在汽车中应用先进高强钢和低密度材料可实现汽车轻量化,进而同时提高燃油效率、降低CO2排放和提高碰撞安全性。截至目前,先进高强钢已经发展到力学性能更为优异的第三代先进高强钢,代表性钢种包括中锰钢、淬火配分钢(Q&P钢)、轻质钢等[1~3]。其中中锰钢因其优良的综合力学性能和较低成本而广受关注。中锰钢获得优良力学性能的关键工艺是两相区临界退火,通过溶质元素在所形成的奥氏体和铁素体两相间的配分,增强了奥氏体稳定性并在最终组织中引入残余奥氏体,进而在变形过程中通过马氏体相变贡献额外加工硬化,可同时提高强度和塑性。尤其是Al含量较高的中锰钢,既可以通过提高相变温度缩短临界退火时间,进而更适合工业连续退火工艺,还可以降低钢的密度,同时实现高强和轻量化目标,因而广受关注。但提高Al含量导致相变点显著升高,晶粒粗化且形成δ铁素体,使得屈服强度明显降低,如Li等[4]报道的热轧0.2C-3Al-6Mn (质量分数,%,下同)钢在700℃退火1 h后,屈服强度低至600 MPa;Lee等[5]开发的热轧0.3C-10Mn-6Al钢在700~1000℃之间退火10 min后,屈服强度降至400 MPa。

通过V、Nb微合金化进行强化可以提高中锰钢的屈服强度,如Zhu等[6]在9Mn钢中添加0.3%(V + Nb),两相区退火后屈服强度提高到950 MPa,并且表现出1230 MPa的抗拉强度和40%的延伸率。另外,通过低温回火保留初始组织中的位错、维持马氏体硬度可以更经济地提高屈服强度,如Sugimoto等[7]开发出0.2C-1.5Si-3Mn热轧中锰钢,经280℃回火1.5 h后屈服强度和延伸率同时达到1035 MPa和14%;Lee等[8]开发的热轧0.1C-1Si-10Mn-0.3Mo-0.5V钢,在400℃回火1 h后屈服强度达1012 MPa,并且兼具20.7%的延伸率。He等[9]开发出的10Mn-V钢,经过温轧、冷轧和回火热处理后,屈服强度达到2.2 GPa,同时表现出16%的均匀延伸率。然而,回火对含Al中锰钢力学性能影响的研究还很少,尤其是Al含量高导致形成粗大高温铁素体时,回火工艺将如何影响马氏体、δ铁素体和残余奥氏体以及相对应的力学性能,还尚未见系统的研究。本工作研究了回火温度对含δ铁素体高铝中锰钢力学性能和显微组织的影响。

1 实验方法

实验用钢的化学成分为0.4C-7Mn-1.3Si-3Al-0.4(V + Nb),通过Thermo-Calc软件计算相图可知相变平衡温度A1和A3分别为654和894℃。用50 kg真空感应炉熔炼钢水并浇铸成钢锭,锻成60 mm厚锻坯,然后加热至1150℃均匀化2 h,在1100~900℃之间热轧至5 mm厚,空冷至室温。热轧钢板在300、400、500、600和700℃回火处理1 h后空冷至室温。为便于讨论,以上不同温度回火后的样品和热轧板分别记为T300、T400、T500、T600、T700和HR。

使用WDW-200C万能试验机进行室温拉伸力学性能测试,拉伸速率1 mm/min。拉伸试样宽6 mm,标距长25 mm,拉伸方向与轧制方向平行。利用JSM-6701F扫描电子显微镜(SEM)、PHI 710型Auger电子能谱仪上配置的电子背散射衍射仪(EBSD)、D8 DISCOVER A25 X射线衍射仪(XRD)和JEM-2200FS透射电子显微镜(TEM)测试样品的显微组织和残余奥氏体分数。通过配置在SEM和TEM上的能谱仪(EDS)检测显微组织基体和析出相的化学成分。SEM测试的样品首先采用2000号砂纸磨平,然后进行机械抛光,最后在4% (体积分数)硝酸酒精溶液中腐蚀。XRD和EBSD检测样品经磨光在20% (体积分数)高氯酸酒精溶液中电解抛光,电解电压为20 V,温度25℃。TEM样品首先机械减薄至50 μm左右,冲压成直径3 mm的圆片,然后在-20℃下经8% (体积分数)高氯酸酒精溶液双喷电解。残余奥氏体体积分数的计算基于马氏体(200)、(211)衍射峰和奥氏体(200)、(220)和(311)衍射峰的积分强度[10]。奥氏体中的平均C含量利用XRD中(200) γ 峰,采用如下公式计算[11]:

式中,Cγ 是奥氏体中的C含量(质量分数,%),aγ 是奥氏体的平均晶格常数,通过如下公式计算[12]:

式中,λ是Co靶的波长(λ = 0.178897 nm);θ是Bragg衍射角;h、k和l是(200) γ 晶面的Miller指数。

式中,ρ和β分别是位错密度和马氏体(211)衍射峰的半高宽(FWHM);b是Burgers矢量模(b = 0.248 nm)。由于δ铁素体晶粒热轧时被轧扁并沿着轧制方向展长,故可以在热轧板垂直于横向的纵截面上直接观察和测量δ铁素体晶粒的长度和厚度,并利用Image-Pro plus进行统计。

2 实验结果

2.1 拉伸性能

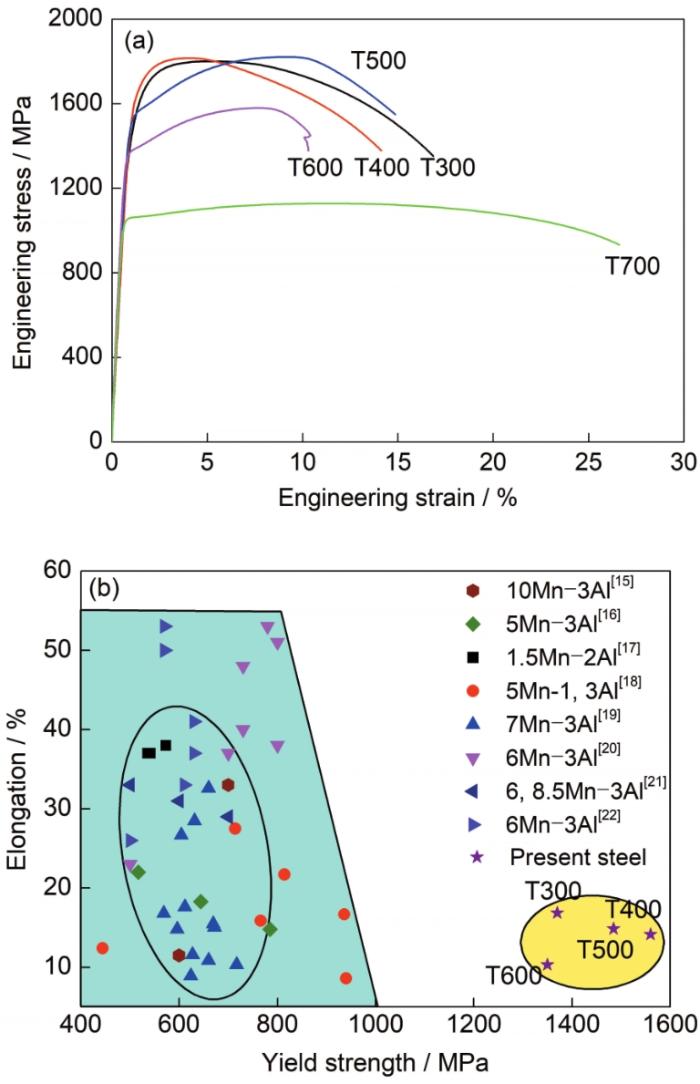

不同温度回火后的工程应力-应变曲线见图1a,对应的力学性能指标总结于表1。300和400℃回火后的拉伸曲线相似,抗拉强度均在1800 MPa左右,但回火温度300℃时的颈缩后延伸率和断后延伸率较高而屈服强度较低;回火温度升至500℃时,均匀延伸率提升至9.2%,显著高于400℃回火样品而屈服强度略降80 MPa,但断后延伸率和抗拉强度基本不变;回火温度升至600℃后,屈服强度、抗拉强度、均匀延伸率和断后延伸率相比于500℃均降低;回火温度升高至700℃时,屈服强度和抗拉强度与600℃回火样品相比分别大幅降低了300 MPa和450 MPa,虽然均匀延伸率和断后延伸率均显著提高到11.6%和26.6%,但加工硬化率明显很低,屈服后强度只增加85 MPa。图1b总结了现有类似Al含量的中锰钢屈服强度和延伸率[15~22]。可知,屈服强度多在600~700 MPa且不超过1 GPa,这是由于Al含量高导致中锰钢存在粗大高温δ铁素体,且在后续热处理过程中难以细化,因此硬度低、屈服强度低。相比之下,本工作钢虽然也含有δ铁素体(见下文实验结果),但屈服强度高达1370~1560 MPa,远远高于类似Al含量的中锰钢,同时延伸率依然保持在10%以上,力学性能优势明显。

图1

图1

不同温度回火后拉伸试样的工程应力-应变曲线及其与文献所报道类似Al含量中锰钢力学性能[15~22]的对比

Fig.1

Engineering stress-strain curves of tensile samples after tempering at different temperatures (T300, T400, T500, T600, and T700 represent tempering of hot-rolled plate at 300, 400, 500, 600, and 700℃, respectively) (a) and the comparison of the resultant yield strength and other medium Mn steels having the similar Al contents in Refs.[15-22] (b)

表1 不同回火样品的力学性能

Table 1

| Sample | YS MPa | UTS MPa | UEL % | TEL % | WHI MPa |

|---|---|---|---|---|---|

| T300 | 1370 | 1800 | 5.3 | 16.7 | 430 |

| T400 | 1560 | 1815 | 4.0 | 14.1 | 255 |

| T500 | 1485 | 1820 | 9.2 | 14.9 | 335 |

| T600 | 1350 | 1580 | 7.6 | 10.3 | 230 |

| T700 | 1045 | 1130 | 11.6 | 26.6 | 85 |

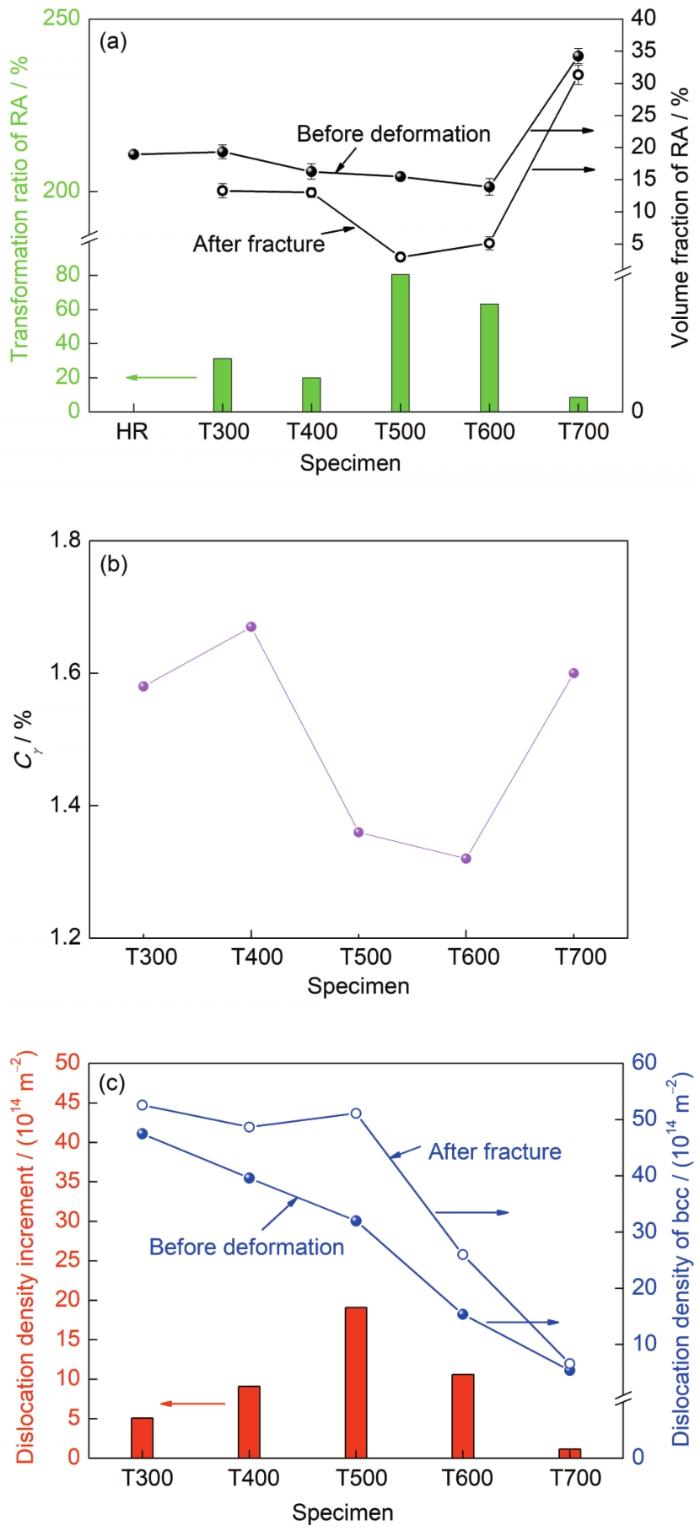

图2a是热轧试样变形前残余奥氏体体积分数和不同拉伸试样变形前后的残余奥氏体体积分数、奥氏体转化量,图2b为变形前奥氏体中的C含量,图2c为bcc相的位错密度在变形前后的变化及位错密度增量。热轧样品经300℃回火后,残余奥氏体体积分数保持在19%不变,600℃回火后,残余奥氏体体积分数由19%下降至14%;拉断样品残余奥氏体体积分数随回火温度升高亦降低,但500和600℃回火样品变形后奥氏体体积分数减少得较多,且以500℃回火样品变形时转变量最多;当回火温度达到700℃时,残余奥氏体体积分数达到最高至33%,但变形时残余奥氏体转变量最低。另外,T700样品拉伸塑性最高,而T500和T600样品塑性最低,但是这2个样品在拉伸变形中奥氏体转变分数最高,相反T700转变最少,这说明T500和T600样品中残余奥氏体在最小拉伸应变下依然转变最多,因此力学稳定性最差;而T700样品在最大拉伸应变下残余奥氏体转变最少,因此力学稳定性最好。相对应地,T500和T600样品变形前其C含量较低,残余奥氏体体积分数最高的T700样品奥氏体中C含量较高,也即低C含量降低了奥氏体的稳定性,导致T500和T600样品在变形过程中残余奥氏体转变分数更多。回火温度和变形对bcc相位错密度的影响如图2c所示,回火温度从300℃增加至700℃,bcc相中的位错密度始终在降低,这符合预期;而拉断后,T400和T500样品的位错密度与T300样品相差不大,因此T500样品的位错增量最大,加工硬化能力最好;而温度升高至600和700℃时,拉断样品的位错密度依然随温度逐渐下降。

图2

图2

不同温度回火试样变形前后残余奥氏体体积分数和奥氏体转化量、变形前奥氏体中C含量以及bcc相位错密度的变化和增量

Fig.2

Variation of volume fraction of retained austenite (RA), transformation ratio of RA (HR—hot rolling) (a), carbon content in austenite (Cγ ) before deformation (b), and dislocation density of bcc phase and its increment (c) in T300, T400, T500, T600, and T700 samples

2.2 显微组织演变

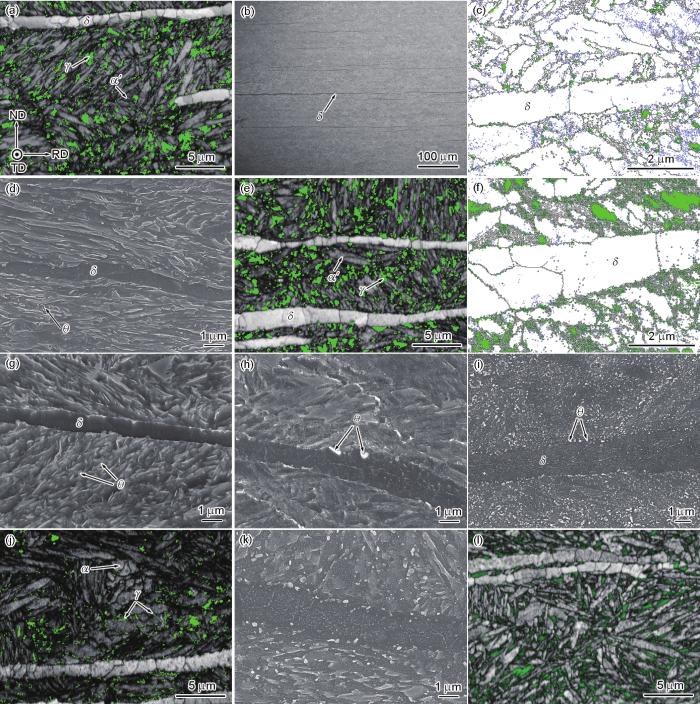

图3是热轧板、不同温度回火样品显微组织的EBSD和SEM像。热轧板的显微组织主要由马氏体基体、残余奥氏体和δ铁素体组成,细小的微米尺寸(约1 μm)的残余奥氏体晶粒镶嵌在马氏体基体中(图3a),δ铁素体沿轧向伸长,如图3b所示类似层状镶嵌在马氏体基体中,平均长度300 μm左右,在δ铁素体与马氏体相界面的垂直方向所测量出的δ铁素体片层的厚度为2~3 μm (图3b),更细致地观察发现δ铁素体被大角晶界分割成长3 μm左右的竹节状晶粒,其内还存在小角度亚晶界(< 15°) (图3c),推测是由于热轧过程中发生动态再结晶及再结晶后的变形和动态回复的缘故。当在300~600℃回火时,随着回火温度升高至300~600℃,渗碳体开始在回火马氏体基体和马氏体/δ铁素体相界面析出(图3d和g),并且随回火温度升高析出数量增加,而在相界面析出的渗碳体优先粗化(图3h和i)。当回火温度提升至600℃时,大量渗碳体析出导致Cγ 和奥氏体稳定性下降,部分大块残余奥氏体发生转变,留下的残余奥氏体更为细小(图3j)。同时由于部分马氏体发生再结晶和晶粒长大而形成大块状铁素体。相比之下,δ铁素体没有变化。回火温度为700℃时,回火马氏体中渗碳体数量明显降低,残余奥氏体体积分数显著提高,且残余奥氏体由单一等轴状转变为等轴和片层2种形貌,块状铁素体数量进一步增多,如图3k和l所示。

图3

图3

热轧和不同温度回火后试样显微组织的EBSD和SEM像

Fig.3

EBSD (a, c, e, f, j, l) and SEM (b, d, g, h, i, k) images of microstructure for specimens HR (a-c), T300 (d-f), T400 (g), T500 (h), T600 (i, j), and T700 (k, l) observed along the transverse direction (TD) (α', γ, α, δ, and θ represent martensite, austenite, ferrite, δ-ferrite, and cementite, respectively; the green and white colors in EBSD images represent austenite and martensite/ferrite, respectively; the blue and black lines represent low angle boundary (< 15°) and high angle boundary (> 15°), respectively; ND and RD are normal and rolling directions, respectively)

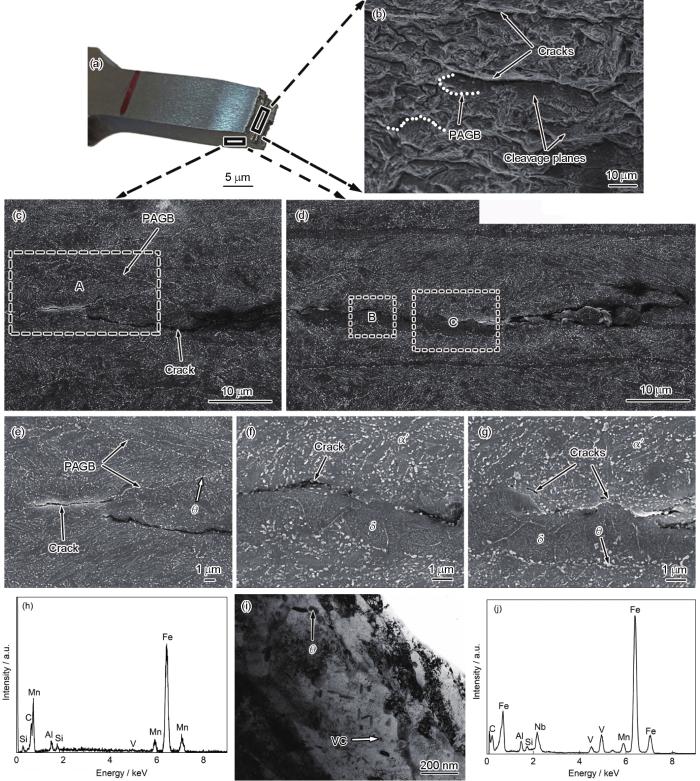

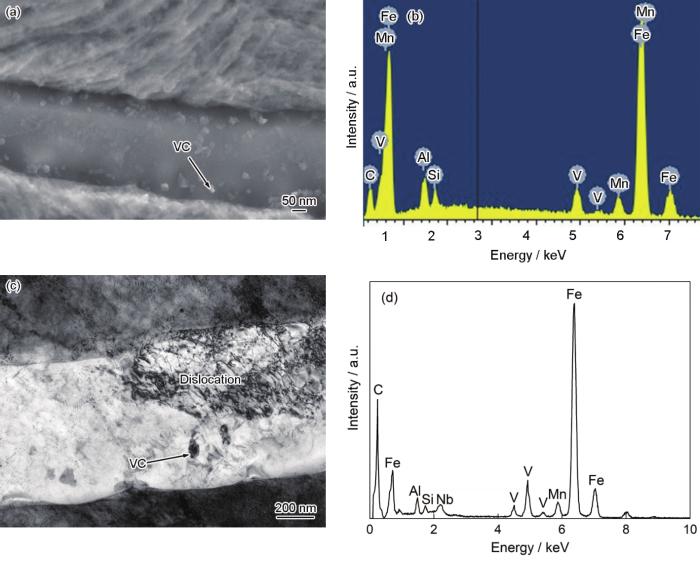

由于600℃回火样品强度、塑性均明显偏低,所以重点研究了600℃回火样品脆性来源。图4a为T600样品断后的宏观形貌,图4b~g是T600拉伸试样断口形貌及裂纹沿拉伸方向传播路径的SEM像。由图4b可以看出,样品断口形貌由大量解理面组成,韧窝数量少,断裂形式主要为沿晶断裂。通过观察裂纹沿拉伸方向的传播路径发现,裂纹主要沿原奥氏体晶界和马氏体/δ铁素体相界传播(图4c和d)。图4e~g分别为图4c和d中A、B和C区域的放大图。观察发现,裂纹扩展所经过的原奥氏体晶界和马氏体/δ铁素体相界上均存在大量较粗大的渗碳体颗粒,尺寸在200~500 nm之间。相比之下,回火马氏体各种亚结构(packet、block、lath)界面上析出的渗碳体更加弥散细小,尺寸在50~100 nm之间;且渗碳体中Mn元素富集程度高于钢中平均含量(图4h)。在回火马氏体板条内也析出更为细小的短棒状渗碳体和VC,VC尺寸在15~20 nm,如图4i和j所示。另外,回火马氏体板条界面和板条内存在大量位错,如图4i所示。

图4

图4

T600样品拉断后宏观形貌及其中裂纹扩展的SEM像和TEM像及EDS

(a) fractured specimen

(b) fracture SEM images after tensile test (PAGB—prior austenite grain boundary) (c, d) cracks propagation along the rolling direction (e-g) magnification views of areas marked by A, B, and C in Figs.4c and d, respectively (h) EDS on the cementite from the particle marked by white arrow in Fig.4e (i) TEM image exhibiting the distribution of cementite and VC inner martensite lath (j) EDS on the VC from the particle marked by white arrow in Fig.6i

Fig.4

Macrostructure of fractured specimen, SEM and TEM images of the fracture morphology and crack propagation, and corresponding EDS for T600 specimen

3 分析讨论

3.1 回火温度对屈服强度的影响

表2 本研究钢和文献[15,23]中研究钢的化学成分、δ相体积分数、平均晶粒尺寸、热轧温度和轧制压下率对比

Table 2

图5

图5

T300样品中VC在δ铁素体中分布的SEM像和TEM像及EDS

Fig.5

SEM (a) and TEM (c) images of VC distribution inner δ-ferrite of T300 specimen and the corresponding EDS on VC (b, d)

由

当回火温度由300℃提升至400℃时,马氏体中析出更多细小的渗碳体(图3d和g)。细小渗碳体的析出强化作用导致马氏体基体的强度提升,因此T400试样的屈服强度由1370 MPa提高到1560 MPa。随回火温度提升至500℃,虽然bcc相中位错密度继续下降,但是渗碳体继续大量析出,只有在相界和原奥氏体晶界处的部分渗碳体粗化,同时因为VC在600℃回火时已经在马氏体和δ铁素体大量析出(图4i),且一般VC在回火马氏体的析出温度在400~750℃之间,析出峰值温度在600~650℃区间[31~34],因此推测500℃回火时纳米尺度的VC粒子也开始析出,导致对位错的钉扎作用较400℃增强,因此导致屈服强度仅略微下降75 MPa。回火温度升高至600℃,渗碳体在相界、原奥氏体晶界处显著粗化,部分马氏体再结晶导致位错密度大幅降低,且马氏体中的C大量配分至奥氏体和渗碳体而部分转变成块状铁素体,导致在较低屈服强度就沿相界开裂且快速失效;回火温度至700℃时,已经处于两相区,此时渗碳体大量溶解且马氏体经逆相变转变为奥氏体和大量块状铁素体,导致位错密度显著降低和C大量配分至奥氏体,屈服强度继续显著下降。

3.2 T600样品产生回火脆性的原因

所有样品中T600样品的断后延伸率最低。由图4可知,其断口形貌主要由剪切面组成,包含很少的韧窝,断裂形式为沿晶断裂,表明试样的断裂属于脆性断裂。裂纹主要沿原奥氏体晶界和δ铁素体相界萌生并扩展。这是由于大量尺寸较大的渗碳体(200~500 nm)沿原奥氏体晶界和δ铁素体相界呈网状密集分布,弱化晶界结合力[35,36]。相比之下,在回火马氏体亚结构界面上分布的渗碳体尺寸在50~100 nm之间,且分布更加均匀。因此,原奥氏体界面和δ铁素体/马氏体相界面更易于裂纹的萌生。另外,大量渗碳体的析出降低了奥氏体的稳定性,冷却过程中可形成新鲜马氏体(图3j),其是断裂敏感性高的脆性相。另外,残余奥氏体由于稳定性较低,在第2阶段形变过程中快速转变成形变诱导相变马氏体,随残余奥氏体在变形过程中快速转变殆尽,在原奥氏体晶界和马氏体/δ铁素体相界等界面结合力差的位置发生了应力集中而萌生裂纹,然后经脆性马氏体相快速扩展,最终导致断裂。

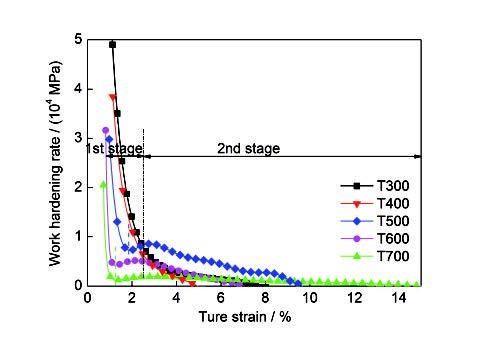

3.3 回火温度对加工硬化行为的影响

图6为不同温度回火样品的加工硬化率随真应变的变化曲线。随真应变增加T300和T400样品的加工硬化率一直在降低,且下降速率逐渐变慢;而T500、T600和T700样品加工硬化率先快速下降,再升高然后不断降低直至断裂。基于此,将各样品的加工硬化曲线分为2个阶段。第1阶段,所有样品的加工硬化率都随应变增加逐渐下降,且随回火温度升高也逐渐降低,推测是因为此阶段加工硬化主要由马氏体中位错增殖和交割导致[37],回火温度升高位错密度降低,所以加工硬化率减小。第2阶段,加工硬化率的变化可以分为2类。对于T300和T400样品,此阶段加工硬化率随真应变增加虽然下降但速率降低,推测是由于此阶段开始发生奥氏体向马氏体相变转变贡献了额外加工硬化。T300样品中奥氏体转变量超过T400样品(图2a),这是由于400℃回火时C向奥氏体的配分程度超过300℃,因此提高了奥氏体中的C含量和稳定性(图2b),导致变形时奥氏体转变更缓慢,因此加工硬化率降低。当回火温度升高至500℃时,大部分渗碳体依然弥散析出,但部分位于相界处的渗碳体开始粗化(图3h),残余奥氏体稳定性略有降低,导致变形过程中残余奥氏体转变最多,从而导致持续的加工硬化和较大的均匀延伸率;回火温度升高至600℃时,马氏体/δ铁素体相界和原奥氏体晶界渗碳体析出量显著增多且粗化(图3i),导致这些位置在更低屈服强度就开始萌生裂纹,且由于奥氏体中的C含量下降、稳定性继续降低甚至冷却后形成马氏体,虽然奥氏体转变可贡献加工硬化率,但裂纹经马氏体可快速扩展导致很快失效(图2a、2b和图6)。700℃回火时,加热过程中析出的渗碳体大部分在保温时溶解,溶解的C在高温下大量配分至奥氏体,导致残余奥氏体体积分数和稳定性均显著提高,结果变形过程只有约10%奥氏体发生相变(图2a)且转变缓慢,因此加工硬化率最低。

图6

图6

不同温度回火样品的加工硬化曲线

Fig.6

Strain-hardening curves of samples after tempering at different temperatures

4 结论

(1) 所开发的高铝中锰钢在400~500℃回火时,马氏体中位错密度虽略有下降,但细小渗碳体和VC纳米级粒子等析出强化增强,导致屈服强度最高;同时在该温度区间回火促进了C原子由马氏体向奥氏体配分,提高了奥氏体稳定性而贡献了相对持久的加工硬化,最终获得屈服强度1500 MPa左右、抗拉强度1800 MPa和断后延伸率14%的最佳综合力学性能。

(2) 高铝中锰钢在600℃回火时的断后延伸率最低,这是由于此时沿原奥氏体晶界和马氏体/δ铁素体相界析出大量粗大渗碳体而易于萌生裂纹。另外,大量渗碳体析出降低了奥氏体稳定性而在冷却时可转变为马氏体,而且变形时稳定性差的残余奥氏体会快速转变为马氏体。结果在原奥氏体晶界和马氏体/δ铁素体相界等界面结合力差的位置萌生的裂纹,经脆性马氏体相快速扩展导致断裂。

(3) 高铝中锰钢中长300 μm的δ铁素体片层经热轧过程动态再结晶细化为3 μm左右竹节状晶粒,其内部存在热轧过程中析出的VC和大量位错及亚晶界,导致δ铁素体显著强化;另外,由于δ铁素体体积分数较小,且呈孤岛状嵌在马氏体基体,导致该钢屈服强度主要由马氏体基体决定,因此远高于文献中其他Al含量类似的中锰钢。据此,本研究所采用的合金化策略、组织设计与制备工艺路线为开发含Al轻质高强钢提供了可行的技术路线。

参考文献

Austenite stability effects on tensile behavior of manganese-enriched-austenite transformation-induced plasticity steel

[J].

Enhancement of the mechanical properties of a Nb-microalloyed advanced high-strength steel treated by quenching-partitioning-tempering process

[J].

Deformation behavior of ferrite-austenite duplex lightweight Fe-Mn-Al-C steel

[J].

Mechanical properties and austenite stability in hot-rolled 0.2C-1.6/3.2Al-6Mn-Fe TRIP steel

[J].

Coupled strengthening in a medium manganese lightweight steel with an inhomogeneously grained structure of austenite

[J].

Influence of Nb and V on microstructure and mechanical properties of hot-rolled medium Mn steels

[J].

Impact toughness of medium-Mn transformation-induced plasticity-aided steels

[J].

Novel medium-Mn (austenite + martensite) duplex hot-rolled steel achieving 1.6 GPa strength with 20% ductility by Mn-segregation-induced TRIP mechanism

[J].

High dislocation density-induced large ductility in deformed and partitioned steels

[J].

Characterization of microstructure obtained by quenching and partitioning process in low alloy martensitic steel

[J].

Effect of deep cryogenic pretreatment on microstructure and mechanical properties of warm-deformed 7 Mn steel after intercritical annealing

[J].

Innovative processing of obtaining nanostructured bainite with high strength-high ductility combination in low-carbon-medium-Mn steel: Process-structure-property relationship

[J].

Comparison of dislocation densities of primary and secondary recrystallization grains of Si-Fe

[J].

The estimation of dislocation densities in metals from X-ray data

[J].

Revealing fracture mechanisms of medium manganese steels with and without delta-ferrite

[J].

Microstructure and mechanical properties of high strength and high toughness micro-laminated dual phase steels

[J].

Mechanical stabilisation of retained austenite in δ-TRIP steel

[J].

Influence of Al on the microstructural evolution and mechanical behavior of low-carbon, manganese transformation-induced-plasticity steel

[J].

Study on heat treatment process and strengthening-plasticizing mechanism of Fe-

Fe-

Tensile properties of medium Mn steel with a bimodal UFG α + γ and coarse δ-ferrite microstructure

[J].

Microstructural evolution and deformation behavior in the Fe-(6, 8.5) Mn-3Al-0.2C TRIP steels

[J].

Effect of two-step intercritical annealing on microstructure and mechanical properties of hot-rolled medium manganese TRIP steel containing δ-ferrite

[J].

The influence of silicon additions on the deformation behavior of austenite-ferrite duplex medium manganese steels

[J].

Six decades of the Hall-Petch effect—A survey of grain-size strengthening studies on pure metals

[J].

Processing of ultrafine ferrite steels

[J].

Constitutive modeling of the mechanical properties of V-added medium manganese TRIP steel

[J].

The respective hardening contributions of dislocations and twins to the flow stress of a twinning-induced plasticity steel

[J].

Improved mechanical properties of V-microalloyed dual phase steel by enhancing martensite deformability

[J].

Structure-properties relationship of ultra-fine grained V-microalloyed dual phase steels

[J].

Effects of transformation temperature on VC interphase precipitation and resultant hardness in low-carbon steels

[J].

Analysis of the formation conditions and characteristics of interphase and random vanadium precipitation in a low-carbon steel during isothermal heat treatment

[J].

Effect of composition and isothermal holding temperature on the precipitation hardening in vanadium-microalloyed steels

[J].

Tempering characteristics of a vanadium containing dual phase steel

[J].

Effects of Cr concentration on cementite coarsening in ultrahigh carbon steel

[J].

Coarsening of inter-and intra-granular proeutectoid cementite in an initially pearlitic 2C-4Cr ultrahigh carbon steel

[J].

Free dislocations and boundary dislocations in tempered martensite ferritic steels

[J].