在高温力学性能中,疲劳裂纹扩展速率(fatigue crack growth rate,FCGR)是表征合金服役过程中损伤容限的重要指标之一。国内对高温合金疲劳裂纹扩展行为已有一些研究报道[6,7],但数据较为零散,所研究的温度范围一般在设计使用温度附近,对于使用温度附近较宽的温度范围内,尤其是服役温度上限甚至稍超上限情况下的疲劳裂纹扩展行为却鲜有报道,对抗疲劳裂纹扩展行为在服役温度范围内高温段的敏感性和本质原因尚缺少系统性归纳和深入研究。而航空发动机涡轮盘等高温转动件在服役过程中可能经历较大的温度波动[6],若抗疲劳裂纹扩展能力在某温度下急剧恶化,已损伤的构件在达到此温度服役时极有可能短时间内发生失效断裂,从而严重威胁飞行器的安全飞行,造成严重后果[7]。

基于以上原因,需明确典型涡轮盘用高温合金疲劳性能的温度敏感性规律和本质原因。本工作选取3种典型粉末高温合金FG4096、FGH4097和FGH4098,2种典型变形高温合金GH4720Li和GH4738,通过系列的疲劳裂纹扩展实验设计和对比分析,结合分子动力学计算,对镍基高温合金存在疲劳裂纹急剧扩展敏感温度这一现象进行梳理,并对其本质原因进行探究,以期为涡轮盘用高温合金寿命和服役稳定性的合理评估提供实验和理论参考。

1 实验方法

为研究温度对典型镍基高温合金疲劳裂纹扩展行为的影响,选取3种典型粉末高温合金FGH4096、FGH4097和FGH4098,2种典型变形高温合金GH4720Li和GH4738,化学成分如表1所示。FGH4096合金的成型工艺采用热等静压+等温锻造;FGH4097和FGH4098合金采用直接热等静压成型工艺。FGH4096合金热处理制度为:1150℃、2 h,600℃盐淬+ 760℃、16 h,炉冷至550℃,空冷;FGH4097合金热处理制度为:1200℃、8 h,炉冷+ 1170℃,空冷+ 870℃、32 h,空冷;FGH4098合金热处理制度为:1180℃、1~2 h,油淬+ 815℃、8 h,空冷。GH4738和GH4720Li合金经真空感应熔炼+真空自耗重熔的双联冶炼,均匀化后进行开坯,然后模锻成盘件,热处理制度分别为:1020℃、4 h,油冷+ 845℃、4 h,空冷+ 760℃、16 h,空冷和1110℃、4 h,油冷+ 650℃、24 h,空冷+ 760℃、16 h,空冷。

表1 实验用典型镍基高温合金的化学成分 (mass fraction / %)

Table 1

| Superalloy | C | Cr | Mo | W | Al | Ti | Co | Nb | Zr | B | Hf | Fe | Si | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FGH4096 | 0.035 | 16.00 | 4.00 | 4.00 | 2.10 | 3.70 | 13.00 | 0.70 | 0.033 | 0.011 | - | - | - | Bal. |

| FGH4097 | 0.045 | 9.02 | 3.76 | 4.96 | 4.91 | 1.74 | 15.69 | 2.59 | 0.017 | 0.012 | 0.30 | - | - | Bal. |

| FGH4098 | 0.054 | 12.65 | 3.83 | 2.18 | 3.45 | 3.70 | 20.20 | 0.90 | 0.050 | 0.021 | - | - | - | Bal. |

| GH4738 | 0.037 | 19.05 | 4.40 | - | 1.35 | 2.90 | 14.20 | - | 0.050 | 0.005 | - | 0.18 | 0.07 | Bal. |

| GH4720Li | 0.012 | 15.17 | 3.00 | 1.30 | 2.42 | 4.85 | 14.70 | - | 0.030 | 0.012 | - | - | - | Bal. |

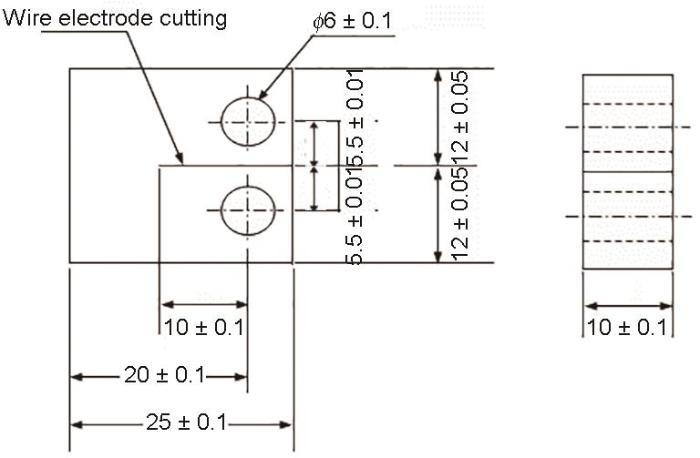

疲劳裂纹扩展实验按照JB/T 8189—1999并参照ASTM标准E647-81采用标准紧凑拉伸(CT)试样,如图1所示。高温疲劳裂纹扩展速率实验在CMT5204GLW高精度疲劳裂纹扩展试验机上进行。根据本工作所研究的几种典型合金的服役温度范围将实验温度设定为550~800℃,采用纯疲劳载荷,应力比R = 0.05。除GH4738合金的应力强度因子范围(ΔK)初始值为40 MPa·m1/2,其他合金初始ΔK均为30 MPa·m1/2。

图1

图1

疲劳裂纹扩展速率紧凑拉伸(CT)试样示意图

Fig.1

Schematic of compact tension (CT) specimen for fatigue crack propagation test (unit: mm)

采用线切割在疲劳裂纹扩展实验后的CT试样上取样进行显微组织观察,样品经机械打磨和抛光后进行电解抛光和电解侵蚀,之后在Supra55场发射扫描电镜(FESEM)上进行组织形貌观察;断口形貌和裂纹扩展路径分别采用FESEM和DMR光学显微镜(OM)观察。电解抛光液为20%H2SO4 + 80%CH3OH (体积分数),电压18 V,侵蚀3~5 s,电解侵蚀液为150 mL H3PO4 + 10 mL H2SO4 + 5 g CrO3,电压5 V,侵蚀5 s。

分子动力学计算采用LAMMPS软件,对Ni中大量存在的Σ5[001](210)晶界进行研究。计算所用到的Ni和O的相互作用势函数采用嵌入原子势(embedded atom method,EAM),并用Lennard-Jones势(L-J势)将其联合。构建的晶界模型在3个方向上均使用周期性边界条件来避免表面效应的影响,提高计算效率,且在垂直晶界的方向上足够长并设置真空层,消除上下端面之间的作用力。将构建的模型采用最速下降法进行能量最小化,能量停止容差1.0 × 10-12,力停止容差1.0 × 10-12,最大迭代次数100000,计算力或能量的最大次数100000。

2 实验结果

2.1 疲劳裂纹扩展行为特征

3种典型粉末高温合金FGH4096、FGH4097和FGH4098设计使用温度及上限附近的疲劳裂纹扩展行为如图2所示。从图2a、c和e可以看出,FGH4096、FGH4097和FGH4098合金的抗疲劳裂纹扩展能力逐渐提高;温度对合金的疲劳裂纹扩展速率有较大影响,疲劳裂纹扩展速率随温度的升高而增加。但3种合金的裂纹扩展寿命和速率随温度并非是均匀变化,以FGH4098合金为例(图2f),温度从700℃升高到750℃时,疲劳寿命由3946 cyc大幅下降到791 cyc,继续升温至800℃疲劳寿命骤降至了224 cyc。此外,温度高于750℃后裂纹扩展速率也明显加快,当ΔK = 35 MPa·m1/2时,700℃时裂纹扩展速率为1.95 × 10-3 mm/cyc,750℃时增至2.01 × 10-2 mm/cyc,而800℃时则增加到了5.35 × 10-2 mm/cyc。这表明FGH4098合金在750℃及以上高温段存在疲劳裂纹急速扩展现象,即存在发生裂纹急速扩展的敏感温度。FGH4096和FGH4097合金也呈现出类似特征。

图2

图2

温度对粉末高温合金疲劳裂纹扩展行为的影响

Fig.2

Effects of temperature on fatigue propagation behavior of FGH4096 (a, b), FGH4097 (c, d), and FGH4098 (e, f) powder metallurgy superalloys

(a, c, e) da / dN-ΔK curves (da / dN—fatigue crack growth rate, ΔK—stress intensity factor range)

(b, d, f) fatigue crack growth lifetime (N) vs temperature

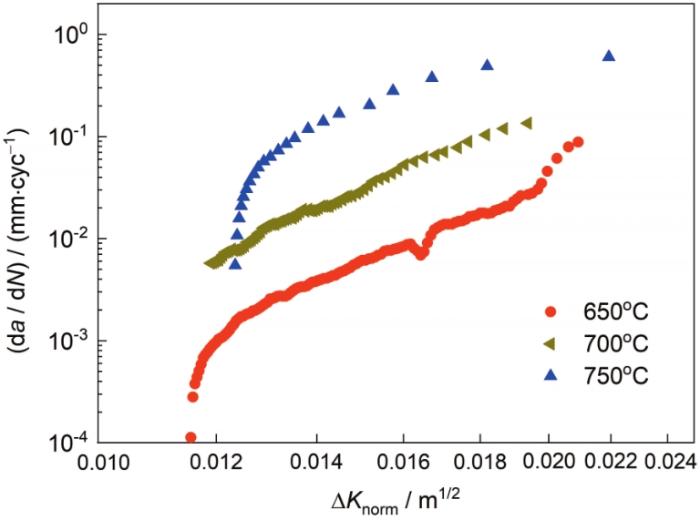

2种变形高温合金GH4720Li和GH4738的疲劳裂纹扩展行为随温度的变化也有相似规律,如图3所示。可见,GH4720Li合金服役温度范围内的抗疲劳裂纹扩展能力总体优于GH4738合金。GH4720Li合金650℃的疲劳裂纹扩展速率初始增长较快,曲线呈现典型疲劳裂纹第一阶段扩展特征,然后进入稳定扩展阶段的Paris区;700℃时疲劳裂纹扩展曲线与650℃有较大差别,初始扩展速率较快,第一阶段的扩展特征不明显;800℃时,裂纹一旦在试样表面形成,几个加载周次下便发生断裂,裂纹扩展速率较快。从图3d可以看出,750℃是合金疲劳寿命出现较大下降的敏感温度,在此温度下疲劳寿命对温度更为敏感,温度稍有升高,疲劳寿命便会出现较大程度的降低。GH4738合金在750℃左右也存在一个敏感温度,发生疲劳裂纹的急剧扩展,相应寿命快速下降;800℃时试样只经历了10 cyc后便很快断裂,裂纹扩展速率非常快(图3b)。因此,变形高温合金服役温度内也存在疲劳裂纹急速扩展的现象。

图3

图3

温度对变形高温合金疲劳裂纹扩展行为的影响

Fig.3

Effects of temperature on fatigue propagation behavior of GH4738 (a, b) and GH4720Li (c, d) wrought superalloys

(a, c) da / dN-ΔK curves (b, d) Nvs temperature

2.2 温度对合金组织和性能的影响

温度升高会使合金力学性能下降,从而导致抗疲劳裂纹扩展能力降低[9]。温度对合金疲劳裂纹扩展的影响主要体现在几个方面:(1) 高温下合金组织发生变化使疲劳性能降低[10];(2) 合金力学性能衰减,尤其是对疲劳性能具有较大影响的屈服强度(σy)和弹性模量(E)[11];(3) 高温促进原子扩散,晶界作为元素快速扩散通道易形成空洞从而弱化晶界强度,导致疲劳裂纹扩展速率增加,该现象在保载条件下尤为显著[12];(4) O从裂纹尖端进入基体,沿晶界扩散并与活泼元素发生氧化反应导致晶界弱化,增加裂纹沿晶界扩展倾向,加速裂纹扩展[13~16]。本节以GH4720Li合金为例,讨论温度对合金组织和性能的影响,以及与疲劳裂纹扩展行为的关联性,其他几种合金也存在类似规律。

GH4720Li合金经不同温度疲劳裂纹扩展实验后显微组织的SEM像如图4所示。晶界上分布有不规则的大块一次γ′相(用

图4

图4

GH4720Li合金经不同温度疲劳裂纹扩展实验后显微组织的SEM像

Fig.4

Low (a, c, e, g) and high (b, d, f, h) magnified SEM images of GH4720Li alloy after fatigue crack propagation test at 650oC (a, b), 700oC (c, d), 750oC (e, f), and 800oC (g, h) (

为研究高温力学性能衰减对合金疲劳裂纹扩展行为的影响,对GH4720Li合金不同温度下疲劳裂纹扩展速率曲线进行修正。基于裂纹尖端张开位移原理[17],对ΔK进行修正,其修正值(ΔKnorm)为:

表2 GH4720Li合金不同温度下的弹性模量(E)及屈服强度(σy)

Table 2

| Temperature / oC | E / MPa | σy / MPa |

|---|---|---|

| 650 | 192 | 1120 |

| 700 | 189 | 1070 |

| 750 | 184 | 1020 |

| 800 | 182 | 950 |

图5

图5

GH4720Li合金修正后的da / dN-ΔKnorm曲线

Fig.5

Corrected da / dN-ΔKnorm curves of GH4720Li alloy (ΔKnorm—corrected ΔK)

在粉末高温合金LSHR 650~725℃疲劳裂纹扩展行为的研究中发现,真空环境下温度对裂纹扩展速率的影响不大,但在空气环境中温度对裂纹扩展速率则有较大影响,裂纹扩展的温度敏感性增加,在保载条件下作用更加明显[18]。综上可知,GH4720Li合金疲劳寿命在高于750℃出现较大程度降低与显微组织和力学性能演变存在一定关联性,但显微组织和力学性能演变不足以引起疲劳寿命如此明显的降低,并非寿命衰减的主要原因。

2.3 氧化对疲劳性能的影响

如前所述,空气环境中的氧亦会对高温时的疲劳裂纹扩展产生较大影响。为了进一步分析疲劳寿命在敏感温度下显著下降的本质原因,以FGH4098合金为例,对700~800℃的疲劳断口进行观察,如图6所示。由图可知,在700℃下疲劳裂纹主要以穿晶的形式扩展;而在750℃时疲劳裂纹只在预制裂纹开始约200 μm内以穿晶断裂为主,之后便转变为沿晶模式,断口上穿晶断裂的痕迹很少。800℃时疲劳裂纹从起裂开始便完全沿晶扩展,呈现出“冰糖”状的断口形貌。结合图2f中的FGH4098合金疲劳寿命随温度升高而下降的趋势可知,随着疲劳寿命的快速下降,800℃疲劳寿命仅有224 cyc,较750℃的寿命下降了3倍多。断口从穿晶断裂向沿晶断裂转变时存在一个转折点,将断口形貌与ΔK对应,将断裂特征明显转变的转折点对应的ΔK定义为沿晶断裂模式转折点ΔKT (图6中虚线)。结合图2e可以看出,800℃左右是FGH4098合金疲劳寿命显著下降的敏感温度,ΔKT也快速下降至起裂端,说明裂纹急速扩展现象与快速加剧的晶界弱化密切相关。

图6

图6

FGH4098合金在不同温度下疲劳断口形貌的SEM像

Fig.6

SEM fracture images of FGH4098 alloy under 700oC (a), 750oC (b), and 800oC (c) (Dashed lines in Figs.6b and c show the intergranular fracture mode turning point ΔKT)

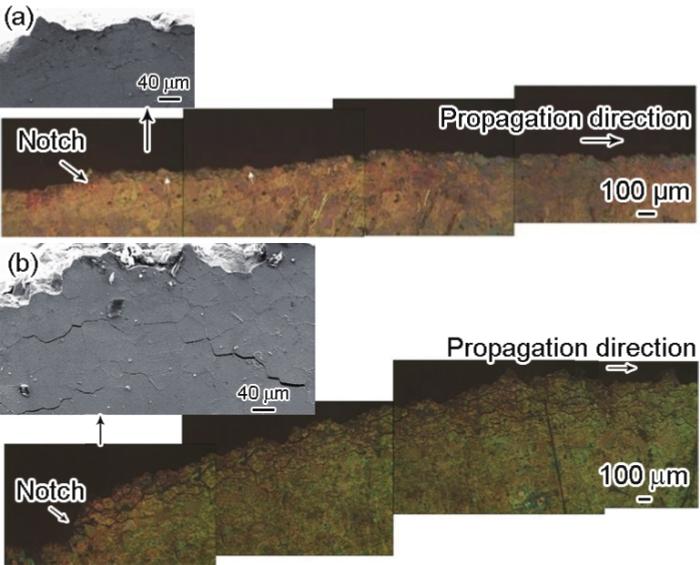

为进一步验证在敏感温度下随温度升高合金的ΔKT出现较大程度降低,对不同温度下的裂纹扩展路径进行比对分析。FGH4098合金不同温度下的疲劳裂纹扩展路径如图7所示。由图可知,700℃疲劳裂纹扩展起始区域的疲劳裂纹以穿晶为主的方式扩展,无明显的二次裂纹产生。800℃下疲劳裂纹从起始扩展时便以沿晶方式扩展,疲劳主裂纹附近尤其与加载方向近似垂直的晶界处存在较多的沿晶二次裂纹,可见在敏感温度下,ΔKT接近裂纹初始扩展的ΔK,裂纹直接进入快速扩展区并以较快速率扩展,导致合金的疲劳寿命较700℃时显著下降。

图7

图7

FGH4098合金CT试样不同温度下表面疲劳裂纹扩展路径

Fig.7

Fatigue crack propagation paths in CT sample of FGH4098 alloy under 700oC (a) and 800oC (b)

综上,在敏感温度下裂纹扩展寿命出现显著降低的本质原因是ΔKT下降而导致。当温度升高使ΔKT降低到与裂纹初始扩展的ΔK相近甚至更低时,裂纹萌生后便很快进入快速扩展区,导致裂纹扩展寿命显著降低。

3 分析与讨论

从前文可知,在服役温度范围内的高温条件下,高温合金疲劳裂纹扩展存在寿命显著降低的敏感温度,该现象的产生与高温条件下显微组织和力学性能演变有一定关联性,但并非主要原因。晶界氧化是高温疲劳性能骤降的关键因素,为此对该现象的本质进行深入的研究。

3.1 氧化损伤分量的确定

Pairs公式da / dN = C(ΔK) m (C和m为与材料特征相关的常数,材料微观组织结构、循环加载频率和波形、环境、温度及应力比等对其有影响)通常被作为描述金属材料在常温和高温下疲劳裂纹在第二阶段稳定扩展期的基本模型。基于此,不同学者针对高温环境对疲劳裂纹扩展过程的影响进行了大量研究,提出了高温疲劳裂纹扩展速率的物理模型和经验模型,但因物理模型需进行假设并引入相关参数,且在实际应用中难以获得,所以经验模型应用更广[6]。Jiang等[19]将高温下疲劳裂纹扩展拆分为力学疲劳过程与高温氧化过程共同作用的结果,疲劳裂纹扩展从形式上是疲劳力学损伤和氧化损伤这2类损伤机理的线性叠加,根据以往研究报道[20,21]结合本工作研究实际得到经验模型:

式中,(da / dN)Total为总裂纹扩展速率,(da / dN)F为疲劳力学损伤引起的裂纹扩展速率分量,(da / dN)O为氧化损伤引起的裂纹扩展速率分量。基于

合金的σy和E与温度密切相关,因此,裂纹扩展中的疲劳力学损伤分量仍是与温度相关的函数。已有研究[22]表明,疲劳裂纹扩展速率的变化可通过修正Paris公式中的参数C来体现,参数C在对数坐标下是温度的线性函数,而m通常被认为是常数。将不同温度的da / dN-ΔK曲线Paris区进行拟合,获得的m值取平均值,根据此m值对da / dN-ΔK曲线重新拟合,获得不同温度下的C值。在疲劳加载条件相同时,疲劳力学损伤分量曲线的参数C与温度T也呈线性关系,即lgC = a + bT (a和b为拟合系数)。RR1000、U720Li等合金疲劳裂纹扩展行为的研究[16,23]表明,排除氧化损伤分量后剩下的疲劳力学损伤分量的m值不变。因此,(da / dN)F = CF(ΔK)

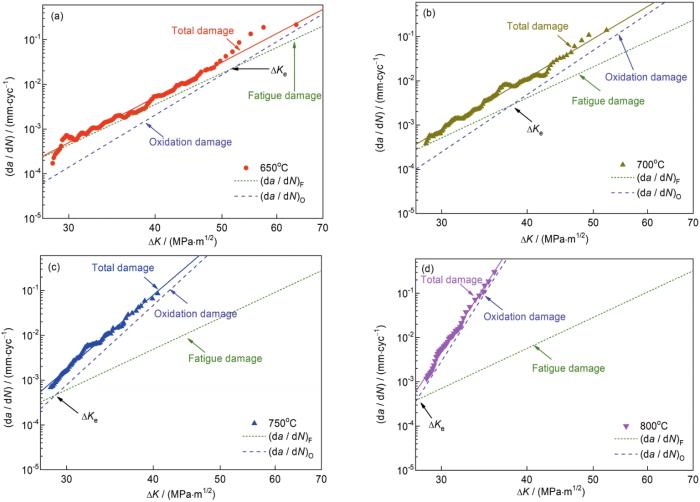

以FGH4097合金为例,根据图2c数据进行拟合和计算,不同温度下(da / dN)F和(da / dN)O对疲劳裂纹扩展行为的影响机制如图8所示。可见,在650℃疲劳裂纹扩展实验中(图8a),当ΔK较低时氧化损伤较弱,(da / dN)F高于(da / dN)O,疲劳力学损伤是驱动裂纹扩展的主导机制,呈现出穿晶断口形貌;随着裂纹扩展,当ΔK高于52.6 MPa·m1/2这个交汇点时,晶内产生的滑移带及孪晶界为O提供了更多向材料内部扩展的通道,O在晶界聚集程度增加,晶界发生明显氧化从而导致晶界强度降低[19],(da / dN)O上升并超过了(da / dN)F而占据主导,因而断口开始以沿晶断裂为主。2种损伤机制的交汇点即该条件下合金中2种损伤机制贡献相同的情况,将该点对应的载荷定义为等损伤载荷(ΔKe)。温度升高至700℃时(图8b)氧化反应加快,随着裂纹扩展(即ΔK增大),(da / dN)O对裂纹扩展的贡献快速增加,裂纹尖端的晶界氧化更为显著,主导机制在交点ΔK = 38.3 MPa·m1/2处发生转变。温度进一步升高至800℃时(图8d),O在应力作用下沿晶界快速侵入,(da / dN)O迅速增加,因而ΔKe降到了起裂位置附近,即疲劳裂纹从一开始扩展便由氧化损伤机制主导,断口也因晶界弱化加剧而呈现近乎完全沿晶形貌。正因如此,使合金疲劳寿命曲线在800℃左右出现拐点,疲劳裂纹扩展速率急速增加,寿命快速下降。

图8

图8

FGH4097合金不同温度下的疲劳裂纹扩展机制分析

Fig.8

Fatigue crack propagation mechanism analyses of FGH4097 alloy at 650oC (a), 700oC (b), 750oC (c), and 800oC (d) ((da / dN)F—fatigue damage component, (da / dN)O—oxidation damage component, ΔKe—load with equal fatigue and oxidation damage)

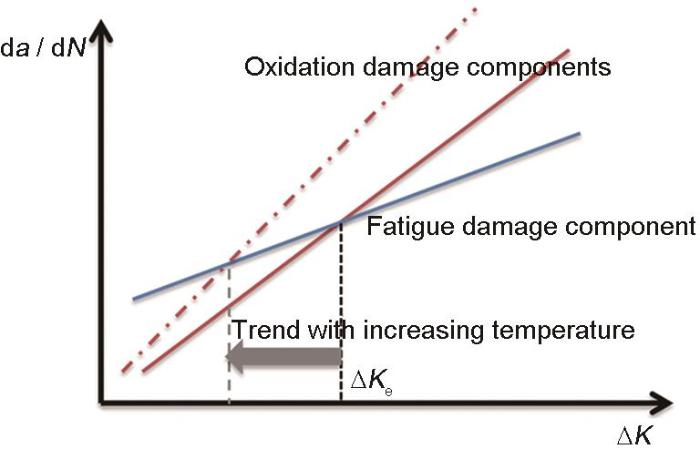

通过疲劳裂纹扩展过程中损伤分量的分析可以看出,随着ΔK的增加,(da / dN)F和(da / dN)O的比重会发生变化。随着疲劳裂纹的扩展,达到ΔKe时主导机制由疲劳力学损伤变换为氧化损伤,相应的疲劳裂纹也会由穿晶扩展转变为沿晶扩展,如图9所示。随着温度的升高,裂纹扩展起始阶段氧化损伤的占比更高,对裂纹扩展的贡献更大,ΔKe下降,这意味着裂纹的扩展范围缩短,当ΔK稍微增加时,裂纹扩展便由氧化损伤所驱动,因而由穿晶向沿晶扩展转变,导致快速断裂,呈现出疲劳裂纹扩展行为明显的高温敏感现象。

图9

图9

疲劳裂纹扩展过程中的等损伤载荷(ΔKe)示意图

Fig.9

Schematic diagram of ΔKe during fatigue crack propagation

3.2 晶界氧化损伤的分子动力学研究

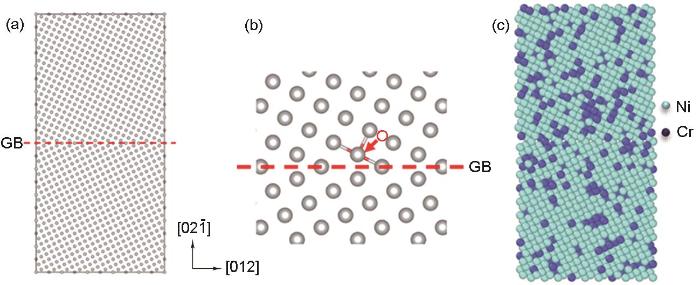

以上实验和讨论均表明O对合金在高温下的疲劳裂纹急剧扩展具有显著影响,并且O主要作用于晶界,为此采用分子动力学进一步揭示O和温度对晶界弱化的作用,进而从理论上揭示在环境-载荷共同作用下高温合金晶界弱化的微观过程。对Ni的fcc单胞进行弛豫,获得晶格常数为0.3517 nm,与文献[24]中的0.3518 nm相近。采用Atomsk软件搭建倾斜角为36.9°的10000个原子Σ5[001](210)晶界模型,并用LAMMPS结构弛豫,如图10a所示。O原子更倾向在Ni的八面体间隙位置偏聚,所以在晶界附近八面体间隙位置加入O原子(图10b)。为对比Ni和NiCr晶界的分离功,构建无序固溶NiCr的Σ5[001](210)晶界模型,并取能量最低的模型,如图10c所示。

图10

图10

分子动力学计算用Σ5[001](210)晶界模型

Fig.10

Grain boundary model of Σ5[001](210)

(a) pure grain boundary (GB) model of Ni

(b) position of O in Ni model

(c) NiCr grain boundary model after disordered solution treatment

式中,EFS是一个晶界断裂后新产生的2个自由表面的总能量,EGB为晶界模型的总能量,S为晶界模型横截面积。

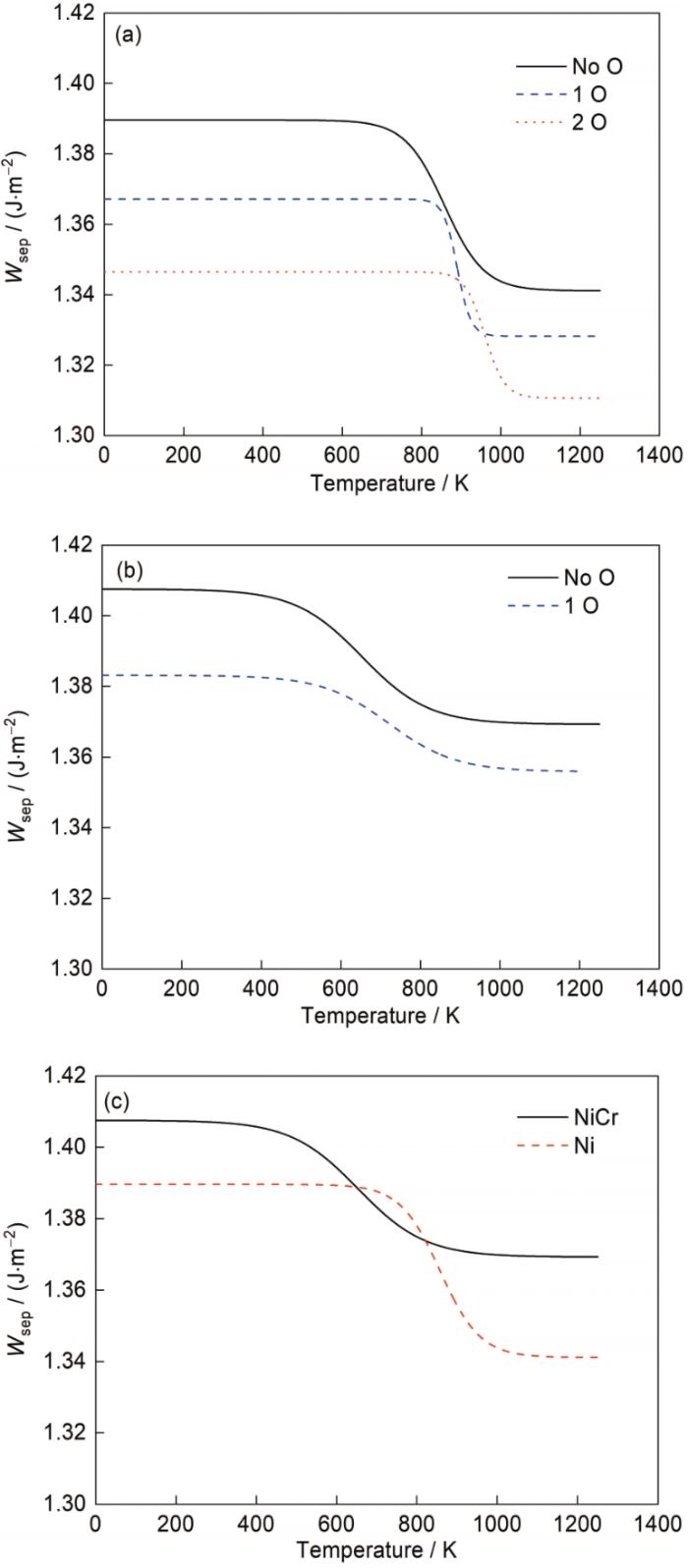

经计算,0 K下的晶界分离功为1.39 J/m2,之后用Nose-Hoover热浴法控制体系温度,先在NVT系综下进行预平衡,再在NPT系综下进行长时间平衡,并在平衡25 ps后对体系势能进行平均计算,得到纯Ni和NiCr的Σ5[001](210)晶界分离功随温度和O浓度的变化规律,如图11所示。可见,在无O的条件下,随温度升高,Ni的Σ5[001](210)晶界分离功在750 K之前基本不变,与0 K的分离功相近,在750 K之后突然下降,之后又趋于稳定,说明随温度升高晶界在750~1000 K之间发生弱化,晶间断裂所需的能量降低。而随着晶界附近间隙O原子的加入,晶界分离功显著降低,即晶界发生了弱化,与有O环境下合金抗疲劳裂纹扩展能力下降的现象[18]相符。加入O原子后晶界分离功的变化趋势同样是基本稳定-突然降低-基本稳定,即在800~1000 K之间由于温度影响发生了晶界的弱化。随着O原子浓度升高,晶界氧化程度升高,晶界分离功降低,使晶界的力学性能下降。

图11

图11

O浓度和温度对晶界分离功的影响

Fig.11

Effects of O concentration and temperature on grain boundary separation energy (Wsep)

(a) Σ5[001](210) grain boundary of Ni

(b) Σ5[001](210) grain boundary of NiCr

(c) comparison between Ni and NiCr

无序固溶NiCr模型的晶界分离功随温度变化呈现与纯Ni模型相似的规律,且有O条件下晶界分离功降低,晶界弱化。从图10可以看出,Cr的加入使晶界分离功升高,即晶界更稳定,不易发生弱化。但是NiCr模型晶界分离功下降的温度区间为600~850 K,拐点温度较纯Ni晶界模型降低约150 K。

分子动力学的计算结果表明,晶界分离功快速下降的温度与疲劳裂纹急速扩展的拐点温度(约1000 K)大致相同,说明此温度下镍基高温合金疲劳性能的迅速下降与晶界弱化相关。分子动力学计算以Σ5[001](210)晶界为例,而实际合金中有多种类型的晶界,并且除了Ni、Cr元素外还有其他多种元素和析出相的作用,对疲劳性能也有一定影响,所以分子动力学计算结果与实验中的温度拐点存在一定差异。后续工作将进一步考虑晶界分离功下降过程拐点温度存在的原因以及掺杂元素对晶界分离功影响的本质,以及不同元素对晶界弱化的贡献程度。

综上所述,以FGH4096、FGH4097、GH4738等合金在内的典型镍基粉末高温合金和变形高温合金均存在高温疲劳寿命急剧降低的敏感温度,该现象并非偶然,在镍基高温合金中存在必然性和共性。而高温显微组织和力学性能演变并非该现象的主要原因,高温疲劳性能下降的拐点主要与高温晶界氧化相关,一旦达到拐点温度,合金的疲劳寿命将发生骤降,对构件的整体安全产生重大影响。

4 结论

(1) 镍基高温合金在服役温度范围内疲劳寿命随温度升高并非呈现线性下降规律,在高温段存在疲劳裂纹急速扩展的现象,即对应存在疲劳裂纹急速扩展的敏感温度。不同合金在敏感温度附近,均表现出疲劳裂纹急速扩展、疲劳寿命快速下降的共性现象。

(2) 通过不同温度下镍基高温合金组织演变、力学性能衰减等因素的分析表明,合金高温段疲劳寿命出现较大程度降低与高温显微组织和力学性能演变存在一定的关系,但并非主要原因;不同温度的疲劳断口形貌和疲劳裂纹扩展路径对比结果表明,晶界的高温氧化弱化是高温段疲劳寿命骤降的主要原因。

(3) 采用经典的损伤分量线性叠加模型对氧化损伤和疲劳损伤的作用进行分析,结果表明,随着温度的升高氧化损伤的占比明显增加,使疲劳寿命在高温段出现拐点,疲劳裂纹扩展速率急速增加,寿命快速下降。

(4) 分子动力学计算从理论上揭示了在环境-载荷共同作用下晶界弱化的微观过程。随温度升高晶界分离功降低,存在突变的温度拐点,而O在晶界上的富集会使分离功降低,晶界进一步弱化。

参考文献

Present research situation and prospect of hot working of cast & wrought superalloys for aero-engine turbine disk in China

[J].In recent years, the demand for high-performance aero-engines has become crucial in China, and the service environment of turbine disk alloy becomes increasingly severe. A series of high resistant cast & wrought superalloys for turbine disks, such as GH4065, GH4720Li, GH4068, and GH4151, with working temperatures > 700°C, have been studied, produced, and applied widely. The current studies on cast & wrought alloys for turbine disks in China were summarized under the categories of homogenization treatment, cogging, disk forging, and microstructure and property regulation to promote the development of these superalloys and improve their comprehensive properties. The difficulties encountered during the research and preparation of these hard-to-deform superalloys and explored the alloys' potential development trend were outlined. The review would improve the production stability of the disk superalloys and promote their development.

国内航空发动机涡轮盘用铸锻难变形高温合金热加工研究现状与展望

[J].

Development and application of P/M superalloy

[J].

粉末高温合金研究进展与应用

[J].

Effect of temperature on the creep behavior and mechanism of GH4169 alloy

[J].

温度对GH4169合金蠕变行为及机制的影响

[J].

Creep behavior of FGH96 superalloy at different service conditions

[J].The FGH96 superalloy is extensively used as a gas turbine disk under high temperature due to its excellent tensile and creep properties. With recent developments in the aviation industry, the velocity of the aircraft has increased significantly, thereby increasing the temperature and stress on the turbine disk materials during their service. Therefore, creep deformation is crucial in the turbine disk superalloy. In this study, the creep characteristics of FGH96 superalloy were systematically studied at 650-750oC and 690-810 MPa and the creep mechanism of the alloy under different service conditions was investigated via SEM, EBSD, and TEM. For the creep temperature of 704oC, the creep properties of the alloy decreased with the increase in stress level. When the applied loading stress was 690 MPa, the creep properties of FGH96 alloy decreased significantly with the increase in temperature, and its steady-state creep strain rate was more sensitive to the service temperature. Further, every 30oC increase in the service temperature increased the creep rate by an order of magnitude. For the temperature in the range 650-750oC and the applied loading stress in the range 690-810 MPa, the creep deformation of the alloy was dominated by dislocation slip and resulted in various micro-twins on the continuous (111¯) planes. Moreover, the creep fracture of FGH96 alloy presented typical intergranular fracture under different service conditions in this study.

不同服役条件下FGH96合金的蠕变特征

[J].采用SEM、EBSD和TEM等手段研究了FGH96合金在650~750℃、690~810 MPa条件下的蠕变特征,揭示FGH96合金在不同服役条件下的蠕变机理。结果表明,当蠕变温度为704℃时,FGH96合金的蠕变性能随着应力水平的提高而降低;当加载应力为690 MPa时,FGH96合金的蠕变性能随着温度提高而显著降低,且FGH96合金的稳态蠕变速率对服役温度更为敏感,服役温度每提高30℃,将会导致蠕变速率提高一个数量级。当温度处于650~750℃范围、应力处于690~810 MPa范围时,FGH96合金的蠕变变形均以位错滑移为主,且位错在滑移过程中,会在(111¯)原子面上形成大量的微孪晶。在不同服役条件下,FGH96合金的蠕变断裂均呈现典型的沿晶断裂特征。

Effects of stress and temperature on creep behavior of a new third-generation powder metallurgy superalloy FGH100L

[J].

Modeling of temperature influence on the fatigue crack growth behavior of superalloys

[J].

Temperature sensitivity of fatigue crack growth rate for GH4720Li alloy

[J].

GH4720Li合金疲劳裂纹扩展速率的温度敏感性

[J].

The effect of grain-boundary-engineering-type processing on oxygen-induced cracking of IN718

[J].

Microstructure degradation in high temperature fatigue of TiAl alloy

[J].

Fatigue crack growth in polycrystalline IN 718 superalloy

[J].

Effect of creep and oxidation on reduced fatigue life of Ni-based alloy 617 at 850oC

[J].

On the mechanism of oxidation-fatigue damage at intermediate temperatures in a single crystal Ni-based superalloy

[J].

Influence of orientation-dependent grain boundary oxidation on fatigue cracking behaviour in an advanced Ni-based superalloy

[J].

Evidence for internal oxidation during oxygen enhanced crack growth in P/M Ni-based superalloys

[J].

High temperature fatigue crack growth in powder processed nickel based superalloy U720Li

[J].

Fatigue crack propagation in nickel-base superalloys—Effects of microstructure, load ratio, and temperature

[J].

Grain size effects in a Ni-based turbine disc alloy in the time and cycle dependent crack growth regimes

[J].

Role of oxygen in enhanced fatigue cracking in a PM Ni-based superalloy: Stress assisted grain boundary oxidation or dynamic embrittlment?

[J].

Judgment criterion of the dominant factor of creep-fatigue crack growth in a nickel-based superalloy at elevated temperature

[J].

An interaction crack growth model for creep-brittle superalloys with high temperature dwell time

[J].

Creep, fatigue and oxidation in crack growth in advanced nickel base superalloys

[J].

Effects of microstructure on high temperature dwell fatigue crack growth in a coarse grain PM nickel based superalloy

[J].

The effect of segregated sp-impurities on grain-boundary and surface structure, magnetism and embrittlement in nickel

[J].

Segregation behavior of alloying elements at Ni Σ5 [001](210) symmetrical tilt grain boundary in nickel-based superalloys and their stabilization and strengthening mechanisms for the grain boundary

[J].

Molecular dynamics simulation of symmetrical tilt grain boundary of body-centered cubic tungsten

[J].

钨对称倾斜晶界的分子动力学计算模拟

[J].