目前镁合金产品主要通过铸造方式成型[3],例如压铸工艺主要用于生产汽车和电子通讯产品行业的零部件,砂型铸造工艺主要用于制备军工装备和航空航天领域的尺寸较大、结构复杂、综合力学性能要求较高的关键镁合金部件。铸造、锻造和焊接工艺都属于等材制造,距今已有3000多年的历史;约300年前人类发明了车削、铣削和磨削等减材制造工艺,从此进入复杂机器时代;约30年前在美国诞生了增材制造(additive manufacturing)技术,也被称为快速原型(rapid prototyping)和3D打印(three dimensional printing)等,这一技术的爆发正在推动制造业的重大变革。增材制造的制造哲学是降维与程式化原理,基于离散堆积成形思想,先建立目标零件的三维计算机辅助设计(CAD)模型,再采用计算机将数据模型按照一定的厚度分层切片,即将零件的三维数据信息转化成一系列的二维轮廓信息,而后在计算机控制下将材料逐点、逐线、逐层的累积,最终成形出三维实体零件。目前等材制造制备的零件数量最多,减材制造次之,增材制造最少,但是增材制造制备的零件的单价是最高的,等材制造制备的零件的单价最低,故增材制造技术的整体发展趋势是从技术概念上的三足鼎立最终走向价值分享的三分天下[4]。

增材制造的应用对象包括金属、陶瓷、塑料、砂型和生物细胞等,其中金属增材制造技术被誉为3D打印行业“皇冠上的明珠”,是增材制造中最有前景和最为前沿的研究方向之一,有望实现合金及其复合材料、高熔点难加工金属构件的直接制造,是先进制造技术的重要发展方向。根据热源和原材料的不同,金属增材制造技术主要包括3种:铺粉式的选区激光熔化(selective laser melting,SLM)技术,也称激光粉末床熔融(laser powder bed fusion,LPBF)技术;送粉式的激光熔化沉积(laser melting deposition,LMD)技术,也称激光定向能量沉积(laser-directed energy deposition,LDED)技术;送丝式的电弧熔丝增材制造(wire arc additive manufacturing,WAAM)技术。LMD技术适合修复和再制造,有利于在线混粉高通量打印来筛选合金成分,成形尺寸较大,可制备梯度构件,但是激光光斑直径较大导致加工精度中等(± 1 mm)且变形较大;WAAM技术采用丝材作为原材料,材料和设备成本较低,成形效率高而且材料利用率高,可成形尺寸大,但是存在冷却速率较低、变形量大、加工精度低(± 2 mm)、不能制备复杂形状等缺点;SLM技术虽然存在原材料成本较高、目前的成形效率较低和成形尺寸较小等缺点,但是其激光光斑直径小使加工精度高,从而可以成形任意复杂形状或者多孔结构,而且激光束能量集中产生的熔池体积小且激光与粉床的相互作用时间短,从而具有最高的冷却速率,形成具有细小晶粒和第二相的快速凝固非平衡组织,力学性能优异,故SLM技术是最有前景且研究最广泛的金属增材制造技术。

一方面SLM工艺最高的加工精度(约等于激光光斑直径,大概100 μm)使其能够直接制备多孔结构的生物医用镁合金,另一方面SLM工艺最高的冷却速率(106~108 K/s)使得打印态合金的显微组织最细小均匀从而力学性能最优异,有助于直接近净成形高性能镁合金结构件。因此,镁合金的增材制造研究主要是针对SLM工艺[5],LMD和WAAM工艺制备镁合金的报道较少。Tandon等[6]在2016年最早采用LMD制备了致密度大于99%的Mg-4Y-3Zr (质量分数,%)合金:孔洞主要分布在连续多道的搭接区域,粉末和沉积态的平均晶粒尺寸分别为2和8 μm,沉积态和后续热处理态的室温拉伸性能与典型的铸造WE43B合金相当。Liao等[7]采用LMD制备了Mg-10Gd-3Y-0.4Zr (GW103K,质量分数,%)镁稀土合金并研究了T6热处理对沉积态显微组织和力学性能的影响规律:沉积态和T6态GW103K合金的屈服强度、抗拉强度和延伸率分别为118 MPa、232 MPa、13.9%和191 MPa、298 MPa、8.9%,沉积态与砂型铸造态相比,屈服强度相当,抗拉强度和延伸率更高;传统的T6热处理制度(525℃、4 h + 225℃、10 h)导致晶粒尺寸从19 μm显著粗化到158 μm并产生大量的稀土氢化物GdH2方块相,沉积-T6态与铸造-T6态相比,屈服强度和抗拉强度更低但是延伸率更高。Zheng等[8]在2022年研究了LMD制备Mg-15Gd-1Al-0.4Zr (GA151K,质量分数,%)过程中热循环对显微组织的演变规律:热循环相当于不完全固溶和时效热处理,导致晶间第二相从Mg3Gd转变为Mg5Gd,同时过饱和Mg基体中析出β'-Mg7Gd纳米析出相。镁合金的WAAM工艺研究大都集中在试样(单道多层成形)工艺参数的优化和沉积态显微组织和力学性能的表征[9],还没有实现零部件的制备,主要涉及传统的商业化Mg-Al-Zn体系[10,11],WAAM工艺的冷却速率较低导致平均晶粒尺寸较大及屈服强度较低,例如沉积态AZ31镁合金的晶粒尺寸为20~40 μm[10],但是该工艺沉积态的致密度最高使其延伸率是3种工艺中最高的。

相比于LMD和WAAM工艺,镁合金的SLM工艺研究起步较早,且取得了较好的研究成果,有突出的应用潜力。本文主要综述了国内外关于SLM制造镁合金的研究进展,系统概括了镁合金粉末制备、SLM成形过程中冶金缺陷的形成机理及控制方法、SLM态独特的显微组织和力学性能、后处理对SLM态显微组织和性能的影响规律、镁合金专用SLM设备的开发等方面的研究现状,最后提出了今后的研究展望。

1 SLM制造镁合金的优势

目前镁合金产品主要通过铸造方式生产,然而物理冶金制备大构件时存在三大难题难以克服:大熔炼量浇铸时冷却速率很慢,从液体变成固体时单位体积形成的晶体数量很少,故晶粒长得特别粗大导致力学性能较差;凝固结晶时高熔点的物质先结晶,低熔点的物质后结晶,大熔炼量导致溶质场、流动场不均匀,同一个构件从表面到芯部化学成分不一样即宏观偏析导致力学性能不一致;大构件凝固时一般从表面开始结晶,金属凝固结晶时体积是收缩的,这样就导致凝固最后阶段构件内部容易形成缩孔或缩松等缺陷从而损害力学性能。此外铸造过程需要专门开发模具,研发周期较长,材料利用率较低,能耗高污染重,而且采用砂型铸造制备大型复杂构件时成品率较低。正是由于铸造过程存在以上缺点,大铸件后续一般要做锻造处理来改善缺陷、细化显微组织并提升力学性能,但是液压锻造机的最大加载力是有限的,国内生产的世界最大的8万吨级液压锻造机锻造钛合金零件的最大面积仅为5 m2,超过5 m2的钛合金零件就无法锻造成形,目前镁合金锻坯的最大成形能力约为2000 mm × 400 mm × 300 mm,从某种意义上来说传统铸造变形工艺制备大型构件的制造能力具有一定的局限性。此外,镁合金的晶体结构为hcp结构,室温下可开动的滑移系较少,故对镁合金进行塑性加工一般在高温下进行[12],这需要消耗较多的能量。

相比之下,SLM技术具有传统制造工艺难以比拟的优势:激光通过逐点逐线逐层扫描成形,成形大构件由大化小,大构件是由无数个百微米级别的微小熔池堆叠而成,成形零件尺寸可随着成形设备的增大而无限增大,理论上不存在尺寸限制,熔池内化学成分均匀从而整个构件不存在宏观偏析,各个部位的冶金凝固条件基本一致,而铸造过程难以控制成形大型复杂构件时各个部位的冶金凝固条件保持一致;SLM快速凝固过程形成的晶粒非常细小,故打印态的力学性能尤其是拉伸强度相比于铸态合金有显著提升[13];SLM过程通过分层切片把复杂的三维形状变成简单的二维轮廓信息,从而可成形近乎无限复杂的零件,成形过程无需开发模具,有利于缩短研发周期加快产品的迭代,材料利用率高(基板上未成形区域的粉末回收筛分后可继续使用)。综上,SLM技术具有加工精度高、高效灵活、力学性能优异等优势,因此采用该技术制造镁合金构件有望克服传统制造技术的局限性,是进一步提高镁合金力学性能并扩大其应用范围的有效策略。

2 SLM制造镁合金的挑战

(1) 球形粉末制备困难:镁合金粉末活性大、易燃易爆的特性使得全球范围内掌握镁合金粉末制备技术的公司较少。

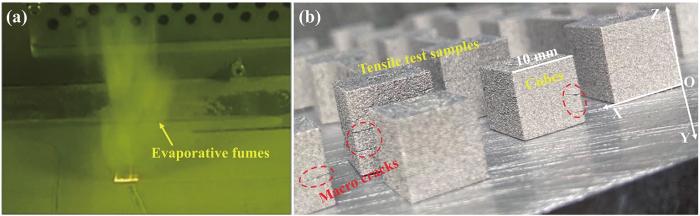

(2) 成形过程不稳定:Mg的沸点较低(约1091℃),饱和蒸气压较高(620℃时蒸气压为0.13 kPa,当温度升高到1027℃时蒸气压显著增大到51 kPa[18]),导致打印过程中粉末蒸发飞溅(spatter,熔池中排出的液态颗粒)严重,烟尘(plume,熔池上方金属蒸气、等离子体和蒸气凝结的细小颗粒的混合物)较大,金属蒸发会影响成形过程中能量、动量和质量的传递[19]。图1a[20]表明,SLM制造镁合金过程中存在大量的蒸发烟尘,而SLM制造铁基合金、铝合金、钛合金等基本不产生烟尘或者极少量的烟尘,烟尘不能及时去除停留在打印区域上方会对激光能量产生散射,从而激光输入熔池的能量不稳定,导致成形过程不稳定。

图1

(3) 易形成孔洞:打印过程中Mg的蒸发是不可避免的,动态瞬息万变的匙孔(keyhole)容易失稳产生匙孔隙,而且SLM过程凝固速率很快导致Mg蒸气来不及从熔池中逸出从而形成孔洞。

(5) 易氧化:尽管成形舱室内通入高纯Ar气,但是Mg与O的亲和力较高(镁合金中加入稀土元素后稀土与O的亲和力更高),打印过程中Mg会与惰性气氛和粉末间隙中的少量氧发生轻微的氧化现象,另外镁合金粉末出厂之前都会做惰化处理导致粉末表面存在氧化物。

3 SLM制造镁合金的研究现状

3.1 SLM制造镁合金的研究概况

图2展示了SLM制造镁合金的发展历程:从2010年报道纯Mg[23~27]开始,陆续有Mg-Al系[18,28~41]、Mg-Zn系[42~57]、Mg-Sn系[58]、Mg-Mn系[59]、Mg-Ca系[60]、WE43镁稀土合金[61~71]、Mg-Y-Sm-Zn-Zr镁稀土合金[72,73]、镁基复合材料[74~77]以及Mg-65Zn-5Ca (原子分数,%)非晶合金[78]出现,本团队针对SLM工艺开发了一系列高强度Mg-Gd系镁稀土合金[20,79~84] (如G10K、GZ112K、GZ151K、GWZ1031K等)和生物医用JDBM-NZ30K镁稀土合金[85,86]。镁合金的SLM研究大多针对商业化的镁合金牌号,如WE43、AZ91D、AZ31、AZ61、ZK60、ZK61等,缺乏SLM专用镁合金牌号(兼具良好的工艺性能即成形工艺区间宽和不易产生孔洞裂纹缺陷、打印态及后处理态良好的力学性能)的开发。镁合金的SLM研究不仅仅局限于通过优化工艺参数制备高致密度实体来提升力学性能,以期制备结构件获得工程应用,另一方面,Mg是人体必需的微量元素且弹性模量与人体骨骼接近、固有的生物降解性和良好的生物相容性,加上SLM技术的制造精度高,目前有很多关于镁合金的SLM制备形状复杂的多孔点阵结构来研究该生物医用植入物的耐腐蚀性能、生物降解性和细胞相容性的报道,以期制备生物医用材料获得临床应用[87]。本文聚焦于SLM制备实体镁合金的显微组织和力学性能的研究进展,以期为将来SLM制备航空航天、军工装备、汽车等领域用的高性能镁合金构件提供参考。

图2

图2

SLM制造镁合金的发展历程

Fig.2

Timeline displaying the historical background of research and development on SLM of Mg alloys (LPSO—long period stacking ordered, FSP—friction stir processing)

早期镁合金的SLM研究主要采用纯Mg粉。2010年,Ng等[23]最早尝试用纯Mg粉进行单道熔池实验,结果表明不规则形状粗大(75~150 μm)的Mg粉无法形成完整连续的单道熔池,而球形细小(5~45 μm)的Mg粉可形成完整连续的单道熔池,且激光能量传递到熔池周围粉末使其在熔池附近烧结。随后Ng等[24]在2011年用SLM制备了20 mm长的激光单道扫描熔池,研究了激光加工参数对显微组织和力学性能的影响规律:SLM过程高冷却速率形成细小的α-Mg等轴晶粒;激光能量密度提高导致冷却速率下降,因而平均晶粒尺寸增大;SLM制备的纯Mg的硬度和Young's模量与人骨接近,有良好的生物医用应用前景。Hu等[26]在2015年采用SLM制备了块体纯Mg并研究了粉末粒径对成形质量的影响:大于400目细粉(平均粒径为25.85 μm)不能均匀铺展开来,这是因为细粉颗粒间的摩擦力更大降低了粉末的流动性,而且细粉相比于粗粉更容易被保护气流吹走;用大于250目粗粉(平均粒径为43.32 μm)成形的试样的表面质量相比于大于400目细粉更好,这是因为熔化粗粉需要更多的激光能量且粗粉相比于细粉不容易被熔池捕获;细粉成形试样表面存在较多未熔化和球化的颗粒,在相同的激光能量密度下细粉粉末形成的熔池温度更高导致氧化和球化现象更严重;采用粗粉成形试样的致密度和显微硬度都高于细粉。

SLM制造镁合金生物医用材料是非常有潜力的方向,调控镁合金过快的降解速率是关键技术瓶颈。中南大学帅词俊团队采用SLM制备了许多生物镁合金,主要包括Mg-xMn (x = 0~3%,质量分数)[59]、Mg-xSn (x = 0~7%,质量分数)[58]、ZK30[53]和ZK60[43]及其添加Cu[45]、Gd[48]和氧化石墨烯[49]的复合材料和Mg-65Zn-5Ca (原子分数,%)非晶合金[78]:SLM态纯Mg具有相对粗大的枝晶结构(20~25 μm),加入Mn和Sn元素可以显著细化晶粒到5~10 μm并且增强耐腐蚀能力;SLM快速凝固过程带来的细小晶粒、均匀的显微组织和固溶度的提升可以改善ZK60合金的腐蚀行为;Cu元素的加入可以释放铜离子和产生碱性环境从而增强抗菌性和生物相容性;加入Gd元素会在晶内形成长周期堆垛有序(long period stacking ordered,LPSO)结构(Mg12GdZn)从而形成均匀降解模式并提升抗降解能力,这是因为LPSO结构是不稳定的层错相,可优先降解形成致密的降解产物膜以保护Mg基体,而且晶内的平行层片结构可以阻碍降解扩展到周围晶粒;ZK30合金中加入氧化石墨烯后会细化晶粒和抑制MgZn2析出相的形成,从而降低生物降解速率;SLM过程提供了很大的过冷度来实现快速凝固,这抑制了晶粒的形核和生长从而获得了非晶结构,SLM态Mg-65Zn-5Ca (原子分数,%,近共晶成分)合金主要由具有化学均匀性的无定形相组成,非晶合金具有优异的耐腐蚀性能。Liu等[60]在2017年用SLM制备了多孔Mg-2%Ca (质量分数)合金:随着激光能量密度增大,更多粉末被熔化,导致扫描道宽化和孔隙率降低;熔池内部温度梯度(G)大而凝固速率(R)趋近于0,故G / R很大有利于形成等轴晶;而远离熔池G减小而R增大导致G / R减小,热量向外扩散(垂直于熔池方向),最终形成柱状晶;熔池边界的冷却速率和过冷度最大导致晶粒最细小;与传统铸造镁合金(晶粒尺寸300~500 μm)相比,SLM态晶粒显著细化(5~30 μm);多孔Mg-Ca合金的显微硬度为60~68 HV,优于铸造纯Mg,主要强化机制为细晶强化和固溶强化;SLM制备的多孔结构抗压强度为111.19 MPa,弹性模量为1.264 GPa,低于骨组织(抗压强度130~180 MPa,弹性模量3~20 GPa),需通过调整激光参数来调控孔隙率加以改善,但是其未来临床应用前景广阔。随后Zhang等[44]在2018年研究了Zn含量对SLM制备的多孔ZK61合金表面形貌、孔隙率、显微组织和力学性能的影响规律:随着Zn含量的提升(Mg-xZn-0.3Zr,x = 5.2、15和30,质量分数,%),表面质量下降,晶粒明显细化,析出相经历了从MgZn→MgZn + Mg7Zn3→Mg7Zn3的连续转变,细晶强化、固溶强化和析出强化共同导致显微硬度显著提升。Li等[62]在2018年研究了拓扑有序多孔WE43镁合金的体外降解行为、力学性能和生物相容性:该多孔结构体外降解28 d后仍然保持结构完整性而没有明显的降解颗粒分离,Young's模量(700~800 MPa)基本不变,屈服强度从20 MPa减小到13 MPa,满足松质骨的力学性能要求,体外细胞毒性小于25%,是理想的骨替代材料。

随着镁合金SLM研究的进一步发展,逐渐报道了添加增强相的镁基复合材料以及成分更加复杂的添加多元混合稀土的Mg-Y-Sm-Zn-Zr合金。2018年,Wu和Wang[74]采用仿真热传导分析研究了碳纳米管(carbon nano tubes,CNTs)对SLM制备AZ31B镁合金的激光吸收率、熔池特征和蒸发孔隙率的影响规律:由于CNTs对激光的吸收率较高,加入1.5%CNTs (质量分数)后粉末对1070 nm波长激光的吸收率从76.4%提升到了84.3%,这有利于改善镁合金的激光吸收率偏低的问题;激光吸收率提升使得熔池的最高温度和熔池沿3个方向的尺寸都增大;显微组织不是完全致密,存在一些微孔,晶粒尺寸小于1 μm。Niu等[75]在2021年采用SLM制备了AZ91D + SiC纳米颗粒的复合材料:纳米颗粒与熔体发生反应形成高密度的形核质点,固/液界面的纳米颗粒显著阻碍Al溶质原子的扩散导致界面处溶质富集因而提升晶粒生长限制因子;与不加纳米颗粒相比,添加SiC纳米颗粒后剩余熔体的过冷度更大,从而激活更多潜在的形核质点,晶粒生长模式由柱状晶向等轴晶转变,晶粒尺寸显著细化(添加体积分数为5%SiC纳米颗粒后平均晶粒尺寸从(3.3 ± 1.1) μm减小到(1.1 ± 0.2) μm)并且显微组织均匀性得到提升从而提升了材料的力学性能。Wang等[72]在2020年通过模拟仿真和实验相结合的方法研究了SLM制备Mg-3.4Y-3.6Sm-2.6Zn-0.8Zr (质量分数,%) 合金的热行为和致密化现象:粉末是通过将铸态合金锭磨削球磨得到的,因而形状为颗粒状而不是球形,但是也能成功铺粉和制备较高致密度样品;熔池的温度和尺寸与激光功率正相关,与扫描速率负相关;线能量密度影响熔池的流动和气泡的移动从而影响致密化行为;在优化的激光功率和扫描速率下,气泡能顺利逸出,熔融液态的存在时间为355.58 μs,成形件的最优致密度为95.98% ± 1.4%。

3.2 镁合金粉末制备

Mg属于活性材料,Mg形成MgO放出的热量为603.2 kJ/mol,Mg以粉末形式存在时很有可能会发生爆炸,小于74 μm的粉末的爆炸下限为10 g/m3,压力上升速率等于6.3 MPa/s,镁合金粉末生产过程中要充分考虑Mg的这些特性。镁合金粉末生产的基本方法包括4大类:机械破碎、熔融金属的雾化、蒸发冷凝和电解。机械破碎制备的粉末粒径较大,最小的粒径分布为300~600 μm。惰性气体雾化生产的镁粉是多分散的,粒径分布从几微米到0.5~1 mm不等,制得粉末经过筛分过程得到所需的粒径分布,目前增材制造所需球形镁合金粉末主要通过此方法制备。Mg蒸气的高蒸气张力允许使用镁蒸发和蒸气冷凝的方法来生产细镁粉,例如物理气相沉积和化学气相沉积。通过在Mg熔点以下电解可熔熔体(熔体中含有MgCl2),粉末状态的结晶Mg在阴极析出,这种方法制备的粉末的不同之处是化学纯度高。

表1列举了典型的商业化镁粉:目前世界上能较大规模生产商业化镁粉的公司较少,除了表1中列举的3家企业,加拿大的Niagara Metallurgical Products公司也能生产商业化镁粉但是具体的镁粉产品信息未知,中国和美国各有一家企业能生产较多种类的镁粉。美国生产的MAP+系列粉末用于增材制造,例如SLM、LMD、电子束选区熔化、冷喷涂沉积等,MAP系列粉末用于粉末锻造、粉末挤压、热/冷等静压、等通道转角挤压等。中国唐山威豪镁粉有限公司构建了Ar气保护下离心气雾化生产球形镁粉的制造系统,制粉过程在高纯Ar气气氛保护下进行以保证安全性,制备的镁粉具有颗粒形状规则、球形率高、松装密度大、流动性好、活性镁含量高、吸湿率低、安定性好、重现性高等优点,是国内高校或企业镁粉的主要供应商。本团队与唐山威豪镁粉有限公司合作定制了高强度Mg-Gd-(Y)-(Zn)-Zr镁稀土合金粉末和生物医用镁稀土合金JDBM-NZ30K。

表1 典型的商业化的镁粉

Table 1

| Type | Chemical composition (mass fraction, %) | Particle size distribution | Source |

|---|---|---|---|

| Pure Mg | Mg: 99 min. | 315-630 μm | Eckart |

| Mg: 99.5 min. | 100-315 μm | ||

| Mg: 97 min. | < 71 μm | ||

| Pure Mg | 99.8 Mg | A: +200 mesh: 0.5% max., | MEP |

| -325 mesh: 60% max.; | |||

| B: +200 mesh: 0% max., | |||

| -325 mesh: 95% min. | |||

| MAP + 21 | Mg-2.7Nd-1.3Gd-0.3Zn-0.6Zr | A: < 150 μm, D50 = 90 μm; B: < 25 μm | |

| MAP + 43 | Mg-4Y-3Nd-0.5Zr | ||

| MAP + 91 | Mg-(8.5-9.5)Al-(0.45-0.9)Zn-(0.17-0.3)Mn | ||

| MAP 21 | Mg-2.7Nd-1.3Gd-0.3Zn-0.6Zr | A: +80 mesh: 5% max., -325 mesh: 20% max.; B: +325 mesh: 5% max., -325 mesh: balance | |

| MAP 43 | Mg-4Y-3Nd-0.5Zr | ||

| MAP 91 | Mg-(8.5-9.5)Al-(0.45-0.9)Zn-(0.17-0.3)Mn | ||

| AZ31B | Mg-3Al-1Zn-0.3Mn | 80-325 mesh size: +325 mesh: 5% max | |

| AZ91E | Mg-(8.5-9.5)Al-(0.45-0.9)Zn-(0.17-0.3)Mn | ||

| WE43B | Mg-4Y-3Nd-0.5Zr | ||

| Pure Mg | Mg: 99.9 min. | A: 15-53 μm; B: 20-63 μm; C: 100-200 mesh: D10, D50, D90 = 57, 81, 179 μm; D: 200-300 mesh: D10, D50, D90 = 46, 61, 85 μm; E: 300-500 mesh: D10, D50, D90 = 31, 42, 59 μm; F: -500 mesh: D10, D50, D90 = 21, 34, 52 μm; | TWMP |

| AZ91D | Mg-8.90Al-0.43Zn-0.19Mn | ||

| AZ31 | Mg-2.8Al-0.7Zn-0.4Mn | ||

| WE43 | Mg-4.01Y-3.04RE-0.51Zr | ||

| ZK60 | Mg-5.6Zn-0.5Zr | ||

| ZK61 | Mg-5.20Zn-0.33Zr | ||

| Mg-Al series | Mg∶Al = 60∶40, 55∶45, 50∶50, 40∶60, 20∶80, 10∶90 | ||

| Mg-Zn series | Mg∶Zn = 95∶5, 90∶10, 70∶30, 50∶50, 30∶70, 20∶80, 10∶90 |

考虑到镁粉储存、运输、操作过程中的安全性,镁粉出厂前一般都要进行惰化或者钝化处理导致发生氧化现象,从而降低镁粉的活性。镁粉储存运输过程中都是1~2 kg一袋进行真空封装以隔绝空气,存放在恒温防爆柜避免潮湿且远离任何火源来保证安全性。图3[20]为唐山威豪镁粉有限公司制备的GWZ1031K预合金化粉末的SEM表征[20]:绝大部分粉末是球形的,尽管经历了筛分过程仍然存在一些黄色箭头所指的卫星球颗粒和白色箭头所指的不规则形状颗粒(图3a[20]),粉末表面存在许多细小的直径几百纳米的白色颗粒(图3b[20]),GWZ1031K预合金化粉末主要由细小的α-Mg基体和晶界上的网状β-(Mg, Zn)3(Gd, Y)共晶相组成(图3c[20]),粉末颗粒的平均晶粒尺寸为(2.1 ± 0.8) μm,细小的晶粒尺寸源于熔体雾化过程中极高的冷却速率,EDS面扫结果表明粉末表面的白色颗粒为氧化物颗粒(图3d[20]),XRD谱证明其是Y2O3氧化物,相比于Mg元素和其他合金化元素,稀土Y元素与O的结合倾向是最高的[66]。

图3

3.3 SLM制造镁合金过程

3.3.1 SLM工艺参数对致密度的影响规律

不同的SLM工艺参数会导致制备的构件在致密度、显微组织和力学性能等方面具有显著的差异,调整工艺参数是为了获得合适的激光能量密度来成形高致密度高性能合金。与传统制造工艺相比,SLM工艺具有更多可调整的工艺参数,而且各个工艺参数协同作用影响加工质量,因而SLM工艺参数优化过程比较复杂。SLM工艺参数主要包括激光相关、扫描相关、粉末相关和温度相关4大类。激光相关参数主要包括激光功率、光斑直径、激光波长等,扫描相关参数主要包括扫描速率、扫描间距(相邻两道次激光中心位置间的距离)和扫描策略等,粉末相关参数主要包括层厚、颗粒尺寸、形状和分布以及粉床堆垛密度等,温度相关参数主要包括基板和粉床的加热温度、温度均匀性等。其中研究最多的工艺参数是激光功率P (W)、扫描速率V (mm/s)、扫描间距S (μm)和层厚t (μm),这4个参数共同组成了体积能量密度(

图4

图4

SLM成形GZ112K合金的扫描速率-扫描间距(V-S)加工图,及3个加工区域对应的缺陷特征:孔洞缺陷、致密区、未熔合缺陷[79]

Fig.4

V-S process map for SLM of GZ112K alloy (a), and defect features corresponding to the three processing zones: pores defects (b), forming zones (c), and lack of fusion defects (d)[79] (V—scanning speed, S—hath spacing between adjacent laser scanning tracks)

表2[18,26~28,30~32,34,42,43,46,51,52,63,64,66,69,75,79~81]汇总了SLM制备镁合金的工艺参数和相应的致密度:考虑到不同的研究采用不同的定制或者商业化的SLM设备,对不同成分的镁合金而言,35~9600 J/mm3的体积能量密度都可能获得高致密度;对于相似化学成分的镁合金,获得高致密度的体积能量密度波动很大,例如35.0~238.1 J/mm3的体积能量密度都能获得致密度高于99%的WE43合金样品。因此,体积能量密度并不能很好地表示工艺参数对熔池熔化和凝固过程的影响规律。不同的工艺参数组合可以产生相同的体积能量密度,但是很少有研究报道这些样品之间的差异。基于此,Deng等[83]在2022年采用不同的激光功率和扫描速率进行了激光单道扫描和块体成形实验:相同线能量密度下,单道熔池的深度和宽度以及块体的孔隙率都变化很大,这说明同时改变P和V时体积能量密度存在局限性不再适用,只改变体积能量密度公式中的一个参数时体积能量密度是适用的;通过数学建模和灵敏度分析发现扫描速率对熔池深度的影响大于激光功率,而激光功率对熔池宽度和孔隙率的影响大于扫描速率。

表2 SLM制备镁合金的工艺参数[18,26~28,30~32,34,42,43,46,51,52,63,64,66,69,75,79~81]

Table 2

| Raw material | Chemical composition | Process parameter | η | Relative | Ref. | |||

|---|---|---|---|---|---|---|---|---|

| (mass fraction, %) | P | V | S | t | J·mm-3 | density | ||

| W | mm·s-1 | μm | μm | % | ||||

| Pure Mg | 99.81Mg | 90 | 100 | 100 | 30 | 300 | 96.13 | [26] |

| Pure Mg | 99.81Mg | 70 | 500 | 30 | 30 | 155.6 | 97.5 | [27] |

| AZ91D | Mg-8.95Al-0.44Zn-0.19Mn | 200 | 333 | 90 | 40 | 151.5 | 99.52 | [28] |

| AZ91D | Mg-9.08Al-0.65Zn-0.23Mn | 50 | 200 | 30 | 30 | 277.8 | 98.1 | [75] |

| AZ91D + 5%SiC | Mg-9.08Al-0.65Zn-0.23Mn + | 97.9 | ||||||

| 5% (volume fraction) SiC | ||||||||

| AZ61 | Mg-6.25Al-1.24Zn-0.27Mn | 150 | 400 | 60 | 40 | 156.3 | 99.4 | [32] |

| AZ61 | Mg-6Al-1Zn | 80 | 3.333 | 50 | 50 | 9600 | 98 | [30] |

| AZ31 | Mg-2.97Al-0.89Zn | 75 | 125 | 70 | 50 | 171.4 | 99.63 | [34] |

| A9 | Mg-9Al | 70 | 500 | 30 | 30 | 155.6 | 95.7 | [31] |

| A9 | Mg-9Al | 15 | 20 | 80 | 50 | 187.5 | 82 | [18] |

| ZK60 | Mg-5.2Zn-0.5Zr | 200 | 300 | 80 | 20 | 416.7 | 94.05 | [42] |

| ZK60 | Mg-5.6Zn-0.5Zr | 50 | 8.333 | 100 | 100 | 600 | 97.4 | [43] |

| ZK60 | Mg-5.2Zn-0.3Zr | 50 | 600 | - | - | - | 98 | [52] |

| ZK60 | Mg-5.6Zn-0.5Zr | 120 | 600 | 70 | 10 | 285.7 | 94.9 | [51] |

| Z1 | Mg-1Zn | 180 | 700 | 70 | 20 | 183.7 | 99.35 | [46] |

| WE43 | - | 200 | 1100 | 130 | 40 | 35.0 | 99.7 | [66] |

| WE43 | Mg-3.5Y-1.6Nd-0.7Gd-0.4Zr | 200 | 700 | 40 | 30 | 238.1 | > 99.8 | [63] |

| WE43 | Mg-4Y-3.3Nd-0.5Zr | 195 | 800 | 200 | 30 | 40.6 | 99.6 | [64] |

| WE43 | Mg-3.96Y-2.30Nd-0.56Zr | 175 | 700 | 90 | 50 | 55.6 | 99.48 | [69] |

| G10K | Mg-10.17Gd-0.18Zr | 80 | 200 | 100 | 30 | 133.3 | 99.22 | [80] |

| GZ112K | Mg-11.82Gd-2.03Zn-0.43Zr | 80 | 300 | 100 | 30 | 88.9 | 99.95 | [79] |

| GZ151K | Mg-13.57Gd-0.85Zn-0.30Zr | 200 | 700 | 70 | 30 | 136.1 | 97.9 | [81] |

3.3.2 SLM工艺参数对显微组织的影响规律

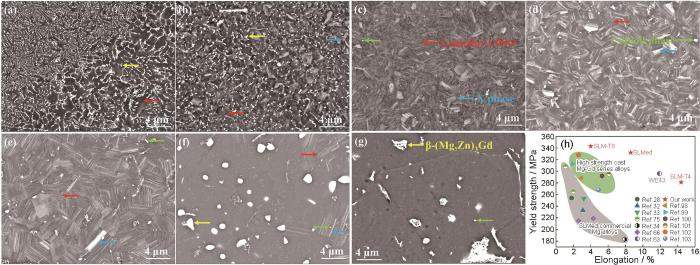

高度集中分布的激光能量以及激光和粉末床极短的交互作用时间导致形成细小的熔池和非常高的冷却速率(约为106 K/s),故SLM态合金通常为具有细小的晶粒和第二相的快速凝固非平衡组织。图5[79]为半连续铸造和SLM制备的GZ112K合金的显微组织。传统的半连续铸造工艺冷却速率较低(约为10 K/s)使得铸态GZ112K合金的晶粒和晶界共晶相粗大,其平均晶粒尺寸和共晶相面积分数分别为37.9 μm和7.3%。然而,SLM态GZ112K合金具有显著细化的晶粒和更少更薄的共晶相,其平均晶粒尺寸和共晶相面积分数分别减小为1.53 μm和3.4%;而且SLM态GZ112K合金的显微组织非常均匀,熔池内外没有显著的区别而且没有出现粗大柱状晶。此外,随着激光扫描速率的增大,熔池的冷却凝固速率加快,晶粒生长粗化的时间缩短因而平均晶粒尺寸减小,另一方面快速凝固的溶质捕捉效应[79]导致更多的合金化元素固溶进α-Mg基体内,从而使共晶相的面积分数也减小。

图5

2014年,Wei等[28]制备了实体AZ91D:SLM态AZ91D合金由较为细小均匀的等轴晶组成,样品内部扫描道搭接区域由于重熔导致冷却速率降低因而平均晶粒尺寸(2.9 μm)大于扫描道中心区域(1.0 μm);与压铸态合金相比,SLM态合金的Mg和Al元素分布更为均匀,这是因为溶质捕捉效应使得α-Mg基体和β-Mg17Al12共晶相的成分差异减小,另一方面熔池中心和边界巨大的温度梯度导致强烈的Marangoni对流效应促进Mg和Al元素的均匀分布。Bär等[65]对SLM态生物降解WE43合金进行了详细的显微组织分析:SLM态WE43合金由2种类型的晶粒组成,即平均晶粒尺寸为(1.4 ± 0.6) μm的小晶粒和平均晶粒尺寸为(20.4 ± 6.3) μm的不规则形状大晶粒;未受热影响的最后一个熔池由3部分组成,熔池边界是由熔体向固体转变的部分熔化区,熔池底部的层片区(位于Mg基面上的枝晶层片,层片边界上分布着富含Nd元素的纳米金属间化合物相),熔池中心区域由于冷却速率和温度梯度降低形成了等轴晶形貌。但是Zumdick等[63]发现,相比于铸态合金(平均晶粒尺寸为(44.3 ± 15.9) μm),SLM态和粉末挤压态WE43合金由非常细小均匀的显微组织组成,平均晶粒尺寸分别为(1.1 ± 0.4)和(1.3 ± 0.7) μm,粉末挤压态的晶粒尺寸略大于SLM态。

3.3.3 SLM工艺参数对力学性能的影响规律

工艺参数会改变SLM态镁合金的显微组织和缺陷特征,从而显著影响力学性能。Deng等[79]系统研究了扫描速率和扫描间距对SLM态GZ112K合金室温拉伸性能的影响规律:随着扫描速率的减小,虽然晶粒尺寸略微增大导致细晶强化效应减弱,但是α-Mg基体内Gd和Zn元素的固溶度更高导致更显著的固溶强化效应,以及硬脆共晶相的面积分数更高导致更显著的第二相强化效应,最终SLM态GZ112K合金的屈服强度逐渐增大;100 mm/s扫描速率的试样气孔缺陷和硬脆共晶相含量较高导致延伸率较低,1000和1500 mm/s扫描速率的试样存在大量的未熔合缺陷,导致强度和塑性都显著下降甚至不如半连铸态合金,成形区(300~700 mm/s)试样的强度和塑性都优于半连铸态;扫描间距较小时,搭接重熔区域更大从而形成更多的气孔导致延伸率较低,扫描间距较大时,容易形成未熔合缺陷,同时恶化强度和塑性,扫描间距为100 μm时,保证了合适的搭接率从而导致最优的室温拉伸性能;在最优的工艺参数下,SLM态GZ112K合金的拉伸强度显著优于半连铸态,尤其是屈服强度从163 MPa显著提升到325 MPa,同时塑性略优于半连铸态。

表3[20,28,31~35,39,46,55,63,66,74,75,79~82,84]总结了最优工艺参数下SLM态和后处理态镁合金的室温拉伸性能:相比于铸态合金,SLM态镁合金都具有显著提升的拉伸强度(显著的细晶强化和固溶强化效应),但是SLM态镁合金的塑性或高或低;对于相似的化学成分(如AZ91D和WE43),采用不同设备和不同参数进行成形即使都具有很高的致密度,但是室温拉伸性能尤其是延伸率波动很大,这说明SLM态镁合金的力学性能稳定性较差,虽然不同文献采用的粉末化学成分是接近的,但是粉末是不同厂家生产的,导致粉末的物理化学性质(如O含量、流动性、空心粉含量等)有差异从而成形工艺参数相差较大,最终导致SLM态镁合金的力学性能波动较大;向镁合金粉末中添加增强相(如SiC和CNTs)后会提升拉伸强度但是降低塑性;Mg-Gd系镁稀土合金的室温拉伸性能优于传统的商业化镁合金体系(如AZ31、AZ91D、ZK60、WE43等),尤其是屈服强度较高。

表3 最优工艺参数下SLM态和后处理态镁合金的室温拉伸性能[20,28,31~35,39,46,55,63,66,74,75,79~82,84]

Table 3

| Alloy | Chemical compositions of powder | State | YS | UTS | EL | Ref. |

|---|---|---|---|---|---|---|

| (mass fraction, %) | MPa | MPa | % | |||

| A9 | Mg-9Al | As-built | - | 274 | 1.09 | [31] |

| AZ91D | Mg-8.95Al-0.44Zn-0.19Mn | As-built | 254 | 296 | 1.83 | [28] |

| AZ91D | Mg-9.08Al-0.65Zn-0.23Mn | As-built | 265 | 298 | 2.0 | [75] |

| AZ91D + 5%SiCnp | Mg-9.08Al-0.65Zn-0.23Mn + | As-built | 308 | 345 | 1.1 | [75] |

| 5% (volume fraction) SiCnp | ||||||

| AZ91D | Mg-9.08Al-0.65Zn-0.23Mn | As-built | 208 | 339 | 8.3 | [39] |

| AZ61 | Mg-6.25Al-1.24Zn-0.27Mn | As-built | 233 | 287 | 3.1 | [32] |

| HIPed | 126 | 274 | 8.2 | [35] | ||

| AZ31B | Mg-2.97Al-0.89Zn | As-built | 183 | 212 | 7.9 | [34] |

| AZ31B/CNTs | AZ31B + 1.5%CNTs | As-built | 245 | 286 | - | [74] |

| AZX912 | Mg-8.55Al-0.64Zn-1.81Ca-0.18Mn | As-built | 253 | 332 | 3.2 | [33] |

| Z1 | Mg-1Zn | As-built | - | 148 | 11.0 | [46] |

| ZK60 | - | As-built | 137 | 246 | 15.5 | [55] |

| T4 | 107 | 224 | 16.7 | |||

| T6 | 191 | 287 | 14.1 | |||

| WE43 | Mg-3.48Y-1.62Nd-0.71Gd-0.40Zr | As-built | 296 | 308 | 11.9 | [63] |

| WE43 | - | As-built | 215 | 251 | 2.6 | [66] |

| T6 | 219 | 251 | 4.3 | |||

| G10K | Mg-10.17Gd-0.18Zr | As-built | 203 | 271 | 10.3 | [84] |

| T5 | 285 | 360 | 2.9 | |||

| GZ112K | Mg-11.00Gd-1.77Zn-0.43Zr | As-built | 332 | 351 | 8.6 | [82] |

| T4 | 281 | 311 | 14.4 | |||

| T6 | 343 | 371 | 4.0 | |||

| GZ151K | Mg-13.57Gd-0.85Zn-0.30Zr | As-built | 345 | 368 | 3.0 | [81] |

| T5 | 410 | 428 | 3.4 | |||

| GWZ1031K | Mg-11.02Gd-2.41Y-0.96Zn-0.40Zr | As-built | 310 | 347 | 4.1 | [20] |

| T5 | 365 | 381 | 0.8 | |||

| T4 | 255 | 328 | 10.3 | |||

| T6 | 316 | 400 | 2.2 |

然而,SLM态镁合金的延伸率一般较低,并没有完全发挥出细小晶粒大幅度改善塑性的潜力。例如,SLM态AZ91D合金在83.3~167.7 J/mm3激光能量密度下的延伸率为1.24%~1.83%,低于压铸态3%的延伸率[28];SLM态AZ61合金在138.89~208.33 J/mm3激光能量密度下的延伸率为2.14%~3.28%,低于铸态5.2%的延伸率[32]。Wei等[28]分析了SLM态AZ91D镁合金的断裂模式:不同激光能量密度对断口形貌没有显著影响,所有的拉伸断口都呈现韧性-脆性复合断裂特征,断口中均观察到韧窝、撕裂棱和准解理面,这种断裂模式主要与合金中多相的显微组织和微孔有关;较软的α-Mg基体促进韧性断裂特征,脆性β-Mg17Al12共晶相和微孔导致应力集中降低塑性,促进形成解理状脆性特征;断口中韧窝较浅且断裂面上存在孔洞和微裂纹等缺陷,导致延伸率较低。

图6[20,32,34,55,63,75,81,82,84]对比了典型镁合金在铸态、SLM态和挤压态下的室温拉伸性能:SLM态镁合金的屈服强度相比于铸态合金显著提升,接近甚至超过挤压态合金,这主要归因于SLM态细小的晶粒,例如SLM态GZ151K合金的平均晶粒尺寸约为2 μm[81],与差温挤压态GZ151K合金双峰组织中细小的再结晶晶粒相当(约1.6 μm)[12];SLM态镁合金的抗拉强度大都明显高于铸态合金(只有SLM态AZ31合金的抗拉强度略低于铸态合金),大都低于挤压态合金(只有SLM态WE43合金的抗拉强度高于挤压态合金);SLM态镁合金的延伸率相比于铸态合金或高或低(SLM态AZ91D、AZ61、AZ31、GZ151K和GWZ1031K合金的延伸率低于铸态合金,而SLM态ZK60、WE43、G10K和GZ112K合金的延伸率高于铸态合金),但是都低于挤压态合金。整体而言,SLM态镁合金的力学性能介于铸态和挤压态之间。

图6

3.4 SLM制造镁合金冶金缺陷的产生机理

3.4.1 气孔

SLM制造镁合金很容易产生圆形气孔缺陷,这直接影响着构件的致密度和力学性能。气孔一般在高能量密度输入即高激光功率或者低扫描速率下产生,此时熔池最高温度更高,Mg的低沸点和高饱和蒸气压使其蒸发更严重,产生更多的Mg蒸气,Mg蒸气会对熔池产生反冲压力,熔池巨大的温度梯度导致熔池内部形成强烈的Marangoni对流效应,熔池深度远大于熔池宽度产生匙孔(keyhole)熔化模式,而SLM过程的凝固速率很快,较多Mg蒸气来不及从熔池中逸出因而以气孔形式存在于熔池内部[79]。激光能量密度越高,Mg的蒸发情况越剧烈,产生更多的Mg蒸气,匙孔效应更明显,从而产生的圆形气孔越多,尺寸越大。

激光与熔化的金属液接触后在表面发生吸收和反射2个过程,其能量交换发生于熔池表面,而熔池其他位置熔化所需热量由热传导提供,表面局域能量过高使得金属液蒸发,形成了一个蒸气和外界气体共同填充的凹陷,由其形貌被称作匙孔(keyhole)[88]。气孔缺陷一般与高激光功率低扫描速率熔化条件下产生的深而窄的蒸气凹陷即匙孔相关。在匙孔内部激光束经历了多次反射,这增强了激光能量吸收率(匙孔可被认为是光学黑体,匙孔内部的激光吸收率接近100%)。与激光熔化平板相比,SLM铺粉过程会一定程度上影响匙孔的稳定性,可能是因为飞溅的粉末遮挡了激光,导致瞬时输入能量降低,产生了能量波动从而更容易形成孔洞。清华大学联合美国阿贡国家实验室采用高速X射线成像直接观察了由于匙孔根部临界失稳导致在Ti-6Al-4V合金中形成孔洞缺陷的具体过程[89],匙孔失稳形成气孔的过程主要包括匙孔失稳形成气泡和气泡被熔池边界捕捉2个步骤,匙孔失稳形成气泡的具体过程如图7[89]:该临界状态(介于稳定熔化和形成匙孔孔隙之间)的匙孔呈“J”型,且在运动过程中在前壁上端形成了一个小的凹陷(mini匙孔),这个mini匙孔的凸起部分与匙孔后侧接触导致匙孔崩塌,在下方形成了一个封闭的气泡,接着气泡收缩碰撞形成了2个小的气泡,匙孔在激光作用下钻深并扩展。这些气泡缺陷的形成与匙孔根部的临界失稳有关,熔池的周期性波动会向熔池底释放出声学波(冲击波),进而驱动气泡快速远离匙孔并被凝固前端捕捉从而形成气孔缺陷。Wang等[90]采用多物理场热流体流动模型来模拟上述匙孔孔隙的形成过程,模拟结果和实验结果吻合得较好。

图7

综上,提高熔池-匙孔结构的稳定性能够有效抑制SLM制造镁合金过程中气孔缺陷的形成。使用激光离焦的方式能增大激光作用面积即增大激光光斑直径,降低激光功率密度,进而减小熔池-匙孔结构的深宽比从而有利于提高其稳定性,但目前还没有文献系统研究激光光斑直径对成形区间以及缺陷的影响规律。

3.4.2 未熔合

未熔合缺陷都是在较低的激光能量密度下产生的,为扫描道次或者层间的不规则形状孔洞,一般通过增大激光能量密度可以完全避免。但是实际上即使使用了名义上足够的激光能量,蒸发产物会导致激光传递给粉床的能量衰减,扫描道次周围的粉末剥蚀(powder denudation)和飞溅重新沉积(spatter redeposition)可能导致粉层厚度不均匀,激光能量输入和层厚的波动仍然会导致形成未熔合缺陷。SLM过程所输入的激光能量不足以产生足够的液相,成形时熔池内部处于固-液相混合的状态,颗粒间难以达到有效的结合,从而形成未熔合缺陷,即使粒子之间存在一定程度的熔合,所制备样品的机械强度也会较低,具有松散的金属结构。在高扫描速率下会发生球化现象[37],导致金属粉末在基板或者以前的凝固层上形成不连续的金属珠,不仅不利于同一层粉末之间的冶金结合,还会影响下一层粉末的铺粉质量,也不利于层间的结合,因而导致形成较多的不规则形状的未熔合缺陷。然而,目前工艺参数对SLM态镁合金球化现象的影响规律尚不清晰,球化现象的产生和传播机理值得深入研究。Deng等[79]研究了扫描间距对相邻扫描道次之间搭接面积的影响规律:低扫描间距下搭接面积较大,更多的区域被重熔导致出现气孔的可能性增大,从而降低延伸率,而且低扫描间距也会降低SLM成形效率;高扫描间距会降低搭接区域的高度,铺下一层粉时搭接区域的深度远大于层厚会导致激光无法穿透熔化所有粉末,从而形成层间未熔合缺陷,显著恶化力学性能;合适的扫描间距使得搭接区域与其他区域的高度接近,铺下一层粉时厚度更均匀,因此搭接率(搭接区域的宽度除以激光单道的宽度)控制在30%~50%比较合适。

3.4.3 裂纹

几种裂纹情况如下。

(1) 热裂纹。热裂纹是在高温下(液相线和固相线之间的温度)产生的,主要分为凝固裂纹和液化裂纹2种[91]。凝固裂纹是在凝固最后阶段产生的,此时晶粒完全长成,晶界上存在液膜,大致出现在熔池中央,晶界开裂,断裂面呈现枝晶形貌。凝固裂纹的主要影响因素如下:凝固温度区间,凝固最后阶段液相的数量和分布,初始凝固相种类,晶界液相的表面张力,晶粒结构(细小等轴晶或者粗大柱状晶),正在凝固金属的塑性,及金属收缩的倾向性和收缩受阻的程度,所有这些影响因素都直接或者间接与化学成分相关。例如,凝固温度区间越大,凝固的脆弱区间越大,导致更容易产生凝固裂纹;细小的等轴晶相比于粗大柱状晶更不容易产生凝固裂纹。SLM制备2系、6系和7系高强度铝合金的凝固裂纹大都通过添加晶粒细化剂形成完全均匀细小的全等轴晶组织而消除。2019年,Wei等[46]研究了Zn含量(1、2、4、6、8、10、12,质量分数,%)对SLM制备Mg-Zn二元合金开裂行为的影响规律,图8[46]为SLM制备的Mg-Zn合金的内部缺陷特征:Zn含量的提升显著恶化合金的致密化行为,Mg-1%Zn合金无裂纹且几乎完全致密,Mg-(2%~10%)Zn合金都存在开裂现象且裂纹密度随着Zn含量增加先增大后减小,Mg-12%Zn合金虽然无裂纹但是存在较多微孔;Mg-Zn合金的凝固温度区间相比其他常见镁合金更大,裂纹内部的扫描电子显微镜(SEM)观察表明,存在液相而且裂纹在共晶相处萌生。上述结果都表明,SLM制备Mg-Zn合金的裂纹为凝固裂纹(裂纹的方向大致平行于打印堆垛方向);对于Mg-1%Zn合金,共晶相含量少且非连续,凝固最后阶段糊状区的强度可以抵抗凝固收缩应力因而不产生裂纹;对于Mg-(2%~6%)Zn合金,共晶相含量逐渐增多且条状分布导致糊状区强度下降,因而产生裂纹且裂纹密度增加;对于Mg-(6%~10%)Zn合金,共晶相含量更多且网状分布,凝固最后阶段剩余液相的流动性显著增强从而对凝固裂纹产生回填作用,故裂纹密度减小;对于Mg-12%Zn合金,共晶相的回填作用最为显著,从而完全抑制了凝固热裂纹。

图8

液化裂纹出现在部分熔化区,该区域的热效应超过共晶温度,晶界液化导致部分熔化区的强度削弱,熔池内部的凝固收缩和热收缩超过部分熔化区的强度就会形成裂纹,液化裂纹出现在熔池外围的热影响区,也属于晶界开裂,断裂面未呈现枝晶形貌。液化裂纹的主要影响因素如下:液化程度,晶粒结构,热塑性,金属收缩的倾向性和收缩受阻的程度。热输入越高即激光能量密度越大会导致液化程度增大,晶界偏析加剧和晶粒粗大也会使得液化程度加剧,这些都会促进液化裂纹的产生。Liu等[51]在2021年报道了SLM制备ZK60合金的热裂现象:在SLM态ZK60样品中存在严重的凝固开裂和液化开裂现象,低熔点的Mg7Zn3共晶相沿着裂纹析出,正在沉积层由于凝固温度区间大导致凝固开裂,而已沉积层由于热影响超过α-Mg和Mg7Zn3的共晶温度(340℃)导致富含Mg7Zn3共晶相的位置发生局部熔化产生液化开裂,2种裂纹汇聚成联通的网络显著降低SLM态试样的致密度,凝固温度区间大和共晶温度低共同导致了SLM态ZK60合金严重的热裂倾向;目前通过调整激光能量密度很难同时抑制裂纹和未熔合、孔隙、严重变形的发生,后续需要研究样品尺寸、预热、扫描策略等对裂纹敏感性的影响规律。Liang等[57]在2022年发现激光能量密度对SLM成形ZK60合金中热裂纹具有显著影响:在高激光能量密度下会产生凝固裂纹,可通过调整工艺参数减小激光能量密度而消除,但是液化裂纹存在于熔池的热影响区,不能通过调整工艺参数而消除。随后通过向ZK60合金中添加1% (质量分数)的稀土元素Y把原来的低熔点Mg7Zn3共晶相转变为具有优良热稳定性的I相(Mg3YZn6)从而强化晶界抑制晶界的液化,另一方面平均晶粒尺寸从7.2 μm减小到2.0 μm,2者共同导致SLM态ZK60 + 1%Y样品中完全没有裂纹[56]。

(2) 冷裂纹。冷裂纹是由于样品的内应力超过材料的强度极限时在较低温度下(固相线以下温度)产生的。冷却速率对冷裂纹有较大影响:冷却速率越高,产生的残余应力越大,就越容易产生裂纹。SLM过程中超高温度梯度作用下移动的微小熔池在强基底约束下的快速凝固收缩属于超常物理冶金现象,会在SLM态零件内产生应力水平很高、演化和交互作用过程极其复杂的热应力、相变组织应力和约束应力,这些应力存在极其强烈的非线性强耦合交互作用和应力集中,导致零件发生严重翘曲变形甚至开裂。图9[83]为SLM态GZ151K方块(8 mm × 8 mm × 10 mm)中纵截面的裂纹分布:热裂纹一般是平行于打印堆垛方向的微小裂纹,均匀地分布在试样的整个截面;而SLM态GZ151K方块中的裂纹为垂直于打印堆垛方向的宏观大裂纹,在一定高度处集中分布;SLM态GZ151K方块中的第一道裂纹大致出现在4 mm高度处,这表明打印前期120多层(层厚为30 μm)并没有产生裂纹,而热裂纹涉及到每一个熔池的凝固过程不会在打印一定高度后才产生,故SLM态GZ151K方块中的裂纹是冷裂纹。SLM过程中超高的温度梯度和快速加热冷却循环会产生较大的热应力,热应力来源于凝固过程中熔池的凝固收缩和凝固结束后冷却阶段的热收缩,且热应力随着打印高度的增加逐渐累积增大[92],打印到一定高度后热应力超过材料在当前温度下的抗拉强度就会产生冷裂纹,一旦产生裂纹热应力就得到部分释放,要继续随着打印零件高度的增加而累积热应力到超过材料的抗拉强度再产生冷裂纹,如此循环往复,因而冷裂纹是随着打印过程进行在一定高度处循环出现。

图9

通过减小热应力的方式可以减弱开裂现象,例如提高基板加热温度(基板加热温度越高,温度梯度越小,导致残余应力越小,但是比较难实现较大构件的均匀加热)、优化扫描策略(分区岛状扫描策略的扫描线长度更小和层间旋转一定角度如90°或73°可以减小残余应力)可以减小热应力[92],对商业化的SLM设备进行改进以在线去应力或者闭合裂纹:采用激光二极管发射的强度均匀的成形光照亮正在构建的表面可以在线退火,显著减小热应力的同时不发生晶粒长大[93];增加一束激光采用相互垂直的扫描方向对第一束激光刚扫描的区域进行后续加热来减小温度梯度和冷却速率,可以显著减小热应力且扫描长度越长会导致更明显的热应力循环和热应力峰值[94];引入3D激光冲击喷丸处理可以引入压应力从而闭合裂纹[95]。此外,选用本征塑性较好的合金成分进行SLM成形也有利于避免开裂现象。

3.4.4 氧化物

即使在室温极低的氧分压条件下Mg也能发生氧化。例如,在温度为31℃、氧分压为10-4 Pa条件下,MgO也可以形成。Salehi等[96]研究了Ar气条件下镁粉和O的交互作用,发现MgO氧化膜可以在粉末颗粒上形核和生长,氧化膜的生长速率由O的固态扩散速率决定。氧化膜会阻碍致密化过程、产生球化效应,然后破坏熔化层之间颗粒的合并和润湿。氧化物通常会导致萌生裂纹并降低SLM制备构件的力学性能。氧化物的形成主要归因于打印过程中熔池吸收氧和原始粉末表面的氧化膜或氧化物颗粒。Ng等[24]在SLM态纯Mg中没有发现孔洞和裂纹,但是α-Mg的晶界上存在氧化物白色相,这是因为SLM过程中Marangoni对流效应导致氧卷入熔池内与熔体发生反应形成氧化物。Gangireddy等[64]在SLM态WE43合金中发现了富含Y和Zr的氧化物,并在高倍透射电子显微镜(TEM)下观察到氧化物由很多细小的几十纳米直径的球形颗粒组成,这表明氧化物源于最初的粉末材料为了安全处理而进行的钝化或惰化过程。Esmaily等[67]在SLM态WE43合金中发现了高密度的均匀分布的细小的氧化物薄片,氧化物富含Zr、Y和Nd元素且主要来源于原始粉末,高密度氧化物的存在使得SLM态WE43合金相比于铸态WE43合金耐腐蚀性能下降。Deng等[80]在SLM态G10K合金中发现了均匀分布的片状Gd2O3白色氧化物,这源于原始粉末的氧化物和打印气氛中的少量氧,尺寸较大且团聚的氧化物与基体的界面结合不好会对力学性能产生不利影响。

尽管在准备和加工过程中氧化不能完全避免,但是可以通过设计合理的加工路径和化学成分来减弱氧化现象。然而由于SLM过程的复杂性,原始粉末的氧化物对SLM制造镁合金的致密化过程、力学性能和腐蚀行为的影响规律目前还不清楚。对于氧化问题,可从降低Mg表面活性的角度设计一种可以降低氧化膜表面张力从而减弱氧化效应的合金体系,还可通过调控SLM工艺参数来降低镁粉的氧化速率[13],例如增大粉末的层厚有利于降低粉层内部的氧化水平。此外,通过巧妙的成分设计和合理的制造过程使得SLM态镁合金中的氧化物纳米弥散化变废为宝:一方面可以提供强化作用,另一方面细小的纳米氧化物可以作为Zener钉扎质点阻碍晶粒长大。另外,也可以通过在金属Mg中添加活性元素、钝化元素以及稀土元素来减少镁合金粉末中氧化物的含量[13]:Mg-Be和Mg-Al合金中的活性金属元素可以先于Mg被氧化,从而避免了Mg粉末的大规模氧化;从钝化效果来看,过渡金属元素(如Fe、Mn、Cu、Ni)的加入会对Mg与O之间的表面活性产生负面影响,进而减缓甚至抑制氧化过程;稀土元素的添加同样会阻止镁合金中氧化现象的发生。

3.4.5 元素烧损

激光的瞬时高能量会导致SLM过程中元素剧烈的蒸发飞溅从而发生元素烧损,从而影响凝固组织、耐腐蚀性能和力学性能。Pawlak等[29]在SLM制造AZ31合金过程中观察到了大量的烟尘排放,打印舱室内的烟尘排放产物为Mg在工艺过程中氧化和蒸发的产物。剧烈的粉末蒸发飞溅现象只存在于SLM制造低沸点高饱和蒸气压金属,例如Mg和Zn[97],SLM制造铝合金和铁基合金不存在如此剧烈的粉末蒸发飞溅。蒸发飞溅会对SLM过程产生显著的影响:扫描道边缘的粉末被吹走(powder denudation),蒸发金属的反冲压力会影响打印过程中熔池的稳定性,剧烈的蒸发飞溅会显著影响成形质量,改变沉积层的化学成分和显微组织,严重限制SLM制造高质量构件。

元素烧损主要由SLM过程的温度和蒸气压控制,高温和高蒸气压使得元素更容易发生烧损。Salehi等[96]绘制了Mg和Al元素的蒸气压随温度变化的曲线:400℃下Al元素的蒸气压(2.9 × 10-14 Pa)比Mg元素的蒸气压(0.36 Pa)小13个数量级,熔体Mg在725和886℃时的蒸气压分别为1013和10132 Pa,所以提高熔池温度会显著提升蒸气压,这会使熔融液体转变为气体。SLM过程中Mg熔体的温度主要由激光能量密度决定,因此激光能量密度对合金元素的蒸发具有重要影响。Wei等[42]研究了SLM制备ZK60合金过程中的元素蒸发现象:随着扫描速率的增大,元素蒸发现象减弱,试样的表面质量提升但是粉末不能完全熔化;成形过程中主要发生了Mg和Zn元素的蒸发烧损,SLM态合金中Mg:Zn元素质量比大于原始粉末,但是Mg和Zn元素的总含量减小而Zr含量提升;根据Langmuir模型,在900~3000 K温度范围内Zn元素的蒸发通量是Mg的7.96%~17.75%,而原始粉末中Zn含量仅为Mg的5.2%,因而Zn元素相比Mg蒸发烧损更剧烈导致Mg:Zn元素质量比大于粉末;在Ar气氛下Zn的扩散性高于Mg,相邻扫描道次的激光扫描会将蒸发的Mg重新熔化进入熔池从而部分弥补Mg元素的损失。Hyer等[66]在SLM制备实体WE43合金时发现,低激光功率、低扫描速率即高能量密度时,由于Mg的剧烈蒸发烧损,导致SLM态试样中稀土总含量(主要是Y和Nd)增大到接近10% (质量分数),化学成分的改变使得试样的密度超过WE43的标准密度(1.84 g/cm3)即致密度大于100%,这是因为在Mg、Y、Nd、Zr和Gd 5个元素中Mg的蒸气压最高,相差近20个或更多数量级;高激光功率、高扫描速率时Mg的蒸发烧损减弱,稀土总含量为7%~8% (质量分数),这有利于提升生产效率。王金业等[40]在2022年研究了粉末粒度对SLM成形AZ91D镁合金过程中烟尘产生的影响规律:细粉相比粗粉更容易被熔化,相同激光能量密度下更容易发生过烧现象,元素烧损严重,产生的烟尘量更大;筛除20 μm以下的细粉末可有效减少烟尘的产生量,同时制件的抗拉强度提升了6%。

Deng等[79]采用电感耦合等离子体光谱仪(ICP)测定了半连续铸锭、粉末和不同工艺参数下SLM态GZ112K试样的化学成分:与粉末相比,所有SLM态试样的Gd和Zr含量更高但是Mg和Zn含量更低;根据Langmuir模型计算了不同元素的蒸发速率:Mg的蒸发速率随着熔池温度的升高而迅速增大,在923 K (纯Mg的熔点)到2000 K温度范围内,Mg的蒸发速率分别是Gd、Zn和Zr的8.2 × 106~2.0 × 1014倍、7.9~20.8倍和5.4 × 1012~1.6 × 1027倍,故与Mg的蒸发烧损相比,Gd和Zr的蒸发烧损可忽略不计。考虑到原始粉末中Mg的含量约为Zn的44倍,故SLM过程中Zn的蒸发烧损比Mg更剧烈,因为与Mg相比,Zn的沸点更低且蒸气压更高。随着激光能量密度的增大,熔池温度升高导致Mg和Zn的蒸发烧损加剧,所以SLM态试样中Gd和Zr含量逐渐升高,Mg和Zn总含量减少,Mg∶Zn元素质量比增大。

对于Mg的蒸发问题,合金化的方法可以有效提高沸点和熔点的温度区间从而减弱Mg的蒸发[13]。Gieseke等[25]把密闭成形腔室内的绝对压强提升到0.3 MPa,这样使得Mg的沸点提升到1220℃,而Ng等[23]发现在0.1 MPa压强下Mg的沸点仅为1093℃,Mg的沸点提升了127℃可以显著减弱蒸发飞溅并扩大成形工艺参数区间,但是增大压强后基板的尺寸减小为50 mm × 50 mm,最大打印高度也只有50 mm,这是为了安全性考虑限制镁粉的最大重量不超过500 g。此外,提高成形腔室内压强会导致熔池的温度升高,粉末剥蚀和液态飞溅更加剧烈,对SLM成形过程造成不利影响[19]。通过降低激光能量密度可以减弱Mg的蒸发烧损,但是激光能量密度太低会产生未熔合缺陷,因此,采用合适的工艺参数同时抑制蒸发和提升致密度值得深入研究。此外,目前还不清楚从铸锭到粉末再到SLM态试样的元素烧损规律,只有阐明粉末制备和SLM过程中的元素烧损规律才能根据想要获得的SLM态合金成分倒推所需的铸锭成分、制粉工艺和SLM工艺。

3.5 后处理对SLM态镁合金显微组织和力学性能的影响

3.5.1 固溶和时效热处理

虽然SLM过程冷却速率很高,但是大部分SLM态镁合金晶界上仍然存在硬脆共晶相无法形成单相过饱和固溶体,因此有必要进行后续热处理来调整显微组织和改善力学性能。Hyer等[66]对SLM态WE43合金进行了T6热处理,但是热处理制度(536℃、24 h + 205℃、48 h)是针对铸态WE43合金设计的,高温长时间的固溶处理导致晶粒显著粗化导致强度减弱,人工时效热处理析出薄片状的β1-Mg3Nd析出相可以强化合金,2者共同导致T6热处理后抗拉强度保持251 MPa不变,屈服强度从215 MPa略微增加到219 MPa,延伸率从2.6%增加到4.3%。上述T6热处理并没有显著改善力学性能,有必要针对SLM态独特的快速凝固非平衡组织开发专用的后续热处理制度。

Deng等[82]对SLM态GZ112K合金进行了详细的固溶和时效热处理制度优化,图10[28,32~34,63,66,75,82,98~103]为SLM态GZ112K合金在不同温度下固溶1 h的显微组织和热处理前后的室温拉伸性能:在300℃低温下,只有少部分共晶相发生溶解,形成晶内的层片状LPSO结构,没有形成X相;350℃下晶界开始形成X相,但是晶界仍然残留大量的粒状共晶相;在400~480℃范围内,共晶相完全转变为晶界X相和晶内层片状LPSO结构(一部分共晶相直接转变为晶界X相,另一部分共晶相先溶解进基体形成过饱和固溶体再析出晶内层片状LPSO结构),同时形成少量的稀土氢化物GdH2方块相;在500和520℃下开始产生块状β-(Mg, Zn)3Gd第二相,这是因为此温度超过了LPSO结构的形成温度区间而且Gd元素无法完全固溶进基体从而析出第二相。对比分析不同固溶温度和时间的显微组织和室温拉伸性能,400℃、12 h为SLM态GZ112K合金最优的固溶热处理制度,不仅可以把硬脆共晶相完全转变为变形能力较好的LPSO结构,而且平均晶粒尺寸仅从1.63 μm略微长大到3.1 μm。人工时效热处理(175℃、256 h)后大量的棱柱面β'时效析出相和基面LPSO结构垂直分布可以显著强化合金。

图10

图10

SLM态GZ112K合金在不同温度下固溶1 h的显微组织及热处理前后的室温拉伸性能[28,32~34,63,66,75,82,98~103]

Fig.10

Microstructures of the solution treated GZ112K alloys at temperatures of 300oC (a), 350oC (b), 400oC (c), 450oC (d), 480oC (e), 500oC (f), and 520oC (g) for 1 h, and the room-temperature tensile properties of the GZ112K alloys before and after heat treatment (h)[28,32-34,63,66,75,82,98-103]

400℃、12 h 热处理并不能使铸态GZ112K合金发生硬脆共晶相的转变和溶解,故此热处理制度是针对SLM态GZ112K合金的显微组织专门优化的。SLM态细小的晶粒缩短了晶界到晶内的原子扩散距离且共晶相含量较少有利于溶解,可能导致400℃较低温度下就能实现共晶相的转变和溶解;另一方面,SLM态较高的残余应力也可能促进共晶相的转变和溶解。SLM态GZ112K合金展现出优异的强塑性:屈服强度为332 MPa,抗拉强度为351 MPa,延伸率为8.6%;T4热处理(400℃,12 h)后强度下降,但是延伸率显著提升到14.4%;T6热处理大幅度提升强度但是恶化塑性,SLM-T6态GZ112K合金的屈服强度高达343 MPa,显著高于其他SLM态镁合金[28,32~34,63,66,75]的屈服强度,甚至比文献中高强度Cast-T6态Mg-Gd系合金[98~103]的屈服强度更高(图10h[82]),这主要来源于SLM-T6态细小的晶粒(3.1 μm)导致细晶强化、致密的β'时效析出相形成析出强化、层片状LPSO结构和X相的第二相强化以及来自于基面相和柱面相共存的额外的复合强化。SLM态GWZ1031K合金进行T6热处理后,合金元素的种类和含量不同使其T6态加工硬化率较高,从而抗拉强度达到400 MPa,T5热处理导致很高的屈服强度(365 MPa)但是延伸率很低[20]。与铸态和Cast-T6态相比,SLM态和SLM-T6态GWZ1031K合金具有显著更高的强度和略高的延伸率。需要注意的是,SLM-T4态与SLM-T6态GWZ1031K合金的室温拉伸性能甚至挤压态和挤压-T5态(200℃,96 h)相当。Fu等[81]发现SLM态GZ151K合金进行直接时效热处理(T5,200℃、64 h)可以同时提高强度和塑性,这和T5热处理通常导致强度提升塑性下降不同,SLM态GZ151K合金较高的残余应力使其屈服强度甚至高于挤压态GZ151K合金,T5热处理过程中析出强化提升强度,残余应力释放提升塑性,但是由于力学性能波动较大,SLM态和SLM-T5态GZ151K合金只取了最优的力学性能数据。2022年,Liang等[55]研究了热处理制度对SLM态ZK60合金的显微组织和力学性能的影响规律:SLM态ZK60镁合金中晶界由网状Mg7Zn3相组成,晶内存在3种析出相(具有富Zr核的富Zn相、不含Zr的富Zn相和富Zr颗粒),SLM态延伸率高达15.5%;固溶热处理(410℃、24 h)后晶界Mg7Zn3相固溶进基体,晶内析出相主要演变为具有Zn2Zr核的富Zn相,T4热处理降低强度的同时延伸率略微提升到16.7%;时效热处理后析出杆状的β

3.5.2 热等静压

热等静压(HIP)是粉末冶金工艺中常见的后处理工艺,用于闭合孔洞提升致密度。SLM态镁合金的孔洞缺陷和低延伸率还有很大的改善空间,但是对SLM态镁合金进行HIP处理的研究还比较少。Liu和Guo[35]在2020年对SLM态AZ61镁合金进行了HIP (450℃、103 MPa、3 h)处理:SLM态合金的孔隙率为0.8%,平均孔洞尺寸为(43 ± 27) μm,HIP处理后大部分孔洞被闭合,致密度接近100%;HIP处理后硬脆β-Mg17Al12相从晶界连续析出转变为非连续析出,平均晶粒尺寸从(2.2 ± 0.3) μm显著增加到(23.9 ± 6.0) μm;HIP处理后显微硬度从98.9 HV减小到87.4 HV,但是仍然高于锻造态的硬度(63.5 HV);HIP处理后晶粒的显著长大导致屈服强度从233 MPa显著降低至126 MPa,孔洞的闭合和硬脆共晶相的溶解使得延伸率从3.1%大幅度提升至8.2%,致密度提升和固溶强化效应使得HIP处理后的抗拉强度和SLM态接近。后续需要优化HIP处理的条件,如缩短保温时间或者降低处理温度来控制晶粒长大,从而提升屈服强度。

2019年,Gangireddy等[64]对SLM态WE43合金进行了HIP处理并研究了HIP对显微组织演变和动态力学行为(分离式Hopkinson压杆测试系统)的影响规律:对于高孔隙率样品HIP可以显著闭合孔洞,例如将孔隙率从12.4%减小到2.7%,但是对于0.3%低孔隙率样品进行HIP处理后孔隙率不变;HIP处理后富含Nd的带状析出相破碎转变为更短更厚的板状析出相,但是所有经 HIP 处理的样品在15%应变附近发生45°剪切失效,显示出强度急剧下降。Esmaily等[67]在2020年发现SLM态WE43合金经过HIP (520℃、103 MPa、4 h)或者HIP + 固溶热处理(525℃、8 h)后晶粒尺寸没有显著长大但是可以改善耐腐蚀性能,表明SLM态WE43合金具有相当稳定的显微组织,具体原因值得深入研究。

3.5.3 搅拌摩擦加工

搅拌摩擦加工(friction stir processing,FSP)是一种大塑性变形技术,同时使用高应变、高应变速率和高温来使材料完全流动,从而在搅拌区产生晶粒细化、第二相破碎、显微组织均匀化、致密化等效应。FSP处理可以球化共晶相、提升显微组织均匀性、减小孔隙率,从而提升SLM态AlSi10Mg合金的塑性和疲劳寿命[104]。采用FSP来调整SLM态镁合金的显微组织和增强力学性能的报道很少,Deng等[80]在2021年研究了FSP和时效热处理对SLM态G10K合金显微组织和力学性能的影响规律:SLM过程巨大的温度梯度和合金中较低的Zr含量(0.23%,质量分数)无法提供足够的生长限制因子,导致SLM态G10K合金中存在平行于打印堆垛方向的粗大柱状晶;FSP处理后孔隙率从0.779%减小到0.015% (图11a和b[80]),熔池边界消失,柱状晶向等轴晶转变(图11c和d[80]),平均晶粒尺寸从26.85 μm显著细化到5.78 μm,带来介观和微观尺度上的均匀化效应;FSP处理后同时提升强度和塑性,屈服强度从180 MPa增至202 MPa,抗拉强度从228 MPa增至272 MPa,延伸率从2.2%显著增大至7.5%;对SLM态和FSP态G10K合金进行直接时效热处理(T5,200℃、32 h),FSP-T5态G10K合金中的β'时效析出相的面积数密度和长径比都高于SLM-T5态(FSP处理引入的位错和晶格畸变等晶体缺陷会促进析出相的异质形核),因而其峰时效硬度增量更大,FSP-T5态G10K合金的强塑性也都显著高于SLM-T5态。

图11

3.6 镁合金专用SLM设备开发

绝大多数镁合金的SLM报道都是采用商业化的SLM设备进行成形,很少针对Mg的蒸发飞溅、易开裂等特性而开发镁合金专用SLM设备或者改进商业化SLM设备。SLM成形锌合金时也会产生剧烈的蒸发飞溅现象,Wen等[97]在2019年采用有限元模拟仿真研究了循环气体滤网结构对保护气体流动的影响规律:保护气体流动的强度和分布可通过进气压力、排气抽吸功率和循环气体滤网结构调整;高速摄像机拍摄表明Zn蒸气的流动速率为2.29 m/s,大于保护气体的流动速率0.75 m/s;3种滤网结构具有相同的尺寸,但是孔和槽的分布不同(图12a[97]);相比第1种和第3种滤网结构,在第2种滤网结构下,气体的流动速率分布是几乎均匀的,气体流动速率大约为0.9 m/s,气流汇聚而有力(图12b[97]);与第3种滤网的槽相比,孔有利于压缩气流从而形成汇聚而有力的气流,向上的流动分离和湍流都减少到最低限度,使所有金属蒸气及时通过排气口排出;与第1种滤网孔洞均匀分布相比,孔洞上下错开分布的第2种滤网结构减少了来自相邻孔的2股气流之间的干扰,从而有助于形成均匀的气流;在最优气流即第2种滤网结构下,所有的金属蒸气都被吹走并被吸入排气口,成形腔室内没有Zn蒸气的残留物(图12c[97])。因此,SLM过程中成形腔室内的气流强度对于整个打印表面应该是均匀的,从而保证基板上不同位置的打印质量是一样的,气体流动速率应尽可能高从而加快蒸发产物的去除,及时去除蒸发产物有利于避免缺陷和提升成形过程稳定性。

图12

4 总结与展望

本文综述了选区激光熔化增材制造技术制造镁合金的研究进展,详细总结了SLM工艺参数对成形缺陷、显微组织和力学性能的影响规律,阐述了各类冶金缺陷的产生机理及避免方法,并总结了不同后处理方式对显微组织和力学性能的影响规律。目前SLM制造镁合金的力学性能明显优于铸造合金,略低于挤压合金,但是SLM在制备大型复杂构件时具有得天独厚的优势,因此SLM制造镁合金构件时具有极大的工程应用潜力。根据目前的国内外研究现状和发展趋势,未来的镁合金SLM研究需要对以下几方面重点突破。

(1) SLM专用镁合金材料的研发

目前尚无通过验证的商业化SLM用镁合金粉体材料,镁合金粉体材料的标准化和商品化成为限制其SLM研究的主要障碍之一。对于粉末的详细表征,包括化学成分(尤其是O含量)、形貌特征、粒径分布、流动性、空心粉、堆垛密度等,需要建立相应的标准和规范来评价镁合金粉末的质量。目前镁合金的SLM研究主要针对传统的商业化铸造镁合金和高强度Mg-Gd系镁稀土合金,这些合金成分都是针对慢速凝固过程开发设计的,而SLM过程独特的快速凝固非平衡超常冶金条件可能带来新的强化元素和强化相,阐明新的强韧化机理,从而形成新一代SLM专用高性能镁合金材料。

(2) SLM制造镁合金冶金缺陷控制

SLM制造镁合金的主要特点是剧烈的蒸发飞溅,大量的烟尘和对熔池的反冲压力会影响熔池的稳定熔化过程,足够的激光能量输入和有效的气体循环系统能够抑制蒸发飞溅的负面影响,从而实现稳定的成形质量。通过调整工艺参数同时抑制气孔和未熔合缺陷并增大高致密度成形工艺区间窗口具有重要意义。气孔缺陷不可能完全消除,需要通过同步辐射原位拉伸实验明确少量气孔缺陷对力学性能的影响程度。SLM制造镁合金过程中容易累积非常大的热应力,从而形成热裂纹或者冷裂纹,需要明确开裂机制并从工艺参数和化学成分2个角度加以调控。实现粉末制备→前处理→SLM成形→后处理的闭环控制可以有效避免氧化物的形成。Mg的蒸发飞溅必然会导致SLM态的化学成分偏离粉末,需明确工艺参数对化学成分变化的影响规律,从而可以根据最终所需的SLM态化学成分来倒推粉末成分和工艺参数,以及控制元素的选择性烧损来制备新材料或者成分梯度材料。目前SLM制造镁合金冶金缺陷的控制主要通过大量实验来获得最佳工艺参数,缺少对激光与镁合金粉末相互作用的热力学和动力学过程的理解,需要结合数值模拟仿真方法来更好地理解和调控镁合金SLM制造过程,从而控制冶金缺陷和调控显微组织,还需要建立SLM制造镁合金工艺参数-缺陷-显微组织-力学性能的大数据库,用机器学习的方法更有效地进行工艺参数优化和调控显微组织和力学性能。此外,工艺参数会影响成形件的表面质量、尺寸精度以及成形过程的稳定性,有必要开发针对表面质量和尺寸精度的在线监测和智能化控制系统。

(3) SLM态镁合金专用后处理制度的研发

目前还没有去应力退火处理对SLM态镁合金显微组织和力学性能的影响规律的报道,而后处理制度需针对SLM态独特的快速凝固细小非平衡组织而专门优化设计,从而避免后处理过程中SLM态细小晶粒的显著粗化,SLM态镁合金经过后处理后强度和塑性都要得到改善。需要设计一个镁合金成分使其SLM态组织为细小的单相α-Mg过饱和固溶体,SLM态只需简单的T5时效热处理(同时可以消除残余应力)就可析出大量的纳米级强化相,显著的细晶强化和析出强化效应使得SLM-T5态合金具有优异的力学性能。

(4) 镁合金专用SLM设备的研发

镁合金专用SLM设备的研发需从以下2点考虑:抑制Mg的蒸发飞溅或者优化成形腔室内的循环气体的流场来及时去除蒸发烟尘以避免残留在成形腔室内;通过提高基板加热温度(> 200℃)或者基板内部采用隔热材料以及采用激光二极管发射的强度均匀的成形光进行上加热来减小温度梯度、增加一束激光用于在线消除热应力、引入3D激光冲击喷丸等来减小热应力累积从而避免变形开裂现象的产生。

(5) SLM制造高强度高模量耐热镁基复合材料

SLM制造镁基复合材料的研究报道较少,SLM过程微小熔池的超常冶金条件有利于添加一些常规铸造工艺难以添加甚至无法添加的高模量或者耐热增强相,采用球磨、干法或湿法包覆工艺都比较容易实现亚微米或者纳米级增强相的均匀分散,SLM过程熔池内部的Marangoni对流效应也会促进增强相的均匀分布,最终获得Mg基体加均匀分布高模量耐热增强相的镁基复合材料,需阐明镁基复合材料的强化机制、弹性模量提升机制和耐热机制,高模量和耐热对于航空航天、军工装备等领域的应用具有重要价值。

(6) SLM制造镁合金的应用

目前SLM制备镁合金生物医用植入物的研究在动物实验阶段,尚未取得临床应用。SLM制备航空航天、军工装备和轨道交通等领域的高性能复杂镁合金结构件还鲜有报道,制备实体零件的尺寸越大,变形开裂就越严重,需要加以重视。未来航空航天等领域对构件的要求不再是均匀的化学成分、显微组织和力学性能,同一个构件不同部位可能需要不同的密度、强度、模量等,而SLM技术有利于实现常规铸造无法实现的功能梯度材料的制造。通过优化材料成分、制造工艺、改进设备、降低成本等方面最终有望实现SLM制造镁合金的应用。

参考文献

Recent developments and applications on high-performance cast magnesium rare-earth alloys

[J].

Research advances of magnesium and magnesium alloys worldwide in 2021

[J].

Tensile properties of high strength cast Mg alloys at room temperature: A review

[J].

Development trends in additive manufacturing and 3D printing

[J].

Recent progress and perspectives in additive manufacturing of magnesium alloys

[J].

Additive manufacturing of magnesium alloy powders: Investigations into process development using Elektron®MAP + 43 via laser powder bed fusion and directed energy deposition

[A].

Microstructure and mechanical properties of laser melting deposited GW103K Mg-RE alloy

[J].

Effect of multiple thermal cycles on the microstructure evolution of GA151K alloy fabricated by laser-directed energy deposition

[J].

Recent developments and challenges accompanying with wire arc additive manufacturing of Mg alloys: A review

[J].

Wire arc additive manufacturing of AZ31 magnesium alloy: Grain refinement by adjusting pulse frequency

[J].

Magnesium alloy 3D printing by wire and arc additive manufacturing (WAAM)

[J].

Fabrication of high-strength Mg-Gd-Zn-Zr alloys via differential-thermal extrusion

[J].

Research progress on selective laser melting (SLM) of magnesium alloys: A review

[J].

Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder

[J].

A study of the microstructural evolution during selective laser melting of Ti-6Al-4V

[J].

Effect of δ phase on high temperature mechanical performances of Inconel 718 fabricated with SLM process

[J].

Additively manufactured hierarchical stainless steels with high strength and ductility

[J].Many traditional approaches for strengthening steels typically come at the expense of useful ductility, a dilemma known as strength-ductility trade-off. New metallurgical processing might offer the possibility of overcoming this. Here we report that austenitic 316L stainless steels additively manufactured via a laser powder-bed-fusion technique exhibit a combination of yield strength and tensile ductility that surpasses that of conventional 316L steels. High strength is attributed to solidification-enabled cellular structures, low-angle grain boundaries, and dislocations formed during manufacturing, while high uniform elongation correlates to a steady and progressive work-hardening mechanism regulated by a hierarchically heterogeneous microstructure, with length scales spanning nearly six orders of magnitude. In addition, solute segregation along cellular walls and low-angle grain boundaries can enhance dislocation pinning and promote twinning. This work demonstrates the potential of additive manufacturing to create alloys with unique microstructures and high performance for structural applications.

Effects of processing parameters on properties of selective laser melting Mg-9%Al powder mixture

[J].

Metal vaporization and its influence during laser powder bed fusion process

[J].

Microstructure evolution and mechanical properties of a high-strength Mg-10Gd-3Y-1Zn-0.4Zr alloy fabricated by laser powder bed fusion

[J].

A review of laser welding techniques for magnesium alloys

[J].

Absorbance study of powder conditions for laser additive manufacturing

[J].

Layer manufacturing of magnesium and its alloy structures for future applications

[J].

Microstructure and mechanical properties of selective laser melted magnesium

[J].

Experimental investigation on selective laser melting of bulk net-shape pure magnesium

[J].

Corrosion behaviour of laser powder bed fused bulk pure magnesium in Hank's solution

[J].

Effect of energy input on formability, microstructure and mechanical properties of selective laser melted AZ91D magnesium alloy

[J].

Design of experiments approach in AZ31 powder selective laser melting process optimization

[J].

Microstructure evolution and biodegradation behavior of laser rapid solidified Mg-Al-Zn alloy

[J].

Microstructure and mechanical properties of selective laser melted Mg-9 wt%Al powder mixture

[J].

Influence of laser process parameters on the densification, microstructure, and mechanical properties of a selective laser melted AZ61 magnesium alloy

[J].

Weakest region analysis of non-combustible Mg products fabricated by selective laser melting

[J].

Selective laser melting of magnesium AZ31B alloy powder

[J].

Influence of hot isostatic pressing (HIP) on mechanical properties of magnesium alloy produced by selective laser melting (SLM)

[J].

Island-to-acicular alteration of second phase enhances the degradation resistance of biomedical AZ61 alloy

[J].

Balling behavior of selective laser melting (SLM) magnesium alloy

[J].

Plastic strain distribution throughout the microstructure duality during the fracture process of non-combustible Mg products fabricated by selective laser melting

[J].

Study on microstructure and properties of selective laser melted (SLM) magnesium alloy AZ91D

[J].

选区激光熔化AZ91D镁合金的组织与性能

[J].

Effect of particle size distribution of AZ91D magnesium alloy powder on selective laser melting process

[J].

AZ91D镁合金粉末粒度分布对其选区激光熔化成形的影响

[J].

An additively manufactured magnesium-aluminium alloy withstands seawater corrosion

[J].

Influence of element vaporization on formability, composition, microstructure, and mechanical performance of the selective laser melted Mg-Zn-Zr components

[J].

Laser rapid solidification improves corrosion behavior of Mg-Zn-Zr alloy

[J].

Study on porous Mg-Zn-Zr ZK61 alloys produced by laser additive manufacturing

[J].

Microstructure, biodegradation, antibacterial and mechanical properties of ZK60-Cu alloys prepared by selective laser melting technique

[J].Magnesium (Mg) alloys are receiving increasing attention for body implants owing to their good biocompatibility and biodegradability. However, they often suffer from bacterial infections on account of their insufficient antibacterial ability. In this study, ZK60-xCu (x = 0, 0.2, 0.4, 0.6 and 0.8 wt%) alloys were prepared by selective laser melting (SLM) with alloying copper (Cu) to enhance their antibacterial ability. Results showed that ZK60-Cu alloys exhibited strong antibacterial ability due to combination of release of Cu ions and alkaline environment which could kill bacteria by destroying cellular membrane structure, denaturing enzymes and inhibiting deoxyribonucleic acid (DNA) replication. In addition, their compressive strength increased due to grain refinement and uniformly dispersing of short-bar shaped MgZnCu phases. Moreover, ZK60-Cu alloys also exhibited good cytocompatibility. In summary, ZK60-Cu alloys with antibacterial ability may be promising implants for biomedical applications.

Selective laser melting of Mg-Zn binary alloys: Effects of Zn content on densification behavior, microstructure, and mechanical property

[J].

In vitro degradation behavior and cytocompatibility of ZK30/bioactive glass composites fabricated by selective laser melting for biomedical applications

[J].

Uniform degradation mode and enhanced degradation resistance of Mg alloy via a long period stacking ordered phase in the grain interior

[J].

Influence of graphene oxide (GO) on microstructure and biodegradation of ZK30-xGO composites prepared by selective laser melting

[J].

Laser additive manufacturing of Mg-based composite with improved degradation behaviour

[J].

Hot cracking in ZK60 magnesium alloy produced by laser powder bed fusion process

[J].

Additive manufacturing of ZK60 magnesium alloy by selective laser melting: Parameter optimization, microstructure and biodegradability

[J].

Comparison of the biodegradation of ZK30 subjected to solid solution treating and selective laser melting

[J].

Printability, mechanical and degradation properties of Mg-(x)Zn elemental powder mixes processed by laser powder bed fusion

[J].

Microstructure evolution of laser powder bed fusion ZK60 Mg alloy after different heat treatment

[J].

Elimination of extraordinarily high cracking susceptibility of ZK60 Mg alloy fabricated by laser powder bed fusion

[J].

Formability, microstructure, and thermal crack characteristics of selective laser melting of ZK60 magnesium alloy

[J].

The microstructure, mechanical properties and degradation behavior of laser-melted Mg-Sn alloys

[J].

The enhancement of Mg corrosion resistance by alloying Mn and laser-melting

[J].

Effect of laser processing parameters on porosity, microstructure and mechanical properties of porous Mg-Ca alloys produced by laser additive manufacturing

[J].

Selective laser melting of magnesium alloys

[J].

Additively manufactured biodegradable porous magnesium

[J].An ideal bone substituting material should be bone-mimicking in terms of mechanical properties, present a precisely controlled and fully interconnected porous structure, and degrade in the human body to allow for full regeneration of large bony defects. However, simultaneously satisfying all these three requirements has so far been highly challenging. Here we present topologically ordered porous magnesium (WE43) scaffolds based on the diamond unit cell that were fabricated by selective laser melting (SLM) and satisfy all the requirements. We studied the in vitro biodegradation behavior (up to 4 weeks), mechanical properties and biocompatibility of the developed scaffolds. The mechanical properties of the AM porous WE43 (E = 700-800 MPa) scaffolds were found to fall into the range of the values reported for trabecular bone even after 4 weeks of biodegradation. Scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FTIR), electrochemical tests and µCT revealed a unique biodegradation mechanism that started with uniform corrosion, followed by localized corrosion, particularly in the center of the scaffolds. Biocompatibility tests performed up to 72 h showed level 0 cytotoxicity (according to ISO 10993-5 and -12), except for one time point (i.e., 24 h). Intimate contact between cells (MG-63) and the scaffolds was also observed in SEM images. The study shows for the first time that AM of porous Mg may provide distinct possibilities to adjust biodegradation profile through topological design and open up unprecedented opportunities to develop multifunctional bone substituting materials that mimic bone properties and enable full regeneration of critical-size load-bearing bony defects.The ideal biomaterials for bone tissue regeneration should be bone-mimicking in terms of mechanical properties, present a fully interconnected porous structure, and exhibit a specific biodegradation behavior to enable full regeneration of bony defects. Recent advances in additive manufacturing have resulted in biomaterials that satisfy the first two requirements but simultaneously satisfying the third requirement has proven challenging so far. Here we present additively manufactured porous magnesium structures that have the potential to satisfy all above-mentioned requirements. Even after 4 weeks of biodegradation, the mechanical properties of the porous structures were found to be within those reported for native bone. Moreover, our comprehensive electrochemical, mechanical, topological, and biological study revealed a unique biodegradation behavior and the limited cytotoxicity of the developed biomaterials.Copyright © 2017 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Additive manufactured WE43 magnesium: A comparative study of the microstructure and mechanical properties with those of powder extruded and as-cast WE43

[J].Laser powder-bed fusion (L-PBF), an additive manufacturing (AM) method, was employed to produce WE43 magnesium cubes with minimal porosity. These samples were subjected to microstructural analysis by utilizing optical light and scanning electron microscopy techniques in addition to x-ray diffraction and compared to powder extruded and as-cast WE43 reference samples. The mechanical properties of the three materials were evaluated via tensile testing. Furthermore, the microstructure of the original powder material was investigated. The additive manufactured samples and the powder extruded (PE) samples showed an extremely fine, homogeneous microstructure with grain sizes of similar to 1 mu m and very fine secondary phases; the crystallographic structure of these phases could not be indisputably identified via XRD except for yttrium oxides. The microstructure of the as-cast material revealed different phases. Laser scan traces can clearly be observed in the microstructure as a result of the applied exposure strategy or small clusters of orientated grains that may be correlated to differing heat impacts between the center and edge-near areas of the sample due to melt pool preservation during the direction change of the laser path. Tensile tests show a significant alteration of properties in comparison to the tested conventional as-cast material. The tensile tests of the additive manufactured and powder extruded material revealed an ultimate tensile strength of 308 and 306 MPa at 12 and 22% elongation to failure, respectively. For both materials, an upper and lower yield point phenomenon was observed which is attributed to the fine grain size. The presented investigations render the additive manufacturing (AM) process suitable to produce samples that show a homogeneous and dense microstructure, mostly independent of the build direction, with exceptional high mechanical properties and to exhibit to a great extend similar features to powder extruded samples.

Microstructure and mechanical behavior of an additive manufactured (AM) WE43-Mg alloy

[J].Magnesium alloys are highly attractive in aerospace and auto industries due to their high strength-to-weight ratio. Additive manufacturing of Mg alloys can further save cost from materials and machining time. This paper investigates the microstructure and dynamic mechanical behavior of WE-43 Mg alloy built through the powder bed fusion process. Samples from four different combinations of processing parameters were built. These builds were studied in both as-built and hot isostatically pressed conditions. The resultant complex microstructures were studied under scanning and transmission electron microscopes while their dynamic mechanical behavior was evaluated using a split-Hopkinson pressure bar testing system. Effects of initial porosity and microstructural evolution during HIP treatment on mechanical response are discussed.

Laser additive manufacturing of biodegradable magnesium alloy WE43: A detailed microstructure analysis

[J].WE43, a magnesium alloy containing yttrium and neodymium as main alloying elements, has become a well-established bioresorbable implant material. Implants made of WE43 are often fabricated by powder extrusion and subsequent machining, but for more complex geometries laser powder bed fusion (LPBF) appears to be a promising alternative. However, the extremely high cooling rates and subsequent heat treatment after solidification of the melt pool involved in this process induce a drastic change in microstructure, which governs mechanical properties and degradation behaviour in a way that is still unclear. In this study we investigated the changes in the microstructure of WE43 induced by LPBF in comparison to that of cast WE43. We did this mainly by electron microscopy imaging, and chemical mapping based on energy-dispersive X-ray spectroscopy in conjunction with electron diffraction for the identification of the various phases. We identified different types of microstructure: an equiaxed grain zone in the center of the laser-induced melt pool, and a lamellar zone and a partially melted zone at its border. The lamellar zone presents dendritic lamellae lying on the Mg basal plane and separated by aligned Nd-rich nanometric intermetallic phases. They appear as globular particles made of MgNd and as platelets made of MgNd occurring on Mg prismatic planes. Yttrium is found in solid solution and in oxide particles stemming from the powder particles' shell. Due to the heat influence on the lamellar zone during subsequent laser passes, a strong texture developed in the bulk material after substantial grain growth. STATEMENT OF SIGNIFICANCE: Additively manufactured magnesium alloys have the potential of providing a major breakthrough in bone-reconstruction surgery by serving as biodegradable porous scaffold material. This study is the first to report in detail on the microstructure development of the established magnesium alloy WE43 fabricated by the additive manufacturing process of Laser Powder Bed Fusion (LPBF). It presents unique microstructural features which originate from the laser-melting process. An in situ transmission electron microscopy heating experiment further demonstrates the development of two distinct intermetallic phases in additively manufactured WE43 alloys. While one forms already during solidification, the other precipitates due to the ongoing heat treatment during LPBF processing.Copyright © 2019 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Additive manufacturing of dense WE43 Mg alloy by laser powder bed fusion

[J].

A detailed microstructural and corrosion analysis of magnesium alloy WE43 manufactured by selective laser melting

[J].

Microstructure, mechanical properties, corrosion resistance and cytocompatibility of WE43 Mg alloy scaffolds fabricated by laser powder bed fusion for biomedical applications

[J].

Corrosion behaviour of WE43 magnesium alloy printed using selective laser melting in simulation body fluid solution

[J].

Biodegradable magnesium alloy WE43 porous scaffolds fabricated by laser powder bed fusion for orthopedic applications: Process optimization, in vitro and in vivo investigation

[J].

Analysis of element loss, densification, and defects in laser-based powder-bed fusion of magnesium alloy WE43

[J].

Thermal behavior and densification during selective laser melting of Mg-Y-Sm-Zn-Zr alloy: Simulation and experiments

[J].

Research on formability, microstructure and mechanical properties of selective laser melted Mg-Y-Sm-Zn-Zr magnesium alloy

[J].

Selective laser melting manufactured CNTs/AZ31B composites: Heat transfer and vaporized porosity evolution

[J].

Effective control of microstructure evolution in AZ91D magnesium alloy by SiC nanoparticles in laser powder-bed fusion

[J].

Effect of heat treatment on microstructure and micro-wear resistance of selective laser melted Mg-Al-Zn alloy with La2O3 addition

[J].

Laser powder bed fusion of a magnesium-SiC metal matrix composite

[J].

Amorphous magnesium alloy with high corrosion resistance fabricated by laser powder bed fusion

[J].

Fabrication of high-strength Mg-Gd-Zn-Zr alloy via selective laser melting

[J].

Influence of friction stir processing and aging heat treatment on microstructure and mechanical properties of selective laser melted Mg-Gd-Zr alloy

[J].

Microstructure and mechanical properties of high strength Mg-15Gd-1Zn-0. 4Zr alloy additive-manufactured by selective laser melting process

[J].

Effect of heat treatment on microstructure evolution and mechanical properties of selective laser melted Mg-11Gd-2Zn-0.4Zr alloy

[J].

Limitations of linear energy density for laser powder bed fusion of Mg-15Gd-1Zn-0.4Zr alloy

[J].

Laser powder bed fusion of an age-hardenable Mg-10Gd-0.2Zr alloy with excellent strength-ductility synergy

[J].

Challenges and solutions for the additive manufacturing of biodegradable magnesium implants

[J].

Additively manufactured biodegradable porous magnesium implants for elimination of implant-related infections: An in vitro and in vivo study

[J].

Additively manufactured biodegrabable metal implants

[J].Additive manufacturing (AM) can produce complicated structures accurately and freely, giving the implant a macro and micro geometry, which makes the implant match the patient's defect site and realize the needs for personalized clinical treatment. Thus, AM provides a new manufacturing method for biodegradable metals. Presently, biodegradable metals are the hotspot issues of metallic biomaterials research. Additively-manufactured biodegradable metals are new research field. In this paper, a comprehensive review on the AM of Mg-, Zn-, and Fe-based biodegradable metals, which focuses on their processes and influencing factors, mechanical properties, biodegradation behavior, and biocompatibility, is given. Finally, the future development trend of the AM biomedical metallic materials is explored.

增材制造可降解金属医用植入物

[J].增材制造技术由于其高精度、高自由度等特点,可赋予医用金属植入物定制化的宏观与微观结构,使植入物与患者待修复缺损部位实现更好的生物力学适配,满足临床治疗个性化方案的需求,并为医用金属植入物的制造提供新途径。可降解金属目前是医用金属的研究热点,增材制造可降解金属医用植入物是个新方向,本文重点对增材制造镁基、锌基、铁基可降解金属的工艺流程及影响因素、力学性能、降解行为、生物相容性相关结果进行分析与总结,并展望了增材制造技术在医用可降解金属植入物领域的未来发展方向。

Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed X-ray imaging

[J].We used ultrahigh-speed synchrotron x-ray imaging to quantify the phenomenon of vapor depressions (also known as keyholes) during laser melting of metals as practiced in additive manufacturing. Although expected from welding and inferred from postmortem cross sections of fusion zones, the direct visualization of the keyhole morphology and dynamics with high-energy x-rays shows that (i) keyholes are present across the range of power and scanning velocity used in laser powder bed fusion; (ii) there is a well-defined threshold from conduction mode to keyhole based on laser power density; and (iii) the transition follows the sequence of vaporization, depression of the liquid surface, instability, and then deep keyhole formation. These and other aspects provide a physical basis for three-dimensional printing in laser powder bed machines.Copyright © 2019 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Critical instability at moving keyhole tip generates porosity in laser melting

[J].Laser powder bed fusion is a dominant metal 3D printing technology. However, porosity defects remain a challenge for fatigue-sensitive applications. Some porosity is associated with deep and narrow vapor depressions called keyholes, which occur under high-power, low-scan speed laser melting conditions. High-speed x-ray imaging enables operando observation of the detailed formation process of pores in Ti-6Al-4V caused by a critical instability at the keyhole tip. We found that the boundary of the keyhole porosity regime in power-velocity space is sharp and smooth, varying only slightly between the bare plate and powder bed. The critical keyhole instability generates acoustic waves in the melt pool that provide additional yet vital driving force for the pores near the keyhole tip to move away from the keyhole and become trapped as defects.Copyright © 2020, American Association for the Advancement of Science.

Mechanism of keyhole pore formation in metal additive manufacturing

[J].

Residual stresses in selective laser sintering and selective laser melting

[J].

Reducing residual stress by selective large-area diode surface heating during laser powder bed fusion additive manufacturing

[J].High residual stresses are typical in additively manufactured metals and can reach levels as high as the yield strength, leading to distortions and even cracks. Here, an in situ method for controlling residual stress during laser powder bed fusion additive manufacturing was demonstrated. By illuminating the surface of a build with homogeneously intense, shaped light from a set of laser diodes, the thermal history was controlled thereby reducing the residual stress in as-built parts. 316L stainless steel bridge-shaped parts were built to characterize the effect of in situ annealing on the residual stress. A reduction in the overall residual stress value of up to 90% was realized without altering the as-built grain structure (no grain growth). Some annealing effects on the cellular-dendritic solidification structure (patterns of higher solute content) occurred in areas that experienced prolonged exposure to elevated temperature. A comparison of the in situ process to conventional post-build annealing demonstrated equivalent stress reduction compared to rule-of-thumb thermal treatments. Use of this method could reduce or remove the need for post processing to remove residual stresses.

Prediction study on in-situ reduction of thermal stress using combined laser beams in laser powder bed fusion

[J].

Healing cracks in selective laser melting by 3D laser shock peening

[J].

An investigation into interaction between magnesium powder and Ar gas: Implications for selective laser melting of magnesium

[J].

Laser additive manufacturing of Zn porous scaffolds: Shielding gas flow, surface quality and densification

[J].Zn based metals have exhibited promising prospects as a structural material for biodegradable applications. Pure Zn porous scaffolds were produced by laser powder bed fusion (LPBF) based on data files of designing and CT scanning. Massive Zn evaporation during laser melting largely influenced the formation quality during LPBF of Zn metal. The metal vapor in processing chamber was blown off and suctioned out efficiently by an optimized gas circulation system. Numerical analysis was used to design and testify the performance of gas flow. The surface of scaffolds was covered with numerous particles in different sizes. Processing pores occurred near the outline contour of struts. The average grain size in width was 8.5 μm, and the hardness was 43.8 HV. Chemical plus electrochemical polishing obtained uniform and smooth surface without processing pores, but the diameter of struts reduced to 250 μm from the design value 300 μm. The poor surface quality and processing pores were resulted by the splashing particles included spatters and powders due to the recoil force of evaporation, and the horizontal movement of liquid metal due to overheating and wetting. The insufficient melting at the outline contour combined with good wetting of Zn liquid metal further increased the surface roughness and processing pores.

Characterization and strengthening effects of γ′ precipitates in a high-strength casting Mg-15Gd-1Zn-0.4Zr (wt.%) alloy

[J].

Mechanical properties of newly developed age hardenable Mg-3.2 mol%Gd-0.5 mol%Zn casting alloy

[J].

Heat treatment and mechanical properties of a high-strength cast Mg-Gd-Zn alloy

[J].

Microstructure and mechanical properties of Mg-Gd-Dy-Zn alloy with long period stacking ordered structure or stacking faults

[J].

Microstructure evolution and mechanical properties of an ultra-high strength casting Mg-15.6Gd-1.8Ag-0.4Zr alloy

[J].

Microstructure and super high strength of cast Mg-8.5Gd-2.3Y-1.8Ag-0.4Zr alloy

[J].