镍基高温合金具有优异的高温力学性能和抗氧化性能,广泛应用于航空发动机和燃气轮机涡轮叶片等热端部件[1~3]。在高温恶劣的工作环境下,该材料的抗氧化能力是当前研究的热点。提高材料抗氧化能力的主要方法有在合金表面覆盖热障涂层[4,5]和添加抗氧化元素。在添加的合金元素中,Cr和Al可以氧化生成含有Al2O3和Cr2O3的结构致密的保护性氧化膜,成为镍基高温合金中的主要抗氧化元素。这2个元素含量的比值会影响氧化膜中的物相种类,当Cr / Al比较高时,氧化膜主要是Cr2O3;比值较低时,氧化膜主要是Al2O3[6]。镍基合金体系不同,氧化膜出现Cr2O3 / Al2O3对应的Cr / Al比不同。Giggins和Pettit[7]研究Ni-(5~30)Cr-(1~6)Al (质量分数,%,下同)系列合金的氧化行为时,得出Cr含量高(> 10%,质量分数,下同)而Al含量低(< 2%)即Cr / Al比大于5时,形成的氧化膜外层主要是Cr2O3,内层是Al2O3;当合金中Al含量高(> 4%)时,Cr / Al比小于5,其氧化膜仅为Al2O3。Barrett和Lowell[8]研究Ni-(0~37)Cr-(0~32)Al合金氧化行为时发现,Cr含量高(> 18%)且Al含量低(< 5%)时,Cr / Al比大于3.6,氧化外层主要由Cr2O3构成;当Al含量高(> 5%)时,氧化层则由Al2O3构成。Chen等[9]研究表明,72.6Ni-16.7Al-10.7Cr合金Cr / Al比为0.64,氧化层外层为Al2O3,中间层为尖晶石NiAl2O4和Cr2O3,内层为NiO。

Ta元素对镍基高温合金氧化行为也有显著影响,它的作用受合金中其他元素的影响,也与其加入量有关。Yang[10]对Ni-12.8Al-4.8Cr-4.2Co-1.6W-3.1Mo-1.0Re合金进行高温氧化对比实验,发现加入3.0%Ta后氧化层由外层NiO和内层Al2O3组成,Ta促进了保护性Al2O3氧化层的形成,提高了合金抗氧化性;而加入8.8%Ta导致合金无法形成稳定的Al2O3,形成的NiTa2O6等复杂氧化物反而使合金抗氧化性降低。Kim等[11]在研究Ni-(10~16)Cr-5Al-(3~6)Ta合金的氧化行为时发现,在1000℃高温下,Ta的氧化物能够显著提高合金的抗氧化性。Park等[12]对Ni-(8~15)Cr-(3~8)Al-(0~10)Ta合金在1000℃下氧化300 h研究发现,在Al含量低的时候,Ta含量的变化比Cr元素对氧化行为的影响更显著;而高Al含量下,Ta和Cr含量的变化对氧化行为影响不明显。Han等[13]研究Ni-12Cr-4.2Al-(3.8~5.8)Ta合金时发现,含5.8%Ta合金的氧化速率低于含3.8%Ta的合金,这是因为在高Ta含量的高温合金中形成了连续致密的CrTaO4。Park等[14]研究Ni-8Cr-(4~5)Al-(3~6)Ta合金的结果显示,添加5%Ta会减慢Al2O3的形成,使镍基高温合金在850℃条件下抗氧化性下降;当Ta含量大于5%,Ta可以降低O活性或限制Al在氧化层中的向外扩散,增强合金的抗氧化性。Liu等[15]和Guo等[16]研究认为,Ta会降低Al的向外扩散速率,从而抑制DD32M合金和β-NiAl合金表面氧化层的生长。可以看出,Ta对镍基高温合金的抗氧化性能的影响是通过影响Al、Cr等合金元素的氧化物种类而发生作用的,当Ta含量达到3%时就可以提高合金抗氧化性能,高Ta含量(如8.8%)对合金抗氧化性能产生有害影响,而中等Ta含量(5%~6%)对抗氧化性能的影响因合金种类差异而不同。

DZ445合金含有14%Cr、4%Al和5%Ta,前期研究[17]表明,其外层氧化物主要是Cr2O3,属于高Cr / Al比和中Ta含量的镍基合金体系;分析了该合金在850~900℃下300 h的氧化行为,发现CrTaO4的形成使合金的氧化速率降低,氧化速率常数从3.10 × 10-3 mg2/(cm4·h)变为4.71 × 10-4 mg3/(cm6·h),激活能从335 kJ/mol变为423 kJ/mol。考虑到合金长时间服役,本工作进一步考察了DZ445在900℃下长达2600 h的氧化行为,分析该合金长时间氧化产物、氧化膜结构和氧化动力学及其氧化机制。发现长时间氧化条件下该合金氧化膜形成多层结构,这种多层结构使得该合金呈现出优异的抗氧化能力。

1 实验方法

实验采用DZ445高温合金,化学成分如表1所示。该合金的制备工艺如下:真空感应熔炼炉熔炼并浇注成母合金锭,以7 mm/min抽拉速率在定向凝固炉中拉制成直径16 mm、长200 mm的合金圆棒。随后进行热处理,工艺为:1210℃、2 h、AC + 1080℃、2 h、AC + 850℃、24 h、AC (AC为空冷)。

表1 DZ445镍基高温合金的化学成分

Table 1

| Composition | Co | Cr | Mo | W | Al | Ti | Ta | C | Zr | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| Mass fraction / % | 10.00 | 14.00 | 1.50 | 4.00 | 4.00 | 3.00 | 5.00 | 0.08 | 0.03 | Bal. |

| Atomic fraction / % | 9.90 | 15.70 | 0.90 | 1.30 | 8.70 | 3.70 | 1.60 | 0.39 | 0.02 | Bal. |

在热处理后的试棒上通过线切割制成尺寸为10 mm × 10 mm × 3 mm的样品用作氧化实验。试样表面经SiC砂纸水磨至2000号,之后用6 μm金刚石抛光膏进行抛光。用千分尺测量抛光后的样品尺寸,并计算其表面积。随后,将研磨好的试样放入酒精中用高频超声波清洗以保证表面清洗干净。氧化实验前,用清水、酒精清洗Al2O3坩埚,去除其表面油污,并在900℃下保温24 h,以去除杂质,确保氧化过程中质量稳定。将试样放入坩埚一起称重,作为其初始重量,最后将样品放入马弗炉中分别在850、900和925℃进行300~2600 h等温氧化实验。

采用不连续称重法测定样品的氧化增重以确定其动力学曲线。在选定的时间点(3 h、6 h、12 h、24 h、48 h、72 h、96 h、120 h、…、2600 h),从炉中将坩埚和样品一起取出空冷至室温,使用精度为10-4 g电子天平称重。同时,对氧化不同时间后的样品利用D/MAX2000V PC X射线衍射仪(XRD)、VEGA 3 Easy Probe扫描电子显微镜(SEM)及其附带的能谱仪(EDS)研究氧化物的相组成、表面形貌、横截面形貌和氧化层的元素组成。

观察样品横截面时,需要先对样品进行化学镀镍,再进行金相制备。首先在室温下把样品放入13 g/L SnCl2·2H2O + 40 mL HCl +去离子水溶液中敏化处理2 min,然后放入0.2 g/L PdCl2 + 7 mL HCl + 去离子水溶液中活化处理0.5~1 min,最后在85~90℃的水浴锅中进行化学镀镍,化学镀液为23~28 g/L NiSO4·6H2O + 25~35 g/L NaH2PO2·H2O + 10~16 g/L Na3C6H5O7·2H2O + 10~15 g/L CH3COONa + 10~16 g/L C3H6O3 +去离子水,时间约为60 min,溶液的pH值为4~5。组织观察用腐蚀剂为5 g CuSO4 + 10 mL HCl + 20 mL H2O,腐蚀时间为45 s。

2 实验结果

2.1 氧化物相分析

DZ445合金在900℃氧化不同时间后的XRD谱如图1所示。可以看出,不同时间的氧化产物种类基本一致,主要包括NiCr2O4、TiO2、Cr2O3、CrTaO4和Al2O3。与氧化300 h相比,氧化500 h的XRD谱中Cr2O3的衍射峰数量减少,NiCr2O4的衍射峰数量增加,TiO2衍射峰强度提高,表明氧化表层中Cr2O3的含量减少,NiCr2O4和TiO2含量增加。氧化500 h后,表面氧化物的种类随时间延长保持稳定。但氧化不同时间的XRD谱中,都没有W、Co和Mo的氧化物。

图1

图1

DZ445镍基高温合金在900℃氧化不同时间的XRD谱

Fig.1

XRD spectra of the DZ445 Ni-based superalloy after the oxidation at 900oC for different time

2.2 表面形貌

图2

图2

900℃下DZ445镍基高温合金氧化不同时间表面形貌的SEM像

Fig.2

SEM images of the surface of the DZ445 Ni-based superalloy oxidized at 900oC for 500 h (a), 915 h (b), 1100 h (c), 1500 h (d), 1800 h (e), 2200 h (f), and 2600 h (g) (A and B in Fig.2a indicate bright white part and dark black part of oxide film, respectively)

表2 DZ445镍基高温合金在900℃氧化500 h后表面氧化膜不同区域的元素分布 (atomic fraction / %)

Table 2

| Area | O | Al | Cr | Ni | Ti | Ta | Co |

|---|---|---|---|---|---|---|---|

| A | 61.83 | 2.04 | 17.00 | 11.32 | 5.94 | 0.08 | 1.79 |

| B | 60.28 | 25.25 | 4.40 | 7.96 | 1.08 | 0.03 | 1.00 |

2.3 横截面形貌

图3是ZD445合金在900℃氧化不同时间后横截面形貌的SEM像。可以看出,氧化不同时间后的氧化膜都呈现出多层结构。氧化300 h时,氧化膜为最外层、次外层和最内层的3层结构,分别标记为P1、P2和P4 (图3a)。从氧化500 h开始(图3b~h),氧化膜演变为4层结构,从外到内依次定义为最外层、次外层、次内层、最内层,分别用P1、P2、P3和P4来标记,各个层内的EDS分析结果如表3所示。可见,最外层P1主要富含Cr、Ni和O,结合XRD结果推测该层物相主要是Cr2O3和尖晶石NiCr2O4;次外层P2主要含有Ta、Ti和O元素,推测其主要氧化物是CrTaO4和TiO2;最内层P4主要含Al和O元素,主要氧化物是Al2O3;次内层P3与最内层P4相比,其Al含量降低,Ni 和Cr含量增加,推测该层中主要氧化物有Al2O3、NiO和NiCr2O4。

图3

图3

DZ445镍基高温合金在900℃氧化不同时间横截面形貌的SEM像

Fig.3

SEM images of the cross-section of the DZ445 Ni-based superalloy oxidized at 900oC for 300 h (a), 500 h (b), 915 h (c), 1100 h (d), 1500 h (e), 1800 h (f), 2200 h (g), and 2600 h (h) (P1, P2, P3, and P4 indicate the outermost layer, subouter layer, subinner layer, and innermost layer, respectively. The bright edge on the top of the outermost layer is nickel plated)

表3 DZ445镍基高温合金在900℃氧化不同时间后的氧化膜各层元素分布的EDS分析 (atomic fraction / %)

Table 3

| Oxide layer | Time / h | Al | Cr | Ta | Ti | Ni | O | Co |

|---|---|---|---|---|---|---|---|---|

| P1 | 300 | 1.11 | 32.03 | 0.00 | 2.05 | 1.77 | 62.64 | 0.40 |

| 500 | 3.32 | 19.35 | 0.18 | 3.59 | 10.65 | 58.36 | 4.56 | |

| 915 | 0.69 | 28.19 | 0.06 | 1.60 | 5.38 | 62.54 | 1.54 | |

| 1100 | 3.30 | 21.54 | 0.17 | 2.31 | 10.64 | 57.94 | 4.09 | |

| 1500 | 1.76 | 16.81 | 0.12 | 7.12 | 14.59 | 55.35 | 4.24 | |

| 1800 | 5.43 | 16.38 | 0.18 | 4.59 | 8.49 | 61.37 | 3.57 | |

| 2200 | 2.69 | 20.75 | 0.07 | 1.52 | 11.36 | 58.75 | 4.87 | |

| 2600 | 2.20 | 21.02 | 0.22 | 1.80 | 10.29 | 62.13 | 2.34 | |

| P2 | 300 | 4.58 | 11.30 | 6.14 | 8.11 | 1.13 | 68.61 | 0.15 |

| 500 | 2.63 | 10.42 | 6.49 | 7.64 | 5.98 | 65.13 | 1.72 | |

| 915 | 1.09 | 6.72 | 9.37 | 8.36 | 4.51 | 69.75 | 0.23 | |

| 1100 | 4.22 | 6.69 | 7.29 | 6.79 | 3.45 | 71.07 | 0.50 | |

| 1500 | 1.36 | 10.97 | 6.95 | 8.65 | 7.00 | 63.13 | 1.96 | |

| 1800 | 2.12 | 9.64 | 7.54 | 8.21 | 3.28 | 68.16 | 1.05 | |

| 2200 | 1.53 | 8.89 | 7.14 | 8.03 | 4.85 | 68.33 | 1.23 | |

| 2600 | 0.73 | 6.53 | 9.26 | 8.58 | 3.75 | 70.90 | 0.25 | |

| P3 | 300 | - | - | - | - | - | - | - |

| 500 | 24.43 | 3.55 | 0.82 | 1.21 | 11.94 | 56.75 | 1.32 | |

| 915 | 14.27 | 3.04 | 1.14 | 1.03 | 15.43 | 64.82 | 0.28 | |

| 1100 | 27.66 | 1.46 | 0.38 | 0.44 | 9.71 | 59.57 | 0.77 | |

| 1500 | 23.14 | 3.90 | 0.21 | 0.28 | 17.83 | 53.29 | 1.34 | |

| 1800 | 22.94 | 4.47 | 0.83 | 1.27 | 10.50 | 58.72 | 1.27 | |

| 2200 | 21.70 | 4.67 | 0.20 | 0.62 | 15.97 | 55.44 | 1.40 | |

| 2600 | 20.97 | 3.02 | 0.49 | 0.42 | 12.67 | 61.35 | 1.07 | |

| P4 | 300 | 36.55 | 0.77 | 0.18 | 0.24 | 2.62 | 59.12 | 0.51 |

| 500 | 33.37 | 2.30 | 0.32 | 0.41 | 3.14 | 59.47 | 0.99 | |

| 915 | 34.07 | 1.97 | 0.19 | 0.30 | 4.56 | 58.05 | 0.88 | |

| 1100 | 35.85 | 1.18 | 0.15 | 1.54 | 0.79 | 60.35 | 0.13 | |

| 1500 | 35.53 | 1.52 | 0.06 | 0.29 | 3.90 | 57.92 | 0.78 | |

| 1800 | 35.24 | 1.90 | 0.07 | 0.90 | 1.53 | 60.12 | 0.24 | |

| 2200 | 33.48 | 1.30 | 0.11 | 0.57 | 4.41 | 59.45 | 0.69 | |

| 2600 | 33.84 | 1.97 | 0.17 | 0.74 | 1.74 | 61.34 | 0.20 |

DZ445合金在900℃氧化不同时间后各氧化层的厚度变化曲线如图4所示。在氧化500 h后,最外层和次外层的厚度增幅很小;次内层在氧化500 h后形成,随时间增大呈现增厚的趋势;最内层厚度在整个氧化时间段表现为减小的趋势,可能原因是贫γ′层Al消耗不足,不足以维持内氧化。

图4

图4

DZ445镍基高温合金在900℃氧化不同时间后各氧化层的厚度变化曲线

Fig.4

Thicknesses of the oxidizing layer of the DZ445 Ni-based superalloy after oxidizing at 900oC for different time in air

2.4 氧化动力学

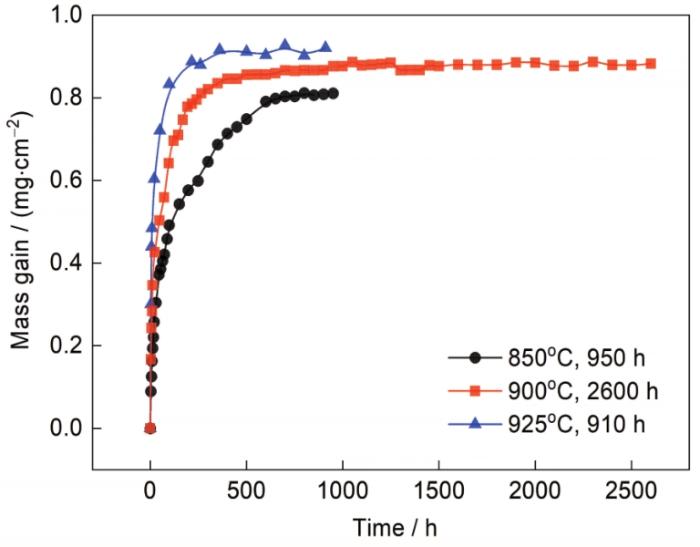

图5是DZ445合金在850、900和925℃下的氧化增重动力学曲线。其中900℃下氧化时间为2600 h,850和925℃下增重进入稳定变化时停止实验,氧化时间分别为950和910 h。可以看出,这3个温度下的氧化规律相似,初始阶段氧化增重较快,随着时间的延长其增加速率降低;在相同的时间下,温度越高,氧化增重也越大。

图5

图5

DZ445镍基高温合金在不同温度下的恒温氧化动力学曲线

Fig.5

Isothermal oxidation kinetics curves of DZ445 Ni-based superalloy oxidized at 850oC for 950 h, 900oC for 2600 h, and 925oC for 910 h

图6

图6

DZ445镍基高温合金在不同温度下氧化增重的双对数曲线

Fig.6

Double logarithmic graphs of the mass gain (ΔW) and oxidation time (t) at different temperatures

图7

图7

lnK和1 / T的关系图

Fig.7

Logarithm of lnK plotted against the temperature reciprocal (1 / T) before and after the formation of the continuous subouter layer and subinner layer

表4 900℃下不同时段的氧化动力学方程指数(n)、恒温氧化速率常数(K)和氧化激活能(E)

Table 4

| Time | n | K | E / (kJ·mol-1) |

|---|---|---|---|

| Before the formation of CrTaO4 layer | 2.17 | 1.0 × 10-2 mg2·cm-4·h-1 | 325 |

| Between the formation of subouter and subinner layer | 4.17 | 1.93 × 10-3 mg3·cm-6·h-1 | 424 |

| After the formation of subinner layer | 25.00 | 3.5 × 10-5 mg25·cm-50·h-1 | 485 |

式中,E为氧化激活能,A为指前因子,R为气体常数,T为绝对温度。通过lnK-1 / T关系曲线的斜率(图7),可以获得E。计算得出在所研究的温度范围段,不同n值对应的3个不同氧化阶段的激活能分别为325、424和485 kJ/mol。

3 分析讨论

由以上结果可知,在所研究的温度范围段,DZ445合金长时间氧化后其膜层形成4层结构:最外层氧化物相主要是Cr2O3、NiCr2O4和TiO2,次外层主要物相为CrTaO4和TiO2,次内层为Al2O3、NiCr2O4和NiO,最内层为Al2O3。次外层和次内层的形成改变了氧化速率方程指数,降低了氧化速率常数。

3.1 最外层、次外层和最内层的物相构成

DZ445合金在氧化不同阶段氧化膜各层中主要物相种类不一样,这主要是由合金中元素含量、与O发生反应的自由能及其扩散能力决定的。反应自由能越低,越容易发生反应;某一元素含量越高,扩散能力越大,该元素氧化物越容易形成。

表5 900℃下DZ445镍基高温合金元素氧化物生成的Gibbs自由能(ΔG)[17,21,23] (kJ·mol-1)

Table 5

| Oxide | ΔG | Oxide | ΔG |

|---|---|---|---|

| NiO | -279.2 | NiCr2O4 | -826.2 |

| Cr2O3 | -547.1 | CrTaO4 | -580.3 |

| TiO2 | -733.4 | CoO | -274.9 |

| Al2O3 | -869.2 | WO2 | -379.7 |

| Ta2O5 | -613.5 | MoO2 | -382.9 |

DZ445合金中Cr的含量比Al高,Cr在合金中沿晶界短程扩散的速率明显高于Al元素[31,32],所以氧化初期以Cr的选择性氧化为主,快速形成大量Cr2O3覆盖在合金表面。同时,尽管基体中的Ti含量低,但900℃下Ti扩散比Cr、Al快[22,33],其扩散系数分别为6.00 × 10-16 [34]、2.46 × 10-16 [17]和7.62 × 10-18 [35] m2/s,所以氧化初始时会生成少量TiO2,其他合金如GH4037[36]、GTD-111[37]、Fe-33Ni-19Cr[38]在氧化初期的外氧化层也会出现TiO2或含Ti氧化物。此外,由于Ni是DZ445合金的基体元素,其含量超过50%,远远大于其他元素,易与O反应产生NiO。随着氧化的进行,NiO会与Cr2O3固相反应生成尖晶石NiCr2O4,因此逐渐形成由NiCr2O4、Cr2O3和TiO2组成的外氧化层。

3.2 次内层的形成及其物相构成

次内层氧化物相种类主要是Al2O3、NiCr2O4和NiO,位于次外层(CrTaO4层)和最内层(Al2O3)之间,它的形成是由其邻接的最内层与次外层对元素的屏障作用和合金元素通过贫γ′层的扩散能力决定的。

首先,最外层和次外层的成分基本上随时间的增长不再发生变化(图3和表3),说明这2层对合金元素的向外扩散起到了很好的屏障作用,尤其是次外层的连续CrTaO4层,之前的研究[13,17,44,45]表明该层的出现能够显著降低氧化速率。这可以通过对比CrTaO4、NiCr2O4、Cr2O3和Al2O3的晶体结构的原子排列致密度来进一步佐证,如图8所示。虽然这几种氧化物晶体结构不同,CrTaO4是金红石结构[46],NiCr2O4是尖晶石结构,Cr2O3与Al2O3 (α-Al2O3)都是刚玉型结构[47],但是其中的O2-都近似密排六方紧密堆积,阳离子填充在八面体间隙或四面体间隙中。CrTaO4结构中的阳离子填充在八面体间隙(图8a),NiCr2O4结构中Cr3+占据晶格中的八面体间隙,Ni2+位于四面体间隙(图8b),Cr2O3和Al2O3 (α-Al2O3)结构中的Cr3+和 Al3+同样占据晶格中的八面体间隙(图8c和d)。Ta5+、Cr3+、Al3+、Ni2+和O2-的离子半径分别为0.064、0.062、0.054、0.069和0.132 nm,Cr2O3、Al2O3、NiCr2O4和CrTaO4的致密度分别为21.33%、20.87%、58.59%和(62.17~62.55)%,CrTaO4的致密度最大,NiCr2O4次之。高的致密度使得其构成原子和其他原子扩散通过它的阻力增大[48],扩散系数减小,扩散激活能增大。因此,CrTaO4层更能有效地抑制Cr、Ti及其他合金元素的向外扩散和O原子的向内扩散,NiCr2O4对原子扩散的屏蔽作用次之,Cr2O3和Al2O3阻止元素扩散作用再次之。

图8

图8

CrTaO4、NiCr2O4、Cr2O3和Al2O3的晶体结构

Fig.8

Crystal structures of oxides CrTaO4 (a), NiCr2O4 (b), Cr2O3 (c), and Al2O3 (d)

其次,次内层的形成也由内部基体中合金元素的扩散驱动力决定,而扩散驱动力与浓度梯度有关。Wagner理论[49]和文献[50]均指出,金属/氧化物界面的氧化反应驱动力为金属与O形成氧化物的自由能变化和氧化膜中成分的浓度梯度。图9是Al、Ni、Cr元素在氧化300和500 h时从最内层(或次内层)到基体的浓度梯度曲线。可见,氧化300和500 h的浓度梯度变化趋势基本一致。在氧化层/基体界面,Ni的浓度梯度最大,Cr次之,Al的浓度梯度为负,这说明此时Ni、Cr从基体向氧化层扩散的扩散驱动力比Al更大,能不断从基体向氧化层扩散。与氧化300 h相比,氧化500 h以后Ni、Cr的浓度梯度减小,表明基体扩散过来的元素含量也在逐步降低。

图9

图9

Al、Ni、Cr元素在氧化300和500 h时从最内层(或次内层)到基体的浓度梯度曲线

Fig.9

Concentration gradient distribution curves of alloy elements Al, Ni, and Cr from the innermost layer (or subinner layer) to the matrix after oxidation for 300 h (a) and 500 h (b)

综上,次内层的形成主要取决于CrTaO4层的屏障作用以及元素的扩散驱动力。从实验结果看,氧化300 h时Ni、Cr的浓度梯度较大,说明此时Ni、Cr在CrTaO4层下分布的含量较低,不足以形成NiCr2O4和NiO,所以氧化膜只有3层结构。随着Ni、Cr逐渐从基体向外扩散,氧化500 h后形成4层氧化膜结构。

3.3 长时间氧化下各层的形成机理及其对氧化速率的影响

从上面分析讨论可以看出,DZ445合金在本工作所研究温度的范围内,氧化膜层形成了多层结构(图3),这是由各个合金元素与O结合的自由能及其浓度以及扩散能力决定的,也正是其成分特点使得氧化动力学随时间的延长发生了变化。

结合之前的工作[17],连续的CrTaO4层形成之前,氧化以Cr、Ni和Ti的扩散过程为主(图10a), 此阶段的n较小(约为2),K较大(1.0 × 10-2 mg2/(cm4·h)),E也较小(325 kJ/mol),表明此时氧化速率较快;CrTaO4层形成之后,氧化过程以O向内的扩散和Al原子向外扩散为主(图10b),此时n增大,K减小一个数量级(1.93 × 10-3 mg3/(cm6·h)),E增大为424 kJ/mol,这源于Al原子在基体和氧化膜中的扩散激活能大于Cr、Ni和Ti[17,43,51~53];随着氧化时间的进一步延长,此时氧化膜和基体贫γ′界面附近Ni、Cr浓度梯度远大于Al原子,于是Ni、Cr原子向Al2O3内层扩散(图10c),Al原子向外扩散的趋势较小,形成富NiCr2O4、NiO和Al2O3的次内层,其颜色较最内层(Al2O3为主)浅(图3),此阶段对应的氧化速率进一步剧烈降低,n增大到25.00,K降低了2个数量级(3.5 × 10-5 mg25/(cm50·h)),E也进一步增大到485kJ/mol,且次内层厚度随氧化时间增加的增大幅度很小,说明次外层和次内层的形成为DZ445合金提供了优异的抗氧化能力。

图10

图10

氧化机理示意图

Fig.10

Schematics of oxidation process

(a) before the formation of CrTaO4 layer

(b) between the formation of CrTaO4 layer and subinner layer

(c) after the formation of subinner layer

4 结论

(1) 高Cr / Al比和中Ta含量的DZ445镍基高温合金在900℃下恒温氧化300 h后,氧化膜由外氧化层、次外层和内层构成;在氧化时间≥ 500 h时,在次外层和最内层之间增加了次内层。最外层氧化物相为NiCr2O4、Cr2O3和TiO2,次外层为CrTaO4和TiO2,次内层为Al2O3、NiCr2O4和NiO,最内层主要是Al2O3。

(2) DZ445合金在氧化初期动力学方程指数为2.17,符合平方规律。随着氧化时间的延长,次外层和次内层逐渐形成,动力学方程指数分别增大到4.17和25.00,激活能也分别增大到424和485 kJ/mol。表明这2层的出现使得氧化速率大幅降低,显著增强了合金的抗氧化能力。

(3) 在初期CrTaO4次外层没形成之前,DZ445合金的氧化过程由合金元素向外扩散控制;在CrTaO4层形成之后由Al的向外扩散和O的向内扩散所控制;次内层形成后,氧化过程转变为Ni、Cr的向外扩散和O的向内扩散所控制。

参考文献

Evolution of interfacial microstructure of Ni-Co based superalloy during plastic deformation bonding and its bonding mechanism

[J].

新型Ni-Co基高温合金塑性变形连接中界面组织演化及愈合机制

[J].为解决镍基高温合金的焊接难题,以新型Ni-Co基高温合金为实验材料,采用塑性变形连接的新方法,实现了新型Ni-Co基高温合金的连接。通过OM、EBSD、TEM等分析手段探究了界面的再结晶行为及界面的愈合机制。结果表明,1150℃进行塑性变形连接时,合金的变形抗力小,不易开裂。不同变形量的连接实验表明,在40%的变形量下,合金可以实现界面的完全愈合,其力学性能达到基体同等水平。在塑性变形过程中,界面附近的粗大晶粒首先发生细化,随着变形量的增加,细化的晶粒在连续动态再结晶的辅助作用下,通过界面晶界的迁移消除了原始连接界面,实现界面的愈合。

Precipitation behavior of W-rich phases in a high W-containing Ni-based superalloys K416B

[J].The high temperature strength of Ni-based cast superalloys can be significantly improved by adding tungsten (W), a solid solution strengthening element. Hence, superalloys with high W content have been developed as key materials for the preparation of aircraft engine blades. However, the high segregation coefficient of W results in inconsistent composition and microstructure during the solidification process, which can be difficult to eliminate via heat treatment leading to deteriorated mechanical properties. The Ni-based superalloy K416B contains approximately 16.5%W (mass fraction) and exhibits a high tendency to precipitate W-rich phases, such as the α-W and M6C phases, which not only consume a large amount of W in the matrix but also reduce the solid solution strengthening ability of the alloy. W-rich precipitates also become the origin and propagation paths of cracks during stress-rupture testing. Much research on high W-containing, Ni-based superalloys has focused on the effects of W content on W-rich phase formation and mechanical properties. However, the roles of casting temperature and cooling rate on the formation of the W-rich phase are still unclear. In this work, five groups of K416B alloy test bars with the same composition were prepared with different processes. Three casting temperatures were chosen, and the cooling rate was controlled by burying sand in the thick shell and single shell, respectively. The relationship between the precipitation behavior of the W-rich phase in the K416B alloy and casting temperature, and solidification rate under different casting processes were analyzed using SEM and EDS. When the casting temperature is lowered from 1500°C to 1450°C, the grain size is significantly reduced. Results show massive α-W phases in the residual eutectic of the alloy at different casting temperatures, and the morphology of the α-W phase show few differences. The larger M6C phase in the alloy exists with residual eutectic, and the small M6C phase is embedded at the edge of the residual eutectic. At a high solidification rate, the precipitation of the W-rich phase is inhibited, which is primarily manifested by the decreased number and size of the W-rich phase in the alloy. When casting high W-containing Ni-based superalloys, choosing an appropriate casting temperature and adopting an appropriate heat preservation system to accelerate the cooling rate during solidification will affect the precipitation and transformation of W-rich phases, and optimize the properties of the alloy.

高钨镍基高温合金K416B富W相的析出行为

[J].研究了K416B合金中富W相的析出行为与合金浇注温度和凝固速率的关系。结果表明,在相同冷却速率下,合金的浇注温度由1500℃降低到1450℃时,晶粒尺寸明显减小。在不同浇注温度下,合金中均有块状α-W相在残余共晶中析出,α-W相形貌差别不大。合金的残余共晶中存在大尺寸的M<sub>6</sub>C相,而残余共晶的边缘处有小尺寸的M<sub>6</sub>C相。高凝固速率时,合金中富W相数量减少、尺寸减小,表明富W相析出受到明显抑制。对于铸造高钨镍基高温合金,选择合适的浇注温度以及保温体系加快凝固初期的冷却速率,可以控制富W相的析出和转变,从而优化合金性能。

Effect of pre-oxidation on high temperature oxidation and corrosion behavior of Co-Al-W-based superalloy

[J].In 2006, stable γ' phase was found in Co-Al-W alloy, which provides a new way for developing Co-based superalloys. In order to meet the requirements for applications, the Co-Al-W-based superalloys need to have good oxidation and corrosion resistance. But the oxidation and corrosion resistance of the Co-Al-W-based superalloys is relatively low. In this work, pre-oxidation treatments were used to improve the oxidation and corrosion resistance. Three types of pre-oxidation treatments were carried out at 900 ℃ (in air), 950 ℃ (in air) and 1000 ℃ (in 1%O2+99%Ar), which were marked as 900-PreO, 950-PreO and 1000-LPreO, respectively. High temperature oxidation tests of both the pre-oxidation treated and untreated superalloys were carried out at 1000 ℃. And hot corrosion behaviors were also investigated at both 800 and 850 ℃. XRD, SEM and EDS were used to examine the characteristics of the oxidation and corrosion behaviors. The results show that the pre-oxide layers of the superalloys after different pre-oxidation treatments are compact. During oxidation at 1000 ℃, the Cr2O3 scale in 900-PreO treated superalloy is oxidized to form volatile products, and the diffusion resistance of both oxygen and the metal elements through the oxide layer is poor. In 1000-LPreO treated superalloy, serious spallation of the oxides occurs and leads to poor oxidation resistance. In 950-PreO treated superalloy, since the continuous CoCr2O4 and Al2O3 scales help to reduce the diffusion of oxygen and the metal elements, the mass gain of 950-PreO treated superalloy is consequently decreased. During the hot corrosion process, the pre-oxide layer of 950-PreO treated superalloy can hinder the diffusion of corrosive medium. Therefore, the corrosion resistance can be significantly improved by 950-PreO treatment, and the mass gain is decreased by over 80%.

预氧化对Co-Al-W基高温合金高温氧化和热腐蚀行为的影响

[J].

Thermal barrier coatings for gas-turbine engine applications

[J].Hundreds of different types of coatings are used to protect a variety of structural engineering materials from corrosion, wear, and erosion, and to provide lubrication and thermal insulation. Of all these, thermal barrier coatings (TBCs) have the most complex structure and must operate in the most demanding high-temperature environment of aircraft and industrial gas-turbine engines. TBCs, which comprise metal and ceramic multilayers, insulate turbine and combustor engine components from the hot gas stream, and improve the durability and energy efficiency of these engines. Improvements in TBCs will require a better understanding of the complex changes in their structure and properties that occur under operating conditions that lead to their failure. The structure, properties, and failure mechanisms of TBCs are herein reviewed, together with a discussion of current limitations and future opportunities.

Review: Mechanism of reactive element effect-oxide pegging

[J].

综述: 活性元素作用机理——氧化物“钉扎”模型

[J].

Preparation and performance of a novel wear-resistant and high temperature oxidation-resistant NiCrAlSiC composite coating

[J].MCrAl (M=Ni, Co, or their combinations) coatings have been widely used as high temperature oxidation protection coatings on turbine blades, as they can thermally grow stable, dense and well adherent Al2O3 protective scales. Due to the particulate nature of the exhaust, MCrAl coatings often fail owing to severe high-temperature wear. To improve the anti-wear resistance of the MCrAl coatings, NiCrAlSiC composite coatings were designed and fabricated by the combination of electrophoretic deposition (EPD) and electrodeposition (ED). The compositions, morphologies and structures of the as-deposited composite coatings were characterized by XRD, SEM, EPMA and TEM. A Ni7.4Cr6.2Al14.3SiC (mass fraction, %) coating, as well as a contrast SiC-free Ni7.2Cr6.2Al coating, was prepared. No cracks or micro pores were found either at the coating/substrate interface or in the coating, and elements distributed uniformly in the coating. Compared to the SiC-free coating, oxide scale on the NiCrAlSiC coating transformed from a three-layered structure (NiO, NiAl2O4 and Al2O3) to a thinner two-layered structure (NiAl2O4 and Al2O3), showing better high temperature oxidation resistance. And microhardness of the NiCrAlSiC coating increased 26%, together with the wear rate reduced 52%. Wear mechanism of the NiCrAl coating was abrasive wear, while that of the NiCrAlSiC coating switched to adhesive wear. These results indicate that the addition of SiC improves both high temperature oxidation resistance and wear resistance of the NiCrAl composite coating obviously.

新型耐磨耐高温氧化NiCrAlSiC复合涂层的制备及性能研究

[J].采用“电泳+电沉积”两步法在金属基体上先预沉积CrAlSiC电泳层,再电沉积Ni,制备了NiCrAlSiC复合涂层,并制备不含SiC的NiCrAl涂层为对比样品。采用XRD、SEM、EPMA和TEM对复合涂层进行形貌、结构和成分表征,并研究其高温氧化性能和摩擦磨损性能。结果表明:复合涂层致密并与基体结合良好,涂层内颗粒分散均匀。与不含SiC的NiCrAl复合涂层相比,NiCrAlSiC复合涂层的氧化膜由NiO、NiAl<sub>2</sub>O<sub>4</sub>和Al<sub>2</sub>O<sub>3</sub>三层结构转变为NiAl<sub>2</sub>O<sub>4</sub>和Al<sub>2</sub>O<sub>3</sub>两层结构,且氧化膜更薄;同时,涂层硬度提高26%,磨损速率下降52%,磨损机制由磨粒磨损转变为黏着磨损。SiC颗粒的加入同时提高了NiCrAl涂层的抗高温氧化性能和耐磨性能。

Oxidation of Ni-Cr-Al alloys between 1000 and 1200℃

[J].

Resistance of Ni-Cr-Al alloys to cyclic oxidation at 1100 and 1200oC

[J].

Effects of Cr+ ion implantation on the oxidation of Ni3Al

[J].

Effect of Ti and Ta on the oxidation of a complex superalloy

[J].

High temperature oxidation resistance of Ni-(5~13)Co-(10~16)Cr-(5~9)W-5Al-(1~1.5)Ti-(3~6)Ta alloys

[J].

Statistics of oxidation resistance of Ni-(0-15)Co-(8-15)Cr-(0-5)Mo-(0-10)W-(3-8)Al-(0-5)Ti-(0-10)Ta-0.1C-0.01B superalloys at 1000oC by compositional variations

[J].

Influence of Ta content on hot corrosion behaviour of a directionally solidified nickel base superalloy

[J].

Effects of Al and Ta on the high temperature oxidation of Ni-based superalloys

[J].

Mechanism of the oxidation and degradation of the aluminide coating on the nickel-base single-crystal superalloy DD32M

[J].

Effect of Sm, Gd, Yb, Sc and Nd as reactive elements on oxidation behaviour of β-NiAl at 1200oC

[J].

The influence of CrTaO4 layer on the oxidation behavior of a directionally-solidified nickel-based superalloy at 850-900oC

[J].

High temperature oxidation behaviors of two Ni-Co-Cr-Al-Si-Y coatings deposited by arc ion palting

[J].

两种电弧离子镀Ni-Co-Cr-Al-Si-Y涂层的高温氧化行为

[J].采用电弧离子镀技术在镍基高温合金DD32上制备了两种不同Cr和Al含量的Ni-Co-Cr-Al-Si-Y涂层, 分析了两种涂层的组织及结构, 对比研究了两种涂层分别在1000和1100℃时的静态氧化行为和从1000 ℃到室温的循环氧化行为. 结果表明: 退火后两种涂层均由γ'/γ, β-NiAl以及少量α-Cr析出相组成, 但Al含量高的Ni-Co-Cr-Al-Si-Y涂层含更多的β相. 氧化过程中由于高Al涂层具有较多的Al储存相, 在恒温氧化时能有效修复被破坏的氧化膜, 在循环氧化时氧化膜不易开裂和剥落,在长时间氧化后仍能保持较高的Al含量, 使得涂层能抵抗更长时间的高温氧化.

Spallation and transient oxide growth on PWA 1484 superalloy

[J].

Long-term oxidation behavior and mechanism of DD6 Ni-based single crystal superalloy at 1050oC and 1100oC in air

[J].

Oxidation behavior and mechanism of powder metallurgy Rene95 nickel based superalloy between 800 and 1000oC

[J].

Oxidation behavior of GH984G alloy in steam at 700oC

[J].

GH984G合金在700℃水蒸气中的氧化行为

[J].从氧化动力学、氧化层相组成及微观结构角度,研究了700 ℃超超临界电站用Ni-Fe-Cr基合金GH984G在700 ℃水蒸气中的氧化行为。结果表明:氧化行为符合抛物线规律,氧化过程受扩散控制,稳态增重速率约为8×10<sup>-4</sup> g/(m<sup>2</sup>·h),为完全抗氧化级。氧化过程中首先在基体表面形成Cr<sub>2</sub>O<sub>3</sub>外氧化层,随后形成根状Al<sub>2</sub>O<sub>3</sub>内氧化层并在Cr<sub>2</sub>O<sub>3</sub>外氧化层表面形成少量粒状TiO<sub>2</sub>,最终形成外层Cr<sub>2</sub>O<sub>3</sub>、内层Al<sub>2</sub>O<sub>3</sub>的双层结构,长达2000 h蒸汽氧化过程中无其它氧化物形成且氧化层具有优异的稳定性。氧化初期氧化层表面Cr<sub>2</sub>O<sub>3</sub>为针片状,随后针片状Cr<sub>2</sub>O<sub>3</sub>发生团聚转变为胞状Cr<sub>2</sub>O<sub>3</sub>,进一步延长氧化时间胞状Cr<sub>2</sub>O<sub>3</sub>发生连接,转变为连续、致密的Cr<sub>2</sub>O<sub>3</sub>外氧化层。连续、致密且稳定的Cr<sub>2</sub>O<sub>3</sub>外氧化层和根状Al<sub>2</sub>O<sub>3</sub>内氧化层的氧化层结构使GH984G合金在700 ℃蒸汽条件下具有较低氧化速率和优异抗氧化性。

High-temperature oxidation of FGH96 P/M superalloy

[J].

Isothermal oxidation behavior of DZ125 alloy

[J].

DZ125合金抗高温氧化性能研究

[J].

On the oxidation mechanism of refractory high entropy alloys

[J].

The cyclic oxidation behavior of the single crystal TMS-82+ superalloy in humidified air

[J].

High temperature oxidation behaviour of γ'-strengthened Co-based superalloys with different Ni addition

[J].High temperature oxidation behaviours of gamma'-strengthened Co-based superalloys with various Ni additions were investigated at both 800 degrees C and 900 degrees C. The results show that the superalloys show excellent oxidation resistance due to the formation of compact spinel oxide scales. With the increasing of Ni addition, the concentration of Cr in scale/alloy interface will be increased but that of Co will be decreased. And the growth of Cr2O3 will be promoted, while CoO nucleation will be hindered. Therefore, increasing Ni addition helps the formation of protective spinel oxide scales and delays nodular oxidation, which favours to be better oxidation resistance.

Effect of chromium on the protective properties of aluminide coatings

[J].

Role of volatilization of molybdenum oxides during the cyclic oxidation of high-Mo containing Ni-based single crystal superalloys

[J].

Statistical study of the effects of the composition on the oxidation resistance of Ni-Based superalloys

[J].

Isothermal oxidation behaviour of a Ni-base superalloy at 900 and 1000oC

[J].

一种镍基合金在900和1000℃的高温氧化行为

[J].

Isothermal oxidation behavior of Ni-Al-Co-Cr-Mo-Ti alloy at 850oC and 950oC

[J].

Ni-Al-Co-Cr-Mo-Ti合金在850℃和950℃的氧化行为

[J].

Oxidation behavior of GTD111 Ni-based superalloy at 900oC in air

[J].

Analysis of the homogenization of a nickel-base superalloy

[J].

Intrinsic diffusion in Ni3Al system

[J].

High temperature oxidation behavior of the wrought Ni-based superalloy GH4037 in the solid and semi-solid state

[J].

The cyclic oxidation behaviour of Ni-based superalloy GTD-111 with sulphur impurities at 1100oC

[J].

High temperature cyclic oxidation of Ni-based 800H superalloy at 700oC in air

[A].

Oxidation of nickel-based single-crystal superalloys for industrial gas turbine applications

[J].

Interdiffusion in the face-centred cubic phase of the Ni-Re, Ni-Ta and Ni-W systems between 900 and 1300oC

[J].

Oxidation behavior of a single-crystal Ni-based superalloy over the temperature range of 850oC-900oC in air

[J].

Isothermal oxidation behavior of DZ792 superalloy

[D].

DZ792合金的恒温氧化行为研究

[D].

Diffusion of titanium of single crystal rutile

[J].

A new strategy to intrinsically protect refractory metal based alloys at ultra high temperatures

[J].

An oxidation resistant refractory high entropy alloy protected by CrTaO4-based oxide

[J].

Cation ordering/disordering effects upon photocatalytic activity of CrNbO4, CrTaO4, Sr2CrNbO6 and Sr2CrTaO6

[J].

Crystal structure and valence electron structure of α-Al2O3

[J].

α-Al2O3的晶体结构与价电子结构

[J].

High-temperature oxidation of a single crystal Ni-base superalloy

[J].

The self-diffusion of Ni in NiO and its relevance to the oxidation of Ni

[J].