钛合金具有比强度高、耐腐蚀性好、耐热性强、力学性能优异等特点,是当代飞机结构件和发动机主要结构材料之一[1]。Ti6Al4V合金作为α + β型双相钛合金,常用于航空发动机中冷端压气机风扇叶片、第1~2级整体叶盘等结构件。但是,由于其熔点高(约1668℃),熔融态化学活性大,存在滑移系较少的hcp结构,导致其热加工难度大。同时其强度高、导热系数差、与工具材料容易产生化学反应以及形成“破坏性剪切”切屑,因而其机加工难度也较大;另外,由于Ti6Al4V合金弹性模量小,成形加工时回弹大,其冷成形也相当困难[2,3]。因此,随着航空航天技术的发展,关键构件结构越来越复杂,对力学性能要求越来越高,重量却要求越来越轻,通过传统制造工艺很难满足Ti6Al4V合金复杂精密构件的快速制造要求。选区激光熔化(selective laser melting,SLM)技术由于具有独特的优势,逐渐用于难加工的钛合金复杂精密构件的一体化制造,并能够满足航空航天领域对关键构件综合力学性能的苛刻要求[4]。

近年来,虽然在SLM成形Ti6Al4V合金工艺、微观组织及力学性能方面取得了突破性进展,但在形、性协同控制方面仍然面临一些难题,其中亟待解决的是残余拉应力导致关键构件变形开裂的“控形”问题和冶金缺陷造成整体力学性能较差的“控性”问题。第一,在SLM过程中由于超短时间内超高热量熔化/凝固(冷却)导致的温度梯度机制和熔化表面冷却相、多层堆积高幅拉应力不断累积都不可避免地在成形件内部产生残余拉应力和微裂纹[5],SLM成形过程中产生的残余拉应力及分布是导致成形件力学性能降低的主要原因;第二,冶金缺陷是导致成形件“控性”难的主要因素。SLM在循环往复的“逐点熔化-逐线搭接-逐层堆积”过程中,微熔池处于亚平衡状态,极易在微熔池内部、道与道之间、层与层之间等局部区域产生未熔合、卷入性和析出性的气孔、夹杂等冶金缺陷[6]。这些缺陷很难通过优化工艺完全消除,它们会成为疲劳裂纹源区,大幅降低增材制造成形件的力学性能[7],使成形件难以在长期服役的承力部件上使用,限制了其应用范围。

采用机械喷丸[8]、表面机械研磨[9]、滚压[10]、超声冲击[11]、激光冲击强化(laser shock peening,LSP)[12]等塑性变形方法能使金属表层晶粒细化并诱导一定深度的残余压应力层,是可同时消除内应力和冶金缺陷的有效途径,广泛应用于金属焊接、熔覆、选区熔化与成形等金属构件热效应制造的后处理。其中,LSP技术作为一种先进的表面处理技术,高能激光束作用于金属材料表面,形成高压(吉帕~103吉帕量级)、高能(吉瓦量级)、超快(几十纳秒)和超高应变率(> 106 s-1)的冲击波使金属材料表层产生剧烈塑性变形,从而诱导产生较深的残余压应力层和晶粒细化层,使得金属构件的力学性能得到显著的提升[13,14]。目前,已经有部分学者利用LSP技术来调控成形件中的残余拉应力、改善成形件内部的不均匀微观组织以及闭合成形件内部的微小气孔、裂纹等冶金缺陷,从而显著提高成形件的力学性能。2012年,Dorman等[15]首次开展了LSP对2024-T351铝合金熔覆层残余应力和疲劳寿命影响的研究,结果发现经LSP处理后的试样疲劳寿命提高了18%~47%。2016年,Luo等[16]利用LSP技术对激光熔覆316不锈钢熔覆层进行改性,结果表明,大面积激光冲击将近表层的残余拉应力转化为压应力,且近表层的针状晶被细化为胞状晶,从而有效提高了熔覆层近表层的显微硬度。此后,Kalentics等[17]利用LSP来调控SLM成形件(PH1钢和316L不锈钢)的残余应力,研究了LSP工艺参数(包括激光能量、搭接率、光斑尺寸、有无吸收层)对成形件表层残余应力分布的影响,结果表明,2种材料表层的初始残余拉应力都转变为有益的残余压应力,并且残余压应力的大小和深度与LSP参数有关。之后,Luo等[18]利用LSP技术作为后处理方式调控激光增材制造TC17钛合金,使残余拉应力转化为残余压应力,疲劳强度提高到了451 MPa,提升了23.6%。利用LSP技术对电弧增材制造2319铝合金[19]和Ti17钛合金[20]、激光增材制造Ti6Al4V合金[21]和TA15钛合金[22]成形件表面进行改性,结果发现,LSP诱导产生一定深度的残余压应力层和晶粒细化层,从而使成形件拉伸性能和抗高温氧化性能得到显著提升。Lan等[23]和Jin等[24]采用LSP对电子束熔融成形Ti6Al4V合金的微观组织、应力状态以及疲劳行为进行调控,结果表明,LSP诱导的残余压应力、晶粒细化和梯度分布使Ti6Al4V合金拉伸强度和延伸率都得到了提升,此外,疲劳强度明显增加,达到700 MPa。可见,LSP能够显著细化粗晶,诱导较深的残余压应力层,是一种消除成形件残余拉应力和细化晶粒,从而提升其力学性能的卓有成效的方法。

但是,由于激光增材制造成形件内的残余拉应力、冶金缺陷以及不均匀的微观组织都是分布在成形件的整个深度方向,当LSP仅作为表面后处理时,其作用仅限于表层以下较浅的深度,无法彻底地解决成形件的“控形控性”难题。涉及多种工艺、能量源的复合增材制造是目前研究的热点,也是解决上述问题的有效途径。常规的LSP方法需要吸收层吸收高能脉冲激光不破坏金属表面,在约束层的约束下增加冲击波的峰值压力,从而在金属构件表层获得优异的力学性能。为了适应工业中复杂表面和苛刻环境,在冲击强化过程中,脉冲激光直接辐射在构件表面,其表面层吸收激光能量,在短时间内产生等离子体膨胀,形成冲击波,在次表面层呈现残余压应力,这就是无吸收层激光冲击强化(laser shock peening without coating,LSPwC)技术[25]。

结合前述SLM技术的“控形控性”难题,研究[25]发现采用LSPwC逐层处理不仅能在前层熔化区次表面层产生严重塑性变形诱导压应力并闭合冶金缺陷,而且可以去除前层熔化界面、增加表面粗糙度,易于后层熔化区与其紧密结合。在利用激光冲击波消除熔覆修复层残余拉应力和细化晶粒的基础上,结合激光冲击波产生塑性变形“逐层”消除热效应内应力和冶金缺陷的思想,提出了一种激光热力交互增材制造方法,即采用LSPwC技术大面积搭接冲击产生塑性变形消除SLM每层熔化/凝固过程中产生的内应力并闭合冶金缺陷,如此类推,“逐层”采用SLM + LSPwC组合工艺,最后一层SLM熔化成形后恢复尺寸,采用LSP大面积搭接冲击,实现成形件的高质量整体加工。Kalentics等[26~28]也采用3D LSP方法调控SLM成形件的残余应力场和冶金缺陷分布,但目前还停留在组合工艺参数探索、标准试样力学性能研究阶段,其SLM成形热场与冲击波力场交互作用形成的热力效应、残余应力分布模型、控形控性机理都未进行系统深入的研究。在复杂的激光热力效应交互作用下,残余应力形成过程与演化、冲击波力学效应对成形件组织细化及晶体取向的影响机制、以及热力交互控形控性机制等,与传统激光增材制造和冲击波强化存在显著区别,具有重要理论意义和应用价值,是激光热力效应交互“控形控性”增材制造能否应用的关键所在。

本工作基于激光热力交互增材制造方法,以Ti6Al4V合金为对象,研究了激光熔化/凝固-冲击塑性变形交互作用下残余应力演化过程与再分布规律;并基于微观组织演变规律,获得了激光冲击波力作用诱导的晶粒细化机制;此外,阐明了激光热力交互增材制造过程中的缺陷闭合机理;最后通过拉伸实验,揭示了激光热力交互作用下残余应力/微观组织协同强韧化机理。

1 实验方法

采用Ti6Al4V合金作为加工基板,尺寸为150 mm × 150 mm × 15 mm。使用前,采用砂轮片对基板表面进行打磨,打磨后使用乙醇溶液清洗,去除表面残留油污和杂质等。选用通过气相雾化法制备的Ti6Al4V粉末为原料,粉末的化学成分(质量分数,%)为:Al 5.96,V 3.83,Fe 0.16,C 0.01,N 0.0094,H 0.0016,O 0.1058,Ti余量。该粉末具有较高的球形度,其粒径范围为1~80 μm,用Mastersizer 2000颗粒分析仪测得的粉末颗粒平均尺寸为34 μm,可以满足SLM成形工艺的要求。

SLM实验采用iSLM 150金属3D打印机,配备了波长为1064 nm、最大输出功率为200 W的光纤激光器。除此之外,还包括重涂系统(刮刀铺粉)、光学扫描系统(高速扫描振镜)、保护系统、成形缸(150 mm (X) × 150 mm (Y) × 200 mm (Z))和控制软件等。加工前将基板在120℃下预热2 h。实验过程中为了防止钛合金的氧化,整个SLM加工是在充满Ar气的成形室中进行的,氧含量低于50 × 10-6。SLM具体工艺参数如下:激光功率(P) 200 W,扫描速率(v) 900 mm/s,光斑直径(d) 70 μm,铺粉层厚度(s) 0.03 mm和扫描间距(h) 80 μm。激光扫描策略是把待成形平面划分为若干个条带,条带各层旋转67°,激光在条带区域扫描。采用Gaia型激光冲击强化装置进行LSP实验,装置主要包括:激光器及其外部光路(Nd∶YAG纳秒激光器,波长为1064 nm,脉冲宽度为10 ns,频率为5 Hz)、机械手及其与激光器的协同控制系统、水循环装置。在LSP实验过程中,使用0.1 mm厚的专业铝箔作为吸收层,1 mm厚的水流层作为约束层。LSP具体工艺参数如下:激光能量7.6 J,激光光斑直径3 mm,光斑搭接率50%,冲击路径为“Z”型扫描。

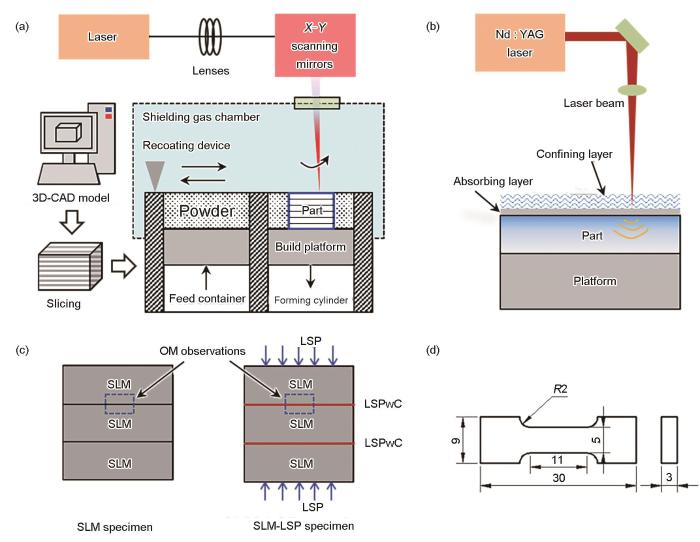

具体实验过程如图1a~c所示:首先通过SLM成形了1 mm厚的熔化层,然后采用3层LSPwC冲击熔化层上表面;接着在冲击后的表面成形了1 mm厚的熔化层,如此往复,得到由3个1 mm厚的熔化层组成的试样;最后,采用3层LSP对上下表面分别进行LSP处理。

图1

图1

选区激光熔化(SLM)、激光冲击强化(LSP)、SLM和SLM-LSP试样制备及拉伸试样尺寸示意图

Fig.1

Schematics of selective laser melting (SLM) (a), laser shock peening (LSP) (b), the preparation of SLM and SLM-LSP specimens (c), and dimensions of tensile specimen (unit: mm) (d) (CAD—computer-aided design, LSPwC—laser shock peening without coating)

试样从基板上线切割后,在酒精中超声清洗以去除残留的粉末及污渍,接着将试样沿横截面切割、打磨并抛光成镜面。然后,将试样用Kroll试剂(100 mL H2O、5 mL HNO3和2 mL HF混合溶液)腐蚀5 s左右。通过Observer.Z1m光学显微镜(OM)对组织进行表征。

使用配有Cu靶Kα 辐射的X-350A型X射线衍射仪(XRD)和sin2ψ (ψ为衍射晶面法线与试样表面法线的夹角,即衍射晶面法线方位角)测量法对试样进行深度方向的残余应力测量。X射线束直径设置为约2 mm,初始扫描角为147°,终止角为138°,测试晶面为(213)晶面。在沿深度方向测量之前,在室温下用电解抛光法逐层去除表面材料。每个深度上的残余应力随机测量5次,取平均值。

使用Tecnai G2 F20型透射电子显微镜(TEM)表征试样的微观结构。TEM试样制备流程如下:通过线切割从试样表面获得厚度为1 mm的薄片,并机械研磨至一定厚度;将磨薄后的片冲裁成直径3 mm的圆片;最后进行双喷电解抛光,将样品减薄至达到观察要求。

使用AX-3000CT型工业microCT系统以最小检测精度0.1 μm检测试样的缺陷,然后通过VGStudio软件重建,分析试样的内部3D缺陷。

拉伸实验在Instron 5565电子万能试验机上进行,恒定应变速率为10-3 s-1,拉伸速率为0.5 mm/min。如图1d所示,同一情况下制备3个相同的试样,获得试样精确的极限抗拉强度(UTS)、屈服强度(YS)和延伸率(EL)。拉伸实验后,利用JSM-7800F型场发射扫描电子显微镜(FE-SEM)观察断口形貌。

2 实验结果

2.1 残余应力分布

SLM和SLM-LSP试样沿深度方向的残余应力分布曲线如图2所示。由于SLM过程中高的热梯度和快速冷却,SLM试样的表面层中存在残余拉应力,表面残余应力达到215 MPa。而且,由于SLM过程中的热效应引起的熔化层低温热处理也会导致SLM试样中残余应力的重新分布[29]。经过层间LSPwC处理后,最大残余压应力约为-390 MPa,表明由连续的SLM熔化层引起的热影响不足以完全释放LSPwC引入的残余压应力。而在SLM试样表面上进行LSP处理后,在冲击波的机械作用下,诱导产生了约1 mm深的残余压应力层。表面的残余压应力最大,约为-485 MPa,且随着深度的增加而减小。SLM-LSP试样中残余压应力延伸得更深,整个深度方向都存在残余压应力。这进一步证明,通过层间LSPwC和表面LSP处理,层间LSPwC处理引入的残余压应力可以与随后的表面LSP处理引入的残余压应力叠加,从而总体上提高残余压应力大小和深度。

图2

图2

SLM和SLM-LSP试样沿深度方向的残余应力分布

Fig.2

In-depth residual stress distributions of SLM and SLM-LSP specimens

2.2 微观组织分析

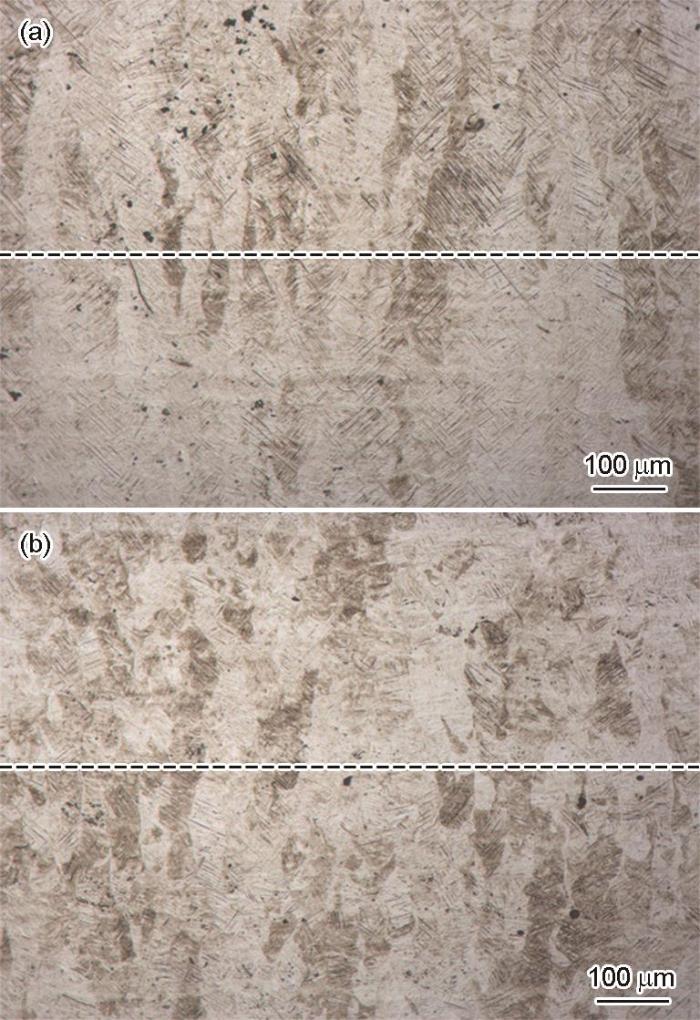

图3

图3

SLM和SLM-LSP试样截面OM像

Fig.3

Cross-setional OM images of SLM (a) and SLM-LSP (b) specimens (The dotted lines represent the interfaces between the third layer and second layer)

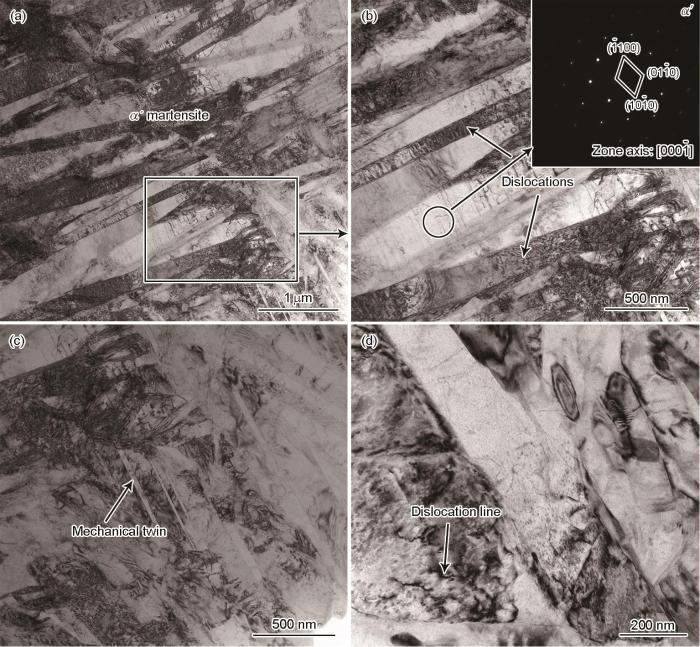

图4

图4

SLM试样表层的TEM像

Fig.4

TEM images in the surface layer of SLM specimen

(a) acicular α' martensite

(b) magnified image of square region in Fig.4a and the corresponding SAED pattern (inset)

(c) mechanical twins (d) dislocation lines

图5为SLM-LSP试样表层的TEM像。由图5a可知,3层LSP处理使SLM试样中α'马氏体尺寸进一步减小。此外,如图5b所示,经过3层LSP处理后,可以观察到一些已经细化的马氏体,而在较粗的马氏体中出现大量2个方向的平行孪晶和高密度位错。研究[30]表明,塑性变形时应变速率对于变形方式以及晶粒细化程度至关重要。在更高应变速率的多层冲击过程中,会导致相同晶粒内滑移系统的改变,即多层冲击以后,在细化的晶粒内又有新的孪晶和位错结构出现。相比于单层激光冲击,多层冲击使应变和应变速率进一步增加,使细化的晶粒按照原先的晶粒细化机制继续被细分。图5c和e分别为图5b中Ⅰ和Ⅱ区域的放大图,进一步对典型的孪晶结构进行表征,发现3层LSP诱导的孪晶均为纳米孪晶,宽度为30~80 nm。同时一些马氏体内部以及孪晶附近还存在大量的位错结构,与SLM试样相比,LSP诱导的位错密度明显增加。图5d和f分别为图5c和e中孪晶结构的SAED花样,可以确定图5c中的孪晶为{

图5

图5

SLM-LSP试样表层的TEM像

Fig.5

TEM images in the surface layer of SLM-LSP specimen

(a) refined α' martensites

(b) a large number of parallel mechanical twins and high density dislocation structures

(c) magnified image of region Ⅰ in Fig.5b

(d) SAED pattern of region Ⅰ in Fig.5b showing {10

(e) magnified image of region Ⅱ in Fig.5b

(f) SAED pattern of region Ⅱ in Fig.5b showing {10

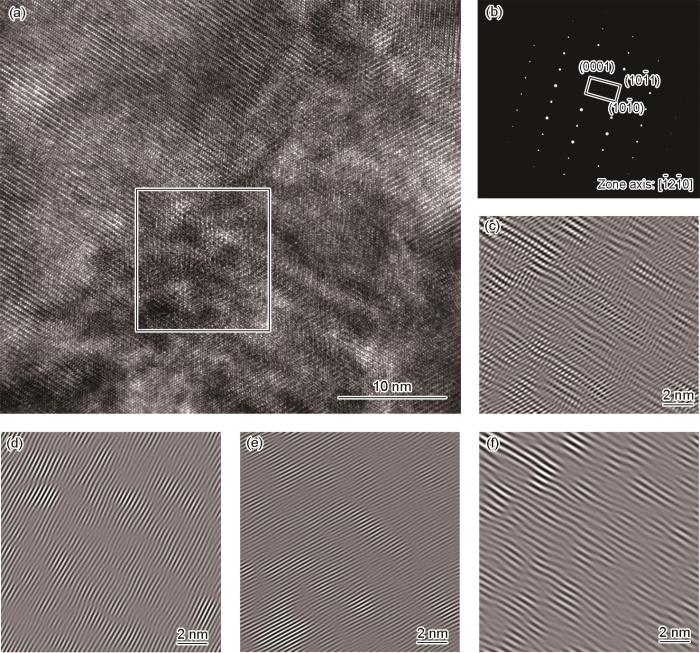

图6

图6

SLM-LSP试样表层中位错结构的TEM分析

Fig.6

TEM analyses of dislocations in the surface layer of SLM-LSP specimen

(a, b) HRTEM image (a) and corresponding SEAD pattern (b)

(c) inverse fast Fourier-transform (IFFT) image of square region in Fig.6a

(d) atom arrangement on the (

(e) atom arrangement on the (

(f) atom arrangement on the (0001) plane

经过激光冲击处理后,SLM-LSP试样表面层的晶粒细化过程如下:当激光冲击波作用在熔化层表面时,大量的位错结构被激活,形成一定数量的位错线和位错缠结。随着应变速率的进一步增大,在粗晶内开始出现大量的平行孪晶以及高密度位错,从而原始粗晶被孪晶界分割成许多细长区域。在这个阶段,晶粒细化过程以平行孪晶为主,伴随着少量位错运动。随着进一步的塑性变形,细长区域内的位错结构在特定位置聚集,进而形成横向的位错缠结和随机分布的位错胞。显然,这些位错结构进一步将细长区域分割形成亚晶。最后,针状和层状α'马氏体细化成了更细的马氏体结构。

2.3 内部缺陷

材料中的缺陷对其性能影响很大。在加载过程中,缺陷的存在会成为裂纹萌生源,从而导致材料过早断裂失效。为了探索LSP对SLM试样内部缺陷的影响,利用microCT对SLM和SLM-LSP试样中缺陷的形状、尺寸和分布进行了定量表征,结果如图7a和c所示。SLM试样内部随机分布着大量细小的孔洞(图7a)。孔洞的形状相对普通,球形度高,尺寸通常小于50 μm。这些孔洞大多是由于能量输入过多或过程不稳定,导致熔池内残留气体而形成的。一方面,在熔化过程中,熔池的温度较高,熔池内气体的溶解度也较高。当熔池冷却时,温度降低,溶解度降低,形成气体残渣的可能性增加。另一方面,材料在成形过程中熔化和凝固速率非常快,在凝固过程中,熔池中的气体没有足够的时间溢出。经过层间LSPwC和表面LSP处理后,SLM试样中的孔洞数量明显减少(图7c)。与SLM试样相比,SLM-LSP试样中减少的孔洞主要集中在LSPwC和LSP处理表面的近表层区域。

图7

图7

SLM和SLM-LSP试样三维孔隙特征的三维重建图以及缺陷尺寸和数量的统计结果

Fig.7

3D reconstruction graphs revealing 3D pore characteristics (a, c) and statistical results of the size and number of defects (b, d) for SLM specimen (a, b) and SLM-LSP specimen (c, d)

在SLM过程中,LSPwC/LSP诱导的缺陷闭合机理主要归因于,经过LSPwC/LSP处理之后去除了SLM试样中的现有残余拉应力并在近表面区域引入了残余压应力场。在新引入的残余压应力场内,由于双向压缩应力状态,孔洞或微小裂纹被压缩甚至闭合。此外,后续的SLM过程中又在残余压应力区域的表面形成了新的熔化层,会将热量引入到下层并促进其在闭合缺陷中的扩散。其热量足以在裂纹附近引起局部熔化,以某种方式逆转了先前描述的熔融机理[27]。通过类似于钎焊的机制,同时存在的局部液态膜和压应力场可以愈合SLM热影响区中存在的缺陷。由于涉及的时间非常短,实际的机制可以称为“快速钎焊”或“快速热等静压”,此过程会在层间LSPwC处理表面层中产生无缺陷的区域。

2.4 拉伸性能分析

图8为2种试样的工程应力-应变曲线。SLM-LSP试样的极限抗拉强度和延伸率均优于SLM试样。特别地,与SLM试样相比,SLM-LSP试样的极限抗拉强度从1053 MPa增加到1543 MPa,提高了46.5%。同时,延伸率从8.11%提升到了15.53%,提高了91.5%。这些结果表明,层间LSPwC以及表面LSP共同作用可以有效消除SLM过程中的不利影响,并明显提高SLM-LSP试样的强度和塑性。

图8

图8

SLM和SLM-LSP拉伸试样的工程应力-应变曲线

Fig.8

Engneering stress-strain curves of the tensile SLM and SLM-LSP specimens

为了探索试样的拉伸断裂机理,分别对SLM和SLM-LSP试样的拉伸断口形貌进行了表征,如图9所示。图9a为SLM试样的断口形貌,发现含有大量的开孔。另外,断口表面的特征是层状/解理断裂模式(图9a1),还可以观察到许多带有微孔的小而浅的韧窝(图9a2)。因此,SLM试样包含脆性和韧性断裂的混合断裂模式。对于SLM试样,解理断裂发生在确定的晶面上,没有相关的塑性变形。相比之下,在层间LSPwC和表面LSP共同作用下,SLM-LSP试样的断口形貌发生了明显的变化,均匀的断口表面出现了大面积的韧窝,脆性断裂特征几乎无法辨识,如图9b所示。韧窝的深度和尺寸均大于SLM试样(图9b1和b2)。众所周知,微韧窝的形成主要是由于微孔洞的结合和生长,深而大的微韧窝通常具有良好的延展性[32]。

图9

图9

SLM和SLM-LSP拉伸试样断口形貌的SEM像

Fig.9

SEM fracture morphologies of SLM (a, a1, a2) and SLM-LSP (b, b1, b2) specimens (B.D.—building direction)

2.5 复合强化机理

影响SLM试样拉伸性能的因素有很多,如残余拉应力、冶金缺陷及不均匀的微观组织等。与SLM试样相比,SLM-LSP试样拉伸性能的提升主要归结于以下3个方面:(1) SLM-LSP试样整个深度方向诱导的残余压应力;(2) SLM-LSP试样中冶金缺陷的闭合;(3) LSP诱导的微观强化。

式中,σNG表示纳米晶强化(208 MPa),σNT表示纳米孪晶强化(167 MPa),σD表示位错强化(95 MPa)。

2.5.1 细晶强化

在激光热力交互增材制造过程中,LSP处理会使SLM-LSP试样上下表层中的晶粒细化为纳米晶。众所周知,晶粒尺寸的减小会显著增加晶界的数量。晶粒细化引起的强化效应通常被称为Hall-Petch强化,其表达式如下[34]:

式中,ky为Hall-Petch常数(114 MPa/μm1/2)[36],d为平均晶粒尺寸(0.3 μm)。由

2.5.2 纳米孪晶强化

LSP处理也会使SLM-LSP试样上下表层中产生大量的纳米孪晶。纳米孪晶的存在也会对材料的性能起到显著的强化作用,其表达式如下[37]:

式中,f为纳米孪晶的体积分数(0.4),t为纳米孪晶的平均厚度(75 nm)。因此,激光冲击波诱导产生高密度、小间距的纳米孪晶,从而显著提高SLM-LSP试样的强度。此外,生成高密度纳米孪晶的同时也会产生大量的孪晶界。孪晶界会像晶界一样,有效地阻碍位错运动,导致位错塞积在对称的孪晶界两侧,降低位错平均自由程,从而促进了SLM-LSP试样的强化。纳米孪晶的存在在提高材料强度的同时也不会削弱其塑性。

2.5.3 位错强化

除了纳米孪晶强化外,激光冲击波还在SLM-LSP试样上下表层中诱导产生了高密度的位错结构。高密度位错引起的Taylor硬化在整体强化中也起到关键作用,具体表达式如下[35]:

因此,LSP诱导的微观强化行为主要表现为细晶强化、纳米孪晶强化和位错强化。在冲击波诱导的残余压应力、冶金缺陷闭合和微观强化的共同作用下,可以在SLM-LSP试样中实现强度-塑性协同提升。

3 结论

(1) 针对SLM成形中的“控形控性”难题,结合LSPwC“逐层”消除内应力和冶金缺陷的思想,提出了激光热力交互增材制造新方法。采用SLM + LSPwC/LSP“逐层”交互处理显著增加了成形件残余压应力大小和层深,改善不均匀微观组织,并有效降低了成形件中整体的冶金缺陷比例,从而同步提高了成形件的强度和塑性。

(2) 在激光冲击波作用下,SLM试样的残余拉应力转化为残余压应力,最大残余压应力达到-485 MPa。并且SLM-LSP试样中残余压应力延伸得更深,整个深度方向都存在残余压应力。

(3) 经LSP处理后,粗的α'马氏体中产生了高密度的位错结构和大量2个方向的孪晶,并逐渐演化为细化的α'马氏体组织。

(4) 热力交互作用可以有效改善SLM试样中的冶金缺陷。SLM试样的缺陷尺寸主要分布在7~20 μm之间,其中尺寸小于10 μm的孔洞占比约为41%。而SLM-LSP试样的缺陷尺寸主要分布在5~15 μm之间,其中尺寸小于10 μm的孔洞占比约为58%,远大于SLM试样中的比例。

(5) 激光热力交互增材制造一体化成形Ti6Al4V合金的极限抗拉强度和延伸率分别达到了1543 MPa和15.53%,相比于SLM试样,分别提高了46.5%和91.5%,具有良好的强度和塑性匹配。主要归因于以下3个方面:冲击波在整个深度方向诱导的残余压应力、SLM-LSP试样中冶金缺陷的闭合以及LSP诱导的微观强化。

参考文献

Current situation of titanium alloy materials used for national aviation

[J].

我国航空用钛合金材料研究现状

[J].

Machining of titanium and its alloys—A review

[J].

Laser additive manufacture of titanium alloys

[J].

Research developments of high-performance titanium alloy by laser additive manufacturing technology

[J].

高性能钛合金激光增材制造技术的研究进展

[J].

Residual stresses in selective laser sintering and selective laser melting

[J].

On the role of melt flow into the surface structure and porosity development during selective laser melting

[J].

Defect induced fatigue behaviors of selective laser melted Ti-6Al-4V via synchrotron radiation X-ray tomography

[J].As a very promising additive manufacturing (AM) technique, selective laser melting (SLM) has gained considerable attentions due to the feasibility of producing light-weight metallic components directly from virtual design data. On the other hand, high strength, low density and high corrosion resistance Ti-6Al-4V alloy has been a preferred AM used material for the aviation and military industries. However, the fatigue damage behaviors of SLMed or AMed components usually suffer from interior defects such as incomplete fusion and gas pores due to unstable process or unsuitable processing parameters. Therefore, thorough investigations on process-induced and metallurgical defects and its influence on the fatigue behavior is required for robust designs and engineering applications of high performance SLM components. As an advanced characterization approach, synchrotron radiation micro computed X-ray tomography (SR-μCT) has been recently to investigate the fatigue damage behaviors of critical components with defects. Based on self-developed in situ fatigue testing rig fully compatible with the BL13W1 at Shanghai Synchrotron Radiation Facility (SSRF), several AMed specimens were prepared for in situ fatigue SR-μCT. The Feret diameter and extreme values statistics were then adopted to characterize the defect size, morphology, population, location and the influence on fatigue life. Fatigue fractography was also examined to further identify the defect to really initiate a fatigue crack. Results show that two types of defects including gas pores and the lack of fusion can be clearly distinguished inside SLM Ti-6Al-4V alloys. Fatigue crack with a typical semi-ellipse usually initiates from the defects at the surface and near the surface. Besides, the defects less than 50 μm and sphericity of 0.4~0.65 dominate for the SLM Ti-6Al-4V alloys. It is also found that the larger the characteristic size of the defect, the lower the fatigue life. Current results can provide a theoretical basis and support to predict the fatigue performance of SLM Ti-6Al-4V alloys. Further investigations should be performed on the relationship between the critical defect and fatigue strength by introducing the Kitagawa-Takahashi diagram.

基于同步辐射X射线成像的选区激光熔化Ti-6Al-4V合金缺陷致疲劳行为

[J].基于自主研制的原位疲劳试验机和高分辨同步辐射X射线三维成像技术,采用Feret直径和极值统计方法定量表征选区激光熔化Ti-6Al-4V合金的缺陷特征尺寸、数量、位置及形貌,原位观测疲劳裂纹的萌生与扩展行为,通过辨识疲劳断口源区的缺陷特征,开展缺陷诱导的疲劳损伤评价研究,从而建立缺陷特征与疲劳寿命之间的关系。分析表明,缺陷主要为未熔合和气孔,等效直径小于50 μm的频率为90%,球度分布于0.4~0.65之间;在不考虑表面粗糙度的情况下,疲劳裂纹优先在试样表面或近表面缺陷处萌生,呈现出典型的半椭圆形貌;同时缺陷特征尺寸越大,疲劳寿命越低。研究结果为增材高性能部件的疲劳性能及寿命评估提供了重要的理论参考。

Influence of different combined severe shot peening and laser surface melting treatments on the fatigue performance of 20CrMnTi steel gear

[J].

Reinforcement of laser-welded stainless steels by surface mechanical attrition treatment

[J].

Microstructure and residual stress improvement in wire and arc additively manufactured parts through high-pressure rolling

[J].

Research on fatigue behavior of the flash welded joint enhanced by ultrasonic peening treatment

[J].

A comprehensive investigation on the effects of laser and shot peening on fatigue crack growth in friction stir welded AA 2195 joints

[J].

Laser shock processing and its effects on microstructure and properties of metal alloys: A review

[J].

Influence of different surface modification treatments on surface integrity and fatigue performance of TC4 titanium alloy

[J].

不同表面改性强化处理对TC4钛合金表面完整性及疲劳性能的影响

[J].对TC4钛合金进行了喷丸强化、激光冲击强化和低塑性抛光3种表面强化改性处理, 测定了不同表面改性处理下的表面粗糙度、显微硬度、残余应力及微观组织, 研究了不同表面改性处理下的旋转弯曲疲劳性能, 利用SEM观察分析了疲劳断口特征, 提出了表面强化改性机理和效果评价方法. 结果表明, 喷丸强化、激光冲击强化和低塑性抛光3种表面强化改性处理后, TC4钛合金的旋转弯曲疲劳寿命提高, 疲劳强度也大幅度提升, 而且疲劳裂纹位于表面强化层下的次表层; 对于未表面强化改性处理的TC4钛合金, 疲劳裂纹位于表面. 基于位错理论, 对次表层裂纹萌生抗力和疲劳强度进行了分析并给出了定量分析模型.

Effect of laser shock peening on residual stress and fatigue life of clad 2024 aluminium sheet containing scribe defects

[J].

Characterization and analyses on micro-hardness, residual stress and microstructure in laser cladding coating of 316L stainless steel subjected to massive LSP treatment

[J].

Tailoring residual stress profile of selective laser melted parts by laser shock peening

[J].

Regain the fatigue strength of laser additive manufactured Ti alloy via laser shock peening

[J].

Microstructure, residual stress and tensile properties control of wire-arc additive manufactured 2319 aluminum alloy with laser shock peening

[J].

Effects of heat treatment combined with laser shock peening on wire and arc additive manufactured Ti17 titanium alloy: Microstructures, residual stress and mechanical properties

[J].

Laser shock peening of laser additive manufactured Ti6Al4V titanium alloy

[J].

Combining manufacturing of titanium alloy through direct energy deposition and laser shock peening processes

[J].

Microstructural evolution and stress state related to mechanical properties of electron beam melted Ti-6Al-4V alloy modified by laser shock peening

[J].This work characterizes microstructural evolutions of electron beam melted (EBM) Ti-6Al-4V alloy modified via laser shock peening (LSP). The depth stress distribution and tensile properties of EBM Ti-6Al-4V alloy were measured before and after LSP. The results indicate that microstructure consists of β phase with 7.2% ± 0.4% vol.% and balance α lamellar in EBM sample, and the α lamella was refined into nano-equiaxed grains and submicro-equiaxed grains after LSP. The dominant refinement mechanism is revealed during LSP. Stacking faults were found in the LSP-treated sample, and their corresponding planes were determined as (0001) basal plane, (10$\bar{1}$0) prismatic plane, and (10$\bar{1}$$\bar{1}$) pyramidal plane obtained by high resolution transmission electron microscopy. The subgrains and high-angle grains formed during dynamic recrystallization were identified by selected area electron diffraction pattern. The LSP treatment produces a significantly residual compressive stress approximately -380 MPa with the depth of compressive stress layer reaching 450 μm. Strength and elongation of the EBM sample were significantly increased after LSP. The strength and ductility enhancements are attributed to compressive stress, grain refinement and grain gradient distribution of α phase.

Effects of laser shock peening on microstructure and fatigue behavior of Ti-6Al-4V alloy fabricated via electron beam melting

[J].

Influence of thermal and mechanical surface modifications induced by laser shock processing on the initiation of corrosion pits in 316L stainless steel

[J].

3D laser shock peening—A new method for the 3D control of residual stresses in selective laser melting

[J].

Healing cracks in selective laser melting by 3D laser shock peening

[J].

3D Laser shock peening—A new method for improving fatigue properties of selective laser melted parts

[J].

An overview of residual stresses in metal powder bed fusion

[J].Metal additive manufacturing (AM) has garnered tremendous research and industrial interest in recent years; in the field, powder bed fusion (PBF) processing is the most common technique, with selective laser melting (SLM) dominating the landscape followed by electron beam melting (EBM). Through continued process improvements, these methods are now often capable of producing high strength parts with static strengths exceeding their conventionally manufactured counterparts. However, PBF processing also results in large and anisotropic residual stresses (RS) that can severely affect fatigue properties and result in geometric distortion. The dependence of RS formation on processing variables, material properties and part geometry has made it difficult to predict efficiently and has hindered widespread acceptance of AM techniques. Substantial investigations have been conducted with regards to RS in PBF processing, which have illuminated a number of important relationships, yet a review encompassing this information has not been available. In this review, we survey and assemble the knowledge existing in the literature regarding RS in PBF processes. A discussion of background mechanics for RS development in AM is provided along with methods of measurement, highlighting the anisotropic nature of the stress fields. We then review modeling efforts and in-process experimental measurements made to advance process understanding, followed by a thorough analysis and summary of the known relationships of both material properties and processing variables to resulting RS. The current state of knowledge and future research needs for the field are discussed.

Microstructural response and grain refinement mechanism of commercially pure titanium subjected to multiple laser shock peening impacts

[J].

Investigations on the microstructure and crack formation of IN738LC samples processed by selective laser melting using Gaussian and doughnut profiles

[J].

Influence of microstructure and strain rate on adiabatic shearing behavior in Ti-6Al-4V alloys

[J].

On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance

[J].

Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall-Petch effect

[J].

Strengthening materials by engineering coherent internal boundaries at the nanoscale

[J].Strengthening materials traditionally involves the controlled creation of internal defects and boundaries so as to obstruct dislocation motion. Such strategies invariably compromise ductility, the ability of the material to deform, stretch, or change shape permanently without breaking. Here, we outline an approach to optimize strength and ductility by identifying three essential structural characteristics for boundaries: coherency with surrounding matrix, thermal and mechanical stability, and smallest feature size finer than 100 nanometers. We assess current understanding of strengthening and propose a methodology for engineering coherent, nanoscale internal boundaries, specifically those involving nanoscale twin boundaries. Additionally, we discuss perspectives on strengthening and preserving ductility, along with potential applications for improving failure tolerance, electrical conductivity, and resistance to electromigration.

The role of pyramidal <c + a> dislocations in the grain refinement mechanism in Ti-6Al-4V alloy processed by severe plastic deformation

[J].

Grain growth and the Hall-Petch relationship in a high-entropy FeCrNiCoMn alloy

[J].

Isotropic and improved tensile properties of Ti-6Al-4V achieved by in-situ rolling in direct energy deposition

[J].

Selective laser melting of biocompatible metals for rapid manufacturing of medical parts

[J].

Achieving high strength and ductility in selective laser melting Ti-6Al-4V alloy by laser shock peening

[J].

Microstructural evolution and tensile property enhancement of remanufactured Ti6Al4V using hybrid manufacturing of laser directed energy deposition with laser shock peening

[J].