Manufacturing and processing of NiTi implants: A review

2

2012

... NiTi形状记忆合金因其优异的性能,如形状记忆效应、超弹性效应、低弹性模量、生物相容性、耐腐蚀和抗疲劳性以及高阻尼性能,已被广泛应用于生物医学领域和工业工程领域[1~3].在NiTi合金中,除了2种常见的相,即高温奥氏体母相B2和低温马氏体相B19ʹ,在B2与B19ʹ之间的相转变过程中还可以观察到中间R相[4,5].在近等原子比NiTi合金中,相变温度可以随着Ni含量变化而变化,Ni含量增加0.1% (原子分数)会使相变温度降低10℃,因此可以通过控制Ni和Ti元素的比例,调整NiTi合金的相变温度[6~8].目前,制备复杂形状NiTi合金的方法主要有传统铸造和粉末冶金技术,然而在制备过程中会产生大量脆性氧化物杂质,并且由于Ni和Ti之间的扩散率不同以及NiTi合金形成过程中会产生高热量反应,传统制备技术很难制备具有较高相对密度的样品[9]. ...

... 增材制造(additive manufacturing,AM)技术可以显著降低制备过程中的氧化程度,并通过在惰性气体环境中固化粉末来获得较高相对密度的样品,并且AM技术制备的NiTi合金得到了广泛的研究[7,10~12],例如:Marattukalam等[7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

Microstructure and corrosion behavior of laser processed NiTi alloy

2

2015

... 目前,大多数研究关注NiTi合金的超弹性性能[8,10,12,27],对其形状记忆效应的研究较少,并且常用的球形金属粉末是昂贵的近等原子比NiTi合金粉末[2,5,7,28],而利用Ni、Ti粉末原位反应制备的NiTi合金成本低廉且具有较高的力学性能[12,27,29].本工作利用LDED技术以及原位合成的方法成功制备出近等原子比NiTi形状记忆合金,并系统研究了NiTi合金的力学性能和形状记忆效应随激光能量密度的变化规律. ...

... 实验采用LDED技术原位合成NiTi合金,利用双粉桶模式可以单独控制Ni粉和Ti粉的流量,并将Ni粉和Ti粉混合,然后送入激光束中形成熔池.实验选用尺寸为150 mm × 150 mm × 10 mm的NiTi合金板为基材,基材表面分别用200、400和600号砂纸进行逐级打磨,并用无水乙醇反复清洗,以除去基材表面残存的氧化物和油污等杂质.选用纯度分别为99.8%和99.9%的球形Ni粉和球形Ti粉作为原材料,成分列于表1.采用TruLaser Cell 3000激光定向能量沉积设备进行打印,一号粉筒输送球形Ni粉,二号粉筒输送球形Ti粉,在高纯Ar气气氛中,通过控制送粉流量使Ni粉与Ti粉原子比为50.7∶49.3.固定扫描速率(v)为15 mm/s和光斑直径(d)为1 mm,通过改变激光功率(P)实现以不同激光能量密度(E)的方式沉积样品,激光能量密度计算公式如下[2,7]: ...

Applications of Ti-Ni alloys for secondary batteries

1

2008

... NiTi形状记忆合金因其优异的性能,如形状记忆效应、超弹性效应、低弹性模量、生物相容性、耐腐蚀和抗疲劳性以及高阻尼性能,已被广泛应用于生物医学领域和工业工程领域[1~3].在NiTi合金中,除了2种常见的相,即高温奥氏体母相B2和低温马氏体相B19ʹ,在B2与B19ʹ之间的相转变过程中还可以观察到中间R相[4,5].在近等原子比NiTi合金中,相变温度可以随着Ni含量变化而变化,Ni含量增加0.1% (原子分数)会使相变温度降低10℃,因此可以通过控制Ni和Ti元素的比例,调整NiTi合金的相变温度[6~8].目前,制备复杂形状NiTi合金的方法主要有传统铸造和粉末冶金技术,然而在制备过程中会产生大量脆性氧化物杂质,并且由于Ni和Ti之间的扩散率不同以及NiTi合金形成过程中会产生高热量反应,传统制备技术很难制备具有较高相对密度的样品[9]. ...

Influence of microstructure on phase transformation behavior and mechanical properties of plasma arc deposited shape memory alloy

2

2018

... NiTi形状记忆合金因其优异的性能,如形状记忆效应、超弹性效应、低弹性模量、生物相容性、耐腐蚀和抗疲劳性以及高阻尼性能,已被广泛应用于生物医学领域和工业工程领域[1~3].在NiTi合金中,除了2种常见的相,即高温奥氏体母相B2和低温马氏体相B19ʹ,在B2与B19ʹ之间的相转变过程中还可以观察到中间R相[4,5].在近等原子比NiTi合金中,相变温度可以随着Ni含量变化而变化,Ni含量增加0.1% (原子分数)会使相变温度降低10℃,因此可以通过控制Ni和Ti元素的比例,调整NiTi合金的相变温度[6~8].目前,制备复杂形状NiTi合金的方法主要有传统铸造和粉末冶金技术,然而在制备过程中会产生大量脆性氧化物杂质,并且由于Ni和Ti之间的扩散率不同以及NiTi合金形成过程中会产生高热量反应,传统制备技术很难制备具有较高相对密度的样品[9]. ...

... 图7为不同激光能量密度下NiTi合金的DSC曲线,并将马氏体相转变开始温度(Ms)、马氏体相转变结束温度(Mf)、奥氏体相转变开始温度(As)、Af列于表3.NiTi合金的相转变特征受多个因素共同影响,包括沉淀物的形成、Ni蒸发、O含量等[8,28,37].当激光能量密度较低时(20.0和21.7 J/mm2),升温时出现R相变,这通常与NiTi合金中含有大量Ni4Ti3相有关[34,38],当激光能量密度较高时(23.3和25.0 J/mm2),由于增加了Ni的蒸发,抑制了Ni4Ti3相生成,未出现R相变.在低激光能量密度的R→B2相变中,出现2个吸热峰,这主要是因为试样内存在较大的残余应力[32],而残余应力的存在会阻碍奥氏体相变的进行,故奥氏体转变会发生滞后现象,当奥氏体相变完成后,试样内残余应力得到释放,故降温过程中,马氏体相变只出现了单峰.当激光能量密度较高时(23.3和25.0 J/mm2),R相变消失,加热时只出现一个吸热峰,对应于B19ʹ→B2相变,降温时也只出现一个放热峰,对应于B2→B19ʹ相变.激光能量密度为20.0、21.7、23.3和25.0 J/mm2时Af分别为102.7、107.1、109.3和111.2℃.可见Af随着激光能量密度增加呈上升趋势,这是由于较高激光能量密度会导致Ni蒸发,从而使相变温度升高,值得注意的是LDED工艺制备近原子比NiTi合金的相转变温度比SLM高70℃[4,8,10,34].另外,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,相变焓ΔHM→A从5.27 J/g增加到20.50 J/g. ...

Laser processing of net-shape NiTi shape memory alloy

2

2007

... NiTi形状记忆合金因其优异的性能,如形状记忆效应、超弹性效应、低弹性模量、生物相容性、耐腐蚀和抗疲劳性以及高阻尼性能,已被广泛应用于生物医学领域和工业工程领域[1~3].在NiTi合金中,除了2种常见的相,即高温奥氏体母相B2和低温马氏体相B19ʹ,在B2与B19ʹ之间的相转变过程中还可以观察到中间R相[4,5].在近等原子比NiTi合金中,相变温度可以随着Ni含量变化而变化,Ni含量增加0.1% (原子分数)会使相变温度降低10℃,因此可以通过控制Ni和Ti元素的比例,调整NiTi合金的相变温度[6~8].目前,制备复杂形状NiTi合金的方法主要有传统铸造和粉末冶金技术,然而在制备过程中会产生大量脆性氧化物杂质,并且由于Ni和Ti之间的扩散率不同以及NiTi合金形成过程中会产生高热量反应,传统制备技术很难制备具有较高相对密度的样品[9]. ...

... 目前,大多数研究关注NiTi合金的超弹性性能[8,10,12,27],对其形状记忆效应的研究较少,并且常用的球形金属粉末是昂贵的近等原子比NiTi合金粉末[2,5,7,28],而利用Ni、Ti粉末原位反应制备的NiTi合金成本低廉且具有较高的力学性能[12,27,29].本工作利用LDED技术以及原位合成的方法成功制备出近等原子比NiTi形状记忆合金,并系统研究了NiTi合金的力学性能和形状记忆效应随激光能量密度的变化规律. ...

Effects of grain refinement on the microstructures and damping behaviors of a Cu-Al-Ni-Mn-Ti shape memory alloy

1

2021

... NiTi形状记忆合金因其优异的性能,如形状记忆效应、超弹性效应、低弹性模量、生物相容性、耐腐蚀和抗疲劳性以及高阻尼性能,已被广泛应用于生物医学领域和工业工程领域[1~3].在NiTi合金中,除了2种常见的相,即高温奥氏体母相B2和低温马氏体相B19ʹ,在B2与B19ʹ之间的相转变过程中还可以观察到中间R相[4,5].在近等原子比NiTi合金中,相变温度可以随着Ni含量变化而变化,Ni含量增加0.1% (原子分数)会使相变温度降低10℃,因此可以通过控制Ni和Ti元素的比例,调整NiTi合金的相变温度[6~8].目前,制备复杂形状NiTi合金的方法主要有传统铸造和粉末冶金技术,然而在制备过程中会产生大量脆性氧化物杂质,并且由于Ni和Ti之间的扩散率不同以及NiTi合金形成过程中会产生高热量反应,传统制备技术很难制备具有较高相对密度的样品[9]. ...

Effect of heat treatment on microstructure, corrosion, and shape memory characteristics of laser deposited NiTi alloy

5

2018

... 增材制造(additive manufacturing,AM)技术可以显著降低制备过程中的氧化程度,并通过在惰性气体环境中固化粉末来获得较高相对密度的样品,并且AM技术制备的NiTi合金得到了广泛的研究[7,10~12],例如:Marattukalam等[7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

... [7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

... 目前,大多数研究关注NiTi合金的超弹性性能[8,10,12,27],对其形状记忆效应的研究较少,并且常用的球形金属粉末是昂贵的近等原子比NiTi合金粉末[2,5,7,28],而利用Ni、Ti粉末原位反应制备的NiTi合金成本低廉且具有较高的力学性能[12,27,29].本工作利用LDED技术以及原位合成的方法成功制备出近等原子比NiTi形状记忆合金,并系统研究了NiTi合金的力学性能和形状记忆效应随激光能量密度的变化规律. ...

... 实验采用LDED技术原位合成NiTi合金,利用双粉桶模式可以单独控制Ni粉和Ti粉的流量,并将Ni粉和Ti粉混合,然后送入激光束中形成熔池.实验选用尺寸为150 mm × 150 mm × 10 mm的NiTi合金板为基材,基材表面分别用200、400和600号砂纸进行逐级打磨,并用无水乙醇反复清洗,以除去基材表面残存的氧化物和油污等杂质.选用纯度分别为99.8%和99.9%的球形Ni粉和球形Ti粉作为原材料,成分列于表1.采用TruLaser Cell 3000激光定向能量沉积设备进行打印,一号粉筒输送球形Ni粉,二号粉筒输送球形Ti粉,在高纯Ar气气氛中,通过控制送粉流量使Ni粉与Ti粉原子比为50.7∶49.3.固定扫描速率(v)为15 mm/s和光斑直径(d)为1 mm,通过改变激光功率(P)实现以不同激光能量密度(E)的方式沉积样品,激光能量密度计算公式如下[2,7]: ...

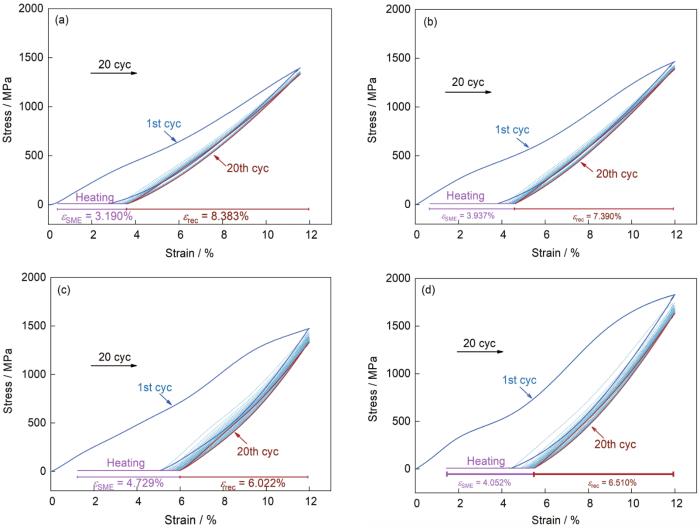

... 近等原子比NiTi合金因具有独特的形状记忆效应而被广泛研究[20,40~42].图9显示了制备的NiTi合金在应变控制下的循环压缩曲线和产生的形状记忆效应,并将结果列于表5.当样品在常温下以12%应变压缩循环20 cyc后,发现随着激光能量密度增加,样品的常温εrec从8.383%减小至6.510%,εrec的变化与B2相含量的变化一致,当样品加载时会发生B2→B19ʹ转变,卸载时发生B19ʹ→B2转变[25],故εrec与B2相含量呈正相关,Marattukalam等[7]研究也表明B2相含量越高,可恢复应变越大.随后将样品加热至Af以上时,此时样品中残留的稳定B19ʹ相会受热驱动的影响转变为B2相,同时加热会消除B19ʹ相的塑性应变[42,43],产生形状记忆效应.在加热条件下,随着激光能量密度增加,样品的εSME从3.190%增加至4.052%,εSME的变化与B19ʹ相含量的变化一致,但样品的η从88.2%降低至73.8%,这是由于样品中Ni4Ti3相含量不同导致的.当激光能量密度为20.0 J/mm2时,样品中含有大量Ni4Ti3相,且随着激光能量密度增加,Ni4Ti3相逐渐消失.Kim和Miyazaki[41]研究表明,Ni4Ti3相对位错具有钉扎作用,可改善NiTi合金的形状记忆效应.本工作的形状记忆恢复率结果远高于SLM制备的富镍Ni50.1Ti40.9的相应值(η = 82.6%)[40],另外,加热后不可恢复应变归因于残留的稳定马氏体[44]. ...

On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing

5

2014

... NiTi形状记忆合金因其优异的性能,如形状记忆效应、超弹性效应、低弹性模量、生物相容性、耐腐蚀和抗疲劳性以及高阻尼性能,已被广泛应用于生物医学领域和工业工程领域[1~3].在NiTi合金中,除了2种常见的相,即高温奥氏体母相B2和低温马氏体相B19ʹ,在B2与B19ʹ之间的相转变过程中还可以观察到中间R相[4,5].在近等原子比NiTi合金中,相变温度可以随着Ni含量变化而变化,Ni含量增加0.1% (原子分数)会使相变温度降低10℃,因此可以通过控制Ni和Ti元素的比例,调整NiTi合金的相变温度[6~8].目前,制备复杂形状NiTi合金的方法主要有传统铸造和粉末冶金技术,然而在制备过程中会产生大量脆性氧化物杂质,并且由于Ni和Ti之间的扩散率不同以及NiTi合金形成过程中会产生高热量反应,传统制备技术很难制备具有较高相对密度的样品[9]. ...

... 增材制造(additive manufacturing,AM)技术可以显著降低制备过程中的氧化程度,并通过在惰性气体环境中固化粉末来获得较高相对密度的样品,并且AM技术制备的NiTi合金得到了广泛的研究[7,10~12],例如:Marattukalam等[7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

... 目前,大多数研究关注NiTi合金的超弹性性能[8,10,12,27],对其形状记忆效应的研究较少,并且常用的球形金属粉末是昂贵的近等原子比NiTi合金粉末[2,5,7,28],而利用Ni、Ti粉末原位反应制备的NiTi合金成本低廉且具有较高的力学性能[12,27,29].本工作利用LDED技术以及原位合成的方法成功制备出近等原子比NiTi形状记忆合金,并系统研究了NiTi合金的力学性能和形状记忆效应随激光能量密度的变化规律. ...

... 图7为不同激光能量密度下NiTi合金的DSC曲线,并将马氏体相转变开始温度(Ms)、马氏体相转变结束温度(Mf)、奥氏体相转变开始温度(As)、Af列于表3.NiTi合金的相转变特征受多个因素共同影响,包括沉淀物的形成、Ni蒸发、O含量等[8,28,37].当激光能量密度较低时(20.0和21.7 J/mm2),升温时出现R相变,这通常与NiTi合金中含有大量Ni4Ti3相有关[34,38],当激光能量密度较高时(23.3和25.0 J/mm2),由于增加了Ni的蒸发,抑制了Ni4Ti3相生成,未出现R相变.在低激光能量密度的R→B2相变中,出现2个吸热峰,这主要是因为试样内存在较大的残余应力[32],而残余应力的存在会阻碍奥氏体相变的进行,故奥氏体转变会发生滞后现象,当奥氏体相变完成后,试样内残余应力得到释放,故降温过程中,马氏体相变只出现了单峰.当激光能量密度较高时(23.3和25.0 J/mm2),R相变消失,加热时只出现一个吸热峰,对应于B19ʹ→B2相变,降温时也只出现一个放热峰,对应于B2→B19ʹ相变.激光能量密度为20.0、21.7、23.3和25.0 J/mm2时Af分别为102.7、107.1、109.3和111.2℃.可见Af随着激光能量密度增加呈上升趋势,这是由于较高激光能量密度会导致Ni蒸发,从而使相变温度升高,值得注意的是LDED工艺制备近原子比NiTi合金的相转变温度比SLM高70℃[4,8,10,34].另外,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,相变焓ΔHM→A从5.27 J/g增加到20.50 J/g. ...

... ,8,10,34].另外,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,相变焓ΔHM→A从5.27 J/g增加到20.50 J/g. ...

The effects of vacuum induction melting and electron beam melting techniques on the purity of NiTi shape memory alloys

1

2006

... NiTi形状记忆合金因其优异的性能,如形状记忆效应、超弹性效应、低弹性模量、生物相容性、耐腐蚀和抗疲劳性以及高阻尼性能,已被广泛应用于生物医学领域和工业工程领域[1~3].在NiTi合金中,除了2种常见的相,即高温奥氏体母相B2和低温马氏体相B19ʹ,在B2与B19ʹ之间的相转变过程中还可以观察到中间R相[4,5].在近等原子比NiTi合金中,相变温度可以随着Ni含量变化而变化,Ni含量增加0.1% (原子分数)会使相变温度降低10℃,因此可以通过控制Ni和Ti元素的比例,调整NiTi合金的相变温度[6~8].目前,制备复杂形状NiTi合金的方法主要有传统铸造和粉末冶金技术,然而在制备过程中会产生大量脆性氧化物杂质,并且由于Ni和Ti之间的扩散率不同以及NiTi合金形成过程中会产生高热量反应,传统制备技术很难制备具有较高相对密度的样品[9]. ...

Thermomechanical characterization of Ni-rich NiTi fabricated by selective laser melting

4

2016

... 增材制造(additive manufacturing,AM)技术可以显著降低制备过程中的氧化程度,并通过在惰性气体环境中固化粉末来获得较高相对密度的样品,并且AM技术制备的NiTi合金得到了广泛的研究[7,10~12],例如:Marattukalam等[7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

... [10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

... 目前,大多数研究关注NiTi合金的超弹性性能[8,10,12,27],对其形状记忆效应的研究较少,并且常用的球形金属粉末是昂贵的近等原子比NiTi合金粉末[2,5,7,28],而利用Ni、Ti粉末原位反应制备的NiTi合金成本低廉且具有较高的力学性能[12,27,29].本工作利用LDED技术以及原位合成的方法成功制备出近等原子比NiTi形状记忆合金,并系统研究了NiTi合金的力学性能和形状记忆效应随激光能量密度的变化规律. ...

... 图7为不同激光能量密度下NiTi合金的DSC曲线,并将马氏体相转变开始温度(Ms)、马氏体相转变结束温度(Mf)、奥氏体相转变开始温度(As)、Af列于表3.NiTi合金的相转变特征受多个因素共同影响,包括沉淀物的形成、Ni蒸发、O含量等[8,28,37].当激光能量密度较低时(20.0和21.7 J/mm2),升温时出现R相变,这通常与NiTi合金中含有大量Ni4Ti3相有关[34,38],当激光能量密度较高时(23.3和25.0 J/mm2),由于增加了Ni的蒸发,抑制了Ni4Ti3相生成,未出现R相变.在低激光能量密度的R→B2相变中,出现2个吸热峰,这主要是因为试样内存在较大的残余应力[32],而残余应力的存在会阻碍奥氏体相变的进行,故奥氏体转变会发生滞后现象,当奥氏体相变完成后,试样内残余应力得到释放,故降温过程中,马氏体相变只出现了单峰.当激光能量密度较高时(23.3和25.0 J/mm2),R相变消失,加热时只出现一个吸热峰,对应于B19ʹ→B2相变,降温时也只出现一个放热峰,对应于B2→B19ʹ相变.激光能量密度为20.0、21.7、23.3和25.0 J/mm2时Af分别为102.7、107.1、109.3和111.2℃.可见Af随着激光能量密度增加呈上升趋势,这是由于较高激光能量密度会导致Ni蒸发,从而使相变温度升高,值得注意的是LDED工艺制备近原子比NiTi合金的相转变温度比SLM高70℃[4,8,10,34].另外,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,相变焓ΔHM→A从5.27 J/g增加到20.50 J/g. ...

The effect of energy input on reaction, phase transition and shape memory effect of NiTi alloy by selective laser melting

1

2020

... 增材制造(additive manufacturing,AM)技术可以显著降低制备过程中的氧化程度,并通过在惰性气体环境中固化粉末来获得较高相对密度的样品,并且AM技术制备的NiTi合金得到了广泛的研究[7,10~12],例如:Marattukalam等[7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

Ultrasonic vibration-assisted laser directed energy deposition in-situ synthesis of NiTi alloys: Effects on microstructure and mechanical properties

4

2020

... 增材制造(additive manufacturing,AM)技术可以显著降低制备过程中的氧化程度,并通过在惰性气体环境中固化粉末来获得较高相对密度的样品,并且AM技术制备的NiTi合金得到了广泛的研究[7,10~12],例如:Marattukalam等[7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

... [12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

... 目前,大多数研究关注NiTi合金的超弹性性能[8,10,12,27],对其形状记忆效应的研究较少,并且常用的球形金属粉末是昂贵的近等原子比NiTi合金粉末[2,5,7,28],而利用Ni、Ti粉末原位反应制备的NiTi合金成本低廉且具有较高的力学性能[12,27,29].本工作利用LDED技术以及原位合成的方法成功制备出近等原子比NiTi形状记忆合金,并系统研究了NiTi合金的力学性能和形状记忆效应随激光能量密度的变化规律. ...

... [12,27,29].本工作利用LDED技术以及原位合成的方法成功制备出近等原子比NiTi形状记忆合金,并系统研究了NiTi合金的力学性能和形状记忆效应随激光能量密度的变化规律. ...

Metal additive manufacturing: A review

2

2014

... 增材制造(additive manufacturing,AM)技术可以显著降低制备过程中的氧化程度,并通过在惰性气体环境中固化粉末来获得较高相对密度的样品,并且AM技术制备的NiTi合金得到了广泛的研究[7,10~12],例如:Marattukalam等[7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

... [13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

Strategic implications of current trends in additive manufacturing

2014

Additive manufacturing: Technology, applications and research needs

1

2013

... 增材制造(additive manufacturing,AM)技术可以显著降低制备过程中的氧化程度,并通过在惰性气体环境中固化粉末来获得较高相对密度的样品,并且AM技术制备的NiTi合金得到了广泛的研究[7,10~12],例如:Marattukalam等[7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

Review of the machining difficulties of nickel-titanium based shape memory alloys

1

2014

... 增材制造(additive manufacturing,AM)技术可以显著降低制备过程中的氧化程度,并通过在惰性气体环境中固化粉末来获得较高相对密度的样品,并且AM技术制备的NiTi合金得到了广泛的研究[7,10~12],例如:Marattukalam等[7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

Machining and phase transformation response of room-temperature austenitic NiTi shape memory alloy

2014

State-of-the-art of surface integrity induced by tool wear effects in machining process of titanium and nickel alloys: A review

2019

The effect of active phase of the work material on machining performance of a NiTi shape memory alloy

2015

Surface characteristics of machined NiTi shape memory alloy: The effects of cryogenic cooling and preheating conditions

2

2017

... 增材制造(additive manufacturing,AM)技术可以显著降低制备过程中的氧化程度,并通过在惰性气体环境中固化粉末来获得较高相对密度的样品,并且AM技术制备的NiTi合金得到了广泛的研究[7,10~12],例如:Marattukalam等[7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

... 近等原子比NiTi合金因具有独特的形状记忆效应而被广泛研究[20,40~42].图9显示了制备的NiTi合金在应变控制下的循环压缩曲线和产生的形状记忆效应,并将结果列于表5.当样品在常温下以12%应变压缩循环20 cyc后,发现随着激光能量密度增加,样品的常温εrec从8.383%减小至6.510%,εrec的变化与B2相含量的变化一致,当样品加载时会发生B2→B19ʹ转变,卸载时发生B19ʹ→B2转变[25],故εrec与B2相含量呈正相关,Marattukalam等[7]研究也表明B2相含量越高,可恢复应变越大.随后将样品加热至Af以上时,此时样品中残留的稳定B19ʹ相会受热驱动的影响转变为B2相,同时加热会消除B19ʹ相的塑性应变[42,43],产生形状记忆效应.在加热条件下,随着激光能量密度增加,样品的εSME从3.190%增加至4.052%,εSME的变化与B19ʹ相含量的变化一致,但样品的η从88.2%降低至73.8%,这是由于样品中Ni4Ti3相含量不同导致的.当激光能量密度为20.0 J/mm2时,样品中含有大量Ni4Ti3相,且随着激光能量密度增加,Ni4Ti3相逐渐消失.Kim和Miyazaki[41]研究表明,Ni4Ti3相对位错具有钉扎作用,可改善NiTi合金的形状记忆效应.本工作的形状记忆恢复率结果远高于SLM制备的富镍Ni50.1Ti40.9的相应值(η = 82.6%)[40],另外,加热后不可恢复应变归因于残留的稳定马氏体[44]. ...

A general solution of unsteady Stokes equations

1

2004

... 增材制造(additive manufacturing,AM)技术可以显著降低制备过程中的氧化程度,并通过在惰性气体环境中固化粉末来获得较高相对密度的样品,并且AM技术制备的NiTi合金得到了广泛的研究[7,10~12],例如:Marattukalam等[7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

Tailoring selective laser melting process parameters for NiTi implants

1

2012

... 增材制造(additive manufacturing,AM)技术可以显著降低制备过程中的氧化程度,并通过在惰性气体环境中固化粉末来获得较高相对密度的样品,并且AM技术制备的NiTi合金得到了广泛的研究[7,10~12],例如:Marattukalam等[7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

Application of laser engineered net shaping (LENS) to manufacture porous and functionally graded structures for load bearing implants

1

2009

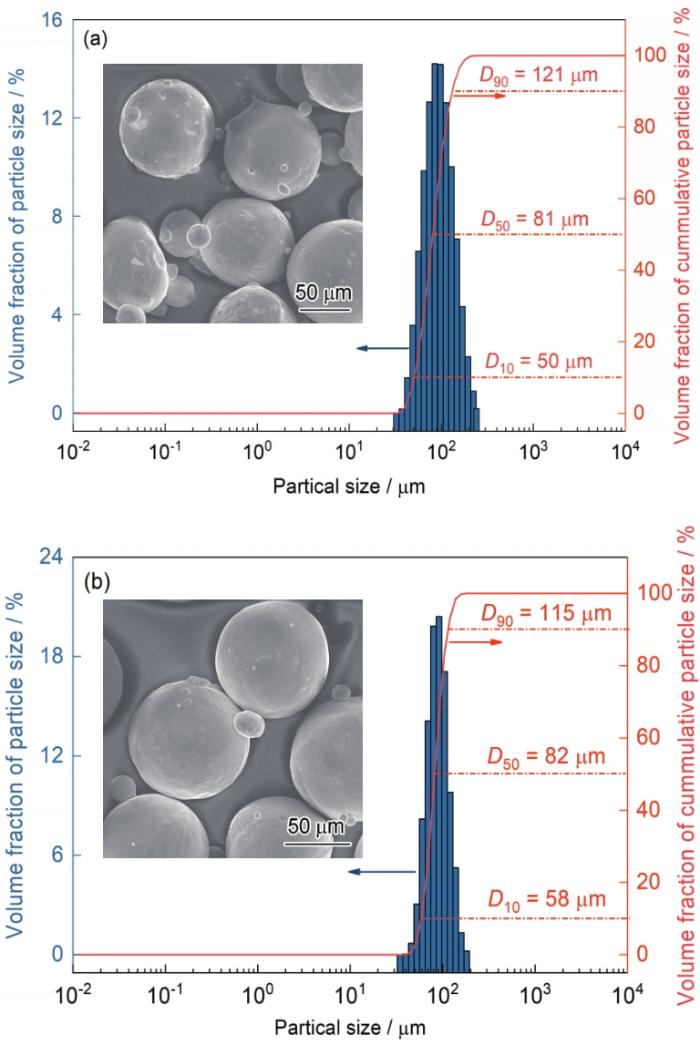

... 图1给出了Ni粉和Ti粉颗粒形貌和尺寸分布.SEM像显示Ni粉和Ti粉颗粒呈球形.常用于LDED成型的金属粉末粒径范围为53~106 μm[23],本工作80%的Ni粉粒径分布范围为50~121 μm,80%的Ti粉粒径分布范围为58~115 μm,满足LDED成型对粉末粒径的范围要求. ...

Functionally graded Co-Cr-Mo coating on Ti-6Al-4V alloy structures

1

2008

... 增材制造(additive manufacturing,AM)技术可以显著降低制备过程中的氧化程度,并通过在惰性气体环境中固化粉末来获得较高相对密度的样品,并且AM技术制备的NiTi合金得到了广泛的研究[7,10~12],例如:Marattukalam等[7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

Ultrahigh-performance TiNi shape memory alloy by 4D printing

3

2019

... 增材制造(additive manufacturing,AM)技术可以显著降低制备过程中的氧化程度,并通过在惰性气体环境中固化粉末来获得较高相对密度的样品,并且AM技术制备的NiTi合金得到了广泛的研究[7,10~12],例如:Marattukalam等[7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

... 选取激光功率为300、325、350和375 W,对应的激光线能量密度为20.0、21.7、23.3和25.0 J/mm2.打印块体样品尺寸为15 mm × 15 mm × 15 mm,实验采用的扫描策略为层间旋转90°.使用电火花线切割机对沉积的样品进行金相样品切割,然后进行机械抛光,使用体积比为HF∶HNO3∶H2O = 1∶3∶5腐蚀液对抛光后的样品表面腐蚀15 s.采用CuKα 靶材D/max-2550/PC型X射线衍射仪(XRD)以10°/min扫描速率进行物相分析.利用Q20差式扫描量热仪(DSC)对样品相变行为进行表征,选定测试温度范围为0~140℃,变温速率为10℃/min.采用Quanta FEG250场发射扫描电子显微镜(FE-SEM)及所附的能谱仪(EDS)观察球形粉末形貌和样品内部的微观结构以及分析元素组成.在样品的x-z面上切割出直径3 mm、厚度0.2 mm薄片,然后使用砂纸机预磨,最后使用离子减薄法获取透射电镜样品,利用JEM-2100透射电镜(TEM)观察样品内部的微观结构.在样品的x-z面上切割出直径4.5 mm、长度10 mm的压缩圆柱试样[30],然后利用Instron 5566万能试验机以0.3 mm/min的应变速率进行室温压缩和形状记忆效应(shape memory effect,SME)测试.SME测试中采用应变控制模式的循环压缩实验,在每个循环过程中,样品在室温下被压缩至12%的应变,然后卸载至10 MPa,通过附在夹具上的高温引伸计测量应变,使用改装压缩夹具上的加热器进行样品加热,使用压缩夹具中的内部液氮流进行样品冷却,使用k型热电偶测量温度.压缩循环20 cyc后,将样品以4℃/min速率加热至比奥氏体转变结束温度(Af)高30℃,并保温5 min以确保样品完全恢复至奥氏体状态.其中,采用常温可恢复应变(εrec)、加热后可恢复应变(εSME)和形状记忆恢复率(η = εSME / εtot × 100%,εtot为加热前的总不可恢复应变)[25]来表征样品的SME性能. ...

... 近等原子比NiTi合金因具有独特的形状记忆效应而被广泛研究[20,40~42].图9显示了制备的NiTi合金在应变控制下的循环压缩曲线和产生的形状记忆效应,并将结果列于表5.当样品在常温下以12%应变压缩循环20 cyc后,发现随着激光能量密度增加,样品的常温εrec从8.383%减小至6.510%,εrec的变化与B2相含量的变化一致,当样品加载时会发生B2→B19ʹ转变,卸载时发生B19ʹ→B2转变[25],故εrec与B2相含量呈正相关,Marattukalam等[7]研究也表明B2相含量越高,可恢复应变越大.随后将样品加热至Af以上时,此时样品中残留的稳定B19ʹ相会受热驱动的影响转变为B2相,同时加热会消除B19ʹ相的塑性应变[42,43],产生形状记忆效应.在加热条件下,随着激光能量密度增加,样品的εSME从3.190%增加至4.052%,εSME的变化与B19ʹ相含量的变化一致,但样品的η从88.2%降低至73.8%,这是由于样品中Ni4Ti3相含量不同导致的.当激光能量密度为20.0 J/mm2时,样品中含有大量Ni4Ti3相,且随着激光能量密度增加,Ni4Ti3相逐渐消失.Kim和Miyazaki[41]研究表明,Ni4Ti3相对位错具有钉扎作用,可改善NiTi合金的形状记忆效应.本工作的形状记忆恢复率结果远高于SLM制备的富镍Ni50.1Ti40.9的相应值(η = 82.6%)[40],另外,加热后不可恢复应变归因于残留的稳定马氏体[44]. ...

4D printing of NiTi auxetic structure with improved ballistic performance

1

2020

... 增材制造(additive manufacturing,AM)技术可以显著降低制备过程中的氧化程度,并通过在惰性气体环境中固化粉末来获得较高相对密度的样品,并且AM技术制备的NiTi合金得到了广泛的研究[7,10~12],例如:Marattukalam等[7]研究表明,激光功率和扫描速率显著影响激光近净成形(laser engineered net shaping,LENS)生产的NiTi合金的相组成、微观结构和耐腐蚀性.Saedi等[10]研究表明,固溶处理对选区激光熔化(selective laser melting,SLM)制备的NiTi合金的强度、超弹性和形状记忆效应有很大影响.Zhao等[11]研究表明,激光能量输入对SLM制备的NiTi合金的显微组织、相变和形状记忆效应有显著影响.Zhang等[12]研究表明,超声振动可以显著影响激光定向能量沉积(laser directed energy deposition,LDED)制备的NiTi合金的显微组织(组织均匀性、内部缺陷、元素组成、晶粒尺寸和相组成)和力学性能(超弹性、显微硬度和Young's模量).在LDED中,金属粉末通过同轴喷嘴被吹送到激光束聚焦的位置,并受到高能量密度的激光作用,产生熔池.如果是Ni和Ti 2种纯金属粉末原料,可以分别装入不同粉筒中,并通过调节送粉速率来制备具有特殊形状记忆效应的富Ni、近等原子比或者富Ti的NiTi合金.粉末原料按照计算机辅助设计模型和规定的扫描路径沉积[1,13~15].传统制备方法无法避免机械加工后处理产生的局部效应,并且这种局部效应也会降低NiTi形状记忆合金的性能[16~20],而LDED技术能够制备完全致密的近净或净成形零件[8,21],也可制备具有功能和分级微结构零件[13,22~24],可以有效避免机械加工后处理产生的局部效应.通过调控LDED工艺参数来制备具有空间和时间相关功能响应的NiTi形状记忆合金,并实现4D打印技术[25,26]. ...

Additive manufacturing of NiTi shape memory alloys using pre-mixed powders

2

2019

... 目前,大多数研究关注NiTi合金的超弹性性能[8,10,12,27],对其形状记忆效应的研究较少,并且常用的球形金属粉末是昂贵的近等原子比NiTi合金粉末[2,5,7,28],而利用Ni、Ti粉末原位反应制备的NiTi合金成本低廉且具有较高的力学性能[12,27,29].本工作利用LDED技术以及原位合成的方法成功制备出近等原子比NiTi形状记忆合金,并系统研究了NiTi合金的力学性能和形状记忆效应随激光能量密度的变化规律. ...

... ,27,29].本工作利用LDED技术以及原位合成的方法成功制备出近等原子比NiTi形状记忆合金,并系统研究了NiTi合金的力学性能和形状记忆效应随激光能量密度的变化规律. ...

Process development and characterization of additively manufactured nickel-titanium shape memory parts

2

2016

... 目前,大多数研究关注NiTi合金的超弹性性能[8,10,12,27],对其形状记忆效应的研究较少,并且常用的球形金属粉末是昂贵的近等原子比NiTi合金粉末[2,5,7,28],而利用Ni、Ti粉末原位反应制备的NiTi合金成本低廉且具有较高的力学性能[12,27,29].本工作利用LDED技术以及原位合成的方法成功制备出近等原子比NiTi形状记忆合金,并系统研究了NiTi合金的力学性能和形状记忆效应随激光能量密度的变化规律. ...

... 图7为不同激光能量密度下NiTi合金的DSC曲线,并将马氏体相转变开始温度(Ms)、马氏体相转变结束温度(Mf)、奥氏体相转变开始温度(As)、Af列于表3.NiTi合金的相转变特征受多个因素共同影响,包括沉淀物的形成、Ni蒸发、O含量等[8,28,37].当激光能量密度较低时(20.0和21.7 J/mm2),升温时出现R相变,这通常与NiTi合金中含有大量Ni4Ti3相有关[34,38],当激光能量密度较高时(23.3和25.0 J/mm2),由于增加了Ni的蒸发,抑制了Ni4Ti3相生成,未出现R相变.在低激光能量密度的R→B2相变中,出现2个吸热峰,这主要是因为试样内存在较大的残余应力[32],而残余应力的存在会阻碍奥氏体相变的进行,故奥氏体转变会发生滞后现象,当奥氏体相变完成后,试样内残余应力得到释放,故降温过程中,马氏体相变只出现了单峰.当激光能量密度较高时(23.3和25.0 J/mm2),R相变消失,加热时只出现一个吸热峰,对应于B19ʹ→B2相变,降温时也只出现一个放热峰,对应于B2→B19ʹ相变.激光能量密度为20.0、21.7、23.3和25.0 J/mm2时Af分别为102.7、107.1、109.3和111.2℃.可见Af随着激光能量密度增加呈上升趋势,这是由于较高激光能量密度会导致Ni蒸发,从而使相变温度升高,值得注意的是LDED工艺制备近原子比NiTi合金的相转变温度比SLM高70℃[4,8,10,34].另外,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,相变焓ΔHM→A从5.27 J/g增加到20.50 J/g. ...

Anisotropic tensile and actuation properties of NiTi fabricated with selective laser melting

1

2018

... 目前,大多数研究关注NiTi合金的超弹性性能[8,10,12,27],对其形状记忆效应的研究较少,并且常用的球形金属粉末是昂贵的近等原子比NiTi合金粉末[2,5,7,28],而利用Ni、Ti粉末原位反应制备的NiTi合金成本低廉且具有较高的力学性能[12,27,29].本工作利用LDED技术以及原位合成的方法成功制备出近等原子比NiTi形状记忆合金,并系统研究了NiTi合金的力学性能和形状记忆效应随激光能量密度的变化规律. ...

On the effects of selective laser melting process parameters on microstructure and thermomechanical response of Ni-rich NiTi

1

2018

... 选取激光功率为300、325、350和375 W,对应的激光线能量密度为20.0、21.7、23.3和25.0 J/mm2.打印块体样品尺寸为15 mm × 15 mm × 15 mm,实验采用的扫描策略为层间旋转90°.使用电火花线切割机对沉积的样品进行金相样品切割,然后进行机械抛光,使用体积比为HF∶HNO3∶H2O = 1∶3∶5腐蚀液对抛光后的样品表面腐蚀15 s.采用CuKα 靶材D/max-2550/PC型X射线衍射仪(XRD)以10°/min扫描速率进行物相分析.利用Q20差式扫描量热仪(DSC)对样品相变行为进行表征,选定测试温度范围为0~140℃,变温速率为10℃/min.采用Quanta FEG250场发射扫描电子显微镜(FE-SEM)及所附的能谱仪(EDS)观察球形粉末形貌和样品内部的微观结构以及分析元素组成.在样品的x-z面上切割出直径3 mm、厚度0.2 mm薄片,然后使用砂纸机预磨,最后使用离子减薄法获取透射电镜样品,利用JEM-2100透射电镜(TEM)观察样品内部的微观结构.在样品的x-z面上切割出直径4.5 mm、长度10 mm的压缩圆柱试样[30],然后利用Instron 5566万能试验机以0.3 mm/min的应变速率进行室温压缩和形状记忆效应(shape memory effect,SME)测试.SME测试中采用应变控制模式的循环压缩实验,在每个循环过程中,样品在室温下被压缩至12%的应变,然后卸载至10 MPa,通过附在夹具上的高温引伸计测量应变,使用改装压缩夹具上的加热器进行样品加热,使用压缩夹具中的内部液氮流进行样品冷却,使用k型热电偶测量温度.压缩循环20 cyc后,将样品以4℃/min速率加热至比奥氏体转变结束温度(Af)高30℃,并保温5 min以确保样品完全恢复至奥氏体状态.其中,采用常温可恢复应变(εrec)、加热后可恢复应变(εSME)和形状记忆恢复率(η = εSME / εtot × 100%,εtot为加热前的总不可恢复应变)[25]来表征样品的SME性能. ...

Microstructure and transformation behavior of in-situ shape memory alloys by selective laser melting Ti-Ni mixed powder

2

2013

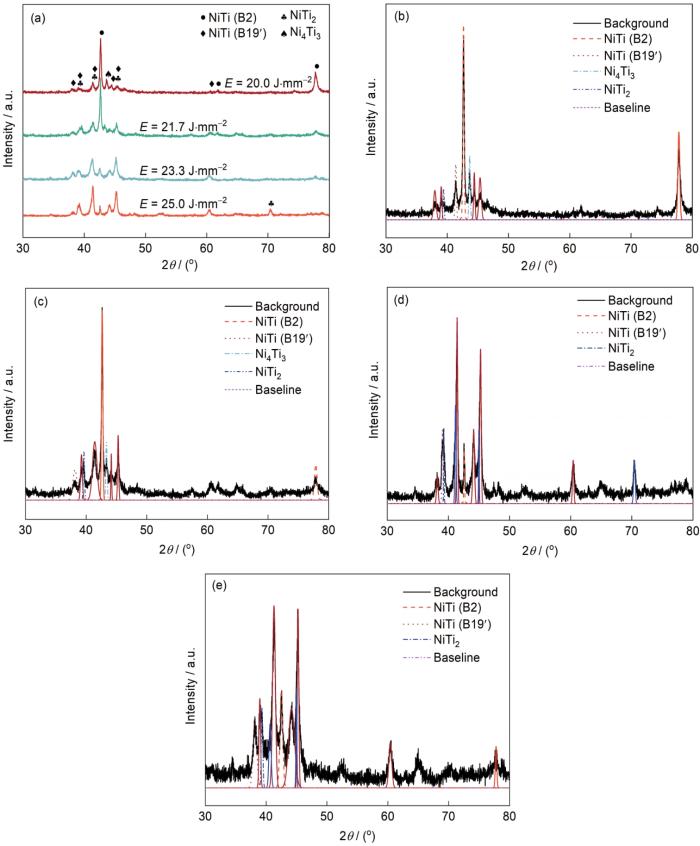

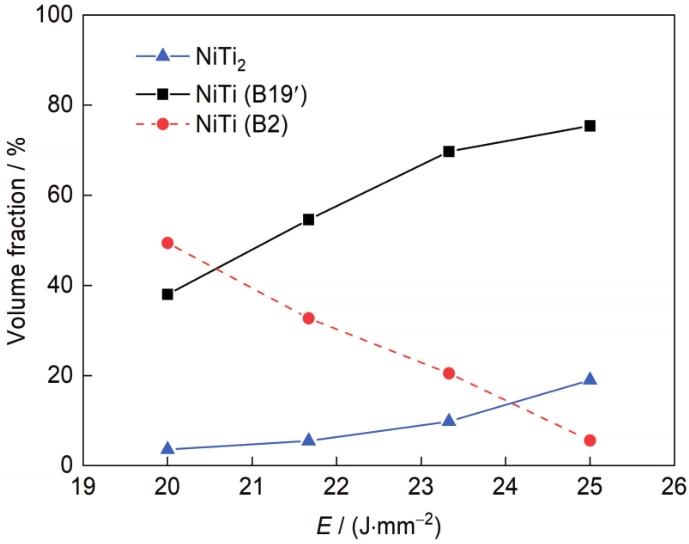

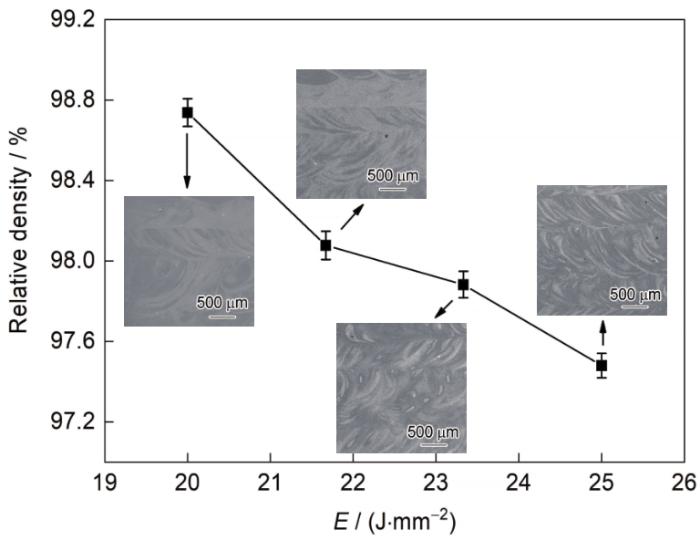

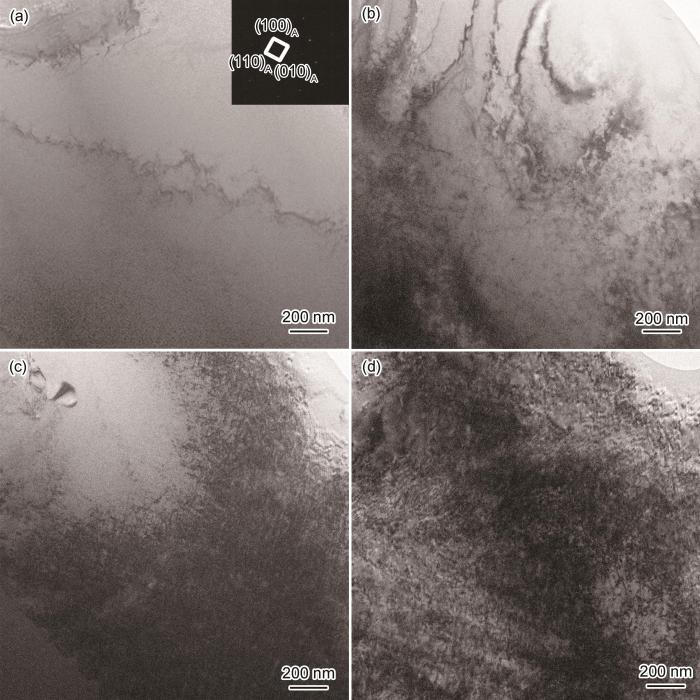

... 图2给出激光能量密度分别为20.0、21.7、23.3和25.0 J/mm2时NiTi合金的XRD谱和物相拟合图.对图2a中各相衍射峰面积进行积分,计算出B19ʹ马氏体相、B2奥氏体相和NiTi2相的体积分数.结果表明,室温下NiTi合金样品的主要组成相为B19ʹ马氏体相和B2奥氏体相,当激光能量密度增加时,奥氏体峰强减弱,马氏体峰强增加.此外还含有NiTi2、Ni4Ti3析出相,当激光能量密度超过21.7 J/mm2时,Ni4Ti3相峰位消失.由物相分析可知在打印过程中发生以下反应[31]: ...

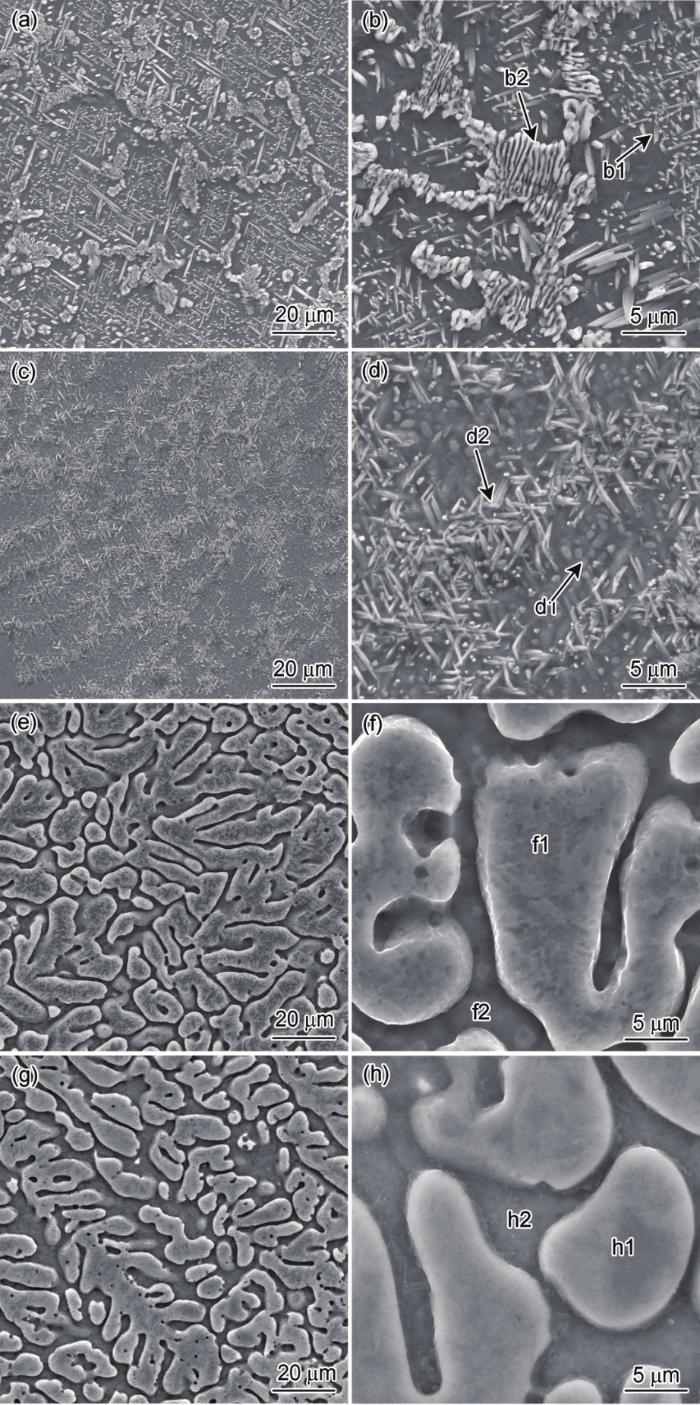

... 图5为不同激光能量密度下NiTi合金的SEM像,其中特征区域的EDS点扫描结果如表2所示.随着激光能量密度增加,样品中组织组成发生了改变,当激光能量密度为20.0 J/mm2时,样品中含有大量针状组织b1 (Ni和Ti原子比为1.34)以及带状组织b2 (Ni和Ti原子比为1.47),由于b1和b2处的Ni / Ti原子比接近Ni4Ti3比例,故可得出针状组织b1和带状组织b2为Ni4Ti3相.当激光能量密度增加至21.7 J/mm2时,带状组织Ni4Ti3相消失,当激光能量密度增加至23.3 J/mm2时,针状组织Ni4Ti3相消失,出现枝晶组织f1 (Ni和Ti原子比为0.95),以及枝晶间隙组织f2 (Ni和Ti原子比为0.52),根据原子比可知,f1为NiTi相,f2为NiTi2相.当激光能量密度增加至25.0 J/mm2时,微观组织与前者相同,但枝晶间隙组织面积增大,即NiTi2相含量增大.综上,Ni4Ti3相会随着激光能量密度增加而消失,NiTi2相含量随着激光能量密度增加而增加,这与前面物相拟合结果相一致,Ni4Ti3相和NiTi2相含量的变化是由于Ni的蒸发烧损导致的,在成形过程中,粉末被快速加热至熔点以上,由于激光在短时间内的高能量输入,金属粉末会从熔池中蒸发,由于Ni的沸点(3186 K)低于Ti (3560 K),且Ti的平衡蒸气压远低于Ni,从而导致Ni的蒸发[32~34],激光能量密度越大,Ni蒸发烧损越剧烈,Ni和Ti原子比越小,就更趋向形成NiTi2相,同时不利于Ni4Ti3相形成.根据修正的NiTi二元合金相图[35]可知,由于NiTi2相的反应温度(1257 K)低于NiTi相反应温度(1583 K),故在较高激光能量密度下NiTi2相更容易生成[31,36]. ...

A short review on the microstructure, transformation behavior and functional properties of NiTi shape memory alloys fabricated by selective laser melting

2

2018

... 图5为不同激光能量密度下NiTi合金的SEM像,其中特征区域的EDS点扫描结果如表2所示.随着激光能量密度增加,样品中组织组成发生了改变,当激光能量密度为20.0 J/mm2时,样品中含有大量针状组织b1 (Ni和Ti原子比为1.34)以及带状组织b2 (Ni和Ti原子比为1.47),由于b1和b2处的Ni / Ti原子比接近Ni4Ti3比例,故可得出针状组织b1和带状组织b2为Ni4Ti3相.当激光能量密度增加至21.7 J/mm2时,带状组织Ni4Ti3相消失,当激光能量密度增加至23.3 J/mm2时,针状组织Ni4Ti3相消失,出现枝晶组织f1 (Ni和Ti原子比为0.95),以及枝晶间隙组织f2 (Ni和Ti原子比为0.52),根据原子比可知,f1为NiTi相,f2为NiTi2相.当激光能量密度增加至25.0 J/mm2时,微观组织与前者相同,但枝晶间隙组织面积增大,即NiTi2相含量增大.综上,Ni4Ti3相会随着激光能量密度增加而消失,NiTi2相含量随着激光能量密度增加而增加,这与前面物相拟合结果相一致,Ni4Ti3相和NiTi2相含量的变化是由于Ni的蒸发烧损导致的,在成形过程中,粉末被快速加热至熔点以上,由于激光在短时间内的高能量输入,金属粉末会从熔池中蒸发,由于Ni的沸点(3186 K)低于Ti (3560 K),且Ti的平衡蒸气压远低于Ni,从而导致Ni的蒸发[32~34],激光能量密度越大,Ni蒸发烧损越剧烈,Ni和Ti原子比越小,就更趋向形成NiTi2相,同时不利于Ni4Ti3相形成.根据修正的NiTi二元合金相图[35]可知,由于NiTi2相的反应温度(1257 K)低于NiTi相反应温度(1583 K),故在较高激光能量密度下NiTi2相更容易生成[31,36]. ...

... 图7为不同激光能量密度下NiTi合金的DSC曲线,并将马氏体相转变开始温度(Ms)、马氏体相转变结束温度(Mf)、奥氏体相转变开始温度(As)、Af列于表3.NiTi合金的相转变特征受多个因素共同影响,包括沉淀物的形成、Ni蒸发、O含量等[8,28,37].当激光能量密度较低时(20.0和21.7 J/mm2),升温时出现R相变,这通常与NiTi合金中含有大量Ni4Ti3相有关[34,38],当激光能量密度较高时(23.3和25.0 J/mm2),由于增加了Ni的蒸发,抑制了Ni4Ti3相生成,未出现R相变.在低激光能量密度的R→B2相变中,出现2个吸热峰,这主要是因为试样内存在较大的残余应力[32],而残余应力的存在会阻碍奥氏体相变的进行,故奥氏体转变会发生滞后现象,当奥氏体相变完成后,试样内残余应力得到释放,故降温过程中,马氏体相变只出现了单峰.当激光能量密度较高时(23.3和25.0 J/mm2),R相变消失,加热时只出现一个吸热峰,对应于B19ʹ→B2相变,降温时也只出现一个放热峰,对应于B2→B19ʹ相变.激光能量密度为20.0、21.7、23.3和25.0 J/mm2时Af分别为102.7、107.1、109.3和111.2℃.可见Af随着激光能量密度增加呈上升趋势,这是由于较高激光能量密度会导致Ni蒸发,从而使相变温度升高,值得注意的是LDED工艺制备近原子比NiTi合金的相转变温度比SLM高70℃[4,8,10,34].另外,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,相变焓ΔHM→A从5.27 J/g增加到20.50 J/g. ...

Spatial control of functional response in 4D-printed active metallic structures

2017

The influence of heat treatment on the thermomechanical response of Ni-rich NiTi alloys manufactured by selective laser melting

3

2016

... 图5为不同激光能量密度下NiTi合金的SEM像,其中特征区域的EDS点扫描结果如表2所示.随着激光能量密度增加,样品中组织组成发生了改变,当激光能量密度为20.0 J/mm2时,样品中含有大量针状组织b1 (Ni和Ti原子比为1.34)以及带状组织b2 (Ni和Ti原子比为1.47),由于b1和b2处的Ni / Ti原子比接近Ni4Ti3比例,故可得出针状组织b1和带状组织b2为Ni4Ti3相.当激光能量密度增加至21.7 J/mm2时,带状组织Ni4Ti3相消失,当激光能量密度增加至23.3 J/mm2时,针状组织Ni4Ti3相消失,出现枝晶组织f1 (Ni和Ti原子比为0.95),以及枝晶间隙组织f2 (Ni和Ti原子比为0.52),根据原子比可知,f1为NiTi相,f2为NiTi2相.当激光能量密度增加至25.0 J/mm2时,微观组织与前者相同,但枝晶间隙组织面积增大,即NiTi2相含量增大.综上,Ni4Ti3相会随着激光能量密度增加而消失,NiTi2相含量随着激光能量密度增加而增加,这与前面物相拟合结果相一致,Ni4Ti3相和NiTi2相含量的变化是由于Ni的蒸发烧损导致的,在成形过程中,粉末被快速加热至熔点以上,由于激光在短时间内的高能量输入,金属粉末会从熔池中蒸发,由于Ni的沸点(3186 K)低于Ti (3560 K),且Ti的平衡蒸气压远低于Ni,从而导致Ni的蒸发[32~34],激光能量密度越大,Ni蒸发烧损越剧烈,Ni和Ti原子比越小,就更趋向形成NiTi2相,同时不利于Ni4Ti3相形成.根据修正的NiTi二元合金相图[35]可知,由于NiTi2相的反应温度(1257 K)低于NiTi相反应温度(1583 K),故在较高激光能量密度下NiTi2相更容易生成[31,36]. ...

... 图7为不同激光能量密度下NiTi合金的DSC曲线,并将马氏体相转变开始温度(Ms)、马氏体相转变结束温度(Mf)、奥氏体相转变开始温度(As)、Af列于表3.NiTi合金的相转变特征受多个因素共同影响,包括沉淀物的形成、Ni蒸发、O含量等[8,28,37].当激光能量密度较低时(20.0和21.7 J/mm2),升温时出现R相变,这通常与NiTi合金中含有大量Ni4Ti3相有关[34,38],当激光能量密度较高时(23.3和25.0 J/mm2),由于增加了Ni的蒸发,抑制了Ni4Ti3相生成,未出现R相变.在低激光能量密度的R→B2相变中,出现2个吸热峰,这主要是因为试样内存在较大的残余应力[32],而残余应力的存在会阻碍奥氏体相变的进行,故奥氏体转变会发生滞后现象,当奥氏体相变完成后,试样内残余应力得到释放,故降温过程中,马氏体相变只出现了单峰.当激光能量密度较高时(23.3和25.0 J/mm2),R相变消失,加热时只出现一个吸热峰,对应于B19ʹ→B2相变,降温时也只出现一个放热峰,对应于B2→B19ʹ相变.激光能量密度为20.0、21.7、23.3和25.0 J/mm2时Af分别为102.7、107.1、109.3和111.2℃.可见Af随着激光能量密度增加呈上升趋势,这是由于较高激光能量密度会导致Ni蒸发,从而使相变温度升高,值得注意的是LDED工艺制备近原子比NiTi合金的相转变温度比SLM高70℃[4,8,10,34].另外,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,相变焓ΔHM→A从5.27 J/g增加到20.50 J/g. ...

... ,34].另外,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,相变焓ΔHM→A从5.27 J/g增加到20.50 J/g. ...

Physical metallurgy of Ti-Ni-based shape memory alloys

1

2005

... 图5为不同激光能量密度下NiTi合金的SEM像,其中特征区域的EDS点扫描结果如表2所示.随着激光能量密度增加,样品中组织组成发生了改变,当激光能量密度为20.0 J/mm2时,样品中含有大量针状组织b1 (Ni和Ti原子比为1.34)以及带状组织b2 (Ni和Ti原子比为1.47),由于b1和b2处的Ni / Ti原子比接近Ni4Ti3比例,故可得出针状组织b1和带状组织b2为Ni4Ti3相.当激光能量密度增加至21.7 J/mm2时,带状组织Ni4Ti3相消失,当激光能量密度增加至23.3 J/mm2时,针状组织Ni4Ti3相消失,出现枝晶组织f1 (Ni和Ti原子比为0.95),以及枝晶间隙组织f2 (Ni和Ti原子比为0.52),根据原子比可知,f1为NiTi相,f2为NiTi2相.当激光能量密度增加至25.0 J/mm2时,微观组织与前者相同,但枝晶间隙组织面积增大,即NiTi2相含量增大.综上,Ni4Ti3相会随着激光能量密度增加而消失,NiTi2相含量随着激光能量密度增加而增加,这与前面物相拟合结果相一致,Ni4Ti3相和NiTi2相含量的变化是由于Ni的蒸发烧损导致的,在成形过程中,粉末被快速加热至熔点以上,由于激光在短时间内的高能量输入,金属粉末会从熔池中蒸发,由于Ni的沸点(3186 K)低于Ti (3560 K),且Ti的平衡蒸气压远低于Ni,从而导致Ni的蒸发[32~34],激光能量密度越大,Ni蒸发烧损越剧烈,Ni和Ti原子比越小,就更趋向形成NiTi2相,同时不利于Ni4Ti3相形成.根据修正的NiTi二元合金相图[35]可知,由于NiTi2相的反应温度(1257 K)低于NiTi相反应温度(1583 K),故在较高激光能量密度下NiTi2相更容易生成[31,36]. ...

The development of TiNi-based negative Poisson's ratio structure using selective laser melting

2

2016

... 图5为不同激光能量密度下NiTi合金的SEM像,其中特征区域的EDS点扫描结果如表2所示.随着激光能量密度增加,样品中组织组成发生了改变,当激光能量密度为20.0 J/mm2时,样品中含有大量针状组织b1 (Ni和Ti原子比为1.34)以及带状组织b2 (Ni和Ti原子比为1.47),由于b1和b2处的Ni / Ti原子比接近Ni4Ti3比例,故可得出针状组织b1和带状组织b2为Ni4Ti3相.当激光能量密度增加至21.7 J/mm2时,带状组织Ni4Ti3相消失,当激光能量密度增加至23.3 J/mm2时,针状组织Ni4Ti3相消失,出现枝晶组织f1 (Ni和Ti原子比为0.95),以及枝晶间隙组织f2 (Ni和Ti原子比为0.52),根据原子比可知,f1为NiTi相,f2为NiTi2相.当激光能量密度增加至25.0 J/mm2时,微观组织与前者相同,但枝晶间隙组织面积增大,即NiTi2相含量增大.综上,Ni4Ti3相会随着激光能量密度增加而消失,NiTi2相含量随着激光能量密度增加而增加,这与前面物相拟合结果相一致,Ni4Ti3相和NiTi2相含量的变化是由于Ni的蒸发烧损导致的,在成形过程中,粉末被快速加热至熔点以上,由于激光在短时间内的高能量输入,金属粉末会从熔池中蒸发,由于Ni的沸点(3186 K)低于Ti (3560 K),且Ti的平衡蒸气压远低于Ni,从而导致Ni的蒸发[32~34],激光能量密度越大,Ni蒸发烧损越剧烈,Ni和Ti原子比越小,就更趋向形成NiTi2相,同时不利于Ni4Ti3相形成.根据修正的NiTi二元合金相图[35]可知,由于NiTi2相的反应温度(1257 K)低于NiTi相反应温度(1583 K),故在较高激光能量密度下NiTi2相更容易生成[31,36]. ...

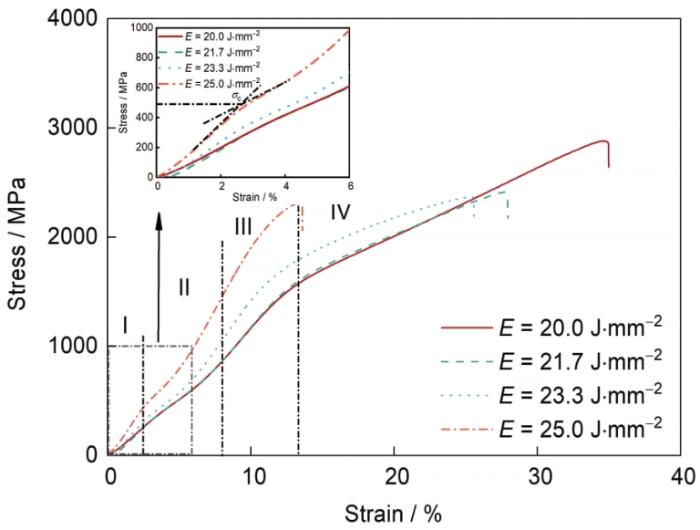

... 图8显示了不同激光能量密度下NiTi合金的室温压缩应力-应变曲线.所有曲线均存在2个屈服平台,这是典型的双屈服现象[39],每条曲线均包括4个阶段:马氏体弹性变形阶段(Ⅰ)、马氏体去孪晶阶段(Ⅱ)、去孪晶马氏体弹性变形阶段(Ⅲ)和去孪晶马氏体塑性变形阶段(Ⅳ).另外,利用切线法获得马氏体去孪晶阶段的临界应力σc,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,σc从313 MPa增加至443 MPa,且激光能量密度为20.0 J/mm2的样品表现出2878 MPa的超高压缩断裂强度(σUCS)与34.9%的较大失效应变(δ),比SLM制备的富镍Ni50.1Ti40.9的相应值[40] (1620 MPa和30.2%)还要高出1258 MPa和4.7%.当激光能量密度继续增加时,样品的σUCS与δ 均有所下降(表4),其中NiTi2相含量增加(图3)是导致压缩性能下降的主要原因,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,NiTi2相体积分数为19%,Li等[36]指出,大量NiTi2金属间化合物会使NiTi合金变脆,从而使NiTi合金具有高σUCS和低δ. ...

Achieving biocompatible stiffness in NiTi through additive manufacturing

1

2016

... 图7为不同激光能量密度下NiTi合金的DSC曲线,并将马氏体相转变开始温度(Ms)、马氏体相转变结束温度(Mf)、奥氏体相转变开始温度(As)、Af列于表3.NiTi合金的相转变特征受多个因素共同影响,包括沉淀物的形成、Ni蒸发、O含量等[8,28,37].当激光能量密度较低时(20.0和21.7 J/mm2),升温时出现R相变,这通常与NiTi合金中含有大量Ni4Ti3相有关[34,38],当激光能量密度较高时(23.3和25.0 J/mm2),由于增加了Ni的蒸发,抑制了Ni4Ti3相生成,未出现R相变.在低激光能量密度的R→B2相变中,出现2个吸热峰,这主要是因为试样内存在较大的残余应力[32],而残余应力的存在会阻碍奥氏体相变的进行,故奥氏体转变会发生滞后现象,当奥氏体相变完成后,试样内残余应力得到释放,故降温过程中,马氏体相变只出现了单峰.当激光能量密度较高时(23.3和25.0 J/mm2),R相变消失,加热时只出现一个吸热峰,对应于B19ʹ→B2相变,降温时也只出现一个放热峰,对应于B2→B19ʹ相变.激光能量密度为20.0、21.7、23.3和25.0 J/mm2时Af分别为102.7、107.1、109.3和111.2℃.可见Af随着激光能量密度增加呈上升趋势,这是由于较高激光能量密度会导致Ni蒸发,从而使相变温度升高,值得注意的是LDED工艺制备近原子比NiTi合金的相转变温度比SLM高70℃[4,8,10,34].另外,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,相变焓ΔHM→A从5.27 J/g增加到20.50 J/g. ...

Origin of abnormal multi-stage martensitic transformation behavior in aged Ni-rich Ti-Ni shape memory alloys

1

2004

... 图7为不同激光能量密度下NiTi合金的DSC曲线,并将马氏体相转变开始温度(Ms)、马氏体相转变结束温度(Mf)、奥氏体相转变开始温度(As)、Af列于表3.NiTi合金的相转变特征受多个因素共同影响,包括沉淀物的形成、Ni蒸发、O含量等[8,28,37].当激光能量密度较低时(20.0和21.7 J/mm2),升温时出现R相变,这通常与NiTi合金中含有大量Ni4Ti3相有关[34,38],当激光能量密度较高时(23.3和25.0 J/mm2),由于增加了Ni的蒸发,抑制了Ni4Ti3相生成,未出现R相变.在低激光能量密度的R→B2相变中,出现2个吸热峰,这主要是因为试样内存在较大的残余应力[32],而残余应力的存在会阻碍奥氏体相变的进行,故奥氏体转变会发生滞后现象,当奥氏体相变完成后,试样内残余应力得到释放,故降温过程中,马氏体相变只出现了单峰.当激光能量密度较高时(23.3和25.0 J/mm2),R相变消失,加热时只出现一个吸热峰,对应于B19ʹ→B2相变,降温时也只出现一个放热峰,对应于B2→B19ʹ相变.激光能量密度为20.0、21.7、23.3和25.0 J/mm2时Af分别为102.7、107.1、109.3和111.2℃.可见Af随着激光能量密度增加呈上升趋势,这是由于较高激光能量密度会导致Ni蒸发,从而使相变温度升高,值得注意的是LDED工艺制备近原子比NiTi合金的相转变温度比SLM高70℃[4,8,10,34].另外,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,相变焓ΔHM→A从5.27 J/g增加到20.50 J/g. ...

Microstructure evolution and deformation behavior of as-cast NiTi shape memory alloy under compression

1

2012

... 图8显示了不同激光能量密度下NiTi合金的室温压缩应力-应变曲线.所有曲线均存在2个屈服平台,这是典型的双屈服现象[39],每条曲线均包括4个阶段:马氏体弹性变形阶段(Ⅰ)、马氏体去孪晶阶段(Ⅱ)、去孪晶马氏体弹性变形阶段(Ⅲ)和去孪晶马氏体塑性变形阶段(Ⅳ).另外,利用切线法获得马氏体去孪晶阶段的临界应力σc,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,σc从313 MPa增加至443 MPa,且激光能量密度为20.0 J/mm2的样品表现出2878 MPa的超高压缩断裂强度(σUCS)与34.9%的较大失效应变(δ),比SLM制备的富镍Ni50.1Ti40.9的相应值[40] (1620 MPa和30.2%)还要高出1258 MPa和4.7%.当激光能量密度继续增加时,样品的σUCS与δ 均有所下降(表4),其中NiTi2相含量增加(图3)是导致压缩性能下降的主要原因,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,NiTi2相体积分数为19%,Li等[36]指出,大量NiTi2金属间化合物会使NiTi合金变脆,从而使NiTi合金具有高σUCS和低δ. ...

Mechanical and shape memory properties of porous Ni50.1Ti49.9 alloys manufactured by selective laser melting

3

2017

... 图8显示了不同激光能量密度下NiTi合金的室温压缩应力-应变曲线.所有曲线均存在2个屈服平台,这是典型的双屈服现象[39],每条曲线均包括4个阶段:马氏体弹性变形阶段(Ⅰ)、马氏体去孪晶阶段(Ⅱ)、去孪晶马氏体弹性变形阶段(Ⅲ)和去孪晶马氏体塑性变形阶段(Ⅳ).另外,利用切线法获得马氏体去孪晶阶段的临界应力σc,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,σc从313 MPa增加至443 MPa,且激光能量密度为20.0 J/mm2的样品表现出2878 MPa的超高压缩断裂强度(σUCS)与34.9%的较大失效应变(δ),比SLM制备的富镍Ni50.1Ti40.9的相应值[40] (1620 MPa和30.2%)还要高出1258 MPa和4.7%.当激光能量密度继续增加时,样品的σUCS与δ 均有所下降(表4),其中NiTi2相含量增加(图3)是导致压缩性能下降的主要原因,当激光能量密度从20.0 J/mm2增加至25.0 J/mm2时,NiTi2相体积分数为19%,Li等[36]指出,大量NiTi2金属间化合物会使NiTi合金变脆,从而使NiTi合金具有高σUCS和低δ. ...

... 近等原子比NiTi合金因具有独特的形状记忆效应而被广泛研究[20,40~42].图9显示了制备的NiTi合金在应变控制下的循环压缩曲线和产生的形状记忆效应,并将结果列于表5.当样品在常温下以12%应变压缩循环20 cyc后,发现随着激光能量密度增加,样品的常温εrec从8.383%减小至6.510%,εrec的变化与B2相含量的变化一致,当样品加载时会发生B2→B19ʹ转变,卸载时发生B19ʹ→B2转变[25],故εrec与B2相含量呈正相关,Marattukalam等[7]研究也表明B2相含量越高,可恢复应变越大.随后将样品加热至Af以上时,此时样品中残留的稳定B19ʹ相会受热驱动的影响转变为B2相,同时加热会消除B19ʹ相的塑性应变[42,43],产生形状记忆效应.在加热条件下,随着激光能量密度增加,样品的εSME从3.190%增加至4.052%,εSME的变化与B19ʹ相含量的变化一致,但样品的η从88.2%降低至73.8%,这是由于样品中Ni4Ti3相含量不同导致的.当激光能量密度为20.0 J/mm2时,样品中含有大量Ni4Ti3相,且随着激光能量密度增加,Ni4Ti3相逐渐消失.Kim和Miyazaki[41]研究表明,Ni4Ti3相对位错具有钉扎作用,可改善NiTi合金的形状记忆效应.本工作的形状记忆恢复率结果远高于SLM制备的富镍Ni50.1Ti40.9的相应值(η = 82.6%)[40],另外,加热后不可恢复应变归因于残留的稳定马氏体[44]. ...

... [40],另外,加热后不可恢复应变归因于残留的稳定马氏体[44]. ...

Effect of nano-scaled precipitates on shape memory behavior of Ti-50.9at.%Ni alloy

1

2005

... 近等原子比NiTi合金因具有独特的形状记忆效应而被广泛研究[20,40~42].图9显示了制备的NiTi合金在应变控制下的循环压缩曲线和产生的形状记忆效应,并将结果列于表5.当样品在常温下以12%应变压缩循环20 cyc后,发现随着激光能量密度增加,样品的常温εrec从8.383%减小至6.510%,εrec的变化与B2相含量的变化一致,当样品加载时会发生B2→B19ʹ转变,卸载时发生B19ʹ→B2转变[25],故εrec与B2相含量呈正相关,Marattukalam等[7]研究也表明B2相含量越高,可恢复应变越大.随后将样品加热至Af以上时,此时样品中残留的稳定B19ʹ相会受热驱动的影响转变为B2相,同时加热会消除B19ʹ相的塑性应变[42,43],产生形状记忆效应.在加热条件下,随着激光能量密度增加,样品的εSME从3.190%增加至4.052%,εSME的变化与B19ʹ相含量的变化一致,但样品的η从88.2%降低至73.8%,这是由于样品中Ni4Ti3相含量不同导致的.当激光能量密度为20.0 J/mm2时,样品中含有大量Ni4Ti3相,且随着激光能量密度增加,Ni4Ti3相逐渐消失.Kim和Miyazaki[41]研究表明,Ni4Ti3相对位错具有钉扎作用,可改善NiTi合金的形状记忆效应.本工作的形状记忆恢复率结果远高于SLM制备的富镍Ni50.1Ti40.9的相应值(η = 82.6%)[40],另外,加热后不可恢复应变归因于残留的稳定马氏体[44]. ...

Shape memory characteristics of highly porous Ti-rich TiNi alloys

2

2016

... 近等原子比NiTi合金因具有独特的形状记忆效应而被广泛研究[20,40~42].图9显示了制备的NiTi合金在应变控制下的循环压缩曲线和产生的形状记忆效应,并将结果列于表5.当样品在常温下以12%应变压缩循环20 cyc后,发现随着激光能量密度增加,样品的常温εrec从8.383%减小至6.510%,εrec的变化与B2相含量的变化一致,当样品加载时会发生B2→B19ʹ转变,卸载时发生B19ʹ→B2转变[25],故εrec与B2相含量呈正相关,Marattukalam等[7]研究也表明B2相含量越高,可恢复应变越大.随后将样品加热至Af以上时,此时样品中残留的稳定B19ʹ相会受热驱动的影响转变为B2相,同时加热会消除B19ʹ相的塑性应变[42,43],产生形状记忆效应.在加热条件下,随着激光能量密度增加,样品的εSME从3.190%增加至4.052%,εSME的变化与B19ʹ相含量的变化一致,但样品的η从88.2%降低至73.8%,这是由于样品中Ni4Ti3相含量不同导致的.当激光能量密度为20.0 J/mm2时,样品中含有大量Ni4Ti3相,且随着激光能量密度增加,Ni4Ti3相逐渐消失.Kim和Miyazaki[41]研究表明,Ni4Ti3相对位错具有钉扎作用,可改善NiTi合金的形状记忆效应.本工作的形状记忆恢复率结果远高于SLM制备的富镍Ni50.1Ti40.9的相应值(η = 82.6%)[40],另外,加热后不可恢复应变归因于残留的稳定马氏体[44]. ...

... [42,43],产生形状记忆效应.在加热条件下,随着激光能量密度增加,样品的εSME从3.190%增加至4.052%,εSME的变化与B19ʹ相含量的变化一致,但样品的η从88.2%降低至73.8%,这是由于样品中Ni4Ti3相含量不同导致的.当激光能量密度为20.0 J/mm2时,样品中含有大量Ni4Ti3相,且随着激光能量密度增加,Ni4Ti3相逐渐消失.Kim和Miyazaki[41]研究表明,Ni4Ti3相对位错具有钉扎作用,可改善NiTi合金的形状记忆效应.本工作的形状记忆恢复率结果远高于SLM制备的富镍Ni50.1Ti40.9的相应值(η = 82.6%)[40],另外,加热后不可恢复应变归因于残留的稳定马氏体[44]. ...

A review of shape memory alloy research, applications and opportunities

1

2014

... 近等原子比NiTi合金因具有独特的形状记忆效应而被广泛研究[20,40~42].图9显示了制备的NiTi合金在应变控制下的循环压缩曲线和产生的形状记忆效应,并将结果列于表5.当样品在常温下以12%应变压缩循环20 cyc后,发现随着激光能量密度增加,样品的常温εrec从8.383%减小至6.510%,εrec的变化与B2相含量的变化一致,当样品加载时会发生B2→B19ʹ转变,卸载时发生B19ʹ→B2转变[25],故εrec与B2相含量呈正相关,Marattukalam等[7]研究也表明B2相含量越高,可恢复应变越大.随后将样品加热至Af以上时,此时样品中残留的稳定B19ʹ相会受热驱动的影响转变为B2相,同时加热会消除B19ʹ相的塑性应变[42,43],产生形状记忆效应.在加热条件下,随着激光能量密度增加,样品的εSME从3.190%增加至4.052%,εSME的变化与B19ʹ相含量的变化一致,但样品的η从88.2%降低至73.8%,这是由于样品中Ni4Ti3相含量不同导致的.当激光能量密度为20.0 J/mm2时,样品中含有大量Ni4Ti3相,且随着激光能量密度增加,Ni4Ti3相逐渐消失.Kim和Miyazaki[41]研究表明,Ni4Ti3相对位错具有钉扎作用,可改善NiTi合金的形状记忆效应.本工作的形状记忆恢复率结果远高于SLM制备的富镍Ni50.1Ti40.9的相应值(η = 82.6%)[40],另外,加热后不可恢复应变归因于残留的稳定马氏体[44]. ...

Tensile actuation response of additively manufactured nickel-titanium shape memory alloys

1

2018

... 近等原子比NiTi合金因具有独特的形状记忆效应而被广泛研究[20,40~42].图9显示了制备的NiTi合金在应变控制下的循环压缩曲线和产生的形状记忆效应,并将结果列于表5.当样品在常温下以12%应变压缩循环20 cyc后,发现随着激光能量密度增加,样品的常温εrec从8.383%减小至6.510%,εrec的变化与B2相含量的变化一致,当样品加载时会发生B2→B19ʹ转变,卸载时发生B19ʹ→B2转变[25],故εrec与B2相含量呈正相关,Marattukalam等[7]研究也表明B2相含量越高,可恢复应变越大.随后将样品加热至Af以上时,此时样品中残留的稳定B19ʹ相会受热驱动的影响转变为B2相,同时加热会消除B19ʹ相的塑性应变[42,43],产生形状记忆效应.在加热条件下,随着激光能量密度增加,样品的εSME从3.190%增加至4.052%,εSME的变化与B19ʹ相含量的变化一致,但样品的η从88.2%降低至73.8%,这是由于样品中Ni4Ti3相含量不同导致的.当激光能量密度为20.0 J/mm2时,样品中含有大量Ni4Ti3相,且随着激光能量密度增加,Ni4Ti3相逐渐消失.Kim和Miyazaki[41]研究表明,Ni4Ti3相对位错具有钉扎作用,可改善NiTi合金的形状记忆效应.本工作的形状记忆恢复率结果远高于SLM制备的富镍Ni50.1Ti40.9的相应值(η = 82.6%)[40],另外,加热后不可恢复应变归因于残留的稳定马氏体[44]. ...