多孔金属材料由金属基体和孔共同组成,与块体金属材料相比,多孔金属材料兼具结构材料和功能材料的双重属性,具有高孔隙率、高电导率、低密度、高比强度、高吸能性等优点,使得多孔金属在现代生活中有着广泛的应用[1,2]。例如在催化领域,20世纪20年代Raney就已通过腐蚀Ni-Al合金获得了具有高催化活性的镍基催化剂,俗称雷尼镍。而后雷尼镍及雷尼铜等多孔金属材料被应用在工业加氢反应及水汽转换反应中[3]。随着人们对多孔金属材料认识不断深入,其制备工艺在不断改良,应用方向也在不断拓展,目前多孔金属材料在催化[4~7]、传感[8]、光学转换[9]、微流体原件[10]、生物植入体[11]以及电极材料[12]等领域均有广泛的应用。

多孔金属按孔洞连通性可分为闭孔金属和开孔金属2类。其中开孔金属具有与外界环境连通的多孔结构,在具有多孔金属诸多特性的基础上还具有良好的物质传输能力[13]。在电催化领域,相互连通的金属框架为电子传输提供了稳定的高速导电网络[14],其大比表面积及多孔结构为电催化反应提供了丰富的电解液/电极界面及快速的物质传输通道[15],此外,部分多孔金属表面存在着高曲率晶面及丰富的缺陷位点,能够进一步增强多孔金属的电催化活性[16]。在生物医用领域,传统医用金属材料虽具有良好的生物相容性及耐蚀性能,但由于其弹性模量等性能与人体硬组织的力学性能不匹配,容易发生“应力屏蔽”效应、骨质疏松等不良现象[17]。开孔多孔金属能够有效降低植入体的弹性模量,减少应力屏蔽效应[18],同时其大的比表面积能够提供充足的组织生长环境,促进骨与血管长入孔隙,提高假体的骨整合能力[19];此外,贯通的多孔结构能够使体液和药物在孔洞中传输,有益于新骨组织的生长[20]。因此,在电催化及生物医用领域,开发具有高性能的开孔多孔金属材料在基础研究及实际应用中具有深刻的研究意义。本文对近年来面向电催化及生物医用领域的开孔多孔金属材料的研究进展进行了系统总结,为其应用提供科学和技术支撑。

1 面向电催化及生物医用领域的开孔多孔金属材料的制备方法

开孔多孔金属材料的制备方法种类繁多,结合金属自身特性,通过对制备方法的合理选择及制备参数的调控,可以对多孔金属的形貌、孔径、比表面积及力学性能等材料性质进行调控,从而满足不同应用的需求。目前主要的制备方法包括烧结法、脱合金法、模板法及高能束快速成型法等。

1.1 烧结法

1.2 脱合金法

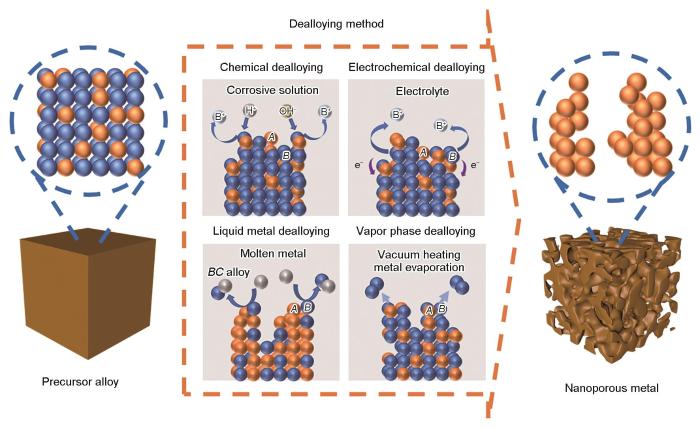

如图1所示,脱合金法是以合金作为前驱体,在脱合金过程中脱去活泼组元,剩余惰性组元形成三维多孔结构的制备方法。目前二元合金是最为常见的脱合金前驱体材料,通过对其中活泼元素的腐蚀,可以获得如多孔Au、多孔Ag、多孔Cu等纯相多孔金属材料[29]。此外,通过脱合金法制备纳米多孔结构只需要体系满足适当的分离极限以及临界电位,即脱合金体系中稳定元素低于特定含量并且腐蚀电位超过临界值时就可以发生脱合金反应[30]。因此,脱合金反应具有非常灵活的前驱体成分及腐蚀条件选择范围,能够实现多组元合金及化合物的有效制备[31,32]。此外,通过对前驱体成分、腐蚀条件的调节及后续处理等工艺,能够对多孔金属的形貌、尺寸、成分等进行调控,最终获得性质迥异的目标多孔金属材料[33,34]。根据脱合金反应条件,可将脱合金法分为化学脱合金法、电化学脱合金法、液相金属脱合金法及气相脱合金法等。

图1

图1

脱合金法制备多孔金属材料示意图

Fig.1

Schematic of the preparation of porous metal by dealloying method

1.2.1 化学脱合金法

化学脱合金法通常使用酸性或碱性溶液对前驱体合金进行化学腐蚀,是最为常见的脱合金方法。在化学脱合金过程中,合金中的活泼组元在腐蚀过程中逐原子层溶解,惰性原子通过表面扩散与自组装形成多孔结构。Ding等[35]使用AuAg合金制备了纳米多孔金箔,随着反应时间的增加,多孔Au的孔壁厚度从最初的5 nm增加到了50 nm。在此基础上,Kertis等[36]通过热处理的方法将多孔Au的尺寸进一步扩展到微米级别。铂基材料同样在脱合金法中具有广泛的应用,Pt作为扩散速率较低的元素,不仅能够在制备过程中减小多孔结构的尺寸,而且能够避免在多孔材料使用过程中的二次粗化,增加多孔结构在腐蚀性条件下的稳定性[36~38]。另一方面,表面活性剂的加入能够对脱合金过程中的原子扩散产生影响,Wang等[39]在脱合金过程中加入焦棓酸及柠檬酸钠作为表面活性剂,由于焦棓酸及柠檬酸钠对Au的{111}及{100}晶面具有选择性吸附的作用,使得Au在自组装过程中优先生成特定的晶面,并最终获得了具有富{111}及{100}晶面的纳米多孔Au材料。

1.2.2 电化学脱合金法

电化学脱合金是由电化学驱动的腐蚀过程。由于合金各组元间存在电极电位差,在外加电场的作用下,活泼组元发生电化学氧化还原反应溶解进电解液中,惰性组元得以保留并最终形成多孔结构[36]。Erlebacher等[40]通过研究Au-Ag合金体系建立了动力学Monte Carlo模型来阐述电化学脱合金反应机制。在活泼原子从前驱体合金表面溶解时,惰性组元在固液界面处发生扩散并形成团簇,并使得更多的活泼原子得以与电解液接触,进一步发生腐蚀反应而形成了凹坑及孔洞,从而形成孔壁-孔道双连续的多孔纳米结构。与化学去合金反应相比,电化学去合金反应通过对电解液成分、腐蚀时间及腐蚀电位等参数的控制,能够更有效地调控多孔结构的形貌及成分[41]。Wang等[42]通过电化学去合金的方法制备了纳米多孔Au电催化剂,发现在加载循环电位信号的过程中,纳米多孔Au的表面会发生重构,使其暴露更多具有高活性的高指数晶面。除此之外,电化学去合金法还适用于活泼金属多孔材料的制备。Fu等[43]使用Mg-Li前驱体合金在隔绝空气的环境中制备了多孔Mg材料,同时使用金属Li作为腐蚀对电极,能够在电化学脱合金过程中对Li进行回收。

1.2.3 液相金属脱合金法

从广义上来说,脱合金反应可以在任何液相介质中进行,而不仅仅局限于常规化学及电化学溶解过程。与常规化学及电化学脱合金法不同,液相金属脱合金法不使用水溶液作为腐蚀介质,而是在熔融金属或熔融盐介质中进行脱合金反应[49]。这种脱合金过程中前驱体各组元不发生氧化还原反应,而是利用各组元在熔融介质中的溶解度不同来实现部分组元的溶解。与传统脱合金法相比,液相金属脱合金法不使用腐蚀性溶液,污染较少,且活泼组元在腐蚀后能够保留在熔融介质中,更利于回收,同时由于反应温度较高,反应速率更快。

Harrison和Wagner[50]早在1959年就发明了液相金属脱合金技术。随着Wada等[51]通过此种方法制备了纳米多孔Ti之后液相金属脱合金法逐渐进入人们的视野。由于较低的表面迁移能力及易于氧化的特质,多孔Ti、Ta等材料一般无法使用传统脱合金方法进行制备,但液相金属脱合金法则能够有效避免这些问题[52,53]。Kim等[54]使用Nb25Ni75合金作为前驱体,熔融金属Mg作为腐蚀介质,制备了多孔铌基材料,发现在熔融介质中的脱合金行为与水相中脱合金反应类似,通过对脱合金动力学参数的调控,可以对多孔材料的比表面积等参数进行调节。但液相金属脱合金法也具有自身的局限性,首先液相金属脱合金需要在相对高温的条件下才能保证腐蚀介质保持液相,此外需要前驱体合金中活泼组元与惰性组元在熔融介质中的溶解度差异较大[55]。此外,由于液相金属脱合金需要在较高温度下进行,惰性组元扩散较快,容易发生粗化现象。针对这一问题,Joo等[31]利用高熵合金稳定性高的特性来改良,通过液相金属脱合金法制备的高熵多孔材料孔径能够保持在10 nm左右。

1.2.4 气相脱合金法

气相脱合金法与液相金属脱合金法类似,都是物理脱合金反应。气相脱合金法利用前驱体合金中各组元在相同温度和真空度条件下蒸气压的差异,使得蒸气压高的金属以气态的形式挥发,惰性组元保留后形成多孔结构[56]。Lu等[57]制备了Co5Zn21前驱体合金,在约100 Pa氢氩混合气条件下前驱体中的Zn发生挥发,最终获得纳米多孔Co。由于Zn具有易挥发的特性,以及与多种金属元素良好的相容性,他们也利用这一工艺制备了多种锌基合金前驱体,并进一步制备了纳米多孔Ti、Ni等材料。这种脱合金方式不受合金组元化学性质的限制,是一种普适性的多孔材料制备方法。但目前此类方法仅适用于锌基前驱体合金,并且对制备真空度要求较高,这些缺点限制了气相脱合金法的规模化应用。

1.3 模板法

模板法是将具有特定孔结构的物质作为模板,通过物理或化学的方法将相关材料沉积到模板孔道中后移去模板,获得多孔材料的方法。其主要特点是模板法中的沉积反应是在有效控制的区域内进行的,使其具有良好的材料结构可控性;同时其能够实现纳米材料合成与组装一体化,解决纳米材料的分散稳定性问题;此外模板法合成过程相对简单,适合批量生产。

在模板法中使用的沉积方式较多,如气相沉积、化学/电化学沉积、溶胶凝胶法等均可使用。模板材料需满足3个条件:首先,模板材料需要形成通孔,以便于沉积;其次,模板材料自身要有足够的稳定性,以保证在沉积过程中结构不塌陷;第三,模板材料要易于去除,保证目标多孔材料的顺利制备。根据模板材料的不同,通常将模板法分为软模板法及硬模板法2类,其区别在于软模板提供的是处于动态平衡的空腔,物质可以透过腔壁扩散进出,而硬模板提供的是静态的孔道,物质只能从开口处进入孔道内部[58]。

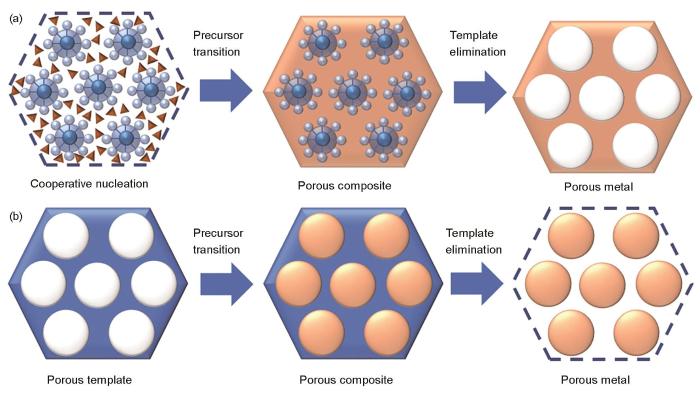

1.3.1 软模板法

软模板法通常使用共聚物分子等表面活性剂作为模板来制备多孔材料。其制备流程如图2a所示,当前驱体溶液与软模板接触时,模板与前驱体之间通过分子间作用力、氢键、静电作用等非共价键相互作用连接在一起。在反应溶液中,表面活性剂通过亲水及疏水官能团相互作用连接到一起,形成不同空间结构特征的聚集体,使得前驱体分子呈现特定的趋向分布,并最终形成多孔结构。因此,表面活性剂自身的性质是决定多孔金属材料结构的关键。Krishnan等[59]报道了一种廉价的多孔Ni制备方法,他们使用聚苯乙烯作为软模板,通过化学镀的方式将Ni与模板连接,通过调节溶剂退火工艺来控制多孔Ni的孔隙率及孔径尺寸。软模板具有形态多样性强、构筑容易等优点,但其结构稳定性相比硬模板较低,使其模板利用效率不高。

图2

图2

模板法制备多孔金属示意图

Fig.2

Schematics of the fabrication of porous metal by template method

(a) soft template method (b) hard template method

1.3.2 硬模板法

硬模板主要使用多孔Si、ZnO、Al2O3等通过共价键维系的刚性模板来制备多孔金属材料,其制备流程如图2b所示。由于硬模板的结构稳定性更强,使得硬模板法可与需要高温等条件的沉积过程联用。随着硬模板制备工艺的发展,人们可以通过硬模板法制备多种二维、三维多孔结构,并能够在较大尺度下保持孔结构的均匀性。由于硬模板具有较高的稳定性和良好的限域作用,能严格地控制纳米材料的形貌和尺寸。

1.4 高能快速成型法

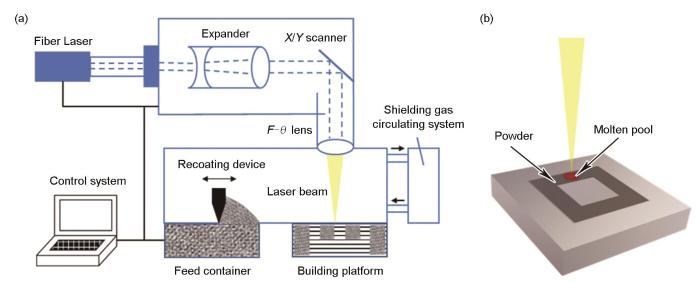

1.4.1 选区激光烧结及选区激光熔化

图3

图3

选区激光熔化装置示意图及加工平台示意图

Fig.3

Schematics of selective laser melting machine (F—focal distance, θ—scanning angle) (a) and enlarged schematic of building platform (b)

1.4.2 电子束熔化

电子束熔化技术是另一种基于粉末床熔融的多孔材料制备工艺。与选区激光成型技术基本原理类似,电子束熔化技术使用高能电子束为能源。电子束熔化一般在真空条件下进行,可以有效防止金属氧化,同时能够保持较高的熔区温度及较低的冷却速率,从而降低材料内应力。目前电子束熔化技术已在钛基多孔材料领域有较为广泛的应用,特别是Ti-6Al-4V多孔合金的制备有较多报道[67,68]。例如Li等[67]制备了孔隙率在60%~85%的Ti-6Al-4V多孔合金,与多孔Al、Ni相比其疲劳寿命更高。除此之外,具有超弹性的Ti-24Nb-4Zr-8Sn同样可以通过此方法来制备,其孔隙率可在67.9%~91.2%间调控。与Ti-6Al-4V多孔合金相比,这种合金具有更高的疲劳强度,是一种具有发展前景的生物医用植入材料[69]。

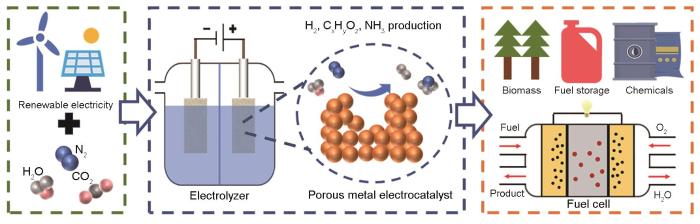

2 开孔多孔金属材料在电催化领域的应用

多孔材料以其高表面积、低密度、高通透性、高导电导热性、结构灵活可调等特点被认为是理想的电极及催化剂材料。如图4所示,多孔材料在电催化析氢、析氧、氧还原、燃料氧化、CO2还原及氮还原等领域均具有广阔的发展前景。

图4

图4

多孔金属材料在电催化领域应用示意图

Fig.4

Schematic of application of porous metal based on electrocatalysis

2.1 电催化析氢

氢能源被认为是最具有发展前景的清洁能源[70],但传统制氢工艺主要是通过化石燃料重整制备,具有高能耗及高污染的缺点。电解水产氢技术以水为原料,通过电能将水分解为H2及O2,具有高转化率及高纯度等优点,同时其能够耦合清洁电能,实现H2的绿色制备,是非常具有发展前景的清洁能源制备手段。

在电解水过程中需要用到催化剂来促进水分解反应以提高转换效率。贵金属Pt以其良好的催化活性及稳定性一直被视为性能最优的电解水产氢催化剂[71]。除此之外,其他多孔贵金属催化剂同样具有良好的电催化析氢活性。Liu等[72]制备了多孔Pd催化剂,其在100 mA/cm2的电流密度下过电位为80 mV,并且能够获得比商用Pt/C催化剂更高的交换电流密度。除此之外,合金化是提升析氢活性的有效策略,Yang等[32]利用脱合金法制备了纳米多孔PdCuNi-S电催化剂,通过各组元间的协同作用能够有效提升催化剂的析氢活性,在10 mA/cm2的电流密度下过电位为48 mV,相比单金属催化剂具有更高的催化活性。Yu等[73]制备了多孔RhCo合金纳米管材料,能够有效提升Rh催化剂的析氢活性。通过Co的合金化作用,能够改善Rh位点上对吸附氢中间体过强的吸附能力,促进H2的释放,提升催化效率。

但贵金属的成本问题抑制了其大规模应用,提高贵金属原子的利用率以及制备高效非贵金属催化剂一直是电解水领域的研究热点[74]。Sun等[75]使用多孔Cu作为骨架,制备了Al7Cu4Ni@Cu4Ni多孔催化剂,这种催化剂具有核壳结构,同时能够保持多孔Cu的完整骨架,能够作为自支撑电极使用。Cu骨架不仅能提供高效的电子传输通道,同时能保证催化剂大的比表面积,促进催化活性的提升。Xu等[76]通过一步烧结法制备了多孔Ni3B催化剂,在析氢过程中Ni3B表面发生氧化,生成Ni3B@NiO/Ni(OH)2复合结构,在5000次循环测试中能够保持良好的催化稳定性。Tan等[47]使用选择相腐蚀的方法制备了纳米多孔Co2P催化剂,通过对前驱体合金液冷却行为的控制,能够调控合金中Co相与Co2P相的分布,从而调节Co2P的孔径尺寸,随着孔尺寸的缩小,Co2P催化剂的比表面积变大,活性位点增多,因而能够获得更高的电催化析氢活性。Xu等[45]通过类似的方法制备了多孔C掺杂Co2P催化剂。他们将C原子直接掺杂在前驱体合金中,能够直接将C掺入Co2P晶格中。具有高电负性的C原子能够有效调节Co活性位的电子结构促进H2释放,同时还能够生成C-Hads中间体促进水的裂解,使其具有良好的碱性电解水析氢活性。

2.2 电催化析氧

电催化析氧反应是电催化水分解及金属-空气电池等电化学能源储存和转换技术中重要的半反应。然而电催化析氧催化剂的过电位较大,稳定性还不够理想,这些都限制了电解水及金属-空气电池等相关器件的性能,因此亟需开发新型高活性、高稳定性的析氧电催化剂。多孔金属材料在电催化析氧领域同样应用广泛。铱基和钌基催化剂以其高催化活性及高稳定性被认为是最好的电催化析氧催化剂。尤其在酸性条件下,由于析氧电位高于大部分催化剂的腐蚀电位,使得铱基和钌基催化剂的不可替代性更强。Jiang等[77]使用嵌段共聚物作为软模板,制备了多孔Ir纳米片催化剂,发现多孔Ir纳米片电化学活性面积较大,使其活性位点能够充分地与电解液接触,从而获得优秀的析氧活性。Liu等[78]制备了多孔Ir纳米线,这种一维多孔复合结构使其具有极大的电化学活性面积(118.2 m2/g),是商用RuO2催化剂的3.7倍,其在10 mA/cm2的电流密度下过析氧电位为250 mV,远低于RuO2催化剂。钌基多孔催化剂同样具有良好的析氧活性,例如多孔RuCu纳米片作为一种pH值适应性高的催化剂,其在酸性及碱性条件下均具有良好的催化活性[79]。作者将这种高活性归因于Cu的电子结构调节作用及在电催化析氧过程中生成的高活性Ru4+活性位。

过渡金属基催化剂在碱性条件下的稳定性高于酸性条件,因此在碱性条件下析氧催化剂的元素选择性更多。Tan等[48]通过电化学脱合金法制备了纳米多孔(Co0.52Fe0.48)2P催化剂,其催化活性相比Co2P催化剂更强,证明了Fe的合金化效应能够有效提升析氧性能。Su等[80]将NiP通过化学沉积的方法镀覆到多孔聚合物表面,获得了具有高电导率的柔性基底,随后通过电沉积的方法将镍铁氢氧化物纳米片沉积到NiP上,进一步提升其电催化析氧活性,其在10 mA/cm2的电流密度下过电位为197 mV,Tafel斜率为51 mV/dec。You和Sun[81]使用多孔Ni为集流体,通过无电镀沉积及低温硫化的方法制备了NiS x 多孔材料,这种催化剂具有多级的多孔结构,能保持良好电导率的同时增加催化剂的比表面积,使其具有全解水催化活性。Xu等[41]制备了多孔(Ni x Fe1 - x )4P5催化剂,这种催化剂同时具有析氢及析氧催化活性。研究发现,在析氧过程中,金属磷化物会转变为具有析氧活性的金属磷氧化物,而在析氢反应中金属磷化物则具有更高的催化活性。Wang等[82]利用泡沫Ni为前驱体,通过化学气相沉积的方法制备了自支撑的多孔Ni-P催化剂,这种催化剂具有多级磷镍复合结构,且各级结构磷镍比不同,这种催化剂的电解效率可达90.2% (10 mA/cm2),在10及20 mA/cm2电流密度下使用该催化剂的全解水器件稳定性可达1000 h。

2.3 电催化氧还原

氧还原反应是金属-空气电池及燃料电池中的重要反应,提高氧还原催化剂的催化活性能够有效降低反应过程所需的能耗,因此高效氧还原电催化剂的开发是清洁能源技术探索的重点研究方向之一。氧还原催化剂的活性取决于其表面含氧中间体吸附能力的强弱,一般认为铂基催化剂在酸性及中性介质中具有较好的氧还原能力。

由脱合金法制备的纳米多孔PtFe纳米线具有较高的电催化氧还原活性,其比催化活性是商用Pt/C催化剂的2.3倍[83]。使用直接脱合金方法的PtNi催化剂的催化活性是商用Pt/C催化剂的4.3倍,且其催化稳定性也有所提升[84]。然而制备这种材料使用的PtNiAl合金中存在多种物相,得到的纳米多孔结构形貌并不均匀。Snyder等[85]使用成分均匀的PtNi固溶体解决了这一问题,他们在制备出PtNi多孔之后,将其进行处理并获得复合多级结构。这种复合结构材料的质量比活性是商用Pt/C催化剂的10倍以上。Li等[86]在纳米多孔Au上包覆一层亚纳米级Pt-Pd壳层,制备了一种新型纳米多孔电催化剂,该催化剂初始质量活性可达1.140 A/mgPt,并在长循环过程中增加至1.471 A/mgPt。研究发现,在氧还原过程中催化剂的表面发生了一系列结构演变,表层的Pt-Pd双金属层首先转变为双层结构,其表层为富Pt三金属相,随后逐渐转变为均一的Pt-Pd-Au合金表面,这种表面能够降低氧还原反应能垒,增强催化活性。Qiu等[87]制备了AlNiCuMoCoFe高熵纳米多孔催化剂并以其独特的高熵效应在氧还原反应中获得比商用Pt/C催化剂高10倍的质量比活性。Oezaslan等[88]利用PtCu、PtCo纳米颗粒作为前驱体,使用脱合金方法制备了多孔铂基纳米颗粒材料并研究了前驱体尺寸对制备材料的影响。当前驱体尺寸小于15 nm时,多孔材料表面呈现出富Pt的趋势且内部成分一致,即形成均匀的核壳结构;当前驱体合金尺寸在15~30 nm之间时,虽然多孔材料表面依然形成Pt壳,但内部金属则具有多种成分,即形成多元核壳结构;当前驱体尺寸大于30 nm时,则有部分合金核暴露在材料表面。

Pd催化剂同样具有氧还原活性,Xu等[89]使用欠电位沉积的方法制备了纳米多孔PdCu催化剂,并应用于氧还原领域中。这种材料的催化活性比Pt/C催化剂活性更高,展现出了Pd催化剂替代Pt催化剂的潜力。其他钯基多孔材料(如PdNi、PdCo等)也可以通过脱合金法来制备,并具有良好的电催化氧还原活性[90~92]。Lv等[93]以二甲基双十八烷基氯化铵为软模板,二甲胺基甲硼烷和次磷酸钠作为B源和P源,制备了三元PdBP介孔纳米球。研究发现,B和P原子可以促进Pd活性位上含氧中间体的分解,同时枝状介孔形貌能够加速电子/物质转移,使其具有良好的氧还原活性。多孔金基材料也具有电催化氧还原活性,Zeis等[94]首先研究了纳米多孔Au对O2及H2O2的催化还原活性,发现纳米多孔Au催化氧还原是一个四电子转移过程,其中包含了O2向H2O2的转化及进一步还原为H2O的过程。通过研究发现,高密度的边缘活性位具有极高的催化活性。

2.4 电催化燃料氧化

燃料电池以其清洁高效、能量转化率高、质能比高、可低温快速启动等特性,被认为是具有发展前景的新能源转换技术[95]。其中直接甲醇燃料电池及直接甲酸燃料电池等使用甲醇及甲酸作为燃料,能够避免H2储运困难的问题,更具有实际应用的前景。其中催化剂的阳极反应速率直接决定燃料电池的整体效率,是燃料电池中最为关键的部件之一。

由于Pt催化剂的高活性以及合金化对其性能的提升,多孔铂基催化剂在燃料电池阳极催化剂领域有着广泛的应用。Liu等[96,97]使用硬模板法制备了PtCo及PtNi合金纳米线,随后以其为前驱体制备了多孔PtCo及PtNi纳米线材料。由于其纳米线提供的电子传输通路、纳米多孔结构的高比表面积以及金属间的协同作用,这种多孔纳米线的催化活性比商用Pt/C催化剂有了大幅提升。Deng等[98]以SiO2为模板制备了Pt中空纳米笼,随后通过化学还原将其转变为Pt-Ni-P介孔纳米笼,其具有介孔表面、中空结构及合金效应并以此获得良好的甲醇氧化活性。Yin等[99]将软模板及硬模板法结合起来,使用SiO2和Pluronic F127为模板制备了Pt及铂基合金介孔笼型纳米球,合金化后的介孔催化剂具有比商用Pt/C催化剂更好的催化活性及抗CO中毒能力。

多孔Au材料同样也被应用于燃料电池领域。Zhang等[100]研究了纳米多孔Au在碱性条件下甲醇的电催化氧化反应。与多晶Au相比,纳米多孔Au的催化活性有着明显提升。一般而言,较小的孔径能够增加催化剂比表面积,暴露出更多具有高催化活性位点,促进催化活性的提升,在甲醇电催化领域,纳米多孔Au有着与众不同的特性。与Pt催化剂不同,纳米多孔Au在电催化氧化甲醇的过程中没有出现催化剂中毒现象。此外,纳米多孔Au对其他分子如葡萄糖、硼氢化物、对硝基酚以及肼等燃料均具有催化活性[101~103]。Chen等[104]将单原子层的Au催化剂负载到纳米多孔Cu表面,使得材料既保持了纳米多孔结构的特性,又节约了Au的使用量,而这种Au/np-Cu复合材料也展现出了比纯Au多孔更高的电催化活性。除了作为催化剂本身,纳米多孔Au由于其高的电导率和大的比表面积也可作为催化剂的载体材料,制备核壳状纳米多孔结构。Ding等[105]利用这种方法将Pt负载到纳米多孔Au基底上制成了核壳结构,并获得了良好的催化活性。当Au基底表面覆盖了纯Pt金属层时,材料对甲酸的催化倾向于高电位下的脱水反应,产物为CO,从而引起催化剂中毒现象。而当催化剂表面为Au-Pt合金时,催化路径为低电位脱氢反应,从而形成CO2[106,107]。

2.5 电催化CO2 还原

电催化CO2还原能够将温室气体CO2通过电化学的方法还原成具有高附加值的含碳产品,具有良好的工业化前景。与电解水反应不同,电催化CO2还原的反应更为复杂,由于CO2的还原电位与析氢电位非常接近,使得在发生CO2还原的过程中会发生析氢副反应,造成产物选择性降低。另一方面,CO2还原的反应路径较多,其产物包括甲酸、甲烷等一碳产物以及乙烯、乙醇等多碳产物。因此,合理筛选催化剂的种类,通过形貌调控及表面改性等方法实现电催化剂的理性设计是CO2还原领域的关键。

研究[111]发现,吸附中间体*CO的吸附能力可以作为指示符,来判断催化剂对CO2还原产物的选择性。其中,*CO吸附最强的金属(如Ni、Pt等),则由于标度关系使得氢吸附能力也最强,从而只发生析氢反应。而*CO结合能最低的金属(如Pb、Sn等),不与C产生化学吸附作用,CO2直接加氢生成甲酸。Li等[112]制备了孔结构可调的泡沫Sn材料并研究了其电催化CO2还原生成甲酸的反应活性。研究发现,多孔结构能够增加催化剂比表面积,扩大固液反应界面并降低扩散阻抗,并以此获得良好的催化活性及稳定性。Kim等[113]通过气泡辅助电沉积的方法制备了多孔SnIn合金电催化剂,其催化活性及选择性受催化剂表面粗糙度及SnIn比例控制。Wang等[114]使用泡沫Cu为基底,在其表面通过电沉积的方法制备了由纳米针组成的多孔Pb催化剂。这种多级结构具有更大的比表面积以及更多的低配位活性位点,使其具有比Pb片更好的催化活性,在-1.7 V电位下,其甲酸选择性达到96.8%。

与*CO结合能较低的金属(如Au、Ag等),其表面产生*CO中间体后会进一步解析生成CO。Welch等[115]通过去合金的方法制备了纳米多孔Au薄膜催化剂,其CO2还原成CO的Faraday效率达到99%,并且在110 h的稳定性测试后CO的Faraday效率依然大于80%。Morimoto等[116]通过阳极氧化及电化学还原的方法制备了多孔Zn催化剂,在-1.1 V (相对于可逆氢电极)下其CO的Faraday效率达到80%,高于锌箔电极。Zhao等[117]通过两步去合金法制备了分级多孔结构的Cu1Au单原子合金,得益于纳米多孔金属提供的丰富活性位和表面空位,其CO的Faraday效率接近100%。Yan等[118]结合3D打印及去合金法制备了具有多级多孔结构的CuAg合金材料,其能够将CO2还原成CO的同时发生析氢反应生成H2,H2/CO合成气比例可以从3∶1调节至1∶2。

当金属活性位与*CO吸附强度适中时,*CO能够在其表面进一步加氢或发生偶联反应生成碳氢或多碳产物,目前只有铜基催化剂能够获得适宜的*CO吸附强度,并被认为是具有生成多碳产物最有发展前景的催化剂。Yang等[119]对比了多孔、实心和破碎形貌的3种Cu2O纳米结构,经过有限元模拟发现多孔结构的C2+产物与C1产物的Faraday效率之比为6.4,分别为实心结构和破碎结构的8倍和7倍,说明多孔结构的限域效应能够有效富集催化反应中间体,从而提高多碳产物选择性。Zhong等[120]使用理论计算和机器学习的方法预测了Cu-Al合金具有最适宜的*CO吸附强度,因此能够获得最好的多碳产物选择性。随后使用去合金法制备了Cu-Al多孔材料。这种催化剂达到了80%乙烯转化Faraday效率,并且电流密度最高能达到600 mA/cm2。

2.6 电催化氮还原

氨(NH3)是重要的化工原料及能源载体,其主要通过Haber-Bosch法来制备。其反应条件苛刻,同时会消耗大量能量并产生CO2。电催化氮还原可以利用清洁电能,能够将H2O和N2直接还原成氨,具有清洁环保及反应条件温和等特点,是新兴的人工固氮工艺。但电催化氮还原的反应电位与析氢电位接近,使得在发生氮还原反应时不可避免地发生析氢副反应,造成选择性降低。此外由于N≡N三键非常牢固,电催化氮还原反应较为困难。因此为了实现高效的电催化氮还原反应,需要设计新型的固氮催化剂,提高N2在催化剂表面的吸附能力,增强N≡N三键的活化效果,以及降低析氢副反应发生。

合金化是提升氮还原催化剂性能的有效手段。Wang等[123]通过两步去合金的方法制备了纳米多孔Pd3Bi催化剂。其中Pd原子与Bi原子之间能够产生强烈的耦合作用,促进Bi位点对N2的吸附并降低N2加氢的反应能垒。Xu等[124]通过去合金法及原位氢注入法制备了H含量可调的纳米多孔Pd-H合金催化剂,其催化活性相比纯Pd催化剂提升明显。研究发现,晶格H原子能够参与到氮还原反应中,同时调节Pd活性位电子结构,促进N2的活化。Pang等[125]制备了成分可调的多孔Pd1Ag1合金催化剂,其具有低配位活性原子及快速的界面电子转移速率,使其具有良好的氮还原催化活性。Fan等[126]制备了纳米多孔NiSb催化剂,其氮还原活性比纳米多孔Ni及纳米多孔Sb催化剂性能提升明显。其中Sb原子对Ni原子电子结构的调节使得Ni位点的电荷发生重新分布,增强了N≡N三键的活化。此外,Sb原子通过调节Ni周围配位环境和电子结构,能够分离H+和N2的表面结合位点,削弱H+和N2之间的竞争吸附。Wang等[127]利用胶束辅助电沉积的方法在泡沫Ni表面沉积了多孔Au,并以其作为电极材料进行氮还原性能研究,其N2还原路径为远端N原子加氢机制。

3 开孔多孔金属材料在生物医用领域的应用

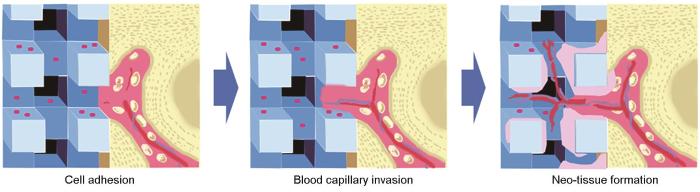

图5

图5

多孔金属植入体周围骨缺损修复示意图

Fig.5

Conceptual illustration of the biological processes of bone formation around the porous scaffold

3.1 骨缺损修复

对骨缺损修复材料而言,其首先必须具备良好的生物相容性,以确保其对人体具有适应性及亲和性;其次,生物医用材料需要具有适宜的力学性能,其弹性模量需要与骨组织接近,防止植入体发生位移及应力屏蔽现象[134],同时还需要具备良好的抗疲劳能力及静态力学性能,防止植入体在使用过程中发生破坏;第三,生物医用材料还需具有良好的耐蚀性,防止植入物中的金属离子溶解进入人体环境,造成离子富集等问题。因此对骨缺损修复材料的研究主要针对上述特性开展研究。

钛基材料具有优异的力学性能和生物相容性,是重要的骨缺损修复材料之一[135]。但钛基材料的弹性模量与骨组织匹配性较差,而通过构造多孔结构能够有效解决这一问题[136,137]。刘世敏等[138]在钛基多孔材料领域进行了深入的研究,为了提高Ti表面的生物活性,利用微弧氧化技术在Ti表面制备了含有Ca、P的多孔TiO2层。结果表明,多孔层的平均孔径及膜层中Ca、P含量等参数可以通过微弧氧化电压调控,并且随着电压的增高膜层中逐渐有羟基磷灰石生成。朱胜利等[139]采用Ar气保护烧结的方法制备了多孔TiNi合金,并对其孔隙率进行了研究。研究发现,在烧结过程中孔隙形成、发展过程分为新孔形成、孔隙的聚集和孔隙的收缩3个阶段,其孔隙率受烧结温度、粉末粒度和压制压力影响。陈民芳等[140]通过碱处理的方法对NiTi形状记忆合金进行表面处理。在1 mol/L NaOH溶液中处理后,NiTi合金表面会生成多孔状的钛酸钠并因此具有较高的类骨磷灰石诱导沉积效果。胡荣香等[141]通过酸碱处理的方法在NiTi合金表面构建了多孔涂层,并对溶液法制备生物活性层特性的工艺参数进行了优化设计。Li等[142]通过粉末烧结制备了多孔Ti-24Nb-4Zr合金,其在模拟体液中具有良好的耐蚀能力,证明Ti-24Nb-4Zr合金具有良好的生物医用前景。Liang等[143]通过飞秒激光烧蚀技术在钛植入体表面构造了多孔结构,随后在其表面进一步修饰了Ca3(PO4)2涂层。这种复合结构具有良好的促进成骨细胞黏附的能力。与纯Ti植入体相比,改性后的植入体周围骨密度明显增加,骨结合能力提升明显。Lai等[144]制备了多种TiNbZr多孔形状记忆合金材料并对其力学性能进行了研究。在孔隙率相同的情况下,孔径较大的样品具有较低的弹性模量,当孔隙率在38.5%~49.7%时,其力学性能较为接近骨组织。Kuczyńska-Zemła等[145]通过激光烧蚀的方法在金属Ti表面制备了规则的多孔结构,这种多孔结构能够促进仿生磷灰石层的形成,诱导细胞均匀生长。Harrysson等[146]通过电子束熔化技术制备了Ti6Al4V髋关节假体,得益于多孔结构的构建,髋关节假体具有较为适宜的力学性能,能够避免应力屏蔽等问题。

Mg的密度与人体骨密度接近,其弹性模量和抗压屈服强度较为接近人体骨,同时Mg具有良好的可降解性和生物相容性,近年来在骨缺损修复领域受到了广泛关注[147]。但Mg化学性质活泼,其降解速率过快,降解时间远小于骨愈合时间,同时在降解过程中还会发生气体积聚等问题[148]。因此需要对镁基材料进行改性处理,以增强其耐蚀能力、力学性能及骨诱导能力。合金化是改良多孔镁基材料性能的有效手段[149,150]。Li等[151]通过选择激光熔化技术制备了拓扑有序的WE43镁合金材料,其具有良好的耐蚀稳定性及生物降解能力。Gu等[152]通过微弧氧化法对Mg-Ca合金表面进行处理,生成多孔结构,其孔径及孔结构厚度随加载电压增加而增大,在400 V电压下制备的多孔层具有良好的耐蚀性及细胞相容性。Yazdimamaghani等[153]通过粉末冶金法制备了多孔镁基材料,并在其表面涂覆了聚已酸内酯涂层。研究发现,聚已酸内酯涂层能够有效增强多孔Mg的耐蚀能力,降低其降解速率。Lai等[154]将多孔镁合金支架植入兔子体内骨缺损模型中,在3个月后支架基本完成降解,同时未出现骨溶解现象。研究发现,在降解支架周围存在纤维囊及新生血管,同时降解部位被新生成骨代替。Wang等[155]构建了Mg-6Zn-0.5Sr多孔材料,生物实验结果表明,这种材料具有良好的力学强度,促进骨生长,有效减少缺损周围骨吸收,具有前交叉韧带修复潜力。

除钛基、镁基材料以外,其他多孔金属材料如铁基、锌基材料等,同样具有良好的力学性能及可降解能力,在骨缺损修复领域应用广泛[156]。与镁基材料不同,铁基材料在降解初期具有适宜的降解速率,但在降解过程中表面会生成难溶氧化层,使得降解速率降低,而多孔材料具有较大的比表面积,能够提高其降解速率。Li等[157]针对增材制造过程中多孔Fe的凝固行为进行调控,以实现Fe晶粒的细化。研究发现由于晶界及缺陷能量较高,易于腐蚀,数量随晶粒细化而增加,多孔Fe中的晶界及缺陷数量明显增加,从而促进多孔Fe材料的降解效果。Nie等[158]制备了Fe-30Mn支架,将其植入新西兰白兔股骨髁缺损,观察其在植入过程中骨修复及支架演化过程。在植入12周后,支架周围出现新形成的骨小梁,24周后骨-支架界面的新骨染色更加显著,48周后支架边缘和内部孔隙处成骨增多,且48周后支架体积减少10.1%~20.9%,弹性模量降低34.1%~42.3%,屈服强度降低15.8%~23.3%,表现出良好的成骨诱导效果。

3.2 牙种植体

种植牙以其美观、天然牙保护性及骨组织等方面的优势,成为近年来最有发展前景的牙修复方式。与骨修复材料类似,牙种植体同样需要适宜的生物相容性、力学性能。此外,口腔内为酸性环境,需要种植体材料具备更强的耐蚀能力。同时由于复杂的口腔环境,牙种植体还需考虑口腔微生物的影响。此外,由于牙种植手术会导致牙周神经纤维的损伤,使得种植体需要具备一定的骨感知效果。因此对材料成分、形貌及结构等特性的调控,是开发新型牙种植体材料的关键。

Ta的化学性质稳定,与Ti一样在生物医用材料领域应用广泛。特别是多孔Ta具有较大的孔隙率、接近于人骨的弹性模量以及较高的摩擦系数,使得多孔Ta在牙种植体领域具备很大的发展潜力[164]。Balla等[165]通过激光近净成形技术制备了多孔Ta材料,其孔隙率为45%~73%,Young's模量可通过孔隙率在1.5~2.0 GPa范围内调控。细胞毒性实验表明,多孔Ta比多孔Ti具有更好的细胞黏附、生长及分化能力。Wang等[166]通过细胞毒性实验及动物体内植入实验研究了多孔Ta材料的生物相容性及成骨能力。研究发现,在植入动物体内2周后多孔Ta与原始骨界面处出现新骨及血管,植入10周后出现骨组织,植入12周后多孔Ta表面被新生骨组织覆盖,并与原始骨连接紧密。Lee等[167]将多孔Ta材料及传统锥形螺纹的口腔种植体植入犬牙窝中,对比其骨生长情况。结果表明多孔Ta材料具有更好的新骨生成能力。Wu等[168]结合磁控溅射及氧化法在ZrO2表面制备了多孔Ta涂层,与没有纳米结构的Ta涂层相比,纳米多孔Ta能够有效促进MC3T3-E1细胞黏附、增殖、成骨分化及矿化。此外,动物实验结果表明多孔Ta涂层能够有效促进骨组织生长,促进骨整合能力。

4 总结及展望

开孔多孔金属材料以其大的比表面积、优秀的物质传输能力、导电导热性好、力学性能适宜等特性在电催化及生物医用等领域应用广泛。本文总结了面向电催化剂和生物医用开孔多孔金属材料的制备方法及其在相关领域的研究进展。

在电催化领域,多孔金属材料具有优秀的导电能力,能够快速进行电子传输;其大的比表面积使得多孔金属材料具有丰富的催化活性位点;同时贯通的孔结构为催化反应提供了充分的反应环境;部分多孔金属材料具有限域效应,能够促进催化中间体的富集并提升催化选择性。尽管多孔金属在电催化领域应用广泛,其在以下方面有望进一步提升。(1) 多孔金属的电催化反应机制。在电催化反应中,多孔结构的孔道作为传质通道,其孔壁表面作为催化活性位参与电化学反应过程,因此多孔结构对电催化反应的微环境及催化剂的催化活性具有重要影响。但目前为止,针对多孔金属结构特性引起的催化中间体吸/脱附过程及多孔材料在电催化过程中的结构转化机制尚不完全明确。因此,设计优化服役过程中多孔金属材料的表征及评价手段,结合理论模拟及机器学习等人工智能技术进行评价及预测,以此归纳多孔金属材料的结构演化规律,指导相关材料的设计应用,具有重要的实际应用价值。(2) 建立标准化的电化学表征方法。由于多孔结构尺寸及形貌种类繁多,以往通过宏观几何面积计算电催化剂活性的方法很难对多孔金属催化剂的本征活性进行表征,通过引入电化学活性面积比电流密度、质量比电流密度及转换频率等指标能够更好地表征多孔电催化剂的本征活性。此外,目前大部分电催化剂的性能表征依然在电解池中进行,其运行环境与实际生产条件差异较大,使用电解槽或燃料电池器件等模型反应器能够更加真实地反应多孔金属材料在工况下的催化效果。

在生物医用材料领域,作为组织工程学中最重要的材料种类之一,多孔金属材料为结构缺损部位提供力学支撑并为细胞黏附、增殖、分化及组织生长提供适宜的环境。人体结构复杂,骨骼间随时间、受力情况及发育情况不同使得结构差异较大,因此实现植入体材料的弹性模量及抗压强度等力学性能与人骨组织的匹配是多孔金属生物医用材料的首要目标。在此基础上,人们对多孔金属材料的生物相容性、可降解性、耐磨性等指标进行进一步改良,使其获得更好的组织修复效果。根据当前阶段的研究状况,多孔金属生物医用材料有望在以下方面实现突破。(1) 多孔结构的仿生化设计。天然人骨组织多为外部致密、内部疏松的多级孔结构。但目前多孔金属材料的结构尺度较为单一,与天然人骨结构存在差别。因此,开发新型多孔金属材料制备技术,实现多孔金属材料的仿生化发展,有望进一步提升多孔金属材料与人骨组织的力学匹配性。(2) 多孔金属材料的表面功能化处理。目前多孔金属材料的表面改性方法主要为修饰有机/无机涂层,随着科技水平的进步,开发新型表面改性方法有望进一步提升多孔金属材料的生物相容性、抗菌能力以及组织修复能力,并实现特定疾病的有效治疗。

参考文献

Scaling behavior of stiffness and strength of hierarchical network nanomaterials

[J].Structural hierarchy can enhance the mechanical behavior of materials and systems. This is exemplified by the fracture toughness of nacre or enamel in nature and by human-made architected microscale network structures. Nanoscale structuring promises further strengthening, yet macroscopic bodies built this way contain an immense number of struts, calling for scalable preparation schemes. In this work, we demonstrated macroscopic hierarchical network nanomaterials made by the self-organization processes of dealloying. Their hierarchical architecture affords enhanced strength and stiffness at a given solid fraction, and it enables reduced solid fractions by dealloying. Scaling laws for the mechanics and atomistic simulation support the observations. Because they expose the systematic benefits of hierarchical structuring in nanoscale network structures, our materials may serve as prototypes for future lightweight structural materials.Copyright © 2021 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Nanoporous metal/oxide hybrid electrodes for electrochemical supercapacitors

[J].Electrochemical supercapacitors can deliver high levels of electrical power and offer long operating lifetimes, but their energy storage density is too low for many important applications. Pseudocapacitive transition-metal oxides such as MnO(2) could be used to make electrodes in such supercapacitors, because they are predicted to have a high capacitance for storing electrical charge while also being inexpensive and not harmful to the environment. However, the poor conductivity of MnO(2) (10(-5)-10(-6) S cm(-1)) limits the charge/discharge rate for high-power applications. Here, we show that hybrid structures made of nanoporous gold and nanocrystalline MnO(2) have enhanced conductivity, resulting in a specific capacitance of the constituent MnO(2) (~1,145 F g(-1)) that is close to the theoretical value. The nanoporous gold allows electron transport through the MnO(2), and facilitates fast ion diffusion between the MnO(2) and the electrolytes while also acting as a double-layer capacitor. The high specific capacitances and charge/discharge rates offered by such hybrid structures make them promising candidates as electrodes in supercapacitors, combining high-energy storage densities with high levels of power delivery.

The preparation of skeletal catalysts

[J].

A new non-centrosymmetric modification of BiB3O6

[J].

Nanoporous gold: Understanding the origin of the reactivity of a 21st century catalyst made by pre-columbian technology

[J].

Fabrication, microstructure and electrocatalytic property of novel nanoporous palladium composites

[J].

Ligand-enabled reactivity and selectivity in a synthetically versatile aryl C-H olefination

[J].

Nanoporous gold: A new material for catalytic and sensor applications

[J].Nanostructured materials are governed by their surface chemical properties. This is strikingly reflected by np-Au. This material can be generated by corrosion of bulk Ag-Au alloys. Based on a self-organisation process, a 3 dimensional sponge like gold structure evolves with ligaments in the range of only a few tens of nanometers. Due to its continuous porosity, the material can be penetrated by gases which then adsorb and interact with the surface. In this perspective we will review potential applications of np-Au resulting from this effect, namely heterogeneous gas phase catalysis, surface chemistry driven actuation, and adsorbate controlled stability of the nanostructure. We will summarize the current knowledge about the low temperature oxidation of CO as well as the highly selective oxidation of methanol. Furthermore, we will address the question how surface chemistry can influence the material properties itself. In particular, we will deal with (a) the actuation of np-Au by the reversible oxidation of its surface using ozone and (b) the adsorbate controlled coarsening of ligaments, using annealing experiments under ozone or inert gas atmosphere.

Preparation, structure, and optical properties of nanoporous gold thin films

[J].Thin nanoporous gold (np-Au) films, ranging in thickness from approximately 40 to 1600 nm, have been prepared by selective chemical etching of Ag from Ag/Au alloy films supported on planar substrates. A combination of scanning electron microscopy (SEM) imaging, synchrotron grazing incidence small angle X-ray scattering, and N2 adsorption surface area measurements shows the films to exhibit a porous structure with intertwined gold fibrils exhibiting a spectrum of feature sizes and spacings ranging from several to hundreds of nanometers. Spectroscopic ellipsometry measurements (300-800 nm) reveal the onset of surface plasmon types of features with increase of film thicknesses into the approximately 200 nm film thickness range. Raman scattering measurements for films functionalized with a self-assembled monolayer formed from 4-fluorobenzenethiol show significant enhancements which vary sharply with film thickness and etching times. The maximum enhancement factors reach approximately 10(4) for 632.8 nm excitation, peak sharply in the approximately 200 nm thickness range for films prepared at optimum etching times, and show high spot to spot reproducibility with approximately 1 microm laser spot sizes, an indication that these films could be useful as durable, highly reproducible surface-enhanced Raman substrates.

Facile synthesis of pentacle gold-copper alloy nanocrystals and their plasmonic and catalytic properties

[J].The combination of gold and copper is a good way to pull down the cost of gold and ameliorate the instability of copper. Through shape control, the synergy of these two metals can be better exploited. Here, we report an aqueous phase route to the synthesis of pentacle gold-copper alloy nanocrystals with fivefold twinning, the size of which can be tuned in the range from 45 to 200 nm. The growth is found to start from a decahedral core, followed by protrusion of branches along twinning planes. Pentacle products display strong localized surface plasmon resonance peaks in the near-infrared region. Under irradiation by an 808-nm laser, 70-nm pentacle nanocrystals exhibit a notable photothermal effect to kill 4T1 murine breast tumours established on BALB/c mice. In addition, 70-nm pentacle nanocrystals show better catalytic activity than conventional citrate-coated 5-nm Au nanoparticles towards the reduction of p-nitrophenol to p-aminophenol by sodium borohydride.

Nanoporous gold biointerfaces: Modifying nanostructure to control neural cell coverage and enhance electrophysiological recording performance

[J].

Preparation of 3D nanoporous copper-supported cuprous oxide for high-performance lithium ion battery anodes

[J].Three-dimensional (3D) nanoporous architectures can provide efficient and rapid pathways for Li-ion and electron transport as well as short solid-state diffusion lengths in lithium ion batteries (LIBs). In this work, 3D nanoporous copper-supported cuprous oxide was successfully fabricated by low-cost selective etching of an electron-beam melted Cu(50)Al(50) alloy and subsequent in situ thermal oxidation. The architecture was used as an anode in lithium ion batteries. In the first cycle, the sample delivered an extremely high lithium storage capacity of about 2.35 mA h cm(-2). A high reversible capacity of 1.45 mA h cm(-2) was achieved after 120 cycles. This work develops a promising approach to building reliable 3D nanostructured electrodes for high-performance lithium ion batteries.

Fabrication methods of porous metals for use in orthopaedic applications

[J].Implant stability is not only a function of strength but also depends on the fixation established with surrounding tissues [Robertson DM, Pierre L, Chahal R. Preliminary observations of bone ingrowth into porous materials. J Biomed Mater Res 1976;10:335-44]. In the past, such stability was primarily achieved using screws and bone cements. However, more recently, improved fixation can be achieved by bone tissue growing into and through a porous matrix of metal, bonding in this way the implant to the bone host. Another potentially valuable property of porous materials is their low elastic modulus. Depending on the porosity, moduli can even be tailored to match the modulus of bone closer than solid metals can, thus reducing the problems associated with stress shielding. Finally, extensive body fluid transport through the porous scaffold matrix is possible, which can trigger bone ingrowth, if substantial pore interconnectivity is established [Cameron HU, Macnab I, Pilliar RM. A porous metal system for joint replacement surgery. Int J Artif Organs 1978;1:104-9; Head WC, Bauk DJ, Emerson Jr RH. Titanium as the material of choice for cementless femoral components in total hip arthroplasty. Clin Orthop 1995;85-90]. Over the years, a variety of fabrication processes have been developed, resulting in porous implant substrates that can address unresolved clinical problems. The advantages of metals exhibiting surface or bulk porosity have led researchers to conduct systematic research aimed at clarifying the fundamental aspects of interactions between porous metals and hard tissue. This review summarises all known methods for fabricating such porous metallic scaffolds.

Hierarchically 3D porous films electrochemically constructed on gas-liquid-solid three-phase interface for energy application

[J].

Nanoporous metals: Fabrication strategies and advanced electrochemical applications in catalysis, sensing and energy systems

[J].Nanoporous metals, a representative type of nanostructured material, possess intriguing properties to generate enormously promising potentials for various important applications. In particular, with the advances of fabrication strategies, nanoporous metals with a variety of superior properties including unique pore structure, large specific surface area and high electrical conductivity have fuelled up great interests to explore their electrocatalytic properties and greatly extend their emerging applications in electrochemical sensing and energy systems. This tutorial review attempts to summarize the recent important progress towards the development of nanoporous metals, with special emphasis on fabrication methods and advanced electrochemical applications, such as electrocatalysts, chemical sensors and energy systems. Key scientific issues and prospective directions of research are also discussed.

Atomic origins of the high catalytic activity of nanoporous gold

[J].Distinct from inert bulk gold, nanoparticulate gold has been found to possess remarkable catalytic activity towards oxidation reactions. The catalytic performance of nanoparticulate gold strongly depends on size and support, and catalytic activity usually cannot be observed at characteristic sizes larger than 5 nm. Interestingly, significant catalytic activity can be retained in dealloyed nanoporous gold (NPG) even when its feature lengths are larger than 30 nm. Here we report atomic insights of the NPG catalysis, characterized by spherical-aberration-corrected transmission electron microscopy (TEM) and environmental TEM. A high density of atomic steps and kinks is observed on the curved surfaces of NPG, comparable to 3-5 nm nanoparticles, which are stabilized by hyperboloid-like gold ligaments. In situ TEM observations provide compelling evidence that the surface defects are active sites for the catalytic oxidation of CO and residual Ag stabilizes the atomic steps by suppressing {111} faceting kinetics.

Stress shielding and bone resorption in shoulder arthroplasty

[J].The radiographs of 64 patients with 70 humeral head replacements were reviewed for signs of stress shielding. Of these, 49 were implanted for rheumatoid arthritis and 21 for osteoarthritis. The radiographic follow-up averaged 5.3 years. Measurements of cortex thickness were performed in 4 regions along the stem of the implant, and the differences between the postoperative radiograph and the radiograph at follow-up were calculated. The size of the stem in relation to the diameter of the humerus was calculated with the use of validated measures, resulting in the relative stem size. In 6 patients (9%) a significant reduction in cortical thickness was observed in the proximal-lateral region of the humeral stem, 5 in rheumatoid patients and 1 in an osteoarthritic patient. In the stress shielding group, the relative stem size was found to be significantly higher than that in the non-stress shielding group (0.58 vs 0.48). Osteoporosis, especially present in rheumatoid arthritis, could well be a risk factor. It was concluded that stress shielding is a long-term complication of shoulder arthroplasty and that the relative stem size is an important factor in its genesis.

Designing, processing and characterisation of titanium cylinders with graded porosity: An alternative to stress-shielding solutions

[J].

Osteoblast adhesion on biomaterials

[J].The development of tissue engineering in the field of orthopaedic surgery is now booming. Two fields of research in particular are emerging: the association of osteo-inductive factors with implantable materials; and the association of osteogenic stem cells with these materials (hybrid materials). In both cases, an understanding of the phenomena of cell adhesion and, in particular, understanding of the proteins involved in osteoblast adhesion on contact with the materials is of crucial importance. The proteins involved in osteoblast adhesion are described in this review (extracellular matrix proteins, cytoskeletal proteins, integrins, cadherins, etc.). During osteoblast/material interactions, their expression is modified according to the surface characteristics of materials. Their involvement in osteoblastic response to mechanical stimulation highlights the significance of taking them into consideration during development of future biomaterials. Finally, an understanding of the proteins involved in osteoblast adhesion opens up new possibilities for the grafting of these proteins (or synthesized peptide) onto vector materials, to increase their in vivo bioactivity or to promote cell integration within the vector material during the development of hybrid materials.

Hierarchical tailoring of strut architecture to control permeability of additive manufactured titanium implants

[J].

Research review of space holders of sintered titanium foams with large pores and high porosity

[J].

大孔径高孔隙率烧结泡沫钛的造孔剂研究述评

[J].

Current status of metal porous materials by powder metallurgy technology

[J].

粉末冶金技术制备金属多孔材料研究进展

[J].

The porous TiNb24Zr4 alloys with controllable porosity fabricated by conventional sintering

[J].

Microstructures and properties of porous TiAl-based intermetallics prepared by freeze-casting

[J].

Preparing a novel gradient porous metal fiber sintered felt with better manufacturability for hydrogen production via methanol steam reforming

[J].

Porous titanium by fiber sintering and its biomimetic Ca-P coating

[J].

纤维烧结多孔钛及其表面生长仿生Ca-P涂层

[J].

The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method

[J].

Spark plasma sintering, microstructures, and mechanical properties of macroporous titanium foams

[J].

Dealloying and dealloyed materials

[J].

Alloy corrosion

[J].

Beating thermal coarsening in nanoporous materials via high-entropy design

[J].

An amorphous nanoporous PdCuNi-S hybrid electrocatalyst for highly efficient hydrogen production

[J].

Hierarchical nanoporous metals as a path toward the ultimate three-dimensional functionality

[J].

Challenges and opportunities for integrating dealloying methods into additive manufacturing

[J].

Nanoporous gold leaf: "Ancient technology"/advanced material

[J].

Structure/processing relationships in the fabrication of nanoporous gold

[J].

Nanoporous metals fabricated through electrochemical dealloying of Ag-Au-Pt with systematic variation of Au:Pt ratio

[J].

Primary and secondary dealloying of Au(Pt)-Ag: Structural and compositional evolutions, and volume shrinkage

[J].

Engineering the internal surfaces of three-dimensional nanoporous catalysts by surfactant-modified dealloying

[J].Tuning surface structures by bottom-up synthesis has been demonstrated as an effective strategy to improve the catalytic performances of nanoparticle catalysts. Nevertheless, the surface modification of three-dimensional nanoporous metals, fabricated by a top-down dealloying approach, has not been achieved despite great efforts devoted to improving the catalytic performance of three-dimensional nanoporous catalysts. Here we report a surfactant-modified dealloying method to tailor the surface structure of nanoporous gold for amplified electrocatalysis toward methanol oxidation and oxygen reduction reactions. With the assistance of surfactants, {111} or {100} faceted internal surfaces of nanoporous gold can be realized in a controllable manner by optimizing dealloying conditions. The surface modified nanoporous gold exhibits significantly enhanced electrocatalytic activities in comparison with conventional nanoporous gold. This study paves the way to develop high-performance three-dimensional nanoporous catalysts with a tunable surface structure by top-down dealloying for efficient chemical and electrochemical reactions.

Evolution of nanoporosity in dealloying

[J].

A nanoporous metal phosphide catalyst for bifunctional water splitting

[J].

Tuning surface structure of 3D nanoporous gold by surfactant-free electrochemical potential cycling

[J].

Eco-friendly synthesis of nanoporous magnesium by air-free electrolytic dealloying with recovery of sacrificial elements for energy conversion and storage applications

[J].

Spontaneously separated intermetallic Co3Mo from nanoporous copper as versatile electrocatalysts for highly efficient water splitting

[J].

Electronic structure modulation of nanoporous cobalt phosphide by carbon doping for alkaline hydrogen evolution reaction

[J].

Scalable synthesis of nanoporous boron for high efficiency ammonia electrosynthesis

[J].

3D nanoporous metal phosphides toward high-efficiency electrochemical hydrogen production

[J].

Versatile nanoporous bimetallic phosphides towards electrochemical water splitting

[J].

Liquid metals dealloying as a general approach for the selective extraction of metals and the fabrication of nanoporous metals: A review

[J].

The attack of solid alloys by liquid metals and salt melts

[J].

Dealloying by metallic melt

[J].

Tuning microstructure and mechanical properties of open porous TiNb and TiFe alloys by optimization of dealloying parameters

[J].

Open porous dealloying-based biomaterials as a novel biomaterial platform

[J].

Optimizing niobium dealloying with metallic melt to fabricate porous structure for electrolytic capacitors

[J].

Recent advancements in the fabrication of functional nanoporous materials and their biomedical applications

[J].

Vapor phase dealloying: A versatile approach for fabricating 3D porous materials

[J].

Three-dimensional bicontinuous nanoporous materials by vapor phase dealloying

[J].Three-dimensional bicontinuous open (3DBO) nanoporosity has been recognized as an important nanoarchitecture for catalysis, sensing, and energy storage. Dealloying, i.e., selectively removing a component from an alloy, is an efficient way to fabricate nanoporous materials. However, current electrochemical and liquid-metal dealloying methods can only be applied to a limited number of alloys and usually require an etching process with chemical waste. Here, we report a green and universal approach, vapor-phase dealloying, to fabricate nanoporous materials by utilizing the vapor pressure difference between constituent elements in an alloy to selectively remove a component with a high partial vapor pressure for 3DBO nanoporosity. We demonstrate that extensive elements, regardless of chemical activity, can be fabricated as nanoporous materials with tunable pore sizes. Importantly, the evaporated components can be fully recovered. This environmentally friendly dealloying method paves a way to fabricate 3DBO nanoporous materials for a wide range of structural and functional applications.

Preparation of nanomaterials employing template method

[J].

模板法制备纳米材料

[J].

Fabrication of mesoporous polystyrene films with controlled porosity and pore size by solvent annealing for templated syntheses

[J].Herein, we aim to develop a facile method for the fabrication of mesoporous polystyrene (PS) films with controlled porosity and pore size by solvent annealing. A PS polymer film is solvent-annealed using N,N-dimethyl formamide (DMF) vapor for the development of phase separation, followed by rapidly cooling to the preset cryogenic temperature. Subsequently, a nonsolvent (methanol) is introduced to extract the crystalline DMF from the DMF-swollen PS, giving mesoporous PS with a network structure after the removal of DMF. The porosity of the mesoporous PS films can be controlled by the degree of swelling. Most interestingly, the phase separation between PS and DMF at the thin-film state under solvent annealing can be regulated by the annealing time through the spinodal decomposition, giving the development of nanonetwork structure with controlled structural features (i.e., framework size and interframework spacing) at invariant porosity. Consequently, after the removal of DMF, mesoporous PS films with controlled porosity and pore size can be obtained and then used as a template for the fabrication of a variety of nanoporous inorganics by templated syntheses, such as nanoporous SiO, TiO, and Ni, providing a cost-effective way to fabricate a range of nanoporous materials with controlled porosity and pore size as well as large specific surface area for aimed applications.

Co-nanocasting synthesis of mesoporous Cu-Mn composite oxides and their promoted catalytic activities for gaseous benzene removal

[J].

Ordered metal nanohole arrays made by a two-step replication of honeycomb structures of anodic alumina

[J].A highly ordered metal nanohole array (platinum and gold) was fabricated by a two-step replication of the honeycomb structure of anodic porous alumina. Preparation of the negative porous structure of porous alumina followed by the formation of the positive structure with metal resulted in a honeycomb metallic structure. The metal hole array of the film has a uniform, closely packed honeycomb structure approximately 70 nanometers in diameter and from 1 to 3 micrometers thick. Because of its textured surface, the metal hole array of gold showed a notable color change compared with bulk gold.

Review on preparation and applications of porous metal materials

[J].

多孔金属材料的制备及应用研究进展

[J].

Research progress and application of preparation technology of porous metal materials

[J].

多孔金属材料的制备工艺研究进展及应用

[J].

Permeability and strength of a porous metal structure fabricated by additive manufacturing

[J].

A study of the microstructural evolution during selective laser melting of Ti-6Al-4V

[J].

Early plastic deformation behaviour and energy absorption in porous β-type biomedical titanium produced by selective laser melting

[J].

Compression fatigue behavior of Ti-6Al-4V mesh arrays fabricated by electron beam melting

[J].

Properties of Ti-6Al-4V non-stochastic lattice structures fabricated via electron beam melting

[J].

Compressive and fatigue behavior of beta-type titanium porous structures fabricated by electron beam melting

[J].

Solar water splitting cells

[J].

Is there anything better than Pt for HER?

[J].The search for cheap and abundant alternatives to Pt for the hydrogen evolution reaction (HER) has led to many efforts to develop new catalysts. Although the discovery of promising catalysts is often reported, none can compete with Pt in intrinsic activity. To enable true progress, a rigorous assessment of intrinsic catalytic activity is needed, in addition to minimizing mass-transport limitations and following best practices for measurements. Herein, we underline the importance of measuring intrinsic catalytic activities, e.g., turnover frequencies (TOFs). Using mass-selected, identical Pt nanoparticles at a range of loadings, we show the pervasive impact of mass-transport limitations on the observed activity of Pt in acid. We present the highest TOF measured for Pt at room temperature. Since our measurements are still limited by mass transport, the true intrinsic HER activity for Pt in acid is still unknown. Using a numerical diffusion model, we suggest that hysteresis in cyclic voltammograms arises from H oversaturation, which is another indicator of mass-transport limitations.© 2021 The Authors. Published by American Chemical Society.

Pd nanoparticle assemblies as efficient catalysts for the hydrogen evolution and oxygen reduction reactions

[J].

Boosted electron-transfer kinetics of hydrogen evolution reaction at bimetallic RhCo alloy nanotubes in acidic solution

[J].

Defect-rich MoS2 ultrathin nanosheets with additional active edge sites for enhanced electrocatalytic hydrogen evolution

[J].

Nonprecious intermetallic Al7Cu4Ni nanocrystals seamlessly integrated in freestanding bimodal nanoporous copper for efficient hydrogen evolution catalysis

[J].

Large-scale synthesis of porous nickel boride for robust hydrogen evolution reaction electrocatalyst

[J].

Mesoporous metallic iridium nanosheets

[J].Two-dimensional (2D) metals are an emerging class of nanostructures that have attracted enormous research interest due to their unusual electronic and thermal transport properties. Adding mesopores in the plane of ultrathin 2D metals is the next big step in manipulating these structures because increasing their surface area improves the utilization of the material and the availability of active sites. Here, we report a novel synthetic strategy to prepare an unprecedented type of 2D mesoporous metallic iridium (Ir) nanosheet. Mesoporous Ir nanosheets can be synthesized with close-packed assemblies of diblock copolymer (poly-(ethylene oxide)- b-polystyrene, PEO- b-PS) micelles aligned in the 2D plane of the nanosheets. This novel synthetic route opens a new dimension of control in the synthesis of 2D metals, enabling new kinds of mesoporous architectures with abundant catalytically active sites. Because of their unique structural features, the mesoporous metallic Ir nanosheets exhibit a high electrocatalytic activity toward the oxygen evolution reaction (OER) in acidic solution as compared to commercially available catalysts.

Ultrafine Ir nanowires with microporous channels and superior electrocatalytic activity for oxygen evolution reaction

[J].

Channel-rich RuCu nanosheets for pH-universal overall water splitting electrocatalysis

[J].Channel-rich RuCu snowflake-like nanosheets (NSs) composed of crystallized Ru and amorphous Cu were used as efficient electrocatalysts for oxygen evolution reaction (OER), hydrogen evolution reaction (HER), and overall water splitting in pH-universal electrolytes. The optimized RuCu NSs/C-350 °C and RuCu NSs/C-250 °C show attractive activities of OER and HER with low overpotentials and small Tafel slopes, respectively. When applied to overall water splitting, the optimized RuCu NSs/C can reach 10 mA cm at cell voltages of only 1.49, 1.55, 1.49 and 1.50 V in 1 m KOH, 0.1 m KOH, 0.5 m H SO and 0.05 m H SO, respectively, much lower than those of commercial Ir/C∥Pt/C. The optimized electrolyzer exhibits superior durability with small potential change after up to 45 h in 1 m KOH, showing a class of efficient functional electrocatalysts for overall water splitting.© 2019 Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim.

Metallization of 3D printed polymers and their application as a fully functional water-splitting system

[J].

Hierarchically porous nickel sulfide multifunctional superstructures

[J].

Fast fabrication of self-supported porous nickel phosphide foam for efficient, durable oxygen evolution and overall water splitting

[J].

Evolution of nanoporous Pt-Fe alloy nanowires by dealloying and their catalytic property for oxygen reduction reaction

[J].

Nanoporous surface alloys as highly active and durable oxygen reduction reaction electrocatalysts

[J].

Oxygen reduction in nanoporous metal-ionic liquid composite electrocatalysts

[J].The improvement of catalysts for the four-electron oxygen-reduction reaction (ORR; O(2) + 4H(+) + 4e(-) → 2H(2)O) remains a critical challenge for fuel cells and other electrochemical-energy technologies. Recent attention in this area has centred on the development of metal alloys with nanostructured compositional gradients (for example, core-shell structure) that exhibit higher activity than supported Pt nanoparticles (Pt-C; refs 1-7). For instance, with a Pt outer surface and Ni-rich second atomic layer, Pt(3)Ni(111) is one of the most active surfaces for the ORR (ref. 8), owing to a shift in the d-band centre of the surface Pt atoms that results in a weakened interaction between Pt and intermediate oxide species, freeing more active sites for O(2) adsorption. However, enhancements due solely to alloy structure and composition may not be sufficient to reduce the mass activity enough to satisfy the requirements for fuel-cell commercialization, especially as the high activity of particular crystal surface facets may not easily translate to polyfaceted particles. Here we show that a tailored geometric and chemical materials architecture can further improve ORR catalysis by demonstrating that a composite nanoporous Ni-Pt alloy impregnated with a hydrophobic, high-oxygen-solubility and protic ionic liquid has extremely high mass activity. The results are consistent with an engineered chemical bias within a catalytically active nanoporous framework that pushes the ORR towards completion.

Surface evolution of a Pt-Pd-Au electrocatalyst for stable oxygen reduction

[J].

Nanoporous high-entropy alloys for highly stable and efficient catalysts

[J].

Size-dependent morphology of dealloyed bimetallic catalysts: Linking the nano to the macro scale

[J].Chemical dealloying of Pt binary alloy precursors has emerged as a novel and important preparation process for highly active fuel cell catalysts. Dealloying is a selective (electro)chemical leaching of a less noble metal M from a M rich Pt alloy precursor material and has been a familiar subject of macroscale corrosion technology for decades. The atomic processes occurring during the dealloying of nanoscale materials, however, are virtually unexplored and hence poorly understood. Here, we have investigated how the morphology and intraparticle composition depend on the particle size of dealloyed Pt-Co and Pt-Cu alloy nanoparticle precursor catalysts. To examine the size-morphology-composition relation, we used a combination of high-resolutionscanning transmission electron microscopy (STEM), transmission electron microscopy (TEM), electron energy loss (EEL) spectroscopy, energy-dispersive X-ray spectroscopy (EDS), and surface-sensitive cycling voltammetry. Our results indicate the existence of three distinctly different size-dependent morphology regimes in dealloyed Pt-Co and Pt-Cu particle ensembles: (i) The arrangement of Pt shell surrounding a single alloy core ("single core-shell nanoparticles") is exclusively formed by dealloying of particles below a characteristic diameter d(multiple cores) of 10-15 nm. (ii) Above d(multiple cores), nonporous bimetallic core-shell particles dominate and show structures with irregular shaped multiple Co/Cu rich cores ("multiple cores-shell nanoparticles"). (iii) Above the second characteristic diameter d(pores) of about 30 nm, the dealloyed Pt-Co and Pt-Cu particles start to show surface pits and nanoscale pores next to multiple Co/Cu rich cores. This structure prevails up to macroscopic bulklike dealloyed particles with diameter of more than 100 nm. The size-morphology-composition relationships link the nano to the macro scale and provide an insight into the existing material gap of dealloyed nanoparticles and highly porous bulklike bimetallic particles in corrosion science.© 2011 American Chemical Society

Nanotubular mesoporous PdCu bimetallic electrocatalysts toward oxygen reduction reaction

[J].

Nanoporous PdNi bimetallic catalyst with enhanced electrocatalytic performances for electro-oxidation and oxygen reduction reactions

[J].

Mesoporous PdCo sponge-like nanostructure synthesized by electrodeposition and dealloying for oxygen reduction reaction

[J].

Nanostructured catalyst with hierarchical porosity and large surface area for on-chip fuel cells

[J].

Ternary palladium-boron-phosphorus alloy mesoporous nanospheres for highly efficient electrocatalysis

[J].Alloying palladium (Pd) catalysts with various metalloid and nonmetal elements can improve their catalytic performance in different chemical reactions. However, current nanosynthesis methods can only generate Pd alloys containing one metalloid or nonmetal, which limits the types of element combinations that may be used to improve Pd-based nanocatalysts. Herein, we report a simple soft-templating synthetic strategy to co-alloy Pd with the metalloid boron (B) and the nonmetal phosphorus (P) to generate ternary PdBP mesoporous nanospheres (MSs) with three-dimensional dendritic frameworks. We use a one-step aqueous synthesis method where dimethylamine borane and sodium hypophosphite serve as the B and P sources, respectively, as well as the co-reducing agents to drive the nucleation and growth of ternary PdBP alloy on a sacrificial dioctadecyldimethylammonium chloride template. The concentration of metalloid to nonmetal and the diameters of dendritic MSs can be tailored. The synthetic protocol is also extended to other multicomponent PdMBP alloy MSs to generate different types of dendritic mesoporous frameworks. Boron and phosphorus are known to accelerate the kinetics of the electrochemical oxygen reduction reaction (ORR) and alcohol oxidation reactions (AORs), because their alloys promote the decomposition of oxygen-containing intermediates on Pd surfaces. The dendritic mesoporous morphology of the ternary PdBP MSs also accelerates electron/mass transfer and exposes numerous active sites, enabling better performance in the ORR and AORs. Extending the surfactant-templating synthetic route to multiple types of elements will enable the generation of libraries of multicomponent metal-metalloid-nonmetal alloy nanostructures with functions that are suitable for various targeted applications.

Catalytic reduction of oxygen and hydrogen peroxide by nanoporous gold

[J].

Electro-oxidation of ethylene glycol on nanoporous Ti-Cu amorphous alloy

[J].

Nanoporous Pt-Co alloy nanowires: Fabrication, characterization, and electrocatalytic properties

[J].Nanoporous Pt-Co alloy nanowires were synthesized by electrodeposition of Co-rich Pt(1)Co(99) alloy into anodic aluminum oxide (AAO) membranes, followed by a dealloying treatment in a mild acidic medium. These nanowires consist of porous skeletons with tiny pores of 1-5 nm and crystalline ligaments of 2-8 nm. Morphological and compositional evolutions of the porous Pt-Co nanowires upon dealloying were investigated, and their formation mechanism is discussed. The nanoporous Pt-Co alloy nanowires are found to exhibit distinctly enhanced electrocatalytic activities toward methanol oxidation as compared to the current state-of-the-art Pt/C and PtCo/C catalysts, thus showing substantial promise as efficient anode electrocatalysts in direct methanol fuel cells.

Microstructure, electrocatalytic and sensing properties of nanoporous Pt46Ni54 alloy nanowires fabricated by mild dealloying

[J].

Pt-Ni-P nanocages with surface porosity as efficient bifunctional electrocatalysts for oxygen reduction and methanol oxidation

[J].

Mesoporous Pt@PtM (M = Co, Ni) cage-bell nanostructures toward methanol electro-oxidation

[J].

Nanostructured porous gold for methanol electro-oxidation

[J].

Nanoporous gold for enzyme-free electrochemical glucose sensors

[J].

Electrocatalytic oxidation ofD-glucose at nanoporous Au and Au-Ag alloy electrodes in alkaline aqueous solutions

[J].

Electrochemical sensor for detection of p-nitrophenol based on nanoporous gold

[J].

A three-dimensional gold-decorated nanoporous copper core-shell composite for electrocatalysis and nonenzymatic biosensing

[J].

Metallic mesoporous nanocomposites for electrocatalysis

[J].We describe the fabrication, characterization, and applications of ultrathin, free-standing mesoporous metal membranes uniformly decorated with catalytically active nanoparticles. Platinum-plated nanoporous gold leaf (Pt-NPG) made by confining a plating reaction to occur within the pores of dealloyed silver/gold leaf is 100 nm thick and contains an extremely high, uniform dispersion of 3 nm diameter catalytic particles. This nanostructured composite holds promise as a prototypical member of a new class of fuel cell electrodes, showing good electrocatalytic performance at low platinum loading (less than 0.05 mg cm-2), while also maintaining long-term stability against coarsening and aggregation of catalytic nanoparticles.

Ultralow-platinum-loading high-performance nanoporous electrocatalysts with nanoengineered surface structures

[J].

Tailoring the structure and property of Pt-decorated nanoporous gold by thermal annealing

[J].

Nanoporous metals by dealloying multicomponent metallic glasses

[J].

Nanoporous PdCu alloy with enhanced electrocatalytic performance

[J].

Nanoporous PdCu alloy for formic acid electro-oxidation

[J].

Catalyst-electrolyte interface chemistry for electrochemical CO2 reduction

[J].

Tuning the pore structure of porous tin foam electrodes for enhanced electrochemical reduction of carbon dioxide to formate

[J].

Facile fabrication of porous Sn-based catalysts for electrochemical CO2 reduction to HCOOH and syngas

[J].

Electrodeposited porous Pb electrode with improved electrocatalytic performance for the electroreduction of CO2 to formic acid

[J].

Nanoporous gold as a highly selective and active carbon dioxide reduction catalyst

[J].Electrochemical conversion of CO2 into useful chemicals is a promising approach for transforming CO2 into sustainably produced fuels and/or chemical feedstocks for industrial synthesis. We report that nanoporous gold (np-Au) films, with pore sizes ranging from 10 to 30 nm, represent promising electrocatalytic architectures for the CO2 reduction reaction (CO2RR) due to their large electrochemically active surface area, relative abundance of grain boundaries, and ability to support pH gradients inside the nanoporous network. Electrochemical studies show that np-Au films support partial current densities for the conversion of CO2 to CO in excess of 6 mA cm(-2) at a Faradaic efficiency of similar to 99% in aqueous electrolytes (50 mM K2CO3 saturated with CO2). Moreover, np-Au films are able to maintain Faradaic efficiency greater than 80% for CO2 production over prolonged periods of continuous operation (110 h). Electrocatalytic experiments at different electrolyte concentrations demonstrate that the pore diameter of nanoporous cathodes represents a critical parameter for creating and controlling local pH gradients inside the porous network of metal ligaments. These results demonstrate the merits of nanoporous metal films for the CO2RR and offer an interesting architecture for highly selective electrocatalysis capable of sustaining high catalytic currents over prolonged periods.

Visualization of catalytic edge reactivity in electrochemical CO2 reduction on porous Zn electrode

[J].

Atomic-level-designed copper atoms on hierarchically porous gold architectures for high-efficiency electrochemical CO2 reduction

[J].

Hierarchically porous CuAg via 3D printing/dealloying for tunable CO2 reduction to syngas

[J].

Protecting copper oxidation state via intermediate confinement for selective CO2 electroreduction to C2+ fuels

[J].

Accelerated discovery of CO2 electrocatalysts using active machine learning

[J].

Electrochemical synthesis of ammonia from N2 and H2O under ambient conditions using pore-size-controlled hollow gold nanocatalysts with tunable plasmonic properties

[J].

Bimodal nanoporous Pd3Cu1 alloy with restrained hydrogen evolution for stable and high yield electrochemical nitrogen reduction

[J].

Nanoporous intermetallic Pd3Bi for efficient electrochemical nitrogen reduction

[J].

Nanoporous palladium hydride for electrocatalytic N2 reduction under ambient conditions

[J].

Hierarchical nanoporous Pd1Ag1 alloy enables efficient electrocatalytic nitrogen reduction under ambient conditions

[J].

Nanoporous NiSb to enhance nitrogen electroreduction via tailoring competitive adsorption sites

[J].

Electrochemical fabrication of porous Au film on Ni foam for nitrogen reduction to ammonia

[J].

Nanoporous gold embedded ZIF composite for enhanced electrochemical nitrogen fixation

[J].The electrochemical nitrogen reduction reaction (NRR) offers an energy-saving and environmentally friendly approach to produce ammonia under ambient conditions. However, traditional catalysts have extremely poor NRR performances because of their low activity and the competitive hydrogen evolution reaction. The high catalytic activity of nanoporous gold (NPG) and the hydrophobicity and molecular concentrating effect of the zeolitic imidazolate framework-8 (ZIF-8) were incorporated in the NPG@ZIF-8 nanocomposite so that the ZIF-8 shell could weaken hydrogen evolution and retard reactant diffusion. A highest Faradaic efficiency of 44 % and an excellent rate of ammonia production of (28.7±0.9) μg h cm were achieved, which are superior to traditional gold nanoparticles and NPG. Moreover, the composite catalyst shows high electrochemical stability and selectivity (98 %). The superior NRR performance makes NPG@ZIF-8 one of the most promising water-based NRR electrocatalysts for ammonia production.© 2019 Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim.

Effects of hydrophobic layer on selective electrochemical nitrogen fixation of self-supporting nanoporous Mo4P3 catalyst under ambient conditions

[J].

Biodegradable and bioactive porous polymer/inorganic composite scaffolds for bone tissue engineering

[J].Biodegradable polymers and bioactive ceramics are being combined in a variety of composite materials for tissue engineering scaffolds. Materials and fabrication routes for three-dimensional (3D) scaffolds with interconnected high porosities suitable for bone tissue engineering are reviewed. Different polymer and ceramic compositions applied and their impact on biodegradability and bioactivity of the scaffolds are discussed, including in vitro and in vivo assessments. The mechanical properties of today's available porous scaffolds are analyzed in detail, revealing insufficient elastic stiffness and compressive strength compared to human bone. Further challenges in scaffold fabrication for tissue engineering such as biomolecules incorporation, surface functionalization and 3D scaffold characterization are discussed, giving possible solution strategies. Stem cell incorporation into scaffolds as a future trend is addressed shortly, highlighting the immense potential for creating next-generation synthetic/living composite biomaterials that feature high adaptiveness to the biological environment.

Synthesis, characterization and the formation mechanism of magnesium- and strontium-substituted hydroxyapatite

[J].

Strontium incorporation to optimize the antibacterial and biological characteristics of silver-substituted hydroxyapatite coating

[J].

Biomimetic porous scaffolds for bone tissue engineering

[J].

Mechanical properties of biomedical titanium alloys

[J].

Improvements in the superelasticity and change in deformation mode of β-type TiNb24Zr2 alloys caused by aging treatments

[J].

Biomedical properties of porous NiTi shape memory alloy and its prospect in medical application

[J].

多孔NiTi形状记忆合金的生物医学特性及其医用前景

[J].

Progress in research on normal sintering of porous TiNi alloys

[J].

用粉末冶金法制备医用多孔TiNi合金的研究

[J].

Effect of voltage on properties of the ceramic coatings prepared by micro-arc oxidation on titanium

[J].

电压对钛表面微弧氧化陶瓷层特性的影响

[J].

Pore features of porous TiNi alloy sintered in argon atmosphere

[J].

氩气保护烧结多孔TiNi合金孔隙特征的研究

[J].

Effect of NaOH concentration on formation of bone-like apatite layer on NiTi shape memory alloy

[J].

NaOH浓度对NiTi形状记忆合金表面类骨磷灰石形成的影响

[J].研究了不同浓度NaOH对NiTi形状记忆合金在模拟体液(SBF)中诱导磷灰石沉积的影响. 用XRD, ESEM, FTIR及XPS等分析了碱处理前后试样表面的结构、形貌、基团和组元化合价的变化. 结果表明, 经1 mol/L NaOH溶液处理的NiTi合金因为钛酸钠的生成而具有较高的生物活性,在SBF中浸泡3 d后自然沉积含CO32-的类骨磷灰石,而且原子吸收光谱分析其在Hank’s溶液中的镍离子溶出量最少. 随着碱处理浓度的提高, NiTi合金表面除钛酸钠外, 还有镍酸钠生成, 使磷灰石形核的孕育期加长, 在Hank’s溶液中的镍离子溶了量也明显增加.

Optimization of bioactive layer processing using chemical method on the surface of NiTi SMA

[J].

NiTi形状记忆合金表面化学法制备生物活性层工艺的优化

[J].

Corrosion behavior of porous Ti-24Nb-4Zr alloy in different simulated body fluids

[J].

Femtosecond laser-induced micropattern and Ca/P deposition on Ti implant surface and its acceleration on early osseointegration

[J].

Effect of pore structure regulation on the properties of porous TiNbZr shape memory alloys for biomedical application

[J].

Effect of laser functionalization of titanium on bioactivity and biological response

[J].

Direct metal fabrication of titanium implants with tailored materials and mechanical properties using electron beam melting technology

[J].

Research progress of 3D printing magnesium-based biomaterials for bone defect repair

[J].

3D打印含镁生物医用材料用于骨缺损修复研究进展

[J].

Prospects and strategies for magnesium alloys as biodegradable implants from crystalline to bulk metallic glasses and composites—A review

[J].

Cytotoxicity assessment of adipose-derived mesenchymal stem cells on synthesized biodegradable Mg-Zn-Ca alloys

[J].

In vitro corrosion and biocompatibility of binary magnesium alloys

[J].As bioabsorbable materials, magnesium alloys are expected to be totally degraded in the body and their biocorrosion products not deleterious to the surrounding tissues. It's critical that the alloying elements are carefully selected in consideration of their cytotoxicity and hemocompatibility. In the present study, nine alloying elements Al, Ag, In, Mn, Si, Sn, Y, Zn and Zr were added into magnesium individually to fabricate binary Mg-1X (wt.%) alloys. Pure magnesium was used as control. Their mechanical properties, corrosion properties and in vitro biocompatibilities (cytotoxicity and hemocompatibility) were evaluated by SEM, XRD, tensile test, immersion test, electrochemical corrosion test, cell culture and platelet adhesion test. The results showed that the addition of alloying elements could influence the strength and corrosion resistance of Mg. The cytotoxicity tests indicated that Mg-1Al, Mg-1Sn and Mg-1Zn alloy extracts showed no significant reduced cell viability to fibroblasts (L-929 and NIH3T3) and osteoblasts (MC3T3-E1); Mg-1Al and Mg-1Zn alloy extracts indicated no negative effect on viabilities of blood vessel related cells, ECV304 and VSMC. It was found that hemolysis and the amount of adhered platelets decreased after alloying for all Mg-1X alloys as compared to the pure magnesium control. The relationship between the corrosion products and the in vitro biocompatibility had been discussed and the suitable alloying elements for the biomedical applications associated with bone and blood vessel had been proposed.

Additively manufactured biodegradable porous metals

[J].Partially due to the unavailability of ideal bone substitutes, the treatment of large bony defects remains one of the most important challenges of orthopedic surgery. Additively manufactured (AM) biodegradable porous metals that have emerged since 2018 provide unprecedented opportunities for fulfilling the requirements of an ideal bone implant. First, the multi-scale geometry of these implants can be customized to mimic the human bone in terms of both micro-architecture and mechanical properties. Second, a porous structure with interconnected pores possesses a large surface area, which is favorable for the adhesion and proliferation of cells and, thus, bony ingrowth. Finally, the freeform geometrical design of such biomaterials could be exploited to adjust their biodegradation behavior so as to maintain the structural integrity of the implant during the healing process while ensuring that the implant disappears afterwards, paving the way for full bone regeneration. While the AM biodegradable porous metals that have been studied so far have shown many unique properties as compared to their solid counterparts, the unprecedented degree of flexibility in their geometrical design has not yet been fully exploited to optimize their properties and performance. In order to develop the ideal bone implants, it is important to take advantage of the full potential of AM biodegradable porous metals through detailed and systematic study on their biodegradation behavior, mechanical properties, biocompatibility, and bone regeneration performance. This review paper presents the state of the art in AM biodegradable porous metals and is focused on the effects of material type, processing, geometrical design, and post-AM treatments on the mechanical properties, biodegradation behavior, in vitro biocompatibility, and in vivo bone regeneration performance of AM porous Mg, Fe, and Zn as well as their alloys. We also identify a number of knowledge gaps and the challenges encountered in adopting AM biodegradable porous metals for orthopedic applications and suggest some promising areas for future research.Copyright © 2020 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Corrosion resistance and surface biocompatibility of a microarc oxidation coating on a Mg-Ca alloy

[J].The Mg-Ca alloy system has been proposed as a potential new kind of degradable biomaterial with possible application within bone. Here microarc oxidation (MAO) coatings were fabricated on top of a Mg-Ca alloy using different applied voltages and the effect of applied voltage on the surface morphology and phase constitution, hydrogen evolution, pH variation in the immersion solution and in vitro biocompatibility of the MAO coating on the Mg-Ca alloy were extensively studied. It was found that the thickness and pore size of the MAO coating increased with the increasing applied voltage, whereas some micro-pores could be seen inside the 400 V treated MAO coating. The 360 V treated MAO coating gave the best long-term corrosion resistance during a 50 days immersion test. All the MAO coatings could promote MG63 cell adhesion, proliferation and differentiation in comparison with the uncoated Mg-Ca alloy sample, due to significantly reduced Mg ion release and pH value variations in the culture medium. After 5 days culture well-spread and elongated MG63 cells could be seen on the surface of the 360 V and 400 V MAO coatings, in contrast to no cells on the uncoated Mg-Ca alloy sample. In summary, MAO showed beneficial effects on the corrosion resistance of, and thus improved cell adhesion to, the Mg-Ca alloy, and should be a good surface modification method for other biomedical magnesium alloys.Copyright © 2010 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Development and degradation behavior of magnesium scaffolds coated with polycaprolactone for bone tissue engineering

[J].

Osteogenic magnesium incorporated into PLGA/TCP porous scaffold by 3D printing for repairing challenging bone defect

[J].Bone defect repair is a challenging clinical problem in musculoskeletal system, especially in orthopaedic disorders such as steroid associated osteonecrosis (SAON). Magnesium (Mg) as a biodegradable metal with properly mechanical properties has been investigating for a long history. In this study, Mg powder, poly (lactide-co-glycolide) (PLGA), β-tricalcium phosphate (β-TCP) were the elements to formulate a novel porous PLGA/TCP/Mg (PTM) scaffolds using low temperature rapid prototyping (LT-RP) technology. The physical characterization of PTM scaffold and Mg ions release were analyzed in vitro. The osteogenic and angiogenic properties of PTM scaffolds, as well as the biosafety after implantation were assessed in an established SAON rabbit model. Our results showed that the PTM scaffold possessed well-designed bio-mimic structure and improved mechanical properties. Findings of dynamic contrast-enhanced magnetic resonance imaging (DCE-MRI) and micro-computed tomography (micro CT)-based angiography indicated that PTM scaffold could increase blood perfusion and promote new vessel ingrowth at 4 weeks after surgery, meanwhile, a plenty of newly formed vessels with well-architective structure were observed at 8 weeks. Correspondingly, at 12 weeks after surgery, micro-CT, histological and mechanical properties analysis showed that PTM could significant enhance new bone formation and strengthen newly formed bone mechanical properties. The mean bone volume in PTM group was 56.3% greater than that in PT group. Biosafety assessments from 0 to 12 weeks after implantation did not induce increase in serum Mg ions concentration, and immune response, liver and kidney function parameters were all at normal level. These findings suggested that the PTM scaffold had both osteogenic and angiogenic abilities which were synergistic effect in enhancing new bone formation and strengthen newly formed bone quality in SAON. In summary, PTM scaffolds are promising composite biomaterials for repairing challenging bone defect that would have great potential for its clinical translation.Copyright © 2019. Published by Elsevier Ltd.

Magnesium alloy based interference screw developed for ACL reconstruction attenuates peri-tunnel bone loss in rabbits

[J].Peri-tunnel bone loss after anterior cruciate ligament (ACL) reconstruction is often observed clinically, which may detrimentally affect tendon graft integration with surrounding bone tissue. Biodegradable magnesium (Mg) based fixators in terms of interference screws may be suitable for fixation of the tendon graft due to their favorable effects on promotion of new bone formation. However, the poor mechanical strength of Mg is still one of the major challenges for its clinical applications. The addition of alloying elements into Mg is one of the strategies to improve their mechanical properties. Here, we prepared magnesium (Mg)-(4 and 6 wt%) zinc (Zn)-(0.2, 0.5, 1 and 2 wt%) strontium(Sr) alloys and tested their potential for attenuating peri-tunnel bone loss in ACL reconstruction. The optimal (6 wt%) Zn and (0.5 wt%) Sr contents were screened with respect to the microstructures, mechanical properties and corrosion behavior of these alloys. As compared to pure Mg, Mg-6Zn-0.5Sr rods and screws showed significantly higher torque and torsional stiffness in both numerical and experimental analysis. The in vitro cyto-compatibility of Mg-6Zn-0.5Sr alloy was assessed with MTT test and fluorescence assay. The Mg-6Zn-0.5Sr interference screw was designed for fixation of the tendon graft to the femoral tunnel in a rabbit model of ACL reconstruction, with a commercially available poly-lactide (PLA) screw for comparison. In vivo high resolution peripheral quantitative computed tomography (HR-pQCT) scanning was performed to measure the degradation behavior of Mg-6Zn-0.5Sr interference screws and peri-tunnel bone quality at 0, 6, 12 and 16 weeks post-surgically. Mg-6Zn-0.5Sr interference screw was completely degraded within 12 weeks after surgery. The peri-tunnel bone loss was significantly attenuated in the Mg-6Zn-0.5Sr group when compared to the PLA group. Importantly, the bony ingrowth rapidly filled the cavity left by the complete degradation of Mg-6Zn-0.5Sr screws at 16 weeks. In histological analysis, more bone formation was observed in peri-tunnel region in the Mg-6Zn-0.5Sr group in comparison to the PLA group at 6 and 16 weeks after surgery. The femur-tendon graft-tibia complex was harvested at the end of week 6 and 16 post-operation for tensile testing. The maximum load to failure was significantly improved in the Mg-6Zn-0.5Sr group at week 16 post-operation. Therefore, our results indicate the potential clinical application of MgZnSr based interference screws in ACL reconstruction.Copyright © 2017 Elsevier Ltd. All rights reserved.

Additively manufactured biodegrabable metal implants

[J].Additive manufacturing (AM) can produce complicated structures accurately and freely, giving the implant a macro and micro geometry, which makes the implant match the patient's defect site and realize the needs for personalized clinical treatment. Thus, AM provides a new manufacturing method for biodegradable metals. Presently, biodegradable metals are the hotspot issues of metallic biomaterials research. Additively-manufactured biodegradable metals are new research field. In this paper, a comprehensive review on the AM of Mg-, Zn-, and Fe-based biodegradable metals, which focuses on their processes and influencing factors, mechanical properties, biodegradation behavior, and biocompatibility, is given. Finally, the future development trend of the AM biomedical metallic materials is explored.

增材制造可降解金属医用植入物

[J].增材制造技术由于其高精度、高自由度等特点,可赋予医用金属植入物定制化的宏观与微观结构,使植入物与患者待修复缺损部位实现更好的生物力学适配,满足临床治疗个性化方案的需求,并为医用金属植入物的制造提供新途径。可降解金属目前是医用金属的研究热点,增材制造可降解金属医用植入物是个新方向,本文重点对增材制造镁基、锌基、铁基可降解金属的工艺流程及影响因素、力学性能、降解行为、生物相容性相关结果进行分析与总结,并展望了增材制造技术在医用可降解金属植入物领域的未来发展方向。

Additively manufactured functionally graded biodegradable porous iron