多主元合金突破了传统合金设计理念的桎梏,将成分范围扩展到了多元相图的中心区域[1~3]。作为多主元合金的一个子集,高熵合金通常由4种或4种以上合金元素以等原子比或近等原子比所构成[4~6]。高熵合金具有独特的组织特性以及优异的力学和物理性能,有望替代部分传统合金和轻质材料,被广泛应用于航空航天、生物医学和船舶等工业领域[7~9]。目前的高熵合金主要以单相结构为主,如分别以CoCrCuFeNi和AlCoCrFeNi为代表的fcc和bcc高熵合金[10,11]。然而,单相高熵合金的强度与塑性之间的内在矛盾限制了其从实验室到工程应用的发展。单相fcc高熵合金通常表现出优异的塑性,而bcc高熵合金的优势在于较高的强度[12~15]。

近期,增材制造为制备具有复杂几何结构的共晶高熵合金部件提供了一条新途径。其中,激光粉末床熔融(LPBF)作为一种新兴的增材制造技术,其原理是利用高能激光束对粉末床进行逐点、逐层扫描以使其快速熔化和凝固,从而直接构建出结构功能一体化的三维金属部件[25,26]。因此,结合共晶高熵合金和LPBF技术各自的优势有望突破高性能复杂结构件的制造瓶颈。目前,通过优化激光工艺参数,已可以打印出近全致密的AlCoCrFeNi2.1共晶高熵合金,其室温力学性能明显优于铸态合金[27,28]。另有研究[29,30]表明,LPBF过程中较高的温度梯度和冷却速率有利于纳米级层片状共晶组织的形成,从而显著提高相界强化效果并促进两相协同变形,验证了共晶结构和力学性能的可协调性。

1 实验方法

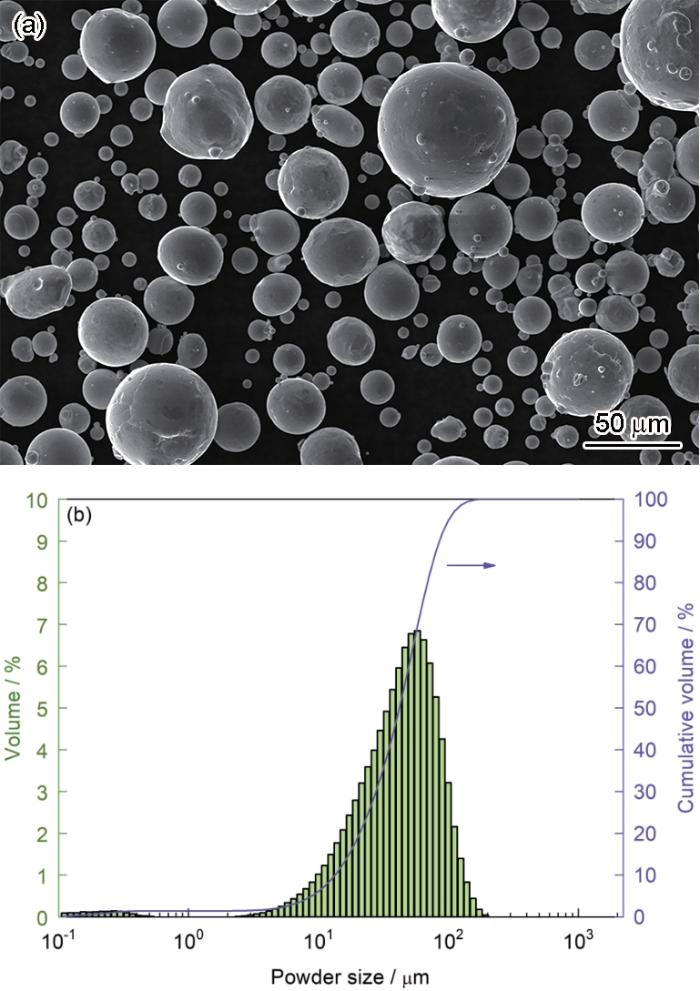

实验分别采用真空感应熔炼炉和Renishaw AM400增材制造系统制备AlCoCrFeNi2.1共晶高熵合金样品。通过Ar气雾化法制备用于LPBF成形的AlCoCrFeNi2.1预合金粉末。采用Mira 3型扫描电子显微镜(SEM)观察粉末的微观形貌,并通过BT-9300ST型激光粒度分析仪测量粉末的粒径分布,结果如图1所示。粉末颗粒具有良好球形度,其粒度范围为13~80 µm。在进行LPBF成形之前,将粉末放置于YZG-5真空炉中在80℃下干燥10 h。LPBF过程在高纯度Ar气保护下进行,工作室内O2水平保持在200 × 10-6以下。使用尺寸为80 mm × 80 mm × 5 mm的304不锈钢板作为基底材料。经过多次工艺优化,实验所选用的激光工艺参数为:激光功率300 W,扫描速率1000 mm/s,扫描间距60 μm,粉末层厚度40 μm,光斑直径70 μm,扫描旋转角度67°。并结合条带式扫描策略对粉末层进行熔融。LPBF成形样品尺寸为30 mm × 20 mm ×10 mm。

图1

图1

AlCoCrFeNi2.1粉末的SEM像和粒径分布

Fig.1

SEM image (a) and size distribution (b) of the AlCoCrFeNi2.1 powders

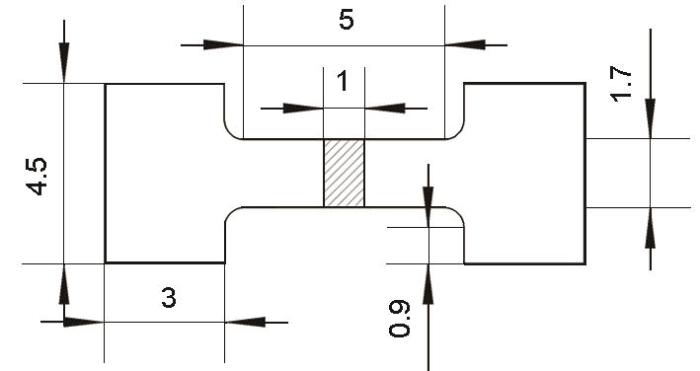

采用DMi8型光学显微镜(OM)观察样品中的缺陷分布。使用Mira 3型SEM观察样品的微观组织。通过D8 Advance型X射线衍射仪(XRD,CuKα,波长0.15406 nm)检测样品的相组成,扫描角度20°~90°,扫描速率4°/min。采用Talos F200型透射电子显微镜(TEM)的扫描透射模式(STEM)及其附带的能量色散X射线谱仪(EDS)进一步分析样品的共晶结构和元素分布。应用Thermo-Calc软件模拟AlCoCrFeNi2.1共晶高熵合金的平衡相图。采用Instron-5848型微力材料拉伸试验机进行拉伸实验,分别在室温(20℃)、500℃和700℃下对试样进行单轴拉伸,拉伸速率0.3 mm/min。拉伸试样尺寸如图2所示。随后通过Apreo型SEM观察试样的断裂情况,分析试样的失效机理。

图2

图2

拉伸试样的尺寸示意图

Fig.2

Schematic illustration of the tensile specimens (unit: mm)

在金相观察之前,对试样进行机械研磨和抛光,然后将其置于(8 g CuSO4 + 40 mL HCl + 40 mL H2O)溶液中蚀刻5 s。TEM样品首先经机械研磨至40 μm厚,然后在-25℃的90%C2H5OH + 10%HClO4 (体积分数)电解液中进行双喷减薄,电压参数20 V。

2 实验结果与讨论

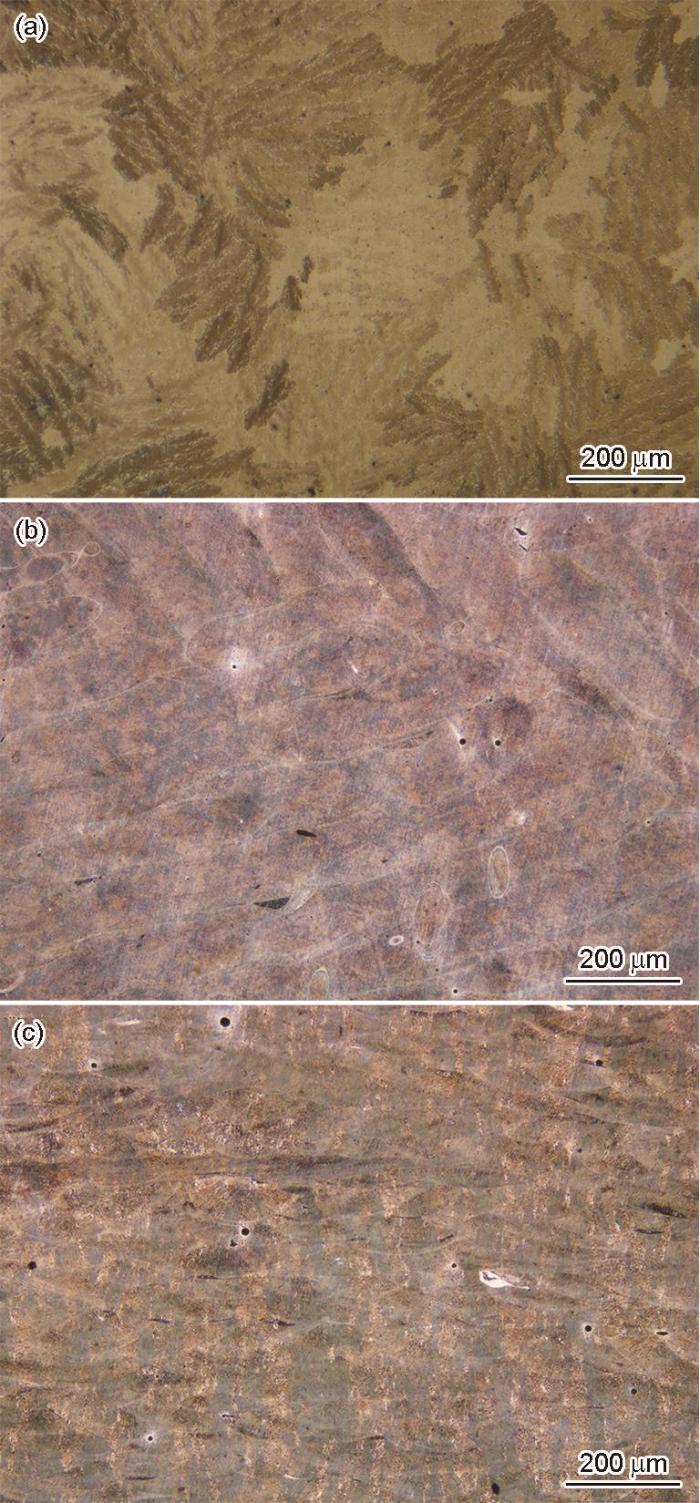

2.1 成形质量

合金的力学性能主要取决于其成形质量,即合格试样内部应无明显的裂纹、夹杂及偏析等冶金缺陷。图3显示了铸态及LPBF成形AlCoCrFeNi2.1试样截面的OM像。可以看出,2种试样均表现出较为致密的组织形貌。铸态样品中可较为清晰地观察到晶粒尺寸和晶界轮廓。而LPBF成形样品则表现出由熔体堆叠成形而产生的独特结构,并且具有明显的组织各向异性。其中,Y-Z面展现出不同沉积层的旋转扫描轨迹,X-Z面显示了由多个小型熔池组成的鱼鳞状结构(X—水平方向,Y—扫描方向,Z—构建方向)。LPBF成形试样的致密度可达99.17% ± 0.21%,仅有少量微米级气孔分布在熔池边界区域,这可能是由于在熔体凝固过程中气体来不及溢出产生的。有研究[33]表明,尽管共晶高熵合金具有良好的流动性能和浇注性能,但在铸造过程中仍难以完全避免缩孔等冶金缺陷的产生。而LPBF成形样品中孔洞尺寸较小且分布较为随机和均匀,因此对试样拉伸性能产生的影响较小。

图3

图3

铸态和激光粉末床熔融(LPBF)成形AlCoCrFe-Ni2.1试样显微组织的OM像

Fig.3

OM images of microstructures of as-cast sample (a), Y-Z plane (b), and X-Y plane (c) of laser powder bed fusion (LPBF)-formed AlCoCrFeNi2.1 sample (X—horizontal direction, Y—scanning direction, Z—construction direction)

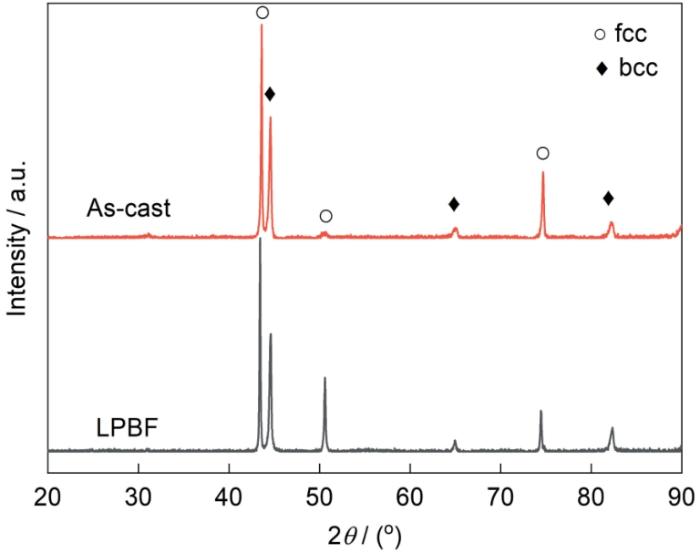

2.2 物相分析

图4为铸态和LPBF成形AlCoCrFeNi2.1试样的XRD谱。可见,2种样品均由fcc和bcc相组成,但衍射峰强度具有明显差异。铸态试样中bcc相的衍射峰强度相对高于LPBF成形试样,意味着bcc相在铸态样品中的比例较高,而LPBF成形样品中fcc相衍射峰较强。这表明制造工艺对AlCoCrFeNi2.1共晶高熵合金的相析出行为产生了影响。这种变化主要与LPBF过程中的快速加热和冷却有关,导致平衡相的生长在较高的温度梯度下受到抑制,从而偏离了共晶成分。同时,LPBF成形样品的衍射峰轻微向左移动,表明LPBF过程导致的微观残余应力和原子固溶引起了强烈的晶格畸变。

图4

图4

铸态和LPBF成形AlCoCrFeNi2.1样品的XRD谱

Fig.4

XRD spectra of as-cast and LPBF-formed AlCoCrFeNi2.1 samples

2.3 微观组织

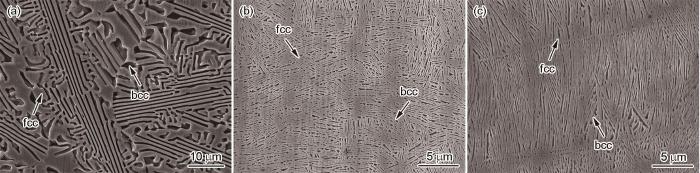

图5

图5

铸态和LPBF成形AlCoCrFeNi2.1样品显微组织的SEM像

Fig.5

SEM images of as-cast sample (a), Y-Z plane (b), and X-Y plane (c) of LPBF-formed sample

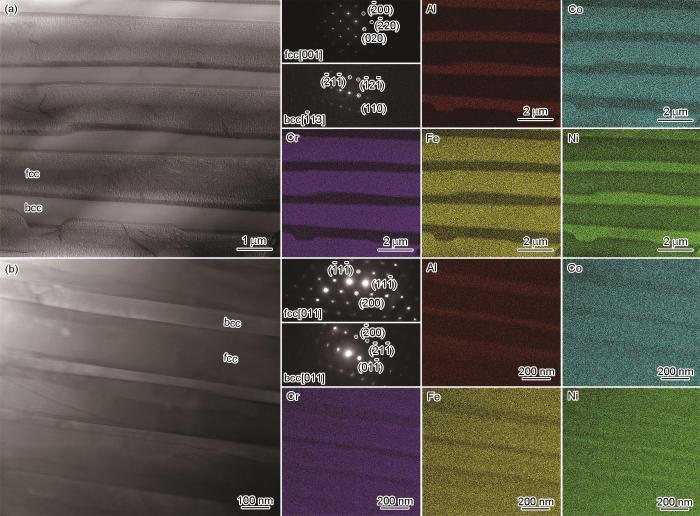

图6为铸态和LPBF成形AlCoCrFeNi2.1试样的STEM像、选区电子衍射花样及EDS分析。2个样品均表现出具有明显不同亮度的层片状共晶结构。通过衍射花样可以看出,铸态样品是由常规的fcc和bcc相组成。而在LPBF成形样品中,除标准fcc点阵外,bcc相中的超晶格点阵表明了B2有序相的形成。因此,制备工艺在决定相的有序性方面发挥了一定作用。此外,铸态样品中共晶片层间距约为1.53 μm,而LPBF成形样品的共晶片层间距仅约为165 nm,表明LPBF工艺有利于获得超细的共晶组织。

图6

图6

铸态和LPBF成形AlCoCrFeNi2.1样品的STEM暗场像、选区电子衍射花样及EDS分析

Fig.6

STEM dark field images, selected area electron diffraction patterns, and EDS maps of as-cast (a) and LPBF-formed (b) AlCoCrFeNi2.1 samples

2种样品的元素分布结果表明,富CrFeCo和富NiAl区域分别对应于fcc和bcc/B2相。相对于铸态样品,LPBF成形样品中的元素偏析情况有所缓解,这主要归因于LPBF快速凝固过程可显著抑制原子的扩散。

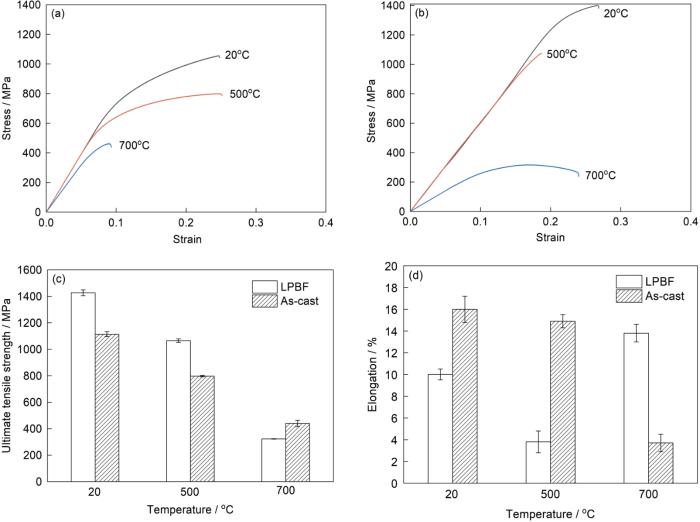

2.4 力学性能

铸态和LPBF成形AlCoCrFeNi2.1共晶高熵合金在不同温度下的应力-应变曲线分别如图7a和b所示;图7c和d分别显示了2种试样的极限抗拉强度和断后伸长率随温度的变化情况。可以看出,2种样品的组织差异导致了相应拉伸性能随温度变化的不同趋势。室温条件下,LPBF成形样品的抗拉强度为(1427 ± 22.5) MPa,比铸态样品提升了约28%,并保持了10%的良好伸长率。其原因是LPBF成形样品中超细的共晶层片在拉伸变形过程中可产生强烈的界面强化。同时,预先存在的由热应力诱导的位错产生了额外的强化效应[29]。然而,铸态样品显示出更高的伸长率,这主要归因于铸态样品中较宽的共晶层片为位错的长程相互作用和滑移提供了更多的空间,从而产生了连续的应变硬化效果。

图7

图7

铸态和LPBF成形AlCoCrFeNi2.1样品在不同温度下的应力-应变曲线及抗拉强度和伸长率随温度的变化情况

Fig.7

Tensile stress-strain curves of as-cast (a) and LPBF-formed (b) AlCoCrFeNi2.1 samples at different temperatures, and variations of ultimate tensile strength (c) and elongation (d) with temperature

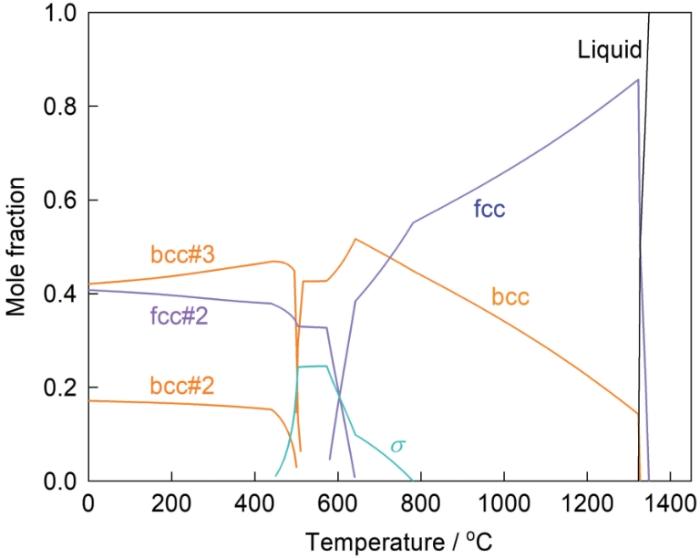

当拉伸实验温度升高至500℃时,尽管2种样品的力学性能均发生了下降,但LPBF成形样品仍保持有接近1100 MPa的抗拉强度,高于大多数高强度结构钢的强度[35~38],表明LPBF成形样品在500℃下仍能保持较为强烈的双相协同强化效果。为了明晰拉伸性能下降的原因,使用Thermo-Calc计算了该合金的热力学平衡相图(图8)。在450~780℃温度范围内,合金中可能会产生多种相变。因此,推测2种样品强度和延伸率同时下降可能与相变有关。相图显示当温度升高至500℃时,合金中的bcc结构将发生转变,fcc相含量显著下降,并伴随着少量σ相的析出。根据无机晶体结构数据库(ICSD),σ相具有四方晶体结构,其晶格参数为a = 0.88 nm,c = 0.46 nm[39]。这种剧烈的相变将会在一定程度上降低共晶层片的变形协调性,造成样品过早失效。

图8

当温度超过640℃,合金中的相变逐渐减弱。因此,拉伸实验温度为700℃时,合金的力学性能将主要取决于晶体和相界强度。其中,铸态样品仍保持了440 MPa的抗拉强度,可媲美数种Fe-Ni-Cr基高温合金 (如GH1135、GH1139及GH1180)[40]。LPBF成形样品的抗拉强度虽明显降低,而塑性显著提高。这主要是因为在高温条件下,晶体和相界的强度均会下降,晶粒易于沿晶界发生相对滑动。并且较高含量的fcc相和相对均匀的元素分布状态也有利于LPBF成形样品塑性的提高。而铸态样品中较为粗大的晶粒所受到的影响则较小。

2.5 变形行为和断裂机制

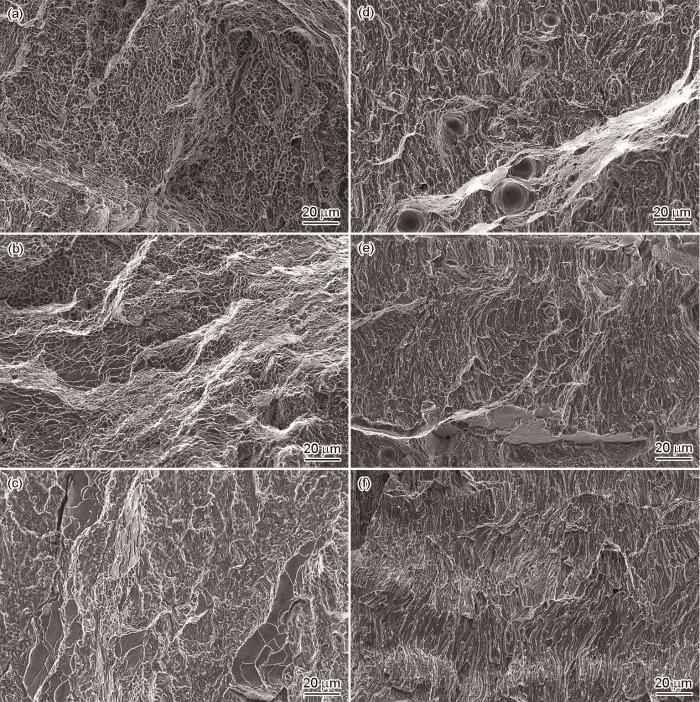

图9所示为铸态和LPBF成形AlCoCrFeNi2.1试样在不同温度拉伸断裂后的断口形貌。可见,在20℃时,铸态试样的断口表面存在包括韧窝、撕裂棱和解理面等断裂特征。同时,断口表面呈现出凹槽型和凹坑型2种裂纹扩展形态,这是由于共晶生长取向与拉伸载荷方向不同导致的。其中,凹槽/凹坑底部为bcc脆性断裂所形成的解理面,而其边缘为发生韧性断裂的fcc相。由此推断,铸态样品在室温下的断裂机制为混合型断裂。当拉伸实验温度为500℃时,铸态试样断口表面的凹坑/凹槽变浅,且解理面范围明显扩大,表明试样的脆性增加,这可能归因于合金中产生的相变。温度升至700℃,铸态断口主要呈现以解理面为主导的准解理断裂特征,仅在部分凹槽区域观察到少量撕裂棱。

图9

图9

铸态和LPBF成形AlCoCrFeNi2.1样品在不同温度下拉伸断裂后断口形貌的SEM像

Fig.9

SEM images of fracture surfaces of as-cast (a-c) and LPBF-formed (d-f) AlCoCrFeNi2.1 samples after tensile fracture at 20℃ (a, d), 500℃ (b, e), and 700℃ (c, f)

由于较高比例的fcc相以及共晶层片的双相协同变形效应,使LPBF成形AlCoCrFeNi2.1的室温拉伸断口呈现出以韧窝和撕裂棱为主的韧性断裂特征,表明合金在断裂前发生了较为剧烈的塑性变形。拉伸实验温度升至500℃时,试样断口表面的韧窝尺寸和深度减小,并伴随着解理面的出现,此现象与铸态样品相似。因此,推断LPBF成形试样在500℃的拉伸断裂机制为混合型断裂。拉伸实验温度为700℃时,样品的断口表面由沿共晶层片断裂的细小的凹槽状韧窝所组成,这是由共晶片层沿晶界或相界发生相对滑动所产生的。

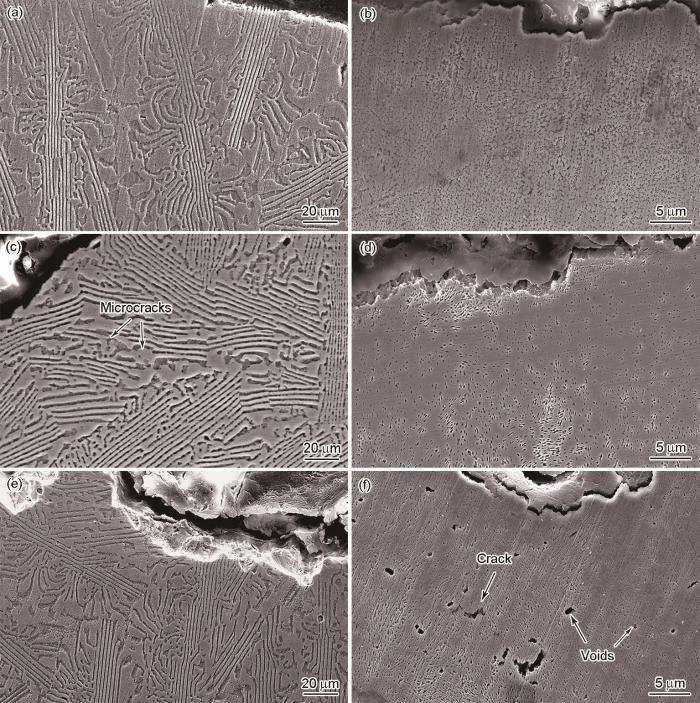

图10显示了铸态和LPBF成形AlCoCrFeNi2.1试样在不同温度拉伸断裂后断口纵剖面的SEM像。可见,铸态室温断口附近的组织中离散分布着许多细小的微裂纹,且主要存在于bcc相中。裂纹尖端被相界所阻挡,表明fcc相可有效抑制这些微裂纹的扩展和聚合,从而使合金获得良好的力学性能。500℃拉伸断裂后,铸态断口附近的共晶层片沿拉伸载荷方向发生了明显的变形弯曲,这是由于两相的不均匀变形所导致的。结合AlCoCrFeNi2.1的平衡凝固相图(图8),剧烈的相变在一定程度上影响了共晶组织的协调变形能力,从而导致试样力学性能的下降。在700℃拉伸条件下,铸态试样的fcc和bcc相中均存在大量的微裂纹,表明此时的fcc相不具备阻碍裂纹扩展的作用,因此导致了合金过早断裂失效。

图10

图10

铸态和LPBF成形AlCoCrFeNi2.1样品在不同温度下拉伸断裂后断口纵截面的SEM像

Fig.10

SEM images of fracture longtudinal sections of as-cast (a, c, e) and LPBF-formed (b, d, f) AlCoCrFeNi2.1 samples after tensile fracture at 20oC (a, b), 500oC (c, d), and 700oC (e, f)

LPBF成形试样的室温拉伸断口纵截面显示了明显的双相协同变形现象。实验温度为500℃时,同样由于相变的影响,LPBF成形试样断口附近的共晶层片呈不均匀变形状态。当温度达到700℃时,断口处形成了许多微孔。这些微孔呈离散分布,且没有扩展为裂纹的倾向。表明样品中相对均匀的共晶组织将有助于在高温拉伸变形过程中动态应变分配,从而有利于合金塑性的提高。

3 结论

(1) 铸态和LPBF成形AlCoCrFeNi2.1共晶高熵合金均表现出致密的微观组织。LPBF成形样品具有明显的组织各向异性,致密度可达99.17%。LPBF过程中极快的凝固速率有利于fcc相比例的升高。

(2) 铸态样品展现出典型的共晶-枝晶结构,LPBF成形样品则是由超细且外延生长的均匀共晶层片组成。此外,LPBF过程显著降低了合金中的元素偏析,并导致了bcc相的有序化转变。

(3) 铸态样品在室温下具有良好的拉伸性能,断裂失效机制为混合型断裂。随着拉伸实验温度的升高,铸态样品的抗拉强度和伸长率均呈下降趋势,断裂机制逐渐转变为准解理断裂。

(4) 由于强烈的相界强化和双相协同变形特性,LPBF成形试样的室温抗拉强度为(1427 ± 22.5) MPa,相对于铸态样品提升了约28%,并保持了10%的良好伸长率。500℃时,由于合金内部复杂的相变,LPBF成形试样的力学性能急速下降。拉伸实验温度为700℃,共晶片层可能沿晶界或相界发生相对滑动,此时合金的断裂机制以韧性断裂为主。

参考文献

Microstructural and compositional design principles for Mo-V-Nb-Ti-Zr multi-principal element alloys: A high-throughput first-principles study

[J].

Enhanced precipitation strengthening of multi-principal element alloys by κ- and B2-phases

[J].

Unraveling dual phase transformations in a CrCoNi medium-entropy alloy

[J].

Mechanistic insights into selective oxidation and corrosion of multi-principal element alloys from high resolution and in situ microscopy

[J].

The similarity of elements in multi-principle element alloys based on a new criterion for phase constitution

[J].

Insights into micro-mechanical response and texture of the additively manufactured eutectic high entropy alloy AlCoCrFeNi2.1

[J].

Processing and characterization of W23Mo23V17Cr8-Ta7Fe22 and WMoVCrTa refractory high entropy alloys

[J].

The comparative study of the microstructural and corrosion behaviour of laser-deposited high entropy alloys

[J].

A precipitation-hardened high-entropy alloy with outstanding tensile properties

[J].

Semi-solid processing of the CoCrCuFeNi high entropy alloy

[J].

Tensile ductility of an AlCoCrFeNi multi-phase high-entropy alloy through hot isostatic pressing (HIP) and homogenization

[J].

A simple strategy for fabrication of an FCC-based complex concentrated alloy coating with hierarchical nanoprecipitates and enhanced mechanical properties

[J].

Phase-transformation ductilization of brittle high-entropy alloys via metastability engineering

[J].

Selective laser melting of an equiatomic CoCrFeMnNi high-entropy alloy: Processability, non-equilibrium microstructure and mechanical property

[J].

A cuboidal B2 nanoprecipitation-enhanced body-centered-cubic alloy Al0.7CoCrFe2Ni with prominent tensile properties

[J].

A promising new class of high-temperature alloys: Eutectic high-entropy alloys

[J].High-entropy alloys (HEAs) can have either high strength or high ductility, and a simultaneous achievement of both still constitutes a tough challenge. The inferior castability and compositional segregation of HEAs are also obstacles for their technological applications. To tackle these problems, here we proposed a novel strategy to design HEAs using the eutectic alloy concept, i.e. to achieve a microstructure composed of alternating soft fcc and hard bcc phases. As a manifestation of this concept, an AlCoCrFeNi2.1 (atomic portion) eutectic high-entropy alloy (EHEA) was designed. The as-cast EHEA possessed a fine lamellar fcc/B2 microstructure, and showed an unprecedented combination of high tensile ductility and high fracture strength at room temperature. The excellent mechanical properties could be kept up to 700 degrees C. This new alloy design strategy can be readily adapted to large-scale industrial production of HEAs with simultaneous high fracture strength and high ductility.

Promising properties and future trend of eutectic high entropy alloys

[J].

Enhanced strength-ductility synergy in ultrafine-grained eutectic high-entropy alloys by inheriting microstructural lamellae

[J].Realizing improved strength-ductility synergy in eutectic alloys acting as in situ composite materials remains a challenge in conventional eutectic systems, which is why eutectic high-entropy alloys (EHEAs), a newly-emerging multi-principal-element eutectic category, may offer wider in situ composite possibilities. Here, we use an AlCoCrFeNi EHEA to engineer an ultrafine-grained duplex microstructure that deliberately inherits its composite lamellar nature by tailored thermo-mechanical processing to achieve property combinations which are not accessible to previously-reported reinforcement methodologies. The as-prepared samples exhibit hierarchically-structural heterogeneity due to phase decomposition, and the improved mechanical response during deformation is attributed to both a two-hierarchical constraint effect and a self-generated microcrack-arresting mechanism. This work provides a pathway for strengthening eutectic alloys and widens the design toolbox for high-performance materials based upon EHEAs.

Rapid solidification of AlCoCrFeNi2.1 high-entropy alloy

[J].

Microstructure, crystallographic orientation and mechanical property in AlCoCrFeNi2.1 eutectic high-entropy alloy under magnetic field-assisted directional solidification

[J].

Microstructural origins of high strength and high ductility in an AlCoCrFeNi2.1 eutectic high-entropy alloy

[J].

Multistage work hardening assisted by multi-type twinning in ultrafine-grained heterostructural eutectic high-entropy alloys

[J].

High-strength and high-ductility AlCoCrFeNi2.1 eutectic high-entropy alloy achieved via precipitation strengthening in a heterogeneous structure

[J].

Tailoring nanostructures and mechanical properties of AlCoCrFeNi2.1 eutectic high entropy alloy using thermo-mechanical processing

[J].

The use of high-entropy alloys in additive manufacturing

[J].

Optimization of laser energy density and scanning strategy on the forming quality of 24CrNiMo low alloy steel manufactured by SLM

[J].

Unique strength-ductility balance of AlCoCrFeNi2.1 eutectic high entropy alloy with ultra-fine duplex microstructure prepared by selective laser melting

[J].

Selective laser melting of dense and crack-free AlCoCrFeNi2.1 eutectic high entropy alloy: Synergizing strength and ductility

[J].

Strong yet ductile nanolamellar high-entropy alloys by additive manufacturing

[J].

High-strength AlCoCrFeNi2.1 eutectic high entropy alloy with ultrafine lamella structure via additive manufacturing

[J].

Tribological properties and wear mechanism of AlCr1.3TiNi2 eutectic high-entropy alloy at elevated temperature

[J].

AlCr1.3TiNi2共晶高熵合金的高温摩擦学性能及磨损机理

[J].采用电磁悬浮熔炼+直接铸造的方法制备了千克级的AlCr<sub>1.3</sub>TiNi<sub>2</sub>共晶高熵合金,借助TEM、APT等表征手段分析了该合金的微观组织与成分分布,使用HT-1000摩擦试验机对比研究了该合金与GH4169镍基高温合金的高温摩擦学性能。结果表明:该共晶高熵合金具有超细的层片状共晶组织(层片间距约350 nm),其共晶两相为晶格错配度只有约2%的bcc相与L2<sub>1</sub>相,L2<sub>1</sub>相中还存在大量的纳米析出相;≤ 600℃时,共晶高熵合金的磨损机理以磨粒磨损为主,其磨损率均低于GH4169合金;800℃时,共晶高熵合金的磨痕表面塑性变形加剧,其摩擦系数明显高于GH4169合金,但2者的磨损率相差不大。GH4169合金高温耐磨性的提高得益于其磨损表面氧化物膜的形成,而共晶高熵合金出色的耐磨性主要与其良好的高温组织稳定性及力学性能有关。

Sluggish diffusion in Co-Cr-Fe-Mn-Ni high-entropy alloys

[J].

Dual-phase synergistic deformation characteristics and strengthening mechanism of AlCoCrFeNi2.1 eutectic high entropy alloy fabricated by laser powder bed fusion

[J].

Stability of a planar interface during solidification of a dilute binary alloy

[J].

Mechanical properties of heat-treated high tensile structural steel at elevated temperatures

[J].

Dependence of mechanical properties of high strength steel S690 on elevated temperatures

[J].

Experimental investigation on mechanical behaviours of TMCP high strength steel

[J].The deterioration of mechanical behaviour of high strength steel (HSS) under elevated temperatures and post-fire condition would lead to reduction of load bearing capacity. To find out the effect of work temperature, welding heat input and cooling rate on the mechanical behaviour of thermal-mechanical control process (TMCP) HSS, a comprehensive experimental investigation on mechanical properties of Q690CFD at ambient and elevated temperatures and post-fire condition was organized in this study. Two types of studied objectives (basic material and welded specimens) were included. For ambient and elevated temperature condition, the elastic modulus, yield and ultimate strength were tested from different work temperatures and different welding heat inputs. For post-fire condition, the residual elastic modulus, residual yield and ultimate strength were tested under different heat inputs and cooling rates. The reduction factors of those mechanical properties were investigated. Finally, a series of predictive equation, which can be used to evaluate the ambient and elevated temperatures and post-fire performance of TMCP HSS, were proposed. The effects of welding heat input and cooling rate were incorporated in the proposed design equations. (C) 2018 Elsevier Ltd.

Application of machine learning to predict the mechanical properties of high strength steel at elevated temperatures based on the chemical composition

[J].

Atom distribution in sigma phases. Ⅰ. Fe and Cr atom distribution in a binary sigma phase equilibrated at 1063, 1013 and 923K

[J].