钢液中直接添加陶瓷类颗粒有较大的难度,TiB2颗粒密度小,易上浮,很容易产生颗粒的聚集和偏析,所以此类颗粒增强钢多通过粉末冶金的方法制备[3~5]。但TiB2颗粒较脆(TiB2断裂韧性(K1C)范围为3~8 MPa·m1/2,硬度为20~30 GPa[2]),易引起颗粒与基体间的应力集中[6],并造成颗粒与基体间界面处的疲劳断裂。此外,Fe-TiB2颗粒增强钢也可通过熔炼Fe-Ti-B三元合金原位反应合成,经伪二元共晶反应生成TiB2颗粒[7~9]。与粉末冶金相比,原位反应所制备的颗粒增强钢具有污染少、无界面应力场的优点,有利于提升Fe/TiB2界面强度[10]。通过原位反应凝固制备的Fe-TiB2颗粒增强钢断裂时通常起始于TiB2颗粒本身,而不是界面处[11]。熔炼铸造的方法比粉末冶金方法更容易降低生产成本,适用于较大规模的生产。

电磁搅拌技术在金属凝固过程中会产生强制对流,常应用于改善金属铸锭凝固组织和性能。电磁搅拌是无接触的强制搅拌方式,避免了对金属熔体的污染,也避免了其它搅拌方法中熔体对搅拌桨或探头的损害。电磁搅拌对金属铸锭有多种改善作用:首先,电磁搅拌可以细化晶粒和提高铸锭的等轴晶率,并破碎枝晶,促进柱状晶向等轴晶转变。多个钢种的研究[16~18]均表明电磁搅拌具有细化晶粒的作用,晶粒细化有助于改善金属的力学性能。其次,电磁搅拌在凝固过程中还可以减轻熔体过热,降低凝固前沿的熔体温度[19]。电磁搅拌有助于减小铸锭中的疏松缺陷,改善铸锭表面质量[20,21],还可以去除杂质,提高组织的洁净度[22~25]。此外,电磁搅拌还有利于消除溶质元素在铸锭中的微观偏析与宏观偏析[26,27]。对于含有析出物的凝固组织,电磁搅拌可在细化组织的同时改善析出物的分布[28,29]。

本工作针对Fe-TiB2颗粒增强钢的凝固组织及性能开展实验研究,考查立式电磁搅拌对凝固过程中TiB2颗粒的细化作用,以及强对流作用下颗粒的分布规律,并考察施加电磁搅拌对TiB2颗粒增强钢的组织及力学性能的影响,为改进其凝固工艺提供参考。

1 实验方法

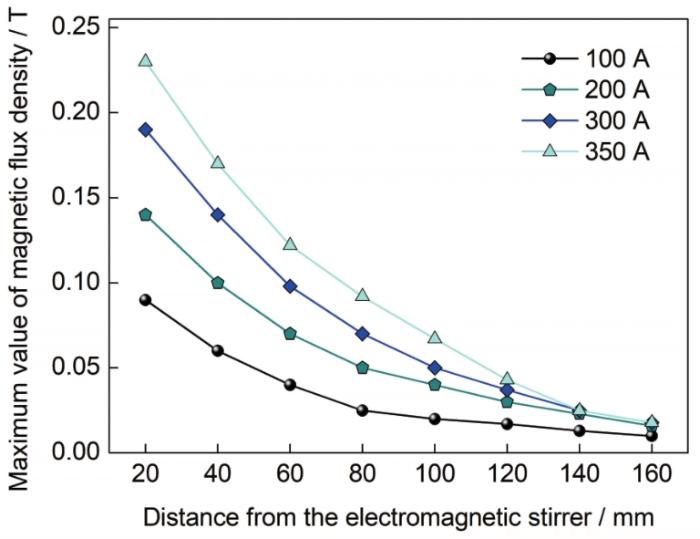

实验采用Fe-10.35%Ti-18%B-0.35%Ce (原子分数,%)合金,原料为纯度99.9% (质量分数)的Fe、Ti、B与Ce元素。合金的成分对应9%TiB2 (摩尔分数)的过共晶成分,且Ti的成分比生成TiB2的化学配比多15%,从而避免生成Fe的硼化物。实验原料在300 ℃烘干30 min后,装入Al2O3坩埚,在SPZ-45型感应加热炉中进行熔炼(功率45 kW,频率10 kHz),Ti与B在Fe熔化后再加入,熔体在1650 ℃保温5 min,期间采用Ar气对熔体进行保护。之后将熔体浇铸入电磁搅拌器中心处的石墨模具中,熔体在电磁搅拌的作用下凝固。铸锭为圆柱形,高度为80 mm,直径为50 mm。凝固过程中,在熔体中发生了化学反应Fe(l)+B(l)+Ti(l)→Fe(l)+TiB2(s),在熔体中生成了TiB2颗粒。为进行对比,进行了同熔炼参数下的无磁场凝固实验,以及不同电流强度下的电磁搅拌实验。采用立式单侧线型电磁搅拌器,磁场移动方向向下。本实验中磁场电源设置励磁电流频率为12 Hz,励磁电流强度分别设为100、200、300和350 A。不同励磁电流强度下,磁体中不同位置的磁感应强度最大值经Gauss计测试,如图1所示。试样中轴位置距磁体表面约为45 mm。

图1

图1

沿远离搅拌器表面方向上的最大磁感应强度分布

Fig.1

Maximum values of magnetic flux density at various distances from the surface of electromagnetic stirrer

铸锭沿纵向剖开,在不同高度进行线切割取样,以纵剖面一侧为观察面,预磨后在10%HClO4 (体积分数)水溶液中进行电化学抛光。采用Ultra Plus场发射扫描电镜(FESEM)观察试样凝固微观组织,同时采用电镜内置能谱仪(EDS)对组织中的相成分进行分析,对TiB2颗粒进行尺寸统计。铸锭制成标准拉伸试样(ISO 6892-1:2011[30]),采用AG-X 100 kN万能试验机进行拉伸性能测试。采用THVP-50型Vickers硬度计进行硬度测试,载荷100 N,保持时间15 s。采用PANalytical X'Pert pro型X射线衍射分析仪(XRD)进行相结构分析。

2 实验结果

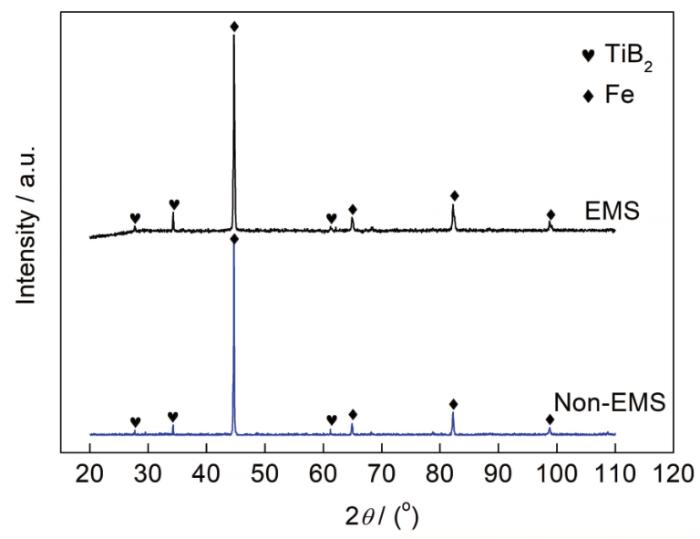

图2

图2

有无电磁搅拌作用下TiB2颗粒增强钢的XRD谱

Fig.2

XRD spectra of TiB2 particle-reinforced steel with and without electromagnetic stirring (EMS)

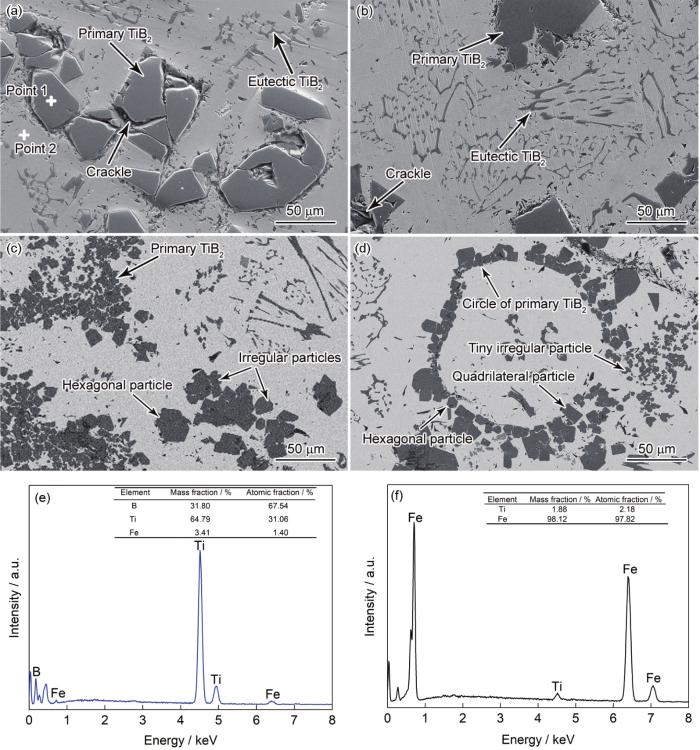

图3为不同磁场条件下TiB2颗粒增强钢的铸态组织。初生TiB2相为黑色的颗粒形态,呈有棱边的块状。无磁场试样中,TiB2颗粒钢中初生TiB2颗粒以粗大的六边形或四边形的形状分布在基体中,团聚情况较为严重。在凝固过程中,粗大的TiB2颗粒容易产生颗粒间及与基体间界面的裂缝(图4a),此种凝固缺陷易对合金力学性能产生危害。EDS结果确认了黑色颗粒的成分为TiB2,仅含有少量的Fe (图4e)。而在Fe基体中则不含有B元素,仅固溶有少量的Ti元素,这是因为在合金配料时为避免生成较脆的Fe-B中间化合物,所多添加的Ti元素(图4f),除了初生TiB2颗粒,Fe-Ti-B熔体在较低温度下的伪共晶反应也可产生层片状的共晶TiB2相,分布于初生TiB2颗粒群间隙的基体中(图3a~c,图4a和b)。

图3

图3

不同励磁电流的磁场下TiB2颗粒增强钢铸锭的显微组织

(a) 0 A;(b) 100 A;(c) 200 A;(d) 350 A

Fig.3

Microstructures of TiB2 particle-reinforced steel under magnetic field with various current intensities

图4

图4

不同励磁电流下铸锭中的TiB2颗粒形态及EDS分析

(a) 0 A;(b) 100 A;(c) 350 A;(d) circle of particles under 350 A magnetic field;(e, f) EDS analyses of the particle (point 1) and matrix (point 2), respectively

Fig.4

Morphologies of TiB2 particles in ingots under various current intensities (a~d) and EDS of points 1 (e) and 2 (f) in Fig.4a

电磁搅拌可以显著细化组织中的TiB2颗粒,且随着电流强度由100 A增至350 A,颗粒尺寸逐步减小(图3b~d)。即使相距较近的颗粒也可体现出明显的尺寸差距,破碎后的颗粒尺寸大幅减小(图4c)。在施加搅拌作用后,只有少数尺寸较大的TiB2颗粒具有六边形或四边形的几何形状(图4c和d),保持规则几何形状的大颗粒是尚未被液流或颗粒间撞击而破坏的初生颗粒,此种颗粒的数量随着励磁电流的上升而逐渐减少。被击碎后的小尺寸颗粒失去了规则的棱角和棱边,呈不规则形状(图4c和d)。虽然施加磁场后颗粒仍会发生团聚现象,但随着组织的细化,颗粒群之间的间隙也逐渐减小,较高的电流强度磁场下,颗粒的分布更加弥散和均匀。较低的100 A电流磁场下,颗粒周围仍有裂纹(图4b),但在较高电流强度下,随着颗粒的尺寸减小,颗粒周围的裂缝缺陷也得到去除(图4c)。在施加350 A电流磁场的试样中,发现颗粒在一些位置形成环状(图3d和4d),环直径约为100~400 μm,TiB2颗粒在环状外围分布,环内是圆形的空白区。分析认为这是立式电磁搅拌在熔体中形成的局部环状对流,颗粒在环流中组成圆形队列,在铸锭纵剖面上表现为环形。与同试样其它区域的颗粒相比,环状区附近的TiB2颗粒尺寸显得更小(图3d),并且环状区附近还出现数量较多的极细小颗粒(图4d),尺寸小于5 μm,表明环流可促进颗粒的破碎和细化。

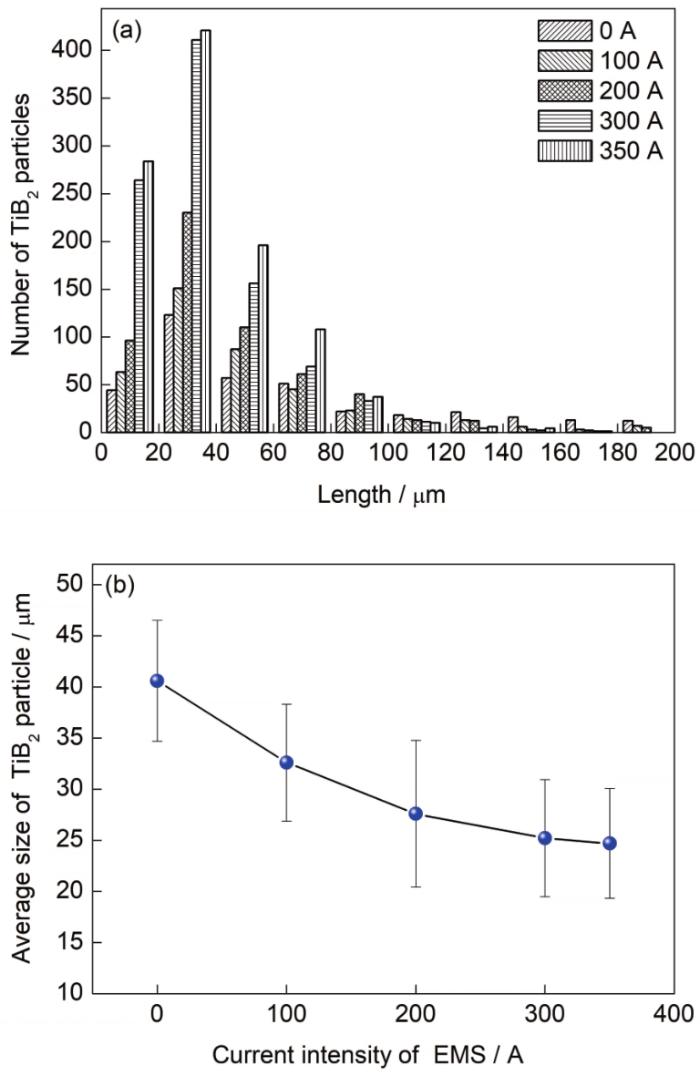

对不同励磁电流强度下铸锭微观组织中的TiB2初生颗粒尺寸进行统计,结果如图5所示。图5a所示为不同尺寸区间内的颗粒数量分布(统计为6 mm2截面中的颗粒数量,每个尺寸区间20 μm),各实验条件下,颗粒数量最多的区间均为20~40 μm,但无磁场条件下的铸锭中,100 μm以下的各区间内颗粒数量均少于其它的施加磁场条件,而在100 μm以上各区间内颗粒数量均明显多于施加电磁搅拌的各条件,表明无磁拌条件下的颗粒粗化现象较显著。在施加电磁搅拌作用后,在100 μm以下的TiB2颗粒数量明显增多,且随着励磁电流的增强,小尺寸颗粒的数量逐步增加,尤其在电流增至300 A以上时,20 μm以下的颗粒数量比200 A时增加超过一倍,20~40 μm区间内的颗粒数量增加也很显著。施加电磁搅拌后,100 μm以上尺寸的颗粒数量减少,尤其是当励磁电流升至300 A以上,几乎没有颗粒分布在160 μm以上的区间内。通过对比各实验条件下的平均TiB2初生颗粒尺寸(图5b),发现颗粒平均尺寸随励磁电流增加而逐步减小,350 A励磁电流下的平均颗粒尺寸为24.7 μm,比无磁场条件下的尺寸下降了39%。

图5

图5

不同励磁电流下铸锭中的初生TiB2颗粒尺寸

(a) number distribution of various size ranges;(b) average size of particles with various currentintensities

Fig.5

The sizes of primary TiB2 particles in ingots under magnetic field with various current intensities

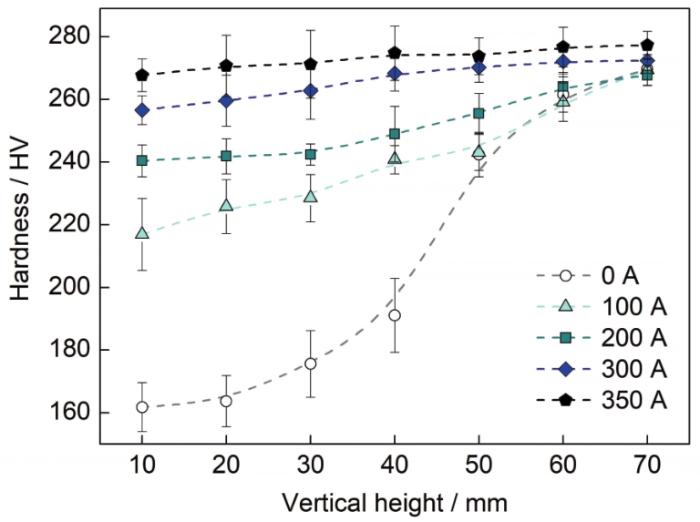

沿铸锭的纵剖面中轴,在不同高度位置每隔10 mm对不同励磁电流强度下的TiB2颗粒增强钢进行硬度测试,结果如图6所示。未施加电磁搅拌时,铸锭中不同高度的硬度有显著的差异,中下部硬度较低,在160~200 HV范围内。随高度升高,硬度逐渐增大,在试样上部达到240~280 HV,顶部与底部的硬度差约为100 HV。不同高度的硬度差异表明铸锭中出现了重力引起的宏观偏析,因为初生颗粒密度小于基体Fe熔体,在熔融状态下逐渐向上浮动,TiB2颗粒硬度较高,使铸锭的中上部硬度提高。施加电磁搅拌后,不同高度上的硬度差异减小:100 A励磁电流下的顶部与底部硬度差约为40 HV,而350 A励磁电流下的顶底部硬度差进一步减少到10 HV以下,不同位置的硬度分布基本均匀。施加电磁搅拌后,颗粒的尺寸减小,分布更弥散,而熔体中颗粒的上浮速度一般随颗粒尺寸减小而减小,此外立式的电磁搅拌磁场移动方向向下,可以驱动中上部的部分颗粒随熔体向下运动,因此施加电磁搅拌有助于降低TiB2颗粒的宏观偏析。组织细化有助于提高合金的硬度,铸锭的整体硬度随着励磁电流的升高而提高,平均硬度在100 A励磁电流下约为240 HV,而在350 A励磁电流下约为275 HV。

图6

图6

不同励磁电流电磁搅拌下铸锭沿纵向不同高度的硬度分布

Fig.6

Hardness distributions of ingots under EMS with various current intensities

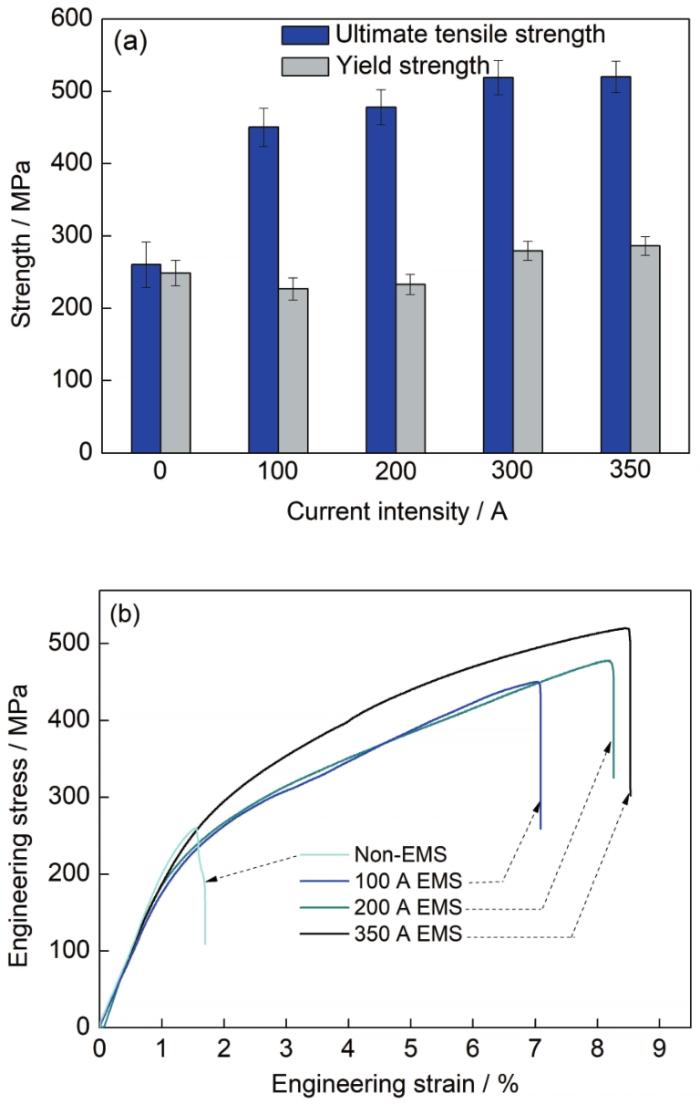

对不同条件铸锭上所取的拉伸试样进行抗拉强度测试,所得的抗拉强度、屈服强度及应力-应变曲线如图7所示。无电磁搅拌条件下,Fe-TiB2合金的抗拉强度较低,约为260.5 MPa,稍高于屈服强度,在屈服后即发生断裂,没有明显的塑性强化过程。因为粗大颗粒的周边易产生裂纹(图4a),促进了材料在屈服后迅速发生断裂。施加电磁搅拌后,材料的应力-应变曲线表明其有较长的塑性强化阶段,抗拉强度得到显著提升,100 A励磁电流下抗拉强度为450.6 MPa,比无搅拌时提升了73%。随着励磁电流的提高,抗拉强度进一步提高,当励磁电流为350 A时,抗拉强度达到520.2 MPa,比无搅拌时提升了99%。较大的励磁电流(大于300 A)对材料的屈服强度也有提升作用,励磁电流为350 A时屈服强度为286.5 MPa,比无磁场时提升了15%。随着励磁电流的增加,不仅抗拉强度提高,材料的断裂应变也逐步提高,100 A电流下断裂应变约为7%,而350 A电流下断裂应变约为8.5% (图7b)。

图7

图7

不同励磁电流电磁搅拌下铸锭的强度和应力-应变曲线

Fig.7

Tensile strengthes (a) and typical stress-strain curves (b) of ingots under EMS with various current intensity

3 分析讨论

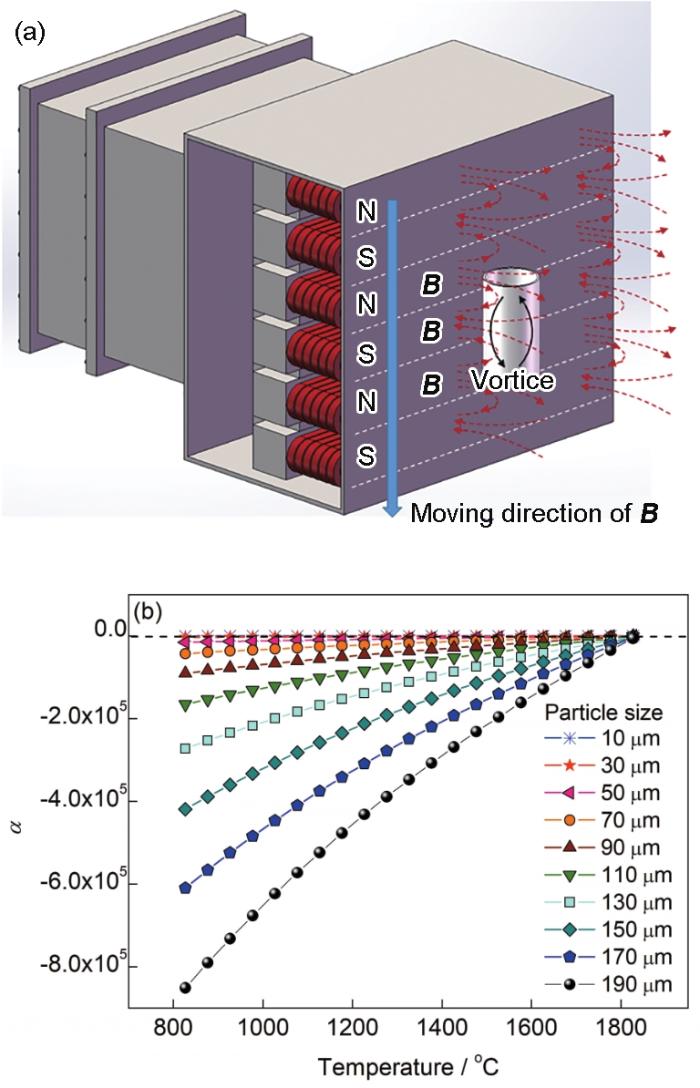

由本实验结果可知,施加立式的线型电磁搅拌后,对铸锭内的颗粒尺寸与分布有显著的影响,进而影响了合金的性能。磁场通过电磁力作用于合金熔体及悬浮其中的颗粒,图8a为磁场驱动熔体的示意图,立式线型电磁搅拌器产生向下运动的磁场,磁力线切割合金熔体,感生电流与磁场交互作用产生Lorentz力,Lorentz力作用于熔体与悬浮于其中的TiB2颗粒。由图1测试所得的磁感应强度分布可知,随距磁体距离的增加,磁场强度减小,因此熔体在近磁体一侧受到的向下驱动力较大,而远磁一侧所受驱动力较小,磁场驱动熔体产生纵向为主的周期性旋转对流。因密度小于基体而有上浮趋势的TiB2颗粒,在纵向强旋流中可随着向下的对流而向下运动,从而降低重力方向的偏析和试样上部的颗粒聚集。本实验所采用的单侧立式电磁搅拌器与传统的旋转电磁搅拌器不同,旋转电磁搅拌器中是横向的旋转磁场,在其作用下熔体进行水平横向为主的周期性旋转对流,虽然同样对颗粒有细化作用,但对颗粒沿竖直方向的运动影响较小,难以使已经聚集在熔体上部的颗粒重新分散。

图8

图8

磁场对Fe-TiB2颗粒增强钢熔体及颗粒的驱动作用示意图及α值变化趋势

Fig.8

Schematic of driving effect of magnetic field (B) on the melt of Fe-TiB2 particle-reinforced steel (a), and α value change with melt temperature and particle size (b)

交流磁场作用于金属熔体通常带有集肤效应,磁感应强度和Lorentz力在熔体表面较大,中心较小,其起作用的范围可用集肤层深度(δ)表示[31]:

式中,σ为熔体的电导率,μ为磁导率,ω为电磁场的频率。通过计算可知,本实验条件下熔体的集肤层厚度约为160 mm,大于试样直径,因此集肤效应对本实验影响较小。为了估算TiB2颗粒所受的电磁力,假设夹杂物的颗粒为球形。电磁搅拌为低频磁场,因此可通过下式计算颗粒受到基体Lorentz力反作用力与自身所受Lorentz力的合力(F)[32]:

式中,σm为熔体基体的电导率;σp为熔体中TiB2颗粒的电导率;dp为TiB2颗粒的直径;f为电磁力[33]:

式中,B为磁感应强度,j为电流强度。

式中,第一项为指向曲率中心的磁张力分量;第二项在磁力线方向上抵消磁压力,使磁压力只有法向的分量起作用,电磁力的合力垂直于磁力线的方向。综合

Fe基体与TiB2颗粒的电导率主要受熔体温度的影响,对于相同温度下同一尺寸的颗粒,

对于相同磁场参数下的某一时刻,不同尺寸的颗粒在不同温度下所受的电磁力由α值决定。图8b给出了α随颗粒直径及温度的变化规律(引用文献中不同温度下的TiB2高温电阻率[34]和液态Fe的高温电阻率[35])。在高温区因为Fe基体与TiB2颗粒的电导率差减小,颗粒在高温区所受的电磁力较小,而随着温度的下降,α的绝对值增大,施加于颗粒上的电磁力逐渐增大。随着颗粒直径的增加,α的绝对值也迅速增大,颗粒所受的电磁力增大。电磁力随温度与颗粒尺寸的变化规律表明,由于颗粒的破碎过程与受力及自身强度相关,同一温度下可能存在一个尺寸临界值,尺寸较大的颗粒受到更大的力容易破碎,而低于临界值的颗粒则不易破碎,如果控制熔体的温度及励磁的时机,可促使颗粒尺寸向某一范围内集中。除了颗粒所受的电磁力作用,被驱动的熔体对流冲击以及颗粒间的撞击也对颗粒的破碎过程起到重要的作用,组织中的颗粒环形态表明了环流对颗粒有细化作用。

4 结论

(1) 在本实验条件下,电磁搅拌可以显著细化组织中的初生TiB2颗粒,颗粒平均尺寸随励磁电流的增加而逐步减小,颗粒分布更加弥散和均匀,颗粒周围的裂缝缺陷也在较高电流强度下得到去除。

(2) 施加电磁搅拌减轻了铸锭中的宏观偏析,使铸锭不同高度上的硬度差异减小,铸锭的整体硬度随着励磁电流的升高而提高。

(3) 电磁搅拌使材料的抗拉强度得到显著的提升,抗拉强度随着励磁电流的提高而进一步提高。

(4) 影响颗粒所受电磁力的因素包括磁场强度、熔体温度和颗粒尺寸,电磁力随磁场强度升高而增大,随熔体温度的上升而减小,随颗粒尺寸的增加而增大。

参考文献

Microstructure refinement for high modulus in-situ metal matrix composite steels via controlled solidification of the system Fe-TiB2

[J].

Material properties of titanium diboride

[J].

In situ fabrication of Fe-TiB2 nanocomposite powder by planetary ball milling and subsequent heat-treatment of FeB and TiH2 powder mixture

[J].

Effect of the structure of TiB2-(Fe-Mo) plasma coatings on mechanical and tribotechnical properties

[J].

Fabrication of sintered compact of Fe-TiB2 composites by pressureless sintering of (FeB+TiH2) powder mixture

[J].

Interfaces and defects in a successfully hot-rolled steel-based composite Fe-TiB2

[J].

Experimental determination of solid-liquid equilibria with reactive components: Example of the Fe-Ti-B ternary system

[J].

In-situ metal matrix composite steels: Effect of alloying and annealing on morphology, structure and mechanical properties of TiB2 particle containing high modulus steels

[J].

Efficient liquid metallurgy synthesis of Fe-TiB2 high modulus steels via in-situ reduction of titanium oxides

[J].

Interface structure and chemistry in a novel steel-based composite Fe-TiB2 obtained by eutectic solidification

[J].A new generation of steels, Fe-TiB2 composites, is designed for automotive applications. The product displays both a high stiffness and a low density in comparison with existing steels and is prepared by eutectic solidification directly from the melt. A homogeneous distribution of TiB2 particles is achieved. The structure and chemistry of the internal interfaces will clearly determine the quality of interfacial cohesion during processing and further loading. Here, fundamental investigations at the atomic level are performed by transmission electron microscopy. The preferred interface planes for diboride particles are prismatic {1 0 (1) over bar 0} planes (in the majority) and the basal plane. No second phase is detected at prismatic planes. Basal type interfaces appear more or less covered by TiC particles, which are also present in the bulk and at iron grain boundaries. The interfacial crystallography and defects are accurately determined. Our results strongly support the good interfacial cohesion assumed for this novel steel-based composite displaying enhanced mechanical behaviour. (C) 2012 Acta Materialia Inc. Published by Elsevier Ltd.

Deformation behavior and damage evaluation in a new titanium diboride (TiB2) steel-based composite

[J].

Damage mechanisms of a TiB2-reinforced steel matrix composite for lightweight automotive application

[J].

Improving the mechanical properties of Fe-TiB2 high modulus steels through controlled solidification processes

[J].

Evolution of inclusions and resultant microstructural change with Mg addition in Mn/Si/Ti deoxidized steels

[J].

Effect of Ce addition on the as-cast and as-forged microstructure of Fe-TiB2 composites

[J].

Analysis of cracking phenomena in continuous casting of 1Cr13 stainless steel billets with final electromagnetic stirring

[J].

Effects of vertical electromagnetic stirring on grain refinement and macrosegregation control of bearing steel billet in continuous casting

[J].

Factors affecting equiaxed zone generation in electromagnetic stirring

[J].

The effect of electromagnetic stirring during solidification on the structure of Al-Si alloys

[J].

Reduction of center porosity of round billet by electromagnetic stirring in horizontal continuous casting

[J].

電磁攪拌による水平連続鋳造ビレットのセンターポロシティ低減

[J].

Prediction of columnar-to-equiaxed transition and porosity in continuous cast billet

[J].

Effect of circumferential electromagnetic stirring of steel on inclusion distribution

[J].

Flow modelling in continuous casting of round bloom strands with electromagnetic stirring

[J].

Effects of electromagnetic field on fluid flow, heat transfer, and inclusion behavior in a continuous casting process

[J].

Influence of electromagnetic stirring (EMS) on the microstructure and mechanical property of Incoloy825 superalloy

[J].

Restraining solute segregation of Al-1%Si alloy in diverse physical field

[J].

The segregation behavior of alloying elements in the Al-5Fe-based alloys during the semisolid deformation

[J].

Precipitation behaviour and control of TiN inclusions in rail steels

[J].

A sharp interface model for the morphological evolution of precipitates in Al cast alloys

[J].

ISO 6892-1:2009 Metallic materials—Tensile testing-Part 1: Method of test at room temperature

[S].

Manufacture of locally reinforced composite discs by casting in the alternating electromagnetic field

[J].

Theory of electromagnetophoresis. I. Magnetohydrodynamic forces experienced by spherical and symmetrically oriented cylindrical particles

[J].

The magnetohydrodynamic force experienced by spherical iron particles in liquid metal

[J].

Electrical resistivities of monocrystalline and polycrystalline TiB2

[J].