随着中青年骨创伤增多和人口老龄化加剧,生物医用材料需求增长迅速。理想的生物医用钛合金材料需具有生物相容性、低弹性模量、高耐腐蚀性能和良好的生物活性等[1]。生物医用钛合金,尤其是Ti6A14V材料因其良好的力学性能、抗腐蚀性和生物相容性,在临床上被广泛应用于人体骨和牙缺损的修复。然而,由于自身的生物惰性,植入体与骨组织之间的生物结合能力不够理想,易因相互磨损发生松动甚至脱落,引起周围组织发炎等问题[2]。而且由于现工程应用钛合金的弹性模量显著高于人骨组织,植入后会发生应力遮蔽现象,导致种植体周围骨吸收,引起种植体松动[3]。同时研究发现,Ti6A14V植入人体后,会与人体体液发生反应而释放V、Al等离子,V可引起恶性组织反应,可能对人体产生毒副作用[4],Al则会引起骨质疏松和精神紊乱等病症[5],且钛合金植入物植入后引起的细菌吸附和繁殖问题也不能忽视[6~9]。目前医用钛合金材料的性能突破途径主要有2个方面:其一是通过成分设计制备综合性能优异的钛合金。研究[10~13]发现,含Mo、Nb、Ta、Zr等无毒元素的β钛合金含有较高含量的β稳定元素,具有较低的弹性模量(E = 55~80 GPa)以及良好的剪切性能和韧性。其二是通过表面改性手段改善使用性能。钛合金植入人体后,其表面与植入环境中的组织细胞发生直接接触作用,所以植入体表面的物化特性是影响植入体植入成功率、稳定性和使用寿命的关键因素[14]。为了增强钛合金植入体的生物相容性,提高其在体内的稳定性,进一步缩短愈合时间,需在植入之前对植入体进行表面改性。

在各种表面改性方法中,喷砂酸蚀(SLA)技术凭借效果显著、操作简便等优点成为常用的表面改性技术之一。SLA的特点在于喷砂后进行酸蚀处理,可清除残留在表面的喷砂颗粒,既保留了喷砂形成的较大“凹面”(一级孔洞结构),又增加了酸蚀形成的较小“凹陷”(二级孔洞结构),喷砂造成的凹陷能够促进细胞在材料表面的停留,而酸蚀处理增加植入体表面的砂坑深度,这使试样表面得到充分粗化,表面积大大增加,有利于提高植入体的结合强度[15]。酸溶液的种类与浓度、酸蚀的时间及温度是主要的工艺参数,对于Ti6A14V合金,使用高温浓HCl和高温浓H2SO4处理更容易获得连续性较好的二级微米孔洞结构[16,17]。但是酸蚀需要较长时间才可以得到理想的微米结构。研究[18]表明,超声波在液体中传播时,可以导致超声空化。此时,液体中的微小气泡在超声波的作用下发生振动、生长、收缩、崩溃等一系列过程,在气泡崩溃时释放出大量的能量,形成局部高温和高压的极端物理环境,引发高速的液体流动,通过增加质量转移、微射流、电子转移活化和电化学修饰而使腐蚀加速。

研究表明,具有微纳米复合结构的表面能够促进成骨细胞的增殖和分化[19],而且通过纳米级和微米级表面特征的结合,模拟骨的分级结构,可以改善体内植入物的骨整合,缩短愈合时间[20]。钛合金表面经热氧化工艺处理后可形成具有不同纳米形貌和结构的氧化膜层,其中感应加热(IHT)是一种基于电磁感应理论和电流的热效应实现对金属热处理的快速热氧化技术[21]。不同于传统热氧化技术,IHT可以以非常快的加热速率实现对金属基体的热氧化处理,并且制备出的表面氧化膜性质均匀,最大程度地减少了对内部基体材料的额外热影响。此外,IHT还具有快速、环保、高效和易操作等优点,除了在金属的熔化和冶炼、钢材的快速热处理等工业生产得到越来越广泛的应用,近年来也逐渐应用在生物医用金属植入物材料表面改性领域[22]。

具有微纳米多级结构的钛合金植入体以其较好的综合性能具有良好的应用前景,但在表面改性、孔形貌的控制、生物活化及骨组织诱导机理方面的研究仍然需要进一步探索。本工作分别采用浓HCl、稀HCl与稀H2SO4混合酸腐蚀Ti6A14V合金,研究了酸蚀试剂、酸蚀时间和超声对Ti6A14V合金酸洗形貌和结构的影响规律。同时结合IHT氧化,在Ti6A14V基体表面构建微/纳尺度结构,寻找最佳表面结构对应的工艺参数,为开发新的表面生物活化方法提供参考。

1 实验方法

1.1 样品制备

1.1.1 基体材料和预处理

实验用Ti6Al4V合金化学成分(质量分数,%)为:Al 6.18,V 4.17,Fe 0.172,C 0.03,N 0.01,H 0.001,O 0.18,Ti余量;合金供货状态为退火态,抗拉强度935 MPa,屈服强度863 MPa,延伸率12%。采用线切割将Ti6Al4V合金加工成10 mm × 10 mm × 2 mm的片状试样。试样表面分别使用丙酮、乙醇和去离子水进行去污处理,依次采用400~1000号的SiC砂纸打磨,再用去离子水进行表面清洗,最终在40℃温度下干燥。

1.1.2 喷砂处理

本实验采用的喷料为250 μm刚玉,压力为0.8 MPa,喷砂枪口与基体表面之间的距离设定为1 cm,角度为90°,喷砂时间为60 s。

1.1.3 酸蚀处理

为探究酸蚀试剂、酸蚀时间、超声等对试样表面酸蚀形貌和结构的影响,对喷砂后的Ti6Al4V基体进行如下酸蚀处理。

(1) 采用(36%~38%)HCl (质量分数,下同)腐蚀Ti6Al4V合金,酸蚀温度为70℃,酸蚀时间分别为10、20和30 min。

(2) 采用20%HCl∶30%H2SO4 = 1∶1 (体积比)混合酸腐蚀Ti6Al4V合金,酸蚀温度为70℃,酸蚀时间为60 min;同时设置超声组,超声功率300 W,超声频率40 kHz。

最后将酸蚀处理后的试样用去离子水超声清洗,烘干,得到所需试样。

1.1.4 感应加热

为在Ti6Al4V合金表面获得微纳米多级结构,在喷砂酸蚀后引入感应加热工艺。采用频率为30 kHz的感应加热设备,加热温度800℃,用红外测温仪进行温度监控。

1.1.5 模拟体液仿生沉积

体外模拟体液(SBF)浸泡实验已被广泛用于预测材料的生物活性。实验中SBF按照Kokubo配方和方法配制[23],依次将试剂按量加入36.5℃去离子水中,然后用Tris溶液和1 mol/L盐酸调节,使溶液最后pH值稳定在7.40。

将待沉积的试样放置在清洁的50 mL塑料试管中,每个试管加入50 mL的SBF,封口后放入36.5℃恒温水浴锅中。SBF每2 d更换一次,全部待沉积试样连续浸泡14 d,取出后在鼓风干燥箱中干燥。

1.2 样品表征和分析

采用Rigaku DMAX-2500PC型X射线衍射仪(XRD)分析试样表面的物相组成。以波长为0.15406 nm的铜靶(CuKα )为辐射源,加速电流为100 mA,加速电压为40 kV,扫描速率为4°/min,扫描角度为10°~90°。

采用SU-70型扫描电镜(SEM)观察分析试样的表面微观形貌和结构,并采用其能谱仪(EDS)对试样表面微区进行元素的定量分析。SEM和EDS测试时的加速电压分别为5和15 kV。

采用LSM-800型激光扫描共聚焦显微镜测量试样表面的三维形貌和粗糙度。激光波长为405 nm,利用Zen Blue软件计算扫描区域的算术平均粗糙度(Sa)。每个样品在表面不同位置上测试3次,Sa的平均值(Ra)作为该试样的平均表面粗糙度。测试前保证试样表面的平整和清洁,测试区域随机选取,使结果更具有代表性。

采用DSA100S型接触角测量仪测量接触角。使用微升注射器将2 μL去离子水滴滴于每个样品的表面上,并将样品预先调整到一定的高度,以确保液滴与样品表面刚好足够的接触。水滴滴落图像由摄像机记录,并通过测量仪自带的图像分析软件计算接触角。

2 实验结果与分析

2.1 喷砂酸洗表面的形貌与结构分析

2.1.1 喷砂+ (36%~38%)HCl酸洗后表面的形貌与结构

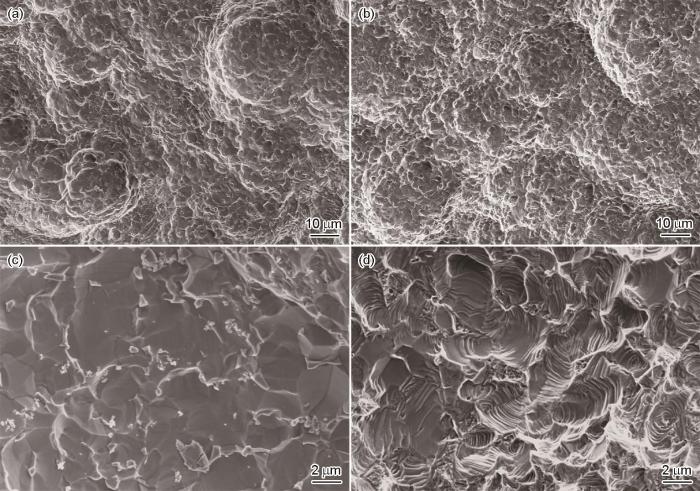

Ti6Al4V合金经喷砂+ (36%~38%)HCl酸洗的SEM像如图1所示。喷砂表面(图1a)粗糙不均匀,出现了凿坑沟壑痕迹、裂纹及尖锐的边角,部分位置还存在嵌入基体的颗粒。这或是由于Ti6Al4V基体表面经磨粒切削和凿入后形成了一些微观缺陷,部分磨粒在高压气体作用下高速冲击并凿入基体表面形成的[24]。嵌入基体的磨粒不仅使Ti6Al4V表面不均匀,还会给种植体材料表面的细胞增殖及骨整合带来不良影响[25~27]。但是喷砂处理也有其相应的优点,Szmukler-Moncler等[28]认为喷砂可以提高种植体在生物体中的牢固程度,经过生物体植入实验10周后,喷砂相比对照组将种植体锚固增加了49.3%。

图1

图1

Ti6Al4V经喷砂 + (36%~38%)HCl酸洗10、20和30 min后的表面SEM像

Fig.1

SEM images of Ti6Al4V after sandblasting (a) + (36%~38%)HCl acid etching for 10 min (b), 20 min (c), and 30 min (d) (Insets in Figs.1b-d show the corresponding high magnified images)

Ti6Al4V合金经喷砂+ (36%~38%)HCl酸洗后,得到直径20~40 μm的凹坑与2~3 μm的微孔的复合结构(图1b~d)。随酸洗时间延长,微孔内壁的阶梯结构更加明显,直径变化较小。酸蚀仅10 min (图1b)时,钛合金表面喷砂后形貌仍较为完整,凹坑边缘清晰可见,但已开始被腐蚀,表面较为粗糙;酸蚀20 min (图1c)后,喷砂后的凹坑边缘更加模糊,出现大量微坑;酸蚀30 min (图1d)后,微坑变得更细小,出现模糊的类似台阶的阶梯状结构。文献[29~31]表明,经过酸蚀处理的植入物表面比没有经过表面处理的植入物具有更好的细胞黏附性。Chauhan等[32]经探究得出结论,对Ti6Al4V酸蚀处理的最优温度为60~80℃,此时合金的表面呈现多孔形貌,这与本实验结果(图1b~d)相符。

2.1.2 喷砂+混合酸酸洗后表面的形貌与结构

图2是Ti6Al4V合金经喷砂 + 20%HCl∶30% H2SO4 = 1∶1 (体积比)混合酸酸洗60 min的SEM像。混合酸酸蚀出现了与浓HCl酸蚀相似的类阶梯状结构。Park等[33]的研究表明,H2SO4和HCl的混合双酸蚀刻处理后会使Ti表面纤维蛋白和成骨细胞附着增加,从而使生物相容性大大提高。Ti6Al4V合金经喷砂+混合酸酸蚀60 min,表面出现了浅浅的波纹形貌(图2c),推测其为阶梯形貌的初始阶段,该酸蚀条件对Ti6Al4V合金腐蚀程度较轻,因而没有形成明显的层状阶梯结构;外加超声后,相同的酸蚀条件下出现了明显的层状阶梯结构(图2d),由此可见,超声能加速Ti6Al4V合金的表面腐蚀。

图2

图2

Ti6Al4V经喷砂 + 20%HCl∶30%H2SO4 = 1∶1 (体积比)混合酸酸洗60 min后的表面SEM像

Fig.2

Low (a, b) and high (c, d) magnified SEM images of Ti6Al4V surface after sandblasting + 20%HCl : 30% H2SO4 = 1 : 1 (volume fraction) acid etching for 60 min without (a, c) and with (b, d) ultrasonic treatment

关于出现阶梯状结构的原因至今尚未明确。任冰等[34]认为由于喷砂的影响,在钛合金表面形成了明显的层叠状破碎裂纹,并且布满尖锐的边角和锯齿状边缘。经过酸蚀后,部分喷砂后残留的碎渣被去除,边角变得圆滑,层片状碎屑被细化,出现了均匀的孔洞结构,大孔洞与小孔洞互相重叠嵌套。随着酸蚀的时间增加,原本腐蚀出的孔洞边缘继续被腐蚀,孔洞变大,而暴露出来的凹坑底部也被继续腐蚀,形成更深一层阶梯的小孔洞。葛永梅[35]提出了晶界腐蚀形成机理,晶界腐蚀是指沿着或紧挨着晶粒边界发生的腐蚀。晶界上原子排列不规则,结构较晶粒内部疏松,且存在位错等缺陷,因而晶界易受腐蚀(热侵蚀、化学腐蚀),由于晶界与晶粒本体存在电位差,当腐蚀进行一定的时间后,部分晶界被腐蚀掉,晶体呈层状分开,出现台阶结构。

超声波能在溶液中引起空化效应,它是指溶液中存在的微小气泡核在超声的作用下不停地迅速生成和崩塌闭合的现象,这种局部短暂超声负压产生空化气泡[36]。由于超声波是一种振动波,在溶液中传播时会在介质中形成周期性交替的正负压,因此产生的空化气泡会被压缩最终破裂[37],在空化气泡消失的瞬间,微小内部空间内会产生剧烈的温度和压强变化,产生瞬间高温(5000 K)和高压(200 MPa),这导致急剧的升温冷却速率(> 109 K/s)[38]。在超声空化过程中会伴随着微射流和声冲流,进而能促进酸液的进一步腐蚀和自由基的产生,这些伴随效应还能对液/固界面起到冲刷、侵蚀作用,使得反应的液/固界面得以活化。此外,超声波还具有搅拌和机械震荡作用,更进一步促进酸蚀反应过程中的传热和传质,使得酸蚀过程加速。

Ti6Al4V合金经过喷砂后,相较混合酸酸洗,(36%~38%)HCl酸洗可以在更短的时间内得到理想的凹坑与微孔的微米复合结构,再考虑到超声对酸洗的加速作用,最终确定喷砂 + (36%~38%)HCl超声酸蚀10 min (下文记作SLA)作为微纳复合结构中微米结构的制备工艺。

2.2 微纳复合结构的表征及分析

2.2.1 表面结构与物相分析

图3为Ti6Al4V合金经过SLA + IHT后在SBF中浸泡14 d的XRD谱。Ti6Al4V合金经过SLA后,表面主要为Ti基体的衍射峰;再经过IHT后表面生成了金红石(rutile)相TiO2;在SBF中浸泡14 d后,表面出现了明显的羟基磷灰石(HA)衍射峰。

图3

图3

Ti6Al4V经SLA + IHT得到的多级结构在模拟体液浸泡14 d前后的XRD谱

Fig.3

XRD spectra of Ti6Al4V after SLA + IHT and soaking in SBF for 14 d (SLA represents the process of sandblasting + (36%~38%)HCl acid etching for 10 min with ultrasonic treatment, SBF—simulated body fluid, IHT—induction heating treatment, HA—hydroxyapatite)

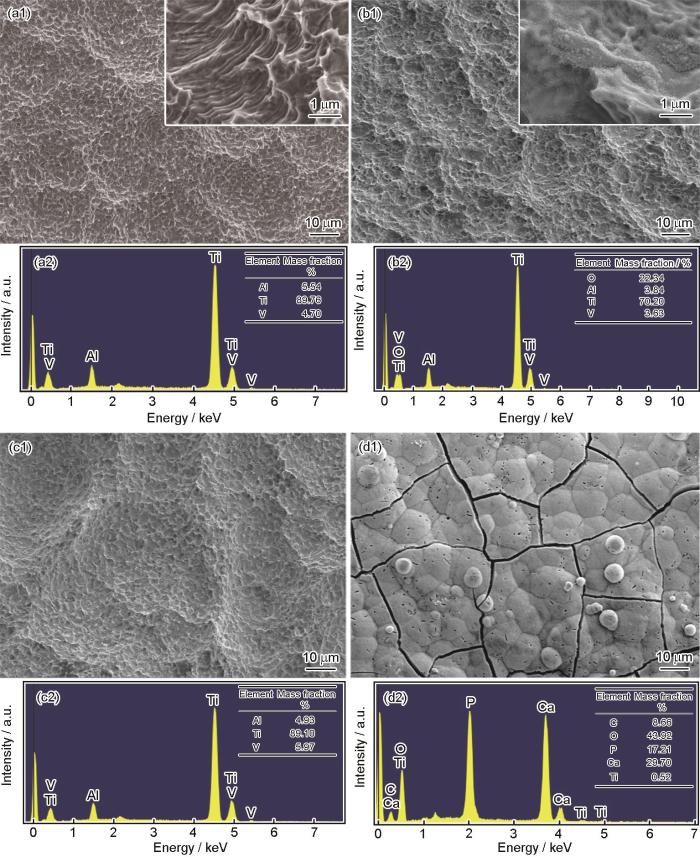

Ti6Al4V合金经过SLA + IHT形成的多级结构及SBF浸泡结果如图4所示。Ti6Al4V合金经过SLA后,表面形成了20~40 μm的大坑和2~3 μm的小坑的复合结构(图4a1)。再经过IHT后,在微米复合结构表面生成了纳米氧化物(图4b1)。在SBF中浸泡14 d后,喷砂酸蚀表面既没有HA沉积,也没有被腐蚀,而是维持了微米复合结构形貌(图4c1);值得一提的是,经过SLA + IHT得到的微纳米复合结构表面沉积了一层厚厚的HA层(图4d1)。一方面,OH-可以与TiO2的Ti+键合形成Ti—OH,在pH = 7.4时,酸性Ti—OH基团可以去质子化以形成[Ti—OH]-,带负电的[Ti—OH]-表面可以选择性吸附带正电的Ca2+形成CaTiO3。随着Ca2+的增加,表面带正电并吸引

图4

图4

Ti6Al4V经SLA + IHT得到的多级结构在模拟体液浸泡14 d前后的SEM像和EDS结果

Fig.4

SEM images (a1-d1) and EDS results (a2-d2) of Ti6Al4V after SLA (a1, a2) and SBF soaking for 14 d (c1, c2), and after SLA + IHT (b1, b2) and SBF soaking for 14 d (d1, d2)

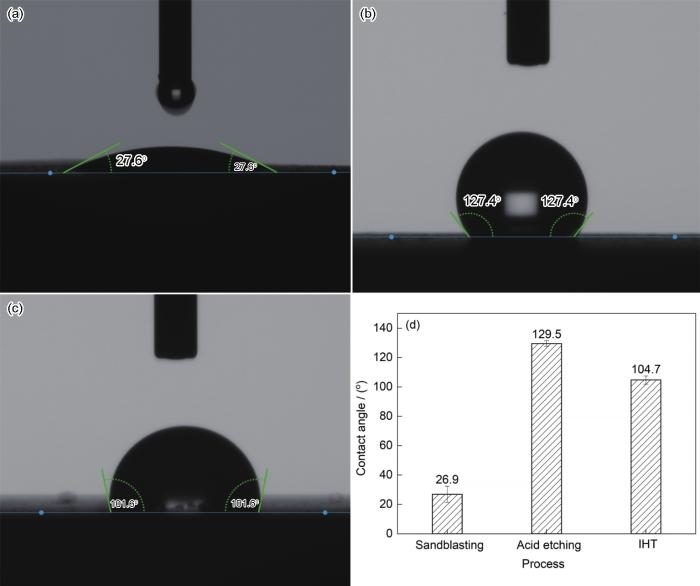

2.2.2 表面粗糙度与润湿性的演变

图5给出了Ti6Al4V合金经过SLA + IHT后表面的三维形貌和粗糙度。Ti6Al4V合金经过喷砂后表面粗糙,表面高度差为70 μm左右(图5a),粗糙度为(3.25 ± 0.20) μm;再经过酸蚀后,高度差减小至约25 μm (图5b),粗糙度减小为(2.68 ± 0.27) μm;最后经过IHT后,表面高度差继续减小至约15 μm (图5c),粗糙度进一步降低为(1.55 ± 0.09) μm。骨植入材料与生物体相互作用的第一阶段是基于整联蛋白受体与细胞外基质(extracellular matrixc,ECM)中配体相互识别和作用的细胞黏附[43],而金属植入体的表面形貌特征会对组织细胞在其上的黏附生长和黏附强度产生很大的影响,最主要的影响因素是微观几何尺寸和表面粗糙度[44]。有研究[45]表明喷砂等机械加工可以增加细胞的黏附性,但也有研究[46]得出相反结论。总之,细胞类型、表面粗糙度及具体的加工方法都会对细胞的黏附产生影响,但未给出具体的粗糙度阈值[47]。一般情况下适当提高粗糙度可以提高细胞接触面积,提供更多附着位点,有利于细胞黏附。

图5

图5

Ti6Al4V经喷砂+超声酸洗+感应加热后的表面三维形貌及粗糙度定量检测结果

Fig.5

3D morphologies of Ti6Al4V after sandblasting (a) + acid etching with ultrasonic treatment (10 min) (b) + IHT (800oC) (c), and quantitative measurements of surface roughness (d)

图6

图6

Ti6Al4V经喷砂+超声酸洗+感应加热后的表面水滴形貌图及润湿角

Fig.6

Water droplet on the surfaces of Ti6Al4V after sandblasting (a) + acid etching with ultrasonic treatment (10 min) (b) + IHT (800oC) (c), and contact angles (d)

3 结论

Ti6Al4V合金经喷砂 + (36%~38%)HCl及20%HCl∶30%H2SO4 = 1∶1 (体积比)混合酸酸洗后,表面均形成了几十微米大坑和几微米微孔的复合结构,其中微孔内壁出现阶梯状结构;随酸洗时间延长,微孔内壁阶梯结构更加明显;超声可以加速酸蚀,超声组相比对照组能产生更明显的阶梯状结构。Ti6Al4V合金经喷砂 + (36%~38%)HCl超声酸洗10 min + 800℃ IHT氧化后,表面保留了微米级复合结构的基础上生成了纳米氧化物,得到了微纳米多级复合结构。SBF浸泡实验表明制备的微纳米多级结构具有较高的生物活性。

参考文献

Prospect of development trend of melting technology of titanium and/or its alloys with high efficiency and low energy consumption

[J].

低能耗节约型钛及钛合金熔炼技术的发展趋势

[J].

A comparison of the fatigue behavior of cast Ti-7.5Mo with c.p. titanium, Ti-6Al-4V and Ti-13Nb-13Zr alloys

[J].

Design and performance study on two new low elastic modulus metastable β titanium alloys for biomedical application

[J].

两种新型生物医用低弹性模量亚稳β钛合金的设计与性能研究

[J].

Effect of Ti, Al, and V ions on the relative growth rate of fibroblasts (L929) and osteoblasts (MC3T3-E1) cells

[J].

Effects of aluminum and other cations on the structure of brain and liver chromatin

[J].The reactivity of aluminum and several other divalent and trivalent metallic cations toward chromatin from rat brain and liver has been investigated. Two criteria are used to determine the relative reactivity of these cations toward chromatin. The first involves the ability of the ions to compact the chromatin fibers to the point where chromatin precipitates. The second criterion measures the ability of cations to interfere with the accessibility of exogenous structural probes (nucleases) to chromatin. Of the divalent cations tested, nickel, cobalt, zinc, cadmium, and mercury were the most reactive toward chromatin, on the basis of their ability to induce precipitation of chromatin in the micromolar concentration range. The divalent cations magnesium, calcium, copper, strontium, and barium were much less effective, although all cations precipitate chromatin if their concentration is increased. Of the trivalent cations tested, aluminum, indium, and gallium were very effective precipitants, whereas iron and scandium were without effect at the concentrations tested. Of all the cations tested, aluminum was the most reactive. Aluminum's ability to alter the structure of chromatin was investigated further by testing its ability to interfere with nuclease accessibility. This test confirmed that aluminum does induce considerable changes in chromatin structure at micromolar concentrations. Furthermore, chromatin from cortical areas of the brain was much more sensitive to aluminum than chromatin from liver. These results are discussed in light of the known toxicity of these cations, with particular emphasis on the possible role of aluminum in Alzheimer's disease.

Experiment study on fracture fixation with low rigidity titanium alloy: Plate fixation of tibia fracture model in rabbit

[J].

Antibacterial titanium surfaces for medical implants

[J].

Ti based biomaterials, the ultimate choice for orthopaedic implants—A review

[J].

Development and research status of biomedical titanium alloys

[J].

医用钛合金的发展及研究现状

[J].

Microstructure and mechanical properties of Ti-35Nb-6Ta alloy after thermomechanical treatment

[J].

Effects of surface morphology and composition of medical titanium alloys on biocompatibility

[J].

医用钛合金表面形貌与成分对生物相容性影响研究综述

[J].

Beta type Ti-Mo alloys with changeable Young's modulus for spinal fixation applications

[J].To develop a novel biomedical titanium alloy with a changeable Young's modulus via deformation-induced ω phase transformation for the spinal rods in spinal fixation devices, a series of metastable β type binary Ti-(15-18)Mo alloys were prepared. In this study, the microstructures, Young's moduli and tensile properties of the alloys were systemically examined to investigate the effects of deformation-induced ω phase transformation on their mechanical properties. The springback of the optimal alloy was also examined. Ti-(15-18)Mo alloys subjected to solution treatment comprise a β phase and a small amount of athermal ω phase, and they have low Young's moduli. All the alloys investigated in this study show an increase in the Young's modulus owing to deformation-induced ω phase transformation during cold rolling. The deformation-induced ω phase transformation is accompanied with {332}(β) mechanical twinning. This resulted in the maintenance of acceptable ductility with relatively high strength. Among the examined alloys, the Ti-17Mo alloy shows the lowest Young's modulus and the largest increase in the Young's modulus. This alloy exhibits small springback and could be easily bent to the required shape during operation. Thus, Ti-17Mo alloy is considered to be a potential candidate for the spinal rods in spinal fixation devices.Copyright © 2012 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Manufacturing and processing of NiTi implants: A review

[J].

Advancing dental implant surface technology—From micron- to nanotopography

[J].Current trends in clinical dental implant therapy include use of endosseous dental implant surfaces embellished with nanoscale topographies. The goal of this review is to consider the role of nanoscale topographic modification of titanium substrates for the purpose of improving osseointegration. Nanotechnology offers engineers and biologists new ways of interacting with relevant biological processes. Moreover, nanotechnology has provided means of understanding and achieving cell specific functions. The various techniques that can impart nanoscale topographic features to titanium endosseous implants are described. Existing data supporting the role of nanotopography suggest that critical steps in osseointegration can be modulated by nanoscale modification of the implant surface. Important distinctions between nanoscale and micron-scale modification of the implant surface are presently considered. The advantages and disadvantages of nanoscale modification of the dental implant surface are discussed. Finally, available data concerning the current dental implant surfaces that utilize nanotopography in clinical dentistry are described. Nanoscale modification of titanium endosseous implant surfaces can alter cellular and tissue responses that may benefit osseointegration and dental implant therapy.

Surface treatment and microstructure of biomedical titanium alloy

[D].

生物医用钛合金表面处理及其微结构

[D].

Surface modification of titanium, titanium alloys, and related materials for biomedical applications

[J].

The effects of acid etching on the nanomorphological surface characteristics and activation energy of titanium medical materials

[J].

Effect of cavitation on carbon dioxide corrosion and the development of a test for evaluating inhibitors

[J].

Selective cell affinity of biomimetic micro-nano-hybrid structured TiO2 overcomes the biological dilemma of osteoblasts

[J].

The effects of combined micron-/submicron-scale surface roughness and nanoscale features on cell proliferation and differentiation

[J].Titanium (Ti) osseointegration is critical for the success of dental and orthopedic implants. Previous studies have shown that surface roughness at the micro- and submicro-scales promotes osseointegration by enhancing osteoblast differentiation and local factor production. Only relatively recently have the effects of nanoscale roughness on cell response been considered. The aim of the present study was to develop a simple and scalable surface modification treatment that introduces nanoscale features to the surfaces of Ti substrates without greatly affecting other surface features, and to determine the effects of such superimposed nano-features on the differentiation and local factor production of osteoblasts. A simple oxidation treatment was developed for generating controlled nanoscale topographies on Ti surfaces, while retaining the starting micro-/submicro-scale roughness. Such nano-modified surfaces also possessed similar elemental compositions, and exhibited similar contact angles, as the original surfaces, but possessed a different surface crystal structure. MG63 cells were seeded on machined (PT), nano-modified PT (NMPT), sandblasted/acid-etched (SLA), and nano-modified SLA (NMSLA) Ti disks. The results suggested that the introduction of such nanoscale structures in combination with micro-/submicro-scale roughness improves osteoblast differentiation and local factor production, which, in turn, indicates the potential for improved implant osseointegration in vivo.Copyright © 2011 Elsevier Ltd. All rights reserved.

Biological behaviors of micro/nano-scale bioactive oxide coatings prepared by induction heating on medical titanium and its alloys

[D].

医用钛及钛合金表面微-纳尺度生物活性氧化膜的感应加热制备及其生物学行为

[D].

Non-contact induction heating and SAAP-148 eliminate persisters within MRSA biofilms mimicking a metal implant infection

[J].

How useful is SBF in predicting in vivo bone bioactivity?

[J].The bone-bonding ability of a material is often evaluated by examining the ability of apatite to form on its surface in a simulated body fluid (SBF) with ion concentrations nearly equal to those of human blood plasma. However, the validity of this method for evaluating bone-bonding ability has not been assessed systematically. Here, the history of SBF, correlation of the ability of apatite to form on various materials in SBF with their in vivo bone bioactivities, and some examples of the development of novel bioactive materials based on apatite formation in SBF are reviewed. It was concluded that examination of apatite formation on a material in SBF is useful for predicting the in vivo bone bioactivity of a material, and the number of animals used in and the duration of animal experiments can be reduced remarkably by using this method.

Structures and properties of layered bioceramic coatings on pure titanium using a hybrid technique of sandblasting and micro-arc oxidation

[J].

Biocompatibility of plasma polymerized sandblasted large grit and acid titanium surface

[J].

Thermal oxidation enhances early interactions between human osteoblasts and alumina blasted Ti6Al4V alloy

[J].

Early bone healing around 2 different experimental, HA grit-blasted, and dual acid-etched titanium implant surfaces. A pilot study in rabbits

[J].To compare early bone healing around different experimental titanium implant surfaces and to evaluate the role of a calcium phosphate-coated implant surface because it relates to bone-implant contact (BIC).An experimental hydroxyapatite (HA) grit-blasted and dual acid-etched titanium surface (BAE-1) was compared to an experimental HA grit-blasted and dual acid-etched surface treated with nanometer-scale crystals of HA (BAE-2). Both experimental implant surfaces were implanted onto the tibias of 4 New Zealand white rabbits. The animals were killed at 1,6, 21, and 90 days after the implant surgery. Descriptive histology was performed at the healing responses of both implant surfaces. Quantitative morphology assessment provided measurements of BIC, number of bone multicellular units (BMUs), average penetration of BMUs, and maximum penetration of BMUs that were manually made using imaging computer software.The overall BIC for the BAE-2 implant was higher than that for the BAE-1 implant at 21 days of healing. However, there was no significant difference at 90 days of healing.It is concluded from this animal pilot study that the bioactive BAE-2 implant surface provided a better BIC with healthy bone remodeling at 21 days of healing.

Biological properties of acid etched titanium implants: Effect of sandblasting on bone anchorage

[J].

Improvement of in vitro titanium bioactivity by three different surface treatments

[J].Dental implants are usually made from commercially pure titanium or titanium alloys. The aim of this investigation was to determine the influence of surface treatments of commercially pure titanium samples on in vitro bioactivity.Commercially pure (cp) titanium (Ti) sheets were submitted to three different surface treatments, including, for all samples, etching with an HCl/H(2)SO(4) solution. Part of each etched sample was further submitted either to anodic oxidation by using an H(3)PO(4) solution or to thermal oxidation. Treated and non-treated samples were analyzed by using scanning electron microscopy (SEM), profilometry and photoelectron X-ray spectroscopy (XPS). The in vitro assessment was carried out through the immersion of samples in simulated body fluid (SBF). In vitro testing was carried out by SEM and by the determination of calcium (Ca) content in solution by atomic absorption spectrometry (AAS). The non-treated titanium samples were used as the control group.This study has shown that, after up to 7-day exposure, a calcium phosphate layer precipitated only on samples submitted to at least one of the three treatments used. This result, based on SEM images, is in good agreement with Ca content and XPS analysis, in which remarkable effects of surface modifications on Ti samples are highlighted.These results suggest that suitable surface treatments, such as employed here, may improve in vitro titanium bioactivity in a SBF solution at 37 degrees C. This behavior suggests a possibility of a further favorable in vivo response.

Surface treatments of titanium dental implants for rapid osseointegration

[J].The osseointegration rate of titanium dental implants is related to their composition and surface roughness. Rough-surfaced implants favor both bone anchoring and biomechanical stability. Osteoconductive calcium phosphate coatings promote bone healing and apposition, leading to the rapid biological fixation of implants. The different methods used for increasing surface roughness or applying osteoconductive coatings to titanium dental implants are reviewed. Surface treatments, such as titanium plasma-spraying, grit-blasting, acid-etching, anodization or calcium phosphate coatings, and their corresponding surface morphologies and properties are described. Most of these surfaces are commercially available and have proven clinical efficacy (>95% over 5 years). The precise role of surface chemistry and topography on the early events in dental implant osseointegration remain poorly understood. In addition, comparative clinical studies with different implant surfaces are rarely performed. The future of dental implantology should aim to develop surfaces with controlled and standardized topography or chemistry. This approach will be the only way to understand the interactions between proteins, cells and tissues, and implant surfaces. The local release of bone stimulating or resorptive drugs in the peri-implant region may also respond to difficult clinical situations with poor bone quality and quantity. These therapeutic strategies should ultimately enhance the osseointegration process of dental implants for their immediate loading and long-term success.

In vivo evaluation of micro-rough and bioactive titanium dental implants using histometry and pull-out tests

[J].We report on the in vivo histological and mechanical performance of titanium dental implants with a new surface treatment (2Step) consisting of an initial grit-blasting process to produce a micro-rough surface, followed by a combined chemical and thermal treatment that produces a potentially bioactive surface, i.e., that can form an apatitic layer when exposed to biomimetic conditions in vitro. Our aim was to assess the short- and mid-term bone regenerative potential and mechanical retention of 2Step implants in mandible and maxilla of minipigs and compare them with micro-rough grit-blasted, micro-rough acid-etched, and smooth as-machined titanium implants. The percent of bone-to-implant contact after 2, 4, 6, and 10 weeks of implantation as well as the mechanical retention after 4, and 6 weeks of implantation were evaluated with histometric and pull-out tests, respectively, as a measure of the osseointegration of the implants. We also aimed to assess the bioactive nature of 2Step surfaces in vivo. Our results demonstrated that the 2Step treatment produced micro-rough and bioactive implants that accelerated bone tissue regeneration and increased mechanical retention in the bone bed at short periods of implantation in comparison with all other implants tested. This was mostly attributed to the ability of 2Step implants to form in vivo a layer of apatitic mineral that coated the implant and could rapidly stimulate (a) bone nucleation directly on the implant surface, and (b) bone growing from the implant surface. We also proved that roughness values of Ra≈4.5 μm favoured osseointegration of dental implants at short- and mid-term healing periods, as grit-blasted implants and 2Step implants had higher retention values than as machined and acid-etched implants. The surface quality resulting from the 2Step treatment applied on cpTi provided dental implants with a unique combination of rapid bone regeneration and high mechanical retention.Copyright © 2011 Elsevier Ltd. All rights reserved.

Effect of acid etching temperature on surface physiochemical properties and cytocompatibility of Ti6Al4V ELI alloy

[J].

Red blood cell and platelet interactions with titanium implant surfaces

[J].

Influence of different acid-etching time on the surface morphology and corrosion resistance of TC4 titanium alloys after sandblasting

[J].

酸蚀时间对喷砂后TC4钛合金表面形貌及抗腐蚀性的影响

[J].

Preparation and properties of nano-porous film on pure medical titanium

[D].

医用纯钛表面纳米膜层的制备及其生物性能研究

[D].

Effect of ultrasonic on corrosion of zinc in hydrochloric acid

[J].

超声波对盐酸腐蚀锌的影响

[J].

Ultrasonic initiation of polystyrene latex synthesis

[J].Polystyrene latex samples have been synthesised from an oil-in-water (o/w) emulsion of the monomer using ultrasonic irradiation as the initiation source. No added chemical initiators were used in any of the reactions. The free radicals formed from the cavitation process under the action of the ultrasound are sufficient to initiate the polymerisation. In the current study, the effects of varying the input intensity of the ultrasound were investigated. A marked increase in the monomer conversion rate as a function of time was seen as the power was increased. Despite this increase in conversion rate, the increasing intensity did not affect the resultant latex particle sizes. In all cases, the particle diameters at the conclusion of a polymerisation were seen to be in the range of 40 to 50 nm. The effects of changing the concentration of surfactant in the polymerisation medium and of changing the temperature were also probed. Increases in both were seen to lead to an increased rate of conversion at a fixed input intensity. Again, the particle diameters were invariant as a function of changing conditions. The small particle sizes and high conversion rates are thought to be due to a continuous nucleation process that is caused by the scavenging of free radicals throughout the polymerisation by freshly formed small oil droplets.

Sonochemical hot spot

[J].

Preparation of different forms of titanium oxide on titanium surface: Effects on apatite deposition

[J].

Wettability and kinetics of hydroxyapatite precipitation on a laser-textured Ca-P bioceramic coating

[J].Surface-textured calcium phosphate coatings at four different length scales were synthesized on titanium-based alloys using a pulsed Nd:YAG laser system by a direct melting technique. The textures were obtained by varying the laser spot overlap with a change in laser traverse speed. Surface roughness measurements of the textured coatings carried out using a white light interferometer indicated a decrease in roughness with increasing laser scan speed. Wettability of the coated samples measured using a static sessile drop technique demonstrated an increased hydrophilicity with increasing laser scan speed. The influence of such textures and the associated surface roughness on the precipitation kinetics of hydroxyapatite (HA) during immersion in simulated body fluid (SBF) was the prime focus of the present paper. The mineralized samples obtained after immersion in SBF were characterized using X-ray diffraction, energy-dispersive spectroscopy and scanning electron microscopy to understand the kinetics of HA precipitation. The results thereafter confirmed that the precipitation kinetics of HA was strongly modulated by the varying surface roughness.

Microstructures of Ti6Al4V matrices induce structural evolution of bioactive surface oxide layers via cold compression and induction heating

[J].

Composition, microstructure and mechanical properties of Ti6Al4V (ELI) alloy bars for surgical implants

[A].

外科植入物用Ti6Al4V(ELI)合金棒材的成分、组织和力学性能

[A].

Effects of substratum morphology on cell physiology

[J].Among the host of substratum properties that affect animal cell behavior, surface morphology has received relatively little attention. The earliest effect of surface morphology on animal cells was discovered almost a century ago when it was found that cells became oriented in response to the underlying topography. This phenomenon is now commonly known as contact guidance. From then until very recently, little progress has been made in understanding the role of surface morphology on cell behavior, primarily due to a lack of defined surfaces with uniform morphologies. This problem has been solved recently with the development of photolithographic techniques to prepare substrata with well defined and uniform surface morphologies. Availability of such surfaces has facilitated systematic in vitro experiments to study influence of surface morphology on diverse cell physiological aspects such as adhesion, growth, and function. For example, these studies have shown that surfaces with uniform multiples parallel grooves can enhance cell adhesion by confining cells in grooves and by mechanically interlocking them. Several independent studies have demonstrated that cell shape is a major determinant of cell growth and function. Because surface morphology has been shown to modulate the extent of cell spreading and cell shape, its effects on cell growth and function appear to be mediated via this biological coupling between cell shape and function. New evidence in the cell biology literature is emerging to suggest that surface morphology could affect other cell behavioral properties such as post-translational modifications. Further elucidation of such effects will enable better designs for implant and cell culture substrata.

Surface modification of implant materials and its effect on attachment and proliferation of bone cells

[J].

Effect of micro-roughness produced by TiO2 blasting—Tensile testing of bone attachment by using coin-shaped implants

[J].The aim of the present study was to examine bone response to micro-rough titanium implants. Forty coin-shaped implants were divided into eight groups according to their surface roughness. The first group had electropolished surfaces. The surfaces of implant groups 2-8 were blasted with TiO2 particles with incremental grain sizes ranging from 7.5-12.5 to 270-330 microns. Five implants from each group were placed into the cortical bone of the proximal tibia in New Zealand Black rabbits. To avoid bone overgrowth during the retention phase the implants were fitted into tight polytetrafluoroethylene (PTFE) caps leaving only the flat test surface exposed to bone. The healing period was set to 10 weeks, and implants with attached bone were evaluated using a tensile testing machine. In groups 1-7 a significant correlation between the micro-roughness of the implant surfaces and retention strength was observed. Maximum bone bonding was observed with implants blasted with 180-220 microns grain size (group 7). Blasting with larger TiO2 particles appeared to decrease the effect. The findings suggest that the best grain size of TiO2 particles for optimising retention of titanium implants in cortical bone should be in the 180-220 microns range.

Relationship between surface properties (roughness, wettability) of titanium and titanium alloys and cell behaviour

[J].

Mechanism investigation on osteoblast adhesion affected by Ti6Al4V biological materials surface roughness

[D].

Ti6Al4V生物材料表面粗糙度对成骨细胞黏附的影响机制研究

[D].