热电材料是一种可以实现热能和电能直接转换的新能源材料,在工业余热和汽车尾气回收利用、下一代集成电路高效制冷和全光谱太阳能发电等领域具有重要且广泛的应用[1,2]。由热电材料作为核心部件制造的能量转换器件可以将这些废热、余热直接转化成电能。其具有体积小、无运动部件、安全可靠、无污染、应用温度范围宽等显著优势。热电材料的综合输运性能主要由无量纲的热电优值(ZT值)表征,ZT = σS2T / κ,其中,σ为电导率;S为Seebeck系数;T为热力学温度;κ为热电材料的热导率,用来反映材料的热输运性能,由晶格热导率(κL)和电子热导率(κE) 2部分组成(κ = κE+ κL);S2σ为功率因子,用来反映热电材料的综合电输运性能。目前,热电材料的应用领域很窄,仅在深空探测发电设备、小功率制冷设备等小范围应用,器件的转换效率低且制造成本很高,因此未获大规模的应用。主要有以下几个原因:(1) 反映热电材料的综合性能的ZT值相对低,还需进一步提升;(2) 热电器件的热电腿(n型或p型热电材料)与电极之间的接触电阻较高;(3) 长时间服役过程中,电极与热电材料之间的元素相互扩散会导致其性能和热稳定性变差。此外,优异的力学性能对于实现热电材料的长期服役也至关重要。因此,如何协同调控热电材料的电、热输运性能,同时提高材料的力学性能是热电研究领域的一个挑战性难题。

在众多热电材料体系中,方钴矿(如n型的CoSb3基[3~5]和p型Fe4Sb12基[6,7]金属间化合物)是一种极具应用前景的中温区热电材料,由于其具有环境友好的化学组成和较高的载流子迁移率一直以来均备受关注。Slack于20世纪90年代提出了声子玻璃-电子晶体(PGEC)概念[8]并被引入热电材料的研究中,方钴矿化合物便是具有这一特征的典型代表[9]。二元方钴矿为bcc结构,单位晶胞中的2a位置含有2个大的二十面体晶格孔隙可以被稀土、碱土等元素填充形成填充方钴矿,填充后方钴矿的晶格热导率会获得数量级的降低,ZT值获得大幅提升[10~15]。单相的n型双填充和多填充方钴矿的最高ZT值分别达到了1.4[12]和2.0[13]。在n型填充方钴矿中引入磁性[16~18]或非磁性[19~22]纳米第二相形成的纳米复合材料可以进一步提升ZT值。近年来,通过传统固相反应结合放电等离子烧结(SPS)技术[8,23]、机械合金化(MA)[24,25]、熔融旋甩结合热压(MS-HP)[26]或熔融旋甩结合SPS技术(MS-SPS)[27,28]、温度梯度区熔法(TGZM)[29]和强塑性变形(SPD)[30,31]等先进合成方法制备出了一系列高性能的p型填充方钴矿材料。其中,采用SPD技术制备的p型DD0.7Fe2.7Co1.3Sb11.8Sn0.2样品最高ZT值达到了1.3[30]。此外,引入纳米第二相[32,33]、特殊结构[34]或优化烧结温度[7,35]等手段也能够获得高性能的p型填充方钴矿材料。其中,通过原位形成Fe3Si纳米第二相的p型方钴矿La0.8Ti0.1Ga0.1-Fe3CoSb12材料[33]最高ZT值达到了1.2。然而,与通过纳米复合、多元素填充或先进制备技术等手段获得的一些n型填充方钴矿材料[10~13,16~22]相比,p型填充方钴矿材料的性能仍然偏低。因此,作为热电器件核心部件中有前途的候选材料,改善p型方钴矿材料的热电性能对开发出高效热电器件具有重要意义。

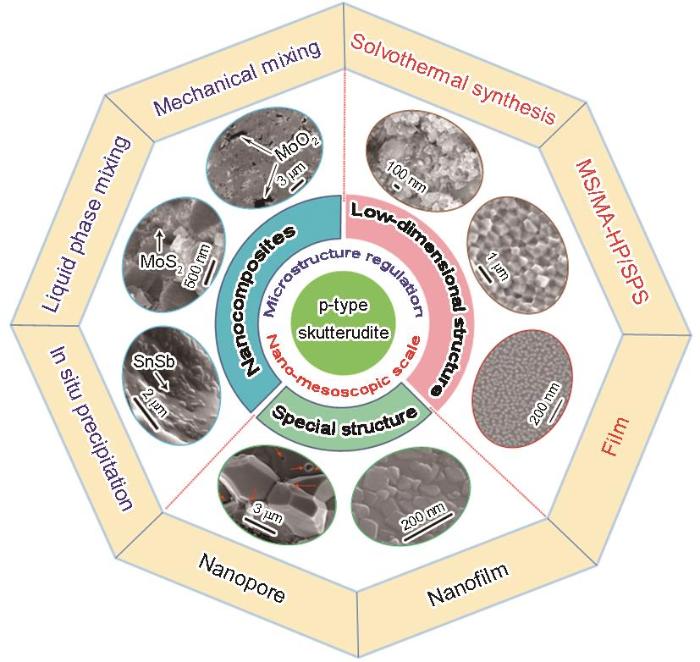

纳米-介观尺度微结构调控是提升热电材料综合输运性能和力学性能的一个重要手段[36]。微结构的调控通常包括细化材料的晶粒尺寸使得其低维化[37]、材料中引入特殊结构[38]、引入纳米第二相制备纳米复合材料[16~22]等。通过在纳米-介观尺度的微结构调控,热电材料的电子和声子输运可以得到协同优化,热电性能大幅提升。此外,在热电材料中引入纳米第二相粒子,利用纳米粒子与热电基体材料之间的钉扎和黏合[21]等效应也可以使材料的力学性能得到显著改善[39]。本文对近年来在纳米-介观尺度上调控p型方钴矿热电材料微结构的主要研究进展做了系统总结,对微结构的一些调控方法(图1[34,40~46])做了详细阐述。通过微结构的调控,p型方钴矿材料的热电性能和力学性能得到大幅提升,为热电器件的应用提供科学和技术支撑。

图1

1 低维结构和引入特殊结构

纳米晶热电薄膜材料、一维纳米线材料等多种低维热电材料实现了热电性能的大幅提升[47,48]。Hicks和Dresselhaus[48]提出,当材料的尺度降低到纳米量级,电子和声子的输运将呈现出明显的维度及尺寸效应,电性能的提升表现在Seebeck系数的提高,源于纳米尺度上的量子阱效应引起的Fermi能附近电子态密度增加[37]。当材料尺寸与声子波长相当时,会增加对声子的散射,从而降低晶格热导率。如果能进一步降低量子阱尺度到声子平均自由程以下,会显著提高材料的ZT值。近年来,p型方钴矿纳米晶和薄膜[42,49]热电材料的制备,使其热电性能得到了显著改善。通过湿化学法[40,50~52]、MA[24,25,53~55]、MS[28,41,56~61]等方法获得了p型方钴矿纳米粉体,以纳米粉体为原料经烧结致密化得到块体材料,获得p型方钴矿纳米晶热电材料。通过电化学沉积[49]或磁控溅射法[42]制备的薄膜低维结构也可以调控p型方钴矿材料的电子和声子输运并改善其电热输运性能。

1.1 块体低维结构

图2

图2

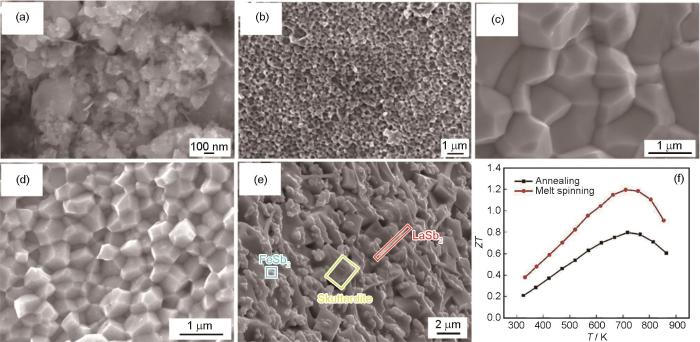

具有低维纳米结构的p型方钴矿材料La0.5Ce0.5Fe3CoSb12样品的SEM像[40],p型填充方钴矿Ce0.45Nd0.45Fe3.5Co0.5Sb12粉体经球磨5 h后的SEM像[25],通过传统固相反应和熔融旋甩法制备的Nd0.9Fe3CoSb12样品的SEM像[41],La x Ti0.1Ga0.1Fe3CoSb12样品甩带自由面的SEM像及La x Ti0.1Ga0.1Fe3CoSb12熔融旋甩样品和退火样品的热电优值(ZT值)[60]

Fig.2

p-type skutterudite materials with low-dimensional nanostructure

(a) SEM image of the La0.5Ce0.5Fe3CoSb12 sample[40]

(b) SEM image of p-type filled skutterudite Ce0.45Nd0.45Fe3.5Co0.5Sb12 powder after ball milling for 5 h[25] (c, d) SEM images of Nd0.9Fe3CoSb12 samples prepared by traditional solid-state reaction (c) and MS method (d)[41] (e) SEM image of the free side of spun ribbon of La x Ti0.1Ga0.1Fe3CoSb12 sample[60] (f) thermoelectric figure of merit

MA法是通过磨球对粉体的反复碾压、摩擦、剪切、冲击,粉体最终被粉碎形成弥散的超细颗粒并实现合金化。对于方钴矿体系,由于存在包晶反应很难通过机械合金化直接获得单相的化合物,通常使用高能球磨制备多相混合物的纳米粉体,再烧结制备纳米晶块体材料[24,25,53~55]。Prado-Gonjal等[24]通过球磨工艺制备了Ce0.5Yb0.5Fe3.25Co0.75Sb12填充方钴矿,粉体的晶粒尺寸约为100 nm,晶粒尺寸的降低使晶格热导率降低,样品在823 K时ZT值最高达到0.93,较传统固相反应制备的样品提高了14%。Rogl等[54]采用高能球磨结合热压烧结技术制备了晶粒尺寸为100~200 nm的高性能DD y (Fe1 - x Co x )4Sb12填充方钴矿,其ZT值在773 K时高达1.3。Jie等[25]经球磨热压快速制备了Ce0.45Nd0.45Fe3.5Co0.5Sb12填充方钴矿,球磨数小时后粉体晶粒尺寸显著降低(图2b[25]),样品的ZT值在750 K以上均达到了1.0。

MS是一种熔体快冷非平衡制备技术,在非晶金属材料的制备领域有着广泛的应用。该方法具有细化晶粒的作用,有利于粉体成分的均匀化和固溶极限的提高。MS法已广泛应用于快速制备p型填充方钴矿纳米粉体[28,41,56~61]。Lee等[57]采用MS结合SPS技术制备高性能的Ce0.91Fe3.4Co0.59Sb12.14方钴矿材料,样品在750 K时ZT值达到1.15。Guo等[41]用MS装置快速制备了Nd0.9Fe3CoSb12方钴矿材料,与传统方法制备的样品(图2c[41])相比,MS样品晶粒尺寸显著降低(图2d[41]),晶粒尺寸的减小使晶界散射增加,显著降低材料的晶格热导率,Nd0.9Fe3CoSb12样品在760 K时ZT值达到了1.0,较传统方法制备的样品提高了35%。Geng等[60]采用MS-HP技术制备了La x Ti0.1Ga0.1Fe3-CoSb12填充方钴矿样品(图2e[60])。由于晶粒尺寸的降低、FeSb2微纳米颗粒以及应变场涨落的产生使得MS样品的晶格热导率显著降低,MS样品的ZT最大值达到了1.2,比传统退火样品高出50% (图2f[60])。

综上,通过湿化学法、MA和MS等方法制备的纳米晶热电材料实现了结构低维化,降低了晶粒尺寸,显著优化了电和热输运性能,为快速制备高性能p型方钴矿热电材料提供了良好前景。

1.2 薄膜低维结构

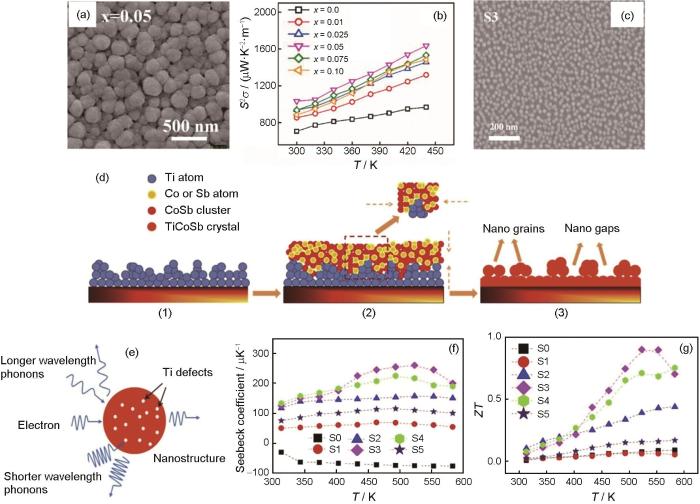

Yadav等[49]使用电化学沉积技术合成了单相Co1 - x Fe x Sb3薄膜,紧密的球状纳米颗粒均匀地覆盖整个薄膜表面(图3a[49])。Fe取代Co提供更多的空穴,随Fe含量增加,载流子浓度提升,纳米颗粒尺寸降低,功率因子和热导率得到优化。Co0.95Fe0.05Sb3薄膜具有最优的电输运性能(图3b[49])及最高的ZT值。Liang等[42]采用磁控溅射法制备了Ti掺杂的p型CoSb3薄膜,球形纳米颗粒均匀分散在薄膜表面(图3c[42])。通过先沉积Ti纳米前驱层(图3d (1)[42])后沉积CoSb3的方式,CoSb3在Ti纳米层上以岛屿模式生长(图3d (2)[42]),经过退火处理(图3d (3)[42])后制备出了含有纳米结构的Ti x Co4Sb12薄膜。该薄膜丰富的纳米结构以及Ti掺杂引起的晶格缺陷(图3e[42])可以显著散射中-短波声子,使材料热导率显著降低。同时,这些特殊的纳米结构和表面形态使Seebeck系数也显著增加(图3f[42]),Ti含量为0.72%的样品在523 K时最高ZT值为0.86,比未掺杂Ti的CoSb3薄膜高6倍(图3g[42])。

图3

图3

Co0.95Fe0.05Sb3薄膜的SEM像[49],Co1 - x Fe x Sb3 (0 ≤ x ≤ 0.1)样品的功率因子(S2σ)[49],CoSb3 + 0.72%Ti薄膜的SEM像[42],Ti掺杂的CoSb3薄膜的生长过程示意图[42],纳米结构和Ti基点缺陷的各种声子散射机制[42],不同Ti含量CoSb3薄膜的Seebeck系数和ZT值与温度(T)的依赖关系曲线图[42]

Fig.3

SEM image of Co0.95Fe0.05Sb3 thin film (a)[49], power factor (S2σ) of Co1 - x Fe x Sb3 (0 ≤ x ≤ 0.1) samples (b)[49], SEM image of CoSb3 + 0.72%Ti thin film (c)[42], schematic illustration of Ti doped CoSb3 thin film growth process ((1) nano Ti layer, (2) CoSb3 growing on the Ti layer, (3) annealed film) (d)[42], various phonon scattering mechanisms by nano-strcucture and Ti based points defect (e)[42], and temperature dependences of Seebeck coefficient (f)[42] and ZT values (g)[42] of the CoSb3 thin films with different Ti contents (Samples with Ti contents of 0, 0.25%, 0.57%, 0.72%, 0.83%, and 1.05% were labeled as S0, S1, S2, S3, S4, and S5, respectively)

1.3 引入特殊结构

Fu等[34]用Te元素掺杂CeFe4Sb12方钴矿时,发现基体晶粒中夹杂了一些尺寸各异的纳米孔,如图4a[34]所示。Te取代了Sb4环中的Sb,由于2者元素电负性的不同存在着电荷补偿作用,这种作用会增加吸引电子的能力,改善载流子浓度,同时纳米孔与方钴矿基体之间势垒的能量过滤效应[66]使Seebeck系数增加。此外,纳米孔带来的额外声子散射使晶格热导率大幅下降,773 K时CeFe4Sb11.9Te0.1样品ZT值达到0.76 (图4b[34]),与基体相比提高约61%。Tan等[43]用Zn来取代CeFe4Sb12中的Fe形成固溶体CeFe4 - x Zn x Sb12样品,在Zn含量超过其固溶极限时,基体晶界上形成了尺寸为50~200 nm的ZnSb纳米膜(图4c[43])。与未掺杂的样品相比,所有Zn掺杂的样品都具有较高的ZT值,主要归功于ZnSb纳米膜引起的Seebeck系数增加。800 K时x = 0.1样品ZT值达到了0.9 (图4d[43]),相比不含Zn的样品提高了15%。

图4

图4

含纳米孔结构的CeFe4Sb11.9Te0.1样品的FESEM像和CeFe4Sb12 - x Te x 方钴矿材料的ZT值[34],具有纳米膜结构的CeFe3.8Zn0.2Sb12样品的FESEM像和CeFe4 - x Zn x Sb12样品的ZT值[43]

Fig.4

FESEM image of CeFe4Sb11.9Te0.1 sample with nanopore structure (Arrows indicate nanopores in grains) (a)[34], ZT values of CeFe4Sb12 - x Te x skutterudite materials (b)[34], FESEM image of CeFe3.8Zn0.2Sb12 sample with nanofilm structure (c)[43], and ZT values of CeFe4 - x Zn x Sb12 samples (d)[43]

通过p型方钴矿热电材料的低维化以及在其块体材料中引入特殊结构,可以利用低维结构、特殊结构的纳米效应或能量过滤效应协同优化电子和声子输运,实现了改善p型方钴矿热电材料输运性能的目的。因此,低维化和引入特殊结构的纳米-介观尺度调控手段是提升p型方钴矿热电材料输运性能的有效途径。

2 纳米复合

除了低维化和引入特殊结构,引入纳米第二相形成具有微-纳米结构的纳米复合材料也是提升方钴矿热电材料性能的有效方法[67]。纳米第二相通常分布在基体的晶内和晶界处,晶界和相界面密度提高,载流子和声子的传输受到干扰后会在界面产生附加势垒,势垒会对载流子产生附加散射,降低载流子迁移率[68,69],起到能量过滤作用[66],使Seebeck系数得以提高[70,71]。当第二相尺寸与声子平均自由程相当时,对声子的散射作用更强,可以有效地降低晶格热导率。此外,制备纳米复合热电材料在提升热电性能的同时还可提高材料的力学性能[72]。当前制备p型方钴矿基纳米复合热电材料的主要方法有:机械混合[44,73,74]、液相混合[45,75~77]、原位析出[33,46,78~81]等。良好的纳米复合热电材料要求纳米相的颗粒尺寸和分布状态是可控的,这对其合成方法提出了巨大挑战,特别是如何实现纳米颗粒的均匀分散是纳米复合热电材料研究领域的核心问题。

2.1 机械混合

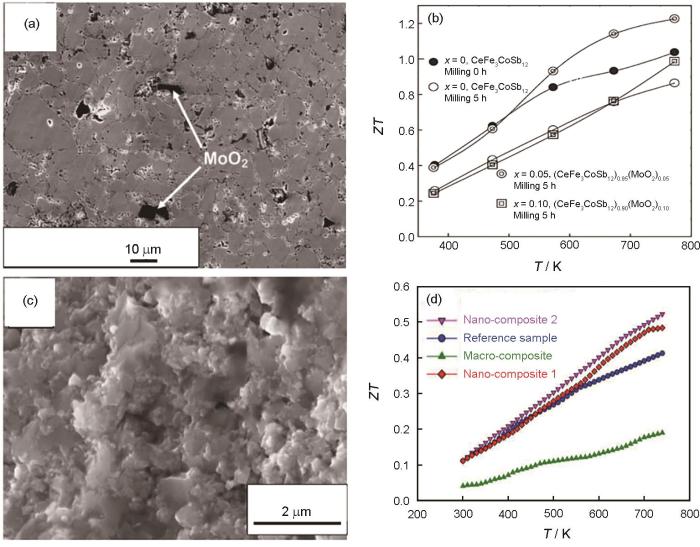

机械混合法是制备纳米复合热电材料的传统方法,制备过程主要是通过在基体粉末中球磨混合引入纳米颗粒,经烧结致密化后得到块体复合材料[44,73,74]。Katsuyama等[44]采用机械球磨的方法研究了MoO2/CeFe3CoSb12纳米复合热电材料,发现MoO2颗粒分散于基体表面(图5a[44]),在提高电导率的同时增加声子在晶界处的散射,有效降低了κL,含5%MoO2 (摩尔分数)样品在773 K时获得最大ZT值1.22 (图5b[44]),与基体相比ZT值提升了16%。Zhang等[74]采用球磨热压法制备了Mm2O3/MmFe4Sb12纳米复合热电材料(Mm表示Ce、La、Nd、Pr等混合金属),尺寸低于200 nm的Mm2O3颗粒大量分散在基体中(图5c[74]),纳米颗粒的存在抑制了高温下的晶粒长大,显著降低了晶格热导率,最终纳米复合材料的ZT值较基体提高了约20% (图5d[74])。机械混合制备纳米复合热电材料具有工艺简单、含量容易控制等优点,是提升p型方钴矿热电材料ZT值的一个有效途径。

图5

图5

CeFe3CoSb12 + 5%MoO2 (摩尔分数)纳米复合样品的SEM像[44],CeFe3CoSb12和(CeFe3CoSb12)1 - x (MoO2) x 复合样品的ZT值[44],MmFe4Sb12 + 16%Mm2O3 (质量分数)纳米复合材料(Nano-composite 2)断口的SEM像[74],MmFe4Sb12 + 16%Mm2O3纳米复合热电材料及参考样品的ZT值[74]

Fig.5

SEM image of CeFe3CoSb12 + 5%MoO2 (mole fraction) nanocomposite (a)[44], ZT values of CeFe3CoSb12 and (CeFe3CoSb12)1 - x (MoO2) x composite (b)[44], SEM image of the fracture surface for MmFe4Sb12 + 16%Mm2O3 (mass fraction) nanocomposite (Nano-composite 2) (c)[74], and ZT values of MmFe4Sb12 + 16%Mm2O3 nanocomposites and reference samples (Reference sample: hot pressed MmFe4Sb12 sample for 2 h (HP-2 h); Macro-composite: MmFe4Sb12 + 16%Mm2O3 composite (HP-2 h); Nano-composite 1: MmFe4Sb12 + 16%Mm2O3 nanocomposite by ball milling (BM) and HP-2 h; Nano-composite 2: MmFe4Sb12 + 16%Mm2O3 nanocomposite by BM, HP-4 h and annealing for 110 h) (d)[74]

2.2 液相混合

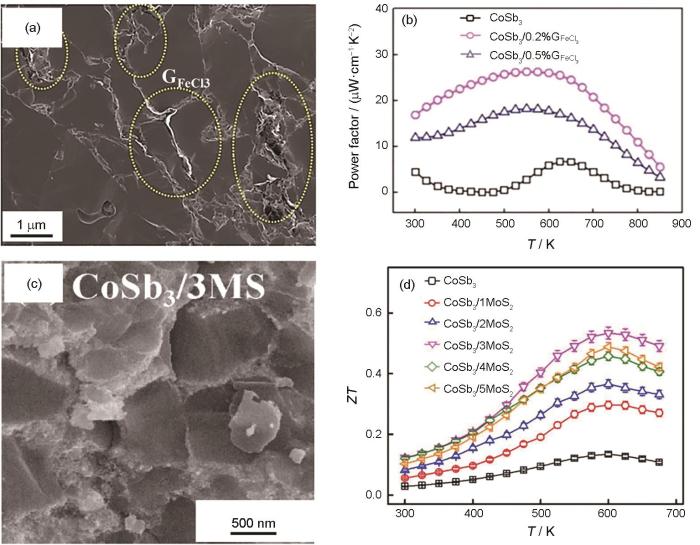

液相混合是以液态溶剂为载体,基体相和分散相以悬浮液的形式共存于一种溶剂中,在制备过程中加以搅拌、超声等手段促进两相混合的方法,液相混合法已在p型方钴矿纳米复合热电材料的制备中得到应用[45,75~77]。Zhou等[75]将BaFe12O19纳米悬浮液与CeFe3CoSb12基体材料超声混合然后离心干燥,结合SPS法制备了BaFe12O19/CeFe3CoSb12磁性纳米复合热电材料。通过优化BaFe12O19纳米颗粒的含量实现了电和热输运性能的协同优化,800 K时含0.05%BaFe12O19 (质量分数)的复合样品ZT值达到了0.7,较基体提升了41.5%。Schmitz等[76]采用超声分散的方法将多壁碳纳米管(CNTs)引入Ce0.14La0.06Co2-Fe2Sb12中,部分CNTs分散在基体的晶界处,另一部分CNTs形成了大的孔状结构的团聚体。沿晶界分散的CNTs导致附加界面对声子的散射,使Seebeck系数增加。团聚的CNTs主要起到与孔隙相当的作用,降低了热导率,最终纳米复合材料的ZT值较基体提升了60%。Zong等[77]用超声分散的方法将FeCl3插层石墨烯纳米层(G

图6

图6

CoSb3/0.2%G

Fig.6

SEM image of cross-sectional areas of CoSb3/0.2%G

2.3 原位析出

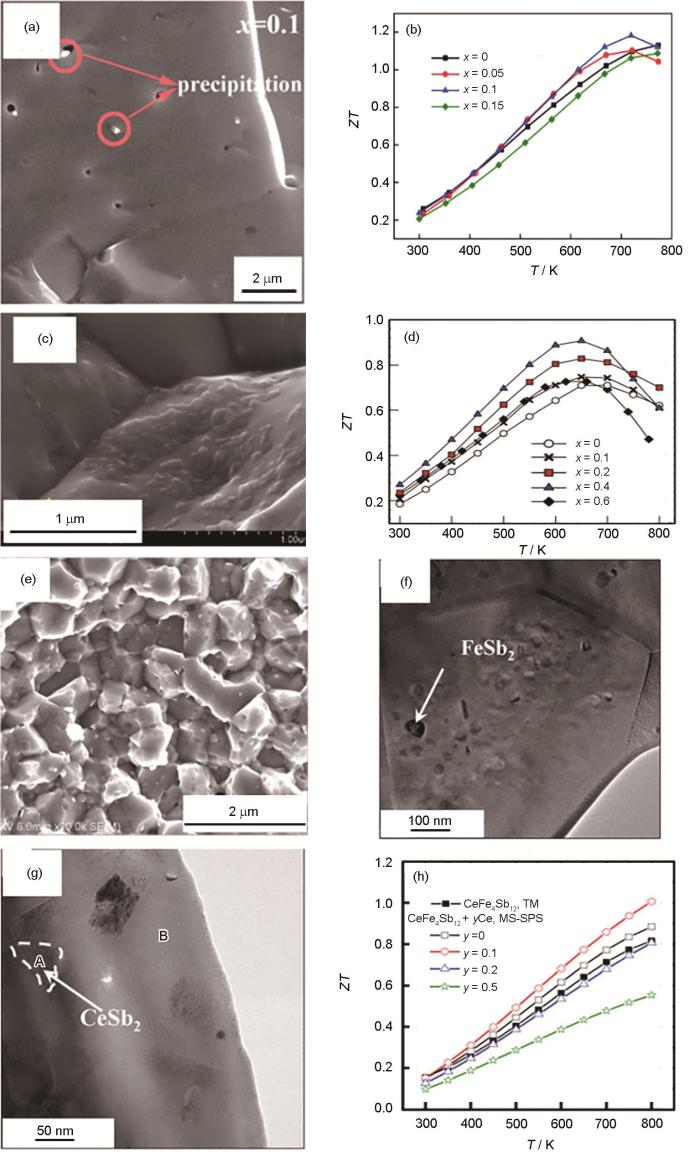

在机械混合和液相混合制备纳米复合热电材料的过程中,纳米颗粒由于其高的比表面能而不可避免地发生团聚现象,导致材料热电性能和力学性能的下降。原位析出的方法解决了这一难题。原位析出法是通过材料内部独特的原位反应得到均匀分布的纳米第二相的一种方法。在p型方钴矿中通过原位析出法制备纳米复合材料是引入均匀分散第二相的常用手段[33,46,78~81]。Peng等[33]采用原位析出法制备了Si x La0.8Ti0.1Ga0.1Fe3(1 + x)CoSb12 p型方钴矿热电材料,原位形成的50~200 nm的Fe3Si分散在基体中(图7a[33])。Fe3Si纳米相的析出引起载流子浓度降低,增加了Seebeck系数,同时原位析出的纳米相使声子散射加剧,引起热导率的显著降低。x = 0.1样品的ZT值在750 K时达到了1.2 (图7b[33])。Duan等[46]制备了p型Sn掺杂的方钴矿Nd0.6Fe2Co2Sb12 - x Sn x,在晶面上原位形成了尺寸小于100 nm的SnSb第二相(图7c[46]),点缺陷和原位析出的沉淀物对声子的强烈干扰和声子共振散射导致材料的晶格热导率显著降低,x = 0.4的样品最大ZT值达到了0.92 (图7d[46]),较基体提高了约30%。FeSb2是p型铁基方钴矿中最常见的杂质相之一,含有FeSb2第二相的复合材料具有良好的热力学稳定性。Tan等[82]通过MS快速制备了具有多尺度纳米结构的高性能p型CeFe4Sb12 + yCe纳米复合材料,由于额外添加了Sb,在晶界上原位析出了CeSb2 (尺寸50~150 nm)和FeSb2 (尺寸< 50 nm)纳米颗粒(图7e~g[82]),多尺度纳米结构使材料热导率显著降低,在800 K时,其最大ZT值高于1,明显高于采用传统的熔融-退火法(TM)制备的样品(图7h[82])。与机械混合法相比,原位析出法制备p型方钴矿热电材料的析出相结构不易控制,但工艺简单、成本低、颗粒分散、尺寸可控,因此也是提高p型方钴矿电和热输运性能的一个有效途径。

图7

图7

La0.8Ti0.1Ga0.1Fe3CoSb12/0.1Fe3Si样品SEM像[33],La0.8Ti0.1Ga0.1Fe3CoSb12/xFe3Si纳米复合材料的ZT值[33],Nd0.6Fe2Co2-Sb11.6Sn0.4样品的SEM像[46],Nd0.6Fe2Co2Sb12 - x Sn x 纳米复合材料的ZT值[46],CeFe4Sb12 + 0.2Ce样品的FESEM像[82],CeFe4Sb12 + 0.1Ce样品的TEM像[82],CeFe4Sb12 + yCe纳米复合材料的ZT值[82]

Fig.7

SEM image of La0.8Ti0.1Ga0.1Fe3CoSb12/0.1Fe3Si sample (a)[33], ZT values of La0.8Ti0.1Ga0.1Fe3CoSb12/xFe3Si nanocomposites (b)[33], SEM image of Nd0.6Fe2Co2Sb11.6Sn0.4 sample (c)[46], ZT values of Nd0.6Fe2Co2Sb12 - x Sn x nanocomposites (d)[46], FESEM image of CeFe4Sb12 + 0.2Ce sample (e)[82], TEM images of CeFe4Sb12 + 0.1Ce sample (f, g)[82], and ZT values of CeFe4Sb12 + yCe nanocomposites (TM—traditional method) (h)[82]

2.4 纳米复合热电材料的力学性能

热电器件的转换效率主要取决于材料的ZT值,然而热电材料模块在加工和实际应用中经常受到服役环境的影响,所以除了优异的热电性能外,出色的力学性能对于实现热电材料的长期服役至关重要。研究[83]表明,n型方钴矿的抗弯强度和断裂韧性分别约为90 MPa和1.7 MPa·m1/2,而p型方钴矿的抗弯强度和断裂韧性分别约为50 MPa和1.1 MPa·m1/2。相比之下,p型方钴矿的力学性能较差,成为方钴矿基热电器件结构失效的重要因素,所以改善p型方钴矿的力学性能是亟待解决的难题。将微米或纳米尺度的颗粒或纤维(如Fe3Si纳米颗粒[33];碳基材料:碳纤维[84]、纳米石墨烯层[85];硼化物:Fe2.25Co0.75B、Ta0.8Zr0.2B[86];Al2O3[87]等)与p型方钴矿结合形成复合材料。通过这种纳米-介观尺度的微结构调控,在增强热电性能的同时可以有效提高复合材料的力学性能[39]。

由于短碳纤维(Cf)具有高的抗磨性、高强度、高模量和良好的电性能,已经成功应用于航空航天、汽车和军事国防工业。Wan等[84]通过传统固相反应制备了CeFe4Sb12/Cf复合材料,短碳纤维的引入提高了纳米复合材料热电性能的同时优化了力学性能,800 K时ZT值达到了0.9。从样品断裂面和光面的SEM像(图8a~d[84])可以看出,裂纹分支、偏转、纤维拉出和裂纹桥接等微结构提高了材料的断裂韧性,基体与纤维之间的强界面以及纤维的高弹性模量使样品的弯曲强度和断裂韧性大幅增加。宗鹏安和陈立东[85]将层片状石墨烯(rGO)与p型方钴矿材料复合制备了Ce0.85Fe3CoSb12/rGO纳米复合材料,位于裂纹之间的rGO桥接了裂纹两端的晶粒(图8e和f[85]),样品受力F作用后诱发裂纹,但需要先拉断石墨烯才能继续扩展(图8g[85]),因此该过程将消耗额外功阻碍裂纹的扩展,产生增韧作用[88]。最终,纳米复合材料的抗弯强度和断裂韧性显著增加,如图8h[85]所示。Rogl等[86]通过高能球磨热压技术在p型DD y -Fe3CoSb12填充方钴矿中加入纳米级Fe2.25Co0.75B、Ta0.8Zr0.2B等硼化物,成功制备了晶粒尺寸约为200 nm的复合材料。含Ta0.8Zr0.2B颗粒的样品823 K时ZT值达到了1.31。硼化物添加剂在优化热电性能的同时也提高了材料的硬度、弹性模量和断裂韧性,使得复合材料的力学性能显著提升。α-Al2O3粒子因其优异的力学性能和高温稳定性而成为纳米分散体的候选者,Wen等[87]采用球磨和SPS技术成功制备了p型α-Al2O3/CoSb3纳米复合材料。α-Al2O3纳米颗粒分散在基体晶粒表面甚至嵌入到基体中。随α-Al2O3纳米粒子的添加,复合材料晶界处的结合强度得到了提升。结果表明,含1.0%α-Al2O3 (质量分数)的复合样品抗压强度和弯曲强度分别达到了632.7和179.7 MPa,与基体相比,分别提高了42.7%和52%。复合材料优异的力学性能主要归因于嵌入在基体中的α-Al2O3纳米颗粒具有明显的钉扎作用。

图8

图8

CeFe4Sb12/3%Cf (体积分数)样品断裂面的SEM像和抛光面的SEM像[84],Ce0.85Fe3CoSb12/1.4%rGO (还原氧化石墨烯,体积分数)样品的断面SEM像[85],石墨烯增韧机理示意图和Ce0.85Fe3CoSb12/y%rGO (体积分数)复合材料的弯曲强度(σ)和断裂韧性(KIC)[85]

Fig.8

SEM images of the fracture surfaces showing crack propagation (a)[84], crack branching and fiber pullout (b)[84], crack deflection and fiber pullout (c)[84] of CeFe4Sb12/3%Cf (volume fraction) sample, SEM image of the polished surface of CeFe4Sb12/3%Cf sample (d)[84]; SEM images showing the fractured surface (e)[85], expanded crack (f)[85] for the Ce0.85Fe3CoSb12/1.4%rGO (reduced graphene oxide, volume fraction) sample; schematic diagram of toughing mechanism by rGO (F—force) (g)[85] and three-point flexural strength (σ) and fracture toughness (KIC) of the Ce0.85Fe3CoSb12/y%rGO (volume fraction) composites (h)[85]

综上,将p型方钴矿基体与微米或纳米尺度的纤维或第二相结合形成纳米复合热电材料,在优化热电性能的同时可以有效地提高热电材料的力学性能。

3 总结与展望

本文综述了近年来在纳米-介观尺度调控p型方钴矿热电材料微结构的主要研究进展。通过低维化、引入特殊结构和纳米第二相等微结构调控手段可以有效提升p型方钴矿热电材料的热电性能和力学性能,为制备高效稳定的热电器件提供了理论和技术支持。通过纳米-介观尺度微结构调控使得p型方钴矿材料的热电性能和力学性能得到一定程度提升,但是与材料的ZT值相对应的热电器件的转换效率和服役周期仍较低。目前,p型方钴矿热电材料的微结构调控研究中仍存在一些问题需要进一步研究。(1) 小型化是热电器件发展的趋势,因此进一步开发新的工艺来制备低维化或具有新颖特殊结构的高性能p型方钴矿材料非常重要;(2) 引入纳米第二相形成具有微-纳米结构的纳米复合热电材料是提升p型方钴矿材料热电性能和力学性能的有效方法。进一步筛选与基体在相界面上有合适能带匹配并且具有稳定物理化学性质的纳米第二相是再次提升p型方钴矿材料热电和力学性能的关键;(3) 探索节能、低成本、可持续的新技术和新工艺来快速制备具有丰富微结构的高性能p型方钴矿材料也尤为重要。

总之,要进一步通过在纳米-介观尺度调控微结构改善p型方钴矿材料的热电性能和力学性能还有很多工作要做。尽管挑战无处不在,但热电材料的研究正成为一项全球性活动。热电材料与其他学科的交叉研究越来越广泛,这将促进热电研究和未来大规模应用的持续快速增长。

参考文献

Cooling, heating, generating power, and recovering waste heat with thermoelectric systems

[J].Thermoelectric materials are solid-state energy converters whose combination of thermal, electrical, and semiconducting properties allows them to be used to convert waste heat into electricity or electrical power directly into cooling and heating. These materials can be competitive with fluid-based systems, such as two-phase air-conditioning compressors or heat pumps, or used in smaller-scale applications such as in automobile seats, night-vision systems, and electrical-enclosure cooling. More widespread use of thermoelectrics requires not only improving the intrinsic energy-conversion efficiency of the materials but also implementing recent advancements in system architecture. These principles are illustrated with several proven and potential applications of thermoelectrics.

Complex thermoelectric materials

[J].

Microstructural analysis and thermoelectric properties of skutterudite CoSb3 materials produced by melt spinning and spark plasma sintering

[J].

Effects of magnetization on thermoelectric transport properties of CoSb3 material

[J].

Skutterudites: A new class of promising thermoelectric materials

[C].

Research progress of p-type Fe-based skutterudite thermoelectric materials

[J].

Effects of sintering temperature on microstructure and thermoelectric properties of Ce-filled Fe4Sb12 skutterudites

[J].

Phonon-glass electron-crystal thermoelectric clathrates: Experiments and theory

[J].

Multiple-filled skutterudites: High thermoelectric figure of merit through separately optimizing electrical and thermal transports

[J].

Dual-frequency resonant phonon scattering in Ba xRy Co4Sb12 (R = La, Ce, and Sr)

[J].

Low thermal conductivity and high thermoelectric figure of merit in n-type Ba x Yb y Co4Sb12 double-filled skutterudites

[J].

n-type skutterudites (R, Ba, Yb) y -Co4Sb12 (R = Sr, La, Mm, DD, SrMm, SrDD) approaching ZT ≈ 2.0

[J].

Filled skutterudite antimonides: A new class of thermoelectric materials

[J].A class of thermoelectric materials has been synthesized with a thermoelectric figure of merit ZT (where T is temperature and Z is a function of thermopower, electrical resistivity, and thermal conductivity) near 1 at 800 kelvin. Although these materials have not been optimized, this value is comparable to the best ZT values obtained for any previously studied thermoelectric material. Calculations indicate that the optimized material should have ZT values of 1.4. These ternary semiconductors have the general formula RM4X12 (where R is lanthanum, cerium, praseodymium, neodymium, or europium; M is iron, ruthenium, or osmium; and X is phosphorus, arsenic, or antimony) and represent a new approach to creating improved thermoelectric materials. Several alloys in the composition range CeFe4-xCoxSb12 or LaFe4-xCoxSb12 (0 < x < 4) have large values of ZT.

Thermoelectric properties of p-type Yb x La y Fe2.7Co1.3Sb12 double-filled skutterudites

[J].

Superparamagnetic enhancement of thermoelectric performance

[J].

Candidate for magnetic doping agent and high-temperature thermoelectric performance enhancer: Hard magnetic M-type BaFe12O19 nanometer suspension

[J].

Magnetoelectric interaction and transport behaviours in magnetic nanocomposite thermoelectric materials

[J].

Grain boundary engineering with nano-scale InSb producing high performance In x Ce y Co4Sb12 + z skutterudite thermoelectrics

[J].

High thermoelectric performance of Yb0.26Co4Sb12/yGaSb nanocomposites originating from scattering electrons of low energy

[J].

Synergistic optimization of electrical-thermal-mechanical properties of the In-filled CoSb3 material by introducing Bi0.5Sb1.5Te3 nanoparticles

[J].

Preferential phonon scattering and low energy carrier filtering by interfaces of in situ formed InSb nanoprecipitates and GaSb nanoinclusions for enhanced thermoelectric performance of In0.2Co4Sb12

[J].

p-type skutterudites RxMy -Fe3CoSb12 (R, M = Ba, Ce, Nd, and Yb): Effectiveness of double-filling for the lattice thermal conductivity reduction

[J].

Enhancing the thermoelectric properties of single and double filled p-type skutterudites synthesized by an up-scaled ball-milling process

[J].

Fast phase formation of double-filled p-type skutterudites by ball-milling and hot-pressing

[J].

Enhanced thermoelectric performance of p-type filled skutterudites via the coherency strain fields from spinodal decomposition

[J].

Melt spinning synthesis of p-type skutterudites: Drastically speed up the process of high performance thermoelectrics

[J].

Rapid preparation of CeFe4Sb12 skutterudite by melt spinning: Rich nanostructures and high thermoelectric performance

[J].

Impurity removal leading to high-performance CoSb3-based skutterudites with synergistic carrier concentration optimization and thermal conductivity reduction

[J].

New bulk p-type skutterudites DD0.7Fe2.7Co1.3Sb12 - xXx (X = Ge, Sn) reaching ZT > 1.3

[J].

Dependence of thermoelectric behaviour on severe plastic deformation parameters: A case study on p-type skutterudite DD0.60Fe3CoSb12

[J].

Toward high thermoelectric performance p-type FeSb2.2Te0.8 via in situ formation of InSb nanoinclusions

[J].

Enhanced thermoelectric and mechanical properties of p-type skutterudites with in situ formed Fe3Si nanoprecipitate

[J].

Thermoelectric performance enhancement of CeFe4Sb12 p-type skutterudite by disorder on the Sb4 rings induced by Te doping and nanopores

[J].

Rapid preparation and thermoelectric properties of Ba and In double-filled p-type skutterudite bulk materials

[J].

A review of CoSb3-based skutterudite thermoelectric materials

[J].

New directions for low-dimensional thermoelectric materials

[J].

Enhanced thermoelectric performance via randomly arranged nanopores: Excellent transport properties of YbZn2Sb2 nanoporous materials

[J].

How nanoparticles can change the figure of merit, ZT, and mechanical properties of skutterudites

[J].

Thermoelectric properties of rare earths filled CoSb3 based nanostructure skutterudite

[J].

Super-rapid preparation of nanostructured Nd x Fe3CoSb12 compounds and their improved thermoelectric performance

[J].

Nano structure Ti-doped skutterudite CoSb3 thin films through layer inter-diffusion for enhanced thermoelectric properties

[J].

Enhanced thermoelectric performance in zinc substituted p-type filled skutterudites CeFe4 - x-Zn x Sb12

[J].

Thermoelectric properties of CeFe3CoSb12-MoO2 composite

[J].

Incorporation of MoS2 nanosheets in CoSb3 matrix as an efficient novel strategy to enhance its thermoelectric performance

[J].

Thermoelectric properties of Sn substituted p-type Nd filled skutterudites

[J].

Properties of nanostructured one-dimensional and composite thermoelectric materials

[J].

Thermoelectric figure of merit of a one-dimensional conductor

[J].

Enhancing thermoelectric properties of p-type CoSb3 skutterudite by Fe doping

[J].

Solvothermal synthesis of nano-sized skutterudite Co4 - x Fe x Sb12 powders

[J].

Solvothermal synthesis of nanostructured ternary skutterudite Fe0.5Ni0.5Sb3

[J].

Solvothermal synthesis and electrical transport properties of skutterudite CoSb3

[J].

Enhancement of thermoelectric figure-of-merit by a bulk nanostructuring approach

[J].

Nanostructuring of p- and n-type skutterudites reaching figures of merit of approximately 1.3 and 1.6, respectively

[J].

Preparation and thermoelectric properties of La filled skutterudites by mechanical alloying and hot pressing

[J].

Effective role of filling fraction control in p-type Ce x Fe3CoSb12 skutterudite thermoelectric materials

[J].

Simple and efficient synthesis of nanograin structured single phase filled skutterudite for high thermoelectric performance

[J].

Phase formation behavior and thermoelectric transport properties of p-type Yb x Fe3CoSb12 prepared by melt spinning and spark plasma sintering

[J].

Super-fast preparation of Nd-filled p-type skutterudite compounds with enhanced thermoelectric properties

[J].

Microstructure evolution and mechanical properties of melt spun skutterudite-based thermoelectric materials

[J].

Rare-earth free p-type filled skutterudites: Mechanisms for low thermal conductivity and effects of Fe/Co ratio on the band structure and charge transport

[J].

Origin of reduction in phonon thermal conductivity of microporous solids

[J].

Thermal conductivity modeling of periodic porous silicon with aligned cylindrical pores

[J].

Intensive suppression of thermal conductivity in Nd0.6Fe2Co2Sb12 - x Ge x through spontaneous precipitates

[J].

The great improvement effect of pores on ZT in Co1 - x Ni x Sb3 system

[J].

Theory of enhancement of thermoelectric properties of materials with nanoinclusions

[J].

High-performance nanostructured thermoelectric materials

[J].

Thermoelectric performance of n-type (PbTe)0.75(PbS)0.15(PbSe)0.1 composites

[J].

Large enhancements in the thermoelectric power factor of bulk PbTe at high temperature by synergistic nanostructuring

[J].

Resonant levels in bulk thermoelectric semiconductors

[J].

Rational design of advanced thermoelectric materials

[J].

BiSbTe-based nanocomposites with high ZT: The effect of SiC nanodispersion on thermoelectric properties

[J].

Synthesis of rare earth filled skutterudite composite with dispersed oxide particles by mechanical milling and SPS techniques and investigation of its thermoelectric properties

[J].

MmFe4Sb12- and CoSb3-based nano-skutterudites prepared by ball milling: Kinetics of formation and transport properties

[J].

Preparation and enhanced thermoelectric properties of p-type BaFe12O19/CeFe3CoSb12 magnetic nanocomposite materials

[J].

Dispersion of multi-walled carbon nanotubes in skutterudites and its effect on thermoelectric and mechanical properties

[J].

Enhanced thermoelectric properties of binary CoSb3 by embedding FeCl3-intercalated graphene nanosheets

[J].

Low-temperature thermoelectric properties of Co0.9Fe0.1Sb3-based skutterudite nanocomposites with FeSb2 nanoinclusions

[J].

High-temperature thermoelectric properties of p-type Yb-filled skutterudite nanocomposites with FeSb2 nanoinclusions

[J].

Raising the thermoelectric performance of Fe3CoSb12 skutterudites via Nd filling and in-situ nanostructuring

[J].

Thermoelectric properties in double-filled Ce0.3In y Fe1.5Co2.5Sb12 p-type skutterudites

[J].

High thermoelectric performance of nonequilibrium synthesized CeFe4Sb12 composite with multi-scaled nanostructures

[J].

Mechanical properties of thermoelectric skutterudites

[C].

The effect of short carbon fibers on the thermoelectric and mechanical properties of p-type CeFe4Sb12 skutterudite composites

[J].

Preparation and mechanical properties of Ce0.85Fe3CoSb12/rGO thermoelectric nanocomposite

[J].

Ce

Attempts to further enhance ZT in skutterudites via nano-composites

[J].

Effects of nano-α-Al2O3 dispersion on the thermoelectric and mechanical properties of CoSb3 composites

[J].