对于金属材料而言,其晶粒尺寸与屈服强度符合Hall-Petch关系。与bcc及fcc结构金属相比,镁合金的Taylor因子更高,使得镁合金具有较大的Hall-Petch系数,因此,细晶强化成为改善镁合金力学性能有效的方法之一[4]。通过塑性变形将晶粒尺寸细化至几个微米甚至亚微米形成的超细晶组织,能够显著提高镁合金的力学性能。剧烈塑性变形法(severe plastic deformation,SPD)是制备超细晶镁合金常用的工艺,其中研究较多的SPD工艺包括等径角挤压[5]、多向锻造[6]、搅拌摩擦加工[7]、高压扭转[8]等。SPD通常以变形态的块体镁合金为原材料,再对其进行多道次塑性变形,方能制备出超细晶镁合金,因此,该工艺流程较长。例如Tang等[9]对挤压态AZ80镁合金进行6道次的等径角挤压将晶粒尺寸细化到0.6 μm。Miura等[10]在室温下对挤压态AZ61镁合金进行多达25道次的多向锻造,制备出晶粒尺寸为0.6 μm的超细晶镁合金。

与SPD工艺不同,粉末冶金(powder metallurgy,PM)工艺以快速凝固制备的镁合金粉末为原材料,经过烧结后,只需要一次塑性变形就能够获得超细晶镁合金,因此,PM工艺越来越受到人们的关注。前期工作[11]利用粉末冶金工艺制备的AZ91超细晶镁合金,经过一次挤压其晶粒尺寸细化到552 nm,拉伸屈服强度为332 MPa,伸长率为10%。Inoue等[12]利用快速凝固及粉末冶金工艺,经过一次挤压制备出的Mg97Zn1Y2超细晶镁合金,其晶粒尺寸能够细化到150 nm以下,拉伸屈服强度达到610 MPa,伸长率为5%。对镁粉进行球磨处理能够细化镁粉的晶粒尺寸,如Taleghani和Torralba[13]对AZ91镁粉进行机械球磨处理,使得其晶粒尺寸细化至25 nm,但同时也发现,球磨处理还会引起Mg17Al12析出相的固溶。Yu等[14]也在球磨处理AZ61镁粉中发现了相同的现象。但他们没有研究球磨处理后的粉体对块体镁合金中Mg17Al12析出相及力学性能的影响。值得注意的是,近期有研究[15~18]发现Mg-Al-Zn系镁合金在塑性变形过程中形成的高密度位错能够诱发Mg17Al12的动态析出,其尺寸能够细化到亚微米甚至100 nm以下,从而提高镁合金的力学性能。如Zhu等[18]利用粉末冶金工艺制备超细晶Mg-7.5Al-0.8Zn合金,通过降低挤压温度来促进Mg17Al12的动态析出,其尺寸小于100 nm。因此,以球磨处理后的镁粉为原材料,利用粉末冶金工艺制备超细晶镁合金有望进一步提高镁合金的性能,但目前对球磨后镁粉制备镁合金的相关研究仍然匮乏。

为了研究球磨处理后的粉体对镁合金晶粒尺寸、析出相及力学性能的影响,本工作通过机械球磨与粉末冶金工艺相结合制备AZ61超细晶镁合金,并对其微观组织、室温力学性能及其强化机制进行分析和讨论,以期制备出综合力学性能优良的超细晶镁合金。

1 实验方法

使用的原材料为雾化法生产的AZ61镁合金粉末,其化学成分(质量分数,%)为:Al 5.9~6.0,Zn 0.7~1.5,Mn 0.15~0.4,Si ≤ 0.1,Cu ≤ 0.05,Fe ≤ 0.05,Ni ≤ 0.05,Mg余量。

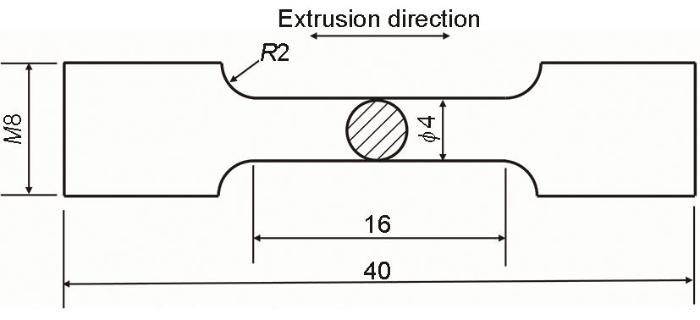

粉末冶金工艺制备超细晶AZ61镁合金的工艺如下:首先,用DYXQM-12L型球磨机将质量为100 g的AZ61镁合金粉末进行球磨,球料比20∶1,公转速率为200 r/min,先正转15 min后反转15 min,然后暂停20 min散热,总球磨时间为600 min。为了防止球磨过程中镁粉发生氧化,对其抽真空后充入Ar气进行保护。将镁粉放入钢制模具在真空热压烧结炉中加热到200℃进行低温烧结,为了得到致密的烧结坯,烧结过程中保压压力为100 MPa,保温保压时间1.5 h,得到直径45 mm的AZ61烧结坯。随后将烧结坯加热至300℃后在四柱液压机上进行热挤压,挤压比为20∶1,得到直径10 mm表面光滑的挤压棒材。采用直径4 mm、长度16 mm、M8螺纹的拉伸试样(如图1所示),在Instron-5982型电子万能材料试验机上进行拉伸实验,拉伸速率0.2 mm/min,每组样品测3个试样,取平均值,拉伸方向平行于挤压方向。利用带能谱仪(EDS)的Merlin Compact扫描电子显微镜(SEM)对镁粉形貌、挤压态镁合金横截面的显微组织及拉伸断口进行观察,并利用Image J软件对Mg17Al12的尺寸及体积分数进行统计(统计个数为150~200个);采用DMI3000金相显微镜(OM)观察烧结后镁合金横截面的形貌;通过D8 Advance X射线衍射仪(XRD,扫描速率0.02°/s,扫描范围为20°~90°,电压40 kV,电流40 mA)对镁粉进行物相分析,并对挤压态AZ61镁合金的纵截面进行宏观织构测试;采用JEM-2100F透射电镜(TEM)对挤压态AZ61镁合金的显微组织进行观察,利用Digital Micrograph软件通过截距法测量晶粒尺寸。

图1

2 实验结果与讨论

2.1 镁粉形貌及XRD分析

图2

图2

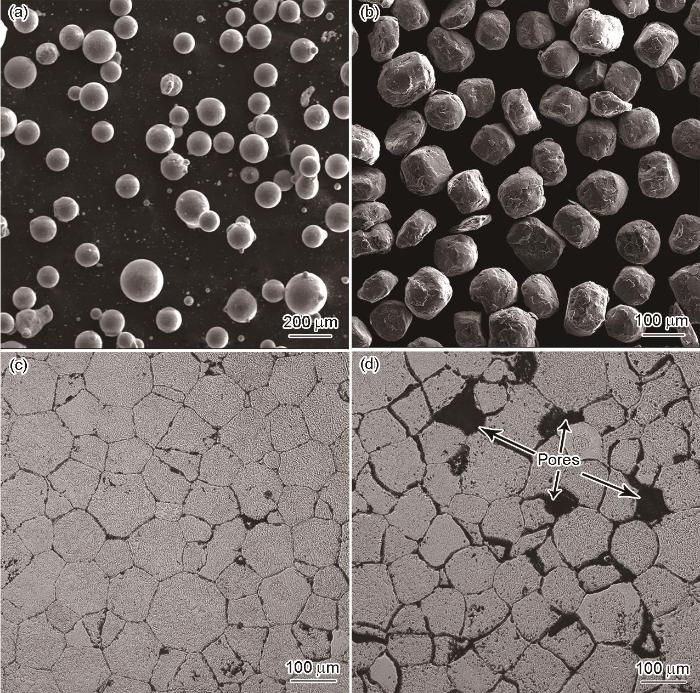

球磨前后AZ61镁粉的SEM像及烧结后AZ61镁合金的OM像

Fig.2

SEM images of raw AZ61 powder (a), mechanically milled AZ61 powder (b); and OM images of sintered raw AZ61 powder (c), sintered mechanically milled AZ61 powder (d)

图2c和d为球磨前后的AZ61镁粉经过烧结之后的OM像。由图2c可见,未经球磨处理的烧结样品中,粉体由烧结前的球状变为以六边形为主,这是由于烧结过程中在压力的作用下使得镁粉产生塑性变形所致;另外,由于原始镁粉尺寸并不均匀,因此,烧结过程中尺寸较小的颗粒能够有效地填充到尺寸较大的镁粉之间,这使得镁粉排列相对紧密。由图2d可见,球磨处理后的烧结样品中,其粉体呈不规则形状,部分形状相对圆润,尺寸较均匀,基本保持了烧结前的特征,这说明烧结过程中压力的作用并未明显改变粉体的形状,而且在制备金相试样过程中该样品中有明显的粉体脱落现象,如图2d中箭头所示为粉体脱落后形成的孔洞,说明球磨处理的烧结样品的致密度不及未经球磨处理的样品。这主要是由于一方面球磨使得粉体的尺寸变得更加均匀,因此,颗粒之间形成的较小的空隙无法得到有效的填充;另一方面,球磨使得粉体产生塑性变形,形成加工硬化效应,增加了粉体硬度,导致烧结过程中变形困难,难以形成有效的流动从而填补粉体之间的空隙。因此,烧结后样品需要通过挤压变形提高其致密性及力学性能。

图3a为球磨前后AZ61镁合金粉末的XRD谱。AZ61镁粉球磨前后都由α-Mg及β-Mg17Al12相组成。经过球磨之后,(

图3

图3

球磨前后AZ61镁粉及烧结后AZ61镁合金的XRD谱

Fig.3

XRD spectra of AZ61 powder (Inset shows the locally high magnification of Fig.3a) (a) and sintered AZ61 alloy (b)

2.2 挤压态AZ61镁合金显微组织分析

图4

图4

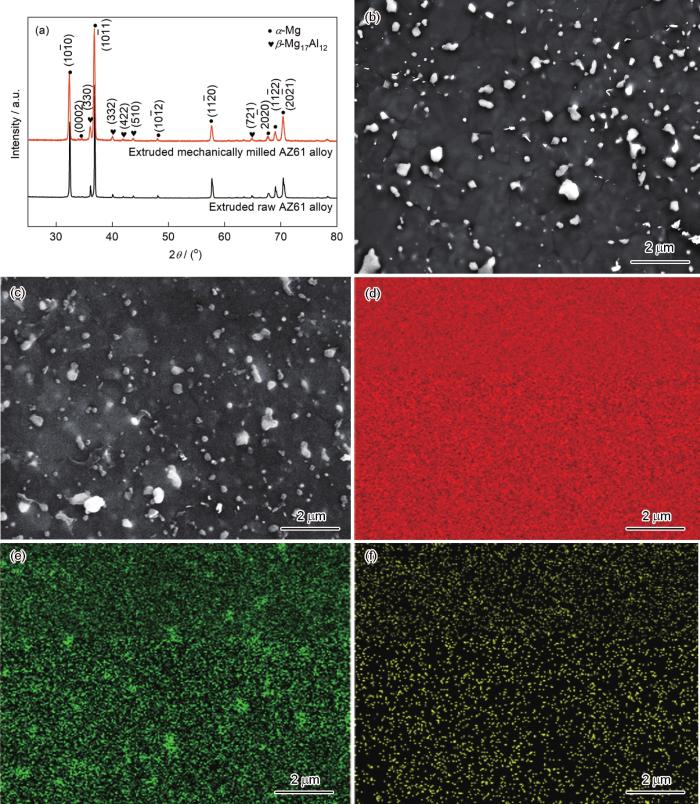

挤压态AZ61镁合金的XRD谱、SEM像及EDS分析

Fig.4

XRD spectra (a) and SEM images of extruded AZ61 alloy without (b) and with (c) mechanical milling, and EDS elemental maps of Mg (d), Al (e), and Zn (f) in Fig.4c

表1 挤压态AZ61镁合金的晶粒尺寸、析出相体积分数及析出相尺寸

Table 1

| Extruded AZ61 alloy | Grain size / μm | Diameter of Mg17Al12 / nm | Volume fraction of Mg17Al12 / % |

|---|---|---|---|

| Without mechanical milling | 0.91 | 230 | 6.6 |

| With mechanical milling | 0.68 | 170 | 11.7 |

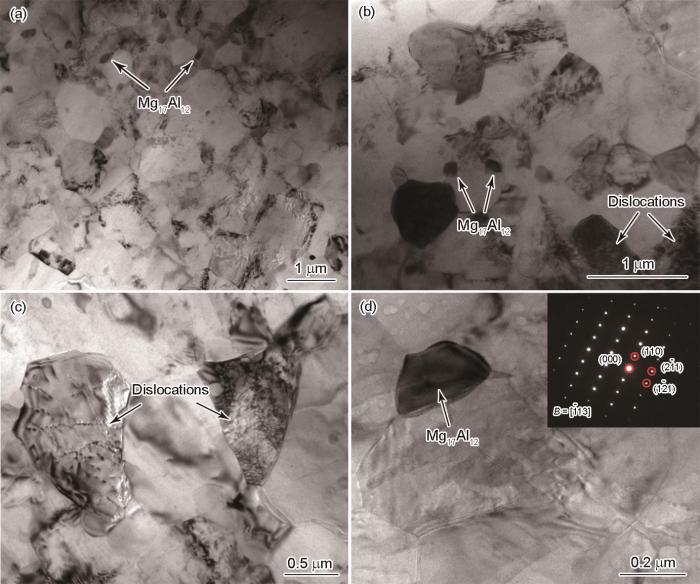

图5为挤压态AZ61镁合金的TEM像。由图5a可见,未经球磨处理的AZ61镁合金中的晶粒主要为等轴晶,晶界清晰,大部分晶粒已经再结晶完全,平均晶粒尺寸约为0.91 μm,但个别晶粒内部有残存的位错,如图5c中箭头所示。经过球磨处理后,晶粒尺寸有所减小,其平均尺寸约为0.68 μm,部分晶粒再结晶不完全,且晶粒内部存在的位错密度较高(图5b),这与球磨处理导致的镁粉的晶格畸变及晶粒细化有关。球磨处理使得晶格畸变及位错密度增加,当位错密度达到临界值时,较大晶粒被小角度晶界分割为亚晶,从而细化晶粒[14]。一般而言,再结晶晶粒尺寸与初始晶粒尺寸呈正相关性,即初始晶粒尺寸越细,再结晶晶粒尺寸也越细。因此,球磨处理后镁合金的晶粒尺寸也更细小。由表1可知,球磨处理后Mg17Al12的体积分数有所增加,提高了再结晶的形核率,也会导致再结晶晶粒尺寸变小。析出相体积分数的增加以及颗粒尺寸的减小与位错密度的增加有关。球磨处理及挤压变形导致晶粒内位错密度与空位增加,为Al原子在Mg基体中的扩散提供了更多通道,促进了Mg17Al12的动态析出,使得析出相的体积分数增加[15]。对AZ61镁合金TEM组织中的细小相进行选区电子衍射(SAED)分析,对衍射斑点进行标定,结果表明其为Mg17Al12析出相(图5d中插图)。对图5a和b中析出相的尺寸进行测量发现,未进行球磨处理的析出相的平均尺寸为230 nm,经过球磨之后析出相的平均尺寸为170 nm,说明球磨能够细化析出相的尺寸,与图4中SEM观察的结果吻合。TEM组织观察表明Mg17Al12主要分布于晶界上,少量分布于晶粒内部。这是由于Al溶质原子在Mg中沿晶界的扩散系数高于晶内扩散系数,使得Mg17Al12沿晶界具有更高的形核率,因此,促进其沿晶界的析出[19]。分布于晶界上的Mg17Al12对晶界具有钉扎作用,能够阻止再结晶晶粒长大[20]。球磨处理的镁合金具有更多的Mg17Al12析出相,因此,这种钉扎作用更强,导致晶粒尺寸更小。

图5

图5

挤压态AZ61镁合金的TEM像

Fig.5

Low (a, b) and high (c, d) magnified TEM images of extruded AZ61 alloy without (a, c) and with (b, d) mechanical milling (Inset in Fig.5d shows the selected area electron diffraction pattern of the precipitates at grain boundaries)

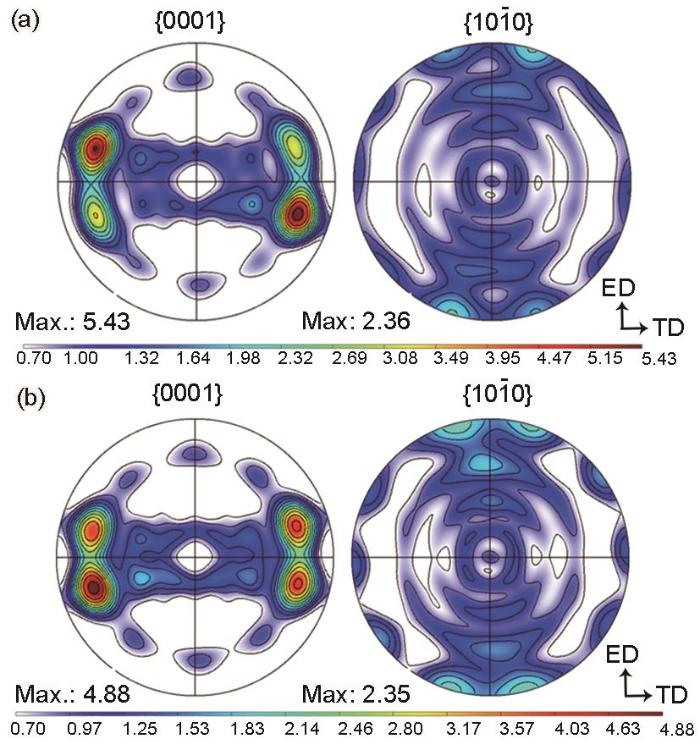

图6

图6

挤压态AZ61镁合金的织构

Fig.6

{0001} and {

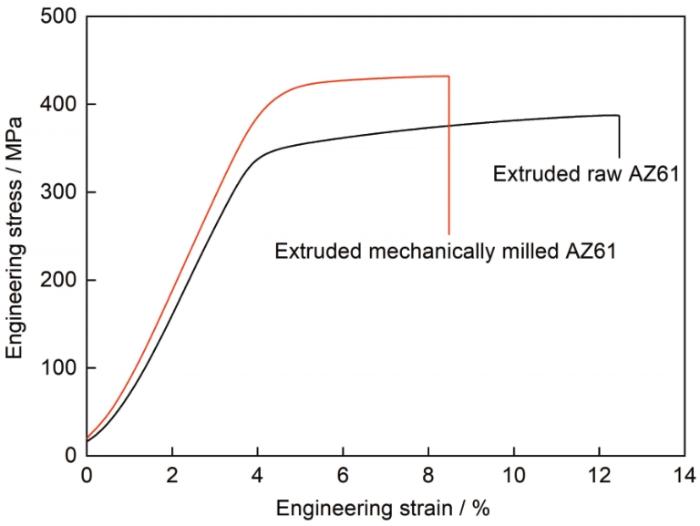

2.3 力学性能

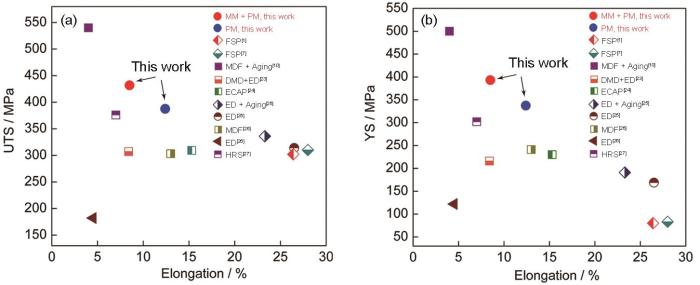

对挤压后的AZ61镁合金进行室温拉伸性能测试,工程应力-应变曲线如图7所示。未经球磨的镁合金的屈服强度、抗拉强度和伸长率分别为337.4 MPa、387.5 MPa和12.4%;经过球磨处理之后屈服强度、抗拉强度和伸长率分别为393.1 MPa、431.9 MPa和8.5%。由此可见,球磨处理使得材料的屈服强度及抗拉强度明显增加,分别提高了16.5%和11.4%,但伸长率有所下降。球磨处理后的AZ61镁合金的强度接近10%SiCp/AZ91 (体积分数)复合材料的强度(屈服强度及抗拉强度分别为371.5和443.9 MPa),但伸长率是10%SiCp/AZ91复合材料的3倍[22]。图8为本工作和其他文献报道[1,7,10,23~27]的不同工艺制备的AZ61镁合金的室温力学性能的统计结果。可见,本工作制备的AZ61镁合金的抗拉强度及屈服强度均高于其他制备工艺,仅低于室温多向锻造工艺制备的AZ61镁合金的强度,但其伸长率较低,仅为本工作AZ61镁合金的1/2~1/3。因此,利用机械球磨及粉末冶金工艺能够制备综合力学性能优良的AZ61超细晶镁合金。

图7

图7

挤压态AZ61镁合金的室温拉伸性能

Fig.7

Tensile stress-strain curves of extruded AZ61 alloy at room temperature

图8

图8

本工作和其他文献报道[1,7,10,23~27]的 AZ61镁合金室温力学性能比较

Fig.8

Comparisons of mechanical properties of this work and other reported[1,7,10,23-27] AZ61 alloys at room temperature (UTS—ultimate tensile strength; YS—yield strength; MM—mechanically milled; PM—powder metallurgy; FSP—friction stir process; MDF—multi-directionally forged; DMD—disintegrated metal deposition; ED—extruded; ECAP—equal channel angular pressing; HRS—hot rotary swaging)

(a) UTS (b) YS

2.4 强化机制分析

由图7可知,经过球磨处理后挤压态AZ61镁合金的屈服强度由337.4 MPa增加到了393.1 MPa,屈服强度的提高归因于细晶强化及Orowan强化。细晶强化机制的贡献通过Hall-Petch公式进行计算:

式中,ΔσH-P为细晶强化机制对屈服强度的贡献,d为晶粒尺寸,σ0为材料晶格间的摩擦力(MPa),k为Hall-Petch系数(MPa·μm1/2)。纯Mg的σ0及k分别为25 MPa和290 MPa·μm1/2[28]。

Orowan强化机制主要是由于Mg17Al12析出相的存在导致的,其贡献用Orowan-Ashby公式进行计算[29]:

式中,ΔσOrowan为Orowan强化机制对屈服强度的贡献,G为剪切模量(Mg为16.7 GPa),b为基面滑移的Burgers矢量模(Mg为0.3196 nm),dp为析出相的平均尺寸,颗粒间距λ的表达式为[29]:

式中,fβ 为析出相的体积分数。

将表1中的数据带入式(

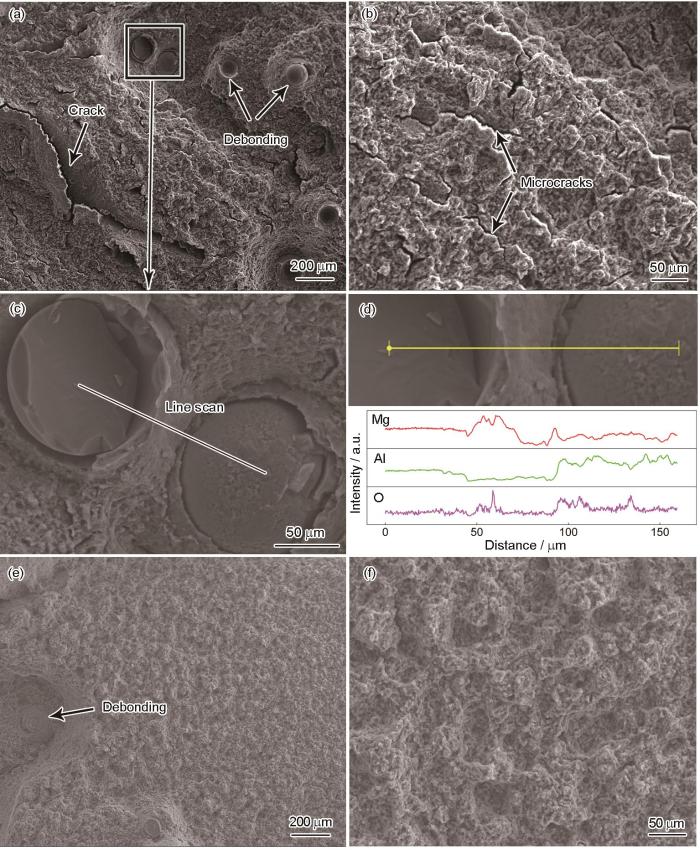

2.5 断口分析

图9为挤压态AZ61镁合金拉伸断口形貌的SEM像。由图9a可见,未经球磨的挤压态样品的拉伸断口高低不平,并伴有较大的裂纹;高倍组织中可以看到有大量的微观裂纹(图9b中箭头所示),说明材料在断裂之前经过了较大的塑性变形。另外,断口中存在镁合金粉体脱黏的现象(图9a中箭头所示),说明虽然经过了热挤压变形,部分粉体之间仍然结合较弱。对图9a中方框标识的脱黏区域进行EDS线扫描(图9c和d),结果表明镁粉内部没有O元素的富集,但脱黏粉体的表面存在O元素的富集,这说明镁粉表面的氧化是导致粉体脱黏的主要原因。从图9e可见,经过球磨处理之后,拉伸断口整体相对平整,粉体脱黏的现象明显减少;图9f所示的高倍组织中没有发现微观裂纹。球磨处理会打破镁粉表面的氧化膜,提高粉体之间的结合力,但断口中仍能观察到个别粉体的脱黏(图9e中箭头所示),并且与周围断口存在较大的高差,说明脱黏的粉体与周围组织存在较大的变形不匹配,这是导致镁合金伸长率下降的原因之一。另外,分布于晶界上的Mg17Al12析出相也会降低镁合金的伸长率[31],球磨处理使得晶界上Mg17Al12析出相数量增加,这是导致伸长率下降的另一重要因素。

图9

图9

挤压态AZ61镁合金拉伸断口的SEM像

Fig.9

SEM fractographs of extruded AZ61 alloy without (a-c) and with (e, f) mechanical milling, and EDS along the line in Fig.9c (d)

3 结论

(1) 球磨处理使得AZ61镁粉由规则的球状形貌转变为不规则的颗粒状,但尺寸更加均匀;球磨引起晶格畸变导致Mg的(

(2) 球磨及粉末冶金制备的AZ61镁合金与未经球磨处理制备的镁合金相比,其晶粒尺寸由0.91 μm细化到0.68 μm;且球磨处理促进了Mg17Al12的动态析出,其体积分数由6.6%增加到11.7%,颗粒尺寸由230 nm细化到170 nm;同时弱化了基面织构。

(3) 经过球磨处理之后AZ61镁合金的屈服强度、抗拉强度分别为393.1和431.9 MPa,相较于未经球磨处理镁合金的强度分别提高了16.5%和11.4%。对细晶及Orowan强化机制进行理论分析,表明细晶强化是AZ61超细晶镁合金的主要强化机制,其贡献达到90%以上,沿晶界分布的Mg17Al12会降低Orowan强化效果,基面织构的弱化也会降低屈服强度。

(4) 球磨处理使得AZ61镁合金的伸长率由12.4%降低到8.5%。未经球磨处理的镁合金的断裂机制是由于镁粉表面的氧化引发粉体脱黏而导致的。经球磨处理的镁合金断裂的原因在于脱黏的粉体与周围组织存在较大的变形不匹配以及晶界上Mg17Al12析出相数量的增加。

参考文献

Tensile properties of AZ61 magnesium alloy produced by multi-pass friction stir processing: Effect of sample orientation

[J].

Effects of homogenization time on aging behavior and mechanical properties of AZ91 alloy

[J].

High strength Mg-9Al serial alloy processed by slow extrusion

[J].

Achieving high strength and high ductility in magnesium alloys using severe plastic deformation combined with low-temperature aging

[J].

Microstructure and anisotropic mechanical behavior of the high-strength and ductility AZ91 Mg alloy processed by hot extrusion and multi-pass RD-ECAP

[J].

Deformation mechanism and dynamic recrystallization of Mg-5.6Gd-0.8Zn alloy during multi-directional forging

[J].Multi-directional forging (MDF) is an effective way to fabricate wrought magnesium alloy with ultrafine grains and random texture. Therefore, microstructure evolution and dynamic recrystallization (DRX) of magnesium alloys during MDF process have been widely investigated. Mg-Zn-RE alloys containing long-period stacking ordered (LPSO) phase have received considerable attention owing to their excellent mechanical properties. In addition, LPSO phase has great effects on the deformation mechanism and DRX behavior. Still, limited comprehensive studies can be found in the literature dealing with the microstructure evolution, deformation mechanism and DRX of magnesium alloys containing LPSO phase in MDF deformation. In this work, MDF was applied to a Mg-5.6Gd-0.8Zn (mass fraction, %) alloy containing LPSO phase. Microstructure characteristics, deformation mechanism and DRX behavior of the material in different passes were examined. Results show that there are several stages of the microstructure evolution. Twinning was activated only in a small part of grains in the early stage of deformation. As the forging direction changes, the number of twinned grains and the volume fraction of DRX grains increased. A mixed structure with coarse deformed grain and DRX grains was sustained till last forging pass, and the average size of DRX grains is about 4 μm with a random orientation. {101ˉ2} tensile twinning is the main deformation mechanism and the selection of twin variants was dominated by the Schmid law. Change in forging direction is beneficial to twinning stimulation in grains of different orientations. Kink and slipping deformation could effectively accommodate the plastic strain where the operation of twinning was hindered. Kink deformation resulted in lattice rotation predominately about the <101ˉ0> axis. DRX grains nucleated at different places during the forging process. Not only the grain boundaries and the twinned region, but also kink boundaries can induce the nucleation of DRX grains. Eventually, the twinned regions were transformed to a strip-like recrystallization structure. Under the combined influence of twinning and kinking, as well as DRX induced by twins, kink bands and grain boundaries, the initial coarse grains were significantly refined.

Mg-5.6Gd-0.8Zn合金多向锻造过程中的变形机制及动态再结晶

[J].

Enhancing mechanical properties of AZ61 magnesium alloy via friction stir processing: Effect of processing parameters

[J].

Achieving ultra-high hardness of nanostructured Mg-8.2Gd-3.2Y-1.0Zn-0.4Zr alloy produced by a combination of high pressure torsion and ageing treatment

[J].

Enhanced strength and ductility of AZ80 Mg alloys by spray forming and ECAP

[J].

Effect of ageing on microstructure and mechanical properties of a multi-directionally forged Mg-6Al-1Zn alloy

[J].

Microstructure and mechanical properties of carbon nanotubes (CNTs) reinforced AZ91 matrix composite

[J].Magnesium alloys are well known for their low density, high specific strength. However, they are often limited by unsatisfactory mechanical properties. To meet the challenge of growing demand for light structural applications, metal matrix composites (MMCs) have attracted more attention. Carbon nanotubes (CNTs) have attracted much attention as the ideal reinforcements for MMCs due to their excellent mechanical strength and Young's modulus. In this work, 0.1%CNTs/AZ91 (mass fraction) magnesium matrix composites were prepared by low temperature powder metallurgy and hot extrusion. The magnesium alloy and composites were observed and analyzed by SEM, XRD and TEM. The room temperature mechanical properties of the composites were tested by Instron 5982 machine. The results showed that the CNTs distributed uniformly in the composites. The CNTs have an effect on reducing grain size, promoting precipitation of β-Mg17Al12 and weakening basal texture. The compressive strength and yield strength of the composites reached 617 and 445 MPa, which increased by 8.8% and 7.2%, respectively. The tensile strength and yield strength were 393 and 352 MPa, which 4.5% and 6.0% MPa higher than the matrix, respectively. It can be found that fine grain strengthening and load transfer play a leading role in improving the strength in the 0.1%CNTs/AZ91 magnesium matrix composites.

碳纳米管(CNTs)增强AZ91镁基复合材料组织与力学性能研究

[J].采用低温粉末冶金及热挤压工艺制备了具有超细晶组织的0.1%CNTs/AZ91 (质量分数)镁基复合材料。通过SEM、XRD、TEM对镁基复合材料的微观组织进行了表征,并对其室温力学性能进行测试。结果表明:CNTs在复合材料中分布均匀,CNTs的加入使得复合材料的晶粒尺寸从0.552 μm细化到0.346 μm,并促进了β相的析出,同时弱化了基面织构。复合材料的抗压强度和屈服强度分别达到了617和445 MPa,较基体提高了8.8%和7.2%;其抗拉强度和屈服强度分别达到了393和352 MPa,与基体相比分别提高了4.5%和6.0%。对强化机制进行分析,发现细晶强化和载荷传递是0.1%CNTs/AZ91复合材料的主要强化机制。

Novel hexagonal structure and ultrahigh strength of magnesium solid solution in the Mg-Zn-Y system

[J].

The microstructural evolution of a pre-alloyed AZ91 magnesium alloy powder through high-energy milling and subsequent isothermal annealing

[J].

The effect of Ti addition on microstructure evolution of AZ61 Mg alloy during mechanical milling

[J].

Prominent role of high-volume fraction Mg17Al12 dynamic precipitations on multimodal microstructure formation and strength-ductility synergy of Mg-Al-Zn alloys processed by hard-plate rolling (HPR)

[J].

Dynamic precipitation and recrystallization in Mg-9wt.%Al during equal-channel angular extrusion: A comparative study to conventional aging

[J].

Increasing strength and ductility of a Mg-9Al alloy by dynamic precipitation assisted grain refinement during multi-directional forging

[J].

Super-high strength Mg-7.5Al-0.8Zn alloy prepared by rapidly solidified powder metallurgy and low temperature extrusion

[J].

Grain boundary diffusion of Al in Mg

[J].

Microstructure and mechanical properties of AZ91 magnesium alloy developed by spark plasma sintering

[J].

Influence of second-phase precipitates on the texture evolution of Mg-Al-Zn alloys during hot deformation

[J].

High strength SiCp/AZ91 composite assisted by dynamic precipitated Mg17Al12 phase

[J].

Effect of addition of Nano-Al2O3 and copper particulates and heat treatment on the tensile response of AZ61 magnesium alloy

[J].

Mechanical properties and structure of AZ61 magnesium alloy processed by equal channel angular pressing

[J].

Microstructure and tensile properties of AZ61 alloy sheets processed by high-ratio extrusion with subsequent direct aging treatment

[J].

Microstructures and mechanical properties of AZ61 magnesium alloy after isothermal multidirectional forging with increasing strain rate

[J].

Microstructure and mechanical properties of AZ61 alloy processed by rotary swaging

[J].

热旋锻对AZ61镁合金显微组织与力学性能的影响

[J].

Effect of deformation temperature on Hall-Petch relationship registered for polycrystalline magnesium

[J].

Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength

[J].

Microstructure and mechanical properties of Mg-Al-Zn alloy sheets severely deformed by asymmetrical rolling

[J].