近年来,具有较高的比强度和较好的导热性能的轻质铝合金材料引起大量增材制造技术研究人员的关注。其中,Al-Cu-Mg (2024Al)合金因具有密度低、强度高的性能,成为航空航天材料中至关重要的组成[7]。但因其具有高的热裂敏感性和较高的激光反射率而难以采用铸造或者增材制造的方式制造构件[8~10]。因此有必要对其进行材料的成分设计而使其适应L-PBF的工艺条件,获得具有较高的成形致密度和良好力学性能的高强铝合金构件。2017年,Martin等[11]提出可以借鉴传统铸造过程中添加孕育剂的方式,向非铸造类型铝合金中添加晶粒细化剂,提高其打印成形性,并在7xxx铝合金中得到有益改善。2020年,Tan等[12]通过球磨方式向2024Al合金中添加Ti细化剂,获得具有细小等轴晶组织的0.7%Ti/2024Al (质量分数)合金构件,但是其构件力学性能尚无法与传统2024Al合金锻件相比拟,且通过球磨等外加方式引入颗粒存在细化效率无法保证、形核剂颗粒与Al基体界面结合差等问题[13]。前期的工作[14]已经表明,通过L-PBF过程工艺参数优化可以获得无裂纹缺陷的2024Al合金构件,L-PBF成形合金微观组织以沿打印方向生长的粗大柱状晶为主,但成形参数窗口较窄,热裂严重,成形难度较大。针对2024Al合金打印成形性较差的问题,通过原位自生方式引入的TiB2纳米颗粒可以有效细化L-PBF成形构件的微观组织[15],显著降低其裂纹敏感性,明显拓宽合金的最佳成形工艺窗口,有效增强2024Al合金的可打印性能,并具有大规模生产的潜力。

近年来,后热处理对于增材制造Al-Si合金构件的影响开始被广泛关注[16],Xiao等[17]的研究结果表明,L-PBF成形的TiB2/Al7SiMg材料经过直接时效热处理之后,形成大量Al2Cu、Mg2Si等析出相,其屈服强度相比于L-PBF成形提高35%。对于Al-Si材料的后热处理研究[18]表明,合适的后热处理设计可以有效消除构件中增材制造过程产生的残余应力,并提高构件的力学性能。2024Al合金作为一种可热处理强化的铝合金材料,其高比强度和高损伤容限主要来源于Cu、Mg元素合金化以及合理的后热处理工艺设计[19,20]。因此研究其增材制造构件的热处理后微观组织及力学性能,对于此类材料之后的应用具有十分重要的作用。本工作进行L-PBF成形2024Al合金及2024Al-2%TiB2合金的后续固溶和T6热处理(固溶+人工时效),研究原位自生TiB2颗粒对热处理态2种合金微观组织和室温拉伸性能的影响,为增材制造铝合金的后热处理工艺研究提供理论基础。

1 实验方法

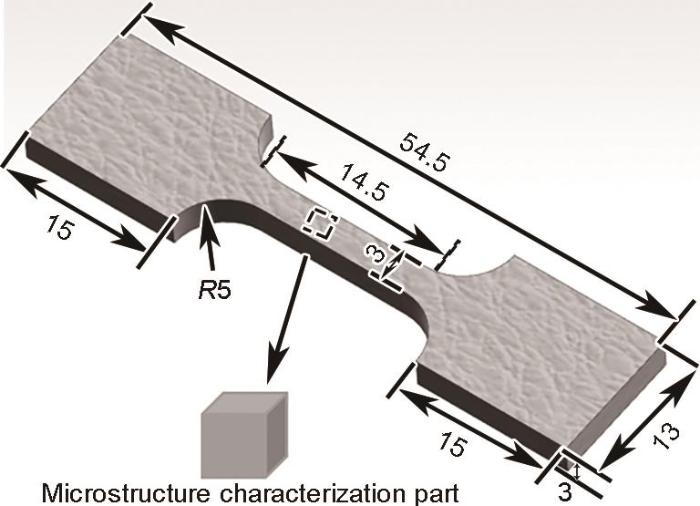

采用原位自生混合盐法制备含TiB2颗粒2024Al合金铸锭,后经气雾化方法制备并筛选获得尺寸介于15~53 μm之间的2024Al (Al-4.2Cu-1.6Mg-0.6Mn,质量分数,%)及2024Al-2%TiB2 (TiB2体积分数为1.3%)合金粉末,具体制备方法见文献[21]。L-PBF成形过程采用ProX 200型3D打印机,成形基板采用同成分的退火轧制态2024Al合金,成形前对基板进行砂纸打磨,去除表面氧化层,并用无水乙醇进行清洗,保证基板表面洁净平整。成形过程中腔体内O2含量不超过2 × 10-4。基于前期研究结果[14],打印过程采用的最优工艺参数为:打印功率250 W,激光扫描速率83 mm/s,扫描间距0.11 mm,铺粉层厚30 μm,扫描策略采用层间旋转90°条形扫描方式。采用L-PBF直接成形拉伸试样,成形试样尺寸为55 mm × 14 mm × 10 mm,经磨抛处理后所得拉伸试样形状及尺寸如图1所示。

图1

图1

拉伸试样及微观组织观察试样取样示意图

Fig.1

Schematic of tensile test specimen and the site of the microstructure characterization part (unit: mm)

T6热处理采用的固溶处理在N60/85HA型马弗炉中进行,510℃固溶处理1 h后样品取出并用室温水冷却。时效处理在管式电阻炉中进行,190℃处理至峰时效状态,于空气中冷却。采用CARAT 930型Vickers硬度计进行材料的硬度测试,测试载荷10 kg,测试时间15 s,每个样品测试10个点之后取硬度平均值。拉伸实验采用Zwick/Roell常温拉伸设备,初始应变速率1 × 10-4 s-1,拉伸样品尺寸根据ASTM E8标准制备,同等状态试样测试3个取平均值。

对打印成形及热处理态试样进行机械研磨和抛光,经Keller试剂(1.5%HCl + 2.5%HNO3 + 1%HF + 95%去离子水,体积分数)腐蚀后,进行后续微观组织表征及形貌观察,微观组织表征试样取样位置如图1所示。采用D8 ADVANCE Da Vinci 型X射线衍射仪(XRD)进行样品物相组成分析,测试角度20°~90°,扫描速率2°/min。采用Image Alm型光学显微镜(OM)进行试样截面金相组织观察,采用MAIA3扫描电子显微镜(SEM)进行微观组织表征,采用背散射电子(BSE)信号对材料表面元素组成进行分析,采用SEM搭载的布鲁克探测器(BRUCKER e-FlashHR)进行电子背散射衍射(EBSD) 实验(实验电压20 kV,测试工作距离17 mm,测试步长0.18~1.80 μm)。EBSD测试之前样品经电解抛光处理表面,消除表面残余应力,电解抛光液组成为30%HNO3 + 70%CH3OH (体积分数),电解抛光电压15 V,抛光时长20 s。采用SDT-Q600差示扫描量热仪(DSC)进行热分析。DSC测试试样质量约15 mg,加热速率10℃/min,测试温度范围25~650℃,测试过程中采用Ar气保护。采用三维计算机断层(CT)扫描技术对L-PBF成形合金内部缺陷进行表征,实验在上海同步辐射光源BL13W1线站进行,数据后处理采用Dragonfly软件进行分析[22]。采用Archimedes排水法(Archimedes principle)测量L-PBF成形铝合金块体试样的致密度,同一样品测试3次后取平均值

2 实验结果

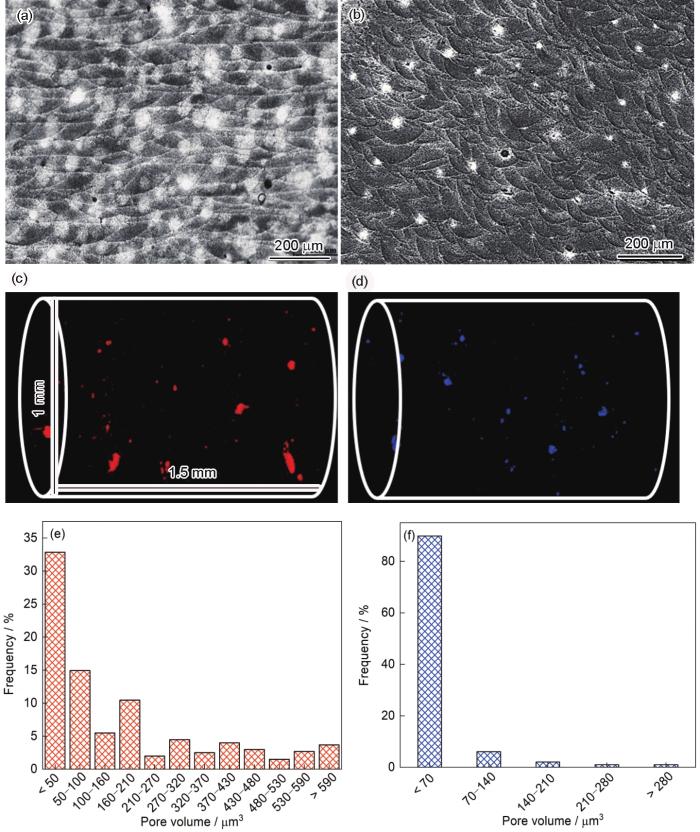

图2a和b为L-PBF成形2024Al合金及2024Al-2%TiB2合金截面OM像。可以看出,在优化的工艺参数下,2种合金表现出相似的宏观结构,显示出沿打印方向的“鱼鳞”状形貌,这种形貌是由大小不一的熔池组成的。同时相邻的熔池之间存在部分重叠,均未出现宏观上的裂纹缺陷。采用Archimedes排水法测得L-PBF成形2024Al合金及2024Al-2%TiB2合金试样的致密度分别约为98.5%和99.1%。图2c和d为2024Al合金和2024Al-2%TiB2合金的三维CT测试结果。可见,2种试样中均有孔洞缺陷而未出现裂纹等成形缺陷。图2e和f为基于三维CT获得的试样内部缺陷尺寸统计图。从图中可以看出,L-PBF成形2024Al合金中的缺陷尺寸分布离散,且存在相当一部分体积在590 μm3以上的大尺寸孔洞,而2024Al-2%TiB2合金中主要缺陷体积在280 μm3以下,超过此体积的缺陷基本消除,且近90%的缺陷体积在70 μm3以下,TiB2颗粒的引入有效减少了大尺寸孔洞的含量,2024Al-2%TiB2合金的可打印性相比2024Al合金大幅提高。

图2

图2

激光粉末床熔化(L-PBF)成形2024Al合金及2024Al-2%TiB2合金的截面OM像、三维CT测试结果及内部缺陷尺寸统计分布图

Fig.2

Cross-sectional OM images (a, b), 3D computed tomography (CT) results (c, d), and statistic distributions (e, f) of the defect size of 2024Al (a, c, e) and 2024Al-2%TiB2 (b, d, f) alloys printed by laser powder bed fusion (L-PBF)

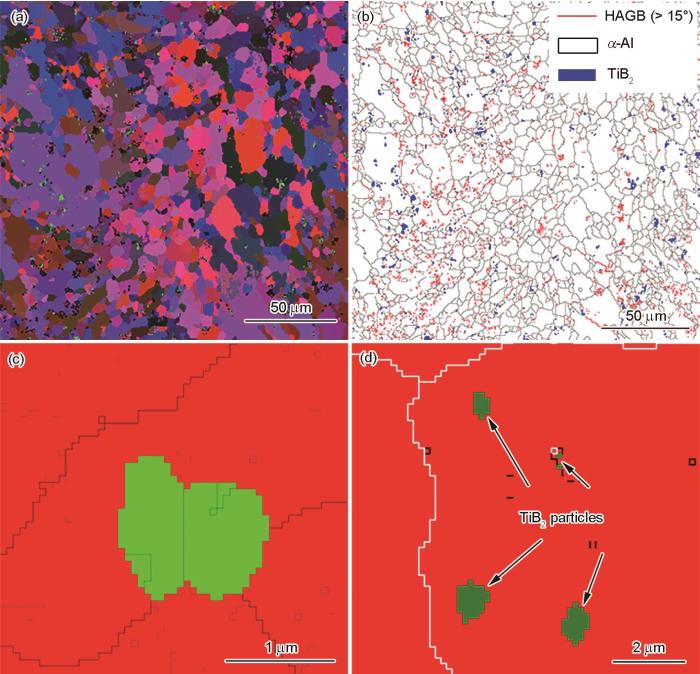

图3a为L-PBF成形2024Al-2%TiB2合金成形组织的晶粒分布图。由图可知,不同于2024Al合金完全的粗大柱状晶组织[14],L-PBF成形2024Al-2%TiB2合金晶粒组织中存在大量等轴晶,等轴晶界以大角度晶界为主(> 15°),平均晶粒尺寸约5.8 μm。图3b~d中TiB2颗粒均匀分布在α-Al晶粒内部和晶界处,未出现大尺寸颗粒团聚现象,TiB2颗粒与基体结合良好。L-PBF过程中,金属粉末在快速移动的高能量激光束下快速熔化后冷却,熔体凝固具有较大的温度梯度和高的冷却速率(105~107℃/s)[23],促使晶粒快速形核,获得相较于铸造等慢冷速构件更细小的晶粒组织。另外,TiB2颗粒为合金凝固提供了异质形核点,有利于促进非均匀形核,细化2024Al合金晶粒组织。

图3

图3

L-PBF成形2024Al-2%TiB2合金的EBSD 结果

Fig.3

EBSD results of 2024Al-2%TiB2 alloy printed by L-PBF

(a) grain distribution diagram

(b) grain boundary map and TiB2 distribution map (HAGB—high angle grain boundary)

(c) TiB2 particle located in the grain boundary

(d) TiB2 particle inside the grain

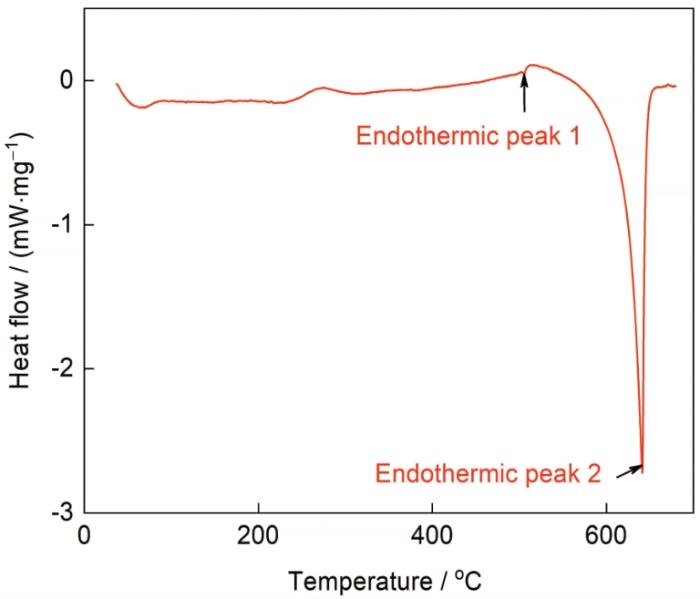

图4为L-PBF成形2024Al合金的DSC曲线。由图可见,曲线在505和641℃各出现1个吸热峰,随着温度的升高,Al基体对第二相的溶解度增加。第1个吸热峰代表合金中第二相的溶解,第2个吸热峰为α-Al基体开始熔化温度,2个吸热峰之间的距离代表2024Al合金的凝固温度区间,合金元素的加入使合金的凝固温度区间远大于纯Al材料,从而大幅提高2024Al合金的热裂敏感性,降低其可打印性能。因此,为防止出现过烧,本工作采用的固溶处理温度为510℃。

图4

图5

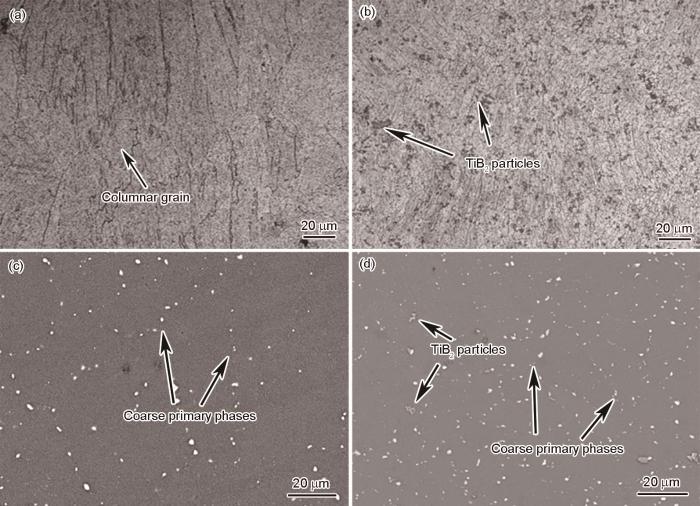

图5

固溶处理态2024Al合金和2024Al-2%TiB2合金OM及SEM-BSE像

Fig.5

OM (a, b) and SEM-BSE (c, d) images of as-ST 2024Al (a, c) and as-ST 2024Al-2%TiB2 (b, d) alloys (ST—solution treatment)

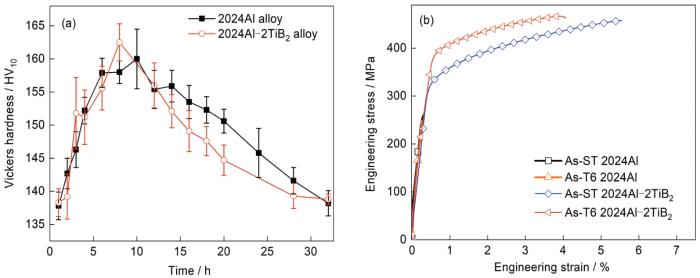

图6a为L-PBF成形的2种合金经固溶处理之后继续190℃的时效硬化行为。可见,随着时效时间的延长,2种合金的硬度先增大后减小,时效硬化过程可分为3个阶段:欠时效阶段、峰时效阶段和过时效阶段。2种材料呈现出快速的时效硬化响应,2024Al-2%TiB2合金在时效处理8 h后达到其峰时效状态,峰时效硬度为(162.5 ± 2.8) HV,2024Al合金在时效处理10 h后达到其峰时效状态,峰时效硬度为(158.0 ± 3.8) HV。之后2种试样进入过时效阶段,硬度随时效时间延长下降。后续拉伸实验试样均采用2种合金的峰时效态样品。

图6

图6

L-PBF成形2024Al合金和2024Al-2%TiB2合金经固溶处理和T6热处理的硬度变化和拉伸曲线

Fig.6

Vickers hardness of 2024Al and 2024Al-2%TiB2 alloys aged at 190oC for different time (a) and tensile stress-strain curves (b) (T6—solution treatment plus aging treatment)

图6b为L-PBF成形的2种合金固溶处理和T6处理之后的室温拉伸曲线。可见,2种合金在断裂前均未出现明显的应力降低,表明其在拉伸过程中未发生颈缩,试样于均匀拉伸时发生断裂。表1给出了2种合金热处理态的屈服强度、抗拉强度和均匀伸长率。对比作者前期研究结果[14],L-PBF成形2024Al-2%TiB2合金在经510℃固溶处理1 h后,相较于L-PBF成形态2024Al-2%TiB2合金抗拉强度提升39.9%,相较于固溶处理后2024Al合金抗拉强度提升90.6%。在T6处理之后,L-PBF成形的2024Al-2%TiB2合金相比于2024Al合金拉伸性能得到大幅度提高。经T6热处理之后,L-PBF成形2024Al-2%TiB2合金抗拉强度比同等状态2024Al合金提高75.4%,其屈服强度相比固溶处理后2024Al-2%TiB2合金也提高了17.4%。同时,T6热处理之后试样的屈服强度和抗拉强度可与锻态2024-T6合金板材相当[24,25]。

表1 不同热处理后L-PBF成形2024Al合金和2024Al-2%TiB2合金的拉伸性能

Table 1

| Condition | Sample | UTS / MPa | YS / MPa | EL / % | Ref. |

|---|---|---|---|---|---|

| L-PBF | 2024Al | 180 ± 3.2 | 0.3 ± 0.18 | [14] | |

| 2024Al-2%TiB2 | 327 ± 6.02 | 225.6 ± 4.96 | 4.15 ± 0.2 | [14] | |

| ST | 2024Al | 240.1 ± 2.6 | 236.8 ± 3.1 | 0.3 ± 0.1 | This work |

| 2024Al-2%TiB2 | 457.6 ± 3.6 | 339.5 ± 1.0 | 5.1 ± 0.3 | This work | |

| T6 | 2024Al | 261.3 ± 4.3 | 252.6 ± 2.5 | 0.3 ± 0.1 | This work |

| 2024Al | ~427 | ~345 | ~5 | [24,25] | |

| 2024Al-2%TiB2 | 458.2 ± 6.5 | 398.4 ± 2.7 | 3.4 ± 0.4 | This work | |

| Annealed | 2024Al | ~220 | ~95 | ~12 | [24,25] |

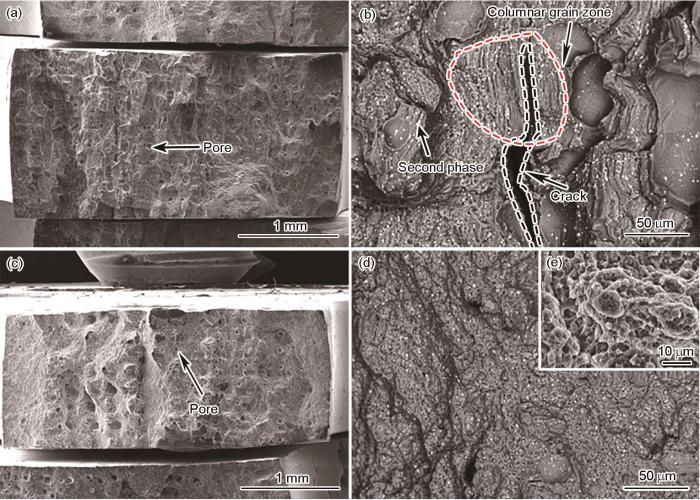

图7

图7

T6热处理态2024Al合金和2024Al-2%TiB2合金的拉伸断口形貌

Fig.7

Macrostructures (a, c) and microstructures (b, d) of fracture of as-T6 2024Al (a, b) and as-T6 2024Al-2%TiB2 (c, d) alloys (Inset in Fig.7d shows the corresponding high magnified image)

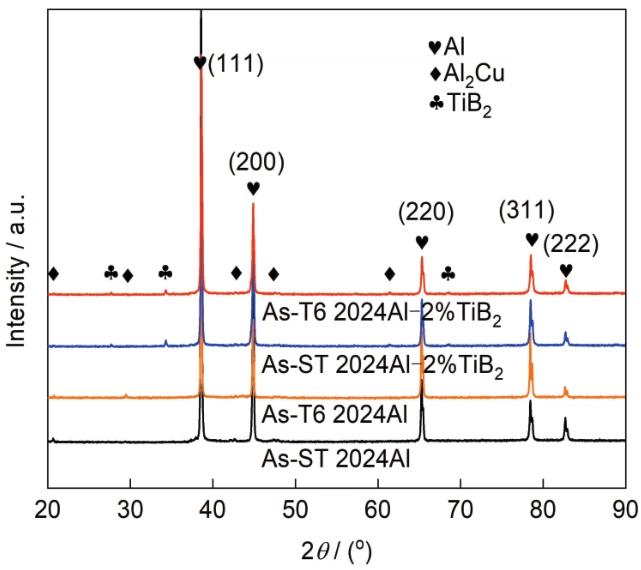

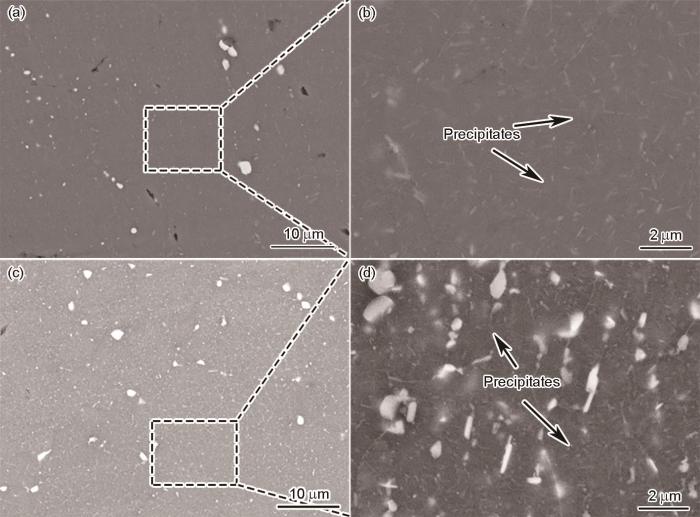

图8和9分别为L-PBF成形的2种合金在经过热处理之后的XRD谱和T6处理后的微观组织SEM-BSE像。由图8可以看出,L-PBF成形的2种合金中α-Al相的主要结晶学取向衍射峰有(111)、(200)、(220)和(311),而2024Al-2%TiB2合金α-Al的(111)衍射峰值比例相较于2024Al合金下降,不同晶面的衍射峰值更加均匀,表明材料的织构取向性减弱。L-PBF成形的2种合金在经固溶处理之后,Al2Cu相的峰几乎消失;在经T6处理之后,Al2Cu相衍射峰重新出现,2024Al-2%TiB2合金经固溶处理和T6处理后TiB2颗粒衍射峰稳定存在。除此之外,2种合金中均没有观察到其他相的存在,这主要是由于析出相的含量过低(≤ 1%,质量分数)而不足以产生XRD衍射峰[28]。

图8

图8

热处理态2024Al合金和2024Al-2%TiB2合金的XRD谱

Fig.8

XRD spectra of the 2024Al and 2024Al-2%TiB2 alloy samples after solution treatment and T6 treatment

图9

图9

T6热处理态2024Al合金和2024Al-2%TiB2合金的SEM-BSE像

Fig.9

SEM-BSE images of as-T6 2024Al (a, b) and as-T6 2024Al-2%TiB2 (c, d) alloys

3 分析讨论

式中,ρ为材料的电阻率,λ为激光波长。TiB2颗粒的电阻率为144 nΩ·m,约为铝合金基体的3倍,因此2024Al-2%TiB2合金的激光吸收率高于2024Al合金,所以TiB2颗粒的引入可以提高体系内有效能量输入,从而提高2024Al合金的成形性。

T6热处理后2024Al-2%TiB2合金的屈服强度(σYS)可用下式计算:

式中,σo为L-PBF成形2024Al合金的屈服强度(约180 MPa),

细小晶粒带来的

式中,k为系数(50 MPa·μm1/2)[28],da为2024Al-2%TiB2合金平均晶粒尺寸(约5.8 μm),db为2024Al合金平均晶粒尺寸(约38.8 μm)。计算得

增材制造成形的2024Al-2%TiB2合金由于颗粒的存在以及L-PBF过程高的冷却速率,可以促使大量位错的产生,拉伸过程中发生位错的塞积,提高材料强度,位错强化可采用下式计算[35]:

由热处理后纳米析出相带来的强化贡献可通过下式计算[35]:

式中,fv为纳米析出相的体积分数,d为析出相尺寸。

由于TiB2陶瓷颗粒硬度较高,位错运动时无法采取切过机制通过TiB2颗粒,而只能采取Orowan绕过机制通过,TiB2颗粒引入带来的ΔσOrowan可通过下式计算[36]:

式中,

通过计算可得

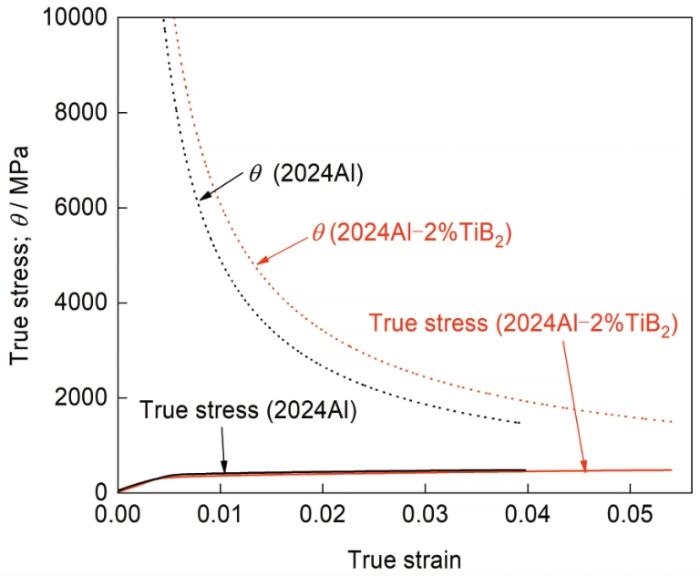

图10

图10

热处理态2024Al合金及2024Al-2%TiB2合金应变硬化速率和真应力-真应变曲线

Fig.10

True tensile stress-strain curves and work hardening rate (θ) of as-T6 2024Al and as-T6 2024Al-2%TiB2 alloys

4 结论

(1) 随着TiB2颗粒的添加,L-PBF成形材料内部未出现明显的裂纹缺陷,2024Al合金中缺陷尺寸分布离散且存在相当一部分体积在590 μm3以上的大尺寸孔洞,而L-PBF成形2024Al-2%TiB2合金中大尺寸缺陷基本消除,且近90%的缺陷体积在70 μm3以下,成形试样致密度得到大幅提高,最优工艺参数下,L-PBF成形2024Al合金相对密度约98.5%,2024Al-2%TiB2相对密度约99.1%。

(2) L-PBF成形2024Al-2%TiB2合金的主要微观组织为尺寸细小的等轴晶,平均晶粒尺寸约5.8 μm,TiB2颗粒均匀分散在等轴晶组织晶界及晶粒内部,有效促进异质形核细化晶粒。

(3) 热处理对2024Al-2%TiB2增材制造合金室温拉伸性能具有明显的提升。经固溶处理之后,L-PBF成形2024Al-2%TiB2合金的屈服强度达到(339.5 ± 1.0) MPa,抗拉强度(457.6 ± 3.6) MPa,相较于L-PBF成形态2024Al-2%TiB2合金抗拉强度提升39.9%,相较于固溶处理后2024Al合金抗拉强度提升90.6%。

(4) L-PBF成形的2024Al-2%TiB2合金在T6热处理后试样的抗拉强度、屈服强度和伸长率分别为(458.2 ± 6.5) MPa、(398.4 ± 2.7) MPa和(3.4 ± 0.4)%,强度与T6处理态锻造2024Al合金板材相当。

参考文献

3D printing of aluminum alloys using laser powder deposition: A review

[J].

Additive manufacturing and foundry innovation

[J].

Overview of additive manufacturing process

[A].

Research and development in materials and processes of superalloy fabricated by laser additive manufacturing

[J].The research and development progress of laser additive manufacturing technology in superalloys are summarized in this paper. The technical characteristics and application of additive manufacturing in superalloys, formation mechanism, and the types of microstructure and metallurgical defects are introduced in detail. Moreover, the defect control methods of additive manufacturing of superalloys are summarized from the aspects of laser parameters and composition design, and the direction of laser process parameter optimization and composition optimization is clarified. Finally, the future development trend and research direction of laser additive manufacturing in superalloys are summarized and prospected from the aspects of process optimization and material design.

激光增材制造高温合金材料与工艺研究进展

[J].概述了激光增材制造技术在高温合金中的进展。介绍了增材制造高温合金的技术特点和应用、微观组织及冶金缺陷的形成机制与种类,并从激光参数以及成分设计2个方面综述了增材制造高温合金的缺陷控制方法,明确了激光工艺参数优化与成分优化的方向。最后,从工艺和材料2个方面对激光增材制造在高温合金中的未来发展趋势与研究方向进行了展望。

Additive manufacturing of metallic components—Process, structure and properties

[J].

Formability and mechanical properties of high-strength Al-(Mn, Mg)-(Sc, Zr) alloy produced by selective laser melting

[J].

选区激光熔化高强Al-(Mn, Mg)-(Sc, Zr)合金成形性及力学性能

[J].基于选区激光熔化(SLM)技术熔体急冷的特点,通过同时增加(Mn + Mg)和(Sc + Zr)合金化元素的含量,设计了SLM专用Al-(Mn, Mg)-(Sc, Zr)合金,系统研究了时效温度对合金组织和力学性能影响。结果表明,合金表现出良好的SLM成形性,不同激光扫描速率下制备样品的致密度均超过99.0%。样品具有典型的熔池状显微结构,熔池边界为等轴晶,熔池内部包含少量的柱状晶,晶粒的平均尺寸约为4 μm。经低温(≤ 350℃)时效处理后,由于Al<sub>3</sub>Sc纳米颗粒的大量析出,使得样品的力学性能大幅提升。样品的最大Vickers硬度为(218 ± 5) HV,最大压缩屈服强度和抗压强度分别达到(653 ± 3)和(752 ± 7) MPa,所有样品的压缩延伸率均超过60%。合金的强度超过现有报道的大多数SLM成形铝合金及经T6处理的AA7075铝合金。多种强化机制共同作用使得SLM成形Al-(Mn, Mg)-(Sc, Zr)合金具有高强度。

Laser solid forming additive manufacturing TiB2 reinforced 2024Al composite: Microstructure and mechanical properties

[J].

Stable cladding of high reflectivity pure copper on the aluminum alloy substrate by an infrared-blue hybrid laser

[J].

Two-dimensional simulation of grain structure growth within selective laser melted AA-2024

[J].

Microcracking and mechanical properties in laser-arc hybrid welding of wrought Al-6Cu aluminum alloy

[J].

3D printing of high-strength aluminium alloys

[J].

Inoculation treatment of an additively manufactured 2024 aluminium alloy with titanium nanoparticles

[J].

Investigation of interfacial reaction products and stress distribution in selective laser melted Al12Si/SiC composite using confocal Raman microscopy

[J].

Roadmap to improve the printability of a non-castable alloy for additive manufacturing

[J].

The role of in-situ nano-TiB2 particles in improving the printability of noncastable 2024Al alloy

[J].

Heat treatment of aluminium alloys produced by laser powder bed fusion: A review

[J].

Simultaneously minimizing residual stress and enhancing strength of selective laser melted nano-TiB2 decorated Al alloy via post-uphill quenching and ageing

[J].

Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism

[J].

Effect of post-heat treatment on microstructure and mechanical properties of laser welded Al-Cu-Mg alloy

[J].

Effect of post weld artificial aging and water cooling on microstructure and mechanical properties of friction stir welded 2198-T8 Al-Li joints

[J].Friction stir welding (FSW) under both air cooling and water cooling conditions with welding parameters of 800-1200 rpm rotation rates and 50-200 mm/min welding speeds was carried out on 2198-T8 Al-Li alloys, and post weld artificial aging was performed on the air cooled joints. No welding defects other than lazy S were observed in the nugget zone (NZ) for all joints. Under air cooling condition, the lowest hardness zone (LHZ) occurred in the heat affected zone (HAZ). FSW resulted in gradual dissolution of original T1, θ′ and δ′/β′ from the base material (BM) to the thermo-mechanically affected zone (TMAZ), and complete dissolution of all precipitates in the NZ with δ′/β′ and Guinier-Preston zones precipitating during cooling. The air cooled joints exhibited no noticeable changes in intrinsic tensile strength with a joint strength reaching 81.3% of the BM, but varied elongation with welding parameters, which was closely related to failure in the NZ and fracture along lazy S. Post weld artificial aging led to the largest hardness recovery in the TMAZ but smaller hardness recovery in the initial LHZ and the NZ. Different aging kinetics across the joint was determined by volume fraction of both original precipitate dissolution during welding and coarse particles formed during aging, and by dislocation density inherited from welding. Post weld artificial aging greatly enhanced the joint strength with the ultimate tensile strength reaching 87.3% of the BM. As compared to air cooling condition, water cooling hardly affected the NZ hardness and did not improve the joint strength, and the reason was discussed in light of precipitates, hardness changes and fracture behavior.

Achieving excellent strength of the LPBF additively manufactured Al-Cu-Mg composite via in-situ mixing TiB2 and solution treatment

[J].

Design of heterogeneous structured Al alloys with wide processing window for laser-powder bed fusion additive manufacturing

[J].

Melt pool temperature and cooling rates in laser powder bed fusion

[J].

Theoretical analysis for condensation heat transfer of binary refrigerant mixtures with annular flow in horizontal mini-tubes

[J].

A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties

[J].

Microstructure and mechanical properties of TiN/Inconel 718 composites fabricated by selective laser melting

[J].The Inconel 718 alloy has become a remarkable candidate material for aerospace jet engines, turbine blades, and some other elevated temperature components owing to its superior tensile strength, anticorrosion and thermal performance. Moreover, TiN ceramic particles with high hardness and chemical stability have been realized to significantly improve the mechanical properties of the alloy matrix at a low content. Accordingly, in this work, the Inconel 718 (IN718) alloy and TiN/IN718 composite were fabricated by the optimized selective laser melting (SLM) process. Further, the microstructures and mechanical properties of the IN718 alloy and TiN/IN718 composite under heat treatments were investigated, respectively. The results show that the TiN particles were highly combined with the matrix, and a transition layer with 0.3 μm was formed in the SLM-fabricated TiN/IN718 specimens. Additionally, the microhardness and tensile strength were significantly improved compared with IN718 alloy (39 HV0.2, 74 MPa, respectively). After the double aging and solution aging (SA) treatments, the number of crack initiation sources was increased owing to the precipitation of the δ phase, which deteriorated the tensile strength of the TiN/IN718 composite. After the homogenization + SA (HSA) treatment, the composite was completely recrystallized, and an appropriate amount of needle- and plate-like δ phases precipitated at the grain boundaries. Hence, the TiN/IN718 composite after the HSA treatment exhibited optimally comprehensive mechanical properties.

选区激光熔化成形TiN/Inconel 718复合材料的组织和力学性能

[J].采用选区激光熔化(selective laser melting,SLM)工艺制备了TiN/Inconel 718 (IN718)复合材料,利用OM、SEM、EDS、EBSD以及XRD等手段研究了SLM成形态和不同热处理条件下TiN/IN718复合材料的微观组织和力学性能。结果表明:SLM成形态TiN/IN718复合材料中TiN颗粒与基体之间紧密结合,并形成了约为0.3 μm厚的过渡层,与IN718合金相比,TiN/IN718复合材料的显微硬度和拉伸强度均有明显改善(分别提高39 HV<sub>0.2</sub>和74 MPa)。双时效(DA)和固溶时效(SA)热处理的TiN/IN718复合材料中,强化相的析出和TiN颗粒的存在导致裂纹萌生源增多,从而造成强度没有得到明显提升。均匀化 + 固溶时效(HSA)热处理后材料发生了完全再结晶,晶粒内部析出了超细球状的γ'/γ''强化相,晶界处和晶粒内部TiN颗粒周围的针状δ相含量增加。因此,经过HSA处理后材料的抗拉强度有显著提升,达到1430 MPa (提高了410 MPa)。

Selective laser melting of nano-TiB2 decorated AlSi10Mg alloy with high fracture strength and ductility

[J].

Microstructural evolution and mechanical performance of in-situ TiB2/AlSi10Mg composite manufactured by selective laser melting

[J].

A heat treatable TiB2/Al-3.5Cu-1.5Mg-1Si composite fabricated by selective laser melting: Microstructure, heat treatment and mechanical properties

[J].

Plasmonic films can easily be better: Rules and recipes

[J].High-quality materials are critical for advances in plasmonics, especially as researchers now investigate quantum effects at the limit of single surface plasmons or exploit ultraviolet- or CMOS-compatible metals such as aluminum or copper. Unfortunately, due to inexperience with deposition methods, many plasmonics researchers deposit metals under the wrong conditions, severely limiting performance unnecessarily. This is then compounded as others follow their published procedures. In this perspective, we describe simple rules collected from the surface-science literature that allow high-quality plasmonic films of aluminum, copper, gold, and silver to be easily deposited with commonly available equipment (a thermal evaporator). Recipes are also provided so that films with optimal optical properties can be routinely obtained.

Comparison of laser welding between TiB2/ZL101 composites and ZL101

[J].

TiB2/ZL101复合材料与ZL101合金激光焊对比研究

[J].

Atomic-scale investigation of the interface precipitation in a TiB2 nanoparticles reinforced Al-Zn-Mg-Cu matrix composite

[J].

Strengthening of A2024 alloy by high-pressure torsion and subsequent aging

[J].

Selective laser melting of a high strength Al-Mn-Sc alloy: Alloy design and strengthening mechanisms

[J].

Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy

[J].

Microstructure evolution and mechanical properties of TiB/Ti6Al4V gradient-material lattice structure fabricated by laser powder bed fusion

[J].

Strengthening mechanisms in direct metal laser sintered AlSi10Mg: Comparison between virgin and recycled powders

[J].

Mémoire sur l'emploi du fer et de l'acier dans les constructions

[J].

Enhancing strength and ductility of AlSi10Mg fabricated by selective laser melting by TiB2 nanoparticles

[J].