长期以来,TiNi基记忆合金因具有优良的形状记忆效应和伪弹性等功能特性而受到学者们的广泛关注[1~16]。在过去的十年间,一种Nb纳米线增强NiTi记忆合金复合材料成为研究热点[17~25]。这种NiTi-Nb复合材料打破了纳米增强相在复合材料中难以展现其本征高性能的禁锢。其中,一篇发表在《Science》的研究[20]指出,若将记忆合金作为纳米线增强复合材料的基体,加载时基体的变形就会以应力诱发马氏体相变为主导,而不是像常规金属材料那样以位错滑移引起的塑性变形为主导。这样就会在一定程度上避免因界面出现位错堆积(应力集中)而对纳米线产生伤害,使复合态的纳米线展现出与自由态纳米线相当的超大弹性应变(4%~7%),获得了集高强度(1.65 GPa)、低模量(25.8 GPa)和准线性超弹性(准线性超弹性变形量6.4%)于一身的超常性能。这样的材料填补了金属、陶瓷和高分子三大类传统材料性能图表的空白区,在牙齿矫正器、心脏起搏器、人体可植入装置和柔性医疗器械等领域都有潜在的应用前景[26]。

根据以往的报道[20],NiTi-Nb复合材料的超常准线性超弹特性与应力诱发马氏体相变密切相关,但与二元NiTi合金相比,该相变具有以下3个特点:(1) NiTi-Nb复合材料需要经历一次适当的预变形之后,才能发生这种“准线性超弹”类型的相变;(2) 在展现准线性超弹特性的拉伸循环中,复合材料中的NiTi相在加载初始就会持续发生应力诱发马氏体相变,似乎此时开启相变所需的外应力降低到了零;(3) 在准线性超弹拉伸循环中,应力诱发马氏体相变并没有导致拉伸曲线出现“相变平台”,而是在加载之初,相变应变就与材料的初始弹性变形混合在一起,形成一条表观弹性模量(拉伸曲线斜率)低于30 GPa的准线性曲线。即相变曲线是“硬化型”的斜线而非通常的“平台型”的水平线。尽管这种奇特的应力诱发马氏体相变特征被归因于预变形后样品内部各复合组元间的耦合作用[20],但是该耦合作用具体如何导致准线性超弹性的产生,目前尚缺乏与之相关的实验性研究。本工作通过同步辐射高能X射线原位拉伸实验研究了不同预变形下NiTi-Nb复合材料内部复合组元间耦合状态的演变过程,并系统分析了准线性超弹特性的形成和变形机制。

1 实验方法

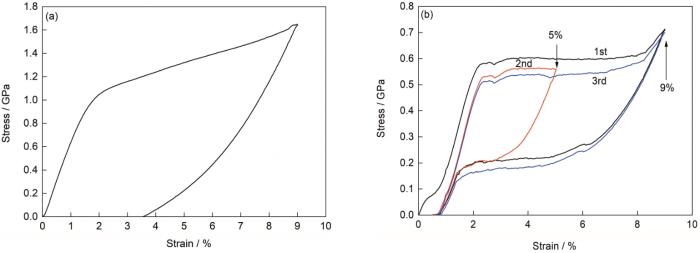

采用真空感应熔炼,将纯度为 99.95% (质量分数)的Ti、Ni 和 Nb熔炼成名义成分为Nb20Ti39Ni41 (摩尔比)的合金锭7 kg。将合金铸锭辅以热锻(热锻温度为850℃)和拔丝加工(拔丝工艺为: 先将锻造棒热拔到直径1.1 mm,再冷拔到直径0.35 mm。热拔温度为400~500℃;冷拔过程中,每当冷变形量达到70%左右就进行中间退火,中间退火温度为450~750℃,直径越小退火温度越低),最终获得直径0.35 mm的丝材作为样品。所有样品在测试前均先置于箱式炉中在350℃处理20 min,空冷。采用Tecnai F20透射电子显微镜(TEM)观察丝材样品的显微组织。采用WDT II-20型万能拉伸试验机对样品进行拉伸力学性能测试,加、卸载速率均为0.05 mm/s。为使样品展现准线性超弹特性,需先对其进行一次9%的预变形。预变形过程为将退火样品加载至9%并卸载,如图1a所示。本实验中涉及的预应变量均为预变形过程中的最大加载应变。为进行对比实验,另将一根二元NiTi丝依次进行最大加载应变为9%、5%和9%的3次拉伸循环,如图1b所示,可将其第一次加卸载循环视为预变形过程,后面的2次拉伸循环用于对比同样经历9%预变形后,二元NiTi合金与NiTi-Nb复合材料不同的应力-应变响应。采用美国阿贡实验室同步辐射高能X射线衍射(HE-XRD,11-ID-C beamline of the Advanced Photon Source,Argonne National Laboratory)设备测试样品中各复合组元的变形行为,高能X射线束斑尺寸为0.6 mm × 0.6 mm,波长0.010798 nm。采用自制原位拉伸台,在同步辐射高能X射线测试过程中对丝材样品进行原位拉伸。原位拉伸过程中,高能X射线束斑始终探测丝材的同一位置区域。

图1

图1

NiTi-Nb复合材料的预变形过程曲线和二元NiTi合金丝的循环拉伸曲线

Fig.1

Pre-deformation process of the NiTi-Nb sample (a) and multiple-step cyclic stress-strain curves of a binary NiTi alloy (b)

2 实验结果与分析

2.1 NiTi-Nb复合材料的显微组织

图2a为NiTi-Nb复合材料丝材的TEM明场像。其中,深色衬度的条带状区域是富Nb相,而浅色衬度区域是NiTi相。由图可见,经过拔丝后,NiTiNb合金中的富Nb相都形成了Nb纳米线(富Nb相中仅固溶少量Ti和Ni,这里简称Nb纳米线),其直径基本介于25~50 nm之间,沿丝材轴向平行排列在NiTi基体中;NiTi相中可清晰分辨出多个纳米尺度(< 100 nm)的晶粒,说明NiTi基体是纳米晶材料。故而该材料是一种纳米线增强纳米晶基体复合材料。图2b为NiTi-Nb复合材料的同步辐射高能XRD花样,图片竖直方向为丝材轴向。可见,复合材料中含有bcc-Nb相和B2-NiTi母相。因此,材料中NiTi在室温下处于母相(奥氏体)状态。Nb(220)和Nb(110)晶面在竖直方向上出现强衍射斑点,说明拔丝加工使Nb相沿丝材轴向形成强织构。

图2

图2

NiTi-Nb复合材料丝材纵截面的TEM像及其同步辐射高能XRD花样

Fig.2

TEM bright field image of the longitudinal section microstructure of the NiTi-Nb composite wire (a) and 2D high-energy XRD pattern of the wire (B2—B2-NiTi, Nb—bcc-Nb) (b)

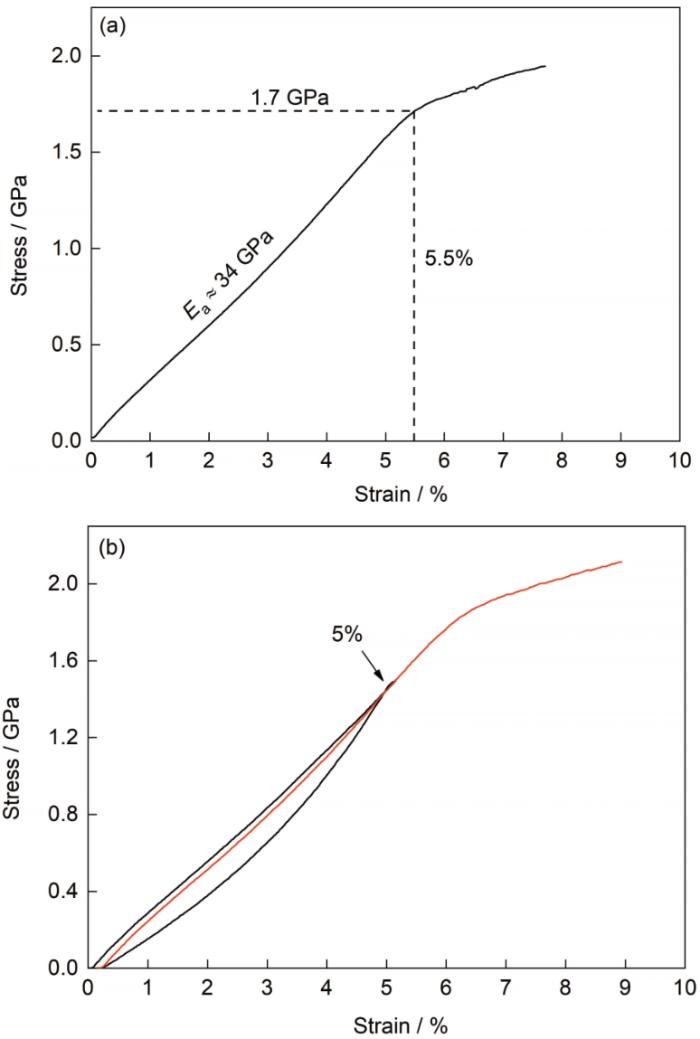

2.2 NiTi-Nb复合材料的准线性超弹性力学响应

NiTi-Nb复合材料样品经历一次9%预变形之后,再次拉伸的应力-应变曲线如图3a所示(预变形过程如图1a所示)。可见,材料展现出高强度、低模量、准线性超弹特性,屈服强度达到1.7 GPa,表观Young's模量约34 GPa,准线性超弹性应变接近5.5%。将另一根同样经过9%预变形的复合材料样品,依次进行最大加载应变为5%和断裂应变的2次拉伸循环,结果如图3b所示。可见,在最大应变为5%的拉伸循环中,该NiTi-Nb复合材料的相变滞后环狭长,滞后曲线呈准线性。作为对比,常规二元NiTi合金的力学响应行为如图1b所示。由图可见,经过一次9%拉伸循环后,二元NiTi合金的拉伸循环曲线仍呈现出类四边形滞后环,并无线性超弹特征。

图3

图3

NiTi-Nb复合材料的准线性超弹性应力-应变曲线

Fig.3

Quasi-linear superelasticity stress-strain curves of the NiTi-Nb composite

(a) typical macroscopic mechanical property of the NiTi-Nb composite after pre-deformation (Ea—apparent Young's modulus)

(b) cyclic tensile stress-strain curves of the NiTi-Nb composite after pre-deformation

2.3 预变形对NiTi-Nb复合材料的影响

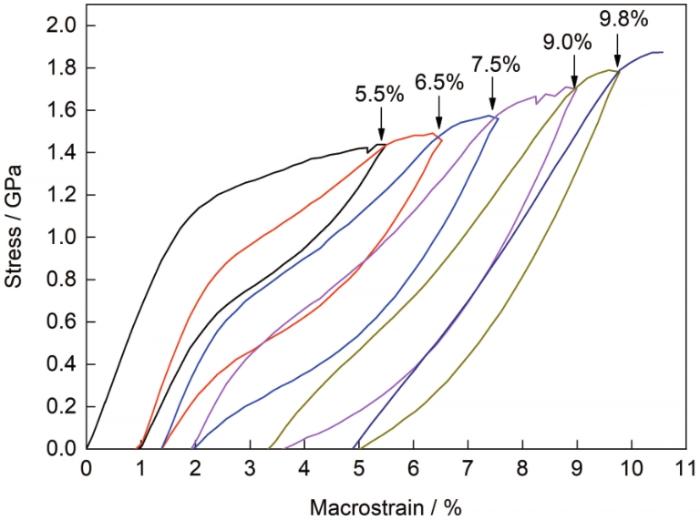

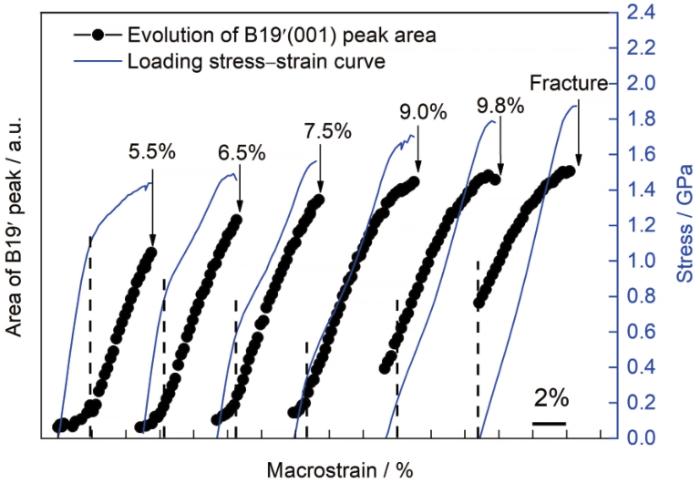

将退火状态的样品进行连续6次加、卸载循环拉伸测试,各循环的最大加载应变依次为5.5%、6.5%、7.5%、9.0%、9.8%和断裂应变,拉伸曲线如图4所示。在这些循环中,若将其中任意一次拉伸循环视为其后一次循环的预变形过程(预应变量为预变形过程中的最大加载应变),则该曲线具有如下特点:(1) 随预应变量的增加,卸载后的残余应变量逐渐增加(塑性变形量逐渐增加);(2) 第1次加载样品仅发生一次屈服,而第2~5次加载样品发生两次屈服。通常认为第一次屈服与应力诱发马氏体相变有关,而第二次屈服则对应上次拉伸循环的最大加载应变位置(应变记忆效应[29,30]);(3) 到了第5次循环(经历9%预变形后),“第一次屈服”变得非常不明显,近乎消失,而“第二次屈服”成为该循环真正的屈服,此时材料展现出近乎完美的准线性超弹的变形特性。可见,“第一次屈服”的消失导致了准线性超弹性的产生;(4) 第6次加载曲线虽然也接近线性,但超弹性应变不到5%,超弹特性较第5次循环差。

图4

图4

NiTi-Nb复合材料不同拉伸循环的应力-应变曲线

Fig.4

Multiple-step cyclic stress-strain curves of the NiTi-Nb composite sample, where the max strains of each cycle are 5.5%, 6.5%, 7.5%, 9.0%, 9.8%, and fracture strain in sequence

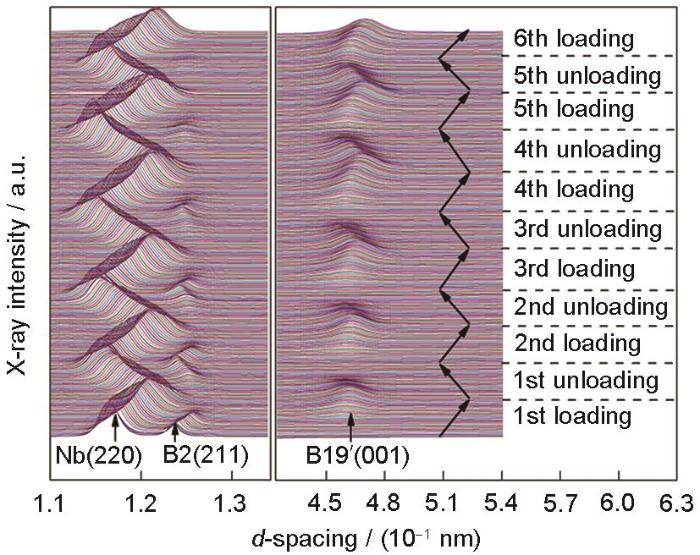

图5为以上6次拉伸循环对应的同步辐射高能X射线原位拉伸测试谱线。该谱线显示了样品中垂直于丝轴向的Nb(220)、B2-NiTi(211)以及B19'-NiTi(001)晶面的衍射峰在6次拉伸循环中的演变。可见,各衍射峰的峰位均随加载而右移(面间距增加),并随卸载而左移(面间距减小)。同时,B2(211)母相峰的强度随着加载而衰减,直至消失(正相变),并随着卸载而浮现并增强(逆相变)。对应母相峰的衰减和增强,B19'(001)马氏体峰随着加载而逐渐浮现、增强,并随着卸载而逐渐消失。这说明在加、卸载过程中,复合材料中的NiTi分别发生了B2-B19'应力诱发马氏体相变和B19'-B2逆相变。

图5

图5

NiTi-Nb复合材料6次拉伸循环对应的的同步辐射高能X射线原位拉伸衍射谱线

Fig.5

Evolutions of the diffraction peaks of Nb(220), B2-NiTi(211), and B19'-NiTi(001) planes in NiTi-Nb composite perpendicular to the loading direction during the multiple-step cyclic tensile test

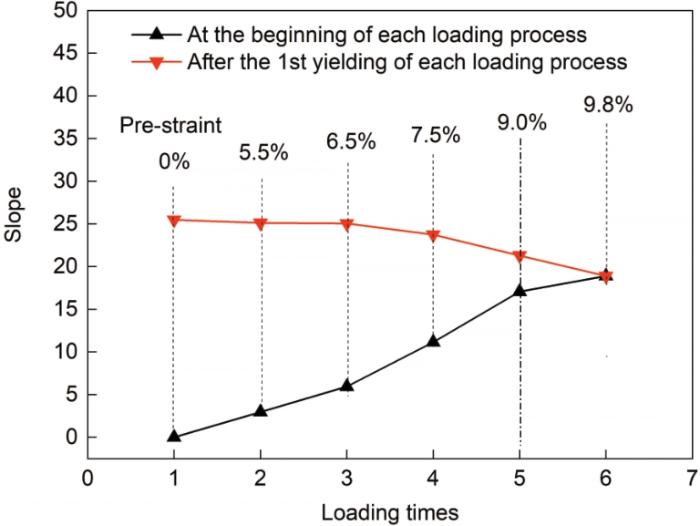

图6给出了6次加载过程中B19'(001)马氏体峰的面积积分曲线,并对第2~6次加载曲线在横坐标轴上进行了适当的平移以便区分。由于B19'(001)峰面积的变化反映了材料中马氏体含量的改变,故而可用来定性分析不同加载阶段应力诱发马氏体相变的转变情况。B19'(001)峰面积曲线的斜率越高,则马氏体相变的转变速率越高。图6中也给出了这6次加载所对应的宏观拉伸应力-应变曲线,用于对比相变与材料力学响应之间的关系。由图可见,前4次拉伸过程中,每次加载,B19'(001)峰面积曲线先以较低的斜率缓慢升高(相变速率低),到达一个“转折点”后,又突然以较高的斜率接近线性升高(相变速率高)。这些标志着相变速率突然增加的“转折点”恰与宏观拉伸曲线的“第一次屈服”位置相对应,如图中竖直虚线标明。上述现象说明在这些循环中,样品在“第一次屈服”之前就发生了应力诱发马氏体相变,只是相变速率较低,相变并不明显;而在“第一次屈服”后的加载过程中,相变转而以更高的速率持续进行。由于相变应变(非弹性因素)的引入会使样品的表观弹性模量(应力-应变曲线斜率)降低,并且相变速率越高,表观模量越低,因此,正是相变速率的突然升高大幅降低了表观模量,使拉伸曲线出现“第一次屈服”。在第5、6次循环中,B19'(001)峰面积曲线在加载初期几乎就以最高的斜率线性升高,即加载初始就发生了高速且持续的应力诱发马氏体相变,导致整个加载前中期相变速率的差别不大。表现在拉伸曲线上,则是“第一次屈服”之前、之后2个阶段的表观模量非常接近,“第一次屈服”变得难以辨认,拉伸曲线更接近线性。图7总结了这6次循环中,加载初期和“第一次屈服”后2个阶段B19'(001)峰面积-宏观应变曲线的斜率(表征相变速率)。可以看出,随着预变形量的增加,加载初期的相变速率逐渐升高,而“第一次屈服”后的相变速率略有降低,2者逐渐接近,最终达到一致。由此可见,准线性超弹性的产生源于“第一次屈服”的消失,而“第一次屈服”的消除源于加载初期和“第一次屈服”后2个阶段的相变速率趋于一致。

图6

图6

NiTi-Nb复合材料在6次加载过程中的应力-应变曲线,以及在加载过程中NiTi马氏体峰面积随宏观应变的演变曲线

Fig.6

Stress-strain curves of the as-annealed NiTi-Nb composite, and the corresponding B19'-NiTi(001) peak area curves in the 6 loading processes (In each loading process, the “first yield point” on the stress-strain curve just corresponds to the “turning point” on the evolution curve of B19' peak areas, as marked by each dash line)

图7

图7

实验涉及的6次循环中,每次加载的初期和“第一次屈服”后2个阶段B19'(001)峰面积-宏观应变曲线斜率的演变

Fig.7

Slopes of B19'-NiTi(001) peak area curves at the beginning and after the 1st yielding of each loading process, which can be seen as a measurement of the transformation velocity

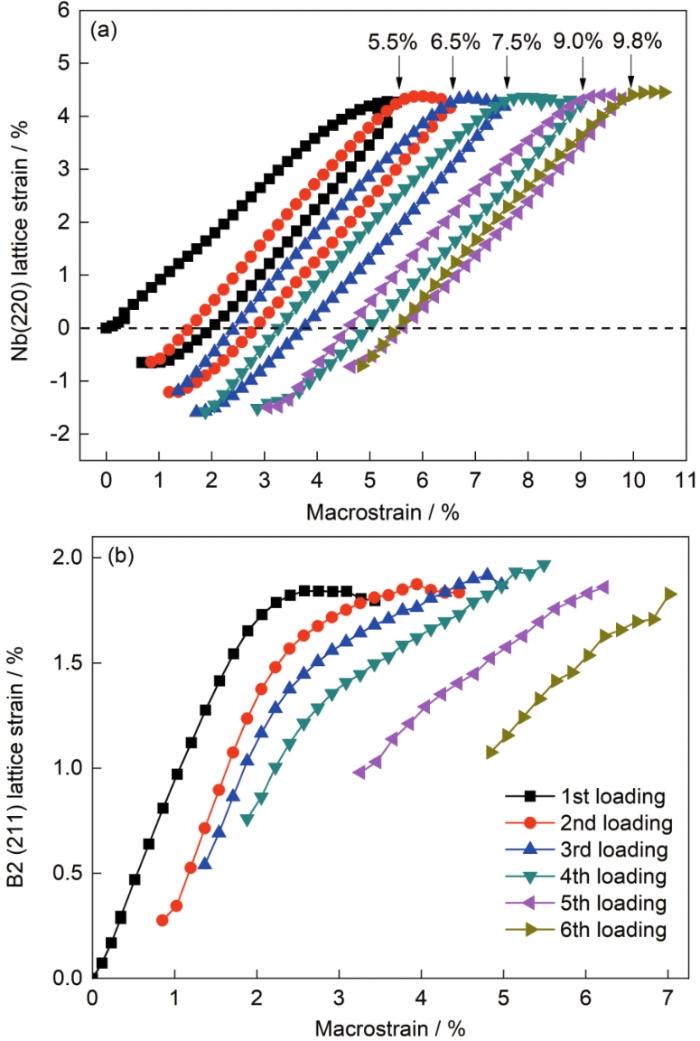

在实验涉及的6次拉伸循环过程中,垂直于丝轴向的Nb(220)晶面的晶格应变随宏观应变的演变曲线如图8a所示。考虑到弹性应变与应力成正比关系,故而图8a亦反映了复合态Nb纳米线分担的轴向应力在不同拉伸阶段的演变情况。由图8a可以看出,第一次卸载后,Nb纳米线产生了0.65%的残余晶格压应变(粗略取Nb的模量93 GPa[31],换算成压应力约0.6 GPa)。在随后的拉伸循环中,每次卸载后,Nb纳米线的残余压应变随着预变形量的增加而呈现先增加后减小趋势。其中,在第3次卸载后Nb纳米线的残余压应变最大(晶格压应变1.59%,换算成压应力约1.48 GPa)。与图8a类似,图8b为B2-NiTi母相(211)晶面的弹性晶格应变-宏观应变曲线,表征了不同宏观加载阶段母相的轴向受力状态。由于母相在加载过程中逐渐消失,而在卸载过程中逐渐浮现,同时给出加、卸载曲线会非常混乱,故而图中只给出各拉伸循环的加载曲线。由图可见,从第二次加载开始,每次加载初始NiTi母相都处于受拉状态,并且该残余拉应变随着预应变量的增加而逐渐增加。

图8

图8

Nb纳米线的弹性晶格应变-宏观应变曲线,及6次加载过程中B2-NiTi母相的弹性晶格应变-宏观应变曲线

Fig.8

Evolutions of the lattice strain for Nb(220) plane (a) and B2-NiTi(211) plane (b) perpendicular to the loading direction during the tensile process, which can be regarded as elastic strain vs total strain (elastic + plastic strain) relation of the embedded Nb nanowire and NiTi phase

2.4 准线性超弹特性的形成原因与变形机制

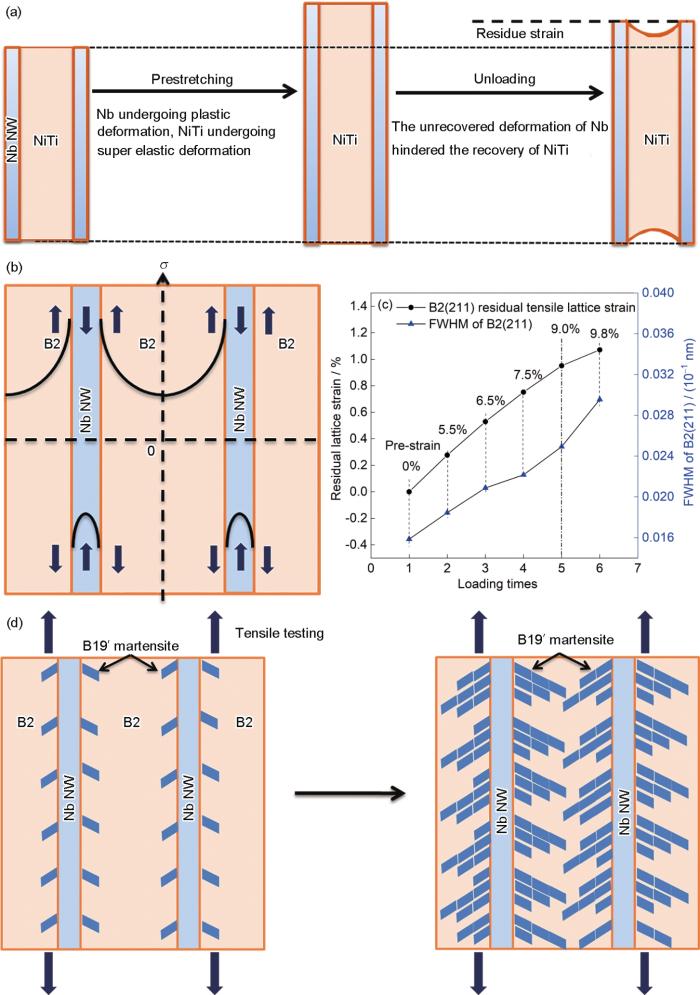

综合图8a和b可以看出,预变形使Nb纳米线受压而使NiTi母相受拉。这“一压一拉”的耦合关系及其耦合过程可通过图9a和b示意:当材料经历预拉伸并卸载后,Nb纳米线发生了塑性变形,并阻挡了NiTi的相变超弹性回复(图9a),因此2者间产生了耦合力,NiTi受到Nb纳米线的耦合拉应力,而Nb纳米线受到NiTi的耦合压应力(图9b)。考虑到2者间耦合力是通过界面传递的,此时NiTi内部应力分布必然会变得不均匀(NiTi母相峰半高宽升高,图9c),界面附近受到Nb纳米线的耦合拉应力最大,而NiTi芯部区域耦合拉应力最小,从界面到芯部会形成梯度应力场(图9b)。在随后的加载过程中,NiTi所受的耦合拉应力能够为应力诱发马氏体相变提供驱动力,而驱动力越大的区域诱发相变所需的外应力越低,那么相变必然从驱动力最大的界面附近开始,沿着梯度应力场向NiTi芯部推进,如图9d所示意。在梯度应力场中,越靠近芯部耦合拉应力越低,因而加载过程中诱发相变从界面向芯部推进所需的外应力逐渐升高,使相变(应力-应变)曲线呈“硬化型”的斜线而非通常的“平台型”的水平线。

图9

图9

样品预变形示意图,预变形后样品内部应力分布示意图,B2-NiTi母相在每次加载前的衍射峰半高宽值和残余应变,及预变形后再次加载过程中马氏体相变从界面向NiTi芯部推进示意图

Fig.9

State evolution diagrams of samples during the tensile loading after a pre-deformation

(a) schematic of the pre-deformation process (NW—nanowire)

(b) schematic of stress distribution inside the specimen after pre-deformation (σ—stress)

(c) full width half maximum (FWHM) values and residual tensile lattice strains of B2-NiTi at the beginning of each loading process, where the increase of FWHM indicates that the stress distribution in B2-NiTi becomes more unequal, and the increase of residual tensile lattice strain indicates the increasing of coupling tensile stress in B2-NiTi

(d) schematic of martensitic transformation process which starts near the NiTi/Nb interface and then gradually moves to the core of B2-NiTi when loading a pre-deformed specimen

则在实验涉及的各拉伸循环的加载起始点,样品的状态演变情况及其对相变的影响如下:随着预变形量的增加,NiTi母相所受耦合拉应力的平均值逐渐升高(母相的残余晶格拉应变逐渐升高,图8b和9c)。当NiTi界面附近某些区域的耦合拉应力接近甚至达到应力诱发马氏体相变所需临界应力(通常是NiTi应力诱发马氏体相变的“上平台”力)时,分布于这些区域的NiTi母相便可在下次加载初始就直接发生马氏体相变,出现开启相变所需的外应力几乎降低到零的现象。继续加载,相变就会沿着梯度应力场从界面向NiTi芯部推移(如图9d所示),展现“硬化型”相变曲线。结合有关图6和7的分析,当预变形量较低时(如前4次拉伸循环),虽然也会出现加载初始就相变的现象,但由于加载初期由耦合拉应力提供的相变驱动力较低(预变形量较小,NiTi母相所受耦合拉应力的平均值较低),导致加载初始的相变速率很低,远低于“第一次屈服”后的相变速率,因而没有出现准线性超弹性变形。随着预变形量的继续增加,NiTi母相所受耦合拉应力的平均值随之升高,加载初期由耦合拉应力提供的相变驱动力逐渐增大,使初始相变速率逐渐升高。当加载初期相变速率增长至接近“第一次屈服”后的相变速率时(如第5次拉伸循环),“第一次屈服”就会变得难以辨认,从而使应力-应变加载曲线更接近线性,展现出完美的准线性超弹特征。但是,再进一步增加预变形量(如第6次拉伸循环),由于相变已接近尾声,该加载循环所涉及的相变转变量大幅减少(图6中第6次加载过程的相变转变量最少。每次加载过程中涉及的相变转变量可通过B19'马氏体峰面积在该加载过程的增量度量),由相变产生的超弹性变形量随之降低。因而,第6次加载曲线虽然也接近线性,但准线性超弹性应变不到5%,超弹特性较第5次循环差。

3 结论

(1) 通过真空感应熔炼、锻造、拔丝加工获得原位自生的Nb纳米线增强NiTi记忆合金复合材料丝材。NiTi基体为纳米晶基体,Nb纳米线沿丝材轴向平行排列在NiTi基体中。

(2) 该NiTi-Nb复合材料在经历一次9%的预变形后会展现高强度、低模量、准线性超弹特性。其屈服强度达到1.7 GPa,表观Young's模量约34 GPa,准线性超弹性应变接近5.5%。

(3) 复合材料经过较低的预变形后,再次加载会出现2次屈服。其中“第一次屈服”与应力诱发马氏体相变有关。“第一次屈服”之前相变就已经发生,只是相变速率很低;“第一次屈服”之后相变速率大幅提高,使拉伸应力-应变曲线斜率陡然降低,从而产生了“第一次屈服”。

(4) 随着预变形量的增加,“第一次屈服”前、后2个阶段的相变速率逐渐接近。当这2个阶段的相变速率非常接近时,“第一次屈服”基本消失,材料展现出准线性超弹特性。故准线性超弹性的产生源于“第一次屈服”的消失,而“第一次屈服”的消除源于加载初期和“第一次屈服”后2个阶段的相变速率趋于一致。

(5) 同步辐射高能X射线原位拉伸测试表明,预变形使NiTi基体和Nb纳米线间产生耦合力,Nb纳米线受耦合压应力,而NiTi母相受耦合拉应力。并且,随着预变形量的增加,NiTi母相所受耦合拉应力逐渐增加。

(6) 分析了预变形后再次加载过程中NiTi-Nb复合材料的变形机制。加载之前NiTi界面耦合力最大,而芯部耦合力最小,从界面到芯部存在梯度应力场。加载过程中应力诱发马氏体相变从界面向NiTi芯部推进,并且诱发相变从界面向芯部推进所需的外应力逐渐升高,使相变应力-应变曲线呈“硬化型”斜线。

(7) 当界面附近耦合力达到诱发马氏体相变所需的临界应力时,便可以在下次加载初始就发生应力诱发马氏体相变。随着预变形量的增加,母相所受耦合拉应力的增加导致加载初期相变驱动力的增加,有助于促进加载初期相变速率的提高,当预变形量(耦合拉应力)足够高时,加载初期的相变速率便可以接近甚至达到“第一次屈服”之后的相变速率,使拉伸曲线展现准线性超弹特征。

参考文献

The lattice instability induced by Ti-site Ni in B2 austenite in TiNi alloy

[J].<p>The shape memory effect exists in the temperature range between martensitic phase transformation temperature and reverse martensitic phase transformation temperature, thus the control of martensitic phase transformation temperature is a key issue for the application of shape memory alloys. Valence electrons have been thought to dominate phase stability and phase transformation temperature in TiNi alloy. Inconsistent with the valence electron theory, Ti-site Ni could lead to a significant decrease of phase transformation temperature in TiNi alloy. To deeply understand the effect of Ti-site Ni, a point-defect-perturbation strategy was proposed to prove that Ti-site Ni indeed induced a local lattice instability in B2 austenite. It is the structural feature of instability final phase that one-dimensional <100><sub>B2</sub> atomic column compression and <111><sub>B2</sub> column expansion from the perturbation site. The final phase is energetic lower than B2 structure, and the lowest energy of final phase is 20 meV/atom lower than B2 structure, when the perturbing Ti-site Ni content reaches 2%~4%. In contrast to the case in austenite, Ti-site Ni did not induce the lattice instability in B19′ martensite. The difference between austenite and martensite is to some extent the origin of the significant decrease of phase transformation temperature brought by Ti-site Ni in TiNi alloy.</p>

TiNi合金B2奥氏体中Ti位Ni诱导的晶格失稳

[J].提出了点缺陷扰动策略,并利用此策略证实Ti位Ni实际上引起了B2奥氏体局域晶格失稳。失稳终态相的结构特征是从扰动位出发的一维方向上的<sub>B2</sub>原子列收缩和<sub>B2</sub>原子列膨胀。失稳终态相的能量低于B2相,最低能量比B2相低20 meV/atom,在Ti位Ni浓度达到2%~4%时出现。与奥氏体情况相反,Ti位Ni无法令B19′马氏体失稳。Ti位Ni显著降低TiNi合金相变温度的现象一定程度上来源于此。

High temperature deformation behavior of high strength and toughness Ti-Ni base bulk metallic glass composites

[J].Room-temperature brittleness and strain-softening during deformation of bulk metallic glasses, and limited processability of shape memory alloys have been stumbling blocks for their advanced functional structural applications. To solve the key scientific problems, a new shape memory bulk metallic glass based composite, through the approach using transformation-induced plasticity (TRIP) effect of shape memory alloys to enhance both ductility and work-hardening capability of metallic glasses, and superplasticity of bulk metallic glass in supercooled liquid region to realize near net forming, was developed in this work. And the Ti-Ni base bulk metallic glass composites (BMGCs) rods were prepared by the levitation suspend melting-water cooled Cu mold process. Microstructure, thermal behavior, mechanical properties and high temperature deformation behavior of the alloy were investigated. The results show that the as-cast alloy microstructure consists of amorphous matrix, undercooled austenite and thermally-induced martensite. Besides, the size of the crystal phase precipitated on the amorphous matrix increases from the surface to the inside. The alloy exhibits excellent comprehensive mechanical properties at room temperature. The yield strength, fracture strength and the plastic strain of alloy are up to 1286 MPa, 2256 MPa and 12.2%, respectively. Under compressive loading in the supercooled liquid region, the composite exhibits approximate Newtonian behavior at lower strain rate in higher deformation temperature, and the optimum deformation temperature is T>480 ℃ and the intersection part with supercooled liquid region (SLR). When the temperature is 560 ℃ and the strain rate is 5×10-4 s-1, the stress sensitivity index m and the energy dissipation rate ψ are 0.81 and 0.895, respectively. Furthermore, the volume of activation is quantified to characterize the rheological behavior.

高强韧Ti-Ni基块体金属玻璃复合材料高温变形行为

[J].采用水冷Cu坩埚悬浮熔炼-Cu模吸铸法制备了 Ti-Ni基块体金属玻璃复合材料(BMGCs)试棒,研究了合金的微观组织、热力学行为以及室温和高温力学性能。结果表明,该铸态合金组织由非晶基体和过冷奥氏体及热致马氏体组成,且晶体相尺寸由表及里增大。在室温压应力加载时,合金表现出优异的综合力学性能,其屈服强度为1286 MPa,断裂强度为2256 MPa,且塑性应变为12.2%。在过冷液相区压应力加载时,合金在高的变形温度和低应变速率下,表现出近Newtonian流变特征,其最佳变形温度为T>480 ℃且与过冷液相区(SLR)的交集部分。温度为560 ℃、应变速率为5×10<sup>-4</sup> s<sup>-1</sup>时,合金应力敏感指数m和能量耗散率ψ分别为0.81和0.895。

Topological modelling of the B2-B19' martensite transformation crystallography in NiTi alloy

[J].

NiTi合金B2-B19'马氏体相变晶体学的拓扑模拟研究

[J].运用拓扑模型研究了等原子比NiTi合金B2-B19'马氏体相变晶体学,根据最优扭转角(ω<sub>o</sub>)准则计算得到ω<sub>o</sub>=-0.969°,并获得了马氏体惯习面指数及母相-马氏体相界面位错结构特征,计算结果与实验测量值非常接近。NiTi合金马氏体相变所产生的相变应变包含一个平行于惯习面的剪切应变和一个垂直于惯习面的轴向应变,轴向应变量表示B2-B19'相变所引起的宏观体积变化为$ε_{33}^{HP}$=6.6879×10<sup>-3</sup>,表明NiTi合金的负热膨胀现象来源于合金中马氏体相变所产生的相变应变。

Microstructure, phase transformation and shape memory behavior of chilled Ti-47Ni alloy ribbons

[J].The micro-actuater materials are needed urgently in micro-electro-mechanical systems (MEMS) which are developing rapidly. The melt-spun Ti-Ni shape memory alloy ribbons have become candidate materials since their fast heat response and large acting density. The bulk Ti-47Ni (atom fraction, %) shape memory alloy is an ideal material to make thermosensitive actuators since its one-stage martensitic transformation and small temperature hysteresis. In order to develop the micro-actuator materials with fast response using in MEMS, the chilled Ti-47Ni alloy ribbons were fabricated by melt-spinning in this research. The effects of the roller speed and the annealing processes on microstructure, phase composition, phase transformation behaviors and shape memory effect of Ti-47Ni alloy ribbons were investigated by CLSM, XRD, DSC and bending test. The results show that the microstructure of as-cast and 300~800 ℃ annealed Ti-47Ni alloy ribbons fabricated under different roller speeds is vertically and horizontally arrayed columnar. The higher the roller speed, the finer the grain is. The annealing processes do nearly affect the microstructure of the alloy ribbons. The composition phases of Ti-47Ni alloy ribbons are martensite (B19' phase, monoclinic structure) and parent phase (B2 phase, CsCl-type structure). The B2→B19'/B19'→B2 type one-stage martensitic transformation occurs in Ti-47Ni alloy ribbons upon cooling and heating, the martensitic transformation temperature and the reverse martensitic transformation temperature are about 54 and 81 ℃, respectively, and the temperature hysteresis is about 27 ℃. With increasing the roller speed, the martensitic transformation temperatures of the alloy ribbons decrease, and the recovery rate of shape memory of the alloy ribbons increases. With increasing the annealing temperature, the transformation behaviors of the alloy ribbons change a little, and the recovery rate of shape memory changes in the range of 93%~98%. The as-cast and annealed Ti-47Ni alloy ribbons are all of excellent shape memory effect.

激冷Ti-47Ni合金薄带的组织、相变和形状记忆行为

[J].为了开发微机电系统用快响应微执行器材料,采用熔体快淬法制备了激冷Ti-47Ni (原子分数,%)形状记忆合金薄带,利用CLSM、XRD、DSC和弯曲实验研究了铜辊速率和退火工艺对Ti-47Ni合金薄带显微组织、相组成、相变行为和形状记忆行为的影响。结果表明,不同辊速制备的铸态和300~800 ℃退火态Ti-47Ni合金薄带的显微组织均呈纵横排列的柱状,辊速越高合金薄带的晶粒越细,退火工艺对合金薄带显微组织影响不大。Ti-47Ni合金薄带的组成相为马氏体(B19'相,单斜结构)+母相(B2相,CsCl型结构),冷却/加热时发生B2→B19'/B19'→B2一阶段马氏体相变,正、逆马氏体相变温度分别约为54和81 ℃,相变热滞约为27 ℃。随辊速增加,合金薄带马氏体相变温度降低,形状记忆恢复率提高。随退火温度升高,合金薄带相变行为变化不大,形状记忆恢复率在93%~98%之间变化。铸态和退火态Ti-47Ni合金薄带皆具有优异的形状记忆效应。

Phase transformation temperature control of weld metal of laser welded TiNi shape memory alloy joint

[J].

TiNi形状记忆合金激光焊接焊缝金属相变温度的控制

[J].

Phase field simulation of auto-catalytic growth effect of coherent Ni4Ti3 precipitate in NiTi shape memory alloy

[J].

NiTi形状记忆合金中Ni4Ti3共格沉淀相自催化生长效应的相场模拟

[J].

Micromechanical constitutive model for phase transformation of NiTi polycrystal SMA

[J].

多晶NiTi形状记忆合金相变的细观力学本构模型

[J].

In situ multi-fields investigation on instability and transformation localization of martensitic phase transformation in NiTi alloys

[J].<p>When NiTi shape memory alloys thin strips under the uniaxial tensile deformation, the stress-induced martensitic transformation tends to exhibit strain localization and instability, and the sample shows reversible transformation bands evolution on macroscopic. The displacement, strain and temperature fields were investigated with in situ optical method, and the full-field strain and temperature information about martensitic localization were quantitatively obtained during uniaxial loading—unloading conditions. Strain field is calculated by digital image correlation (DIC) method, and the temperature field is captured by infrared thermograph, the thickness field and in-plane rotation angle are also calculated by DIC data.The strain, temperature variation, thickness, in-plane rotation both inside and outside of the transformation bands were studied when it nucleation, expansion, combination, reduction and disappear. The results show that transformation strain of the samples are mainly concentrated inside the transformation bands but small outside, and temperature variation mainly concentrated in the transformation fronts, the thickness field in transformation bands is 2% smaller than out of bands. In-plane rotation angle is not only concentrated in the transformation fronts, but also heterogeneous in the transformation bands. In addition, the maximum in-plane rotation angle during tension is 1.5 °. The whole loading-unloading progress is full thermal coupling, transformation localization, martensite and austenitic critical nucleation stress are greatly influenced by temperature variation.</p>

NiTi合金中马氏体相变失稳与局部化的原位多场研究

[J].采用数字图像相关(DIC)方法原位测定了NiTi形状记忆合金薄带在单轴拉伸下变形时的应变场,采用红外热成像法(IR)原位测定其温度 场, 并定量获得了单轴拉伸加载-卸载条件下马氏体带局部化的全场应变与温度信息. 同时研究了相变带的形核、扩展、合并、缩减、 分裂及消失等过程中相变带内和带外应变场、温度场、厚度场及折曲角场的变化规律. 结果表明, 相变应变主要集中在相变带内部, 而带外应变量很小, 温度场和厚度场变化主要集中在相界面移动的前端,折曲角场变化集中在相变前端且带内分布不均匀.

3D finite element simulation of pull-out force of TiNiFe shape memory pipe coupling with inner convex

[J].

内脊型TiNiFe记忆合金管接头拉脱力的三维有限元模拟

[J].

Study on shape recovery temperature of TiNi alloy laser weld joint

[J].

TiNi合金激光焊接接头形状恢复温度的研究

[J].利用热模拟试样模拟TiNi合金激光焊接接头焊缝热影响区, 对焊接接头、焊缝金属、模拟热影响区和母材的相变温度进行差热分析, 研究了焊接接头与其它三者逆相变温度的关系, 并利用OM, SEM和XRD对母材、热影响区和焊缝金属的组织、析出相的分布以及晶体结构进行了研究. 结果表明,TiNi合金激光焊接接头的形状恢复率与母材无明显差别, 但形状恢复温度区间与母材差异较大, 其形状恢复开始温度比母材低40 ℃; 焊缝金属和热影响区逆相变开始温度(A<sub>s</sub>)和结束温度(A<sub>f</sub>)均不同于母材,主要原因是焊缝金属经历了熔化-凝固过程, 失去了母材中原有的晶体择优取向,且析出相尺寸小、分布不均; 而热影响区A<sub>s</sub>和A<sub>f</sub>降低,可能是细小析出相重新固溶于基体所致. 整个接头的逆相变温度区间与焊缝金属近似,调控焊缝金属的相变温度是控制TiNi合金激光焊接接头形状记忆功能的关键.

Effect of aging on microstructure and superelasticity in Ti-50.8Ni-0.3Cr shape memory alloy

[J].

时效对Ti-50

.8Ni-0.3Cr形状记忆合金组织和超弹性的影响 [J].

Preparation of nano-sized SiC reinforced NiTi shape memory composites and their mechanical properties and damping behavior

[J].

纳米SiC颗粒增强NiTi形状记忆复合材料制备及其力学性能和阻尼行为

[J].

Phase field simulation of effects of pores on B2-R phase transformation in NiTi shape memory alloy

[J].

孔隙对NiTI形状记忆合金中B2-R相变影响的相场模拟

[J].建立了适用于含孔隙NiTi合金中B2-R相变的相场模型, 并用该相场模型研究了多孔NiTi合金中B2-R转变的微观组织演化过程以及孔隙率和孔尺寸对R相变体生长动力学行为的影响. 多孔NiTi合金中R相变体以相互协调的方式形成“带状”的三维结构和“鱼骨”状的二维组织, 变体之间形成的孪晶面包括{101}<sub>B2</sub>和{001}<sub>B2</sub>2种, 4组变体相交于<sub>B2</sub>; 这些结果与致密NiTi合金B2-R相变过程相同. 多孔NiTi合金中 R相优先在孔周围形核, 且较大的孔周围有较多的变体形核; R相变体的平均尺寸随孔隙率增大而逐渐减小, 随孔径增大而增加; 相对于规则圆孔, 不规则孔隙可导致R相变体尺寸略微减小; 变体的尺寸均匀性则随孔隙率增大而提高, 但对孔径大小和孔形状不敏感; 孔隙数量越多且孔径越小, 则B2-R转变越倾向于产生均匀而细密的R相组织.

Effect of Cr addition on transformation and cyclic deformation characteristics of Ti-Ni shape memory alloy

[J].The effect of Cr addition on the transformation and the cyclic deformation characteristics in 550℃ annealed Ti-50.8Ni shape memory alloy (SMA) were investigated by differential scanning calorimetry (DSC) and tensile test. The B2→R→M/M→B2 type reversiable transformation occurred in Ti-50.8Ni alloy upon cooling/heating. After the addition of 0.3%Cr in Ti-50.8Ni alloy, the transformation type for Ti-50.8Ni-0.3Cr alloy was B2→R→M/M→R→B2, and the transformation temperatures decreased significantly. At room temperature, the phase composition was parent phase B2 for both Ti-50.8Ni and Ti-50.8Ni-0.3Cr alloys, while the former showed shape memory effect; the latter showed superelasticity. With increasing cyclic deformation number <em>n</em>, Ti-50.8Ni alloy evolved from shape memory effect to linear superelasticity, and its stress inducing martensitic critical stress and the accumulation residual strain increased rapidly; while Ti-50.8Ni-0.3Cr alloy evolved from incomplete superelastic to complete superelastic, and the stress-strain curve shape was stable. With increasing <em>n</em>, the superelastic residual strain <em>ε</em><sub>r</sub> decreased and the superelastic strain recovery ratio <em>η</em><sub>s</sub> of Ti-50.8Ni alloy increased, while the <em>ε</em><sub>r</sub> and <em>η</em><sub>s</sub> in Ti-50.8Ni-0.3Cr alloy kept at lower and higher values, respectively. The superelastic of Ti-50.8-0.3Cr alloy was stable.

Cr掺杂对Ti-Ni形状记忆合金相变和循环形变特性的影响

[J].

Phase field simulation of the effect of applied external stress on growth kinetics of coherent Ni4Ti3 precipitate in NiTi alloy

[J].

外应力对NiTi合金中Ni4Ti3共格沉淀相长大行为影响的相场法模拟

[J].运用相场模型模拟了外加应力对NiTi形状记忆合金中Ni4Ti3沉淀相组织形貌及长大行为的影响。无外加应力作用的时效过程中,4组Ni4Ti3变体均沿着各自对应的(111)B2惯习面从NiTi基体相中析出;而在B2方向施加压应力时,则只有一组Ni4Ti3变体从NiTi基体相中析出,其惯习面法线方向平行于外加应力方向;单轴压应力作用下时效时, Ni4Ti3形核数量明显增加。外加单轴压应力可促进Ni4Ti3变体的形核和长大,但并不改变变体的面积分数、长度、宽度以及长度-宽度比等参数随时效时间变化的趋势;相同时刻,压应力增大使变体长度及宽度均略微增加,但均小于无应力作用下的情形;而相同时刻,变体的面积分数随外加应力的增大而增加。相场模拟结果与实验观察能较好地吻合。

Effects of annealing temperature and stress-strain cycle on superelasticity of Ti-Ni-Cr shape memory alloy

[J].

退火温度和应力-应变循环对Ti-Ni-Cr形状记忆合金超弹性的影响

[J].用拉伸实验研究了退火温度(θ<sub>an</sub>)和应力-应变循环对Ti-50.8Ni-0.3Cr合金超弹性(SE)的影响. 结果表明, 随θ<sub>an</sub>升高, 应力诱发马氏体(M)相变的临界应力σ<sub>M</sub>先降低后升高, 随后趋于稳定, 分别在450和600℃达到最小值(311 MPa)\linebreak 和最大值(583 MPa). 残余应变在θ<sub>an</sub>=350-590℃之间变化不大, 始终保持在较低的水平; 当θ<sub>an</sub>高于590℃时, 残余应变则急剧升高. 随着应力-应变循环次数(N)增加, 350和590℃退火态合金由部分非线性超弹性逐渐转变为完全非线性超弹性, 而650℃退火态合金由部分非线性超弹性逐渐转变为线性超弹性. 此外, 随N增加, 590和650℃退火态合金的能耗作用逐渐下降, 并趋于稳定, 而350℃退火态合金的能耗作用基本保持不变. 要使Ti-50.8Ni-0.3Cr合金获得良好的SE, 退火温度应低于再结晶温度.

Constrained martensitic transformation in nanocrystalline TiNi/NbTi shape memory composites

[J].

The ultrahigh mechanical energy-absorption capability evidenced in a high-strength NbTi/NiTi nanocomposite

[J].

In situ X-ray diffraction study of deformation behavior in a Fe/NiTi composite

[J].A Fe/NiTi composite wire fabricated by simple mechanical processing exhibits a singular deformation feature of strain recovery ratio increase with increasing tensile strain, which is diametrically opposite to that of conventional metal materials. Furthermore, the composite possesses a recoverable strain of over 7% and a higher mechanical damping capability than that of the well-known high damping NiTi shape memory alloy. In-situ synchrotron X-ray diffraction reveals that these extraordinary features originate from the strong interaction between the soft Fe core and the superelastic NiTi tube during tensile cycling. This study offers in-depth understanding of the deformation behavior of the composites composed of soft metal and superelastic shape memory alloy.

A transforming metal nanocomposite with large elastic strain, low modulus, and high strength

[J].Freestanding nanowires have ultrahigh elastic strain limits (4 to 7%) and yield strengths, but exploiting their intrinsic mechanical properties in bulk composites has proven to be difficult. We exploited the intrinsic mechanical properties of nanowires in a phase-transforming matrix based on the concept of elastic and transformation strain matching. By engineering the microstructure and residual stress to couple the true elasticity of Nb nanowires with the pseudoelasticity of a NiTi shape-memory alloy, we developed an in situ composite that possesses a large quasi-linear elastic strain of over 6%, a low Young's modulus of ~28 gigapascals, and a high yield strength of ~1.65 gigapascals. Our elastic strain-matching approach allows the exceptional mechanical properties of nanowires to be exploited in bulk materials.

Locality and rapidity of the ultra-large elastic deformation of Nb nanowires in a NiTi phase-transforming matrix

[J].This study investigated the elastic deformation behaviour of Nb nanowires embedded in a NiTi matrix. The Nb nanowires exhibited an ultra-large elastic deformation, which is found to be dictated by the martensitic transformation of the NiTi matrix, thus exhibiting unique characteristics of locality and rapidity. These are in clear contrast to our conventional observation of elastic deformations of crystalline solids, which is a homogeneous lattice distortion with a strain rate controlled by the applied strain. The Nb nanowires are also found to exhibit elastic-plastic deformation accompanying the martensitic transformation of the NiTi matrix in the case when the transformation strain of the matrix over-matches the elastic strain limit of the nanowires, or exhibit only elastic deformation in the case of under-matching. Such insight provides an important opportunity for elastic strain engineering and composite design.

Influence of internal stress coupling on the deformation behavior of NiTi-Nb nanowire composites

[J].

Local strain matching between Nb nanowires and a phase transforming NiTi matrix in an in-situ composite

[J].

Progress in high performance nanocomposites based on a strategy of strain matching

[J].

基于应变匹配的高性能金属纳米复合材料研究进展

[J].纳米线具有超高强度及超大弹性应变,以其增强的复合材料被预期具有超常力学性能,然而,已有研究结果一直“令人失望”。其原因是纳米线的超常力学性能未能在复合材料中体现。基于对位错滑移型金属基体中的位错与纳米线界面交互作用是“失望”之源的猜想,提出采用点阵切变型金属的切应变与纳米线的弹性应变相匹配的设计概念,选择纳米线Nb/NiTi 记忆合金等体系,证实了纳米线(带、粒子)的超常力学性能得以在复合材料中体现,使复合材料具备超常力学性能成为现实。此外,还发现上述突破可引发复合材料呈现超常力学性能的新机制(大应力耦合效应等)。据此设计的Nb纳米线/NiTi 记忆合金复合材料兼具:弹性应变极限大于6%,弹性模量低于28 GPa,屈服强度高达1.65 GPa。

Origin of high strength, low modulus superelasticity in nanowire-shape memory alloy composites

[J].An open question is the underlying mechanisms for a recent discovered nanocomposite, which composed of shape memory alloy (SMA) matrix with embedded metallic nanowires (NWs), demonstrating novel mechanical properties, such as large quasi-linear elastic strain, low Young's modulus and high yield strength. We use finite element simulations to investigate the interplay between the superelasticity of SMA matrix and the elastic-plastic deformation of embedded NWs. Our results show that stress transfer plays a dominated role in determining the quasi-linear behavior of the nanocomposite. The corresponding microstructure evolution indicate that the transfer is due to the coupling between plastic deformation within the NWs and martensitic transformation in the matrix, i.e., the martensitic transformation of the SMA matrix promotes local plastic deformation nearby, and the high plastic strain region of NWs retains considerable martensite in the surrounding SMA matrix, thus facilitating continues martensitic transformation in subsequent loading. Based on these findings, we propose a general criterion for achieving quasi-linear elasticity.

The microstructure and linear superelasticity of cold-drawn TiNi alloy

[J].

Linear and non-linear superelasticity in NiTi

[J].

Pseudoelastic cycling of ultra-fine-grained NiTi shape-memory wires

[J].

Effect of annealing on the transformation behavior and superelasticity of NiTi shape memory alloy

[J].

Enhancement of the Young's modulus in the ultrafine Cu-Nb filamentary composites

[J].Measurements of the Young’s modulus are reported for in-situ formed Cu-Nb wire composites containing 7.5 and 15.0 vol.% niobium filaments. Comparison of the experimental values for the as-drawn and annealed wires shows rapidly diverging trends with decreasing wire diameter. In composites with the smallest filaments (50–200 Å) the modulus increases by almost 100% upon annealing and exceeds the maximum values calculated from bulk elastic constants. However, plastic strain (in elongation) of as little as 0.02% results in a substantial (∼25%) reduction in modulus, suggesting that most of the enhancment in the annealed composites originates from the thermally induced elastic strains at the matrix-filament interfaces.