电弧增材制造(wire arc additive manufacturing,WAAM)技术具有成本低、沉积速率高、成形过程灵活性强等优势,近年来,采用WAAM技术制备铝合金构件得到了国内外学者的广泛关注。孙佳孝等[7]研究了WAAM制备5356铝合金(Al-Mg)薄壁试样,结果表明,由于增材制造的逐层沉积过程,试样在不同区域的组织形貌存在差异,导致力学性能表现出各向异性。杨光等[8]以5356铝合金为沉积材料,发现成形试样内部存在合金元素偏析的现象,经过均匀化退火后,元素分布均匀性得到改善。李承德等[9]针对ZL114A铝合金(Al-Si) WAAM成形试样进行微观组织与力学性能的研究,结果显示,与砂型铸造相比,WAAM成形试样的枝晶间距较小,力学性能显著提升,断后伸长率约为砂型铸造试样的2倍。Gu等[10,11]借助层间轧制的方式制备出气孔率较低的2219铝合金(Al-Cu)试样,在15 kN的轧制载荷作用下,气孔率从0.176%降低至0.029%,减少了约83.5%。Cong等[12~14]研究了热输入、保护气体、丝材质量及送丝速率等工艺参量对WAAM成形2219铝合金的影响,发现较低的热输入可以显著降低成形件内部的气孔,此外采用热输入较小的冷金属过渡(cold metal transfer,CMT)工艺能够提高成形构件的强度。

综上所述,国内外相关研究人员针对铝合金电弧增材制造的研究主要集中在5xxx系、4xxx系与2xxx系(Al-Cu)铝合金,对于三元Al-Cu-Mg铝合金的研究较少。Al-Cu-Mg合金具有强度高、可加工性能强和抗应力腐蚀性能好等优点,主要用于航空领域的各种高负载构件,如航天器蒙皮、隔框及骨架等,是一种重要的轻质高性能铝合金材料。本工作选用一种典型的Al-Cu-Mg (2024)铝合金为沉积材料,成功制备出形貌良好的薄壁件,重点研究了其微观组织演变,并进一步分析其力学性能。

1 实验方法

表1 2024铝合金焊丝和电弧增材制造(WAAM)成形件的化学成分 (mass fraction / %)

Table 1

| Material | Cu | Mg | Mn | Ti | Fe | Si | Zn | Cr | Al |

|---|---|---|---|---|---|---|---|---|---|

| 2024 alloy standard | 3.80-4.90 | 1.20-1.80 | 0.30-0.90 | ≤ 0.15 | ≤ 0.50 | ≤ 0.15 | ≤ 0.15 | ≤ 0.15 | Bal. |

| Deposited wire | 4.59 | 1.56 | 0.67 | 0.09 | 0.10 | 0.09 | 0.05 | 0.02 | Bal. |

| WAAM deposited specimen | 4.59 | 1.38 | 0.66 | 0.09 | 0.09 | 0.09 | 0.04 | 0.02 | Bal. |

实验采用的增材制造系统主要由CNC数控机床、Miller Dynasty200钨极惰性气体保护焊机(tungsten inert gas,TIG)和自动送丝机组成。与熔化极气体保护焊(melt inert gas,MIG)相比,TIG的热输入较小,实验过程选用交流电流,利用阴极清理效应,实现较好的保护效果。2024铝合金电弧增材制造过程如图1a所示。成形过程中,基板固定于机床工作台上,焊丝置于焊枪前方,采用单一方向扫描策略。由于基板散热条件较好,故成形第一层时电流强度选用较大值(150 A),保证形成稳定的熔池。随后电流强度减小至120 A,进行后续多层的沉积。扫描速率为250 mm/min,送丝速率选用1500 mm/min;采用99.9%的Ar气作为保护气体,气体流量为15 L/min。

图1

图1

WAAM 2024铝合金沉积过程示意图和拉伸试样尺寸示意图

Fig.1

Schematic of deposited process (TIG—tungsten inert gas) (a) and dimensions of tensile test specimen (unit: mm) (b) for WAAM 2024 aluminum alloy

利用电火花切割金相试样,经过SiC砂纸磨削与抛光后,使用Keller试剂进行腐蚀。使用OLS4000型激光共聚焦显微镜对晶粒特征进行观察。借助Supra55扫描电子显微镜(SEM)和Symmetry电子背散射衍射(EBSD)进行元素成分和分布、晶粒织构的测量分析。使用Empyrean型X射线衍射仪(XRD)对成形试样进行物相分析,扫描范围为20°~100°,扫描步长为5°/min。利用DHVS-1000A型Vickers硬度仪进行显微硬度测量,压头载荷为100 g,保压时间为15 s。使用WDW-20型拉伸试验机进行拉伸实验,加载速率为2 mm/min。拉伸试样尺寸如图1b所示。

2 实验结果与分析

2.1 晶粒形貌与织构取向

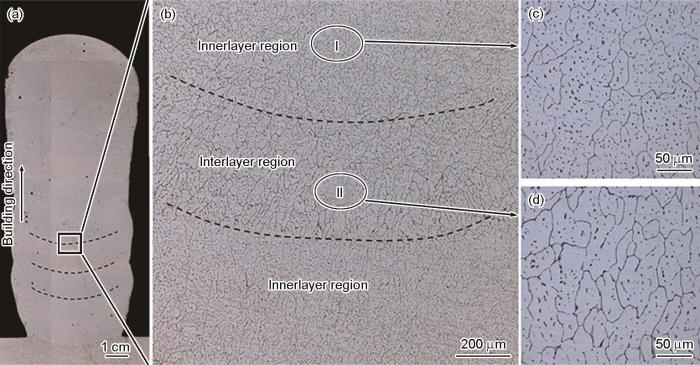

图2a所示为2024铝合金WAAM沉积薄壁试样的宏观形貌。可以看出,试样内部没有裂纹缺陷,但存在少量的气孔。气孔形状为规则的圆形,判断其为氢气孔。铝合金易氧化,形成氧化膜,吸收水分,电弧高温条件下,水直接分解为氢进入熔池。氢由液态向固态转变时,在铝合金的溶解度显著降低[15],产生大量的氢气,WAAM快速凝固时,氢气泡难以充分逸出,残留在试样内部,从而形成氢气孔。此外,试样层间结合良好,没有明显的未熔合现象。由于WAAM过程的逐层沉积,试样宏观上表现出层状特征,将单一沉积层分为层中区域和层间区域,这也与柏久阳等[16]WAAM成形2219铝合金的结论一致。如图2b所示,层中区域与层间区域的晶粒形貌有显著的区别。面积较大的层中区域(Ⅰ)中晶粒为等轴晶形貌,且内部分布着较多的黑色细小颗粒(图2c)。层间区域(Ⅱ)面积较小,晶粒由等轴晶转变为柱状晶,其生长方向有沿沉积方向生长的趋势,直至与层中区域的等轴晶相遇(图2d)。

图2

图2

2024铝合金WAAM成形试样不同位置的组织形貌

(a) macromorphology (b) microstructure of innerlayer region and interlayer region

(c, d) enlarged views of region I (c) and II (d), respectively

Fig.2

Morphologies of WAAM 2024 aluminum alloy deposited specimen at different positions

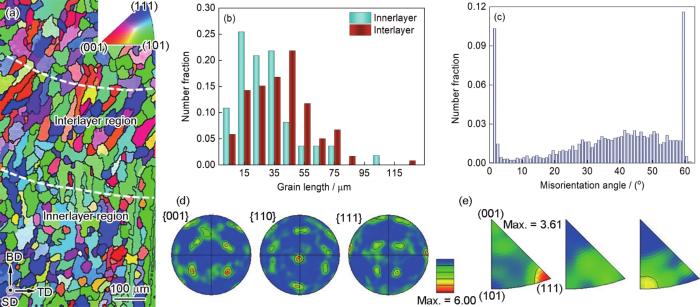

对2024铝合金成形试样进行EBSD分析,结果如图3所示。由图3a可知,层中区域的等轴晶平均长度约为29.0 µm。层间区域的柱状晶外延生长,根据图3b统计柱状晶平均长度为37.8 µm,比层中区域等轴晶长度增加约30.3%。图3c为晶粒取向差分布图,可知晶界取向差主要分布于30°~60°之间,表明晶粒取向差以大角度晶界(> 15°)为主,具有较高的晶界能,占比约为83.4%。另外,成形试样中大部分晶粒颜色为蓝色或绿色(图3a),结合极图(图3d)和反极图(图3e),判断存在织构{001}<111>,织构强度为6.00。Al属于fcc结构,<100>晶向是最容易生长的方向。在增材制造的快速凝固过程中,沿最大温度梯度方向且与<100>晶向平行的晶粒生长最快,而与最大温度梯度方向成大角度的晶粒生长则受到抑制,因此铝合金增材过程产生的凝固组织存在晶粒外延生长的特征,容易产生织构[17,18]。

图3

图3

2024铝合金WAAM成形试样的EBSD分析

(a) EBSD image of microstructure (BD—building direction, SD—scanning direction, TD—transverse direction)

(b) distribution of grain size (c) distribution of grain boundary misorientation

(d) pole figures (e) inverse pole figures (IPFs)

Fig.3

EBSD analyses of WAAM 2024 aluminum alloy deposited specimen, paralleled to the building direction

式中,G和R分别为凝固界面前沿的温度梯度与凝固速率,c为合金溶质浓度,K为平衡分配系数,m为合金液相线斜率,D为液相溶质扩散系数。可以看出,对于2024铝合金凝固过程,晶粒形貌主要取决于温度梯度与凝固速率。层间区域与已凝固的沉积层接触,因此其沿沉积方向的G相对较大,R相对较小,由

2.2 物相组成与元素分布

图4

图4

Al-Cu-Mg合金凝固路径及2024铝合金丝材与WAAM成形试样的XRD谱

Fig.4

Solidification pathways of Al-Cu-Mg alloy (a) and XRD spectra of 2024 aluminum alloy wire and WAAM deposited specimen (b) (Inset in Fig.4b shows the locally enlarged spectrum)

图5

图5

2024铝合金WAAM成形试样SEM分析

Fig.5

SEM image of WAAM 2024 aluminum alloy deposited specimen and EDS results of points P1 and P2 (a), line scanning of bright-white phase showed in the inset (b), and line scanning of gray phase showed in the inset (c)

图6

图6

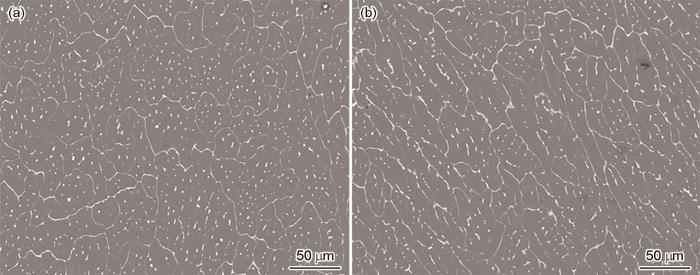

WAAM成形2024铝合金试样层中区域和层间区域的SEM像

(a) innerlayer region (b) interlayer region

Fig.6

SEM images of WAAM 2024 aluminum alloy deposited specimen

图7

图7

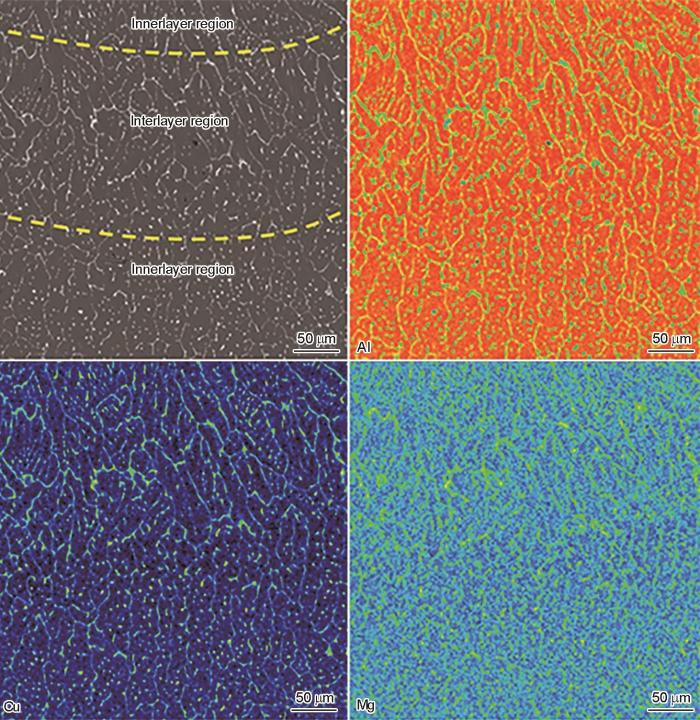

2024铝合金WAAM成形试样面扫描元素分布

Fig.7

Element mapping of WAAM 2024 aluminum alloy deposited specimen

2.3 力学性能

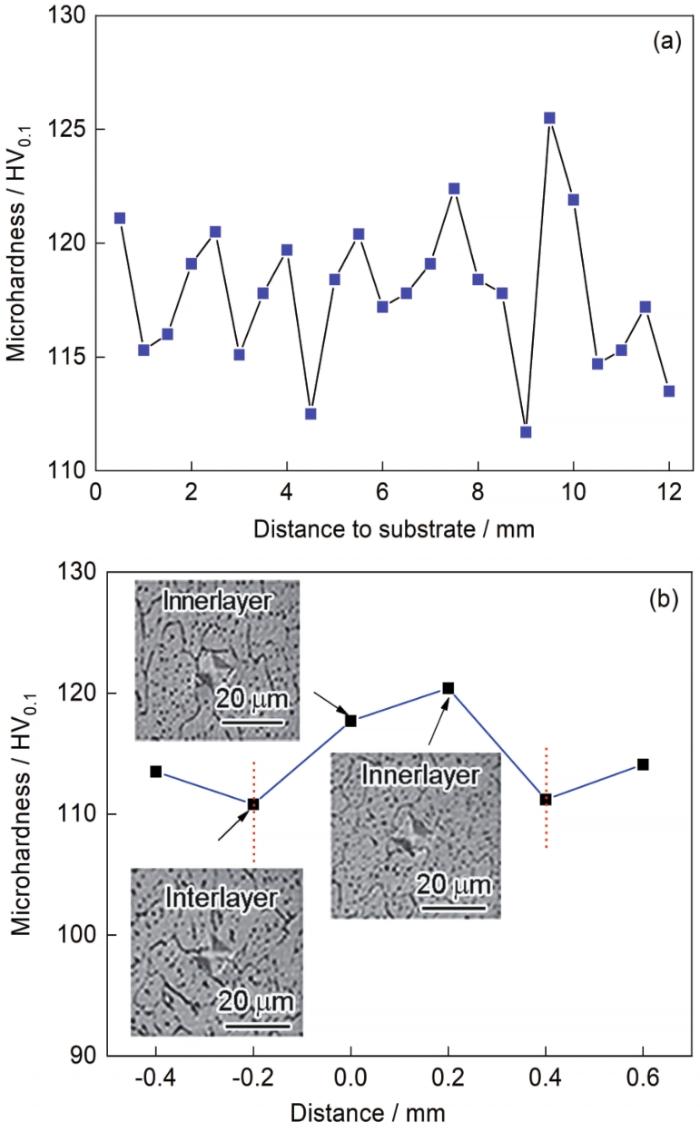

图8

图8

2024铝合金WAAM成形试样和单一沉积层的显微硬度分布

Fig.8

Microhardness distributions of WAAM 2024 aluminum alloy deposited specimen (a) and single layer (b) (Insets in Fig.8b show the microstructures in the innerlayer and interlayer regions)

沿扫描方向对电弧增材制造2024铝合金进行室温拉伸实验。3个拉伸试样的应力-应变曲线如图9a所示。所有被测试样的弹性变形阶段基本一致,且均没有明显的屈服点,平均抗拉强度、屈服强度与断后伸长率分别为(323.5 ± 6.6) MPa、(178.7 ± 6.2) MPa和(9.03 ± 0.67)%。图9b对WAAM成形2024铝合金试样与2024-O和2024-T6合金板材[28]的力学性能进行了比较。可见,WAAM成形2024铝合金的力学性能要远大于铸造退火O态,但要低于锻造T6态。对于可热处理的2xxx系铝合金,Bai等[29]发现增材制造沉积态试样内部的析出相数量稀少,产生的沉淀强化效应可以忽略,使得其力学性能远低于2024-T6板材。

图9

图9

2024铝合金WAAM成形试样室温拉伸曲线和不同方式制备2024铝合金的力学性能比较

Fig.9

Tensile curves of WAAM 2024 aluminum alloy deposited specimens under room temperature (a) and properties comparison of 2024 aluminum alloy prepared by different methods (b)

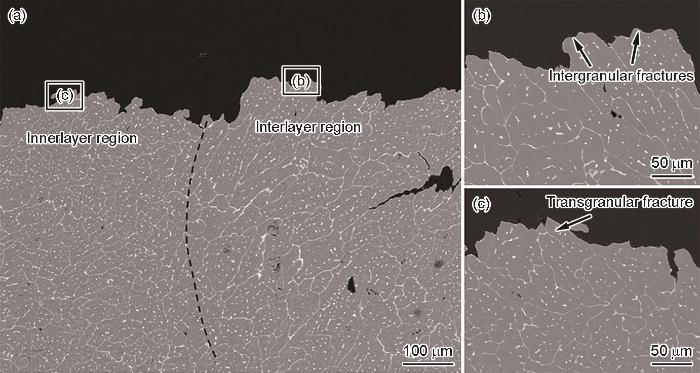

图10a为电弧增材制造2024铝合金拉伸试样的典型断口形貌。如图10a2所示,层间区域放大后的SEM像中可以观察到大量的柱状晶外表面。对断裂的柱状晶的外表面的破碎颗粒进行EDS分析,推断其为α + S共晶组织(图10b)。此外,如图10a1和c所示,层中区域密布着韧窝,韧窝底部残留着细小颗粒,EDS结果显示细小颗粒为共晶组织。由于上述微观组织的分层特征,如图11a所示,层中区域与层间区域出现不同的裂纹扩展行为。与Al基体相比,共晶组织具有硬而脆的特点,能够阻碍位错运动并造成应力集中,产生微裂纹[30];另外,根据第2.2节物相组成与元素分布的分析可知,层间区域Cu元素和Mg元素在晶界偏析严重,共晶组织呈网状沿晶界连续分布,这会降低晶界结合力,有利于微裂纹沿着晶界扩展。如图11b所示,在拉伸载荷下,层间区域裂纹沿着共晶组织分布路径扩展,最终表现为沿晶断裂。而层中区域元素偏析得到缓解,晶粒内部弥散分布着颗粒状的共晶组织,粗大连续的共晶组织减少。此时,颗粒状共晶组织周围较软的Al基体在拉伸载荷下首先发生变形,形成显微孔洞,颗粒状共晶组织残留在孔洞内部。孔洞聚集直至穿过晶粒,最终导致断裂,产生韧窝特征,如图11c所示,故层中区域裂纹扩展模式为穿晶断裂。

图10

图10

2024铝合金WAAM成形试样拉伸断口形貌的SEM像、层间区域SEM像和EDS、层中区域SEM像与EDS

Fig.10

SEM images of fracture surface (a), SEM image and EDS of interlayer region (b), and SEM image and EDS of innerlayer region (c) of WAAM 2024 aluminum alloy tensile specimen (Figs.10a1 and a2 show the locally enlarged images in Fig.10a)

图11

图11

2024铝合金WAAM成形拉伸试样断口裂纹扩展

(a) cross section of fracture (b) image of interlayer region (c) image of innerlayer region

Fig.11

Crack propagation of tensile fracture of WAAM 2024 aluminum alloy tensile specimen

3 结论

(1) 以2024铝合金丝材为沉积材料,采用电弧增材制造工艺制备出三元Al-Cu-Mg合金成形试样,试样内部没有裂纹缺陷,存在少量的显微氢气孔,层中区域和层间区域的晶粒形貌存在差异。

(2) 层中区域大量的共晶组织颗粒呈分散特征均匀分布在晶粒内部,Mg元素在Al基体中的分布均匀性较好;而层间区域共晶组织主要呈网状聚集在晶界,颗粒状的共晶组织数量远少于层中区域,导致元素偏析严重,Cu元素以共晶组织的形式在晶界偏析,Mg元素出现局部富集。

(3) 2024铝合金成形试样的平均显微硬度为(117.9 ± 3.3) HV0.1,平均抗拉强度、屈服强度与断后伸长率分别为(323.5 ± 6.6) MPa、(178.7 ± 6.2) MPa和(9.03 ± 0.67)%,断口形貌中层间区域裂纹主要沿共晶组织分布路径扩展,表现为沿晶断裂,而层中区域裂纹扩展模式变为穿晶断裂。

参考文献

Application of modern aluminum alloys to aircraft

[J].

Development of high strength aluminum alloys and processing techniques for the materials

[J].

高强铝合金的发展及其材料的制备加工技术

[J].

Microstructure and deformation behavior of Ti-6Al-4V alloy by high-power laser solid forming

[J].

Wire and arc additive manufacturing of lightweight metal components in aeronautics and astronautics

[J].

航空航天轻质金属材料电弧熔丝增材制造技术

[J].

Laser additive manufacturing of high-performance metallic aerospace components

[J].

航空航天高性能金属材料构件激光增材制造

[J].

Additive manufacturing of metals

[J].

Microstructure and mechanical properties of 5356 aluminum alloy fabricated by TIG arc additive manufacturing

[J].5356 aluminum alloy has been widely applied in transportation, aerospace and other fields owing to its low density, excellent fatigue property, and superior corrosion resistance. Aluminum alloy is widely manufactured by the arc additive technique that operates at a fast manufacturing speed with simple equipment and high material utilization. The property of 5356 aluminum alloy is closely related to its microstructure. To better control the property of this alloy for the additive manufacturing of forming parts, it is necessary to study the evolution of its microstructure. In this work, 5356 aluminum alloy forming parts were produced by tungsten inert gas welding (TIG) arc additive manufacturing, and their microstructures and mechanical properties were analyzed. The 5356 aluminum alloy formed by TIG additive manufacturing was composed of α-Al matrix and β(Al3Mg2) phase. As the deposition height increased, the layer microstructure transformed from equiaxed grains to columnar grains and tended to stabilize at thermal equilibrium. The top layer exhibited a dendritic microstructure with serious segregation of the Mg element. The middle and lower microstructures were varied and included equiaxed grains, columnar grains, and a mixture of these, with improved Mg-element segregation. As the deposition height increased, the microhardness in the layer first decreased and then stabilized. The microhardness was larger in the interlayers than in the deposition layers. The pores gathered in the interlayers might explain the lower yield strength of the thin-walled parts than the theoretically calculated value. The tensile strength, yield strength, and elongation were all anisotropic, and the tensile property was better in the transverse than in the longitudinal direction. This result was attributable to pore accumulation between the layers of the thin-walled parts and to the uneven microstructure.

5356铝合金TIG电弧增材制造组织与力学性能

[J].采用钨极惰性气体保护焊(TIG)电弧增材制造工艺制备5356铝合金成形件,并对成形件的组织和力学性能进行研究。结果表明,5356铝合金增材制造的相组成为α-Al基体和β(Al<sub>3</sub>Mg<sub>2</sub>)相;随沉积高度增加,沉积层显微组织由等轴晶向柱状晶转变,达到热平衡状态后趋于稳定,这是因为增材制造具有热积累效应;最顶层组织呈现树枝状,且Mg元素偏析严重;中下部组织形态多样,包括等轴晶组织、柱状晶组织及其混合组织,同时Mg元素偏析得到改善。力学性能测试结果显示,随沉积高度的增加,层内显微硬度先降低后趋于稳定,这是因为沉积层组织在增材制造过程中经历逐渐粗化的过程,导致显微硬度下降,达到热平衡状态后显微组织相对稳定,显微硬度也趋于稳定。沉积层层间位置的硬度大于层内,这是因为层间结合处为细小的等轴晶组织。聚集在层间的气孔可能是导致薄壁件屈服强度低于理论计算值的原因。抗拉强度、屈服强度以及伸长率都表现了各向异性,横向拉伸性能优于纵向,这是因为薄壁件层间气孔聚集以及显微组织不均匀。

Microstructure and mechanical property research on wire + arc additive manufactured 5356-aluminum alloy

[J].

电弧增材制造5356铝合金的组织与性能研究

[J].

Microstructure and properties of ZL114A aluminum alloy prepared by wire arc additive manufacturing

[J].

电弧增材制造ZL114A铝合金的组织与性能

[J].

The effect of inter-layer cold working and post-deposition heat treatment on porosity in additively manufactured aluminum alloys

[J].

The strengthening effect of inter-layer cold working and post-deposition heat treatment on the additively manufactured Al-6.3Cu alloy

[J].

Effect of arc mode in cold metal transfer process on porosity of additively manufactured Al-6.3%Cu alloy

[J].

The influence of wire properties on the quality and performance of wire + arc additive manufactured aluminium parts

[J].

Porosity control of wire + arc additively manufactured Al-6.3Cu alloy deposition using AC-GTAW process

[J].

Al-6.3Cu AC-GTAW电弧增材成形的气孔控制

[J].

Formation and reduction of hydrogen porosity during selective laser melting of AlSi10Mg

[J].

Microstructures of 2219-Al thin-walled parts produced by shaped metal deposition

[J].

2219铝合金TIG填丝堆焊成形薄壁试样组织特征

[J].

Fabrication and characterization of high strength Al-Cu alloys processed using laser beam melting in metal powder bed

[J].

Microstructure and mechanical properties of Al-12Si produced by selective laser melting: Effect of heat treatment

[J].

An analytical model for constitutional supercooling-driven grain formation and grain size prediction

[J].

Effect of constitutional supercooling on the numerical solution of species concentration distribution in laser surface alloying

[J].

Steady state columnar and equiaxed growth of dendrites and eutectic

[J].

Study of microsegregation in Al-Cu-Zn ternary alloys by experiment and scheil model

[J].

Al-Cu-Zn合金微观偏析的实验和Scheil模型研究

[J].应用相图计算耦合Scheil模型、简单Scheil方程和实验比较研究了Al--Cu--Zn合金单相凝固过程的凝固路径和微观偏析。相图计算耦合Scheil模型的计算结果显示, Al--Cu--Zn合金单相凝固结束点的溶质含量与凝固初始点的成分同步变化, 溶质含量和溶质分凝系数随凝固过程的进行不断增加; 在热力学计算出合金分凝系数的基础上, 简单Scheil方程可以计算初生相含量, 从不同溶质得到的计算结果是自洽的, 并与相图计算耦合Scheil模型的预测值一致; 实验测定了不同成分铝合金的共晶含量和枝晶间距, 实验数据与模型结果基本一致。

Experimental validation of Scheil-Gulliver simulations for gradient path planning in additively manufactured functionally graded materials

[J].

Influence of alloy composition and heat treatment on precipitate composition in Al-Zn-Mg-Cu alloys

[J].

Effects of thermal cycles on microstructure evolution of 2219-Al during GTA-additive manufacturing

[J].

A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties

[J].

Mechanical properties and fracture behaviors of GTA-additive manufactured 2219-Al after an especial heat treatment

[J].