随着航空航天、汽车、造船工业的发展,对于高强、高韧材料的需求愈加迫切。而强度(即材料抵抗形变和断裂的能力)和韧性(即材料中存在裂纹而不发生失稳断裂的能力)作为决定金属构件服役过程中损伤或失效行为的2个关键力学性能参量,却往往此消彼长,呈倒置关系,即强度提高的同时多会导致断裂韧性的恶化。因此,实现金属材料的同步强化和韧化是材料学家面临的一项长期挑战。

从微观结构方面考虑,细化晶粒是实现金属材料强度和韧性同步提升的有效方法之一,但通常仅当晶粒尺寸在微米尺度时(>1 μm)效果明显[1];当晶粒进一步细化至亚微米~纳米尺度,大量晶界强化材料的同时,不可避免地造成塑性和韧性的损失[2],原因在于纳米晶粒内部位错运动严重受阻,导致应变硬化能力降低,无法有效地钝化裂纹[2,3];另外,在断裂过程中,高密度的大角度晶界也成为微观孔洞的优先形核位置(晶界/三叉晶界处容易产生应力集中)[4,5]。与此同时,高强度也促使纳米结构金属对裂纹尺寸更加敏感(相对于低强度材料而言),仅当裂纹尺寸很小时,纳米结构金属的高强度才能够完全发挥作用;一旦裂纹尺寸超过某一临界值(通常非常小,约几十微米)[6],高强材料的实际承载能力将会极大地受限于断裂韧性和裂纹长度。由于材料在加工或服役过程中,内部会不可避免地引入裂纹、孔洞等缺陷,因此,为确保高强度纳米结构金属在工程服役过程中的安全性,避免由于内部裂纹的存在而导致低载荷下破坏失效,精确测定其断裂韧性并研究其断裂行为和韧化机制至关重要。

与传统均质纳米结构金属通过控制内部结构缺陷(如位错或晶界等)的形成、持续减小特征微观结构尺度来阻碍位错运动实现强化的策略不同,异质纳米结构通过引入2种或2种以上具有显著性能差异的组分单元(组元的微观结构尺寸至少有一维特征尺寸在纳米量级)来实现综合力学性能的优化。通过调整组分间的异质性(如晶粒尺寸、晶体结构、晶体取向或化学成分等的差异[7]),或组分单元的本征属性、几何形态、体积分数、空间排布方式等,可构建出多样化的异质结构,如梯度结构[8,9]、双相结构[10,11]、层状结构[12]、双峰结构[13]等。得益于塑性变形过程中异质组元间的相互约束以及塑性不协调引发的几何必需位错(geometrically necessary dislocations,GNDs)的累积和背应力强化(又称为异质变形诱导强化,hetero-deformation induced (HDI) strengthening[14],具体描述见下节),异质纳米结构金属普遍兼顾高强度、高塑性和加工硬化[15],同时可克服纳米结构金属的极端脆性,实现高的断裂抗力[16],而这是传统均质或随机混合结构金属均无法实现的。

目前,对于异质结构金属的塑性变形机制以及强塑性协同方面的研究较为深入,而对于其断裂行为及韧化机制的研究却相对有限。相比于强度和塑性的测试(通过单轴拉伸实验),断裂韧性的测量过程相对复杂,且对试样尺寸、实验设备、测试方法以及后续的应力/应变分析等要求较高。为准确获得与试样尺寸无关的本征平面应变断裂韧性(KIC或JIC),首先应制备出三维尺寸足够大的块体样品,以满足线弹性断裂力学(B, b0 ≥ 2.5(KIC / σY)2,式中B为试样厚度;b0为初始韧带长度;σY为有效屈服强度)或弹塑性断裂力学(B, b0 ≥ 10 JIC / σY)对试样的尺寸要求[17]。而目前大部分制备方法,无论是自下而上的方法(如物理气相沉积[18]、电沉积[19,20]),还是自上而下的塑性变形技术(如表面塑性变形[21,22]等),所获异质结构样品均难以满足上述尺寸要求。另外,由于样品尺寸有限,通常需要利用微型试样(由标准试样等比例缩小),并采用对试样尺寸要求较小的弹塑性断裂力学(J积分)的方法进行断裂韧性测试。该方法面临的挑战是精准地测量微型试样的加载线位移(load-line displacement,LLD)以便于利用柔度法实时监控裂纹扩展长度。而由于传统夹式COD规(crack opening displacement (COD) gauge)本身尺寸太大,无法适用于微型断裂试样。因此,制备技术和测试方法的局限给异质纳米结构金属断裂韧性的研究带来了巨大挑战。

1 异质结构金属的强化机制

1.1 组元间加工硬化差异对异质层状结构金属力学行为的影响

层状结构是一种特征明显的异质结构,由不同微观结构组元在良好界面结合情况下相互叠加而成,内部含有大量的异质界面,且界面两侧存在较大的力学性能差异。通常,组元间力学性能(如硬度、强度)差异越大,层状结构材料的强化效果越明显[32]。

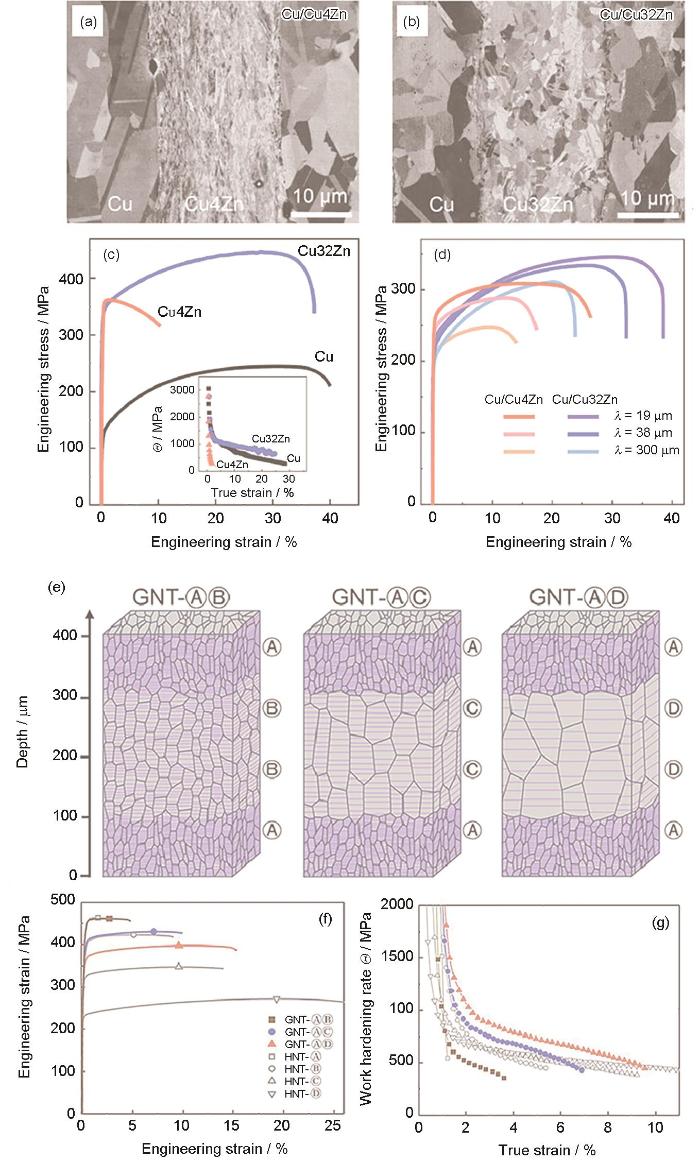

组元间的塑性或加工硬化能力差异也是调整层状结构金属微观应变分布以及宏观力学行为的重要因素[30]。对于2组具有相同组元强度,但加工硬化差异不同的层状结构Cu/Cu4Zn和Cu/Cu32Zn样品(图1a~c[33]),单轴拉伸结果显示:随层厚的减小,2组样品均表现出强度和均匀延伸率的同步提升(图1d[33]),这与GNDs密度的提高有关。但加工硬化差异较大的Cu/Cu4Zn表现出更高的屈服强度(图1d[33])。这表明,在保持组元间强度差异相当的情况下,提高组元间加工硬化能力的差异,将更有助于实现层状结构材料在初始变形阶段的强化作用。全场应变分析发现,组元间加工硬化能力差异越大,塑性变形初期的应变分区越明显,界面处累积的GNDs密度更高,从而提升了层状结构的整体屈服强度[33]。

图1

图1

层状结构Cu/Cu4Zn和Cu/Cu32Zn的局部微观结构(层间距λ = 19 μm)与相应的工程应力-应变曲线,以及3种层状纳米孪晶Cu样品的微观结构示意图与相应的工程应力-应变曲线和加工硬化率曲线,并与相应的单组分进行对照[33,34]

Fig.1

Microstructures and engineering stress-strain curves of laminated Cu/Cu4Zn and Cu/Cu32Zn, or nanotwinned Cu samples (GNT—gradient nanotwinned, HNT—homogeneous nanotwinned)

(a, b) microstructures of laminated Cu/Cu4Zn (a) and Cu/Cu32Zn (b) with layer thickness (λ) of 19 μm[33] (c, d) tensile engineering stress-strain curves of freestanding Cu, Cu4Zn, and Cu32Zn samples (c), and laminated Cu/Cu4Zn, Cu/Cu32Zn with different layer thicknesses (d) (Inset in Fig.1c shows work-hardening rate vs true strain of freestanding Cu, Cu4Zn, and Cu32Zn)[33] (e-g) schematics of microstructures of three sandwiched nanotwinned Cu samples (GNT-ⒶⒷ, GNT-ⒶⒸ, and GNT-ⒶⒹ) (e), and their engineering stress-strain curves (f) and work hardening rate (Θ) vs true strain curves (g) in comparison to their HNT components[34]

这种组元间加工硬化差异(或组分间的塑性变形不兼容)也可以用于设计高性能梯度或层状结构纳米孪晶金属[34]。如图1e[34]所示,通过在2个固定的表层硬组元(较小的晶粒尺寸和孪晶片层间距)中间等比例构建具有不同微观结构(不同晶粒尺寸和孪晶片层间距)的软组元,设计出具有不同组元间加工硬化差异的纳米孪晶Cu样品[34],发现具有较大的加工硬化差异的样品(GNT-ⒶⒹ)表现出更强的抑制应变局域化的能力,并诱导产生更高密度的GNDs。这有助于提高变形稳定性,延长变形初期的弹-塑性过渡阶段,从而获得更高的额外强化和加工硬化[34]。这种通过改变组元间加工硬化差异实现异质纳米结构金属的性能优化的策略,为高性能层状或梯度纳米结构金属的设计提供了新思路。

1.2 异质纳米孪晶结构金属的强化机制

纳米孪晶结构在实现金属的强韧化方面具有独特的优势,这是由于低能的共格孪晶界不仅能够有效地阻碍位错运动从而强化金属,同时还能够为位错提供丰富的存储空间,维持良好的塑性和加工硬化[35]。这种优势不仅体现在均匀纳米孪晶金属中(将纳米孪晶均匀地引入到亚微米或微米尺度的晶粒内部),而且在异质结构中也可发挥有效的强韧化作用。通过动态塑性变形(dynamic plastic deformation,DPD)技术,将纳米孪晶束(nanotwin bundle)作为一种“异质相”引入到纳米晶或粗晶基体中,已实现多种金属或合金的强韧化[36~38]。例如,通过引入体积分数为24%的纳米孪晶束,可将316L奥氏体不锈钢强化到约1.4 GPa[39],并能维持良好的断裂韧性[37]。这是由于纳米孪晶束不仅能够有效地强化金属(归因于其超高的强度[40,41]),同时,在断裂过程中,还能够发挥有效的本征和非本征韧化作用,从而提高异质纳米结构金属的断裂韧性(详见2.2节)[37,38]。

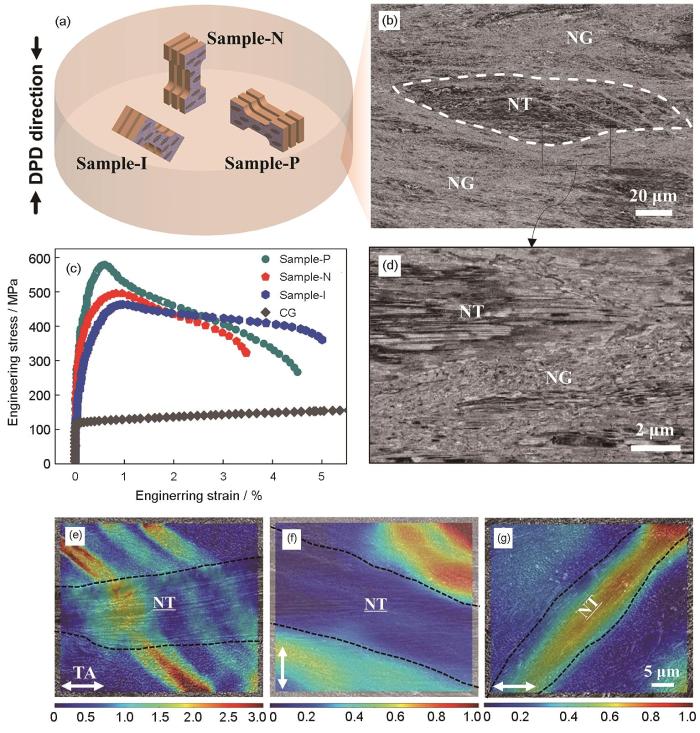

纳米孪晶束取向是调控其强化效果的重要因素。均匀纳米孪晶作为一种典型的二维结构,即相对较小的孪晶片层间距(处于纳米尺度)和相对较大的孪晶片层长度(处于亚微米~微米尺度),导致其塑性变形机制以及宏观力学行为存在显著的各向异性,即:存在3种位错模式(① 硬模式I:位错滑移并穿过孪晶界;② 硬模式II:贯穿位错(threading dislocations)在孪晶片层内部受限滑移;③ 软模式:Shockley不全位错沿孪晶界滑移分别主导着垂直于孪晶界(twin boundaries,TBs)、平行于TBs和45°倾斜于TBs方向上的塑性变形[44])。因此,均匀择优取向纳米孪晶Cu在宏观上表现出显著的各向异性强化和加工硬化,其中垂直于TBs的强度最高,平行于TBs的强度中等,而45°加载时强度最低[44]。

图2

图2

拉伸试样在动态塑性变形(DPD) Cu样品中的取样方式示意图,DPD Cu样品中典型的截面微观结构(显示纳米孪晶束(NT)镶嵌在纳米晶(NG)基体中),纳米孪晶/纳米晶混合结构Cu在不同加载方向下的拉伸工程应力-应变曲线,并与粗晶Cu进行对比,及Sample-P、Sample-N和Sample-I在1.0%宏观应变量下的局部全场应变分布图[45]

Fig.2

Sampling schematic diagram, cross-sectional microstructures, and stress-strain curves of DPD Cu (DPD—dynamic plastic deformation)[45]

(a) schematic of the tensile specimens in the DPD disc and their orientations relative to the twin boundaries (TBs), i.e., parallel, normal, and 45° inclined to TBs, hereafter referred to as sample-P, sample-N, and sample-I, respectively (b, d) typical cross-sectional microstructures of DPD Cu, showing the nanotwins (NT) in the form of bundles embedded in a matrix of nanograins (NG) (c) tensile engineering stress-strain curves for the DPD processed heterogeneous nanostructured Cu and the coarse-grained (CG) Cu serve as a counterpart for comparison (e-g) local strain fields in sample-P (e), sample-N (f), and sample-I (g) at applied strain of 1.0%. The nanotwinned regions are denoted as NT, where the underscore indicated the direction parallel to TBs. The black dash lines indicate the position of the NT/NG interfaces. The tensile axes (TA) are represented by the double-headed arrows

2 异质结构金属的韧化机制

材料的韧化通常可通过本征和非本征2类韧化机制来实现[46]。其中本征韧化来源于材料微观结构本身对裂纹形核和扩展的固有阻力,一般与晶粒尺寸、晶粒形状、第二相颗粒的尺寸和分布等微观结构特征有关;而非本征韧化机制是指通过裂纹偏折、裂纹桥连等机制降低裂纹尖端的局部应力场,从而降低裂纹扩展的局部驱动力。

高强金属(如纳米晶金属、金属玻璃等)通常表现出较差的断裂韧性,也可通过这2类机制实现韧化。例如,设计强度和韧性交替变化的多层或梯度异质结构可有效改善其韧性,其相应的韧化机制会受到裂纹取向、界面强度以及组元微观结构特征等诸多因素的影响。

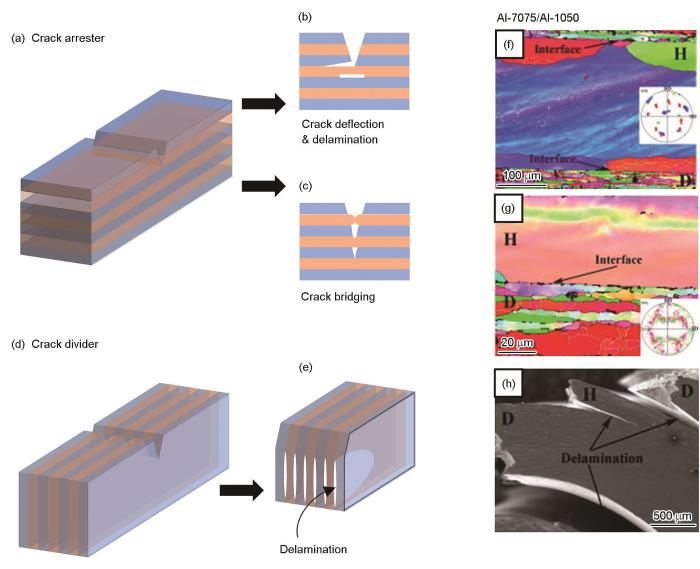

2.1 异质层状结构金属的韧化机制

层状结构金属由于存在大量的层间界面,可以激活多种与界面相关的机制,实现材料增韧,如图3a~e所示。这些韧化机制的启动取决于裂纹与层界面的相对取向[47,48]:当裂纹面和裂纹扩展方向均垂直于异质界面时(即图3a所示的Crack arrester方向),如果界面结合力较弱(对于金属/陶瓷、金属/聚合物等复合材料而言)[48~50],则会因界面脱粘而发生裂纹偏折或层裂(图3b),这会显著降低裂纹尖端的局部应力场强度[51],并促进裂纹尖端钝化[47];而当界面结合力较强,且软/硬层之间存在较大的塑性或韧性差异时(如金属/非晶、粗晶金属/纳米晶金属组成的异质层状结构),微裂纹会优先在脆性非晶或纳米晶层中形核,但随后裂纹扩展会被韧性层所阻碍(图3c)。在此过程中,韧性层可通过塑性变形来耗散能量,并在裂纹尾迹桥连裂纹,阻碍裂纹扩展[52,53]。

图3

图3

层状异质结构材料在不同裂纹取向下的韧化机制,Al-7075/Al-1050异质层状结构金属的EBSD微观结构[54]及其在Crack arrester方向冲击断裂的SEM断面形貌[54]

Fig.3

Toughening mechanisms recorded in laminated materials with different cracking orientations relative to the heterointerfaces (a-e), EBSD and SEM images of the Al-7075/Al-1050 laminate (f-h)

(a-c) crack arrester orientation with both crack plane and crack growth direction perpendicular to the interfaces, where the crack deflection, delamination, or crack bridging may be activated (d, e) crack divider orientation with the crack plane perpendicular to the interfaces while the crack growth direction parallel to the interfaces, where the delamination may be developed (f, g) EBSD maps show the microstructure of the Al-7075/Al-1050 laminate[54] (h) SEM image of a Charpy fractured sample of the Al-7075/Al-1050 laminate tested in crack arrester orientation[54]

层状结构材料中界面的增韧效果与其结合强度密切相关[57]。对于由高碳钢和低碳钢组成的多层结构[58],在Crack arrester方向表现出抗冲击性能的极大改善,这源于缺口附近界面脱粘导致的裂纹钝化。在此过程中,界面结合力越弱,反而越有利于界面脱黏和能量吸收,从而获得更加优异的抗冲击性能[58]。将高碳钢与黄铜进行复合组成异质层状结构,可有效消除高碳钢的韧脆转变行为,并获得优异的低温抗冲击性能[59]。利用该原理,还有望改善高强纳米结构金属的脆性。例如,利用热轧工艺制备将细晶Al-7075铝合金层与粗晶Al-1050层交替堆叠成层状结构(图3f和g[54]),获得的冲击韧性是初始态Al-7075合金的近18倍[54]。这种断裂抗力的优化归因于高强Al-7075的本征韧化以及界面脱粘导致的层裂和裂纹偏折(图3h[54])。由此可见,通过调整界面结合强度及维持可控的界面脱粘是异质层状结构金属获得高韧性的关键。

层状结构材料的断裂行为也表现出显著的尺寸效应[61]。对于纳米多层结构金属(由层厚在纳米级的组元交替叠加构成),其强度/硬度通常随单层厚度的降低(在几百纳米~几纳米范围)而呈现出上升趋势[62]。然而,塑性和韧性却呈现出不同的层厚依赖性[60,63]。研究[60,63]发现,对于由韧性Cu层和脆性的X层(X = Nb或Zr)组成的软/硬交替多层膜(图4a和b[60]),其韧性和塑性随层厚变化并非单调变化,而是存在一个明显的临界层厚值(约25 nm),韧性或塑性在该值附近达到峰值(图4c[60])。原因在于:对于韧/脆多层结构金属,微裂纹首先在脆性层形核,而韧性层可以通过发射位错钝化裂纹,从而限制裂纹的扩展。当层厚大于25 nm时,随着层厚的减小,脆性X层中的裂纹尺寸以及相应的裂纹尖端应力场强度逐渐减小,此时Cu层可以有效地约束裂纹扩展,因而宏观表现为断裂韧性的增加[63];但随着层厚继续降低至25 nm以下,Cu层内位错活动逐渐受到抑制,导致其对含裂纹脆性X层的约束作用减弱,因而断裂韧性降低,表现出宏观脆性[60]。该结果表明,通过构建异质多层结构,并合理调控软/硬层比例或层厚,确保软层对硬层的有效约束作用,可以使脆性金属在不损失高强度的情况下实现增韧。

图4

图4

纳米多层结构Cu/Nb和Cu/Zr的微观结构,及Cu/Nb和Cu/Zr多层膜中断裂韧性(KIC)随Cu层厚度(hCu)的变化关系[60]

Fig.4

Microstructure and fracture toughness of nanolayered metals[60] (a, b) microstructures and corresponding SAED patterns (insets) of Cu/Nb (a) and Cu/Zr (b) nanolayered films (c) dependence of fracture toughness (KIC) on the thickness of Cu layer (hCu) for the Cu/Nb and Cu/Zr films (dots and left y-axis), and the calculated normalized KIC (lines and right y-axis) at different normalized cohesive strengths (σc / μ, where σc is cohesive strength and μ is the shear modulus of Cu layer)

2.2 异质纳米孪晶结构金属的韧化机制

图5

图5

断裂试样在DPD Cu样品中的取样方式示意图,不同取向试样的裂纹扩展阻力(J-R)曲线,及裂纹扩展过程示意图[16]

Fig.5

Schematic illustration of the CT specimens and their orientations, J-integral resistance

(a) schematic illustration of the CT specimens and their orientations in the DPD disc. The CT specimens were labeled with two-letter codes based on the crack plane orientation and crack growth direction with respect to the TBs inside the NTBs, i.e., parallel (P), normal (N), and 45° inclined (I) to the TBs, respectively; i.e., P-P, N-N, I-I and N-P, where the first letter designates the orientation of the expected crack plane with respect to the TBs, while the second letter designates the crack propagation direction with respect to the TBs

(b) J-R curves (c-f) schematic illustration of the failure process under different cracking orientations (The insert SEM image in Fig.5e shows a micro-crack (indicated by the white arrow) initiated at the NT/NG interface)

鉴于纳米孪晶存在明显的各向异性变形和力学行为[44],研究其各向异性韧化行为也十分重要。对于由择优取向纳米孪晶束和纳米晶基体组成的异质纳米结构Cu (微观结构见图2b和d[45]),分别沿着不同的裂纹方向(相对于孪晶界,如图5a[16]所示)进行断裂韧性测试[16],并获得完整的裂纹扩展阻力(J-integral resistance,J-R)曲线(图5b[16])。结果表明:当裂纹面和裂纹扩展方向均垂直于孪晶界时(即图5a[16]中的N-N取向),断裂韧性最高,其JIC值是P-P取向(裂纹面和裂纹扩展方向均平行于孪晶界)的近3倍。这种各向异性断裂韧性与纳米孪晶束的各向异性韧化以及拉长状纳米晶导致的裂纹偏折有关[16]。当裂纹沿N-P和N-N取向扩展时(图5c和d[16]),纳米孪晶束可以发挥桥连韧带的作用,阻碍裂纹扩展;而对于P-P和I-I取向(图5e和f[16]),纳米孪晶束会因与周围纳米晶基体发生塑性变形不协调(图2f和g[45]),而导致两组分界面处提前萌生微裂纹(图5e插图[16]),从而导致纳米孪晶束无法发挥有效的桥连韧化作用。此外,在N-N和I-I取向下(图5d和f[16]),还出现了明显的裂纹偏折,这是由于主裂纹面偏离纳米晶长轴所致。值得注意的是,N-N取向同时激活了裂纹桥连和裂纹偏折2种韧化机制,因而获得了非常优异的强韧性匹配(KIC约90 MPa·m1/2,σy约535 MPa)。由此可见,通过调整纳米孪晶在异质结构中的取向也是优化其强韧性匹配的有效途径。

3 结语与展望

异质纳米结构金属由于存在特殊的界面行为以及异质组元间的耦合作用,使其在强韧化方面表现出明显的优势。其多尺度、多组元、多结构的设计,以及丰富的微观结构特征/参数为异质纳米结构材料的可控设计和强韧性的进一步优化提供了极大的潜力。

在对异质纳米结构金属的塑性变形机制、强化机制认识的基础上,深入系统地理解其断裂行为和韧化机制也至关重要,这也是确保其安全工程服役的关键。关于异质纳米结构金属强化和韧化机制方面的研究,目前学界关注的热点以及面临的挑战主要涉及以下问题:

(1) 断裂韧性测试原理与技术

目前对于块体层状结构金属断裂韧性的研究大都采用定性的Charpy冲击方法,亟需发展定量的准静态断裂韧性测试技术,以获取其本征的断裂韧性值(KIC或JIC)。

显微力学测试技术的发展(如微纳尺度下的悬臂梁弯曲试验),使小尺寸脆性陶瓷/陶瓷或准脆性金属/金属玻璃复合薄膜的本征断裂性能测试取得了很大进展。但对于韧性较好的金属/金属纳米多层薄膜,仍面临着巨大的实验技术挑战(由于裂尖塑性区尺寸较大,其相应的断裂机制在小尺寸试样下发生了根本性的改变)[49]。

对于非均质的异构金属,基于连续介质的断裂力学准则是否有效,仍存在疑问。

(2) 高强、高韧异质纳米结构设计及强韧性优化

将异质层状结构中界面主导的强韧化机制与其他机制(如纳米沉淀、相变、孪生等)结合,以实现综合性能的进一步优化。

利用机器学习预测和设计具有最优化性能的异质结构材料。

(3) 异质纳米结构金属断裂行为及韧化机制的深入探索

由于异质纳米结构金属的多样性,不同类型的异质结构在断裂过程中,也将呈现出不同的断裂模式和韧化机制。例如,对于梯度结构金属,梯度顺序、梯度大小、梯度种类(如梯度位错、梯度孪晶)等如何影响梯度材料的断裂行为,尚不明确。

加载模式(如单调加载或循环加载)以及外部环境(如温度、腐蚀介质等)如何影响异质结构金属的断裂和疲劳裂纹扩展行为,仍需要进一步的探索。

通过实验和计算模拟相结合的方法深入探索异质结构金属的微观断裂行为及相关机制(如裂纹尖端的应力/应变分布、微观孔洞形核机制等)。

以上问题,对于深入理解异质结构金属的强韧化机制,实现其综合力学性能进一步优化以及潜在的工程应用,具有非常重要的意义。

参考文献

Mechanical properties of nanocrystalline materials

[J].

Shear bands at the fatigue crack tip of nanocrystalline nickel

[J].

Deformation of electrodeposited nanocrystalline nickel

[J].

Dislocation activity and nano-void formation near crack tips in nanocrystalline Ni

[J].

The importance of fracture toughness in ultrafine and nanocrystalline bulk materials

[J].The suitability of high-strength ultrafine and nanocrystalline materials processed by severe plastic deformation methods and aimed to be used for structural applications will strongly depend on their resistance against crack growth. In this contribution some general available findings on the damage tolerance of this material class will be summarized. Particularly, the occurrence of a pronounced fracture anisotropy will be in the center of discussion. In addition, the great potential of this generated anisotropy to obtain high-strength materials with exceptionally high fracture toughness in specific loading and crack growth directions will be enlightened. Severely plastically deformed materials are reviewed in light of their damage tolerance. The frequently observed toughness anisotropy allows unprecedented fracture toughness - strength combinations.

Heterogeneous materials: A new class of materials with unprecedented mechanical properties

[J].

Making strong nanomaterials ductile with gradients

[J].

Extra strengthening and work hardening in gradient nanotwinned metals

[J].

Deformation and fracture mechanisms in fine- and ultrafine-grained ferrite/martensite dual-phase steels and the effect of aging

[J].

Effect of the martensite distribution on the strain hardening and ductile fracture behaviors in dual-phase steel

[J].

Mechanical properties of copper/bronze laminates: Role of interfaces

[J].

High tensile ductility in a nanostructured metal

[J].

Perspective on hetero-deformation induced (HDI) hardening and back stress

[J].

Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility

[J].

Anisotropic toughening of nanotwin bundles in the heterogeneous nanostructured Cu

[J].

Thin-film deposition: Principles and practice

[J].

Electrodeposited multilayer thin films

[J].

Electrodeposited multilayer films with giant magnetoresistance (GMR): Progress and problems

[J].

Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper

[J].Nano-grained (NG) metals are believed to be strong but intrinsically brittle: Free-standing NG metals usually exhibit a tensile uniform elongation of a few percent. When a NG copper film is confined by a coarse-grained (CG) copper substrate with a gradient grain-size transition, tensile plasticity can be achieved in the NG film where strain localization is suppressed. The gradient NG film exhibits a 10 times higher yield strength and a tensile plasticity comparable to that of the CG substrate and can sustain a tensile true strain exceeding 100% without cracking. A mechanically driven grain boundary migration process with a substantial concomitant grain growth dominates plastic deformation of the gradient NG structure. The extraordinary intrinsic plasticity of gradient NG structures offers their potential for use as advanced coatings of bulk materials.

Combining gradient structure and TRIP effect to produce austenite stainless steel with high strength and ductility

[J].

Fracture toughness evaluation of nanostructured metals via a contactless crack opening displacement gauge

[J].

Intrinsic fracture toughness of bulk nanostructured Cu with nanoscale deformation twins

[J].

The deformation of plastically non-homogeneous materials

[J].

Strain gradient plasticity: theory and experiment

[J].

Geometrically necessary dislocation and size-dependent plasticity

[J].

On the role of strain gradients and long-range internal stresses in the composite model of crystal plasticity

[J].

The effect of geometrically necessary dislocations on the flow stress of deformed crystals containing a heterogeneous dislocation distribution

[J].

An overview of tailoring strain delocalization for strength-ductility synergy

[J].

Back stress strengthening and strain hardening in gradient structure

[J].

Improved back stress and synergetic strain hardening in coarse-grain/nanostructure laminates

[J].

Effect of work hardening discrepancy on strengthening of laminated Cu/CuZn alloys

[J].To clarify the work hardening discrepancy effect on the strengthening of laminated metals, we designed two laminated Cu/Cu4Zn and Cu/Cu32Zn samples with different layer thicknesses. Cu/Cu4Zn has larger work hardening discrepancy between two constituent layers relative to Cu/Cu32Zn, but the yield strengths of two CuZn constituents are comparable. Uniaxial tensile results suggest Cu/Cu4Zn with larger work hardening discrepancy exhibits a significant strengthening at early deformation stage while Cu/Cu32Zn possesses a better ductility. The underlying mechanisms for the strengthening effect are attributed to more geometrically necessary dislocations accumulated at interfaces and severer strain localization due to the larger work hardening discrepancy.

Work hardening discrepancy designing to strengthening gradient nanotwinned Cu

[J].

Strengthening materials by engineering coherent internal boundaries at the nanoscale

[J].Strengthening materials traditionally involves the controlled creation of internal defects and boundaries so as to obstruct dislocation motion. Such strategies invariably compromise ductility, the ability of the material to deform, stretch, or change shape permanently without breaking. Here, we outline an approach to optimize strength and ductility by identifying three essential structural characteristics for boundaries: coherency with surrounding matrix, thermal and mechanical stability, and smallest feature size finer than 100 nanometers. We assess current understanding of strengthening and propose a methodology for engineering coherent, nanoscale internal boundaries, specifically those involving nanoscale twin boundaries. Additionally, we discuss perspectives on strengthening and preserving ductility, along with potential applications for improving failure tolerance, electrical conductivity, and resistance to electromigration.

Strengthening austenitic steels by using nanotwinned austenitic grains

[J].

Fracture behavior of heterogeneous nanostructured 316L austenitic stainless steel with nanotwin bundles

[J].

Size effect of deformation nanotwin bundles on their strengthening and toughening in heterogeneous nanostructured Cu

[J].

Strength and ductility of 316L austenitic stainless steel strengthened by nano-scale twin bundles

[J].

Mechanical properties and rolling behaviors of Nano-grained copper with embedded nano-twin bundles

[J].

Quantifying the microstructures of pure cu subjected to dynamic plastic deformation at cryogenic temperature

[J].

Deformation mechanisms in an austenitic single-phase duplex microstructured steel with nanotwinned grains

[J].

Deformation compatibility between nanotwinned and recrystallized grains enhances resistance to interface cracking in cyclic loaded stainless steel

[J].

Plastic anisotropy and associated deformation mechanisms in nanotwinned metals

[J].

Anisotropic strengthening of nanotwin bundles in heterogeneous nanostructured Cu: Effect of deformation compatibility

[J].

The conflicts between strength and toughness

[J].The attainment of both strength and toughness is a vital requirement for most structural materials; unfortunately these properties are generally mutually exclusive. Although the quest continues for stronger and harder materials, these have little to no use as bulk structural materials without appropriate fracture resistance. It is the lower-strength, and hence higher-toughness, materials that find use for most safety-critical applications where premature or, worse still, catastrophic fracture is unacceptable. For these reasons, the development of strong and tough (damage-tolerant) materials has traditionally been an exercise in compromise between hardness versus ductility. Drawing examples from metallic glasses, natural and biological materials, and structural and biomimetic ceramics, we examine some of the newer strategies in dealing with this conflict. Specifically, we focus on the interplay between the mechanisms that individually contribute to strength and toughness, noting that these phenomena can originate from very different lengthscales in a material's structural architecture. We show how these new and natural materials can defeat the conflict of strength versus toughness and achieve unprecedented levels of damage tolerance within their respective material classes.

Mechanical behaviour of laminated metal composites

[J].

Micro- and macrostructural factors in DRA fracture resistance

[J].

Overview on micro- and nanomechanical testing: New insights in interface plasticity and fracture at small length scales

[J].

Bending behaviors and fracture characteristics of laminatedductile-tough composites under different modes

[J].

The crack driving force for fatigue crack propagation

[J].

Fracture behavior and deformation mechanisms in nanolaminated crystalline/amorphous micro-cantilevers

[J].In order to quantify the fracture toughness and reveal the failure mechanism of crystalline/amorphous nanolaminates (C/ANLs), in-situ micro-cantilever bending tests were performed on Ag/Cu-Zr and Mo/Cu-Zr-C/ANLs in a scanning electron microscope over a wide range of cantilever widths from several microns to the submicron scale. The results demonstrate that the fracture behavior was strongly influenced by sample size and constituent phases, respectively. The Ag/Cu-Zr micro-cantilevers failed in a ductile manner, with fracture toughnesses higher than the Mo/Cu-Zr samples that exhibited brittle failure. Both materials also displayed different cantilever width-dependences of fracture toughness. The Ag/Cu-Zr beams showed a fracture toughness that increases ith the cantilever width, mainly due to a size-dependent constraining effect on the deformation of the crystalline phase. For the Mo/Cu-Zr beams, the fracture toughness decreased gradually to a low plateau as the cantilever width exceeded similar to 1500 nm, which can be rationalized by a transition in stress condition. The underlying fracture mechanism of the Ag/Cu-Zr micro-cantilevers was identified as the interconnection of microcracks initiated in the amorphous Cu-Zr layers, compared to a catastrophically penetrating crack propagation in the Mo/Cu-Zr samples. The discrepancy in size-dependent fracture behavior between the two material systems is discussed in terms of plastic energy dissipation of ductile phases, crack tip blunting, crack bridging and the effect of strain gradient in the plastic zone on crack propagation. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

Fracture behavior of a laminated steel-brass composite in bend tests

[J].

Impact toughness improvement of high-strength aluminium alloy by intrinsic and extrinsic fracture mechanisms via hot roll bonding

[J].

Cryogenic toughness of commercial aluminum-lithium alloys: Role of delamination toughening

[J].

Making ultrastrong steel tough by grain-boundary delamination

[J].Developing ultrahigh-strength steels that are ductile, fracture resistant, and cost effective would be attractive for a variety of structural applications. We show that improved fracture resistance in a steel with an ultrahigh yield strength of nearly 2 gigapascals can be achieved by activating delamination toughening coupled with transformation-induced plasticity. Delamination toughening associated with intensive but controlled cracking at manganese-enriched prior-austenite grain boundaries normal to the primary fracture surface dramatically improves the overall fracture resistance. As a result, fracture under plane-strain conditions is automatically transformed into a series of fracture processes in "parallel" plane-stress conditions through the thickness. The present "high-strength induced multidelamination" strategy offers a different pathway to develop engineering materials with ultrahigh strength and superior toughness at economical materials cost.Copyright © 2020 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Influence of the alumina thickness at the interfaces on the fracture mechanisms of aluminium multilayer composites

[J].

The impact properties of laminated composites containing ultrahigh carbon (UHC) steels

[J].

Impact properties of a laminated composite based on ultrahigh carbon steel and brass

[J].

Length-scale-dependent deformation and fracture behavior of Cu/X (X = Nb, Zr) multilayers: The constraining effects of the ductile phase on the brittle phase

[J].

A review of high-strength nanolaminates and evaluation of their properties

[J].Nanolaminates are composed of nanoscale-thick alternating layers of different materials and their properties are dependent on the individual layers, the layer thickness and the interfaces between the layers. Nanolaminates composed of cubic crystal structured metals are usually ductile compared to nanolaminates containing hexagonal crystal structured metals. Mechanical properties such as strength and hardness of nanolaminates increase with a decrease in individual layer thickness down to a few nanometers and they become independent when the thickness of individual layers is less than a couple of nanometers. This review provides a detailed analysis of the effects of individual layer thickness and the interface structures on the strength and the strengthening mechanisms of nanolaminates, their ductility and fracture behavior in terms of structural variations including grain morphologies, nanotwins, amorphous phases and crystal structures of the layers. The principles for designing nanolaminates with exceptionally high mechanical and physical properties and their fabrication are also highlighted. Some contradictory issues such as strengthening mechanisms, elastic modulus dependency on individual layer thickness and the effect of a thin amorphous layer on the strength are discussed. This review also provides future research directions in designing the high-strength nanolaminates that will facilitate practical engineering applications through analyzing up-to-date research efforts.

Deformation behavior of nanostructured metallic multilayers

[J].

A maximum in ductility and fracture toughness in nanostructured Cu/Cr multilayer films

[J].