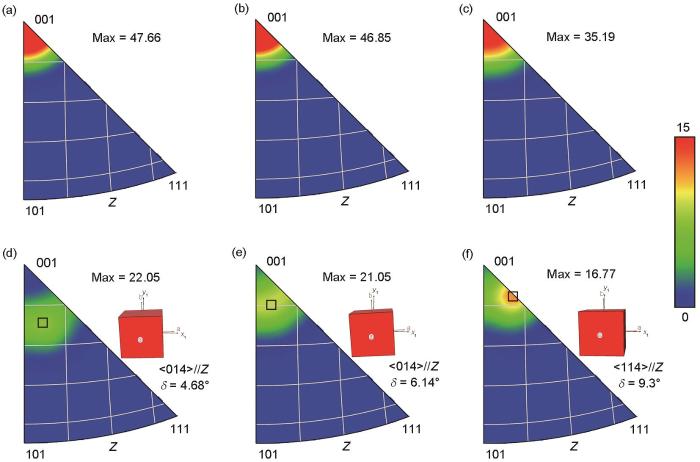

图10为S1与S4工艺下不同扫描间距多道搭接试样的y-z面反极图。可以看出,S1和S4工艺下极点均明显集中,其中S1工艺下极点集中于(001)投影面,呈现出<001>//Z的丝织构特征,而S4工艺下极点则主要集中于(014)和(114)投影面,意味着其内部存在较多的小角度取向偏差晶粒。此外,随着h的增大,S1和S4工艺下的极密度最大值均呈现下降趋势,特别是h从0.09 mm增大到0.12 mm时的下降趋势最为明显(S1工艺下:由46.85降低至35.19;S4工艺下:由21.05降低至16.77),这主要由于熔道顶部出现了较多杂晶。综上所述,S1比S4工艺下的试样具有更强的<001>//Z择优取向,并且减小扫描间距有利于抑制顶部杂晶的产生,进而增强晶粒取向的一致性。

图10

图10

S1和S4工艺下不同扫描间距多道搭接试样y-z面的晶体取向反极图

Fig.10

Inverse pole figures (IPFs) of S1 (a-c) and S4 (d-f) multi-track overlapping samples in the y-z plane under scanning hatches of 0.06 mm (a, d), 0.09 mm (b, e), and 0.12 mm (c, f) (a—the lattice parameter along the x1-axis, b—the lattice parameter along the y1-axis, c—the lattice parameter along the z1-axis, δ—the angle difference with respect to the preferred orientation)

2.4 微观组织

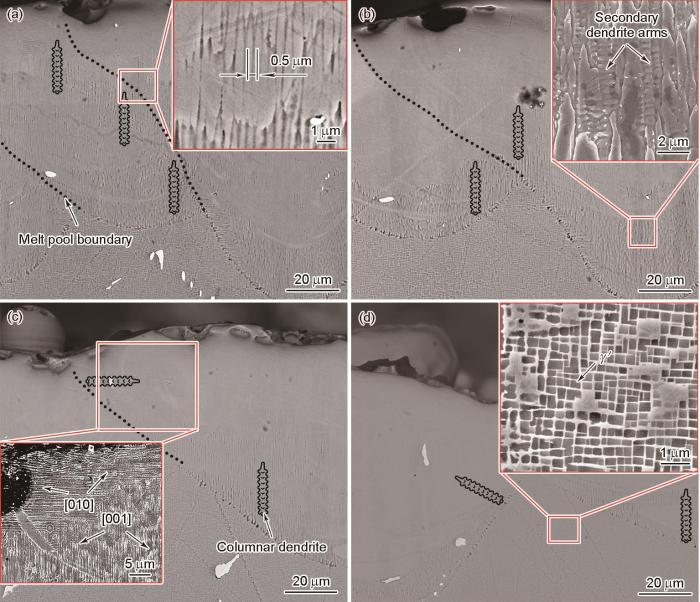

图11为S1工艺下不同扫描间距多道搭接试样搭接区的SEM像。可以看出,当h较小时(0.06和0.09 mm),熔道内部存在大量沿[001]生长的柱状亚晶,一次枝晶臂间距约为0.5 μm (约为铸态的1/600[25]) (图11a插图),特别是重熔区也能外延生长至熔池顶部,即单晶组织保持了较好的完整性。然而当h增大到0.12和0.15 mm时,虽然底部延续了基底的[001]取向,但是重熔区两侧的生长方向发生了偏转,甚至形成了[010]取向的杂晶(图11c插图),即晶体取向的一致性遭到了破坏。此外,在熔道内部可以观察到二次枝晶臂(图11b插图);在DD6合金基底中可以观察到大量边长约1 μm的方形γ'-Ni3Al沉淀强化相(图11d插图),但是熔道内部却难以发现γ'相及其他相,这是由于极快的冷却速率抑制了Al与Ni原子的扩散结合,或者形成的γ'尺寸较小,难以通过SEM观测[26]。综上所述,S1工艺下较小的扫描间距能够获得完整的单晶组织,并且较小枝晶间距和无析出脆性相将有利于提升合金的高温力学性能。

图11

图11

S1工艺下不同扫描间距多道搭接试样的SEM像

Fig.11

SEM images of S1 multi-track overlapping samples under scanning hatches of 0.06 mm (a), 0.09 mm (b), 0.12 mm (c), and 0.15 mm (d) (Insets show the high magnified images)

图12为S4工艺下不同扫描间距多道搭接试样距搭接区的SEM像。可以看出,无论h的大小,熔池底部晶粒均能够延续基底的[001]取向生长,但是熔道顶部存在[010]取向的杂晶,并且搭接区的晶粒取向与[001]取向存在小角度夹角,这对应于图9中“红色-橙色-红色”周期性渐变。此外,从图12c可以看出,柱状胞晶长度自下而上逐渐减小,即发生了“柱状-纺锤状-胞状”的转变,意味着顶部产生了[100]取向杂晶,这主要由于S4工艺下的扫描速率较S1工艺下的大,并且顶部的凝固热流方向与激光扫描方向近乎平行,因此在快的凝固速率和沿x轴热流方向作用下形成了[100]杂晶。综上所述,S4工艺下使用任一扫描间距都难以获得完整的单晶组织,熔道顶部在两侧和中部分别存在[010]和[100]杂晶;未来成形大尺寸构件时,可设置合理的层厚,通过多层堆积重熔来消除这类杂晶。

图12

图12

S4工艺下不同扫描间距多道搭接试样的SEM像

Fig.12

SEM and corrsponding high magnified images of S4 multi-track overlapping samples under scanning hatches of 0.06 mm (a), 0.09 mm (b), and 0.12 mm (c)

3 分析讨论

3.1 单道晶体取向缺陷的形成机理

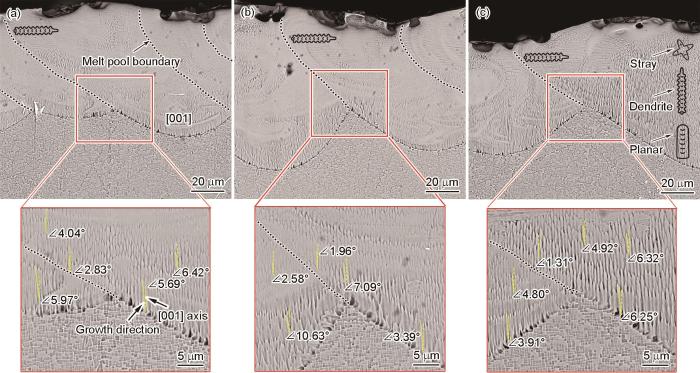

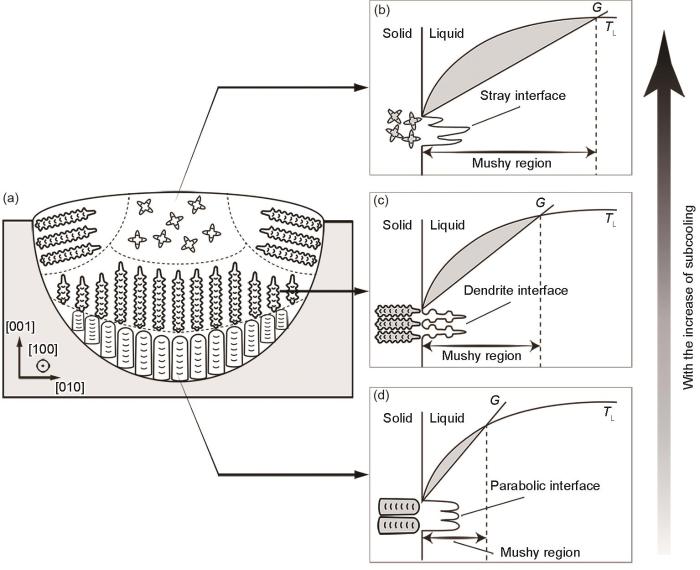

实验结果表明,熔道主要存在3类典型的晶体取向缺陷:顶部的等轴杂晶、两侧的[010]和中部的[100]柱状杂晶、内部的小角度取向偏差,其形成机理如下。

(i) 第一类缺陷是由于顶部产生了成分过冷,从而诱导了柱状晶向等轴晶转变(columnar to equiaxed transition,CET)。依据Gäumann等[13]提出的CET平衡判据:

式中,G为固-液凝固界面温度梯度;R为凝固速率;KCET为发生柱状晶向等轴晶转变的临界值;a和n为材料参数;N0为液相中单位体积内形核位点数;

图13

图13

熔池内晶粒形态演变与固-液凝固界面成分过冷关系示意图

Fig.13

Schematics of the relations between grain evolution (a) and subcooling of the solid-liquid solidification stray interface (b), dendrite interface (c), and parabolic interface (d) front (G—temperature gradient at the solid-liquid solidification interface, TL—temperature of liquid phase)

图14

图14

激光扫描方向、熔池内凝固界面移动方向和晶体择优生长方向关系示意图

Fig.14

Schematics of the relations between the laser scanning direction (

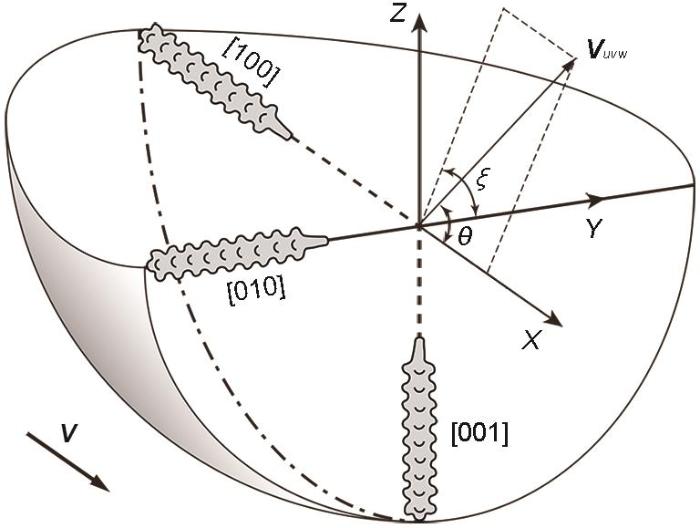

联立

式中,θ

式中,θ为

图15

图15

熔池内[001]、[010]、[100]晶体生长方向示意图

Fig.15

Schematic of the [001], [010], and [100] grain growth directions in the melt pool (θ—the angle between

(iii) 第三类缺陷是由熔池内部熔体流动场紊乱引起的[32]。在激光与粉末作用过程中,熔体在重力、反冲压力和Marangoni效应等多力场驱动下在空间中剧烈流动,形成了自熔池底部向两侧流动的环流,这将改变糊状区溶质原子的空间分布[33],进而使[001]晶体生长产生小角度取向偏转。并且相邻熔道搭接区的环流方向相反,进一步加剧了枝晶偏转的角度差[32]。此外,这类取向缺陷主要发生在大激光功率、小扫描间距的试样中(图9a),该参数下熔池蒸发和汽化严重、熔道多、搭接区大,导致热量积累多、温度场分布复杂,这一定程度增加了熔体流动紊乱程度。值得注意的是,这些取向偏差基本控制在2°以内,没有演变成大角度晶界,也没有导致糊状区枝晶碎裂形成等轴杂晶,但在未来多层堆积过程中可能会逐层累加成为杂晶,故应尽可能提高熔池流动场的稳定性,降低此类缺陷恶化风险。

3.2 多道搭接晶体取向缺陷的形成机理

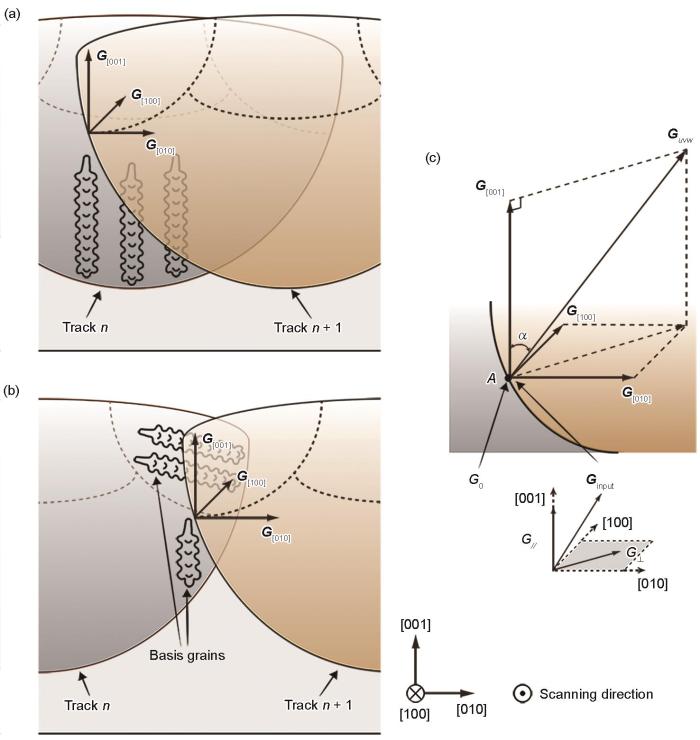

图16

图16

扫描间距h影响搭接区晶体生长示意图

Fig.16

Schematics of smaller scanning hatch (a), larger scanning hatch (b), and heat gradient (c) affecting the grain growth in the overlapping region (G0—residual heat gradient in old melt pool;

进一步地,搭接区的残余热也对晶粒生长有着重要影响。图16c为A点处旧熔池残余热梯度(G0)、激光输入热梯度(

其中,

联立式(

对

综上,较小的扫描间距(熔池重叠率达30%)能充分重熔旧熔池侧边的杂晶,并在搭接区提供完整的[001]引导衬底;考虑S1和S4工艺下残余热对凝固热梯度的不同作用,以及避免构建实体中热量过度积累,故应选择S1工艺及h = 0.09 mm,以获得晶体取向缺陷少的试样。

4 结论

(1) S1 (低功率、低速率)和S4 (高功率、高速率)参数下的单道形态稳定、熔池扁平规则,能够为[001]取向晶体定向生长提供稳定的几何形态、热力学和动力学条件,但多道搭接中的凝固热裂纹和固态裂纹以及熔道边界的富Al析出物难以避免。

(2) 较小的扫描间距能够抹平熔池的双弧状,提高熔道顶部的平整性,并且可以通过重熔来减少熔池两侧的杂晶缺陷。S1相比S4具有更强的<001>//Z择优取向,其低功率和低速率的组合有利于提高熔池温度梯度并降低固-液界面移动速率,从而抑制杂晶的产生。

(3) 熔道内晶体取向有3类缺陷,即顶部等轴杂晶、顶部[010]和[100]柱状杂晶、内部小角度取向偏差,抑制熔池内部CET的形成、调控熔池形态的扁平性和提高熔体流动场的稳定性是保证单晶组织完整性的关键。

参考文献

Recent progress in research and development of nickel-based single crystal superalloys

[J].

镍基单晶高温合金的研发进展

[J].

A review of composition evolution in Ni-based single crystal superalloys

[J].Due to the outstanding creep performance, nickel-based single crystal superalloys (Ni-SXs) are extensively applied in modern aero-engine and industrial gas turbine. Apart from the special single crystal structure which is disadvantageous to extension of creep cracks, Ni-SXs derive the creep strength from intrinsic two-phase microstructure (γphase and γ’ phase). Main microstructural parameters including volume fraction of γ’ phase and the lattice misfit, and the formation and distribution of precipitated phase are determined by the compositions of alloys. Besides, the creep properties are greatly influenced by these microstructural parameters and precipitated phase. This review has summarized the relationships between different alloying elements and microstructures and indicated their influence on creep properties of Ni-SXs. In addition, with the improvements of experimental methods and characterization technique, some recent discoveries have provided additional evidence to support or challenge the pervious creep theories of superalloys. In view of these new discoveries, this review has provided some perspectives which can be referenced in future compositional design of Ni-SXs.

Influence of crystal orientation on microstructure and mechanical properties and its control for nickel-base single crystal superalloys

[J].

镍基单晶高温合金晶体取向的选择及其控制

[J].

Directional solidification under high thermal gradient and its application in superalloys processing

[J].<p>Industrial gas turbines (IGTs) are the key equipment to achieving energy strategy, such as energy conservation and clean power generation. When the large and complex IGT blades are fabricated by the conventional Bridgman directional solidification process, the thermal gradients at the solidification front are low and unstable, resulting in some disadvantages: the coarse dendrite structure with severe dendritic segregation, the increased occurrence of casting defects and the poor performance of mechanical properties. These disadvantages provide a good opportunity for rapid development of the directional solidification with high thermal gradient (HG), such as the liquid metal cooling (LMC). In the present work, the physical basis of HG process, the microstructure, mechanical properties, solution heat treatment, and casting defects of the superalloys processed by HG process, have been reviewed. The HG process increases the thermal gradient and the cooling rate, thus permitting microstructural improvements including a more homogeneous fine-dendrite structure with lower elemental segregation and shrinkage porosity, and refinement of carbide, <i>γ′</i> phase and eutectic, reducing the volume fraction of eutectic and shrinkage porosity. During the solution heat treatment, the HG process increases the incipient melting temperature and reduces the residual segregation as well as the content of solution pore. The HG process could effectively inhibit the formation of freckle chains, increase the critical withdrawal rate of the stray grain formation, and decrease the degree of the misorientation of the <001> grain orientation from the casting axis. Moreover, the HG process could improve the mechanical properties including the stress rupture life, low-cycle fatigue (LCF), high-cycle fatigue properties and short-term strength, but the improvement might be reduced at higher temperature or under the oxidation condition.</p>

高梯度定向凝固技术及其在高温合金制备中的应用

[J].

Common solidification defects and inhibition methods in single crystal superalloy turbine blades

[J].

单晶高温合金涡轮叶片的常见凝固缺陷及控制方法

[J].近年来,随着单晶涡轮叶片气冷结构的复杂化和尺寸的大型化,单晶叶片制备过程中容易出现选晶失败、取向偏离、条纹晶、大角晶界、缘板杂晶、再结晶、雀斑等多种凝固缺陷,导致单晶高温合金性能降低,造成叶片报废。为了减少这些凝固缺陷,提高单晶品质,获得结构完整的单晶组织,熟悉单晶叶片生长过程中的各种常见缺陷,掌握凝固缺陷的形成规律及其控制技术就显得尤为重要。针对这一现状,系统地介绍了单晶叶片生长过程中常见的凝固缺陷,以及凝固缺陷形成规律和控制方法,为减少单晶叶片缺陷,提高叶片品质和合格率奠定了坚实的理论基础,提供了有力的技术保障。

Directional crystallization of high-temperature alloys with elevated temperature gradient

[J].

Research progress on cooling structure of aeroengine air-cooled turbine blade

[J].

航空发动机气冷涡轮叶片冷却结构研究进展

[J].

Research progress of materials design for metal laser additive manufacturing

[J].Laser additive manufacturing is widely recognized to be an effective method to form complicated and custom metallic components. The existing research on metal additive manufacturing utilizes traditional alloy grades, which are designed based on the assumption that solidification occurs at equilibrium; thus, these materials are not well suited to the nonequilibrium metallurgical dynamics that are present in additive manufacturing techniques. Common issues, such as high crack susceptibility, low toughness, and low fatigue capability, as well as anisotropy, frequently occur during the fabrication of additively manufactured metallic parts. It is therefore necessary to conduct research on the design of new materials designed specifically for laser additive manufacturing in order to fully realize the potential advantages and value of the ultrafast solidification conditions. In this article, the technical bottlenecks, material design methods, and the development of new materials that are applicable to laser additively manufactured metal materials are reviewed; these materials include aluminum alloys, titanium alloys, iron-based alloys, and magnesium alloys. Finally, the potential future direction of research related to laser metal additive manufacturing is discussed.

金属激光增材制造材料设计研究进展

[J].

Metallurgy, mechanistic models and machine learning in metal printing

[J].

Quantitative texture prediction of epitaxial columnar grains in additive manufacturing using selective laser melting

[J].

Crystallographic texture evolution in bulk deformation processing of FCC metals

[J].

Research progress in laser additive manufacturing technology of single crystal superalloy

[J].

激光增材制造单晶高温合金研究进展

[J].

Single-crystal laser deposition of superalloys: Processing-microstructure maps

[J].

Single crystal growth controling of CMSX-10 superalloy via laser melting deposition

[D].

CMSX-10高温合金激光熔化沉积单晶生长控制

[D].

Study on microstructure and mechanical properties of nickel-based single crystal supertalloy by laser additive manufacturing

[D].

激光增材制造镍基单晶高温合金显微组织和力学性能研究

[D].

Influence of processing conditions on formation of stray grains in DD5 single-crystal superalloys by laser melting multi-traced deposition

[J].

不同工艺条件对激光熔化多道沉积DD5单晶高温合金杂晶的影响

[J].

Nickel-based superalloy single crystals fabricated via electron beam melting

[J].

Microstructure and mechanical properties of CMSX-4 single crystals prepared by additive manufacturing

[J].

Additive manufacturing of nickel-based superalloy single crystals with IN-738 alloy

[J].

Effect of ruthenium on the precipitation of topologically close packed phases in Ni-based superalloys of 3rd and 4th generation

[J].

Single-track morphology, crystal orientation and microstructure of DD91 nickel-based single crystal superalloy fabricated by selective laser melting

[J].

激光选区熔化DD91镍基单晶高温合金的单道形貌, 晶体取向和微观组织

[J].

Additive manufacturing of Ni-based superalloys: Residual stress, mechanisms of crack formation and strategies for crack inhibition

[J].

Effect of volumetric energy density on microstructure and properties of Hastelloy X alloy manufactured by selective laser melting

[J].

体能量密度对选区激光熔化成形Hastelloy X合金组织及性能的影响

[J].

Crack types, mechanisms, and suppression methods during high-energy beam additive manufacturing of nickel-based superalloys: A review

[J].

Laser glazing rapidly solidified microstructure of DD8 single crystal Ni-based superalloy

[J].

单晶镍基高温合金DD8激光快速熔凝组织

[J].

Microstructures of nickel-base single-crystal superalloy prepared by laser solid forming

[J].

激光立体成形镍基单晶高温合金显微组织研究

[J].

Origin of stray grain formation in single-crystal superalloy weld pools from heat transfer and fluid flow modeling

[J].

Development of microstructures in Fe-15Ni-15Cr single crystal electron beam welds

[J].

Microstructure and grain growth direction of SRR99 single-crystal superalloy by selective laser melting

[J].

Effects of melt-pool geometry on the oriented to misoriented transition in directed energy deposition of a single-crystal superalloy

[J].

Microstructural control in metal laser powder bed fusion additive manufacturing using laser beam shaping strategy

[J].

Variation of crystal orientation during epitaxial growth of dendrites by laser deposition

[J].A nickel-based superalloy was deposited onto a single crystal substrate based on epitaxial laser metal forming (E-LMF). The microstructure development in two depositions has been researched. For the first time, the crystal orientation of dendrites varying beyond 20° was found when the dendrites deflected in deposition. In addition, a new grain boundary was found between different orientation dendrites in a grain, and the detected grain boundary angle was 23°. The result shows that flowing field in laser pool is responsible for this phenomenon.

Phase-field simulation of dendritic growth in a shear flow

[J].

Effects of process parameters on microstructure and cracking susceptibility of a single crystal superalloy fabricated by directed energy deposition

[J].