高强钢经历焊接热循环过程后,将在粗晶热影响区(CGHAZ)产生脆性组织[11],造成粗晶脆化现象,导致其冲击韧性恶化[12]。为改善高强钢CGHAZ的冲击韧性,其微观组织与冲击韧性之间的关系得到了广泛的关注与研究[13~19]。CGHAZ中的微观组织通常包括板条贝氏体(LB)[20]和粒状贝氏体(GB)[21]。对于LB而言,原奥氏体晶粒(PAG)可由一个或多个贝氏体块(packet)组成[22,23],而一个packet又可以重新划分为多个贝氏体束(block)[24]。目前关于PAG、packet和block等微结构对冲击韧性的影响尚无定论。有研究发现,微裂纹穿过PAG边界,发生拐折后继续扩展[25],在packet边界处停止扩展[26],贝氏体packet可以作为有效控制微裂纹扩展的结构单元[27];而Zhang等[28]认为贝氏体block是控制CGHAZ冲击韧性的微结构单元。因此,贝氏体微结构与冲击性能之间的调控关系及其内在机理仍存在争议。

本工作采用Gleeble 3500热模拟试验机模拟了Q500qE钢在不同焊接热输入下CGHAZ的焊接热循环过程,借助光学显微镜(OM)、扫描电镜(SEM)和电子背散射衍射(EBSD)等手段研究焊接热输入、微观组织与冲击韧性之间的关系及内在机理,分析Q500qE钢中控制CGHAZ冲击韧性的最有效贝氏体微结构单元。

1 实验方法

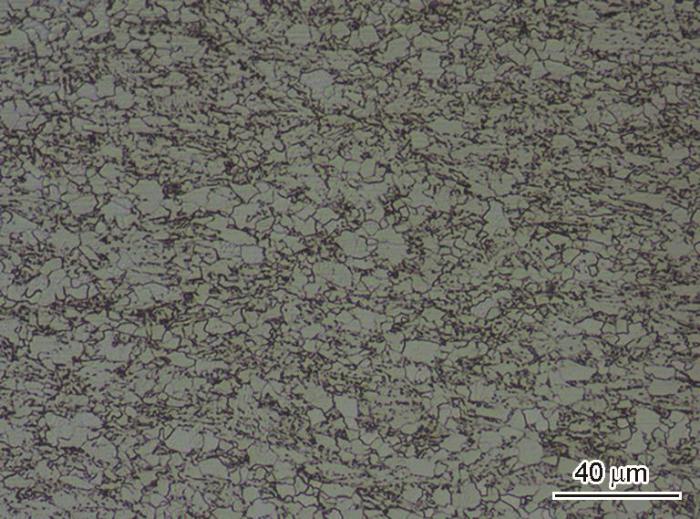

实验材料选用Q500qE钢板,板厚20 mm,其化学成分(质量分数,%)为:C 0.06,Si 0.20,Mn 1.55,P 0.006,S 0.001,Cr 0.30,Ni 0.19,Cu 0.22,Mo 0.177,Ti 0.010,Nb 0.038,Fe余量。在钢的粗轧阶段,开轧温度为1150℃,终轧温度为1080℃;精轧阶段,开轧温度为900℃,终轧温度为820℃;开冷温度为740℃,返红温度为580℃。从轧态钢板上取样,采用Axion-200mat OM进行组织观察,其原始组织为GB和铁素体(F),如图1所示。

图1

参照GB/T 714-2015《桥梁用结构钢》,从Q500qE钢板上沿平行于轧制方向(纵向)取样,加工成直径6 mm、长80 mm的棒状试样和10.5 mm × 10.5 mm × 80 mm的立方体试样若干,分别用于微观组织和断裂行为表征。采用Gleeble-3500热模拟试验机模拟Q500qE钢气体保护焊的CGHAZ焊接热循环过程,其热输入(Ej)分别为15、20、25以及30 kJ/cm。焊接热循环曲线采用HAZ软件包Rykalin-3D传热模型生成,加热速率为100℃/s,试样加热到1350℃保温1 s,使其微观组织完全奥氏体化,而后冷却到200℃,相变完全结束,如图2所示。

图2

图2

不同热输入下粗晶热影响区(CGHAZ)的焊接热循环曲线

Fig.2

Welding thermal cycles of CGHAZs with different heat inputs (CGHAZ—coarse grained heat affected zone)

将焊接热模拟后的棒状试样沿热电偶所在截面切开,经磨制、机械抛光和4% (体积分数)硝酸酒精溶液腐蚀后,在Axion-200mat OM和S-3400N SEM下观察CGHAZ的微观组织。借助Image Pro Plus软件,随机统计20个SEM视场下至少50个PAG的等效圆直径,取其直径的平均值作为PAG的平均尺寸(Dγ );统计20个SEM视场下至少50个贝氏体packet的平均长度(L1)与宽度(L2),packet的平均尺寸(DP)为L = (L1·L2)1/2的算术平均值。然后,使用10%HClO4 + 90%CH3OH (体积分数)溶液对试样进行电解抛光,利用S-3400N SEM搭载的EBSD组件定量表征CGHAZ中板条贝氏体的block宽度,借助Image Pro Plus软件,采用线截距法统计5个EBSD图中至少50个贝氏体block的宽度,求其宽度的算术平均值作为block的平均宽度(WB)。

将经焊接热模拟后的立方体试样加工成标准Charpy V型缺口冲击试样,尺寸为10 mm × 10 mm × 55 mm,V型缺口加工在热电偶所在截面上,在JB-300B型半自动冲击试验机上测试不同热输入下CGHAZ的冲击功KV2 (-40℃)。并且,利用S-3400N SEM观察不同热输入下CGHAZ的冲击断口形貌和二次裂纹形貌,分析微观组织对Q500qE钢冲击韧性的影响规律及其作用机理。其中,解理面尺寸(Df)通过Image Pro Plus软件随机统计每个CGHAZ样品在20个SEM视场下至少50个解理面的等效圆直径,求其等效圆直径的算术平均值获得。

2 实验结果

2.1 CGHAZ的微观组织

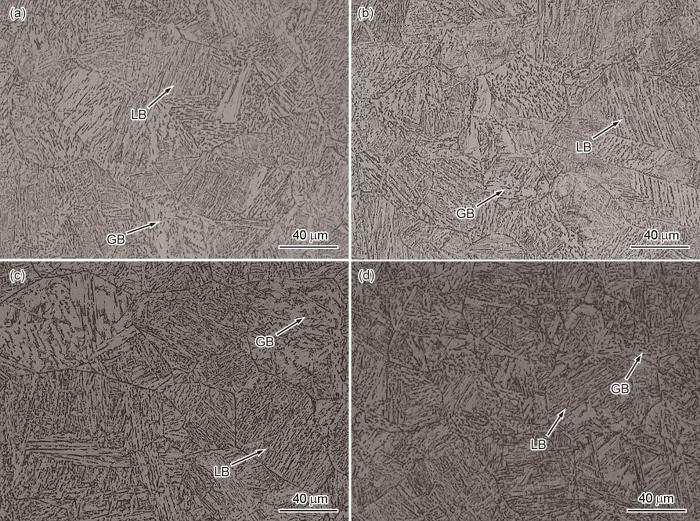

Q500qE钢不同热输入下CGHAZ显微组织的OM像如图3所示。各热输入下的微观组织主要是LB和GB。当焊接热输入为30 kJ/cm时,CGHAZ组织主要由LB和少量GB构成;随着焊接热输入的降低,LB增多,GB减少,组织逐渐细化。

图3

图3

不同热输入下CGHAZ显微组织的OM像

Fig.3

OM images of CGHAZs with different heat inputs (LB—lath-like bainite, GB—granular-like bainite)

(a) 15 kJ/cm (b) 20 kJ/cm (c) 25 kJ/cm (d) 30 kJ/cm

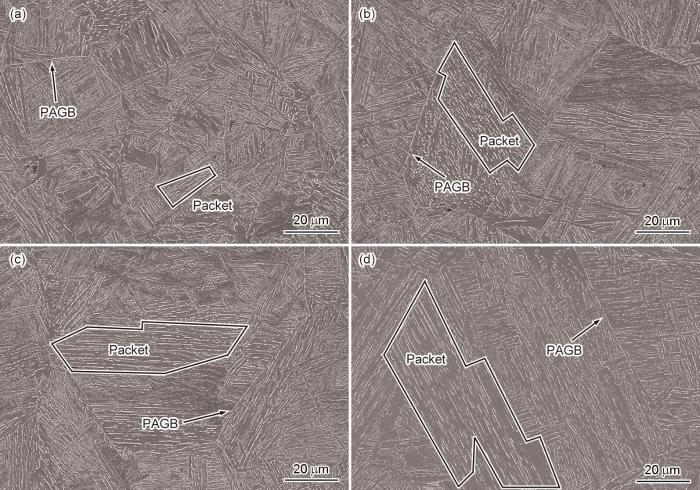

图4

图4

不同热输入下CGHAZ的典型SEM像

Fig.4

Typical SEM images of CGHAZs with different heat inputs (PAGB—prior austenite grain boundary)

(a) 15 kJ/cm (b) 20 kJ/cm (c) 25 kJ/cm (d) 30 kJ/cm

表1 不同热输入下CGHAZ的微结构尺寸测量结果和解理面尺寸统计

Table 1

| Ej / (kJ·cm-1) | Microstructure | Dγ / μm | DP / μm | WB / μm | Df / μm |

|---|---|---|---|---|---|

| 15 | 92%LB + 8%GB | 41.2 ± 4 | 18.9 ± 2 | 4.0 ± 0.5 | 15 ± 2 |

| 20 | 84%LB + 16%GB | 68.7 ± 5 | 48.2 ± 5 | 4.5 ± 0.5 | 28 ± 2 |

| 25 | 78%LB + 22%GB | 81.7 ± 8 | 64.3 ± 6 | 5.2 ± 0.6 | 32 ± 3 |

| 30 | 71%LB + 29%GB | 99.3 ± 9 | 78.8 ± 8 | 5.6 ± 0.7 | 37 ± 3 |

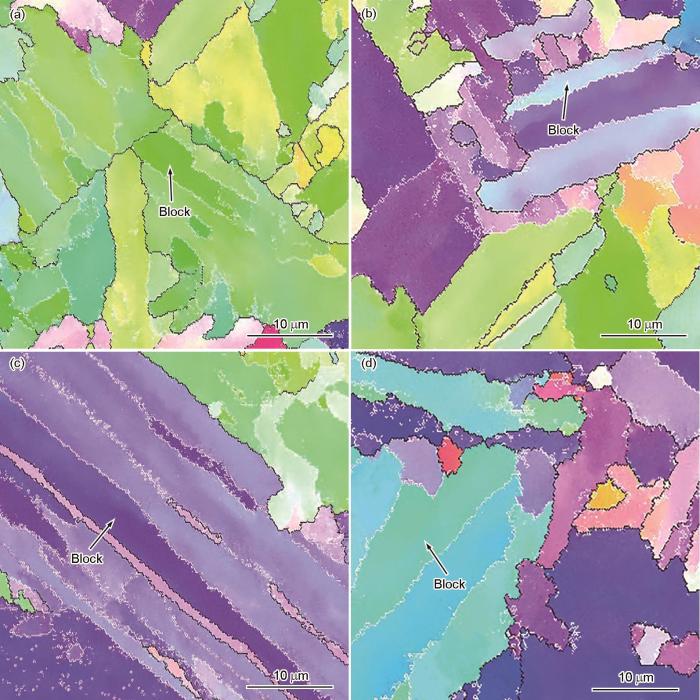

图5

图5

不同热输入下CGHAZ的EBSD像

Fig.5

EBSD images of CGHAZs with different heat inputs

(a) 15 kJ/cm (b) 20 kJ/cm (c) 25 kJ/cm (d) 30 kJ/cm

2.2 CGHAZ的冲击性能

不同热输入下CGHAZ的-40℃冲击功如图6所示。当焊接热输入在15~30 kJ/cm范围内,CGHAZ的KV2随热输入的降低而升高。当热输入为30 kJ/cm时,KV2 = 52 J,低温韧性较差;随着焊接热输入的降低,冲击功在20 kJ/cm时缓慢升至74 J;当热输入降低到15 kJ/cm,冲击功显著升高到153 J,低温韧性明显改善。

图6

图6

不同热输入下CGHAZ的Charpy冲击功

Fig.6

Charpy impact energies at -40oC for CGHAZs with different heat inputs

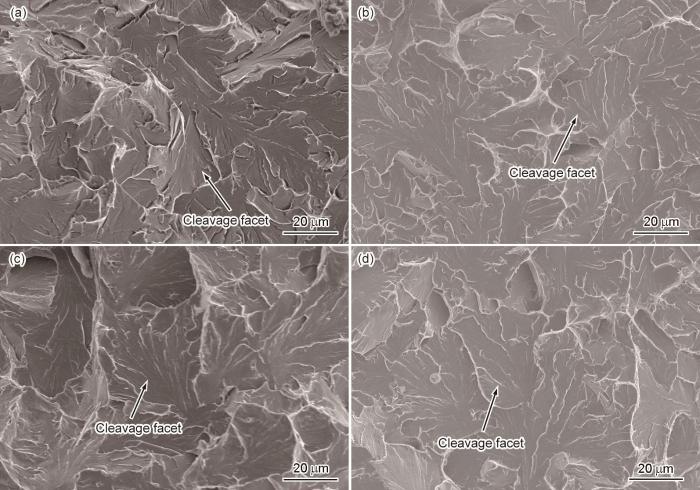

图7

图7

不同热输入下CGHAZ的冲击断口形貌

Fig.7

Impact fracture morphologies of CGHAZs with different heat inputs

(a) 15 kJ/cm (b) 20 kJ/cm (c) 25 kJ/cm (d) 30 kJ/cm

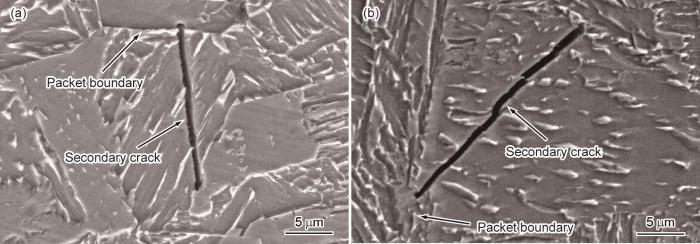

将典型热输入为15和25 kJ/cm冲击断裂的试样沿垂直于断裂表面的平面中心取样,通过SEM观察典型热输入下CGHAZ的二次裂纹形貌,如图8所示。2种热输入下CGHAZ的二次裂纹都在一个贝氏体packet中沿直线传播,笔直穿过贝氏体block,在贝氏体packet边界处止裂。由此可见,贝氏体packet能够阻碍裂纹扩展,而block不能阻碍裂纹的扩展。此外,随着焊接热输入的降低,二次裂纹扩展的单位距离变短,表明微裂纹扩展的阻力明显增大。

图8

图8

典型热输入下CGHAZ的二次裂纹形貌

Fig.8

Secondary crack morphologies of CGHAZs with typical heat inputs of 15 kJ/cm (a) and 25 kJ/cm (b)

3 分析讨论

3.1 热输入对CGHAZ微观组织的影响

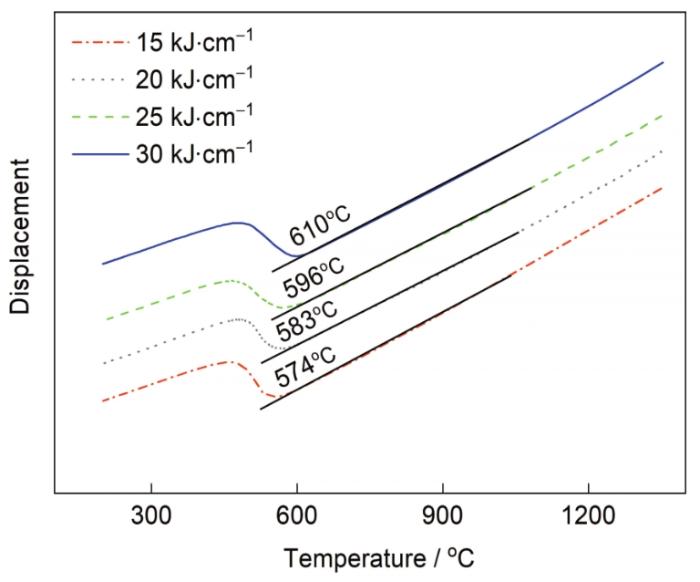

图9为不同热输入下焊接热循环中冷却过程的热膨胀曲线,采用切线法标示出不同热输入下冷却过程中奥氏体向铁素体转变开始温度(Ar3)。可以看出,随着热输入的降低,Ar3逐渐降低。

图9

图9

不同热输入下CGHAZ的热膨胀曲线以及对应的奥氏体向铁素体转变开始温度

Fig.9

Expansion curves and Ar3 of CGHAZs with different heat inputs (Ar3—the starting temperature for γ→α transformation)

3.2 晶粒尺寸对CGHAZ冲击行为的影响

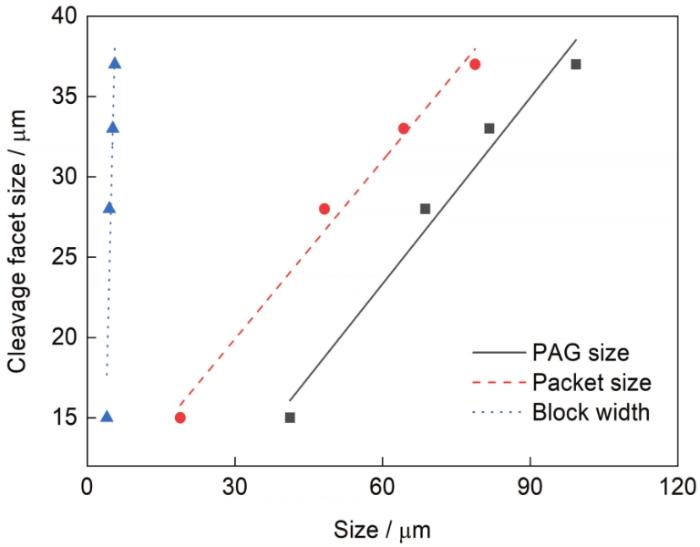

由于不同热输入下冲击断口表面都表现出明显的解理断裂特征,所以将CGHAZ试样断口的Df与Dγ 、DP、WB进行拟合比较,如图10所示,其对应的拟合方程如式(

图10

图10

解理面尺寸与PAG尺寸、贝氏体packet尺寸和block宽度的拟合关系

Fig.10

Cleavage facet size as functions of PAG size, bainitic packet size, and bainitic block width

拟合方程(1)~(3)的线性相关系数分别为0.96、0.99和0.87,可见Dγ 和DP与Df之间的相关性明显优于WB,表明PAG和packet是控制CGHAZ冲击韧性的有效微结构单元。由图8可知,当热输入为15和25 kJ/cm时,CGHAZ的二次裂纹都在一个贝氏体packet中直线传播,并在该packet边界处终止,再结合其与Df良好的线性关系,相较于PAG,贝氏体packet应该是最有效控制CGHAZ冲击韧性的微结构单元。

4 结论

(1) Q500qE钢粗晶热影响区的微观组织主要是板条贝氏体和粒状贝氏体;随着焊接热输入的降低,板条贝氏体增多,粒状贝氏体减少,Ar3逐渐降低,原奥氏体晶粒、贝氏体packet和block微结构的平均尺寸减小。

(2) 随着焊接热输入的降低,粗晶热影响区的冲击功KV2 (-40℃)显著提高;不同热输入的冲击断口都呈现出明显的解理断裂特征,其解理面尺寸随着热输入的降低而减小。

(3) 对于Q500qE钢而言,贝氏体packet是控制粗晶热影响区冲击韧性的最有效微观结构单元,packet边界能够有效阻止二次裂纹的扩展。

参考文献

Review on China's bridge engineering research: 2021

[J].

中国桥梁工程学术研究综述·2021

[J].为了促进中国桥梁工程学科的发展,系统梳理了近年来国内外桥梁工程领域(包括结构设计、建造技术、运维保障、防灾减灾等)的学术研究现状、热点前沿、存在问题、具体对策及发展前景。首先总结了桥梁工程学科在新材料与结构体系、工业化与智能建造、抗灾变能力、智能化与信息化等方面取得的最新进展;然后分别对上述桥梁工程领域各方面的内容进行了系统梳理:桥梁结构设计方面重点探讨了钢桥及组合结构桥梁、高性能材料与结构、深水桥梁基础的研究现状;桥梁建造新技术方面综述了钢结构桥梁施工新技术、预制装配技术以及桥梁快速建造技术;桥梁运维方面总结了桥梁检测、监测与评估加固的最新研究;桥梁防灾减灾方面突出了抗震减震、抗风、抗火、抗撞和抗水的研究新进展;同时对桥梁工程领域各方向面临的关键问题、主要挑战及未来发展趋势进行了展望,以期对桥梁工程学科的学术研究和工程实践提供新的视角和基础资料。(北京工业大学韩强老师提供初稿)

Study on controlling of mechanical and corrostion-resistance proeperties OFQ500EHPS steel for bridge

[D].

Q500EHPS桥梁钢力学性能和耐蚀性能的调控研究

[D].

Development status and prospects of welding technology for bridge steel structures in my country

[J].

我国桥梁钢结构焊接技术发展现状及展望

[J].

Development of high performance steel used for bridge

[J].

高性能桥梁用钢的发展

[J].

Study on applicability of Q500qE steel for Hutong Yangtze River Bridge

[J].

沪通长江大桥Q500qE钢的适用性研究

[J].

Experimental study of welding technique for Q500qE steel used to Tianshenggang Navigational Channel Bridge of Hutong Changjiang River Bridge

[J].

沪通长江大桥天生港专用航道桥Q500qE钢焊接工艺试验研究

[J].

Research and development of high-performance weather-resistant wide and heavy steel plate Q50QqENH with rare earth for bridge

[J].

稀土高性能耐候桥梁宽厚钢板Q500qENH研发

[J].

Study on weldability experimental for high performance Q500qE steel

[J].

高性能Q500qE钢焊接性试验研究

[J].

Development of submerged arc welding wire for new high performances bridge steel Q500qE

[J].

新型高性能桥梁钢Q500qE用埋弧焊丝的研制

[J].

The development of YSF105Q agglomerated flux for submerged welding of Q500qE high strength bridge steel

[J].

Q500qE高强度桥梁钢埋弧焊用YSF105Q烧结焊剂的研制

[J].

Effect of weld thermal cycle on microstructure and fracture toughness of simulated heat-affected zone for a 800 MPa grade high strength low alloy steel

[J].

Effect of welding heat input on simulated HAZ microstructure and toughness of a V-N microalloyed steel

[J].

Influence of necklace-type M-A constituent on impact toughness and fracture mechanism in the heat affected zone of X100 pipeline steel

[J].

X100管线钢焊接热影响区中链状M-A组元对冲击韧性和断裂机制的影响

[J].利用示波冲击试验机对X100管线钢直缝埋弧焊实际焊接接头热影响区不同位置处的冲击韧性进行了测试. 结果表明, 当缺口穿过不完全重结晶粗晶区(ICCGHAZ)时冲击韧性很低(平均为51 J), 而当缺口不穿过ICCGHAZ时冲击韧性则高达183 J. 还利用Gleeble热模拟试验机对热影响区不同区域的组织进行了模拟, 得到均一组织的粗晶区(CGHAZ), 细晶区(FGHAZ)和不完全重结晶区(ICHAZ)的冲击韧性较高, 平均分别为244, 164和196 J, 而ICCGHAZ的冲击韧性只有32 J. 因此, ICCGHAZ是导致冲击韧性骤降的主要原因. ICCGHAZ由粗大的原奥氏体晶粒及沿晶界呈链状分布的马氏体-奥氏体(M-A)组元构成, 晶粒内部为粗大的粒状贝氏体或者上贝氏体. 断口分析表明, ICCGHAZ是整个断面的起裂源, 且裂纹扩展过程中M-A组元易成为解理刻面的起裂源. 示波冲击结果显示, ICCGHAZ的存在使得起裂功显著降低. 对断口下方二次裂纹的研究表明, CGHAZ处的断裂机制为形核控制型, 而在ICCGHAZ处则为扩展控制型. 因此, ICCGHAZ中链状M-A组元的存在是导致热影响区韧性恶化的根本原因, 并且使得断裂行为和断裂机制发生显著变化.

Research status of weldability of advanced steel

[J].New generation advanced steel has been studied with the increased requirement for high property steel by various engineering fields since the 21st century. Correspondingly, their welding materials and welding techniques are crucial for the application of the steels. In this paper, the research status and the development of the welding processes, microstructure and properties of welded joint of the advanced steel, including ultra-fine grained steel, low carbon bainitic steel, high nitrogen austenite stainless steel and high strength automotive steel are introduced. The microstructure evolution of welded joints, the microstructure and properties of welded joints, the formation of inclusions and martenite-austenite (M-A) components and its influence on properties, and the influence of alloying elements and heat input on weld properties are reviewed. Study results show that heat affected zone (HAZ) is the main area which affects the performance of welded joints, and proper welding materials and processes are required to achieve a matching welded joint. The strengthening and toughening mechanism of weld joint, mechanism of fatigue crack growth, effect of welding thermal process on microstructure and properties of steel, are also reviewed. At last, the research prospect on welding materials and welding techiques is presented.

先进钢铁材料焊接性研究进展

[J].进入21世纪以来,随着各工程领域对高性能钢铁材料需求的多样性和要求的提高,新一代先进钢铁材料研发随之展开。其相应的焊接材料和焊接技术成为材料应用的关键。本文重点介绍了超细晶粒钢、低碳贝氏体钢、高氮奥氏体不锈钢、高强汽车钢等先进钢铁材料的焊接工艺与接头组织性能的研究现状与进展。就焊接接头的微观组织演化、焊接接头性能、夹杂物和马氏体-奥氏体(M-A)组元的形成与影响、合金元素和热输入对焊缝组织性能的影响等进行了详细评述。研究表明,焊接热影响区是影响焊接接头性能的主要区域,同时要采用适当的焊材及工艺才能获得性能匹配的焊缝。并对焊接接头的强韧化机理、疲劳裂纹扩展机理、焊接热过程对钢材组织和性能的影响等方面的研究进行了评述。最后,对焊接材料和工艺的未来研究方向进行了展望。

Microstructural characteristics and toughness of the simulated coarse grained heat affected zone of high strength low carbon bainitic steel

[J].

Effect of welding heat input on microstructures and toughness in simulated CGHAZ of V-N high strength steel

[J].

Effect of simulated cooling time on microstructure and toughness of CGHAZ in novel high-strength low-carbon construction steel

[J].

Effect of welding heat input on grain boundary evolution and toughness properties in CGHAZ of X90 pipeline steel

[J].

Investigation on the crystallography of the transformation products of reverted austenite in intercritically reheated coarse grained heat affected zone

[J].

Phase transformation and joint properties of bridge steel plate Q500qE welding coarse grain zone

[J].

桥梁钢板Q500qE焊接粗晶区相变及接头性能

[J].

Austenite to bainite phase transformation in the heat-affected zone of a high strength low alloy steel

[J].

Effect of austenite grain size on the morphology and crystallography of lath martensite in low carbon steels

[J].

Influence of refined hierarchical martensitic microstructures on yield strength and impact toughness of ultra-high strength stainless steel

[J].The hierarchical martensitic features in ultra-high strength stainless steel (UHSSS), including the prior austenite grains, martensite packets, blocks and laths with the descending size, were refined to various extents by employing different thermomechanical processes and then carefully characterized. Their relation to yield strength and impact toughness was analyzed. We conclude that the refinement of martensitic structures could lead to the significant increase of yield strength, which follows the Hall-Petch relation with the effect grain size defined by high angle boundaries (HABs). Impact toughness of UHSSS depends on the frequency and capability for retained austenite (RA) grains at both HABs and martensite lath boundaries to trap the propagating cracks via strain-induced transformation, in which the film-like RA grains at lath boundaries appear to make the greater contribution.

The morphology and crystallography of lath martensite in Fe-C alloys

[J].

Effect of welding heat input on microstructure and impact toughness in CGHAZ of X100Q steel

[J].

Electron backscattering diffraction analysis of secondary cleavage cracks in a reactor pressure vessel steel

[J].

Investigation on the microstructure and toughness of coarse grained heat affected zone in X-100 multi-phase pipeline steel with high Nb content

[J].

Effect of martensitic morphology on mechanical properties of an as-quenched and tempered 25CrMo48V steel

[J].

The influence of lath boundaries and carbide distribution on the yield strength of 0.4%C tempered martensitic steels

[J].

Visualization and analysis of variant grouping in continuously cooled low-carbon steel welds

[J].

Effect of austenite microstructure and cooling rate on transformation characteristics in a low carbon Nb-V microalloyed steel

[J].